Patents

Literature

193results about How to "Low production process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

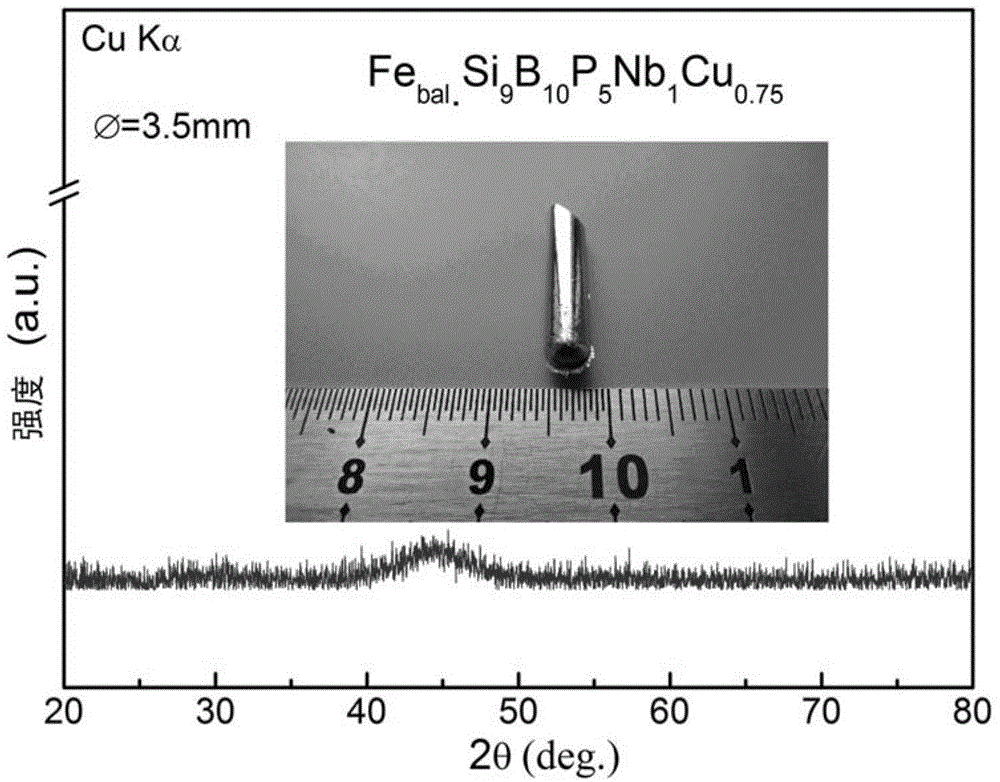

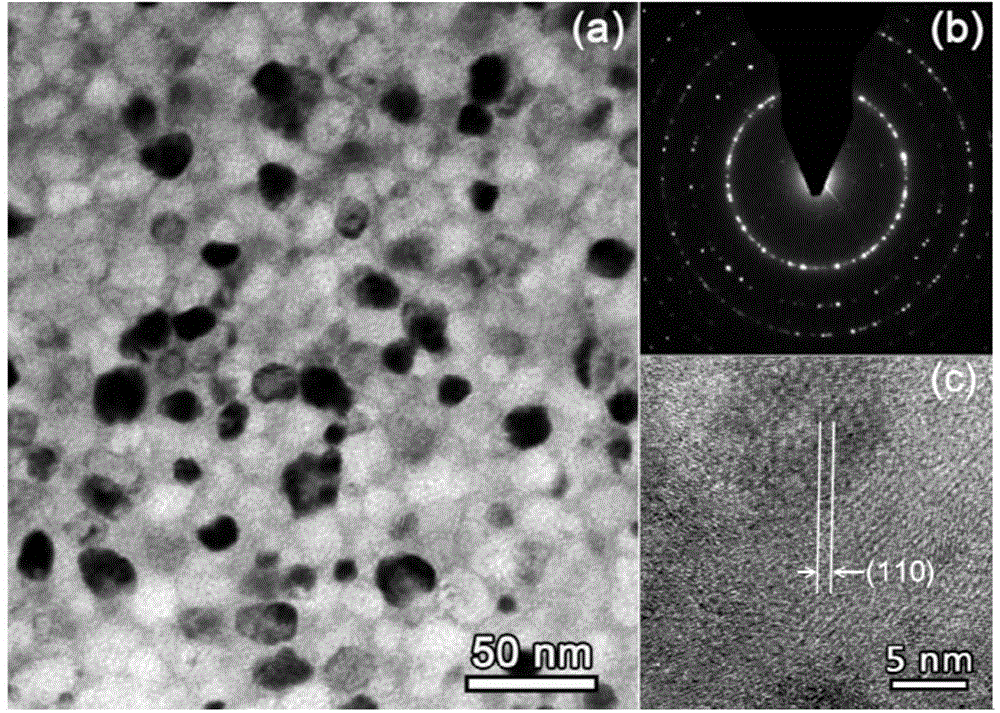

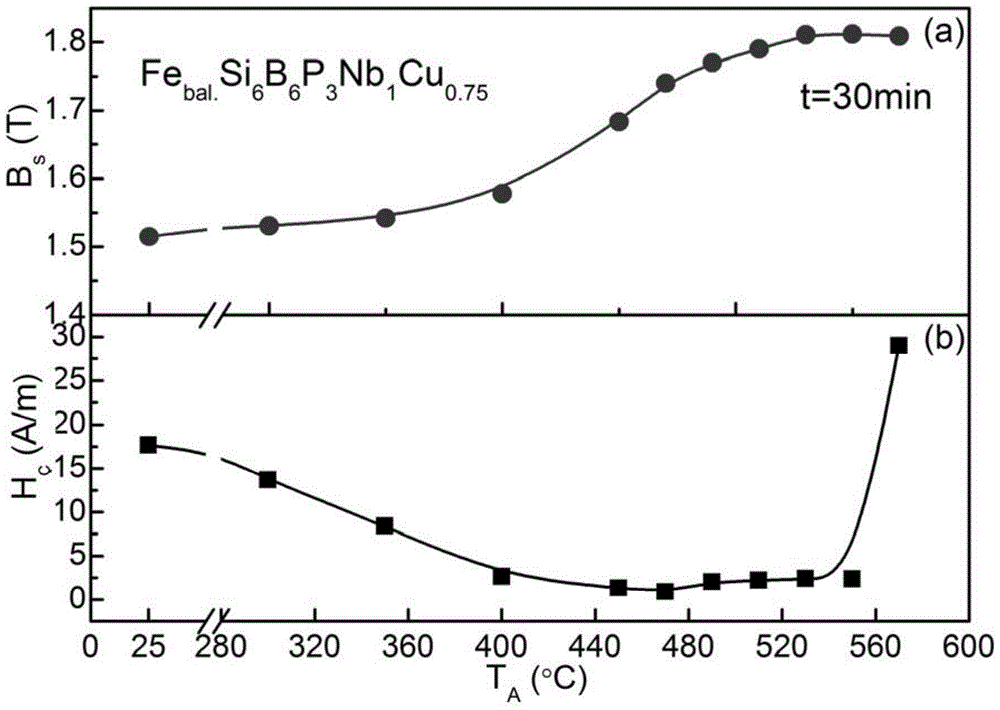

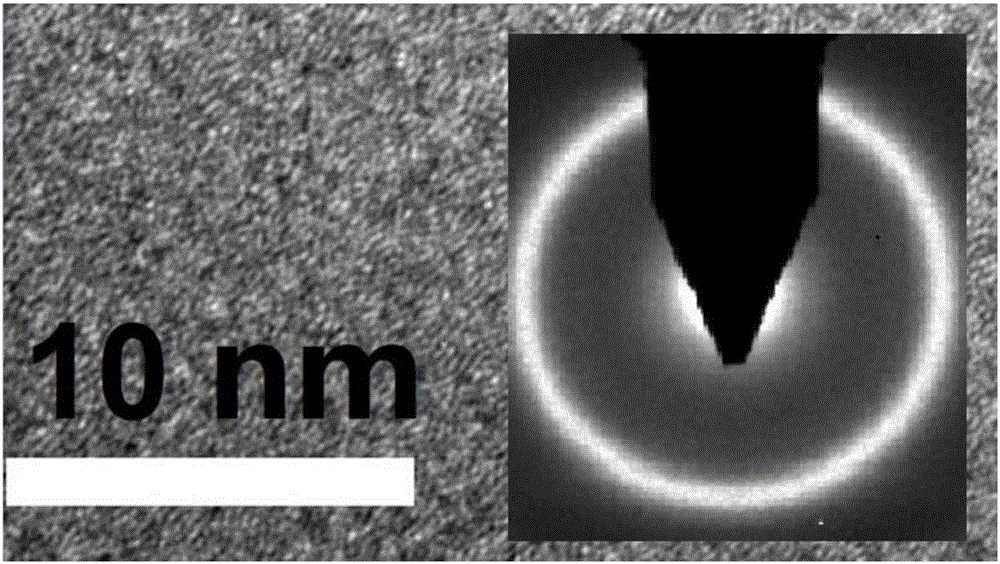

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

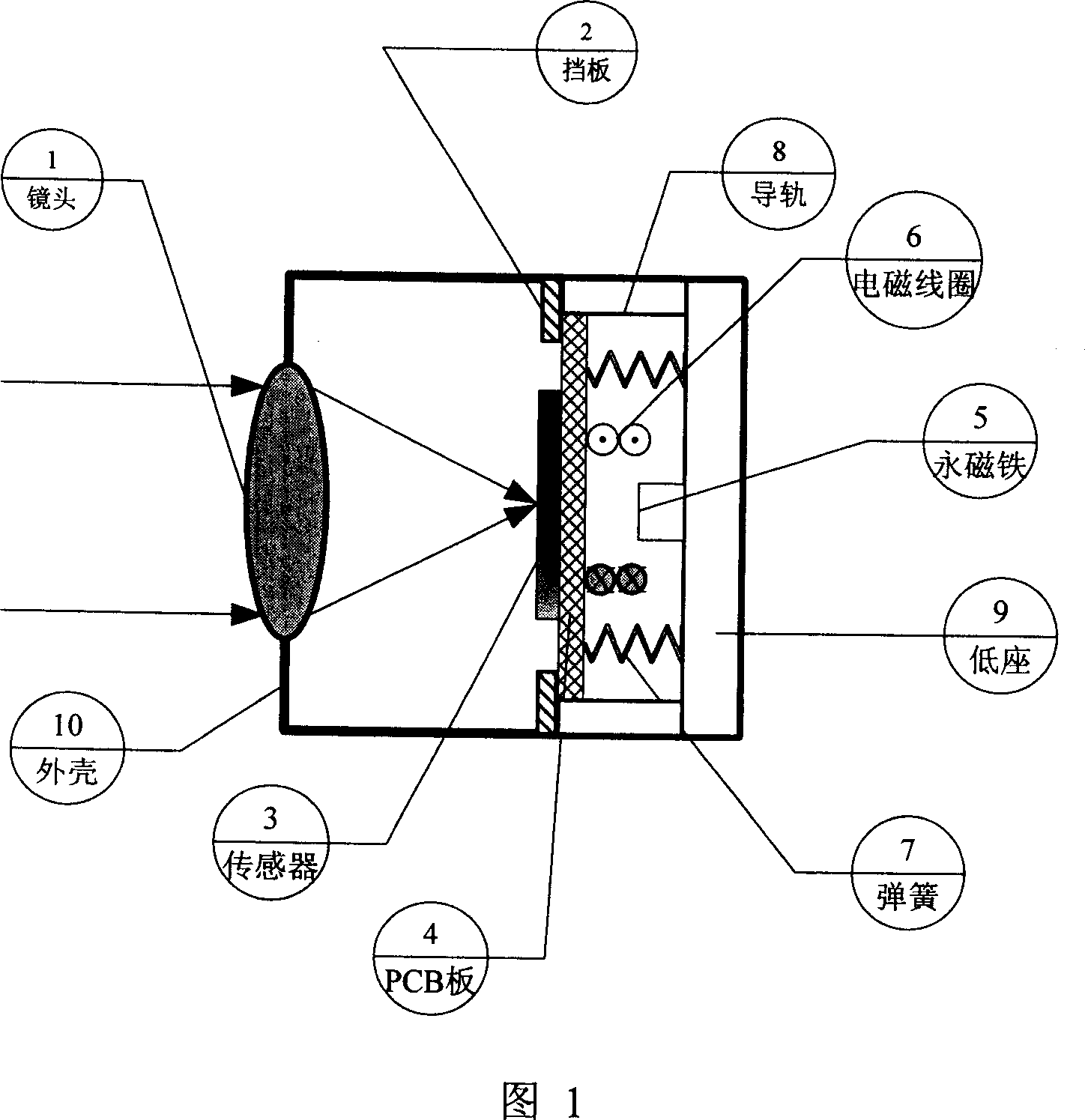

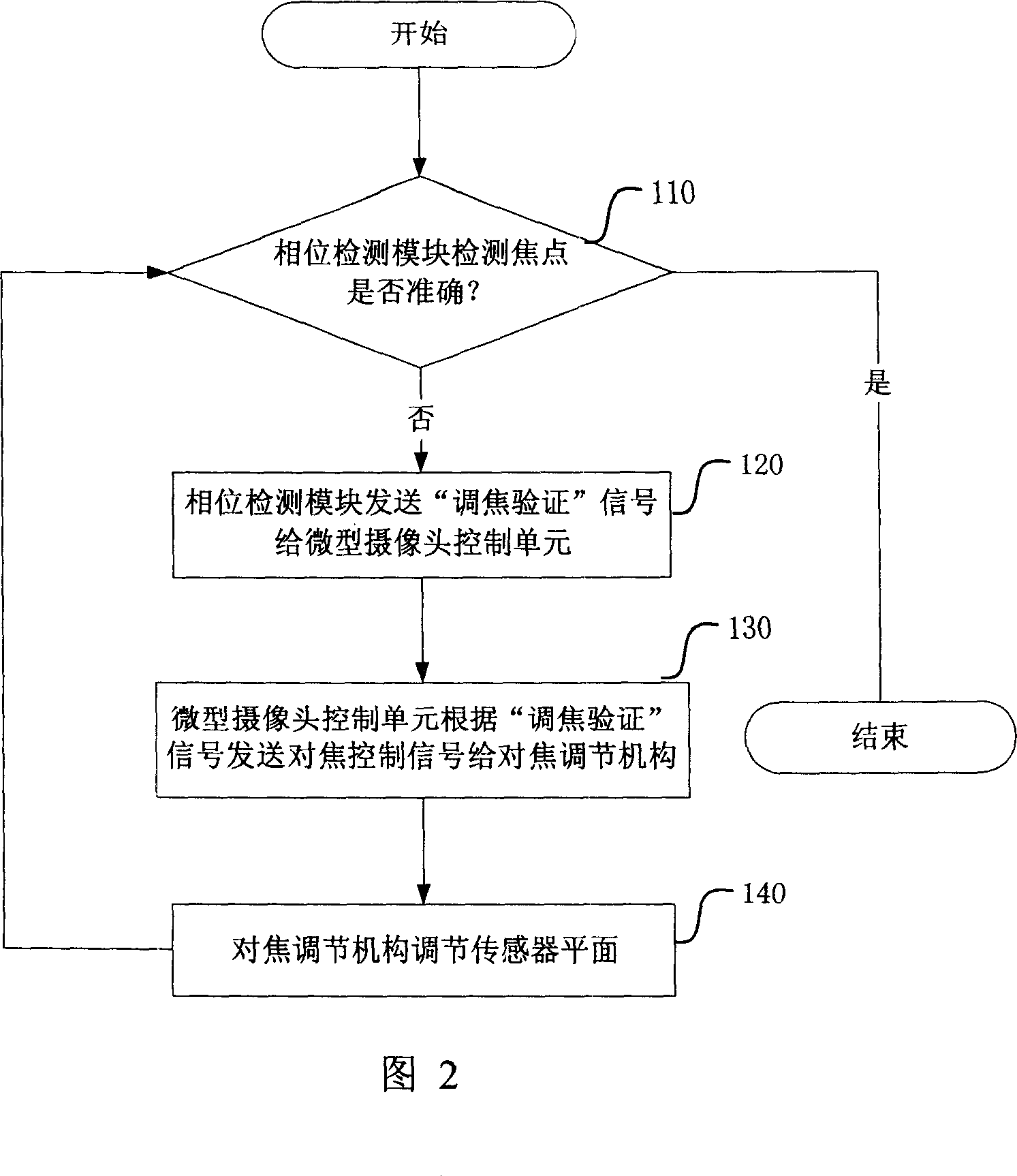

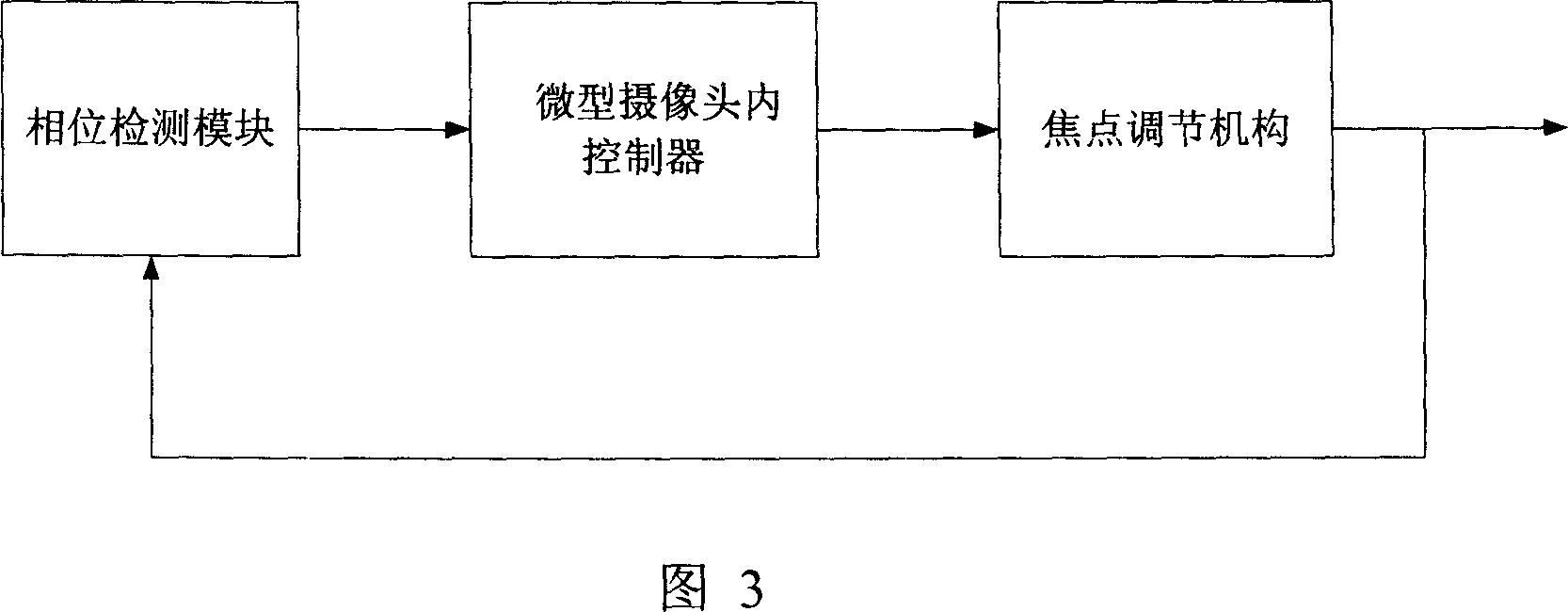

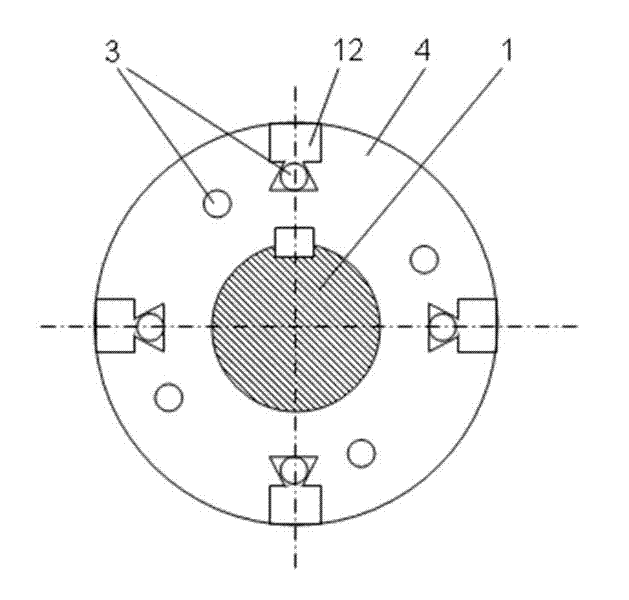

Method for realizing minisize camera automatic focusing and minisize camera thereof

InactiveCN101064779ALow costReduce structural design requirementsTelevision system detailsColor television detailsCamera lensControl signal

A method to realize auto focusing of micro camera and a micro camera are disclosed, and the camera includes enclosure, lens mounted before the enclosure, sensor which includes imaging sensitimeter and phase detecting unit mounted in the enclosure, controller which is used to calculate the adjusting distance and direction according to the detecting signal from sensor, the focusing buffer pool which can align the sensitizing surface and focusing surface of sensor automatically, the focusing buffer pool is location adjusting mechanism driven by electromagnetism, the movable end is connected with sensor, and the other end is mounted on the rear of enclosure, when it receives the control signal for adjusting location and direction output by controller, and drives the movable end to move, and drives the sensitizing surface move to the location of focusing surface of sensor. The invention driven by electromagnetism reduces the difficulty of phone structure and manufacturing technique, and reduces the manufacturing cost, which benefits for the promotion and popularity of photograph camera with auto focusing function.

Owner:ZTE CORP

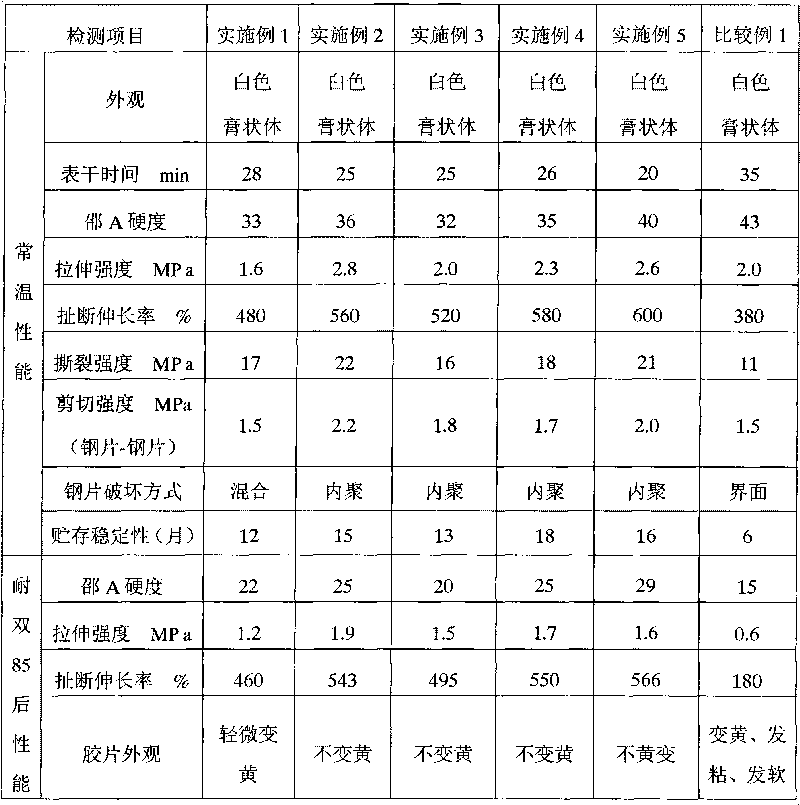

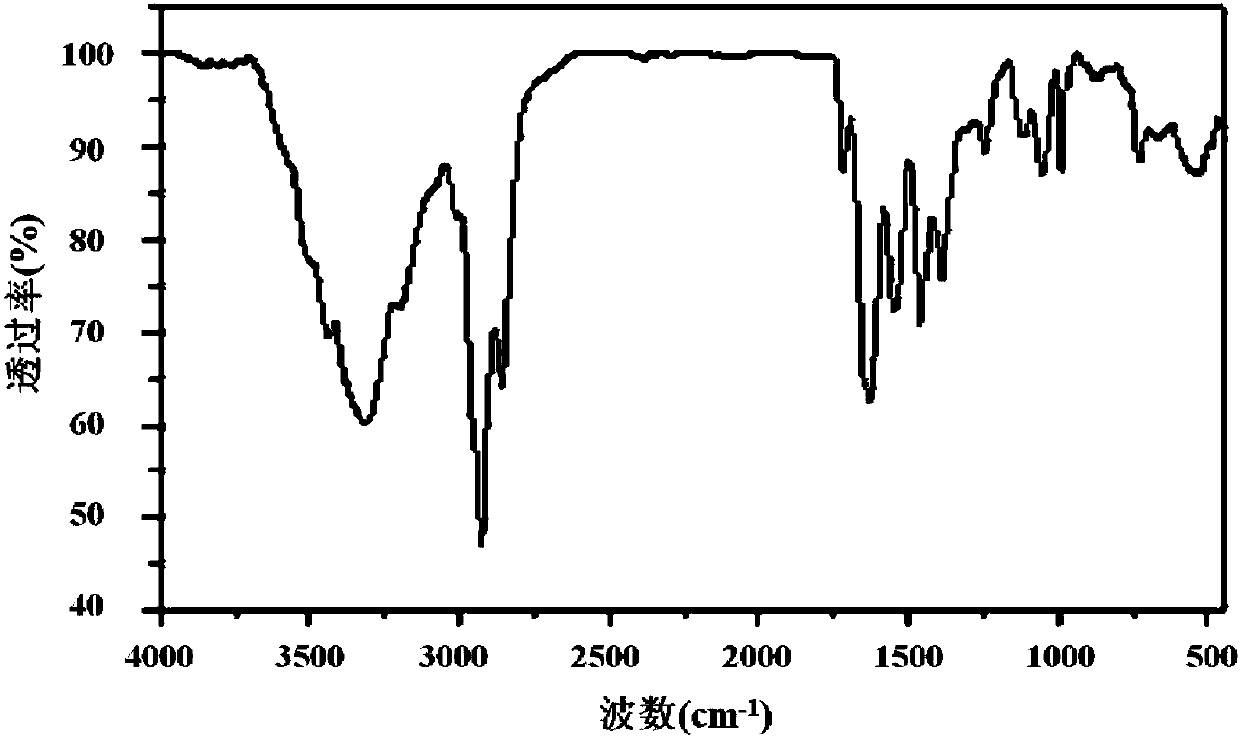

Single-component dealcoholization-type organic silicon sealant

InactiveCN101760172AReduce the requirements of the production processIncrease crosslink densityOther chemical processesAdhesivesChemistryCalcium carbonate

The invention relates to a single-component dealcoholization-type organic silicon sealant which belongs to the technical field of single-component organic silicon sealant and mainly solves the problem of poor adhesiveness and storage stability of the traditional sealant. The single-component dealcoholization-type organic silicon sealant comprises the following components in percentage by weight: 30-70 wt% of hydroxy-terminated poly dimethylsiloxane polymer, 15-50 wt% of nano-scale calcium carbonate, 2-10 wt% of alkoxy silane crosslinker, 0.1-3 wt% of titanate chelate catalyst, 1-5 wt% of thixotropic agent, 0.05-2 wt% of titanate catalyst, 0.1-2 wt% of coupling agent and 0.5- 5wt% of silicone oil plasticizer. The invention has favorable mechanical performance and excellent adhesiveness as well as double-85 resistant performance, has simple construction process and is widely used for splicing and sealing solar modules in the solar photovoltaic industry.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

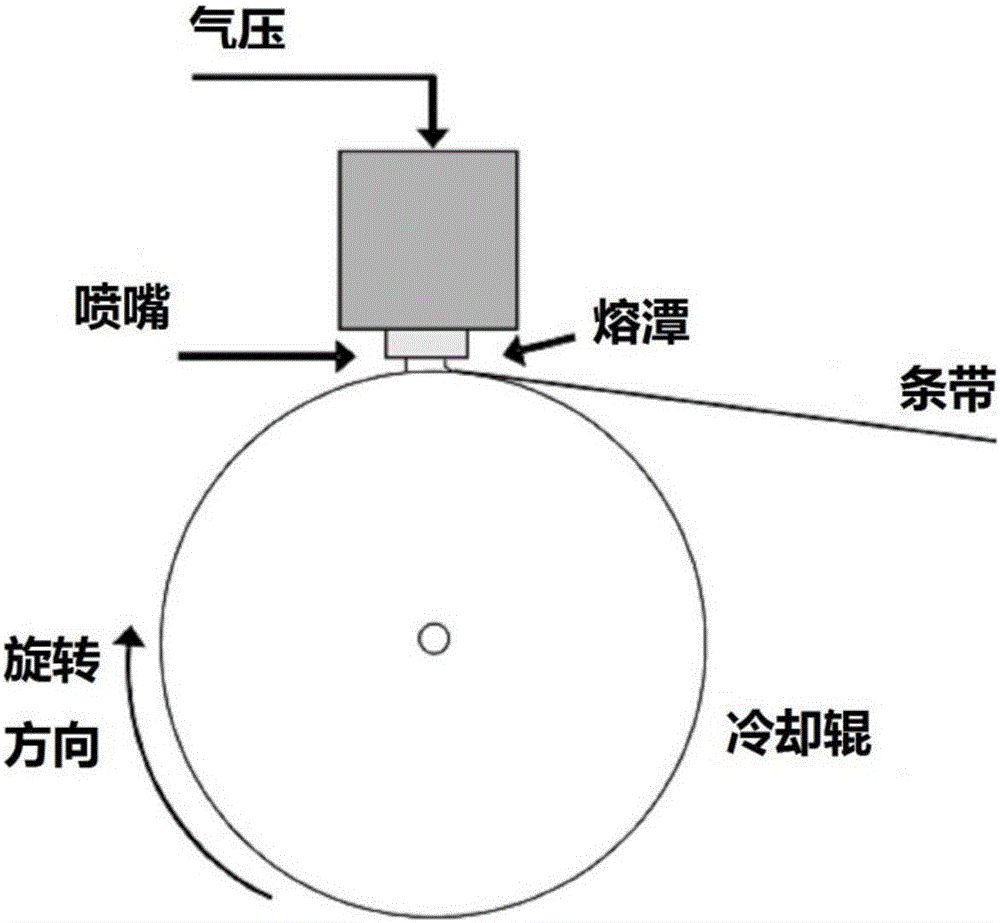

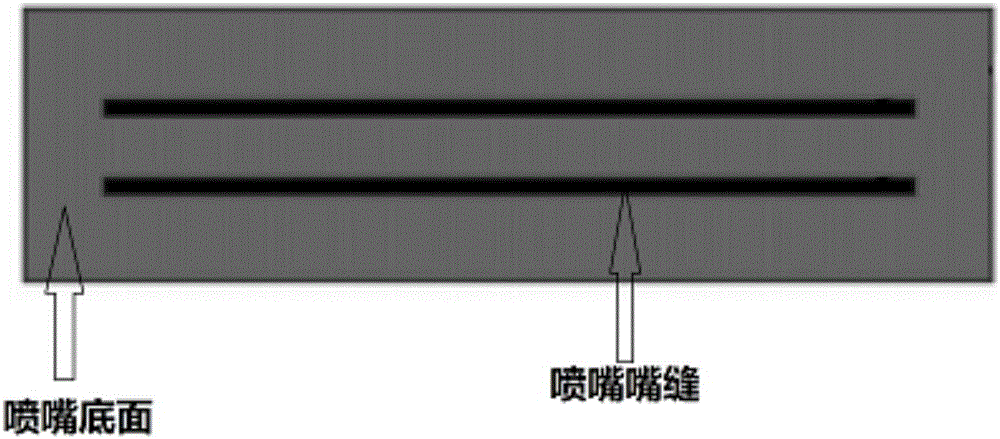

Rare-earth-doped iron-based amorphous thick strip and preparing method thereof

The invention relates to a rare-earth-doped iron-based amorphous thick strip and a preparing method thereof. The component expression of the iron-based amorphous thick strip is FexSiaBbPcYd, wherein x, a, b, c and d are atomic percents of corresponding elements, wherein a is larger than or equal to 0.5 and smaller than or equal to 10, b is larger than or equal to 0.5 and smaller than or equal to 12, c is larger than or equal to 0.5 and smaller than or equal to 8, d is larger than or equal to 0.001 and smaller than or equal to 0.5, and x+a+b+c+d is equal to 100. A plane flow casting method is adopted for manufacturing the strip, during strip manufacturing, a double-line nozzle is adopted, the thickness of the prepared amorphous thick strip ranges from 50 micrometers to 100 micrometers, the lamination coefficient is larger than 0.92, the saturated magnetic induction density is larger than 1.67T. Micro rare earth yttrium is contained in an alloy, the content of impurities of oxygen, sulphur and the like is greatly reduced, and the molten steel mobility is improved; meanwhile the rare earth yttrium improves the amorphous forming capacity of an alloy system, and the amorphous alloy strip with the thickness ranging from 50 micrometers to 100 micrometers can be prepared through the technology method.

Owner:南京腾元软磁有限公司 +3

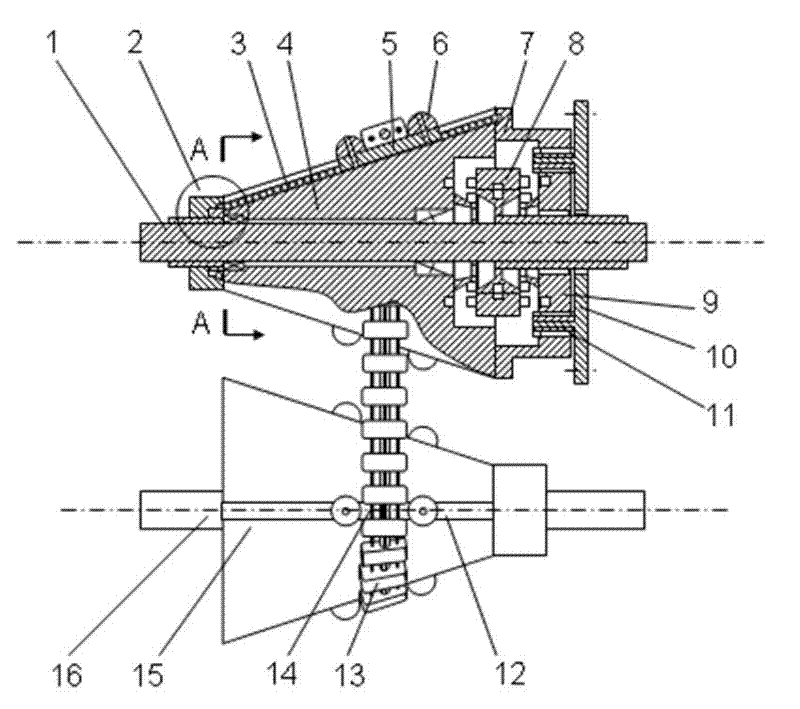

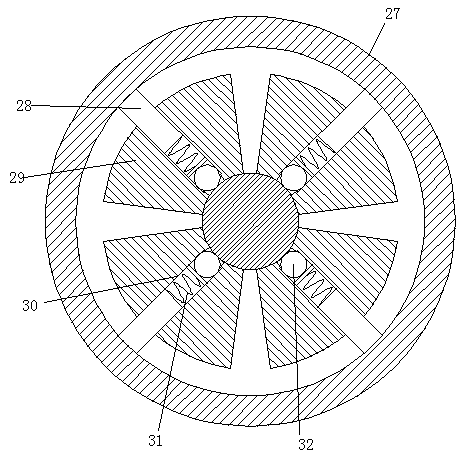

Stepless speed-changing device

InactiveCN102401100AReduced cone length and weightLow production process requirementsGearingStatic friction coefficientEngineering

The invention relates to a stepless speed-changing device, comprising an input cone pulley, an output cone pulley and a transmission chain of the input cone pulley and the output cone pulley, wherein the axis of the input cone pulley is parallel to that of the output cone pulley, and the orientation of the cone surface of the input cone pulley is opposite to that of the cone surface of the output cone pulley. The stepless speed-changing device is characterized in that a contact transmission unit on the transmission chain has a rotating freedom degree on the plane which is vertical to the self center point and surrounds the moving direction of the input cone pulley and the outer cone pulley, and can adapt to the change of the orientation of the conical surfaces so as to adjust the inclined direction automatically. The selection of the manufacturing materials of the contact transmission unit and the cone pulleys and the conical-degree sizes of the cone pulleys meet the self-locking condition for generating friction; and the static friction coefficient among the contact transmission unit and the cone pulleys is larger than the tangential value of the conical degree of the cone surface. The peripheries of the input cone pulley and the output cone pulley are provided with sliding grooves along the bus direction, and variable-diameter sliding blocks slide along the sliding grooves to change the working diameter, so that the stepless speed-changing transmission is realized.

Owner:周承岗

Method utilizing microalgae to produce biodiesel

ActiveCN103642579AHigh yieldOptimum Inoculation DensityFatty acid esterificationBiofuelsAlcoholBiodiesel

The invention belongs to the fields of biological engineering and energy, and specifically relates to a method utilizing microalgae to produce biodiesel. The method comprises the following steps: (1) culturing microalgae; (2) extracting the microalgae fat; (3) carrying out enzyme catalytic reactions so as to prepare microalgae biodiesel. An ester exchange method is adopted during the biodiesel preparation process, lipase is taken as the catalyst, the reaction conditions are mild, free aliphatic acids can be completely and directly esterified by lipase, the alcohol using amount is little, and furthermore the method adopts composite lipase to catalyze the reactions in order to effectively overcome the shortage of substrate specificity of single lipase and improve the ester exchange efficiency of biodiesel. The biodiesels prepared by the method all meet the GB / T20828-2007 standard of biodiesel for diesel engine fuel blending.

Owner:BEIJING EURO & AMERICAN INST OF SCI & TECH

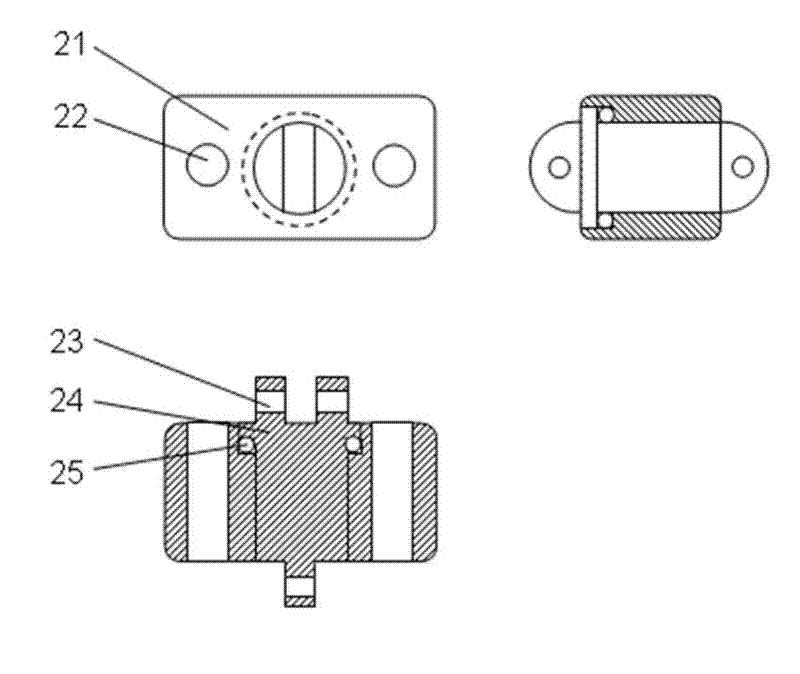

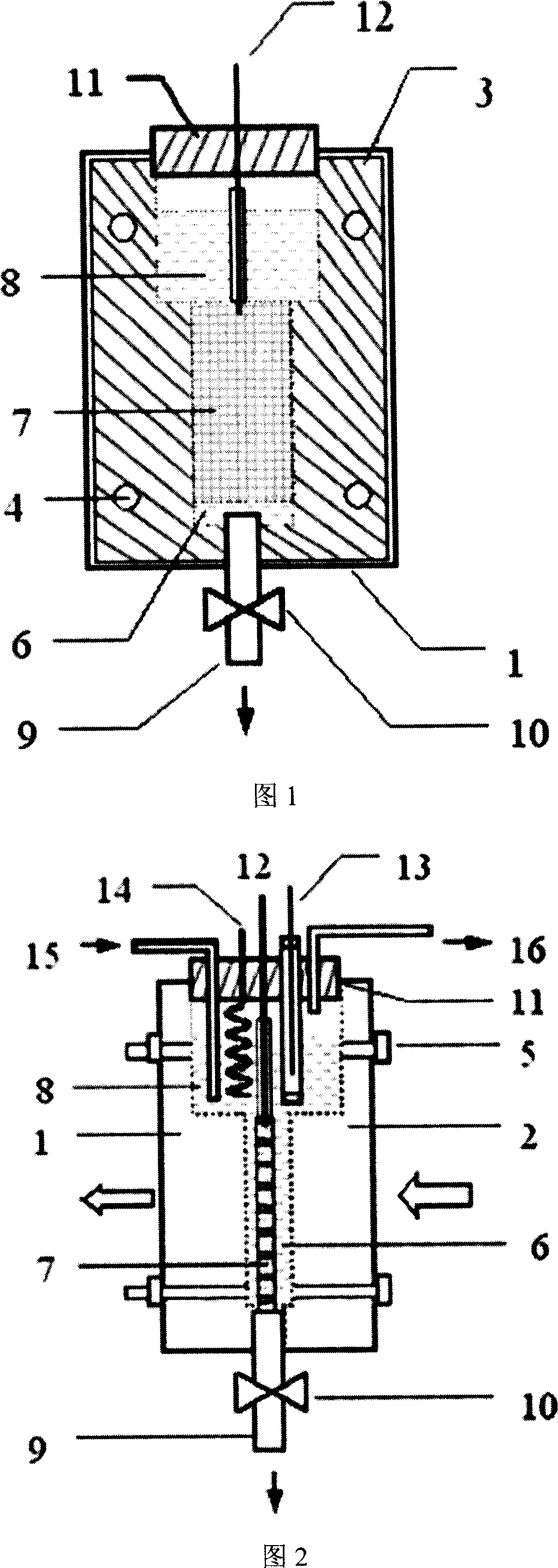

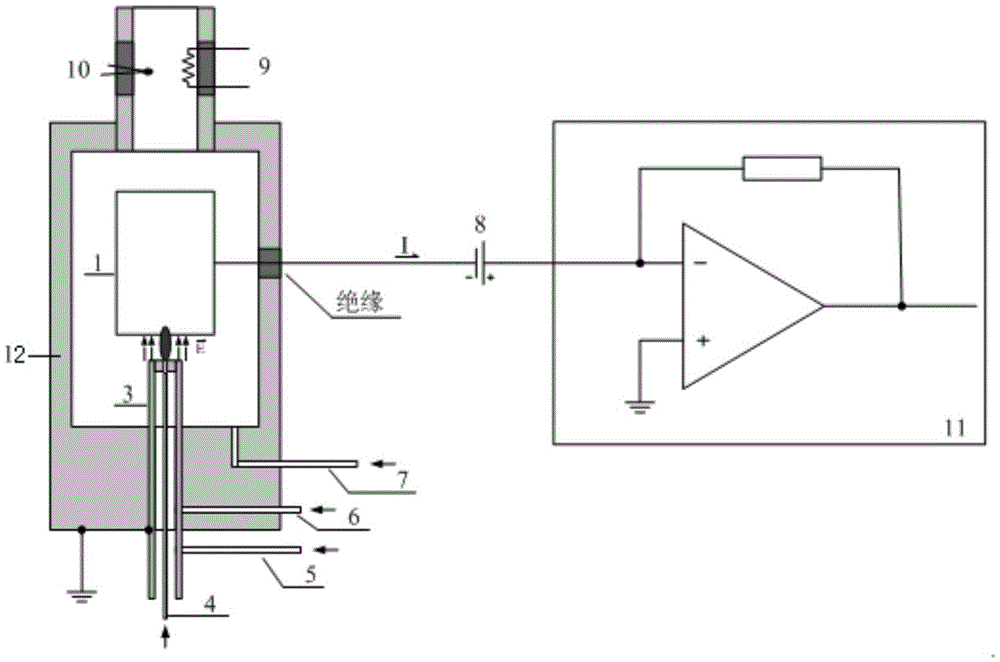

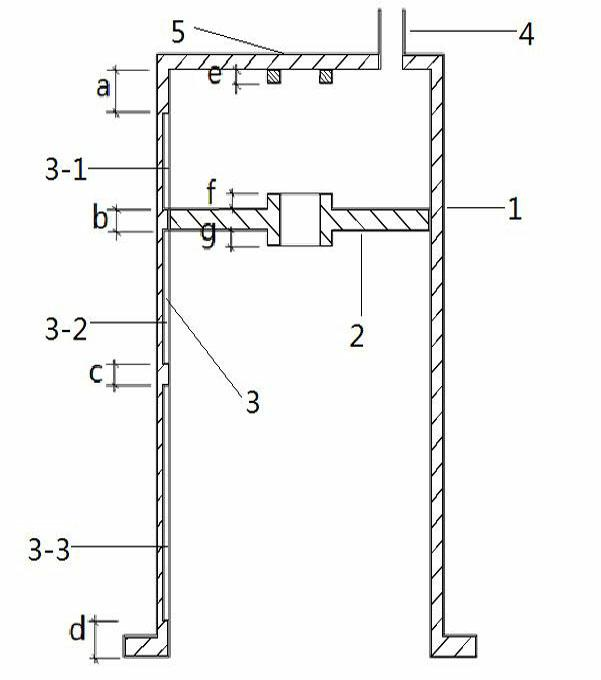

Thin-layer spectral electrochemical investigating pond

InactiveCN101000323ASimple structureLow production process requirementsMaterial analysis by electric/magnetic meansColor/spectral properties measurementsPhysicsCHEMISTRY METHODS

The invention supplies thin bed spectral electro-chemical detecting pool. It is formed by a pair of light permeated boards and diaphragm. Main body upper center is set liquid storing pool cavity. Its lower part diaphragm body is set U shape opening to form sheeting spectra electro-chemical detecting pool in which grating light permeated electrode is set. Its lead wire passes through the sealing-plug in which reference electrode, counter electrode, inert gases inlet pipe and out pipe, are set. The detecting pool bottom is set liquid outlet pipe. The invention has the advantages of easy calibrating light path, adjustable thin bed thickness, high electrolysis efficiency, good deoxidizing effect, convenient installing electrode system, simple structure, and good for spectra electro-chemistry method generalization.

Owner:FUZHOU UNIVERSITY

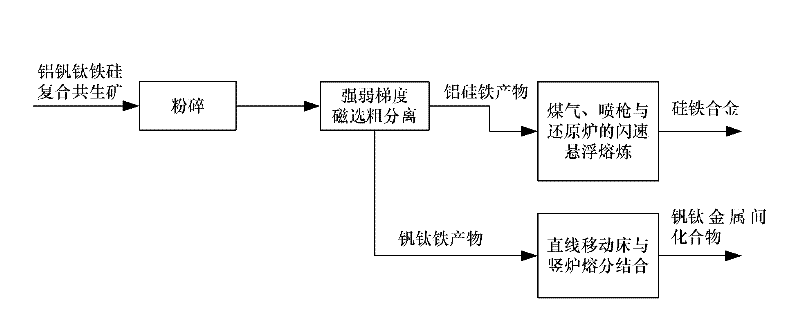

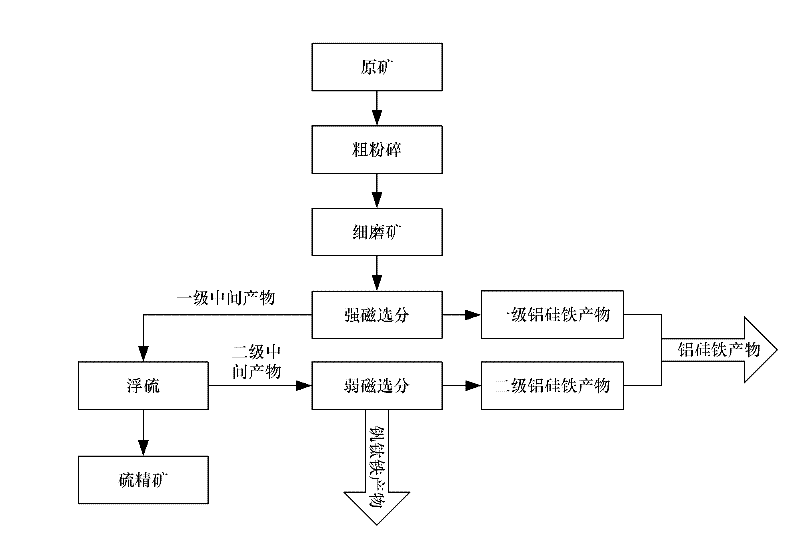

An industrial production method for separating valuable elements from aluminum-vanadium-titanium-iron-silicon composite symbiotic ore for recovery and utilization

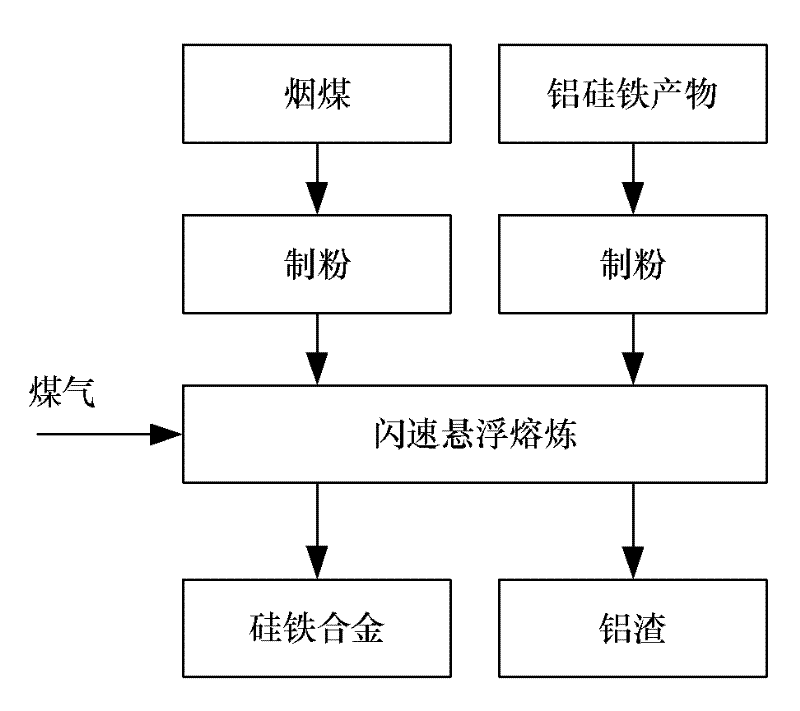

The invention discloses an industrial production method of separating valuable elements from composite paragentic mineral of aluminum-vanadium-titanium-iron-silicon for cyclic utilization. The method comprises the following steps: employing the technique of gradient magnetic separation to separate aluminum-silicon-iron products, vanadium-titanium-iron products and sulfur concentrate from composite paragentic mineral of aluminum-vanadium-titanium-iron-silicon; carrying out flash suspension smelting on the aluminum-silicon-iron products to obtain ferrosilicon alloy and aluminum slag which is used as a raw material for production of alundum; employing the technique of rectilinearly movable bed prereduction-shaft furnace smelting to prepare the vanadium-titanium-iron products into vanadium iron intermetallic compounds and titanium slag. Smelting separation and flash suspension smelting and rectilinearly movable bed prereduction-shaft furnace smelting are combined in the method provided inthe invention, which enables the recovery rate of raw ores to be enhanced.

Owner:陕西延长石油中陕金属矿业有限公司 +1

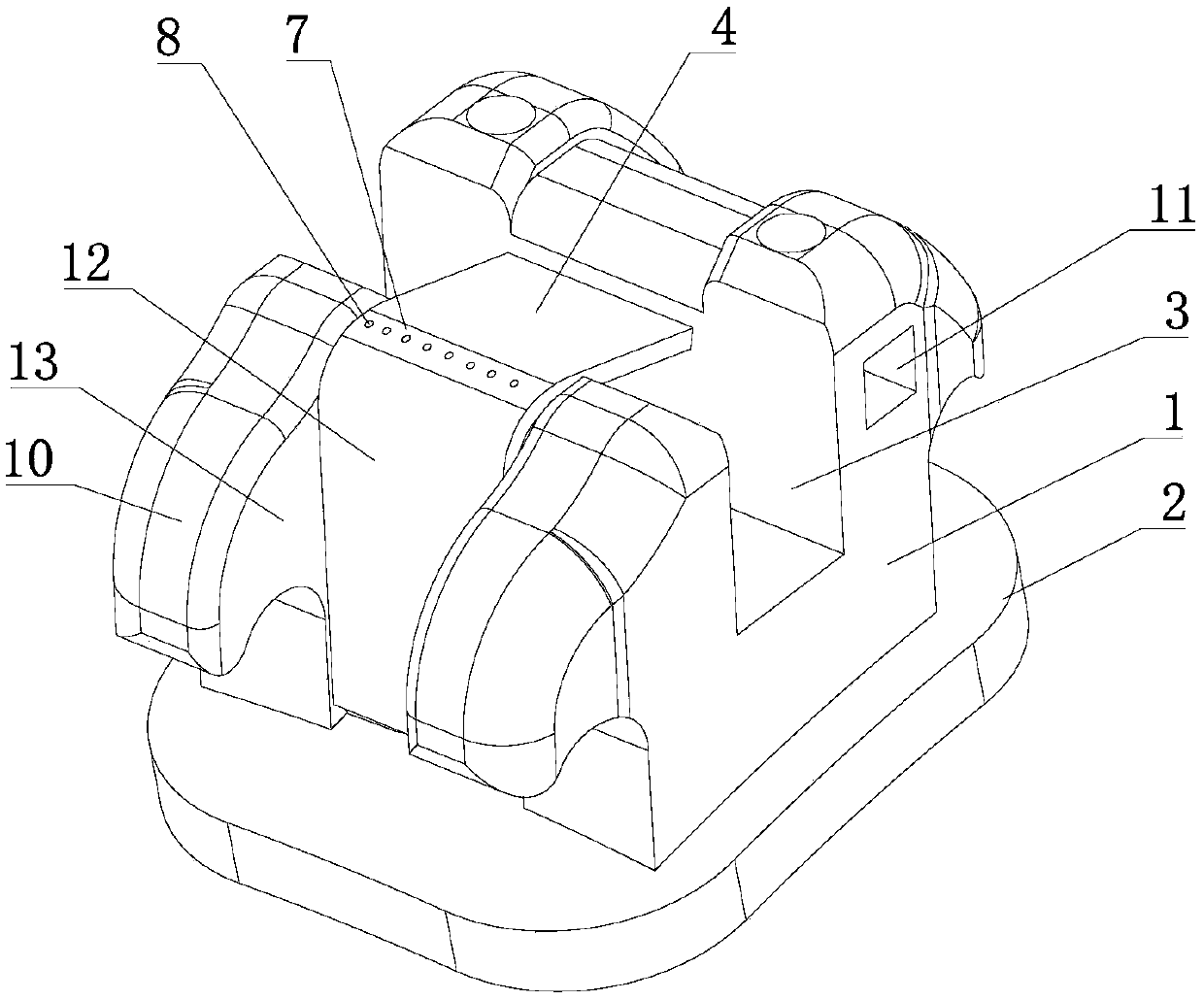

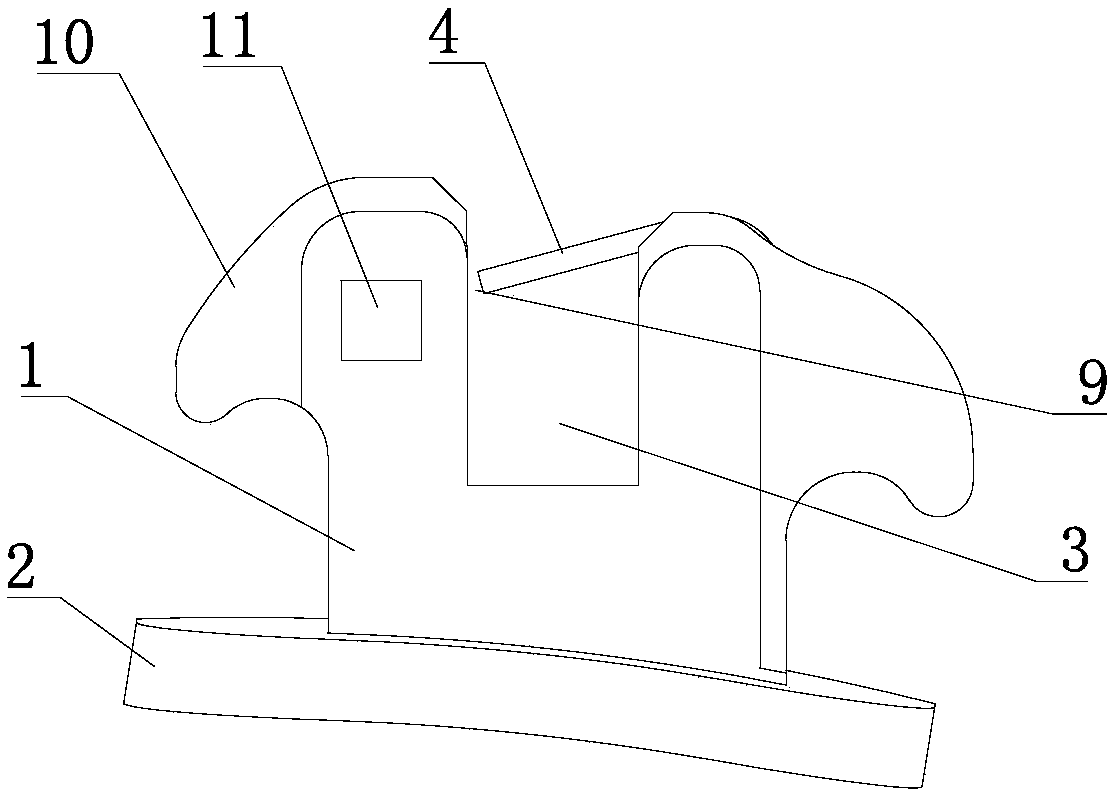

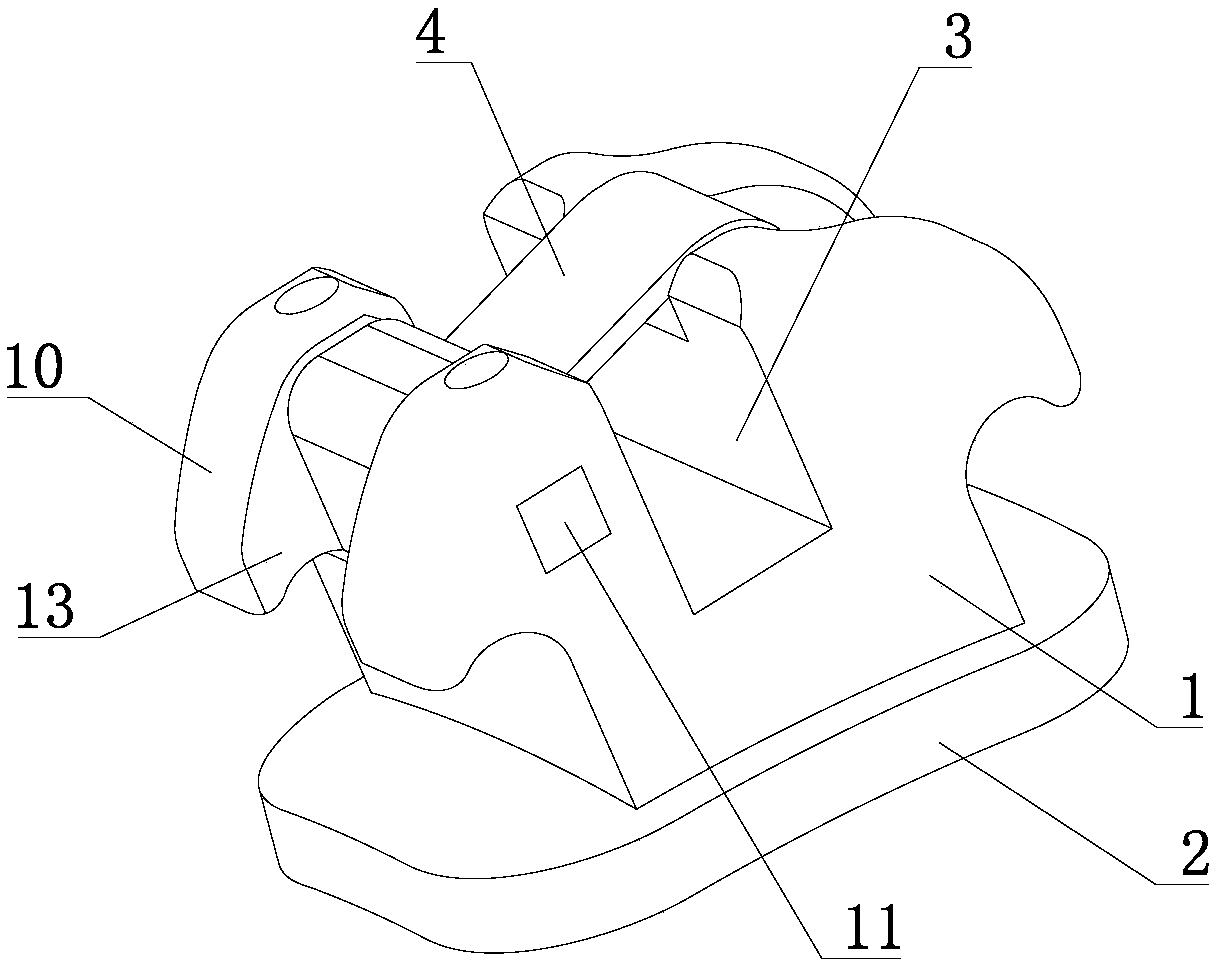

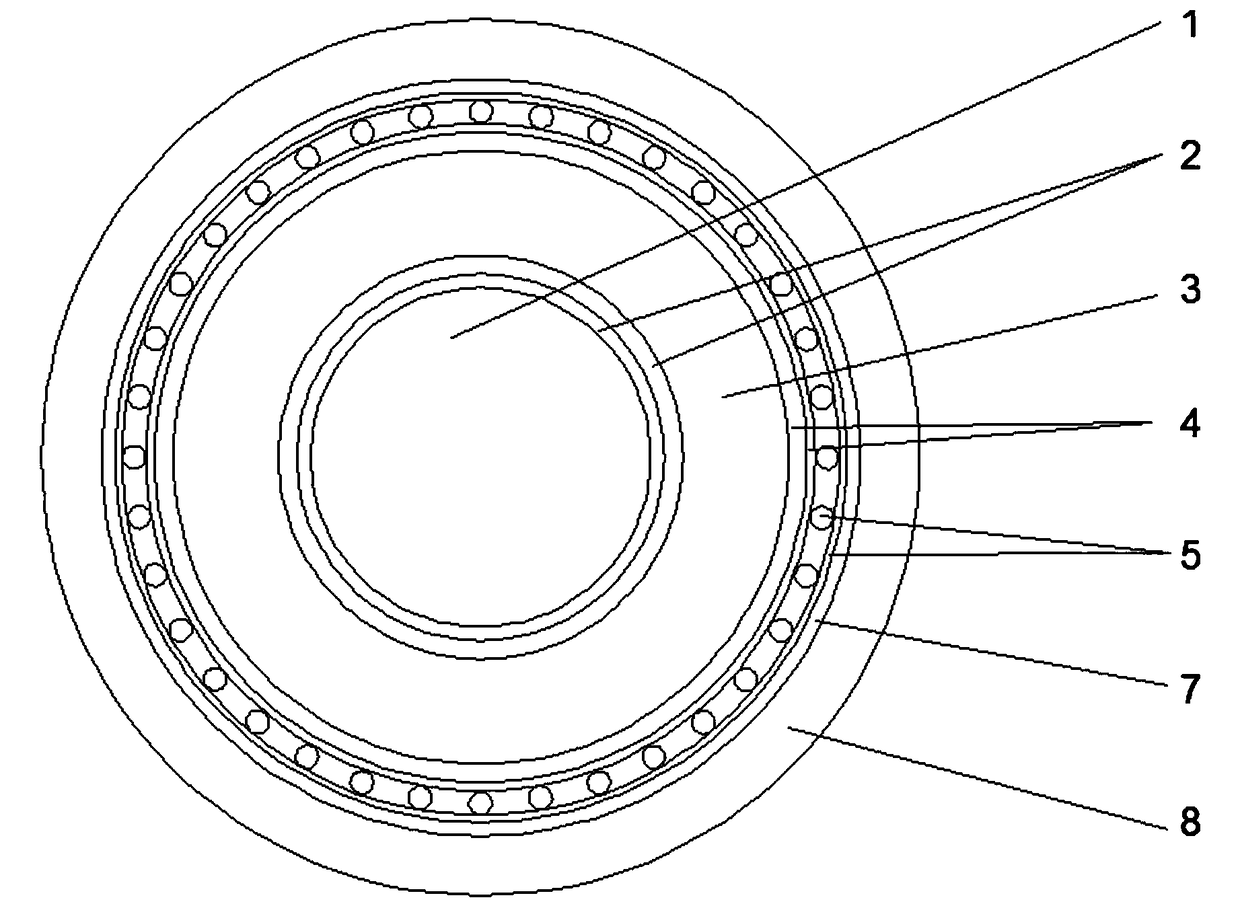

Orthodontic time-sharing self-locking bracket

The invention relates to the field of orthodontic brackets, in particular to an orthodontic time-sharing self-locking bracket comprising a bracket main body and a time-sharing self-locking unit, wherein the bottom of the bracket main body is provided with a bracket base plate in contact with the teeth, and the bracket main body is provided with a bracket groove for mounting an arch wire; the time-sharing self-locking unit includes an elastic pressure plate disposed on a side wall of the bracket groove, and the elastic pressure plate defines a variable-size passage; and the elastic pressure plate has a first working state and a second working state. The orthodontic time-sharing self-locking bracket is exquisite in structure design; the different working states of the elastic pressure plateare reasonably used in different time periods of orthodontic treatment, and a doctor can press the arch wire into the bracket groove conveniently at an early stage, the operation is simple, the friction between the arch wire and the groove is low, and the tooth movement is safe and efficient; at a later stage, a thick square wire presses the elastic pressure plate to the side wall of the groove tofill the clearance, the friction between the arch wire and the groove is high, the precise control of a tooth torque, shaft inclination and position is achieved, the orthodontic effect is greatly improved, and an orthodontic treatment course is shortened.

Owner:吕涛

Preparation method of wear-resistant and anti-static rubber soles

InactiveCN103587135AImprove antistatic performanceWear volume is smallDomestic footwearPolymer scienceWear resistant

The invention discloses a preparation method of a wear-resistant and anti-static rubber soles. The preparation method comprises the steps of (1) plasticization, (2) master batching, (3) mixing, (4) thermal plasticization and molding, and (5) sole preparation. According to the preparation method, the simplicity is realized, the production process requirement is low and the production cost is low. A conductive rubber sole sizing material is good in anti-static performance, wet skid resistance coefficients reach 0.73 to 0.75, the rubber Akron wear volume of rubber soles is smaller than 0.4cm<3> / 1.61km, and the resistance is 0.1 to 1megohm. According to the method, static electricity carried by a human body can be removed in a flammable and combustible production place, so that fire and explosion can be effectively avoided.

Owner:ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

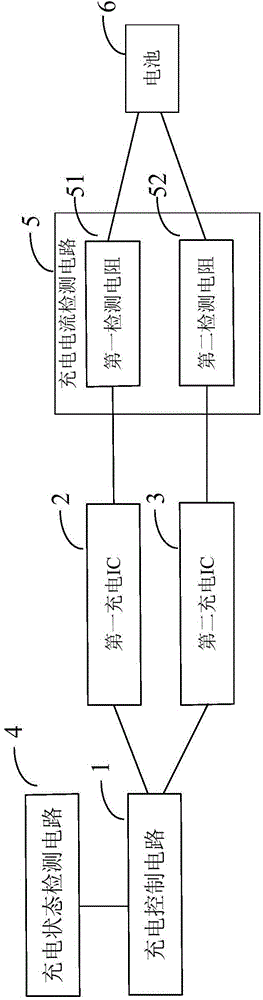

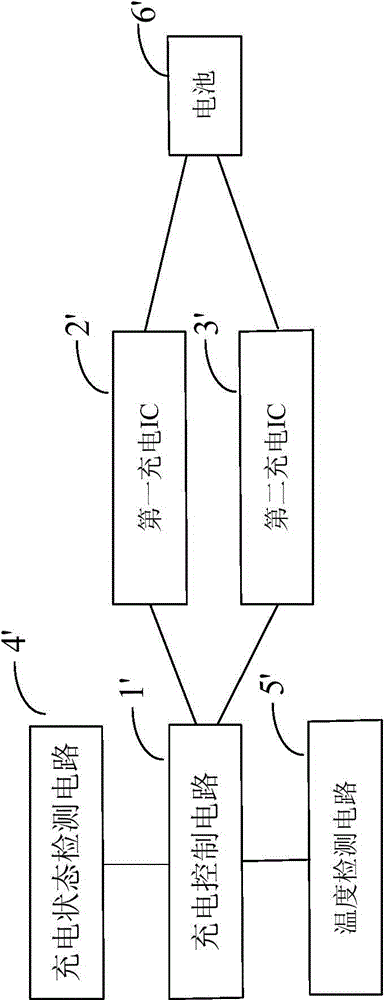

Charging circuit and mobile terminal

ActiveCN105322597ALow costLow production costBatteries circuit arrangementsElectric powerCharge controlControl circuit

The invention relates to the technical field of electrons, and provides a charging circuit. The charging circuit comprises a charging control circuit and at least two charging integrated circuits (ICs), wherein the at least two charging ICs are connected with each other in parallel; a common output end of the charging ICs is connected with a charging input end of a battery; and the charging control circuit is used for controlling the at least two charging ICs to charge the battery. The invention further provides a mobile terminal. According to the charging circuit and the mobile terminal provided by the invention, the cost can be effectively controlled when heavy current charging is achieved.

Owner:VIVO MOBILE COMM CO LTD

Sealing rubber film for solar cell module

ActiveCN104178042ALower working temperatureImprove photoelectric conversion efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesVitrificationPolymer science

The invention discloses a sealing rubber film for a solar cell module. The sealing rubber film consists of the following components in parts by weight: 100 parts of olefin polymer, 5-30 parts of heat conductive material, 0.05-2 parts of anti-ageing agent and 1-20 parts of adhesive force promoting polymer, wherein the olefin polymer is composed of a first olefin polymer and a second olefin polymer; according to the measurement of a DSC (digital scan converter), the glass transition temperature of the first olefin polymer ranges from (minus) 59 DEG C to (minus) 32 DEG C, and the fusing peak of the first olefin polymer ranges from 42 DEG C to 100 DEG C; the fusing peak of the second olefin polymer ranges from 111 DEG C to 130 DEG C, and the melt flow rate measured under the conditions of 190 DEG C and 2.16 kg is 0.5-5g / 10minute; and the mass ratio of the first olefin polymer to the second olefin polymer is (65:35)-(90:10). The rubber film disclosed by the invention does not permeate towards the transparent rubber film on the glass side, is safe and reliable, obvious in heat conduction effect, and capable of lowering the working temperature of the module and improving the photoelectric conversion efficiency when the module continuously works; and meanwhile, the sealing rubber film is simple in manufacturing process and convenient to use.

Owner:乐凯胶片股份有限公司

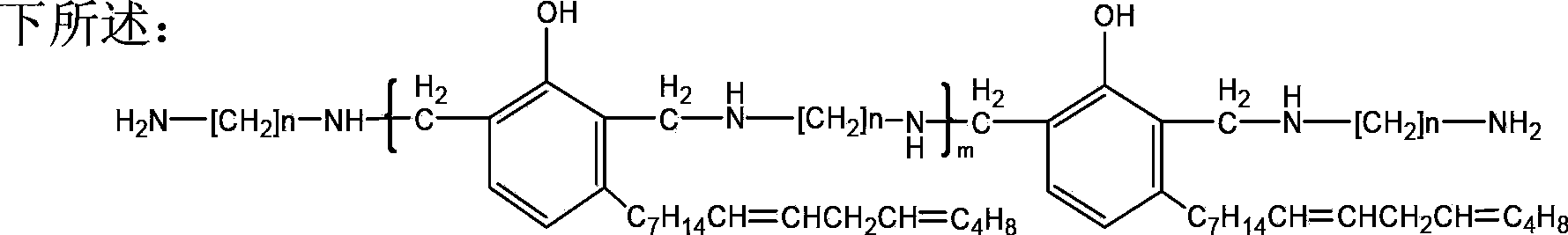

Corrosion inhibitor and preparing method thereof

The invention provides a corrosion inhibitor and a preparing method thereof. The corrosion inhibitor comprises components including, by weight part, 30 to 50 parts of a main agent, 10 to 20 parts of triethanolamine phosphate, 4 to 8 parts of thiourea, 2 to 5 parts of a surface active agent and 17 to 54 parts of a solvent. The main agent comprises a first chemical compound of the formula I structure shown in the specification and a second chemical compound of the formula II structure shown in the specification, and the mass concentration sum of the first chemical compound and the second chemical compound in the main agent is 60%. The corrosion inhibitor can effectively protect an oil and gas field combined station sewage pipeline in the hypersalinity sewage environment containing CO2 and H2S gas, and the beneficial effects of being good in water solubility and compatibility, high in safety, low in filling concentration, excellent in anti-corrosion effect, low in production process needand the like are achieved.

Owner:PETROCHINA CO LTD

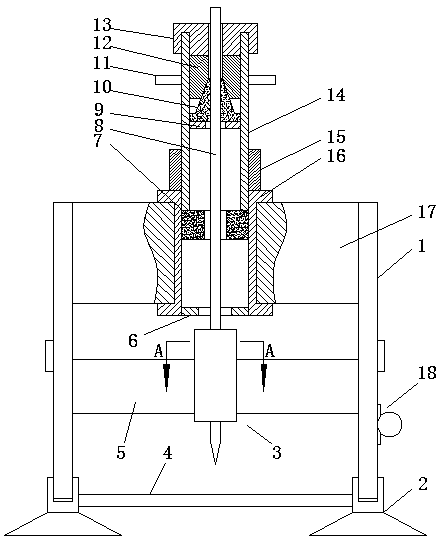

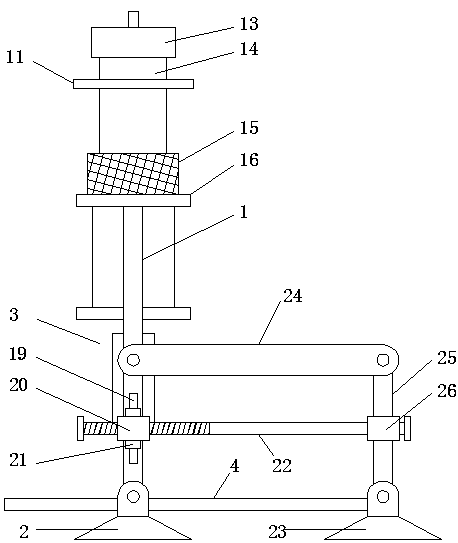

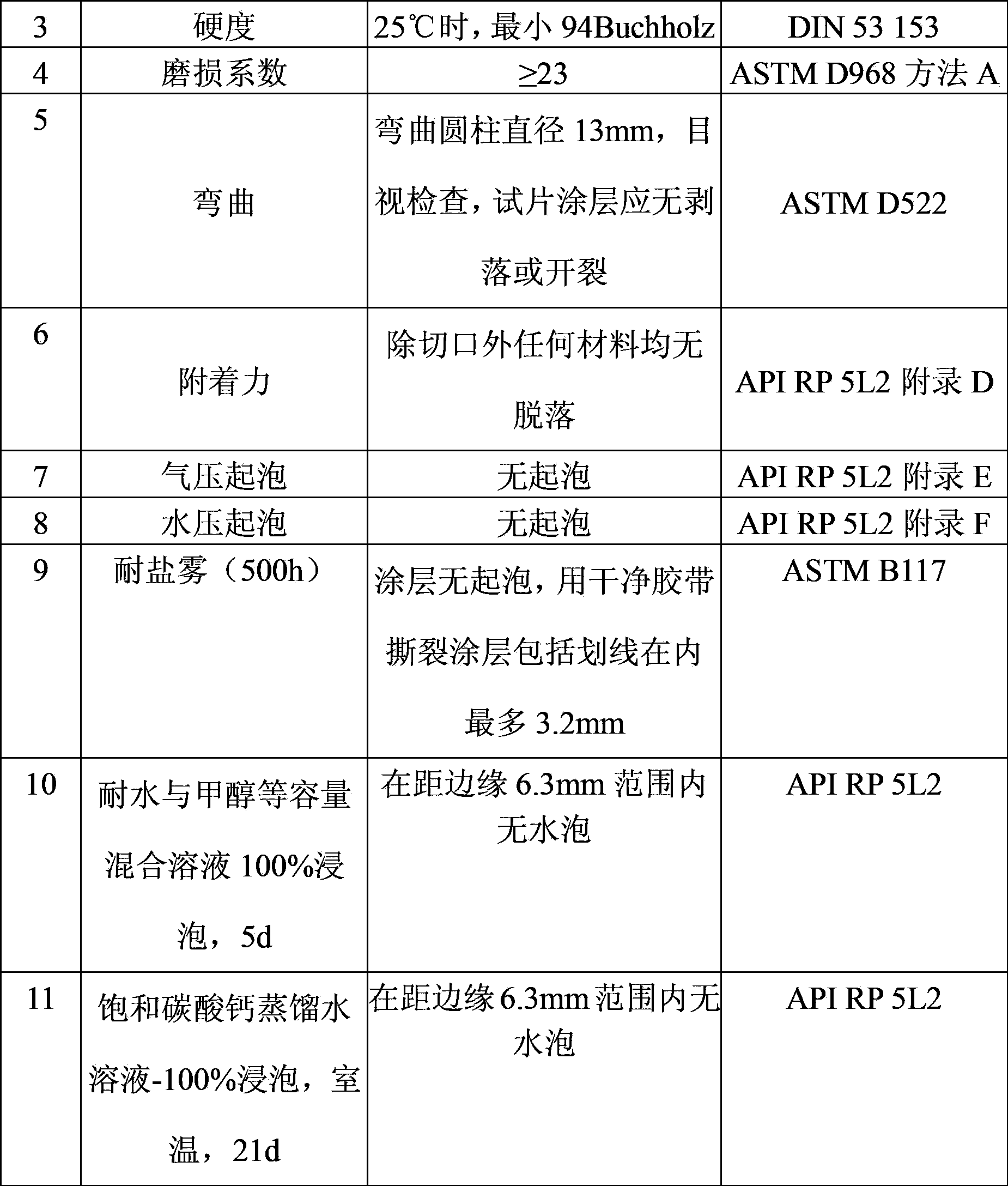

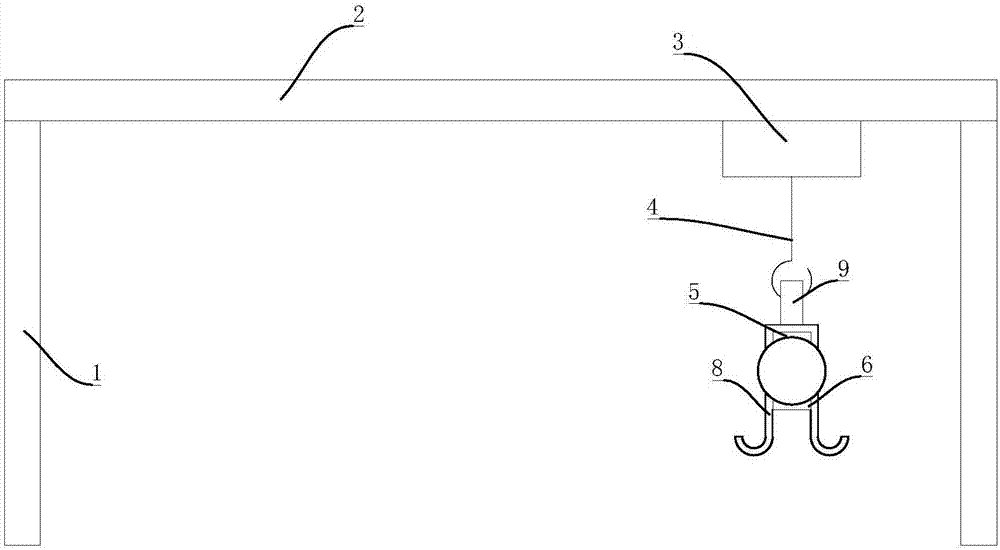

Auxiliary needle feeding device for traditional Chinese medicine acupuncture and moxibustion

ActiveCN109674652AEasy to operateEasy to removeAcupunctureDevices for locating reflex pointsMedicineTherapeutic effect

The invention relates to the field of traditional Chinese medicine acupuncture and moxibustion and in particular relates to an auxiliary needle feeding device for the traditional Chinese medicine acupuncture and moxibustion. The auxiliary needle feeding device comprises a needle body and front supporting legs, wherein the two front supporting legs are arranged oppositely; a transverse supporting rod II is fixed between the upper ends of the two front supporting legs; a needle holding part for clamping the needle body and operating the needle body is arranged in the middle of the transverse supporting rod II; a transverse supporting rod I, which is parallel to the transverse supporting rod II, is fixed between the middle parts of the two front supporting legs; a guide mechanism for guidingneedle feeding on a pillow body is fixed in the middle of the transverse supporting rod I; an angle adjusting mechanism is connected with the lower parts of the front supporting legs; the angle adjusting mechanism can be used for adjusting a needle feeding angle of the needle body. The auxiliary needle feeding device for the traditional Chinese medicine acupuncture and moxibustion is simple and convenient to operate; the whole device is convenient to dismount, the needle feeding stability is improved and pains of patients are reduced; the treatment effect is easy to improve and operation requirements on newbies are reduced; the auxiliary needle feeding device has better practicability and the traditional Chinese medicine acupuncture and moxibustion is easy to popularize.

Owner:HUNAN UNIV OF CHINESE MEDICINE

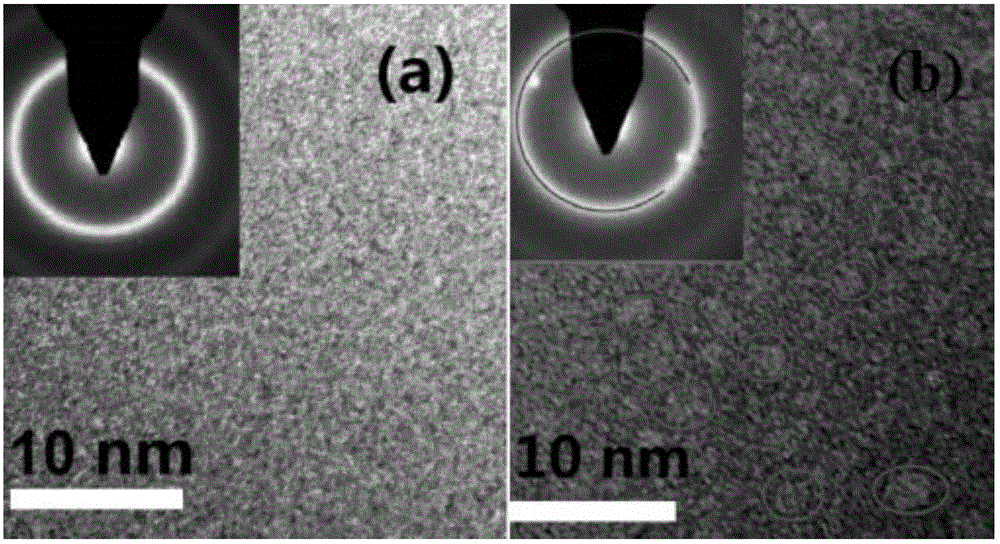

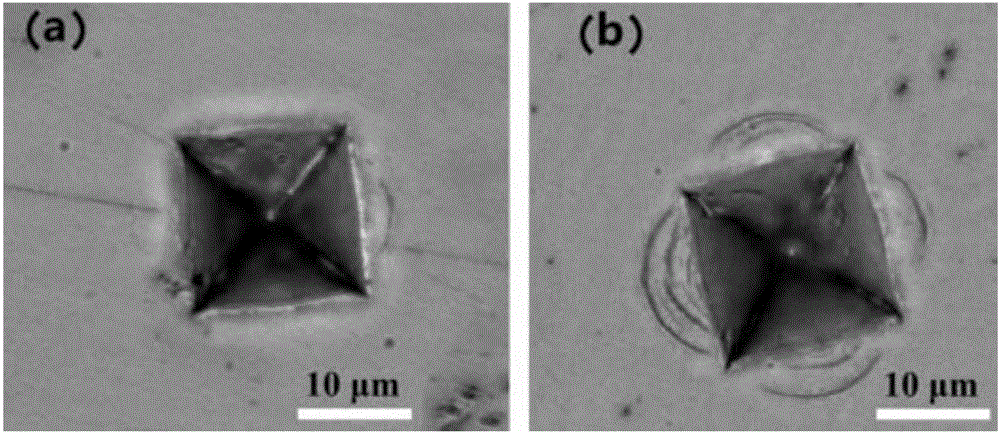

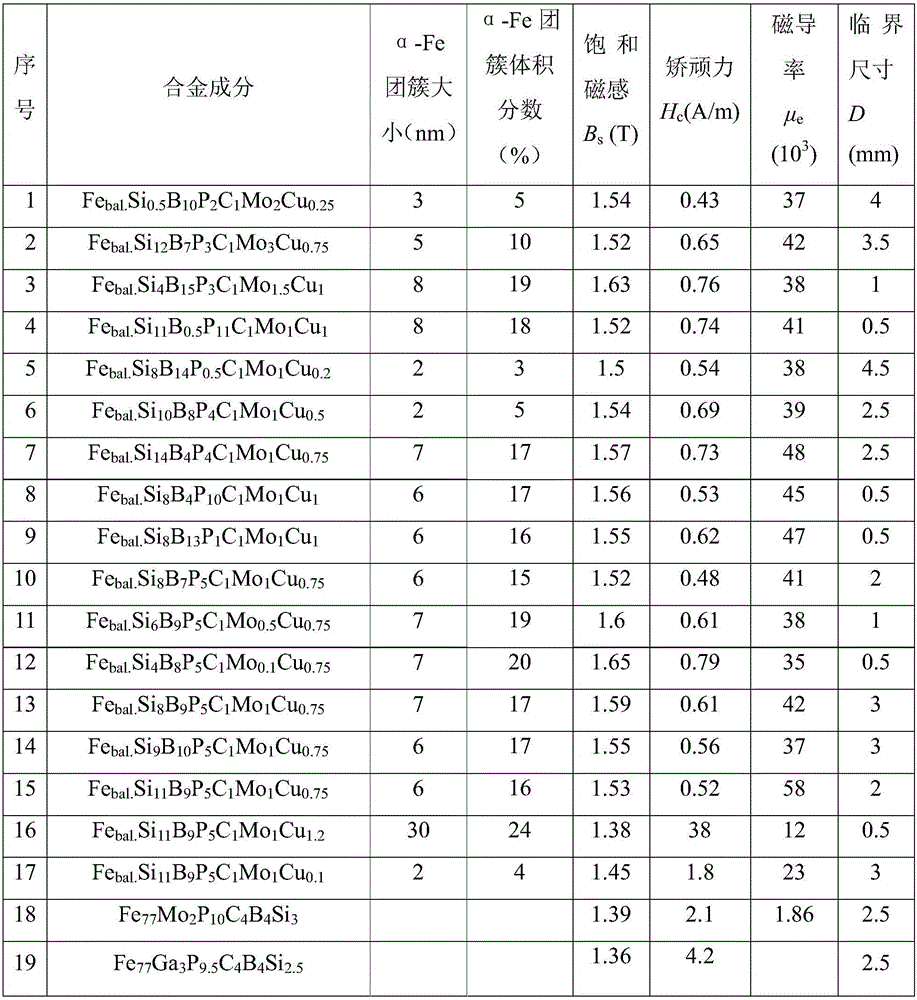

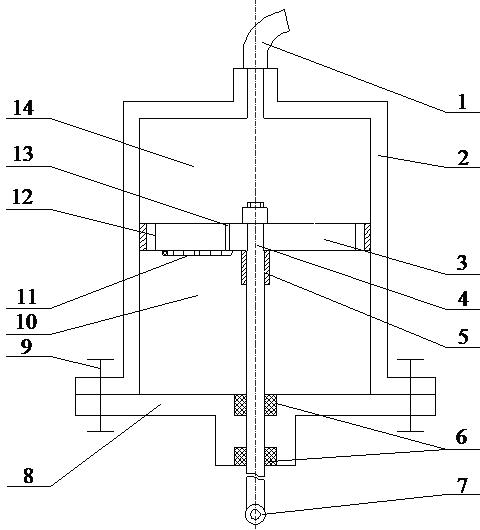

Toughness-enhanced iron-based bulk amorphous soft magnetic alloy and preparation method thereof

ActiveCN105741998AHigh saturation magnetic inductionLow coercivityMagnetic materialsToughnessElectron

The invention relates to toughness-enhanced iron-based bulk amorphous soft magnetic alloy and a preparation method thereof, belonging to the field of a magnetic functional material. The expression formula of the alloy is Fe<x>SiBP<c>C<d>Mo<e>M<f>, wherein M is at least one of Cu, Ag and Au, x, a, b, c, d, e and f respectively represent atomic percent content of each corresponding constituent, a is more than or equal to 0.5 but less than or equal to 14, b is more than or equal to 0.5 but less than or equal to 15, c is more than or equal to 0.5 but less than or equal to 14, d is more than or equal to 0.1 but less than or equal to 5, e is more than or equal to 0.1 but less than or equal to 5, f is more than or equal to 0.2 but less than or equal to 1, x is more than or equal to 72 but less than or equal to 85, and (x+a+b+c+d+e+f) is equal to 100%. With the preparation method provided by the invention, the saturation magnetic induction and the plastic deformation capability of iron-based bulk amorphous can be simultaneously improved; moreover, the production process is simple, is low in cost and is easy for industrialization; and the product has excellent soft magnetic performance and toughness, and can be taken as a structure and a functional soft magnetic material applied to the fields of power, electrons, information, communication and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

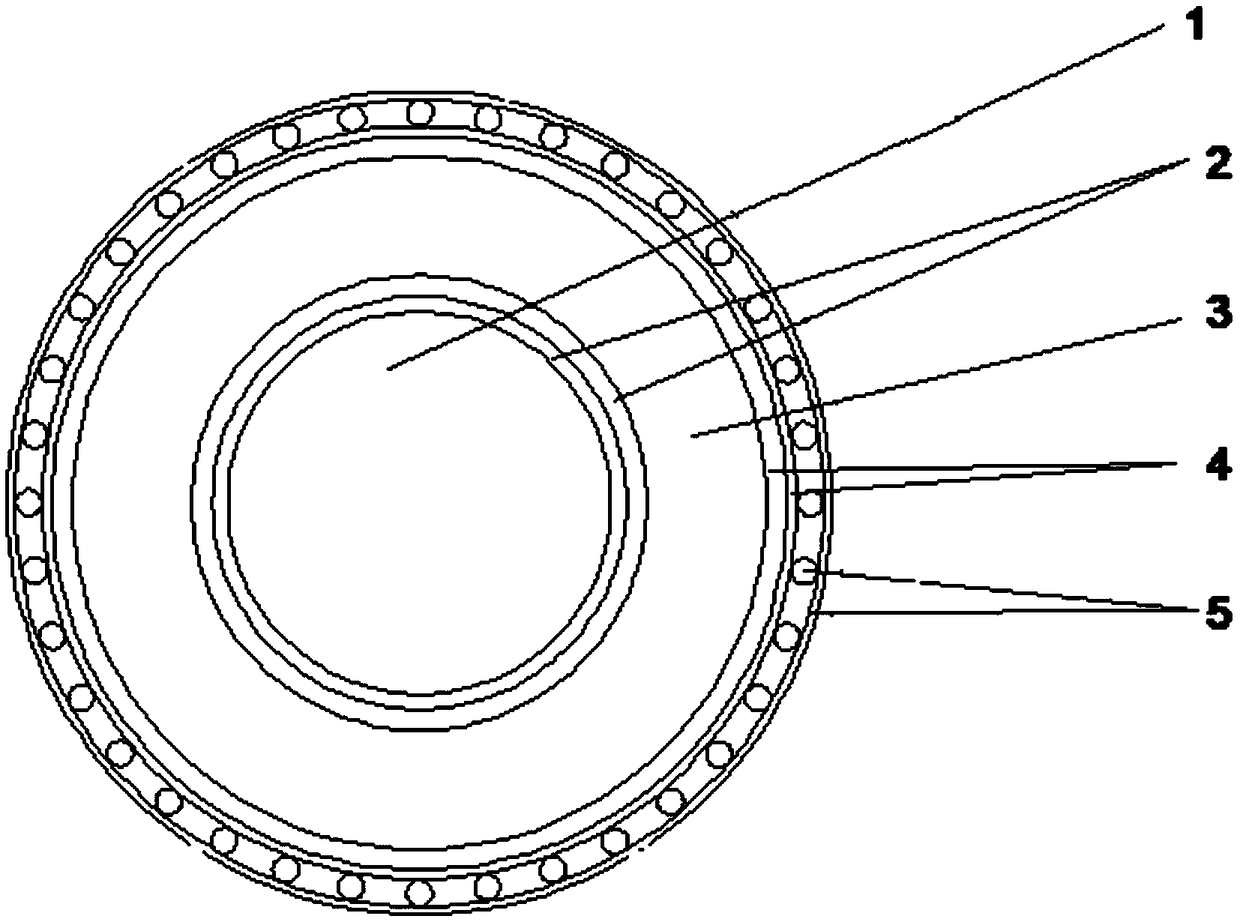

Additional air chamber of volume-variable air spring

The invention discloses an additional air chamber of a volume-variable air spring and relates to an additional air chamber of the air spring for vehicle. The additional air chamber of the volume-variable air spring comprises an additional air chamber cavity, a connecting pipeline for connecting a main air chamber, a piston, a piston rod, a ventilating module, a key groove, a key, a cover plate, an elongated pipeline, and on the like. The additional air chamber can change the volume by controlling the reciprocating motion of the piston, so that the effective volume of the air spring in work is changed, the rigidity of an air spring system is further changed to adapt to various driving situations of vehicles and achieve the purpose of improving the comprehensive performance of a suspension system; as the driving force required during piston movement is small, the ventilating module is timely opened and closed to ensure the stability of the gas pressure at the inner part of the spring, reduce the impact generated in the working process of the spring and provide convenience for the use of the additional air chamber of the volume-variable air spring on the vehicle. The additional air chamber of the volume-variable air spring is simple in structure, low in requirement of producing technique, convenient to maintain and low in manufacturing cost.

Owner:JIANGSU UNIV

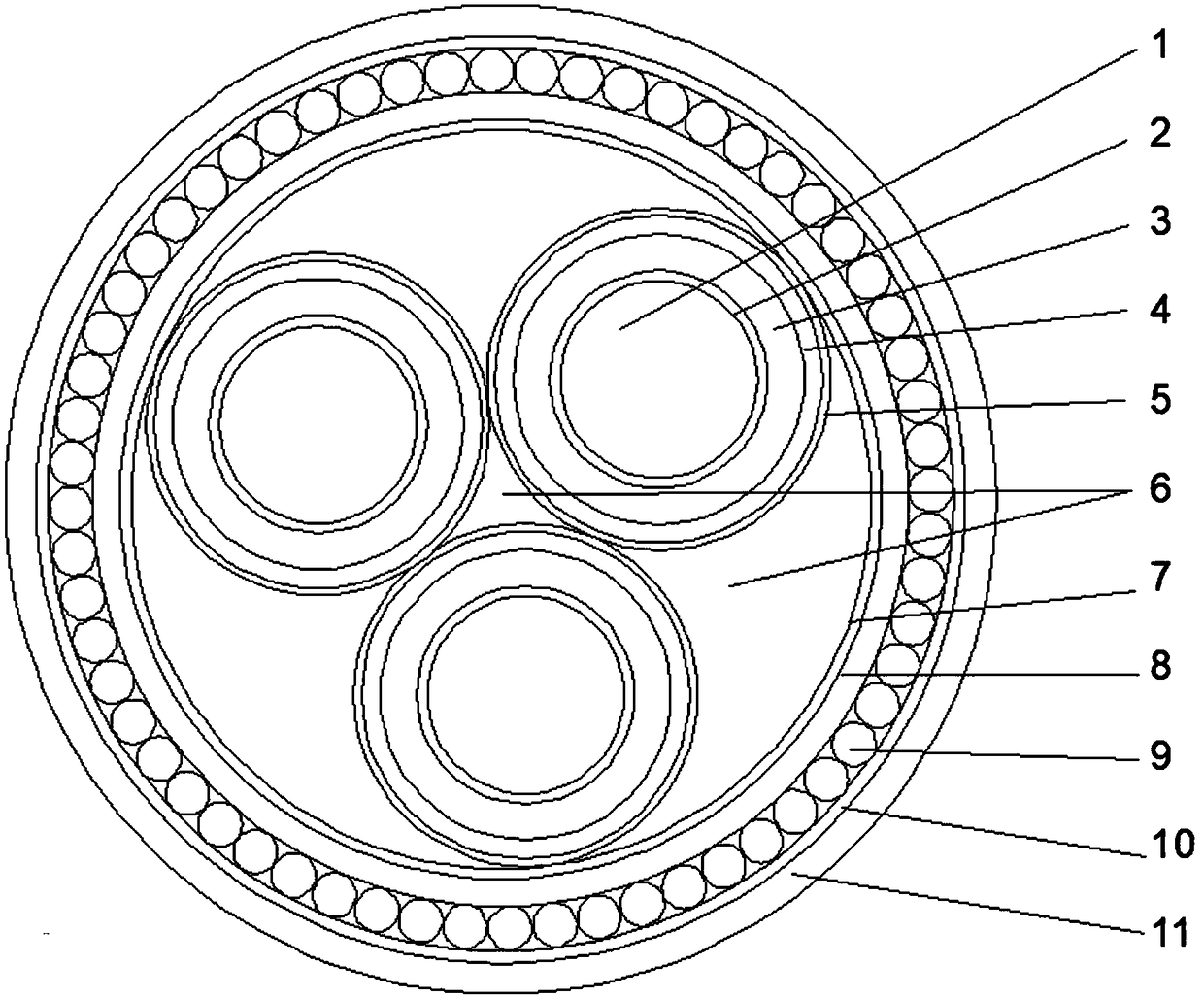

Method for manufacturing an environment-friendly medium-voltage power cable and cable

PendingCN109378136ASimple production processIncrease ampacityApparatus for heat treatmentPower cables with screens/conductive layersElastomerElectrical conductor

The invention relates to a method for manufacturing an environment-friendly medium-voltage power cable and a cable. The method comprises the steps of: 1) manufacturing a wire core; 2) manufacturing acable core; and 3) manufacturing a protective layer. The step 1) comprises 1.1) wrapping a semiconductive conductor shielding layer around a conductor, wherein the semiconductive conductor shielding layer is formed by an extruded environment-friendly polypropylene semiconductive material layer, or firstly wrapping a semiconductive tape around the conductor and then wrapping the environment-friendly polypropylene semiconductive material layer around the semiconductive tape; 1.2) wrapping an insulation layer formed by extruding an environment-friendly polypropylene elastomer insulation material; 1.3) wrapping a semiconductive insulation shielding layer which is formed by extruding a strippable or unstrippable environment-friendly polypropylene semiconductive material to form a semiconductive material extrusion layer, and wrapping the semiconductive tape around the semiconductive material extrusion layer; wherein the environment-friendly polypropylene semiconductive material layer ofthe semiconductive conductor shielding layer, the insulation layer, and the semiconductive material extrusion layer of the semiconductive conductor shielding layer are formed by three-layer co-extrusion.

Owner:JIANGSUSNGSHANG CABLE GROUP

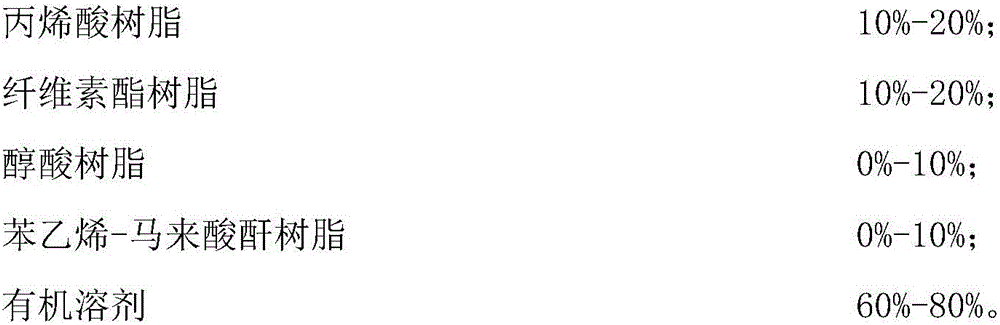

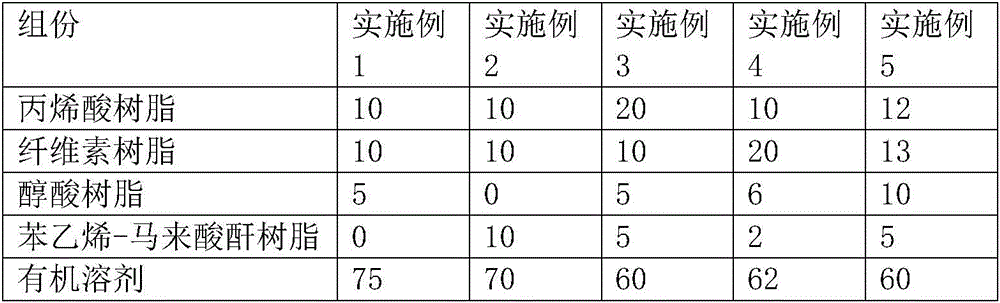

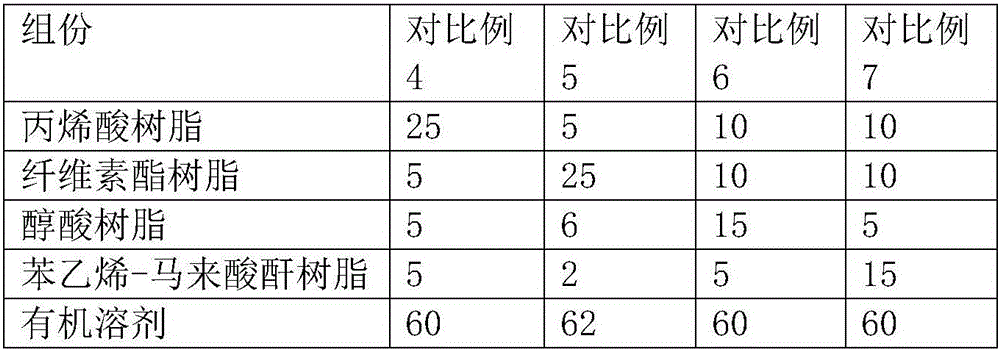

Low-VOC easy-to-offset-printing cold wave release layer coating and preparation method thereof

The invention provides a low-VOC easy-to-offset-printing cold wave release layer coating and a preparation method thereof. The coating is prepared from the following components in percentages by weight: 10% to 20% of acrylic resin, 10% to 20% of cellulose ester resin, 0% to 10% of alkyd resin, 0% to 10% of styrene-maleic anhydride resin and 60% to 80% of an organic solvent. Compared with the prior art, the coating has the advantages of adjustable and controllable stripping quality, excellent offset printing performance and low raw material cost; moreover, the coating adopts a benzene-free system, and has the characteristic of low VOC content.

Owner:SHANGHAI WEIKAI CHEM

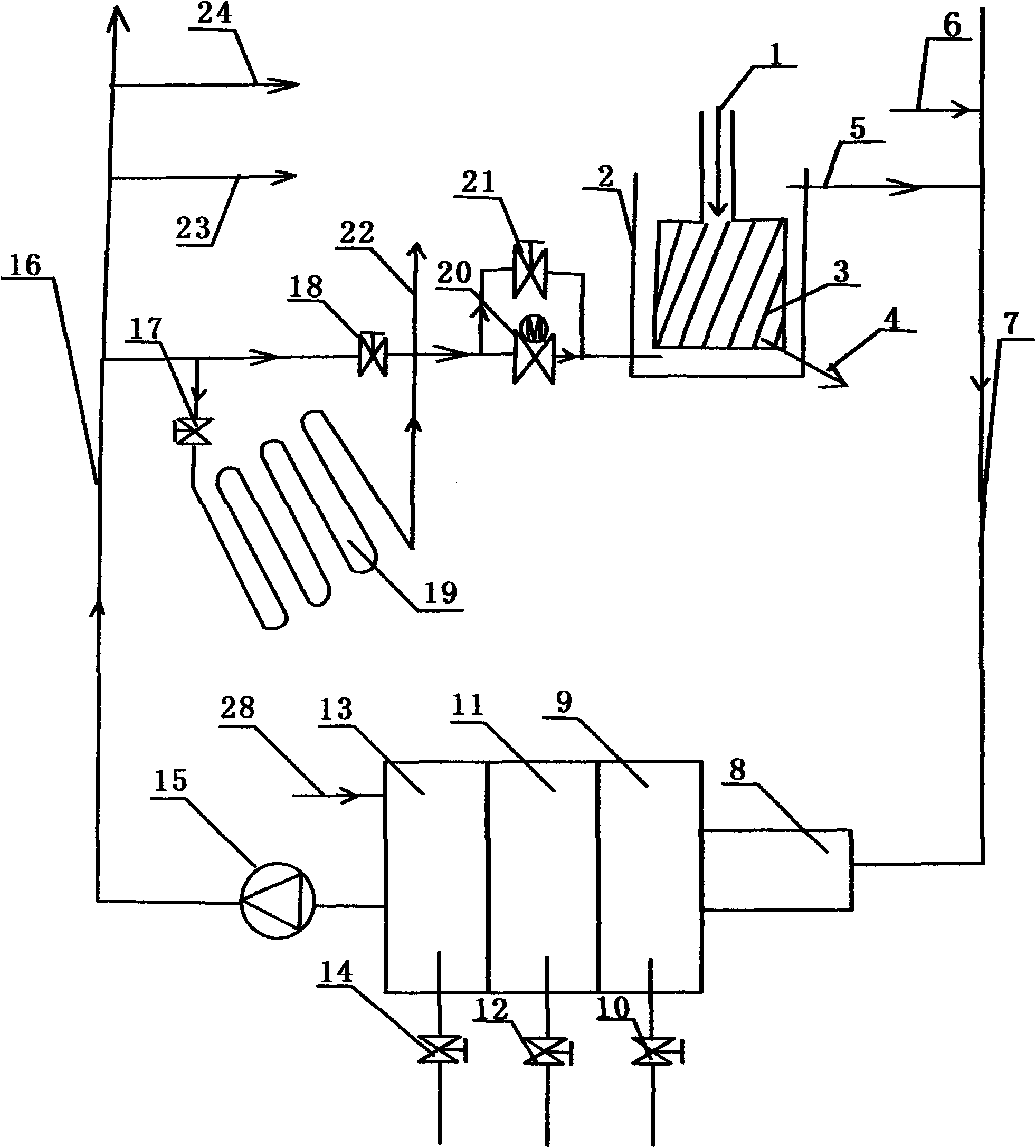

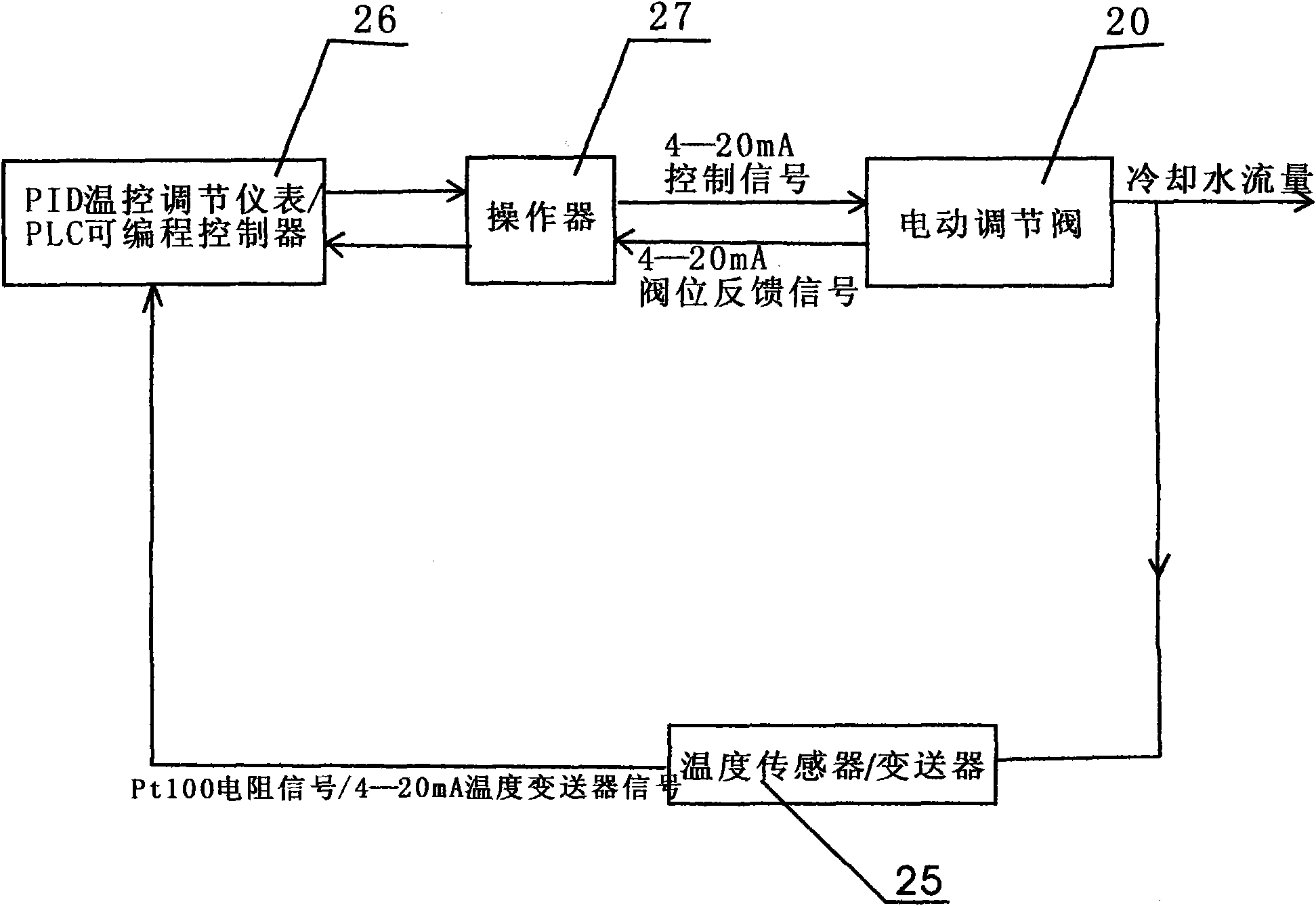

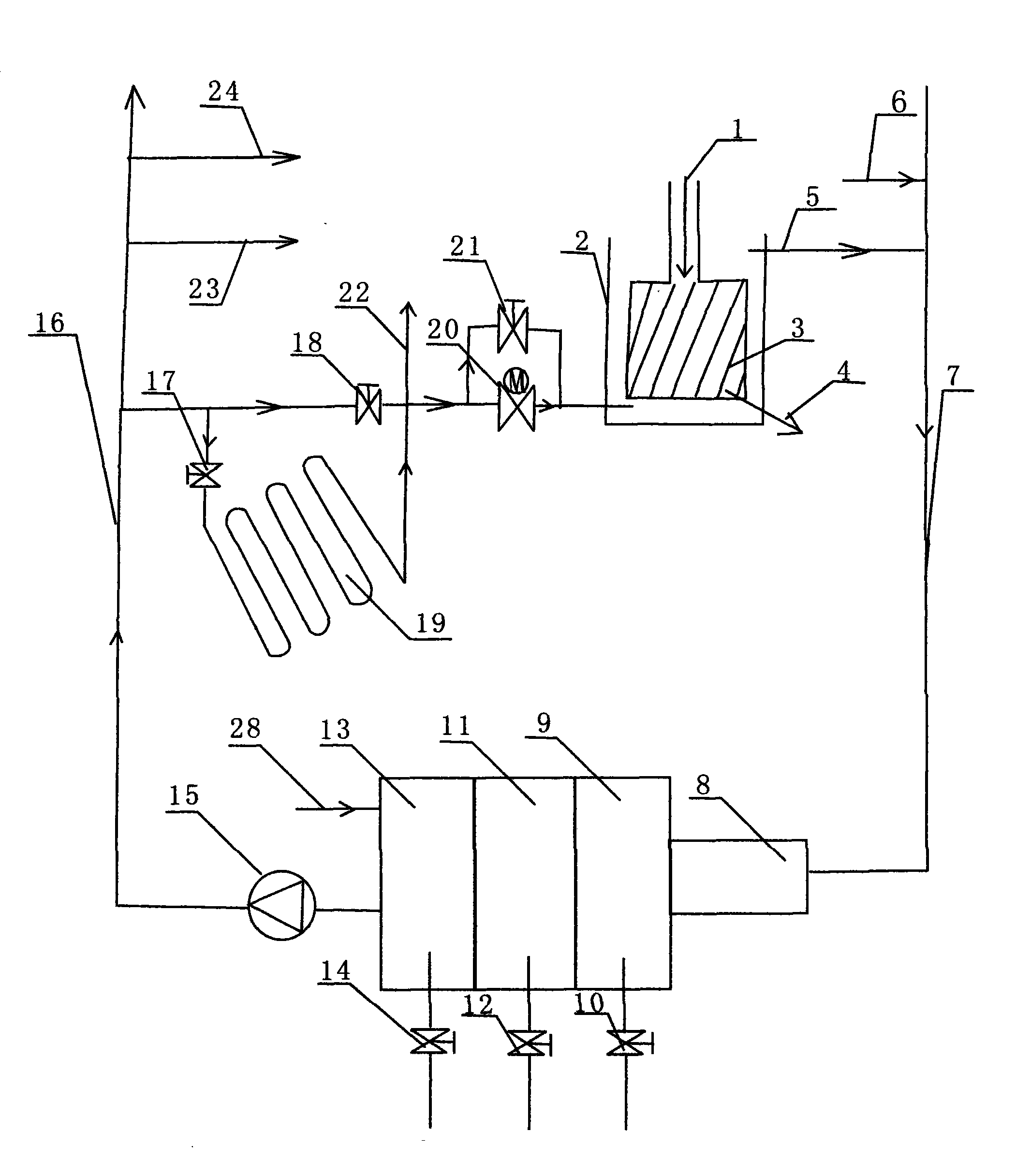

Circulating comprehensive utilization technology and system for white wine-making cooling water and bottle washing water

InactiveCN102031221AQuality improvementStable qualityHollow article cleaningAlcoholic beverage preparationCorrosionDistillation

The invention relates to circulating comprehensive utilization technology for winemaking cooling water and bottle washing water, wine-receiving temperature automation control, a natural environmental-friendly energy-saving cooling method for cooling water in summer, automation cooling water flow control, a circulating system water supply and drainage special pipe network, water treatment and the like in the white wine industry, in particular to circulating comprehensive utilization technology and a circulating comprehensive utilization system for white wine-making cooling water and bottle washing water. By adopting an automation instrument control technique, the aims of accurately controlling the wine-receiving temperature and automatically adjusting cooling water flow are fulfilled, the raw wine quality of the white wine after distillation, condensation and wine receiving at constant temperature is improved and stabilized, the stability and the improvement of an optimal product rate of the white wine bring considerable economic benefits, the labor intensity of winemaking workers is reduced, the production cost of white wine enterprises and the cost of wastewater treatment and discharge are reduced greatly, a large amount of valuable water resource is saved, the scaling and corrosion of the white wine on a condenser are controlled and relieved, the heat exchange efficiency is improved, and the service life of the condenser is prolonged.

Owner:郑慧娟

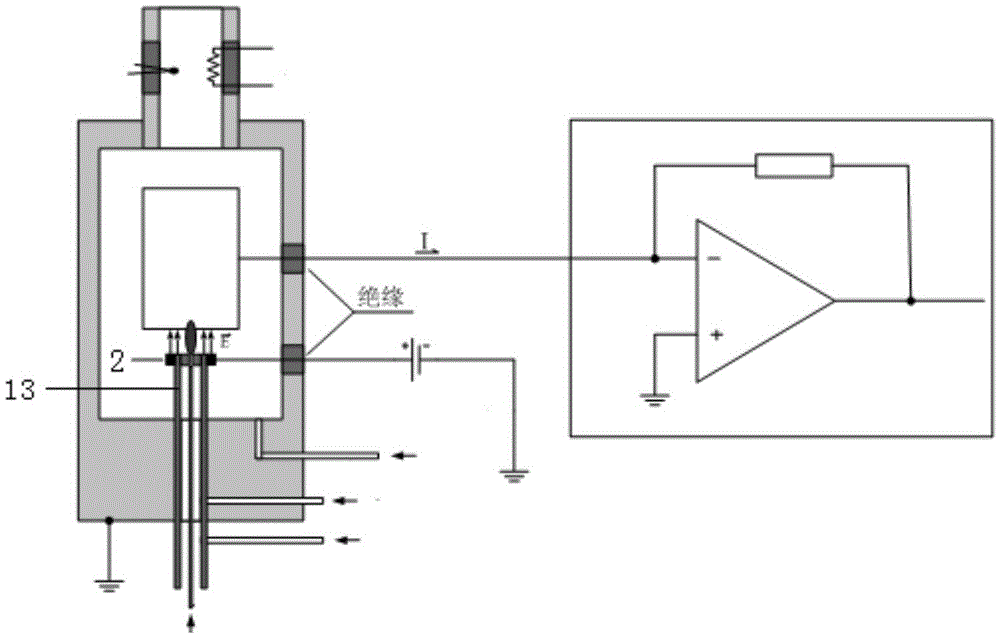

Hydrogen flame ionization detector and working method thereof

InactiveCN105486784AAvoid the risk of performance degradationThe processing technology is simple and matureComponent separationHydrogenHelium ionization detector

The invention relates to a hydrogen flame ionization detector and working method thereof. The hydrogen flame ionization detector comprises an outer cover, a chromatographic column, a collector, a polarization electrode, a conductive nozzle and a detection circuit. The collector is connected with the detection circuit after being connected with a polarization power source in series. The collector is connected with the negative pole of the polarization power source. The conductive nozzle is a ground potential. According to the hydrogen flame ionization detector, polarization voltage is connected to a signal outgoing line of the collector in series, meanwhile, the traditional polarization electrode and the nozzle are combined into a whole, the ground potential is kept, the normal function of the detector is ensured, and the equipment complexity and production technology are simplified.

Owner:WEIFANG UNIVERSITY

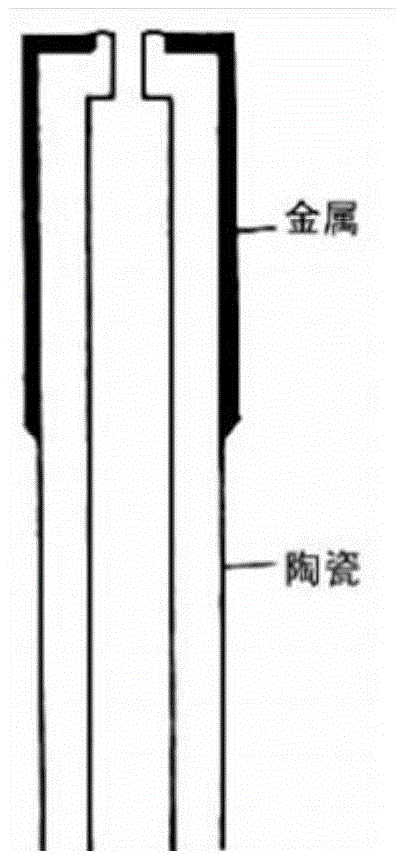

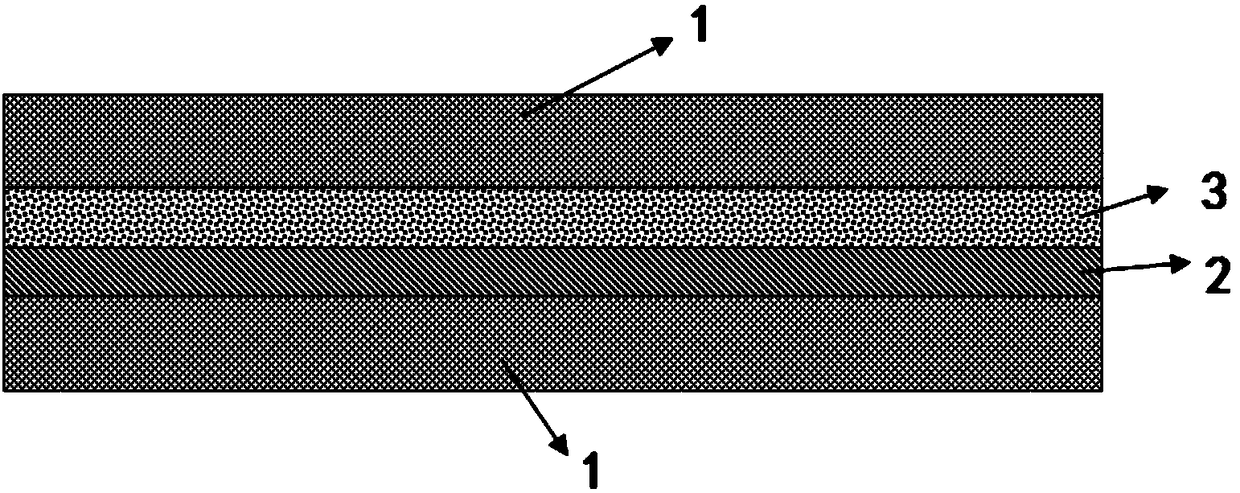

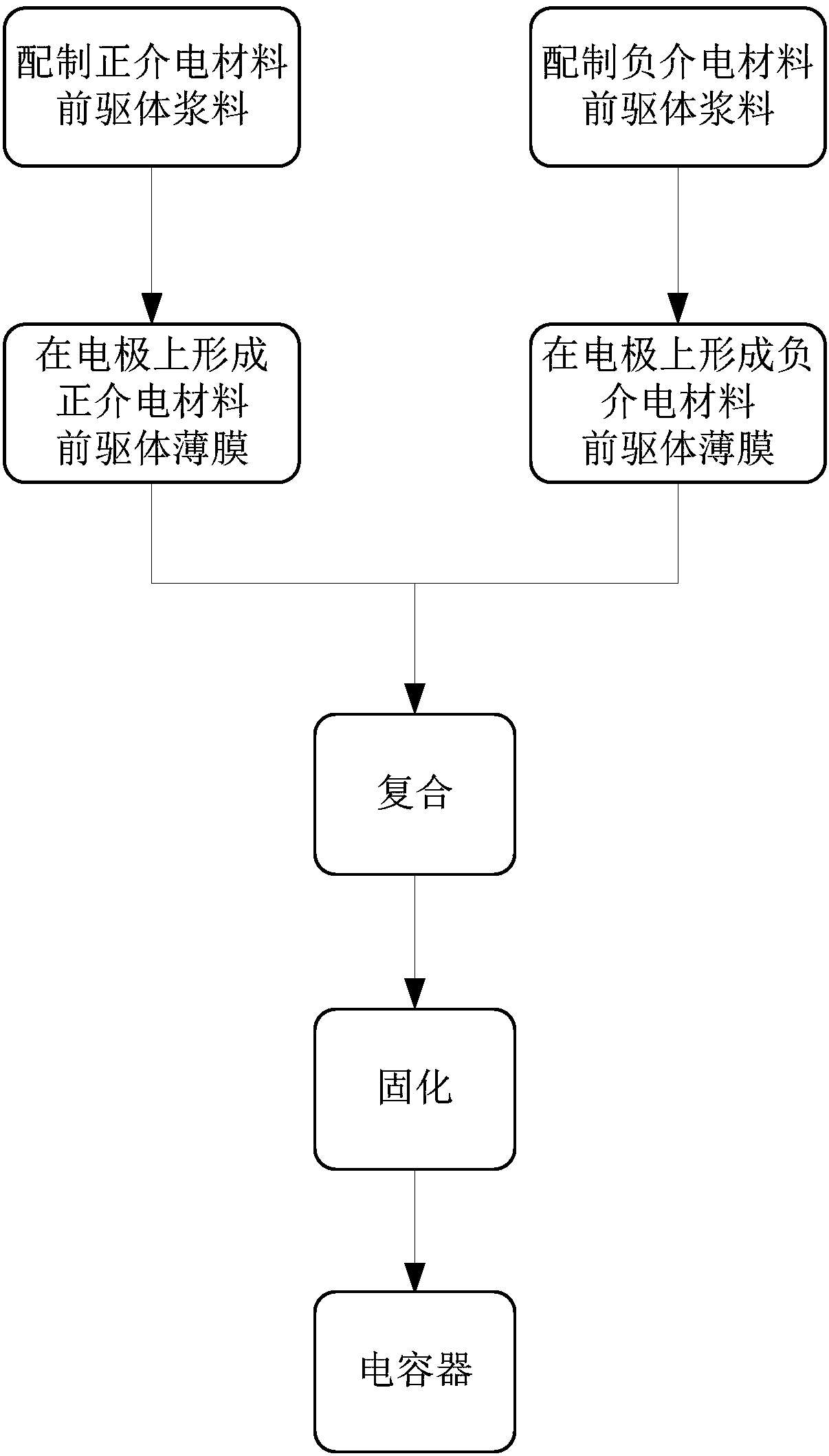

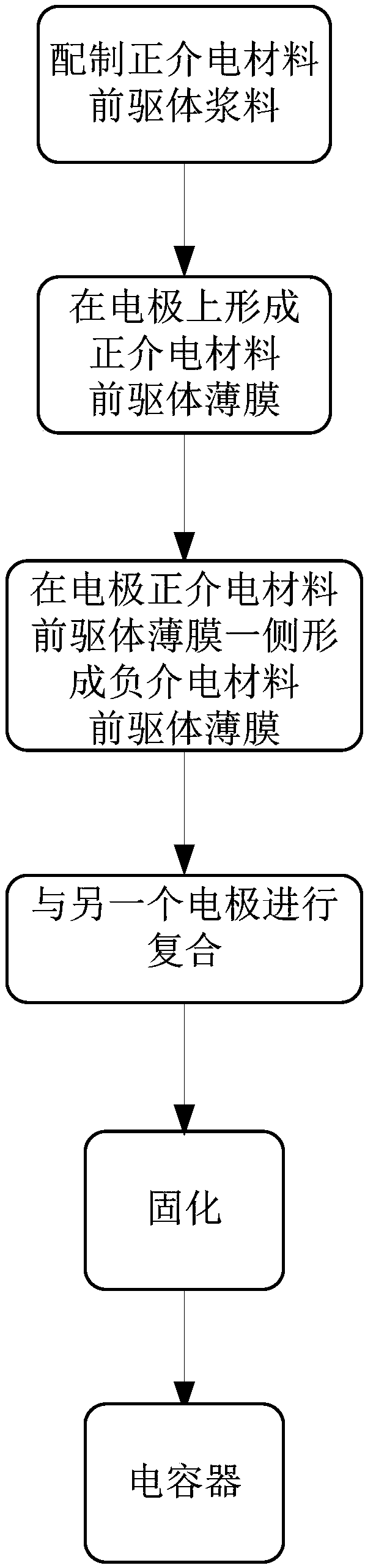

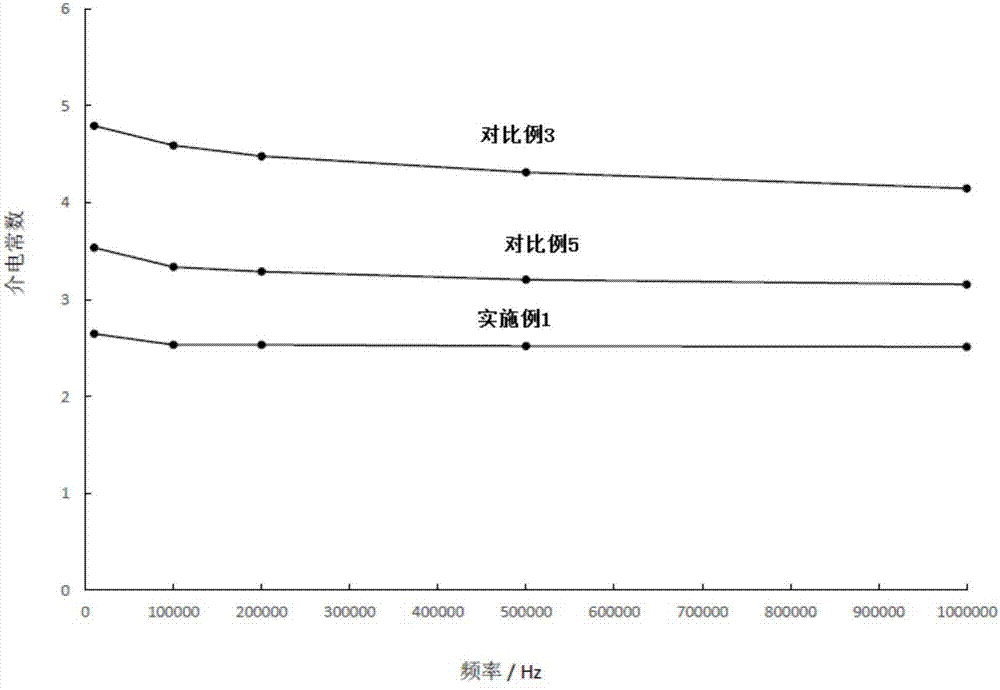

High capacitance density capacitor comprising series structure dielectric and preparation method thereof

ActiveCN108281284AIncrease capacitance densityLow production process requirementsMultiple fixed capacitorsCapacitor manufactureCapacitanceDielectric

The invention discloses a high capacitance density capacitor comprising serial structure dielectric and a preparation method thereof. The capacitor provided by the invention comprises the series structure dielectric. The dielectric is composed of a positive dielectric material and a negative dielectric material which are connected in series. The positive dielectric material is the material of which dielectric constant is a positive value. The negative dielectric material is the material of which dielectric constant is a negative value. The preparation method of the capacitor may comprises thesteps of preparing an electrode of which one side loads positive dielectric material precursor film and the electrode of which one side loads negative dielectric material precursor film, and carryingout combination and solidification to obtain the capacitor. The method also may comprise the steps of preparing the electrode of which one side loads the positive (or negative) dielectric material precursor film, loading the negative (positive) dielectric material precursor film, combining the electrode with another electrode, and carrying out solidification to obtain the capacitor. According to the capacitor and the preparation method, the dielectric is thin, the thickness is about 2mum-100mum, the production technology demands and production cost are reduced, and the capacitor density is high and is 1.5nF / cm<2>-50nF / cm<2>.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

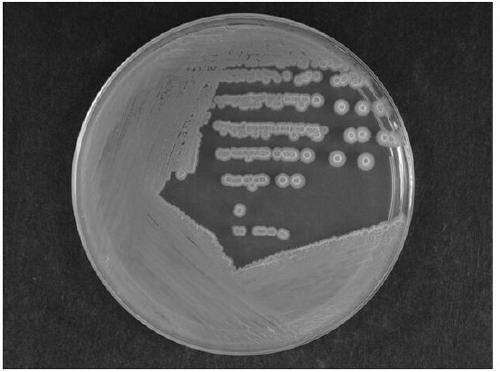

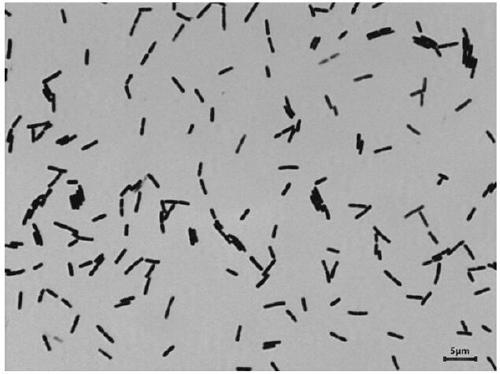

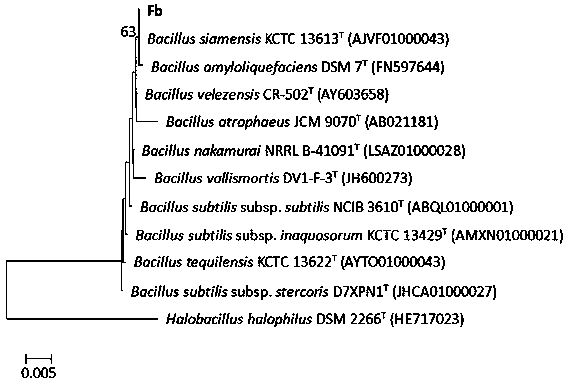

Bacillus velezensis strain and application thereof

ActiveCN111349588AEasy to controlReduce moistureBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a Bacillus velezensis strain and application thereof. The Fb strain is obtained by enrichment culture, primary screening, secondary screening and the like, belongs to the Bacillus velezensis and is gram-positive. The strain is characterized in that: the strain is rod-shaped, 0.4-0.6 microns * 0.9-4.0 microns, and is arranged singly or in pairs; and spores are nearly circular, near-end and cyst is expanded. Through detection, the Bacillus velezensis Fb can resist high temperature of 55 DEG C, the optimal growth temperature is 45 DEG C, and the optimal growth pH value is3.0-7.6. The strain can efficiently degrade tea residues, improve the protein, amino acid and the like of the tea residues and reduce the moisture, cellulose and the like of the tea residues, and thefermented tea residues can be used as a feed raw material; and the strain can realize smokeless, odorless and sewage-free discharge and can realize the cyclic utilization of organic wastes so as to reduce the pollution of the tea residues to the environment, and is a technology which accords with the environmental protection.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

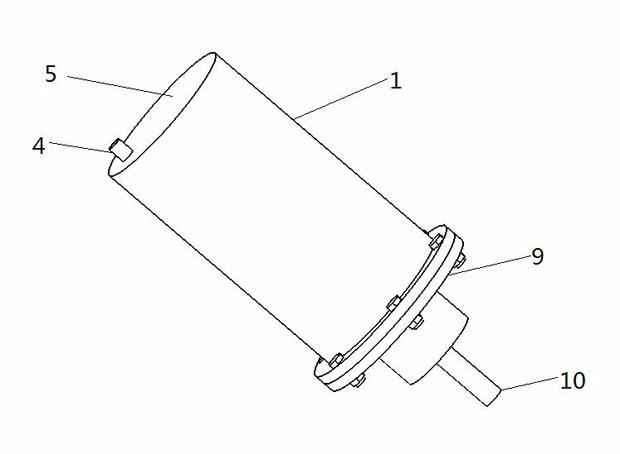

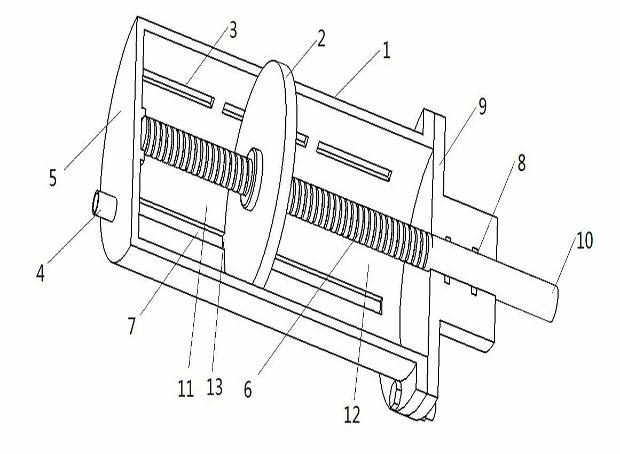

Air spring appending air chamber structure with variable volume

The invention discloses an air spring appending air chamber structure with variable volume for a vehicle, and the structure comprises a cylindrical appending air chamber cavity body of which the two ends are provided with openings, wherein the middle axle of the inner cavity of the appending air chamber cavity body is provided with a screw rod of which the upper end is connected with an external driving device; the screw rod in the appending air chamber cavity body is sheathed with a piston by a screw rod pair, the outer wall of the piston is tightly matched with the inner wall of the appending air chamber cavity body, and the appending air chamber cavity body is divided into an effective volume cavity and a spare volume cavity; the whole inner wall of the appending air chamber cavity body is provided with a piston rotation-limiting groove along the axial direction, and the edge of the piston is provided with a protruding part which is clamped in the piston rotation-limiting groove; the inner wall of the appending air chamber cavity body is provided with three vent grooves at interval along the axial direction; and a gap between every two vent grooves and the thickness of the piston are equal. The air chamber structure provided by the invention has the advantages of simple structure and small volume, and can be used for effectively and reliably achieving the variable volume ofthe appending air chamber.

Owner:JIANGSU UNIV

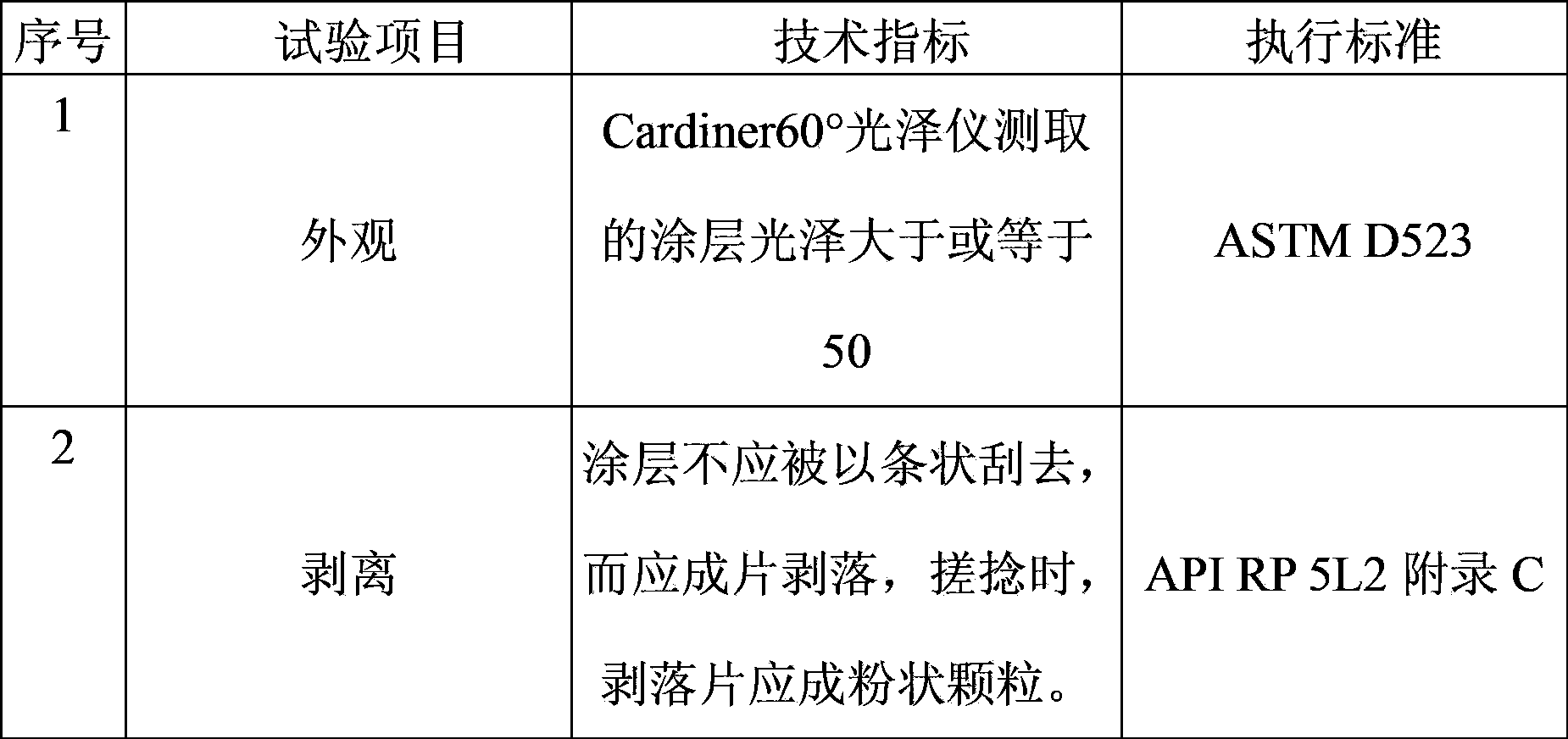

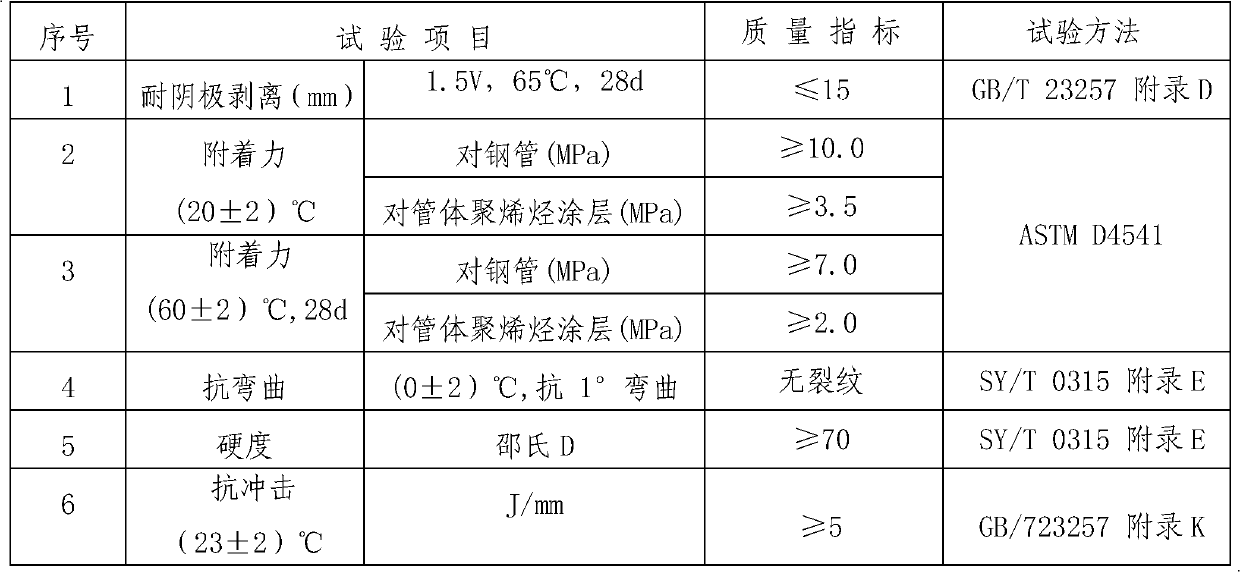

Solvent-free epoxy internal anti-drag coating for natural gas pipeline

ActiveCN103820005ALow viscosityLow production process requirementsEpoxy resin coatingsSolvent freeSolvent

The invention relates to solvent-free epoxy internal anti-drag coating for a natural gas pipeline. A component A consists of the materials in percentage by weight: 45-55 percent of liquid bisphenol-A epoxy resin, 0.3-0.5 percent of a dispersing agent, 15-25 percent of an active diluent, 0.5-1.0 percent of an anti-settling agent, 0.3-0.5 percent of a flattening agent. 0.5-1.0 percent of a coupling agent, 0.3-0.7 percent of a defoaming agent, 10-20 percent of paint, 8-15 percent of wollastonite powder, 5-10 percent of silicon fine powder and 5-15 percent of barium sulfate, wherein the total percent of the materials in the component A is 100 percent; a component B is a polyacrylic acid curing agent; the weight ratio of the component A to the component B is (100:24)-(100:35). The coating disclosed by the invention solves the problem that the conventional coating layer is low in toughness, the viscosity of the coating is lowered, and requirements for a coating production technology and construction conditions are lowered; the coating is high in shearing strength and adhesive force.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Feeding device for warp rebeaming machine

InactiveCN107265301ALow welding strength requirementsLow production process requirementsTrolley cranesLoad-engaging elementsEngineering

The invention discloses a feeding device for a warp rebeaming machine. The feeding device comprises four vertical bottom supports, an I-shaped top support and a travelling crane arranged on the top support. A lifting frame is hung on a lifting hook of the traveling crane and comprises a horizontal cross rod and a vertical rod fixed to the upper portion of the middle of the cross rod; a lifting hook hole matched with the lifting hook is formed in the vertical rod, and hanging hooks shaped like the Chinese character 'ji' are welded to the two ends of the cross rod correspondingly; and the cross rod is embedded into a bottom groove of the hanging hooks. According to the feeding device, a roll shaft is lifted through the hanging hooks at the two ends of the lifting frame, so that the roll shaft is lifted and placed to a feeding frame of the warp rebeaming machine; and the structure is simple, use is convenient, and the efficiency is high.

Owner:湖州市长兴隆昌丝绸有限公司

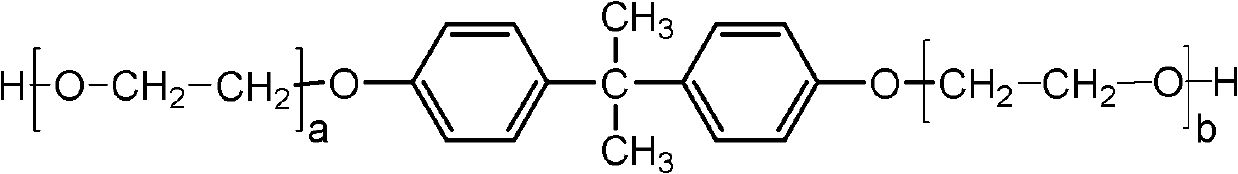

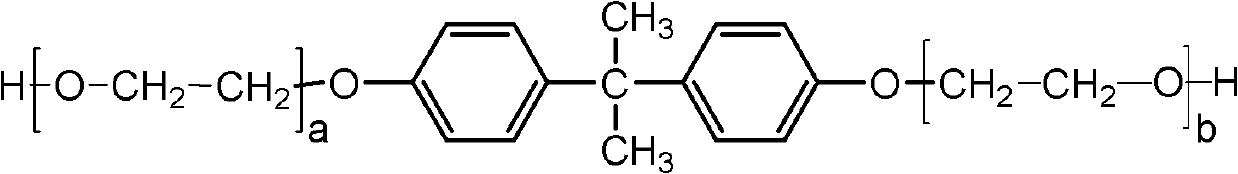

Solvent-free polyurethane joint coating anticorrosive paint for pipelines

ActiveCN103374293AReduces coating bubble problemsLess catalystAnti-corrosive paintsPolyurea/polyurethane coatingsSolventCorrosion prevention

The invention provides solvent-free polyurethane joint coating anticorrosive paint for metal pipelines, relating to the technical field of general corrosion prevention of metal materials and pipeline systems. The solvent-free polyurethane joint coating anticorrosive paint comprises a component A and a component B, wherein the component A contains a hydroxyl component with the average equivalent weight in the range from 200 to 2000, the hydroxyl component takes bisphenol A as a starting agent and contains a polyethylene oxide addition product with a molecular structure shown in descriptions, in the molecular structure, a and b are identical or different integers in the range from 1 to 20, and the component B is polyisocyanate. The solvent-free polyurethane joint coating anticorrosive paint has low water absorption and high reaction activity; a film forming matter has excellent cathodic disbonding resistance and hot water adhesive force resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

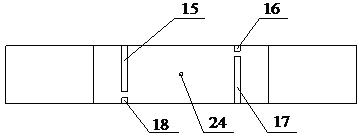

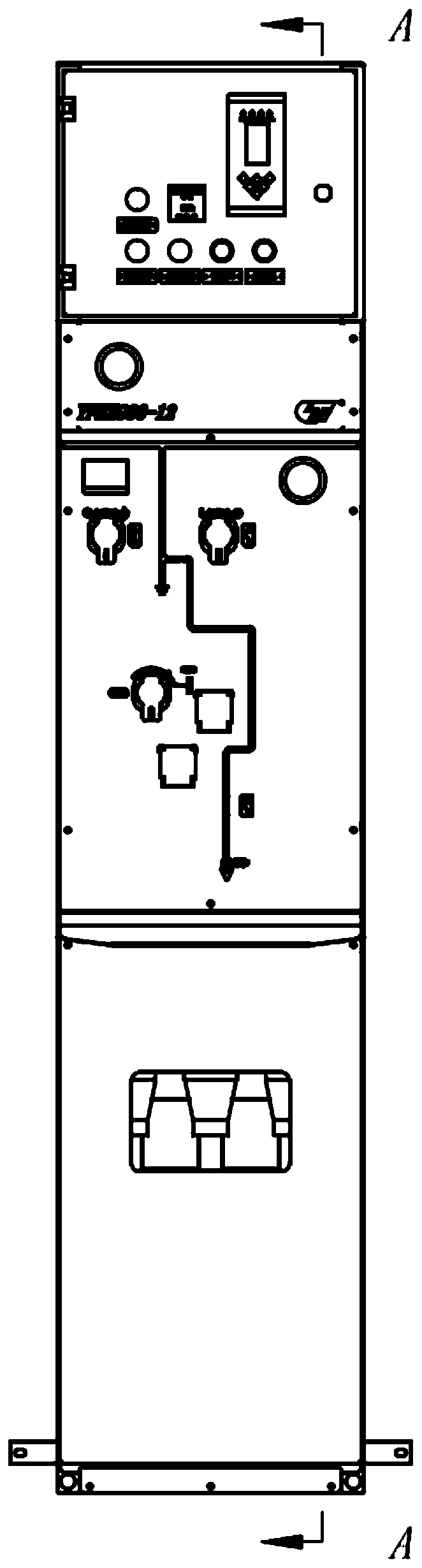

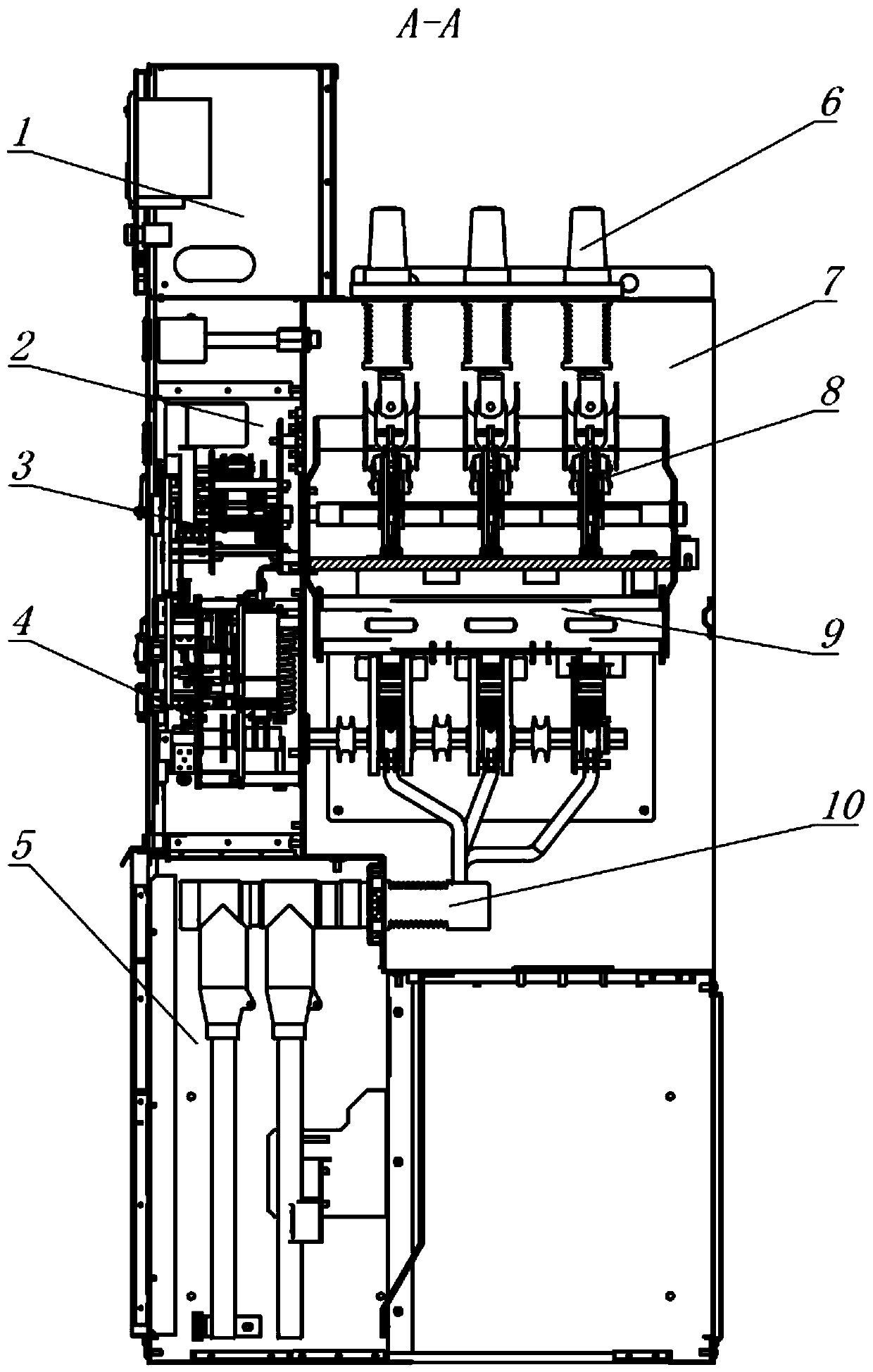

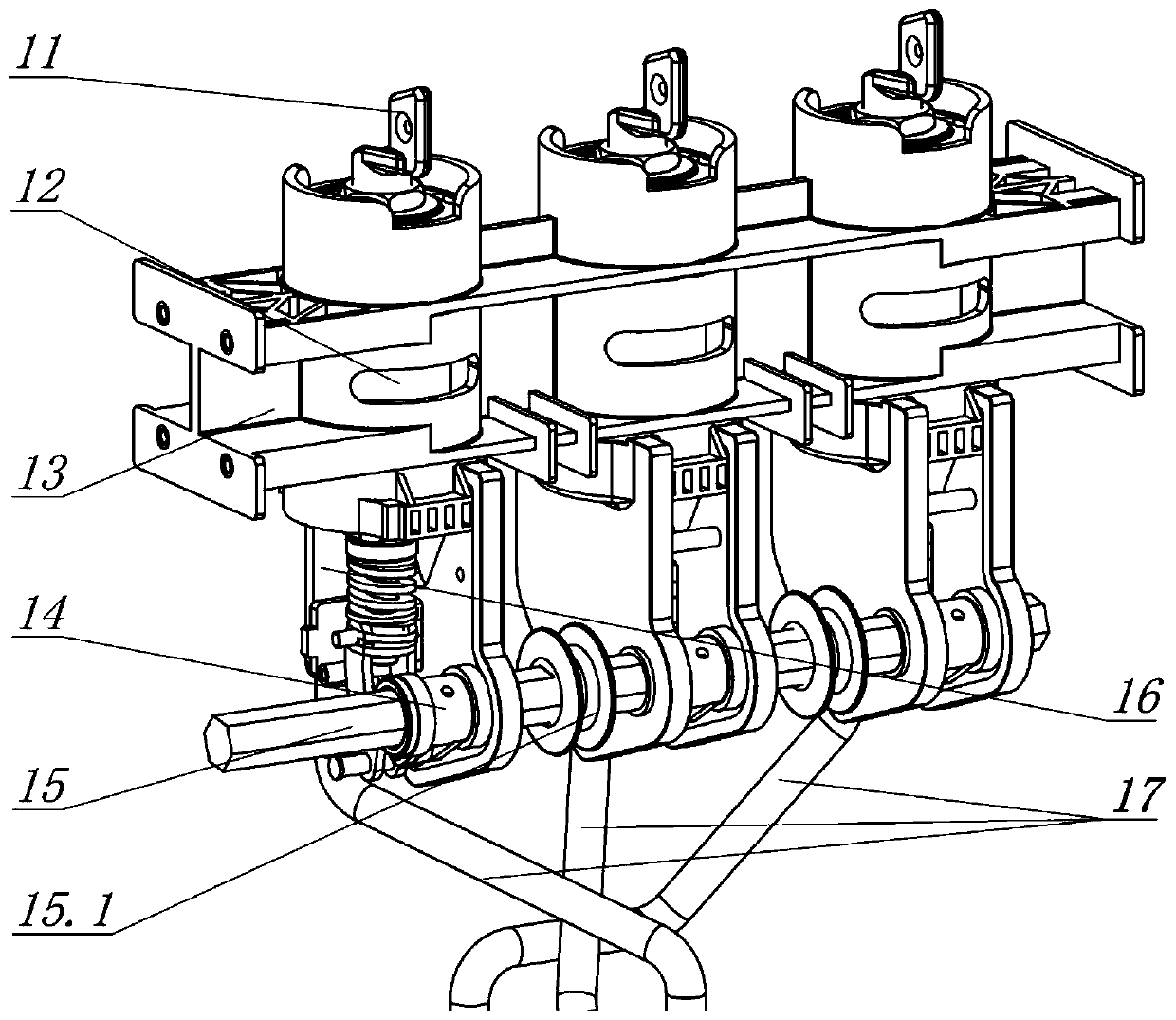

Environment-friendly gas insulated switchgear

InactiveCN110729657AReduce electric field strengthFulfil requirementsSwitchgear arrangementsHigh-tension/heavy-dress switchesEpoxyGas leak

The invention discloses an environment-friendly gas insulated switchgear. The top of an inflation chamber (7) is connected with a wire outlet sleeve (6) in a penetrating manner. The bottom of the inflation chamber (7) is connected in a penetrating manner with a wire inlet sleeve (10) communicated to a cable chamber (5). A three-position switch device (8) and a vacuum circuit breaker device (9) arearranged in the inflation chamber (7). A circuit breaker shaft (15) and an isolation grounding shaft (21) are both inserted into the inflation chamber (7), and the circuit breaker shaft (15) and theisolation grounding shaft (21) drive the vacuum circuit breaker device (9) and the three-position switch device (8) respectively. The environment-friendly gas insulated switchgear has a compact overall structure and reliable performance, and has a maintenance-free function. The problem that harmful insulating gas leaks to damage the environment and the problem that epoxy resin and other solid insulation bring a large amount of solid waste are solved fundamentally.

Owner:江苏云峰科技股份有限公司

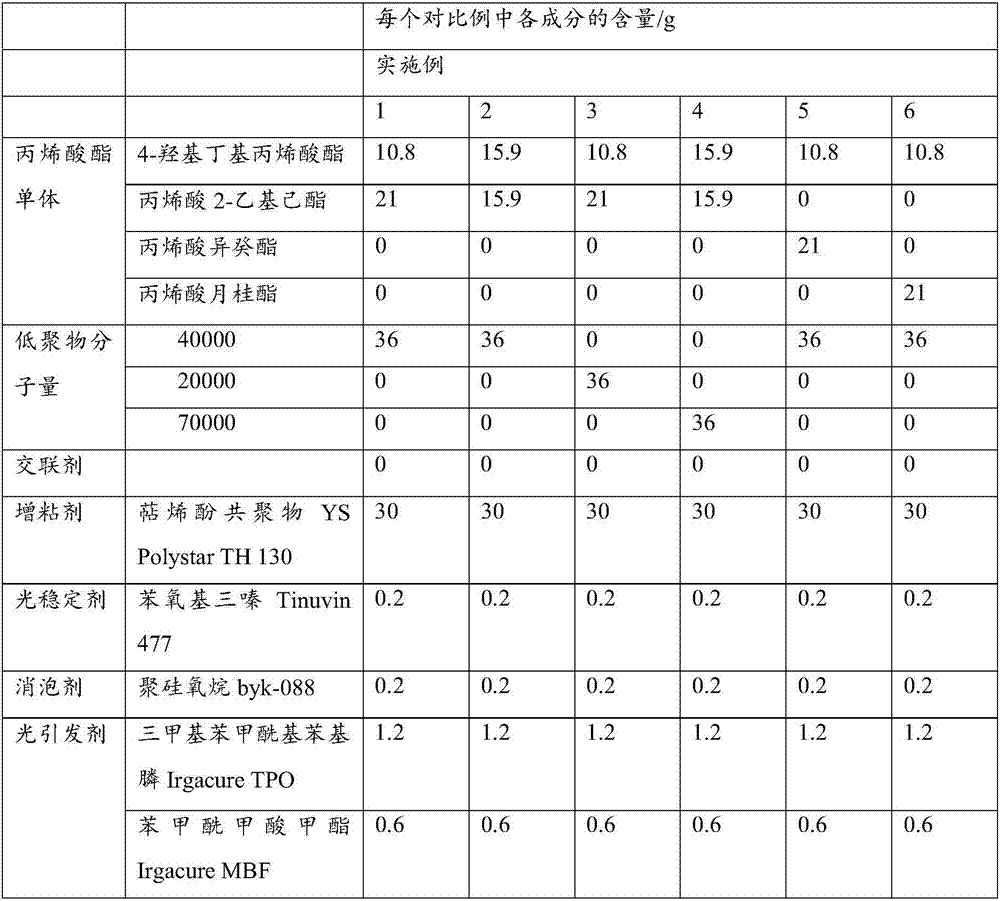

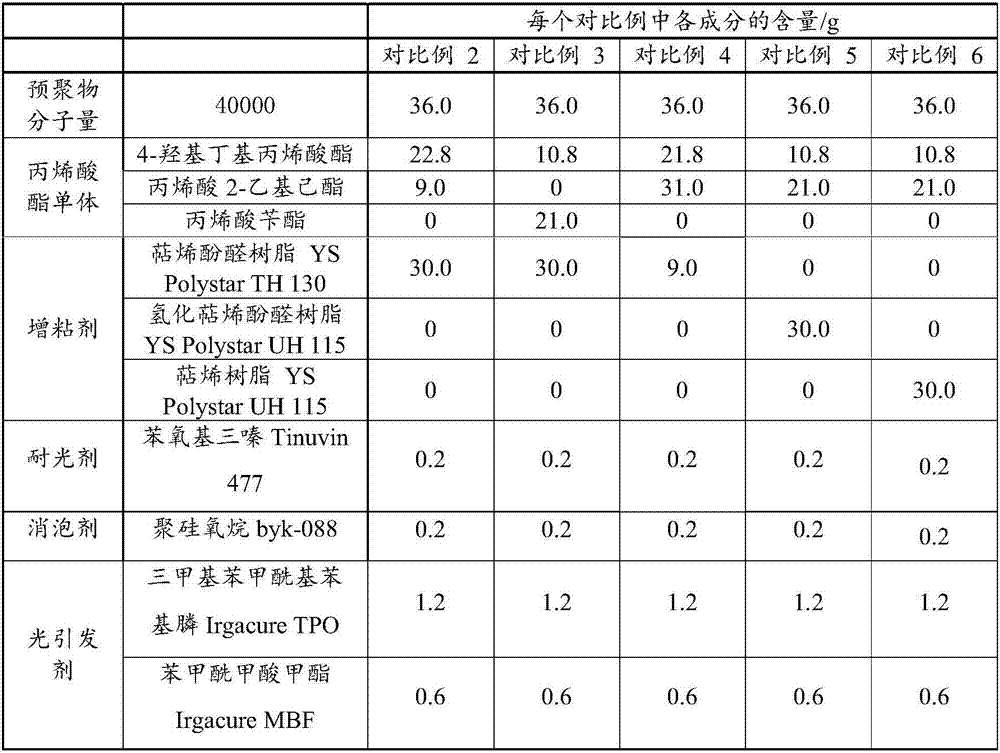

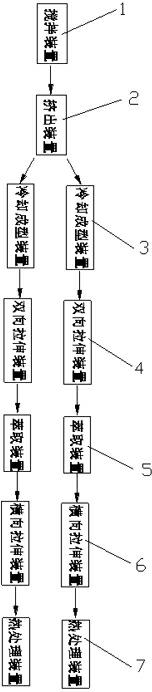

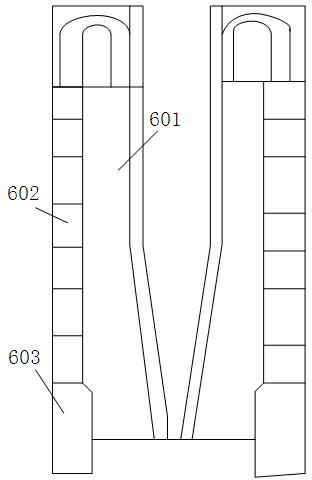

Pressure-sensitive adhesive and preparation method thereof

ActiveCN106928868ALow costImprove performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolyolefin

The invention provides an optical acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive has a relatively low dielectric constant under the condition of 1kHz-1MHz, has the advantages of high peel strength, high transmittance and the like, and is wider in application prospect. The pressure-sensitive adhesive is formed by polymerizing one or more acrylate monomers and an oligomer under the action of a photoinitiator; each acrylate monomer is acrylic saturated alcohol ester or alkyl acrylic saturated alcohol ester; the weight ratio of the acrylate monomers is 10% or more, preferably 15% or more and more preferably20% or more; the molecular weight of the oligomer is20000 or more; and the oligomer is selected from one or more of an acrylic prepolymer, an epoxy prepolymer, an organosilicone prepolymer, a polyurethane prepolymer, a polyether prepolymer, a polyhydroxyl polyolefin oligomer, a polybutadiene prepolymer and a fluorine-modified prepolymer.

Owner:SUZHOU FINESET MATERIAL TECH CO LTD

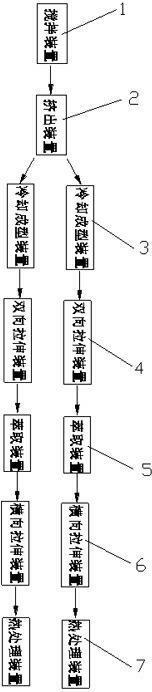

Method and system for preparing dynamic lithium ion battery diaphragm

The invention provides a method for preparing a dynamic lithium ion battery diaphragm. The method comprises the following steps: firstly, adding raw materials in a blender, and abundantly stirring; next feeding the stirred materials into a twin-screw extruder, and heating while continuously extrusion, so as to base sheet; thirdly, shunting the base sheet extruded from the extruder and then feeding the shunted base sheet into two same processing lines and simultaneously and respectively processing, wherein the respective processing line is as follows: 1, cooling and forming; 2, transversely and longitudinally stretching the cooled and formed base sheets through a two-way stretch device at the same time, so that the base sheet is stretched to form a diaphragm; 3, extracting out ore oil fromthe diaphragm with an alkane extractant by virtue of an extraction groove; 4, through a transverse stretch device, shaping, stretching and rectifying the diaphragm subjected to extraction, and ensuring the volatilization of the residual extract on the diaphragm; and 5, thermally treating the diaphragm. According to the invention, the defects that when the battery diaphragm is produced in the prior art, the equipment usage amount is large, the equipment cost is high, and the inferior-quality product incidence and production requirement of the prepared lithium ion battery diaphragm are high aresolved.

Owner:SHANGHAI QIANCHENG TOY TECH

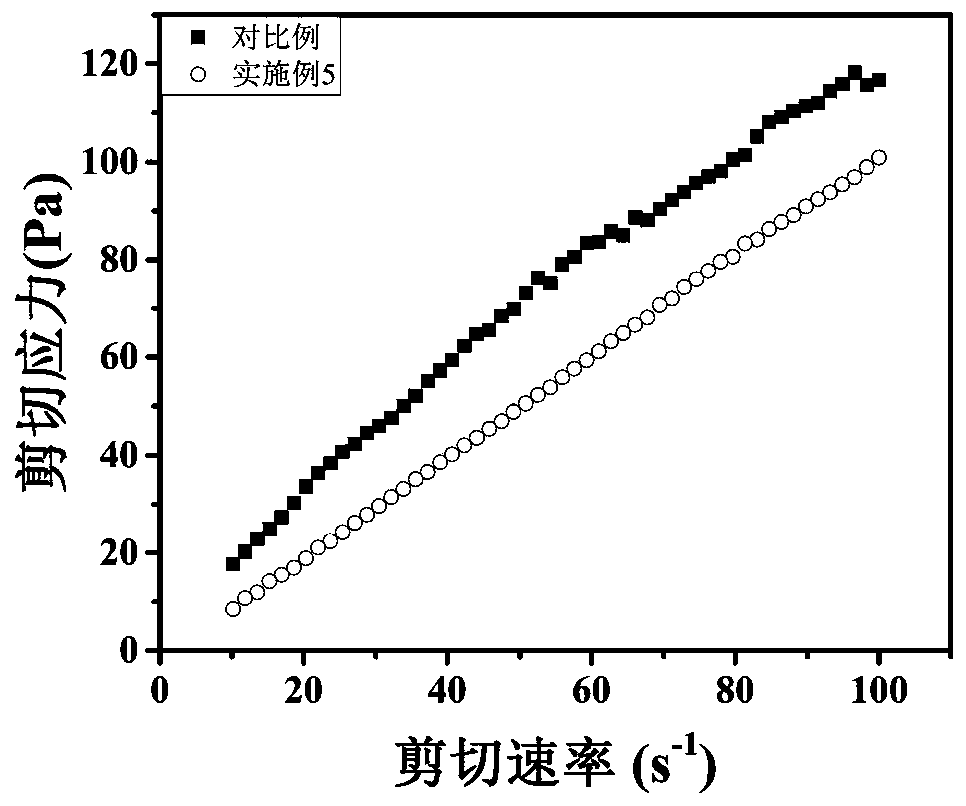

Star-structure polycarboxylic acid dispersing agent as well as preparation method and application thereof

The invention provides a polycarboxylic acid cement dispersing agent with a star-shaped structure and a preparation method thereof. The star-shaped polycarboxylate superplasticizer disclosed by the invention is obtained by the following steps: obtaining a polyether macromonomer with a plurality of amino groups by polymerizing polyethylene polyamine and epoxide anions; carrying out an amidation / imidization reaction to obtain a polymerizable star-shaped macromonomer, and carrying out free radical polymerization on the polymerizable star-shaped macromonomer, unsaturated acid, unsaturated phosphate and an unsaturated macromonomer to obtain the star-shaped polycarboxylate superplasticizer. And the produced product has the advantages of low mixing amount, high water reducing rate, small slump loss, good cement adaptability, remarkable reduction of slurry viscosity at a low water-binder ratio and the like. By adopting free radical polymerization, the invention has the advantages of simple synthesis method, low production process requirements, low production cost, small environmental pollution and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com