Hydrogen flame ionization detector and working method thereof

A hydrogen flame and ionization technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of increased structural complexity and maintenance costs, poor batch consistency, small parts and many processes, etc., to achieve simple and mature processing technology, simplified The effect of production process and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

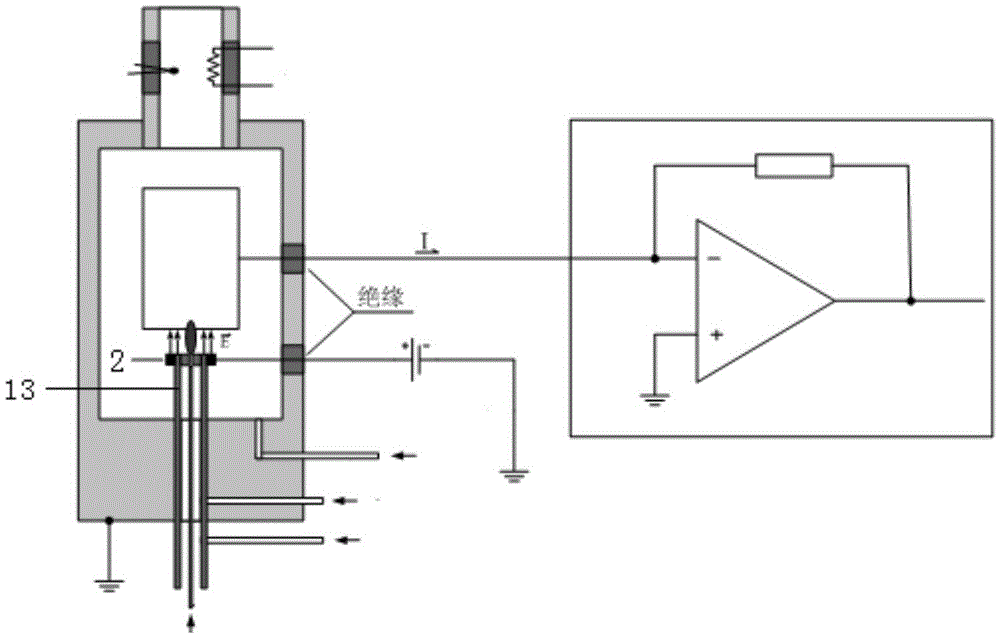

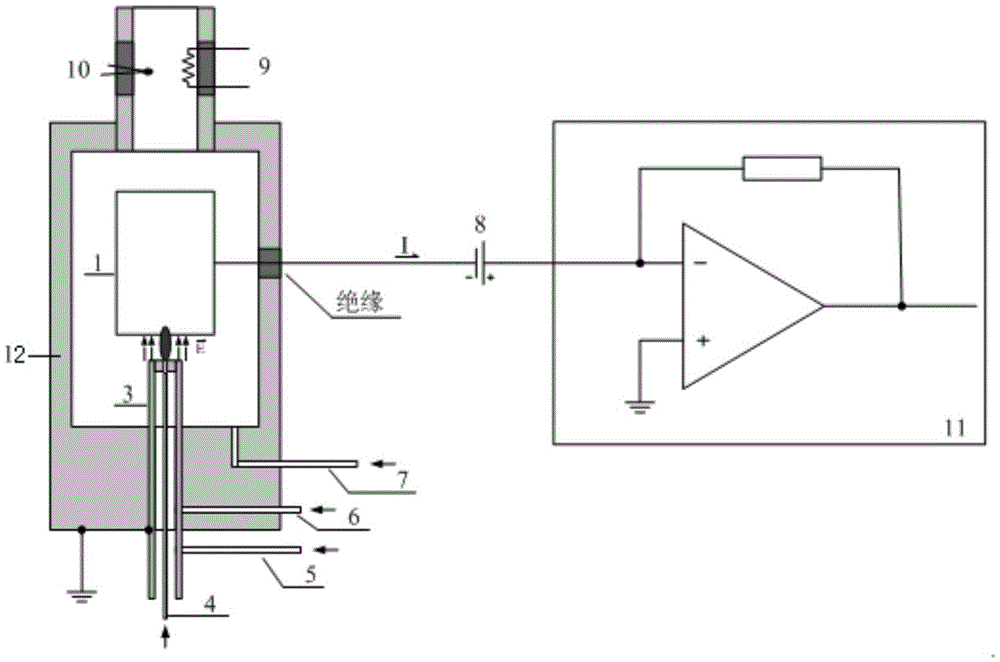

[0021] Such as figure 1 with 3 shown.

[0022] A hydrogen flame ionization detector, comprising an outer cover 12, a chromatographic column 4, a collecting electrode 1, a polarizing electrode 2, a conductive nozzle 3, and a detection circuit 11; Pole 1 is connected to the negative pole of polarized power supply 8; the conductive nozzle is at 3 ground potential. The hydrogen flame ionization detector of the present invention connects the polarization voltage in series to the signal lead-out line of the collector 1, and at the same time combines the traditional polarizer 2 and the insulating nozzle 13 into one, and keeps them at the ground potential to ensure that the detector While maintaining normal functions, the equipment complexity and production process are simplified.

Embodiment 2

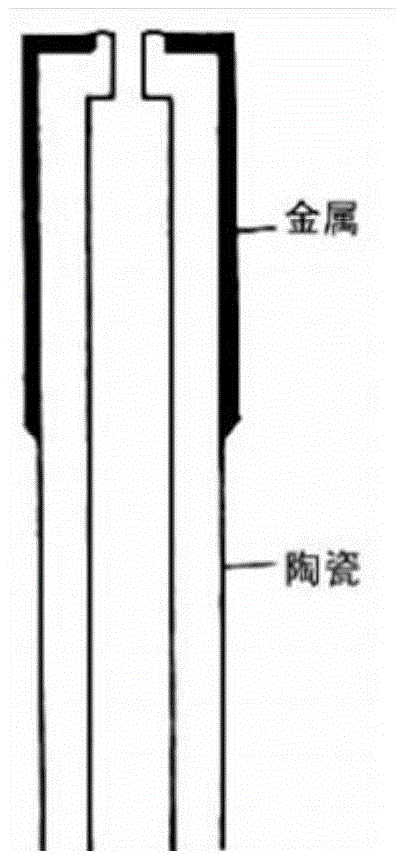

[0024] The difference of the hydrogen flame ionization detector shown in Embodiment 1 is that the conductive nozzle 3 is made of stainless steel. The conductive nozzle 3 is made of stainless steel, which is convenient for precision machining, solves the problem of high processing technology requirements for the insulating nozzle 13 and the polarizing electrode 2, facilitates mass production, and improves production efficiency and production cost.

Embodiment 3

[0026] A kind of working method of hydrogen flame ionization detector as described in embodiment 1-2, comprises steps as follows, the gas that chromatographic column 4 flows out is mixed with make-up gas (nitrogen) and hydrogen earlier, mixes with combustion-supporting gas (air) again Finally, the outlet of the conductive nozzle 3 is ignited by the ignition wire 9 to form a hydrogen flame; the thermal and chemical energy of the flame is used to ionize the organic matter into particles with positive and negative charges; the conductive nozzle 3 maintains the ground potential, and the collector 1 is at a low potential , after the polarizing voltage is applied between the polarizing pole 2 and the collecting pole 1, an electrostatic field E is formed (direction such as image 3 As shown), the charged particles move directionally under the action of the electric field E to form a microcurrent, and the detection circuit 11 amplifies the microcurrent and converts it into a voltage sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com