Two-component addition type silicone rubber and its preparation method

A technology of addition type and silicone rubber, which is applied in the field of two-component addition type silicone rubber and its preparation, which can solve the problems of poor room temperature curing adhesiveness of silicone rubber, tackifier exudation colloidal performance, weak adhesive performance, etc. , to avoid the decline of colloid performance, high application value and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a two-component addition type silicone rubber and its preparation method, the steps are as follows:

[0057] (1) Preparation of modified polydimethylsiloxane

[0058] In parts by weight, 100 parts of toluene, 60 parts of aminoalkyl silicone oil (viscosity at 25°C 400mPas, amine value 0.65mmol / g), 6 parts of hexamethylene diisocyanate were sequentially added to the reaction kettle, and the temperature was controlled to react at 30°C 1.0h, then add 10 parts of hydroxyethyl acrylate, and raise the temperature to 60°C for 6.0h, finally raise the temperature in the kettle to 100°C and lower the vacuum to below -0.09MPa, remove the low boilers in the system for 3h, Modified polydimethylsiloxane was obtained.

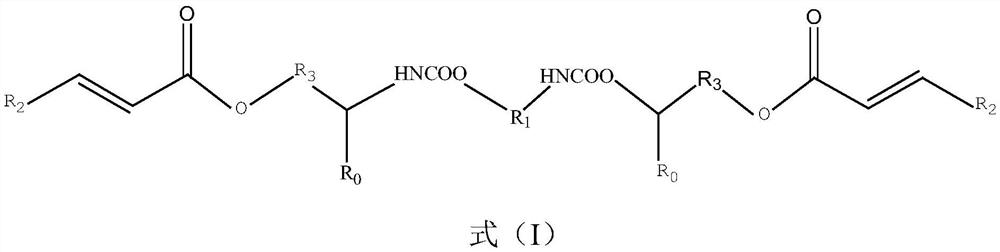

[0059] The reaction formula of above-mentioned preparation method is as follows:

[0060]

[0061] (2) Preparation of component A

[0062]In parts by weight, 30 parts of modified polydimethylsiloxane and 70 parts of vinyl polydimethylsilox...

Embodiment 2

[0067] This embodiment provides a two-component addition type silicone rubber and its preparation method, the steps are as follows:

[0068] (1) Preparation of modified polydimethylsiloxane

[0069] In parts by weight, add 120 parts of xylene, 80 parts of aminoalkyl silicone oil (viscosity at 25°C of 5000mPas, amine value of 0.15mmol / g), and 8 parts of isophorone diisocyanate into the reaction kettle in sequence, and control the temperature at 40°C React for 0.5h, then add 15 parts of hydroxypropyl acrylate, and increase the temperature to 70°C for 4.0h, finally raise the temperature in the kettle to 120°C and reduce the vacuum to below -0.09MPa, and remove the low boilers in the system for 2h , to obtain modified polydimethylsiloxane.

[0070] The reaction formula of the above-mentioned preparation method refers to Example 1.

[0071] (2) Preparation of component A

[0072] In parts by weight, 30 parts of modified polydimethylsiloxane and 70 parts of vinyl polydimethylsilo...

Embodiment 3

[0077] This embodiment provides a two-component addition type silicone rubber and its preparation method, the steps are as follows:

[0078] (1) Preparation of modified polydimethylsiloxane

[0079] In parts by weight, 113 parts of ethyl acetate, 65 parts of aminoalkyl silicone oil (viscosity at 25°C: 1000 mPas, amine value: 0.55 mmol / g), and 7 parts of diphenylmethane diisocyanate were sequentially added to the reaction kettle, and the temperature was controlled at 35 ℃ for 0.7h, then add 11 parts of hydroxyethyl acrylate, and raise the temperature to 65°C for 5.0h, finally raise the temperature in the kettle to 110°C and reduce the vacuum to below -0.09MPa to remove the low boilers in the system After 2.5h, modified polydimethylsiloxane was obtained.

[0080] The reaction formula of the above-mentioned preparation method refers to Example 1.

[0081] (2) Preparation of component A

[0082] In parts by weight, 31 parts of modified polydimethylsiloxane and 62 parts of vinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com