A kind of high-volume pozzolan foam concrete material and preparation method thereof

A technology of foam concrete and volcanic ash, applied in the field of foamed concrete, can solve the problems of low utilization rate of volcanic ash, achieve good mechanical properties, good thermal insulation performance, and reduce natural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

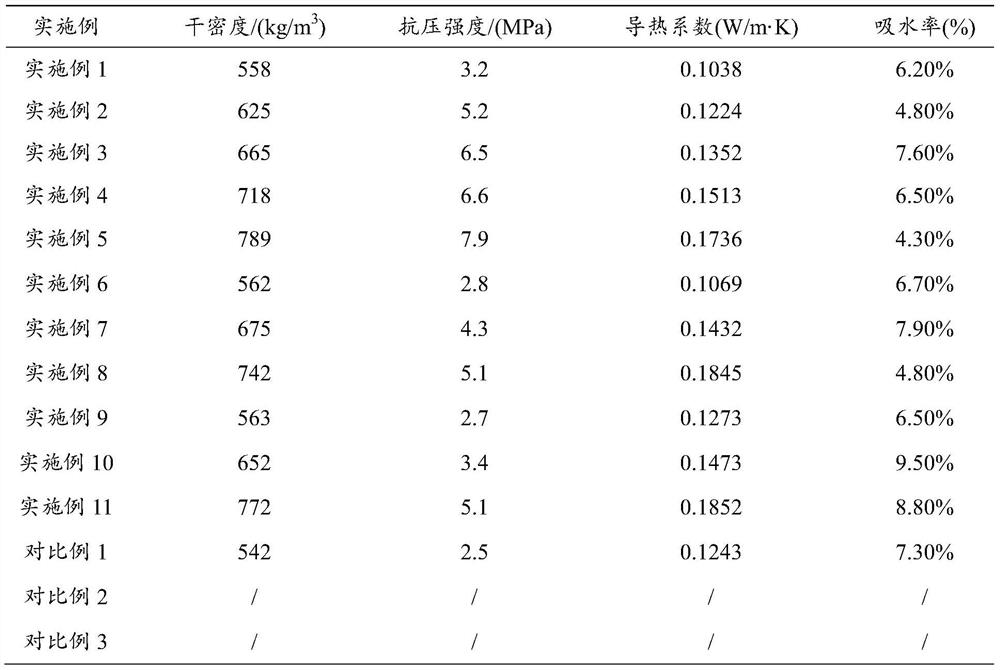

Examples

Embodiment 1

[0059] A large volume of pozzolan foamed concrete material, prepared according to the amount of the following raw materials:

[0060] P·O 42.5 Ordinary Portland cement: 180g, pozzolan (specific surface area is 1500m 2 / kg): 420g, polycarboxylate superplasticizer: 3g, hydroxypropyl methylcellulose ether: 0.3g, lithium carbonate: 9g, polypropylene fiber: 3g, styrene-acrylic emulsion: 6g, hydrogen peroxide: 24g, water : 180g, the water temperature is 30°C.

[0061] The preparation method of large-volume pozzolan foam concrete material comprises the following steps:

[0062] a) Slurry preparation: measure cement, volcanic ash, water, water reducer, foam stabilizer, organic fiber, and water repellent in proportion and add them to the mixer at a stirring speed of 800 rpm for 4 minutes to make a slurry;

[0063] b) adding early strength agent: add metered early strength agent to the slurry obtained in step a), and stir at a stirring speed of 1500rpm for 60s to make a slurry containi...

Embodiment 2

[0070] A large volume of pozzolan foamed concrete material, prepared according to the amount of the following raw materials:

[0071] P·Ⅱ52.5 Portland cement: 210g, pozzolan (specific surface area is 1500m 2 / kg): 490g, naphthalene-based water reducer: 7g, calcium stearate: 2.8g, lithium carbonate: 7g, polyamide fiber: 10.5g, silicone: 2.1g, hydrogen peroxide: 22.4g, water: 280g, water The temperature is 30°C.

[0072] The preparation method of large-volume pozzolan foam concrete material comprises the following steps:

[0073] a) Slurry preparation: measure cement, volcanic ash, water, water reducer, foam stabilizer, organic fiber, and water repellent in proportion and add them to the mixer at a stirring speed of 1000 rpm for 3 minutes to make a slurry;

[0074] b) adding early strength agent: adding metered early strength agent to the slurry obtained in step a), and stirring at a stirring speed of 1800rpm for 50s to make a slurry containing early strength agent;

[0075] ...

Embodiment 3

[0081] A large volume of pozzolan foamed concrete material, prepared according to the amount of the following raw materials:

[0082] P·Ⅱ52.5 Portland cement: 210g, pozzolan (specific surface area is 2000m 2 / kg): 490g, polycarboxylate superplasticizer: 2.1g, hydroxypropyl methylcellulose ether: 1.4g, aluminum sulfate: 14g, polypropylene fiber: 7g, styrene-acrylic emulsion: 5.6g, hydrogen peroxide: 17.5 g, water: 210g, water temperature is 40 ℃.

[0083] The preparation method of large-volume pozzolan foam concrete material comprises the following steps:

[0084] a) Slurry preparation: measure cement, volcanic ash, water, water reducer, foam stabilizer, organic fiber, and water repellent in proportion and add them to the mixer at a stirring speed of 1500 rpm for 2 minutes to make a slurry;

[0085] b) adding early strength agent: add metered early strength agent to the slurry obtained in step a), and stir at a stirring speed of 2000rpm for 30s to make a slurry containing ear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com