Patents

Literature

109 results about "Pozzolana" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pozzolana or pozzuolana (/ˌpɒts(w)əˈlɑːnə/ POT-s(w)ə-LAH-nə, Italian: [potts(w)oˈlaːna]), also known as pozzolanic ash (Latin: pulvis puteolanus), is a natural siliceous or siliceous-aluminous material which reacts with calcium hydroxide in the presence of water at room temperature (cf. pozzolanic reaction). In this reaction insoluble calcium silicate hydrate and calcium aluminate hydrate compounds are formed possessing cementitious properties. The designation pozzolana is derived from one of the primary deposits of volcanic ash used by the Romans in Italy, at Pozzuoli. Nowadays the definition of pozzolana encompasses any volcanic material (pumice or volcanic ash), predominantly composed of fine volcanic glass, that is used as a pozzolan. Note the difference with the term pozzolan, which exerts no bearing on the specific origin of the material, as opposed to pozzolana, which can only be used for pozzolans of volcanic origin, primarily composed of volcanic glass.

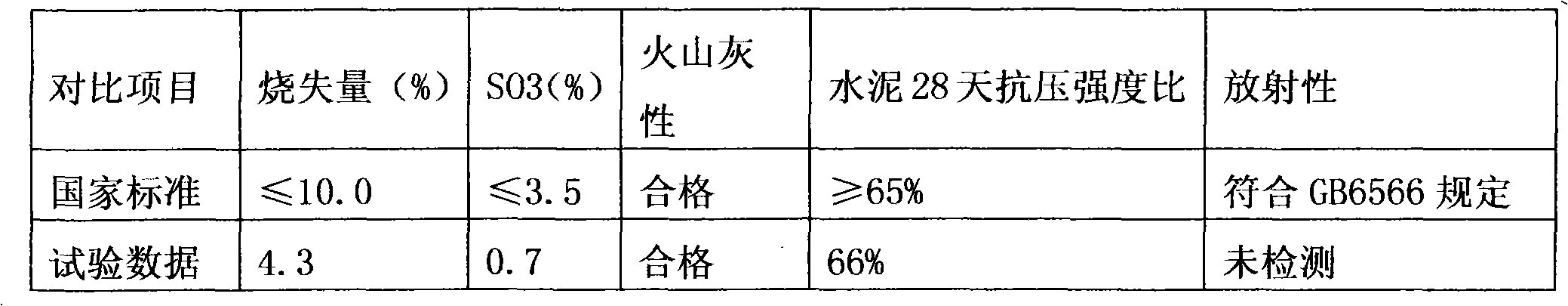

Preparation method and application of PD composite mineral admixture containing silica fume

The present invention provides a preparation method and application of a PD composite mineral admixture containing silica fume. The PD composite mineral admixture comprises components of, by weight percentage, 0%-95% of volcano ash, 0%-95% of mountain flour, 5%-30% of silica micropowder (silica fume) and 0-8% of gypsum, wherein the volcano ash content and mountain flour content can not be zero at the same time, and the gypsum content can be zero according to the requirements. A double-mixing admixture, a ternary-mixing admixture and a quaternary-mixing admixture are prepared by utilizing superimposed effect and interaction effect generated by a quaternary system of ''volcano ash-mountain flour-silica fume-gypsum''. Admixtures with different performance characteristics can be prepared by only adjusting the proportion of the components in the PD composite mineral admixture provided by the invention; the admixture can substitute 15%-50% of cement in concrete and mortar, with equal or excessive amount, and realizes a better effect than an admixture mixed with single volcano ash or mountain flour; and the admixture can be prepared by using local raw materials, or waste stone slag and mountain flour. Therefore, the admixture has good application prospect and promotion value in places lack of conventional admixture.

Owner:张仲 +1

Stone needle ceramic tile and preparation method thereof

The invention discloses a stone needle ceramic tile and a preparation method thereof. The stone needle ceramic tile is prepared from the following raw materials in parts by weight: 35-45 parts of a silica micropowder, 25-35 parts of obsidian, 20-30 parts of sillimanite, 15-25 parts of sea sand, 18-26 parts of flint clay, 12-24 parts of magnesia, 6-14 parts of a bamboo charcoal powder, 10-15 parts of a stone needle powder, 5-10 parts of a magnetic powder, 22-34 parts of modified clay, 4-8 parts of red mud, 3-6 parts of phosphorus ore slag, and 5-10 parts of volcano ash. The stone needle powder, the bamboo charcoal powder and the magnetic powder are added into the ceramic tile, so that the ceramic tile has higher health care value, can produce far infrared rays, ultrasonic pulses, magnetic fields and negative ions, not only can promote blood micro-circulation, regulates metabolism, improves human body immunity, also can adsorb and decompose various free harmful substances, kills bacteria, purifies air, and improves a living environment; and the prepared ceramic tile has the characteristics of high strength, low water absorption rate, good abrasion resistance, good weather resistance and the like, and is durable in use.

Owner:安徽省亚欧陶瓷有限责任公司

Desulfurized gypsum.phosphorous gypsum without roasting, extruding gypsum block and production method thereof

InactiveCN101830678ACompact structureImprove water resistanceSolid waste managementCeramic shaping apparatusResource utilizationHigh intensity

The invention provides dihydrate desulfurized gypsum.phosphorous gypsum without roasting, which is applied to the technical filed of solid waste resource utilization of generating plants and phosphate fertilizer plants and used for preparing water extrusion-resistant gypsum blocks with high strength. The dihydrate desulfurized gypsum.phosphorous gypsum without roasting comprises the following components by weight percent: 60-80% of desulfurized gypsu.phosphorous gypsum, 10-25% of pozzuolana active mineral material, 5-15% of activating material, 0.5-2% of coagulation accelerator, 0.2-1% of intensifier and 30-50% of light aggregate. The preparation method of the invention is as follows: carrying out vibration screening on subhumid original desulfurized gypsum.phosphorus gypsum, mixing and stirring with powder grinded active mineral material, exciting material, coagulation accelerator, reinforcing material, intensifier lightweight aggregate and proper amount of water, extruding and moulding, muggy maintaining and naturally maintaining. In comparison with the traditional methods of gypsum building blocks produced by sintered and cast beta-hemihydrate gypsum, the invention has higher intensity, lower breakage rate, better water-proof performance and higher coefficient of softening, is characterized by stable performance, low cost and easy popularization, and is uneasy to rot roots and crack, thus being applied to indoor separating walls and partitions.

Owner:SHANGHAI JINMA BUILDING MATERIALS

Secondary ettringite type expanding agent and preparation method and application thereof

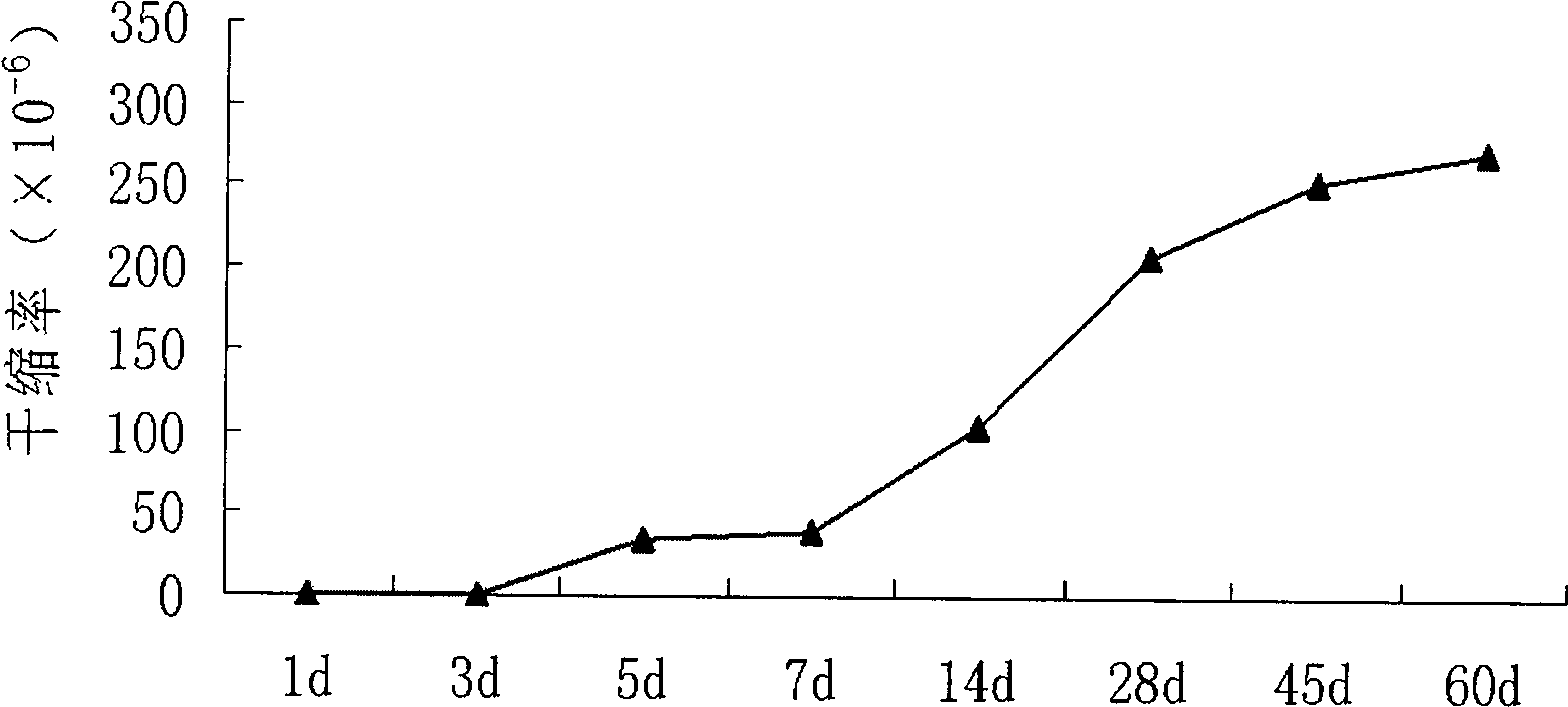

ActiveCN102167536AReduce shrinkage cracksImprove stress statusSolid waste managementAluminitePolymer science

The invention discloses a secondary ettringite type expanding agent and a preparation method and application thereof. The preparation method comprises the following steps of: stirring a pozzolanic material, a calcium material, plaster and water, forming into a blank or spheres, naturally curing, performing dry heating curing in a curing cell for 0.5 to 10 hours, raising the temperature to 100-170DEG C, and keeping the temperature for 0.5 to 10 hours for dehydration and ettringite decomposition reaction, or standing the formed blank or spheres for 2 to 10 hours, curing under steam pressure, and dehydrating for 0.5 to 10 hours, or dehydrating the thermally synthesized aluminosilicate material and wastes thereof at the temperature of higher than 100DEG C for 0.5 to 10 hours; and mixing and grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum, or respectively grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum and uniformly mixing to obtain powder of which the specific surface area is more than 200m<2> / kg, namely the secondary ettringite type expanding agent. The secondary ettringite type expanding agent can endow mortar and concrete with micro-expansion property, and improve the volume stability of the mortar and concrete.

Owner:HOHAI UNIV +1

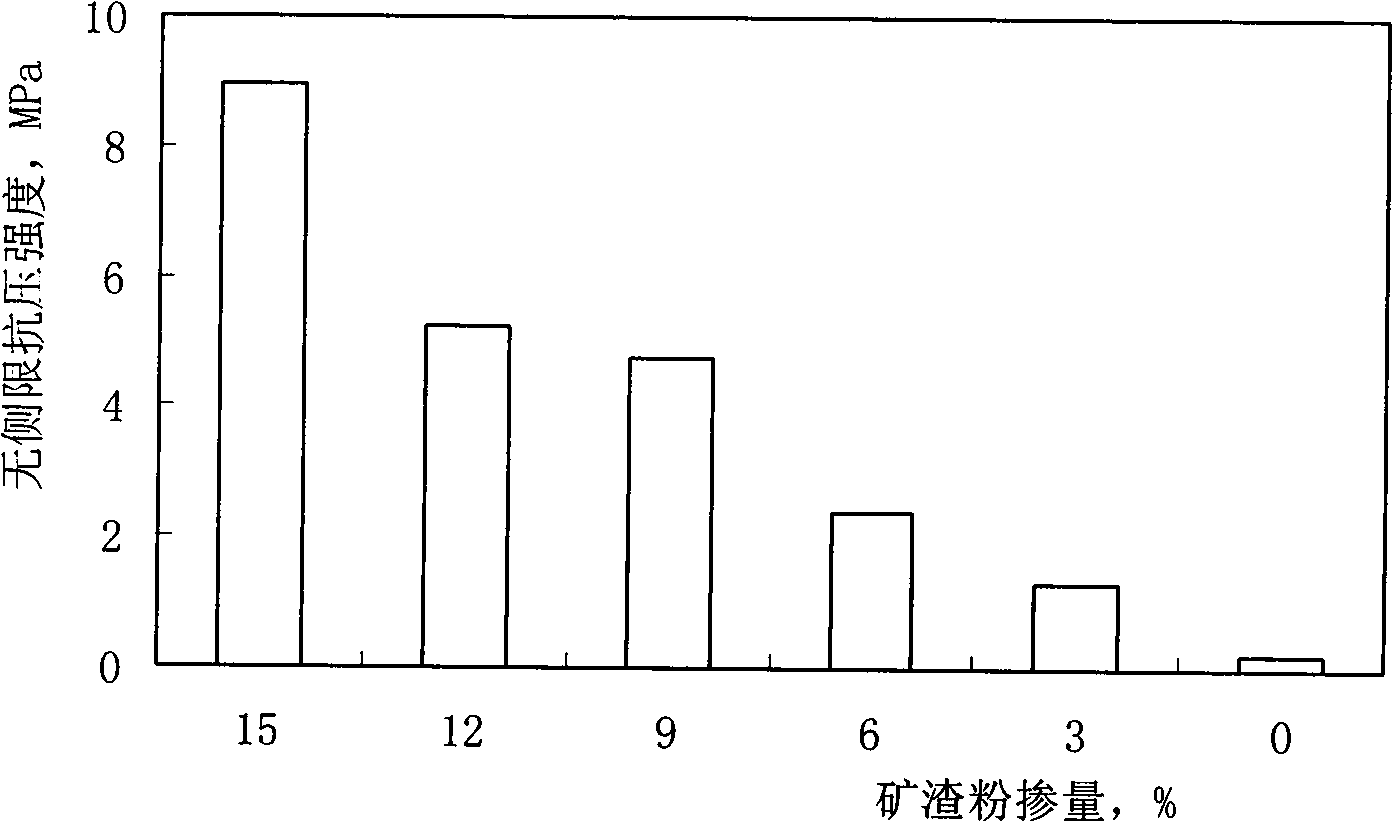

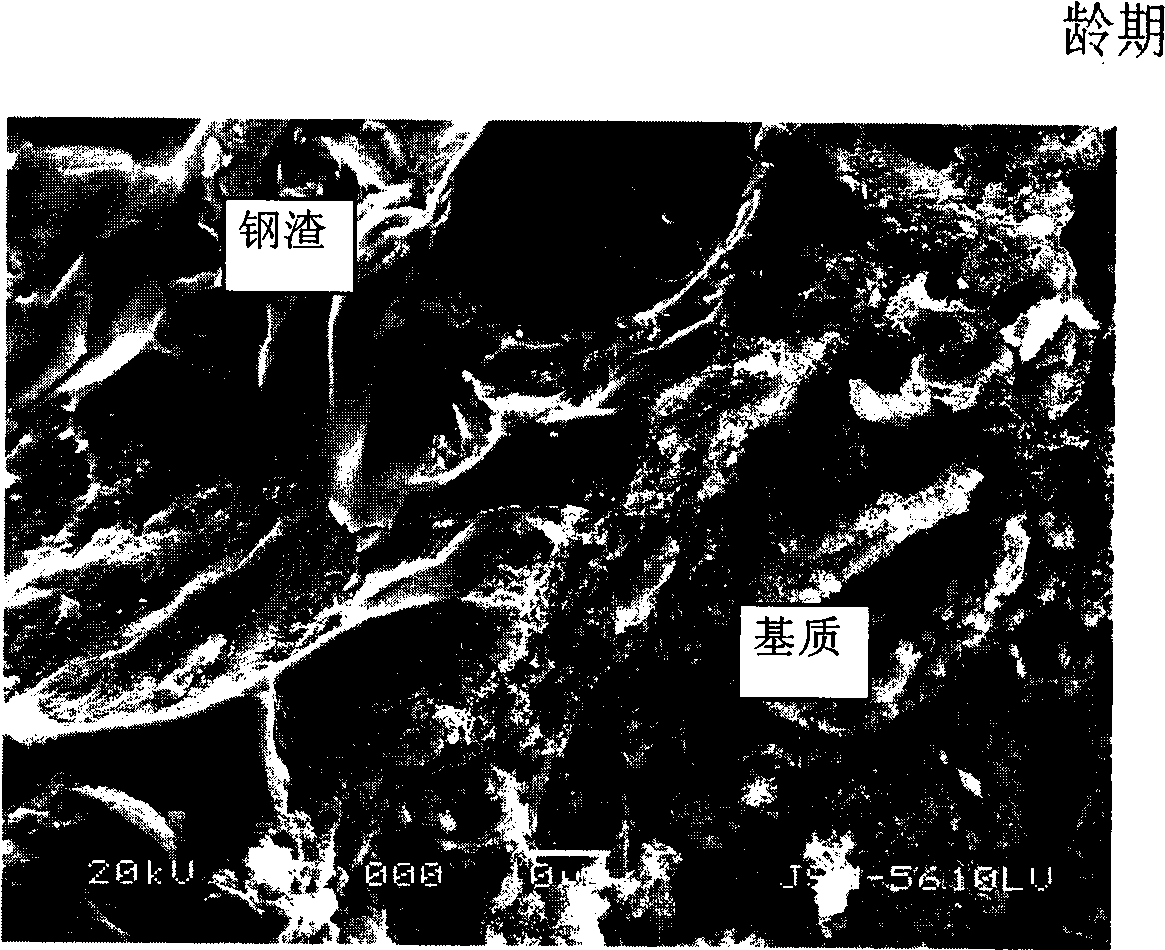

Self-hydration activated pavement base layer

The invention discloses a method which uses steel slag, mineral slag or electric power plant slag as the materials of a self-hydrating activation type pavement basic layer to activate the potential hydrating activation of the mineral slag or the pozzuolana activation of the electric power plant slag by the corresponding interlocking effect of each waste and the self-hydrating activation of the steel slag to form hydrated C-S-H, C-S-A-H, or C-S-A-F-H, ettringite, and calvital hydration product, form the initial strength of the pavement basic layer and ensure the continuous increasing of the later strength; counted by weight portions, the mixture ratio of each material is as follows: 40 to 65 portions of steel slag, as well as 35 to 60 portions of mineral slag and / or electric power plant slag. The pavement basic layer is a non-cement basic layer with excellent performance, and the preparation method thereof is as follows: the materials after being mixed are transported to a constructionfield, paved, rolled, and maintained by moisture retention to a regulated age. The invention uses industrial wastes, can save land and resources and reduce the cost, is beneficial to protecting environment, is simple to be constructed, and is suitable for building the basic layers and the foundation layers of common roads and advanced roads.

Owner:武汉市公路管理处 +1

Calcining-free desulfurization gypsum/phosphogypsum self-insulation gypsum brick and production method thereof

InactiveCN101891438ACompact structureCrystal shape is reasonableSolid waste managementCeramicwareBrickPhosphogypsum

The invention discloses a high-strength waterproof self-insulation gypsum brick prepared by using calcining-free desulfurization gypsum dihydrate / phosphogypsum in the technical field of solid waste recycle of a power plant or a phosphate fertilizer plant and a production method thereof. The brick comprises the following components in percentage by weight: 60 to 80 percent of original desulfurization gypsum dihydrate / phosphogypsum, 10 to 25 percent of active material of volcanic ash mineral, 5 to 15 percent of exciting material, 0.5 to 2 percent of coagulant material, 100 to 200 percent of aggregate and 25 to 40 percent of light aggregate. The preparation method comprises the following steps of: screening semi-moist desulfurization gypsum dihydrate / phosphogypsum, metering, mixing and stirring the screened semi-moist desulfurization gypsum dihydrate / phosphogypsum, the powdery active mineral material ground into powder in advance, the exciting material, the coagulant material, the aggregate and the light aggregate on site, adding a proper amount of water into the mixture, molding the mixture in a molding machine, and then damply and thermally curing the mixture for 24 hours. The method consumes a large amount of solid waste and reduces secondary energy consumption and secondary pollution; and the product has the advantages of light dead weight, high strength, energy conservation, fire prevention, water resistance, acid and alkali resistance and the like, and is suitable for a separating wall, a partition wall, a filling wall, a toilet and a kitchen.

Owner:SHANGHAI JINMA BUILDING MATERIALS

Sintered water permeable brick with smooth and mildew-proofing surface

The invention discloses a sintered water permeable brick with a smooth and mildew-proofing surface. The water permeable brick is prepared from the following raw materials in parts by weight: 40-43 parts of sludge of a sewage plant, 6-7 parts of rice husks, 4-5 parts of potassium feldspar powder, 5-6 parts of pulverized fuel ash, 3-4 parts of bamboo powder, 8-10 parts of activated pozzolana, 19-21 parts of fluorite tailings, 4-5 parts of noan-silicon carbide, 2-3 parts of sodium carboxymethyl cellulose and 3-4 parts of light magnesium oxide. According to the sintered water permeable brick, the fluorite tailings, palm fibers, nano-silicon carbide and other ingredients are added to serve as aggregate ingredients of a brick blank, so that the tensile strength and crack resistance of a brick body can be enhanced, and the porosity of the brick body is further improved; the bamboo powder added into the brick is turned into a bamboo charcoal ingredient by means of sintering, so that the water permeable brick has excellent antibacterial and mildew-proofing effect. The manufactured water permeable brick has an attractive appearance and smooth surface, and integrates strength, water permeability and corrosion resistance into a whole.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Magnesium sulphoaluminate cement

The invention discloses magnesium sulphoaluminate cement, which is characterized by comprising the following raw materials in parts by weight: 90-110 parts of light burned magnesium oxide, 45-55 parts of composite sulfate, 25-30 parts of active aluminum sesquioxide, 30-35 parts of active silicon dioxide, 1.0-1.7 pats of phosphoric acid or phosphate and 65-75 parts of water. The magnesium sulphoaluminate cement has the advantages that: no magnesium chloride participates in reaction; and the defects of scumming, metal corrosion and the like of magnesium oxy-chloride cement are avoided. The magnesium sulphoaluminate cement comprises a pozzolanic material containing the active aluminum sesquioxide and the active silicon dioxide; and since the reaction of pozzolana and the structure of a resultant are stable, the service life of a product is long.

Owner:HUBEI ZHONGBAI TECH

Novel heat-isolation, heat-insulation and energy-saving material and preparation method thereof

The invention discloses a novel heat-isolation, heat-insulation and energy-saving material and a preparation method thereof. The novel heat-isolation, heat-insulation and energy-saving material is prepared from the following raw materials in parts by weight: 22 to 48 parts of slate, 15 to 21 parts of building gypsum, 3 to 6 parts of converter ore slag, 12 to 15 parts of waste rock wool, 22 to 30 parts of floating bead, 11 to 15 parts of sepiolite, 4 to 10 parts of volcanic ash, 4 to 9 parts of hollow inorganic fiber, 10 to 13 parts of modified starch, and 2 to 7 parts of liquefied resin. The novel heat-isolation, heat-insulation and energy-saving material has the advantages that by using the building gypsum, the converter ore slag and the waste rock wool as the main materials, the cost isreduced; by assisting with the slate, the floating bead, the sepiolite and the volcanic ash, the strength and heat insulation property are improved; by adding the hollow inorganic fiber, the fiber layer can be formed, so that the heat insulation property and toughness are improved; by adding the liquefied resin and the modified starch, the components in the material can be firmly bonded together,so that the strength is higher.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

Cement-containing asbestos-free brake disc and preparation method thereof

A disclosed cement-containing asbestos-free brake disc comprises the raw materials in percent by weight: 14-18% of modified phenolic resin, 28-33% of a fiber material, 40-50% of a filling material and 3-9% of cement, wherein the fiber material is composed of one or more of mineral fiber, glass fiber and paper fiber, cement is composed of one or more of portland cement, ordinary portland cement, slag portland cement, portland-pozzolana cement, portland fly-ash cement, composite portland cement, medium-heat portland cement, low-heat portland slag cement and white portland cement. The invention also discloses a preparation method of the cement-containing asbestos-free brake disc. The cement-containing asbestos-free brake disc is high in impact strength and good in high-temperature wear resistance; and the preparation method of the cement-containing asbestos-free brake disc is simple and relatively low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

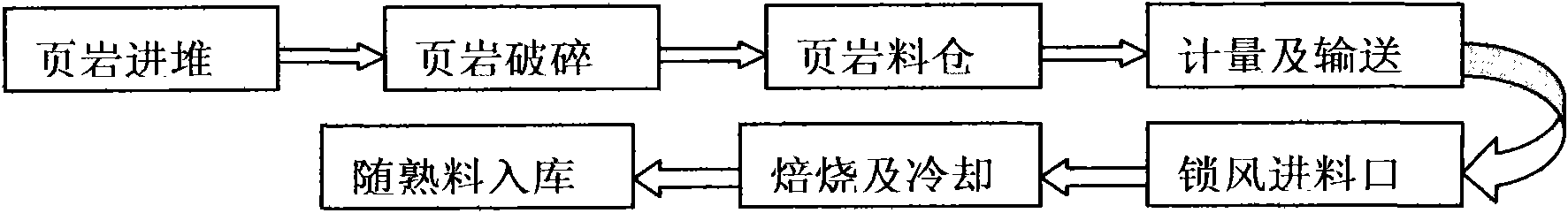

Pozzolana mixture as well as preparation method and application thereof

InactiveCN102211886ANo pollution in the processLarge room for output adjustmentProduction linePozzolana

The invention discloses a preparation method of a pozzolana mixture. The mixture is prepared by mixing smashed shale with kiln-discharging clinker at a weight part ratio of (3-5):20, roasting and then cooling. The preparation method has the beneficial effects that under the condition that any heat source is not added, crude shale is evenly added to a clinker feeding point of a firing system through simple smashing, weighing and transporting devices; roasting is carried out by utilizing the waste heat of the clinker to prepare the shale mixture, so that the shale mixture completely reaches the characteristic of the pozzolana mixture. The preparation method has the beneficial effects that: a, any environment pollution is not generated; b, energy sources such as coal and the like are not consumed; c, the local shale resources are fully utilized; d, a yield regulation space is large; and e, the price difference of the preparation method in the invention and other methods for preparing the pozzolana shale mixture is at least ***, if being calculated by being based on a cement production line with a 100 Mtpa production capability, 12-18 Mtpa of mixtures can be produced in one year, and the profit is ***-***.

Owner:BEICHUAN SIXING CEMENT

Waterproof coating for water conservancy construction

ActiveCN104674762AImprove anti-friction performanceImprove waterproof performanceMarine site engineeringEpoxy resin coatingsFiberEpoxy

The invention discloses a waterproof coating for water conservancy construction. The waterproof coating for the water conservancy construction is characterized by comprising a first layer, a second layer and a third layer from inside to inside, wherein the first layer is made of a fiber-reinforced brittle composite material; manufacturing raw materials of the fiber-reinforced brittle composite material comprise Portland cement, silica sand, coal ash, water, water reducing agents, polyving akohol fibers and steel fibers; the second layer is made of epoxy-group and phenyl-group silicon resin; the third layer is made of the waterproof coating; manufacturing raw materials of the waterproof coating comprise bitumen, pozzolana cement, titanium nitride, calcium carbonate powder, water, dihydric alcohol reducing agents and epoxy emulsion; the thickness of the first layer is 2-3 millimeters; the thickness of the second layer is 1-1.2 millimeters; and the thickness of the third layer is 1.5-2 millimeters. The waterproof coating for the water conservancy construction is high in waterproof effect, can be adhered to concrete well, and is high in high-temperature resistance, high in impact resistance, high in crack resistance and high in friction resistance.

Owner:维特国际新材料(武汉)有限公司

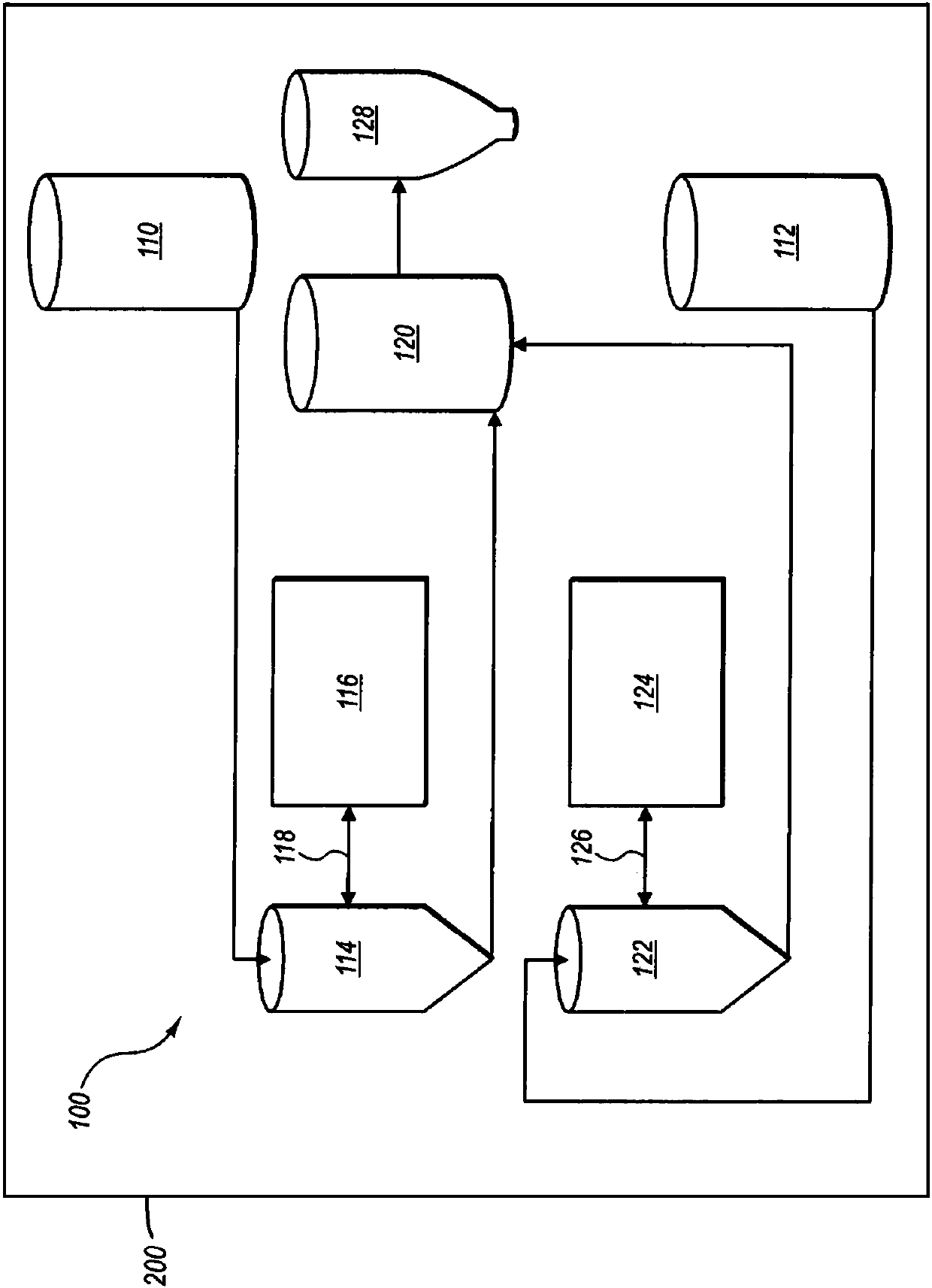

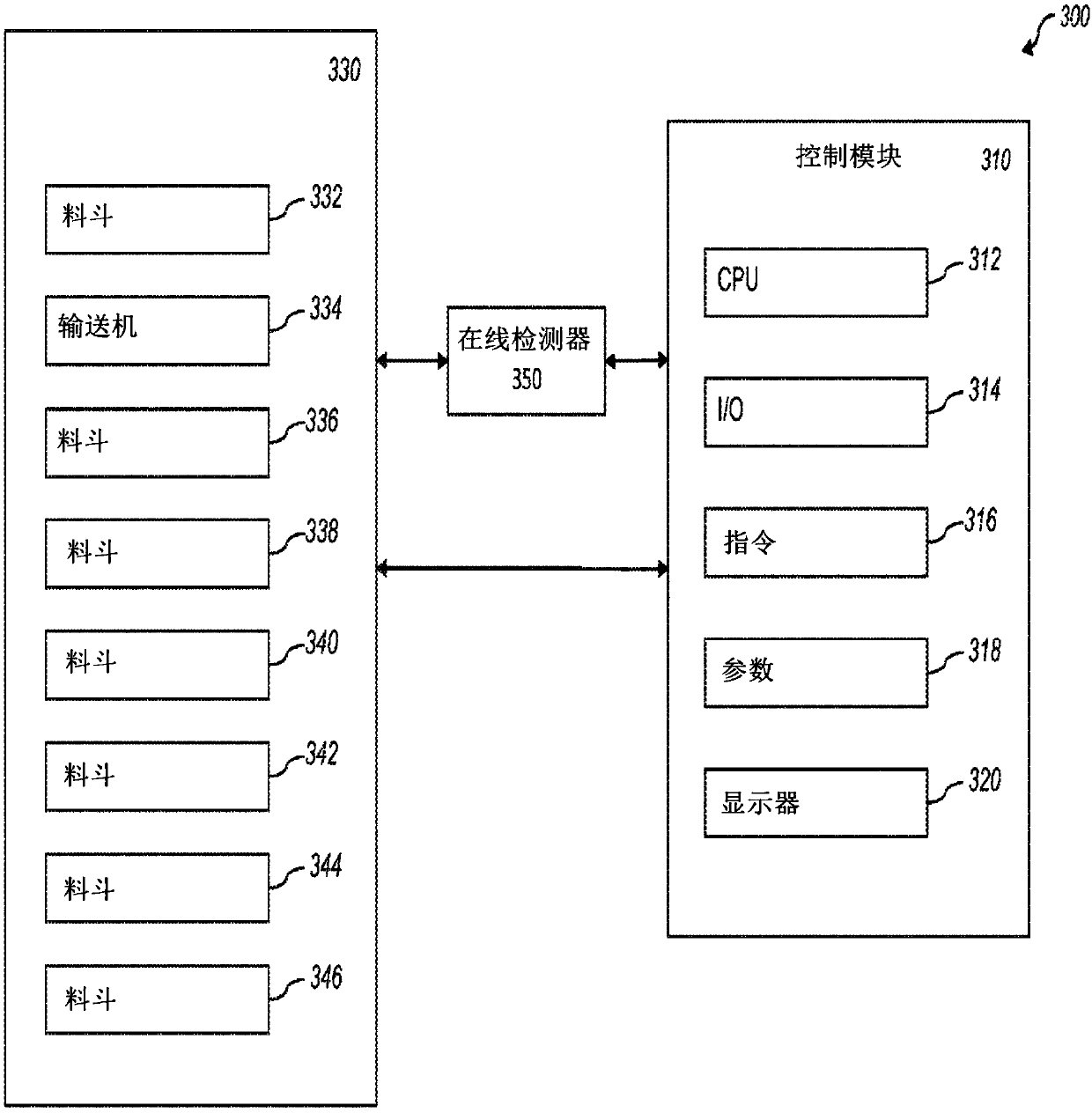

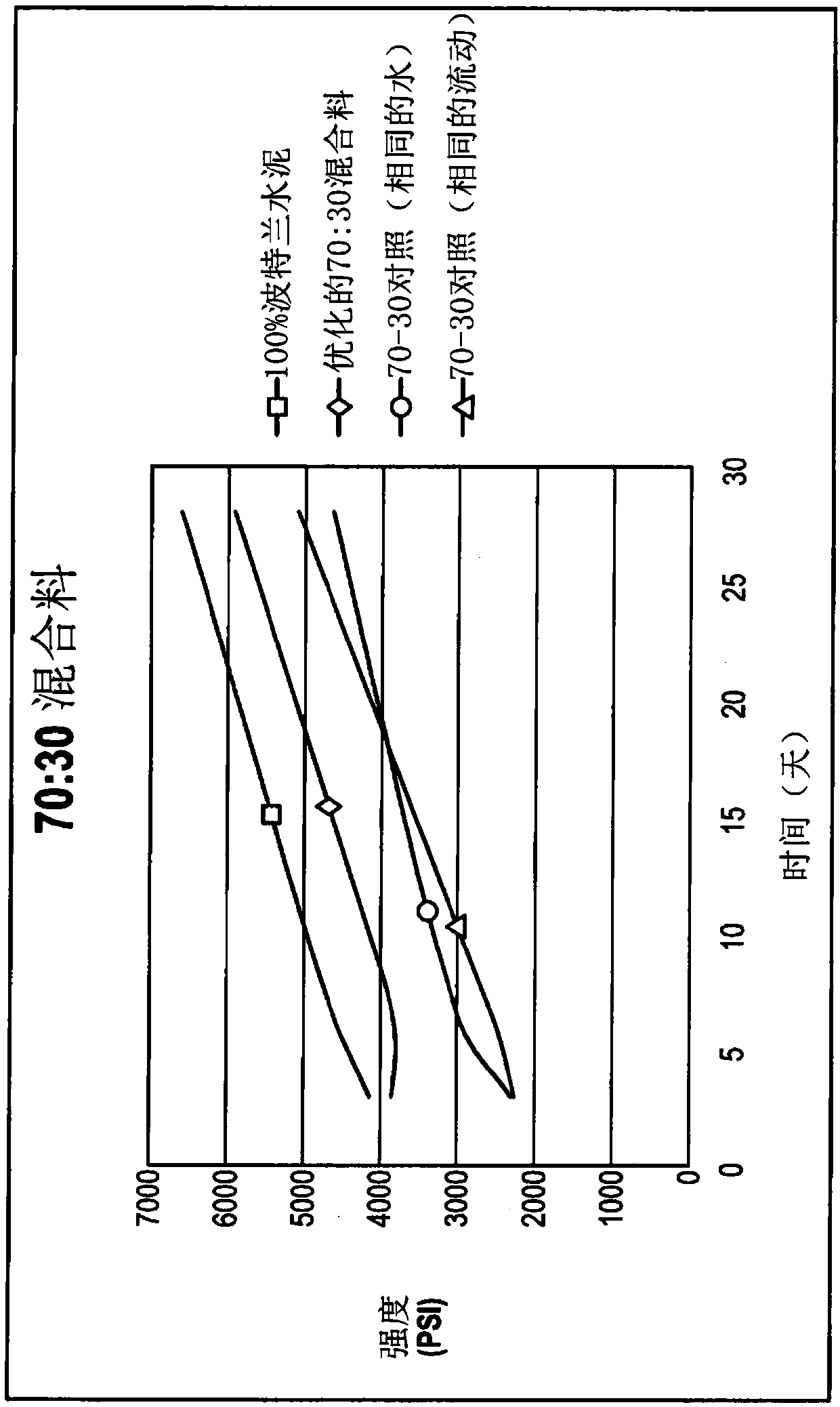

Modification of properties of pozzolanic materials through blending

The invention provides methods for producing a blended pozzolan having one or more characteristics, such as one or more chemical and / or physical characteristic, in an established amount or range fromtwo or more different pozzolans. Two or more pozzolans having different chemical and / or physical characteristics can be blended together and a chemical analyzer used to determine a chemical and / or physical characteristic of the blended pozzolan. Upon determining that the chemical and / or physical characteristic of the blended pozzolan is outside the established amount or range, modifying a blendingratio of the two or more pozzolans to restore the chemical and / or physical characteristic to the established amount or range.

Owner:ROMAN CEMENT

Front and rear end-mounted compaction wheel device for road roller and operation method thereof

ActiveCN105064177ALarge capacityReal-time confirmation of leveling statusRoads maintainenceFiberPozzolana

The invention discloses a front and rear end-mounted compaction wheel device for a road roller and an operation method thereof. The device comprises a wheel body I, a wheel body II and a vehicle body, wherein the wheel body II is positioned in the front part of the vehicle body; the wheel body I is positioned in the rear part of the vehicle body; the wheel body I and the wheel body II are respectively provided with a pair of compaction wheel frames; the bottoms of the compaction wheel frames corresponding to the wheel body I are provided with lifting wheels; each of the wheel body I and the wheel body II is made of 25% of gravel, 15% of limestone, 20% of cement, 5% of inorganic cementing material, 0.5% of hydroxypropyl methyl cellulose, 1.5% of ground calcium carbonate, 2% of polyethylene fiber, 1% of rubber powder, 7% of kaolin powder, 3% of water, 10% of aggregate and 10% of asphalt; and the particle size of the gravel is greater than 1.7mm, and the cement is portland-pozzolana cement. The compaction wheel device for the road roller has the advantages that the structure is novel, workers in an operation room can know the flatness condition of the pavement in real time, agglomerated dirt can be avoided, and the flatness is high.

Owner:中交二公局第四工程有限公司

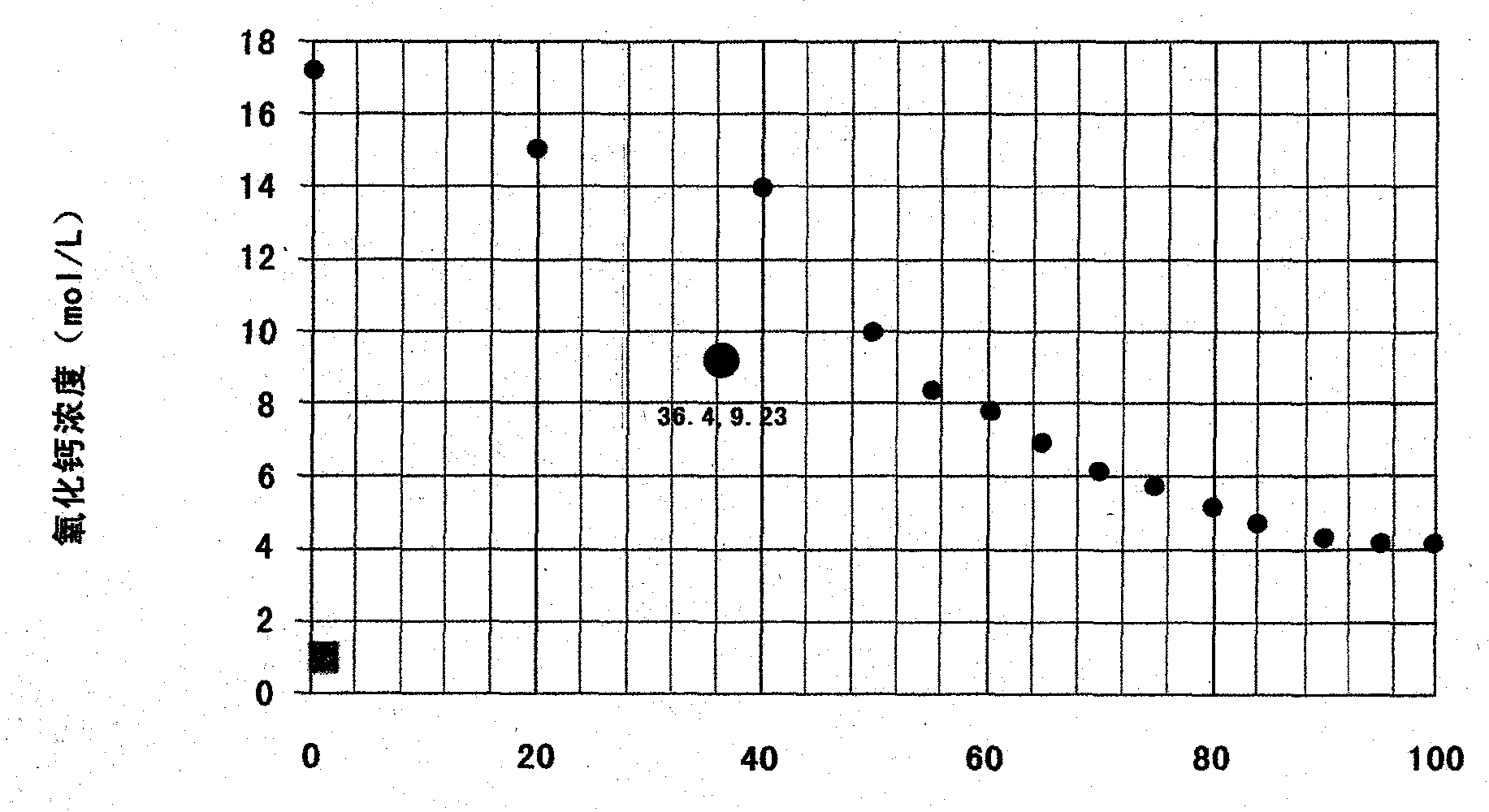

Filling material for reinforcing joint and construction method of filling reinforcing joint

ActiveUS8080104B2High compressive strengthIncrease the lengthSolid waste managementPozzolanaHydrogen-Ion Concentrations

A filler for reinforcement joint that ensures excellent fluidity and retention thereof, exhibiting appropriate length change ratio and high strength performance; and a method of reinforcement joint filling operation using the same. There are provided a filler for reinforcement joint containing a cement, an expanding material, a pozzolana micropowder, a water reducing agent and a sand, and a method of reinforcement joint filling operation using the same, characterized in that the expanding material is a calcium aluminoferrite expanding material, and that the pozzolana micropowder is a silicious micropowder having a silicon dioxide (SiO2) content of 90% or higher and having a hydrogen ion concentration falling in an acid region, and that the water reducing agent is a polycarboxylic acid water reducing agent. The calcium aluminoferrite expanding material preferably has a value of Brain specific surface area of 2000 to 6000 cm2 / g. The sand is preferably a weighty sand of 3.0 g / cm3 or higher density.

Owner:DENKA CO LTD +1

Volcanic ash composite type foaming agent

The invention discloses a volcanic ash composite type foaming agent which adopts the technical scheme that the volcanic ash composite type foaming agent consists of volcanic ash powder, attapulgite argil powder with an air purification function, hydrogen peroxide, lauryl dimethyl amine oxide, cocoyl diethanol amine, a silicone polyether emulsion, polyether modified silicone oil and water, and cream ingredients of the volcanic ash composite type foaming agent are mixed to form cream, and then mixed to form the finished volcanic ash composite type foaming agent. The volcanic ash composite type foaming agent has the characteristics that the foaming capacity is high; the foaming expansion rate is high; the foam generation quantity in unit volume is large; foam holes are fine, smooth and uniform, and are not easy to break; the demoulding speed of a product is high; the surface smoothness is good; and the later strength of the product is high. The product produced by the volcanic ash composite type foaming agent has effects of warm keeping, heat insulation and sound insulation, and has the air purification function, and the volcanic ash composite type foaming agent is suitable for production of lightweight boards, lightweight walls and silencing and noise reduction products.

Owner:刘继军

Cement produced by virtue of waste sintered brick powder and preparation method for cement

The invention discloses cement produced by virtue of waste sintered brick powder and a production method for the cement. The cement is prepared from the following components in parts by weight: 45.5 to 67 parts of Portland cement clinker, 20 to 60 parts of waste sintered brick powder and 3 to 4.5 parts of gypsum. According to the cement and the production method for the same, Portland-pozzolana cement is produced by virtue of the waste sintered brick powder as an artificial pozzolana mixture instead of burnt clay, burnt shale and broken clay bricks, so that the technical problems of environmental pollution and resource waste caused by the waste sintered brick powder produced in a construction waste recycling process are effectively solved, a new manner for recycling the waste sintered brick powder is provided, natural clay and shale resources are also saved, energy consumption in sintering processes of the burnt clay, the burnt shale and the broken clay bricks is reduced, the production cost of the cement is greatly reduced, requirements of cities on cement are met, reclamation of construction waste is realized, a novel technology for a sustainable development strategy is provided, and the cement and the production method for the same are consistent with the policies of resource saving and environmental protection.

Owner:XUCHANG JINKE RESOURCE RECYCLING CO LTD

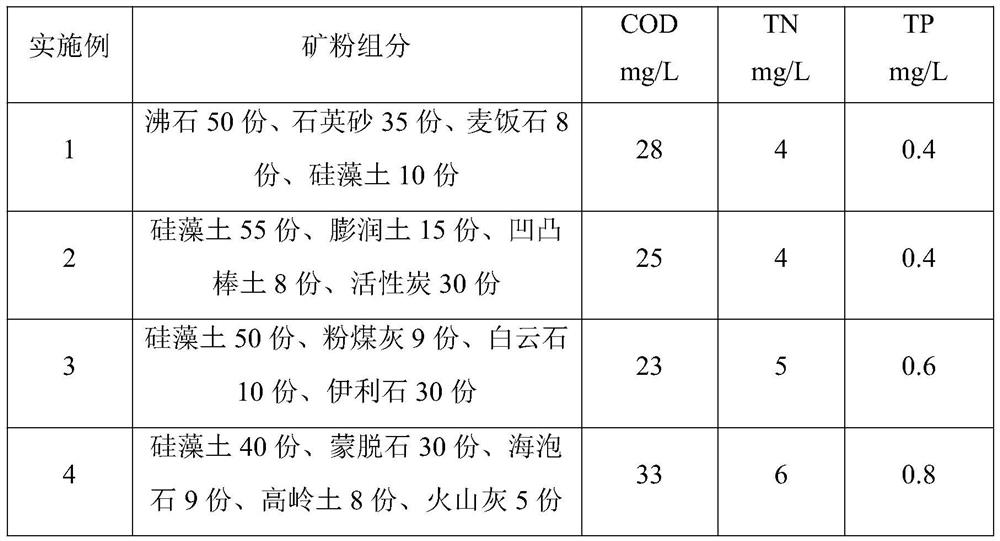

Biological carrier for strengthening wastewater treatment, preparation method and application thereof

InactiveCN112694218AHigh removal rateValid reservationWater contaminantsMultistage water/sewage treatmentPozzolanaKaolin clay

The invention discloses a biological carrier for strengthening wastewater treatment, a preparation method and application thereof, and belongs to the technical field of environmental functional materials and sewage treatment. The biological carrier comprises any four or more of: 10-70 parts of diatomite, 10-30 parts of bentonite, 5-9 parts of attapulgite, 30-40 parts of montmorillonite, 9-14 parts of fly ash, 4-9 parts of medical stone, 20-35 parts of activated carbon, 5-10 parts of dolomite, 3-8 parts of volcanic ash, 9-15 parts of sepiolite, 30-40 parts of illite, 5-10 parts of kaolin, 40-70 parts of zeolite and 35-45 parts of quartz sand. The volume load of wastewater biological treatment is increased, so that the microbial concentration of biological flocs in biochemical water treatment is remarkably increased, meanwhile, the removal rate of refractory organic matters or TOC is increased, the removal rate of inorganic matters is increased, and the effluent quality is improved.

Owner:河北和悦环保科技有限公司

Method for detecting contents of main metal elements in silicate materials

ActiveCN104020163AEasy to detectEasy to operateMaterial analysis by observing effect on chemical indicatorSlagPozzolana

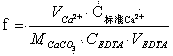

The invention discloses a method for detecting trace elements in silicate materials, which is simple and is strong in operability. The detection method comprises the steps of: (1) preparing a sample to be detected; (2) determining EDTA influence factors; and (3) determining the contents of metal elements such as iron, magnesium, calcium or aluminium. The detection method provided by the invention comprises the step of detecting an iron element, a magnesium element, calcium element and an aluminium element. The detection method disclosed by the invention has the advantages that fast and simple detection for trace metal elements such as iron, magnesium, calcium and aluminium in primary coal ash, blast-furnace slag, volcanic ash and the like, less detection devices are used and the cost is low.

Owner:NANJING TRANSCENDENT NEW MATERIALS TECH CO LTD

Activation of natural pozzolan and use thereof

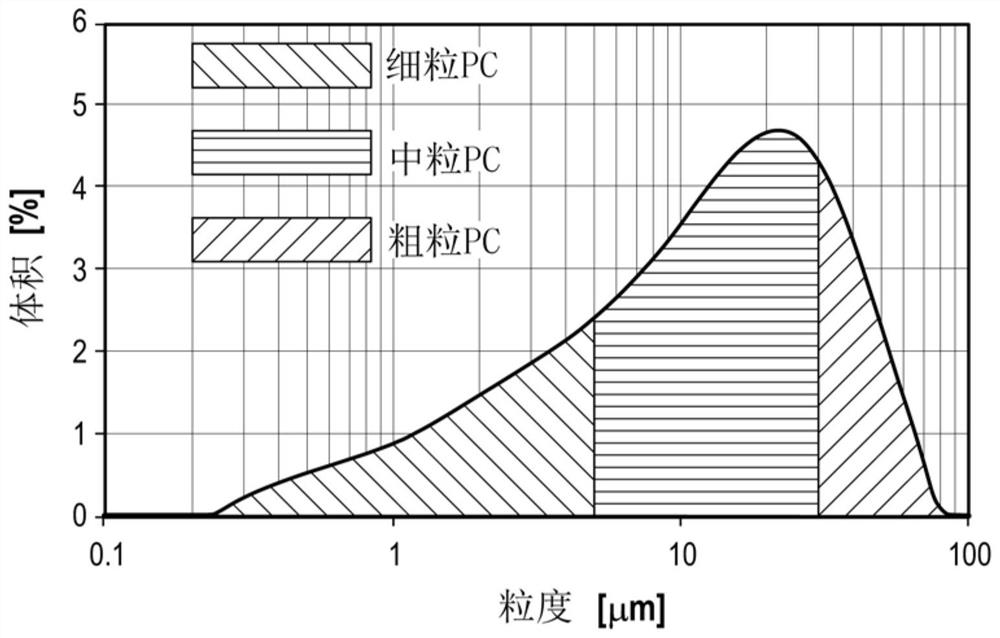

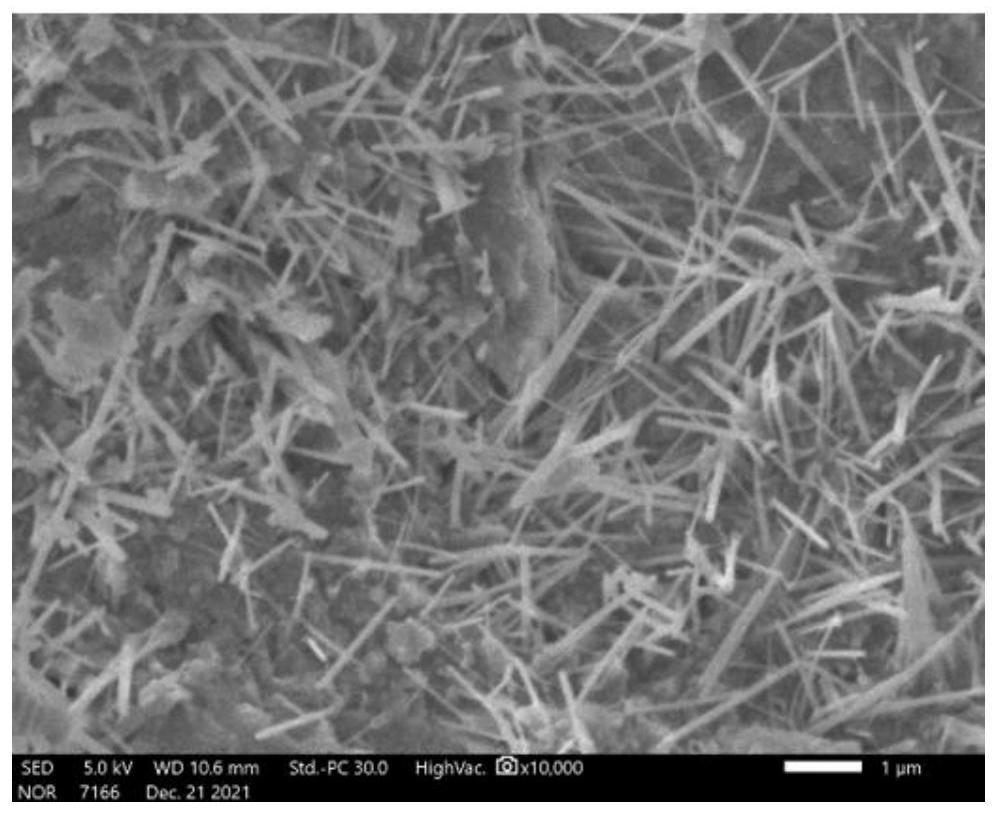

An activated pozzolan composition includes a fine interground particulate blend of an initially unactivated natural pozzolan and a supplementary cementitious material (SCM) different than the initially unactivated natural pozzolan. The initially unactivated natural pozzolan may include volcanic ash or other natural pozzolanic deposit having a moisture content of at least 3%, and the activated pozzolan composition can have a moisture content less than 0.5%. The initially unactivated natural pozzolan may have a particle size less than 1 mm before intergrinding with the SCM. The SCM used to activate the initially unactivated natural pozzolan can be initially coarse or granular with a size greater than 1-3 micrometers and may include granulated blast furnace slag, steel slag, other metallurgical slag, pumice, limestone, fine aggregate, shale, tuff, trass, geologic material, waste glass, glass shards, basalt, sinters, ceramics, recycled bricks, recycled concrete, refractory materials, other waste industrial products, sand, or natural mineral.

Owner:ROMAN CEMENT

Flue gas desulfurizing agent as well as preparation method and application thereof

ActiveCN111330424AReduce porosityImprove pore structureGas treatmentDispersed particle separationHydration reactionPozzolana

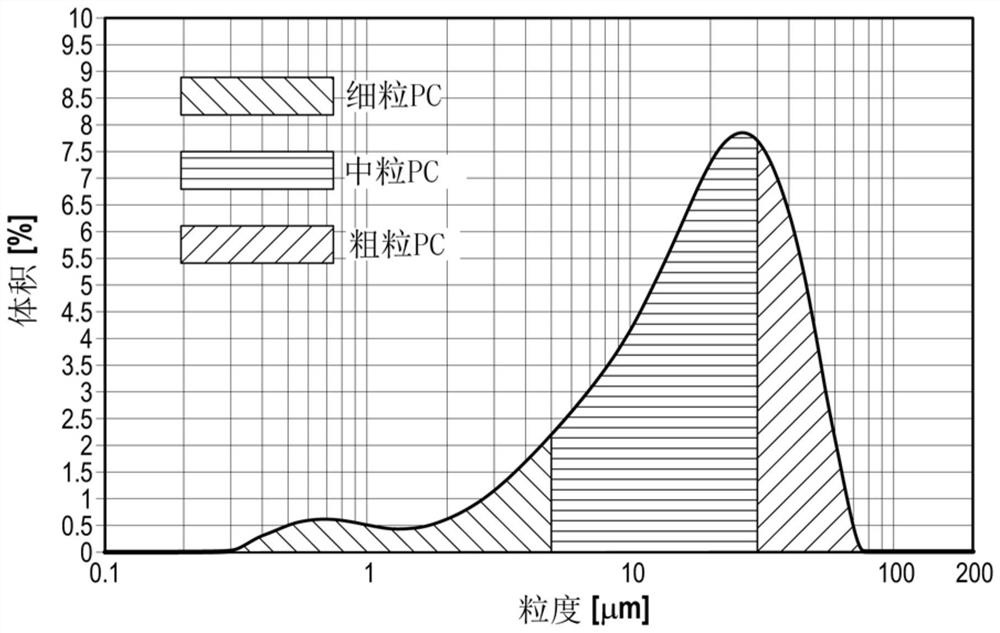

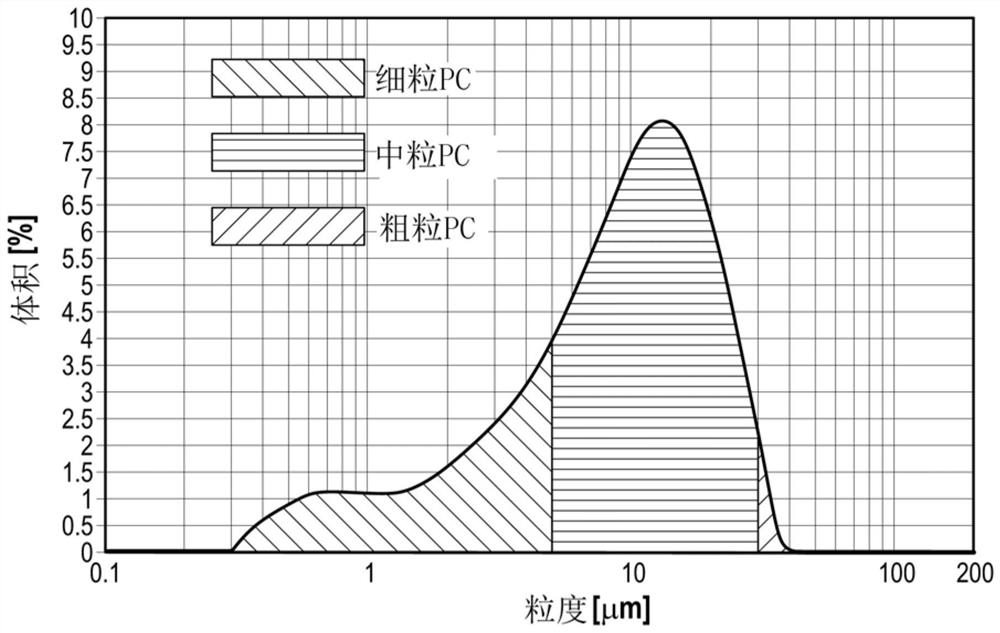

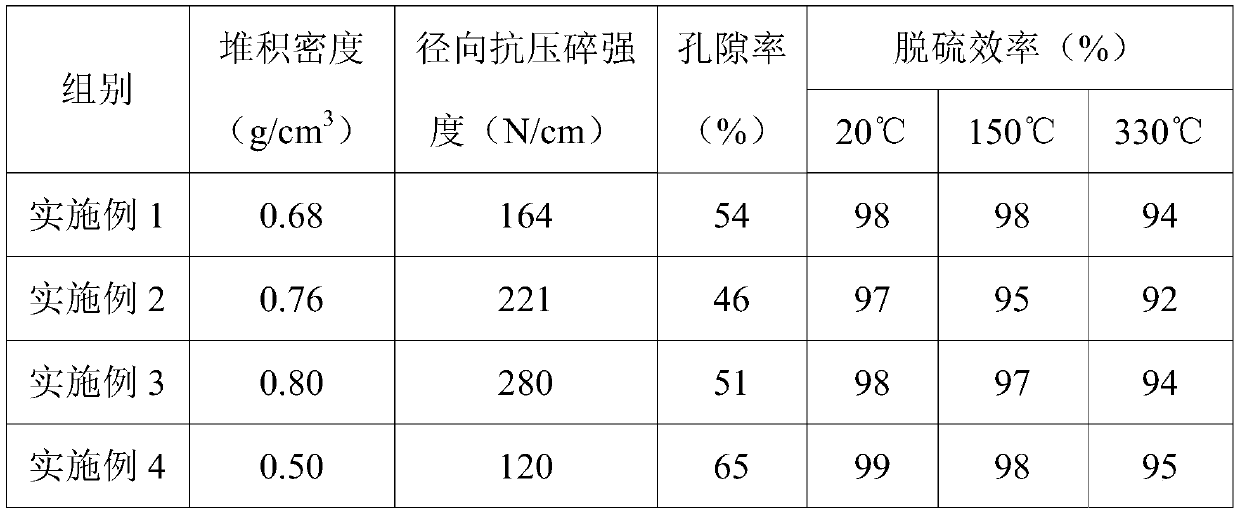

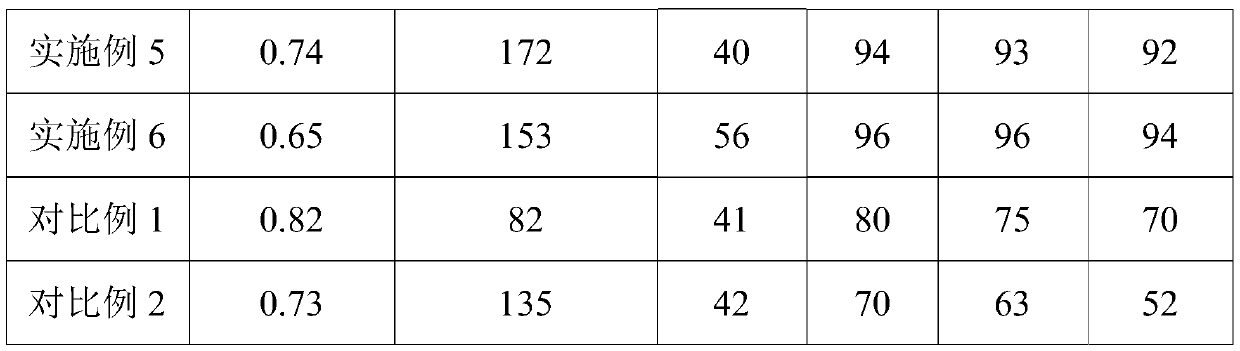

The invention provides a flue gas desulfurizing agent as well as a preparation method and application thereof. The flue gas desulfurizing agent comprises the following raw materials in parts by weight: 30-60 parts of slaked lime powder, 20-60 parts of silica fume, 6-24 parts of a binder and 6-15 parts of crystalline hydrated salt. According to the flue gas desulfurizing agent, active substances inthe slaked lime powder and the silica fume are subjected to a pozzolanic reaction to generate high-strength hydrated silicate; the binder can bind all the raw material components to improve the strength of the flue gas desulfurizing agent; the crystalline hydrated salt plays a pore-forming role by losing crystalline water in the flue gas desulfurizing agent; mutual cooperation of components, theflue gas desulfurizing agent has relatively small stacking density (0.5-0.8 g / cm<3>), relatively high radial crushing strength (120-280 N / cm) and relatively large porosity (40-65%); the desulfurizingagent can be used for a fixed bed reactor or a moving bed reactor, is suitable for purification treatment of SO2-containing industrial flue gas or waste gas at 20-330 DEG C, has relatively high reaction activity, particularly still has relatively high crushing resistance under a relatively high flue gas temperature condition, and is not easy to pulverize and low in bed pressure.

Owner:北京予知环境工程有限公司

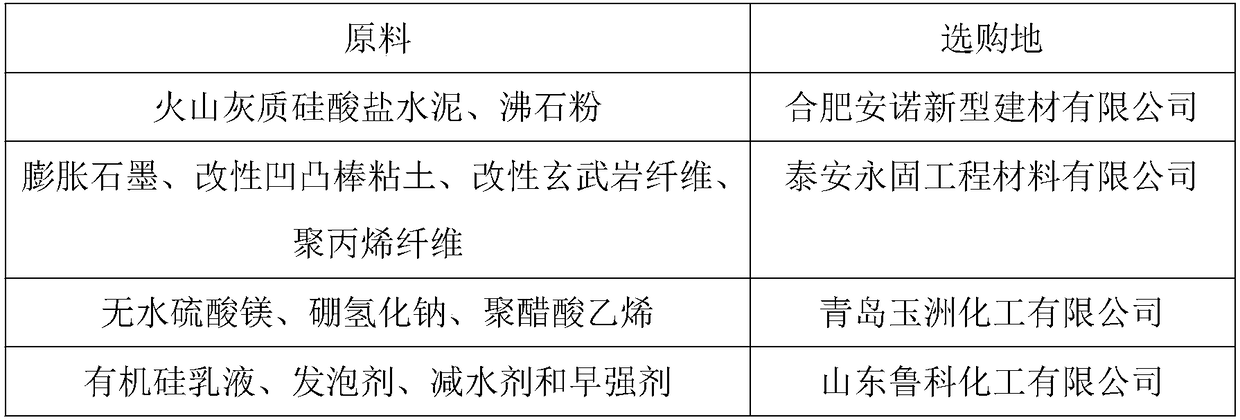

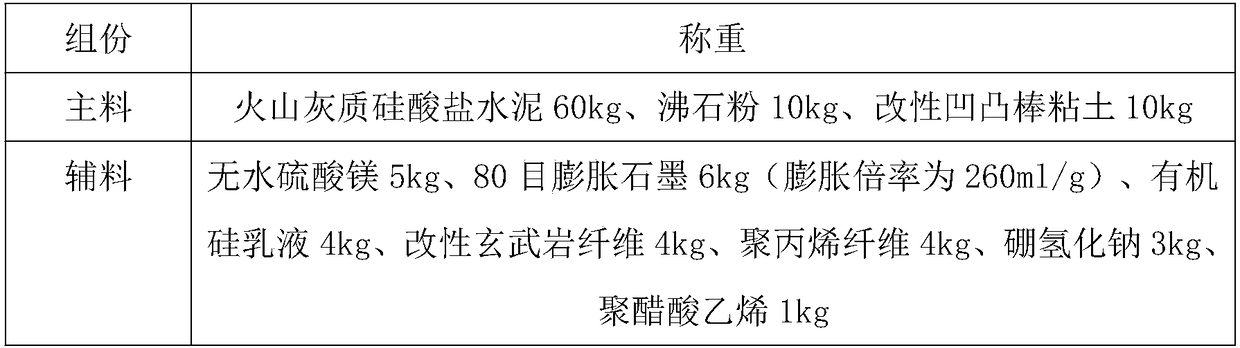

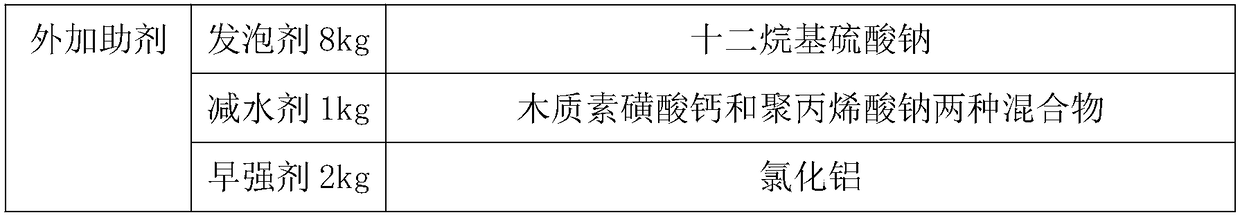

Inorganic foaming refractory door core board and preparation method thereof

InactiveCN108285306AHigh in magnesiumHigh strengthFireproof doorsCeramicwarePolymer sciencePozzolana

The invention discloses an inorganic foaming refractory door core board and a preparation method thereof, and relates to the technical field of production of door core boards. The door core board is prepared from portland-pozzolana cement, anhydrous magnesium sulfate, expanded graphite, zeolite powder, modified attapulgite clay, organic silicone emulsion, modified basalt fibers, polypropylene fibers, sodium borohydride, polyvinyl acetate, foaming agent, water reducing agent and early strength agent. According to the preparation method, the raw materials are subjected to even mixing, injectionmolding, solidification and the like to obtain the door core board. The door core board has the advantages of being environmentally friendly, high in strength and fireproof grade, excellent in corrosion resistance, capable of preventing dampness, high in stability, wide in application range and long in service life.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

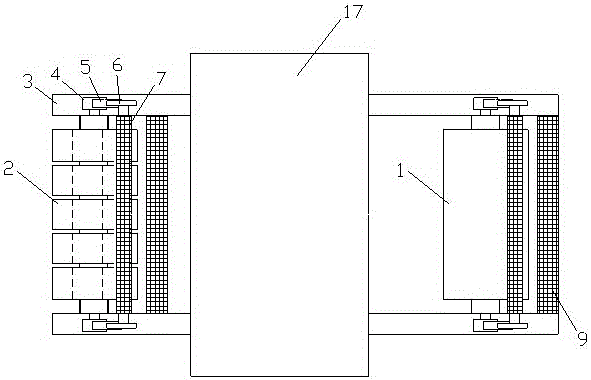

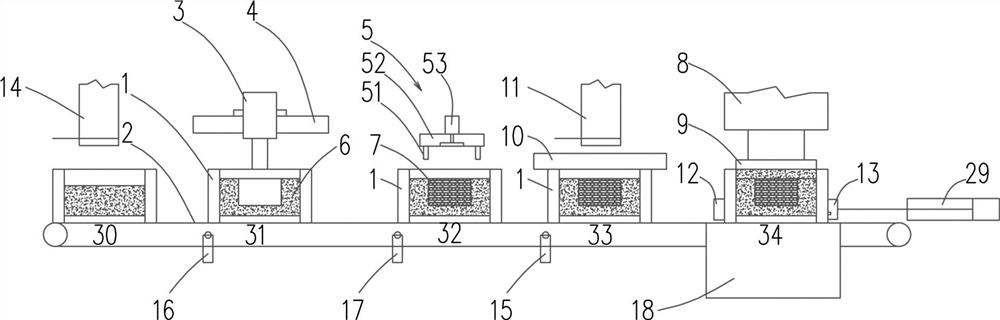

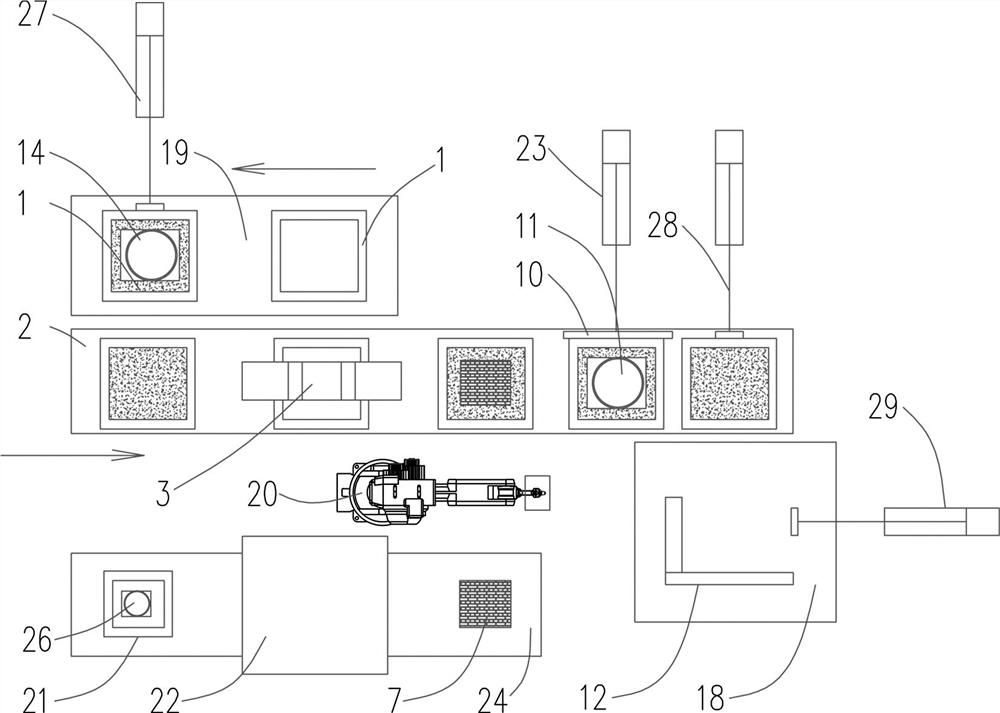

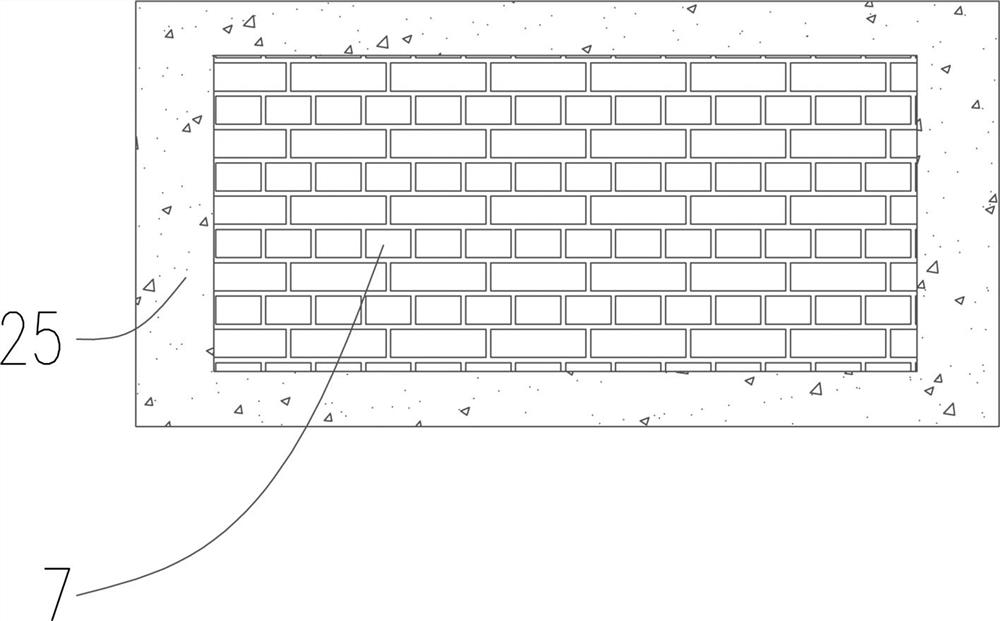

Preparation method and equipment of high-strength ardealite block material and pavement brick

ActiveCN113354379AHigh strengthReduce bite forceCeramic shaping plantsShaping press ramBrickPozzolana

The invention provides a preparation method and equipment of a high-strength ardealite block material and a pavement brick. The high-strength ardealite block material is prepared from the following components in parts by weight: 100 parts of neutralized and dehydrated ardealite material, 0.5-5 parts of cement powder, 1-5 parts of silicate mineral powder, 0.5-5 parts of volcanic ash active powder, 0.1-0.2 part of retarder and 0.06-0.1 part of water-retaining agent. The water accounts for 9-13% of the weight of the mixture; and the particle sizes of the silicate mineral powder and the volcanic ash active powder are less than 1 mum. The preparation method comprises the following steps of preparing a shell from impervious cement concrete, and putting a high-strength phosphogypsum block material into the impervious cement concrete shell, feeding from the top of the impervious concrete, and pressing into pavement bricks under 15-20MPa, and performing steam curing for 3-4 days to obtain the high-strength high-content phosphogypsum pavement brick. The production line for preparing the phosphogypsum pavement brick is sequentially provided with a shell feeding station, a shell forming station, a block material placing station, a top feeding station and a pavement brick pressing station. The compressive strength of the prepared pavement brick exceeds 30 MPa.

Owner:HUBEI YITONG CONSTR ENG CO LTD

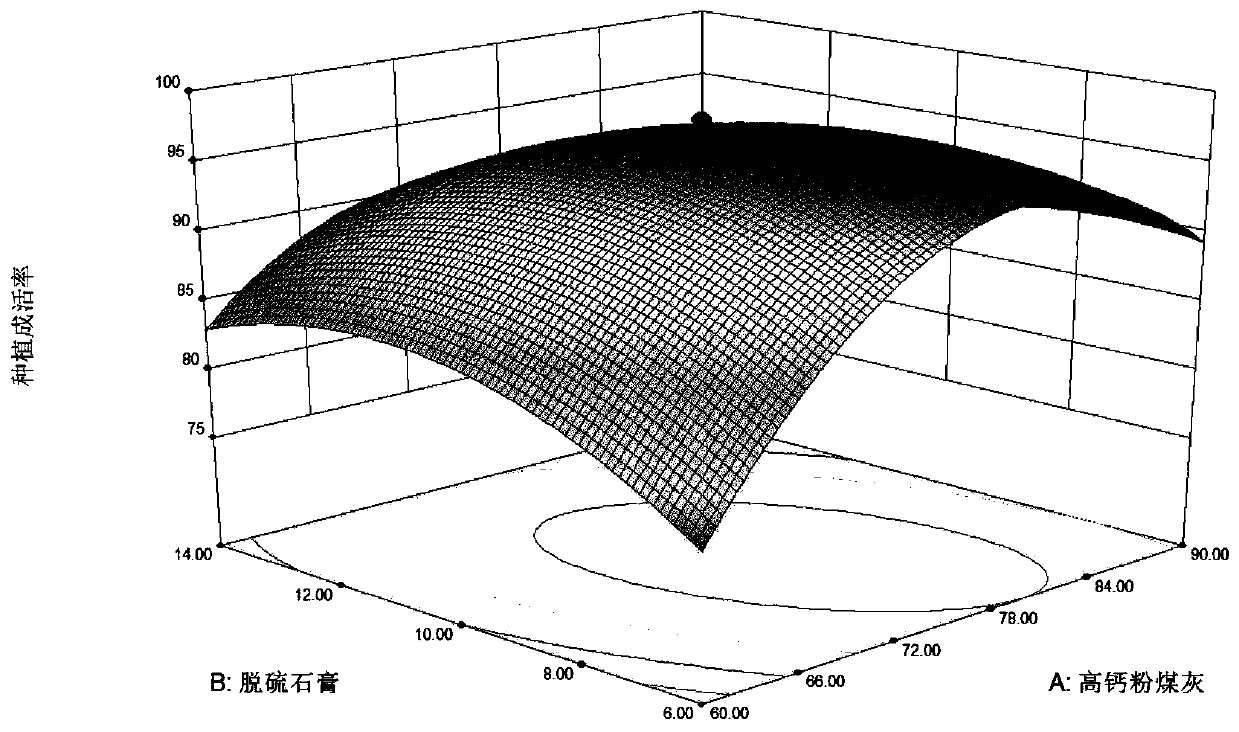

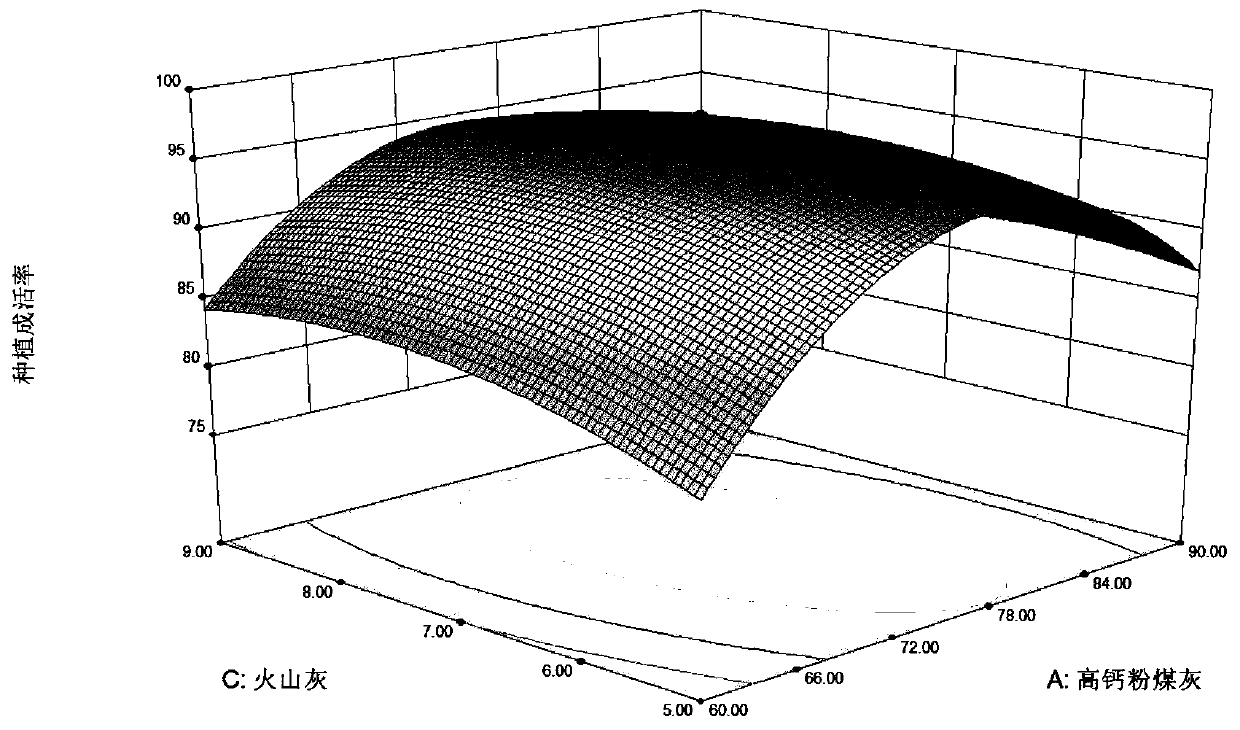

Curing agent for solid waste treatment and application thereof

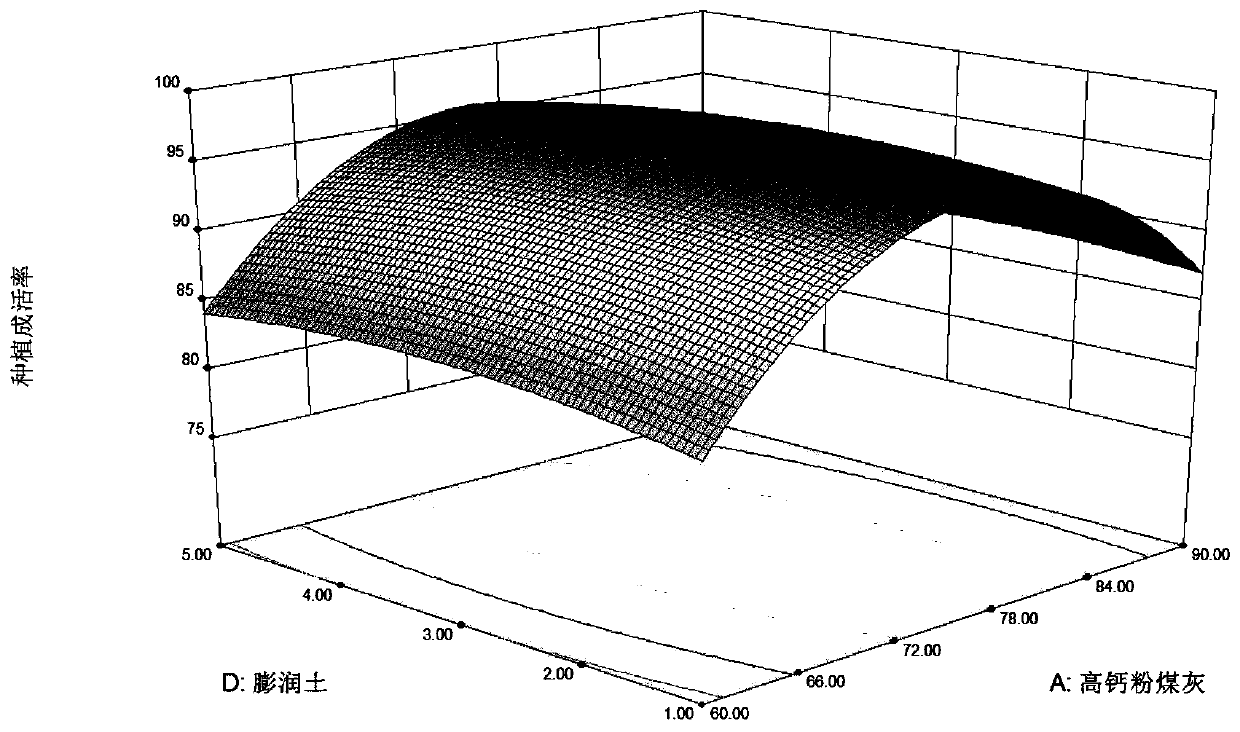

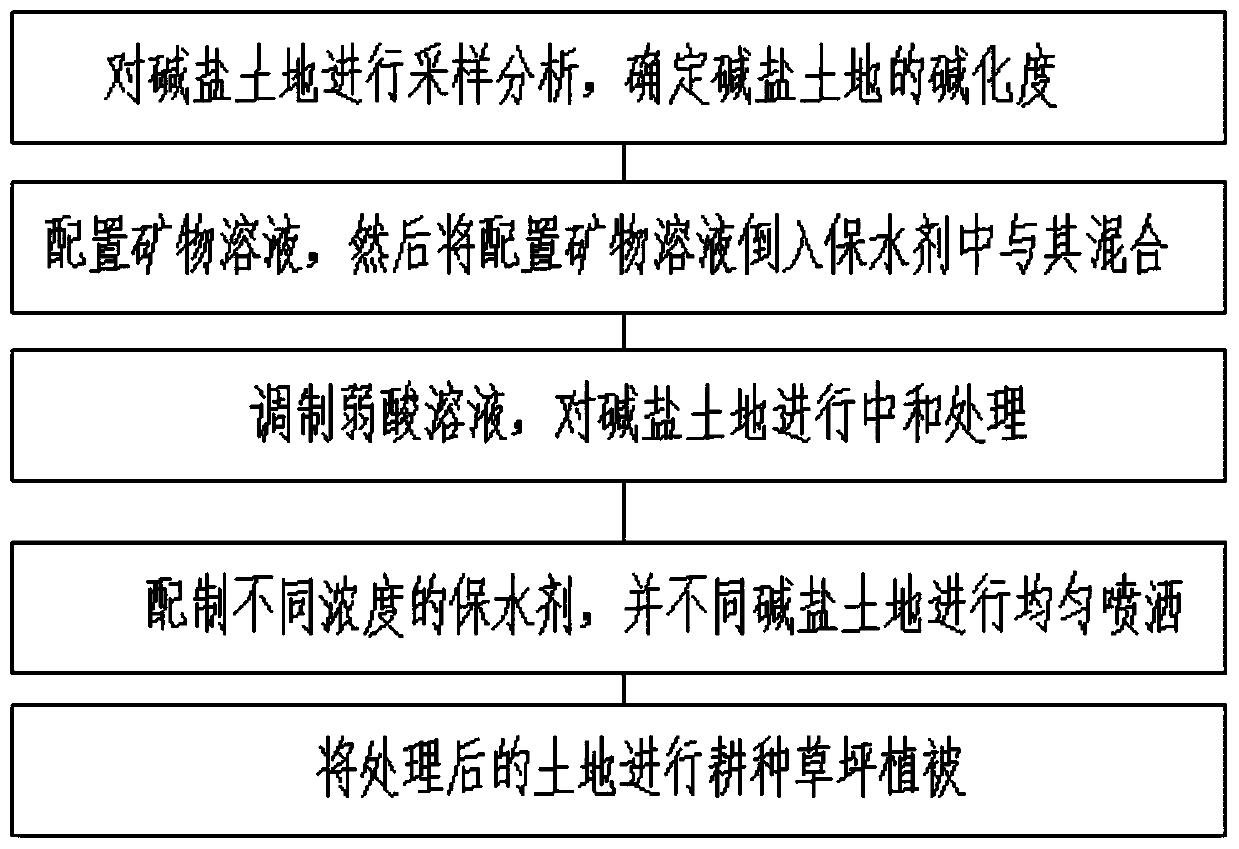

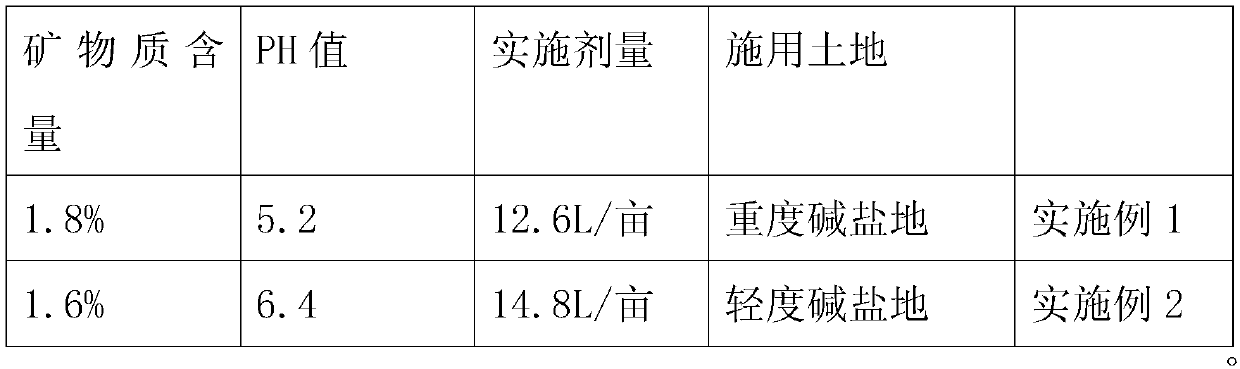

ActiveCN111303890ALow costStrong plasticity and secondary curingAgriculture tools and machinesOther chemical processesAlkali soilPozzolana

The invention provides a curing agent for solid waste treatment. The curing agent comprises the following components in parts by mass: 60-90 parts of high-calcium fly ash, 6-14 parts of desulfurized gypsum, 5-9 parts of volcanic ash, 1-5 parts of bentonite, 1-5 parts of calcium chloride and 1-3 parts of sodium sulfate. The curing agent for solid waste treatment provided by the invention has strongwater absorptivity, and can be applied to practice to achieve the effect of curing oil field rock debris conveniently and efficiently at low cost. Not only the solid waste is effectively recycled, but also the problem that the solid waste of each large enterprise is difficult to treat is solved. The curing agent provided by the invention can realize rapid curing of slurry, and can reduce a large-capacity slurry storage pool. Heavy metal absorbing vegetation is planted and absorbed, a vegetation growth experiment is completed, and the method can be particularly applied to the aspects of drought resistance, severe saline-alkali soil remediation and the like. The ecological balance is protected, the human settlement environment is improved, and an effective promotion effect is achieved for the government to achieve the sustainable development goal.

Owner:新疆盛洁环境技术有限责任公司

Fire-resistant calcium sulphate-based products

ActiveUS10662113B2Reduce Shrinkage ProblemsMaintain dimensional stabilitySolid waste managementPozzolanaKaolin clay

The present invention provides calcium sulphate-based product having reduced shrinkage after exposure to high temperatures, the product comprising gypsum, a pozzolan source (e.g. in an amount between 4-27 wt %) and a metal salt additive (in an amount between 0.5 and 10 wt %). The pozzolan source may be selected from a kaolinitic clay material, fly ash, rice husk ash, diatomaceous earths, volcanic ashes and pumices, micro-silica, silica fume and silicone oil. The metal salt additive may be a metal salt which decomposes between a temperature of 300-500° C. to yield a metal oxide, e.g. magnesium nitrate.

Owner:SAINT GOBAIN PLACO SAS

Powdery volcanic ash foaming agent

The invention discloses a powdery volcanic ash foaming agent. The point of the technical scheme is as follows: the powdery volcanic ash foaming agent consists of volcanic ash, high-viscosity attapulgite clay powder, sodium dodecyl sulfate, sodium percarbonate, sodium polyacrylate, sodium pyrophosphate and sodium poly[(naphthaleneformaldehyde)sulfonate]; and the ingredients of the powdery volcanic ash foaming agent are stirred, ground and packaged to obtain a finished product of the powdery volcanic ash foaming agent. The powdery volcanic ash foaming agent has the advantages of strong foaming ability, high foaming times, large foam output of unit volume, good toughness of a foam outer membrane and rare breakage, good foam stability, no defoaming in long time, delicate foam, uniform holes generated in a medium, low bleeding quantity, good compatibility of the medium and the like. A product produced from the powdery volcanic ash foaming agent can effectively control noise pollution and has functions of thermal insulation and air purification; and the powdery volcanic ash foaming agent is suitable for producing light plates, light walls and silencing noise reduction products.

Owner:黄志斌

Salt-tolerant water-retaining agent containing minerals and preparation method thereof

InactiveCN111153751AKeep intactSimple processing methodAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersIron sulfatePozzolana

The invention discloses a salt-tolerant water-retaining agent containing minerals. The water-retaining agent is prepared from the following components in parts by weight: 2 to 4 parts of polyacrylamide; 3 to 8 parts of sodium polyacrylate; 4 to 7 parts of potassium polyacrylate; 3.5 to 6 parts of ammonium polyacrylate; 3-8 parts of volcanic ash; 3-10 parts of clay, 2-6 parts of limestone, 1.5-6 parts of rare earth, 4-8 parts of plant straws, 6-12 parts of sawdust, 1.2-1.5 parts of lignin, 1-4 parts of resin adhesive, 1.2-4.3 parts of urea, 0.8-1.8 parts of manganese sulfate, 0.6-1.5 parts of mono-potassium phosphate, 1.7-3 parts of ferric sulfate and 1.1-3 parts of zinc sulfate. The water-retaining agent is rich in minerals, can be prepared into different concentrations to neutralize different alkali-salt lands, can fully retain water in the alkali-salt lands, and is simple in overall processing method and worthy of popularization.

Owner:华仲动芯新材料(盱眙)有限公司

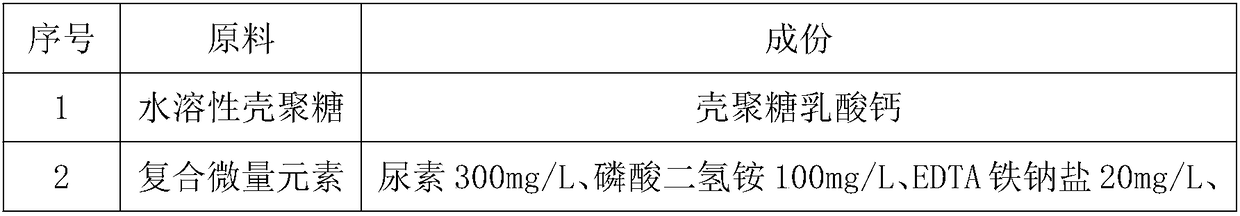

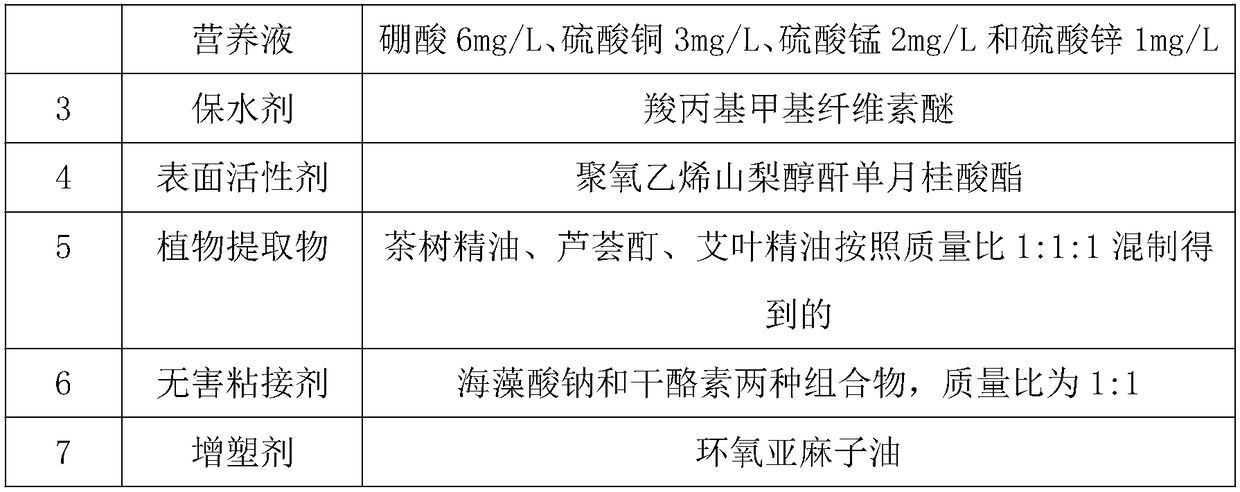

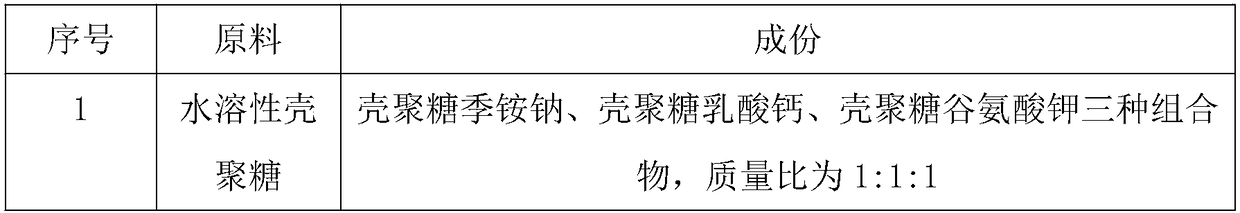

Efficient albizia julibrissin seed coating material and use method thereof

InactiveCN108377693ALow costEasy to useAnimal corpse fertilisersAlkali orthophosphate fertiliserPozzolanaAdhesive

The invention discloses an efficient albizia julibrissin seed coating material and a use method thereof, and relates to the technical field of albizia julibrissin coating materials. The coating material comprises organic matter yeast, peat, pozzolana, water soluble chitosan, shell powder, bread crumbs, sundew pulp, attapulgite, palm fiber, brassinolide, heteroauxin, a compound microelement nutrient solution, a water-retaining agent, a surfactant, plant extracts, a harmless adhesive and a plasticizer. The use method of the coating material includes the steps of mixing the raw materials, cleaning seeds, wrapping the seeds, drying the seeds and the like. The coating material is low in cost, convenient to use and environmentally friendly and can efficiently promote the germination and growth of the albizia julibrissin seeds, increase the survival rate and improve the germination quality.

Owner:ANHUI MEILAN LANDSCAPE ENG CO LTD

Power distribution cabinet body material preparation method

The invention relates to a power distribution cabinet body material preparation method, which specifically comprises: 1, weighing the following raw materials by weight: 30-35 parts of a nickel-based alloy, 10-12 parts of silicon carbide fiber, 12-16 parts of ash calcium powder, 2-8 parts of volcanic ash, 5-18 parts of spinel powder, 10-16 parts of sodium polymethacrylate, 5-9 parts of copper sulfate, 3-9 parts of polyhexamethylene guanidine, 1-5 parts of shellac and 3-23 parts of butyl acrylate; 2, mixing the nickel-based alloy, the silicon carbide fiber, the ash calcium powder, the volcanic ash and the spinel powder, and carrying out ball milling; and 3, adding the sodium polymethacrylate, the copper sulfate, the polyhexamethylene guanidine and the butyl acrylate into the mixture obtainedin the step 2, uniformly stirring, adding the shellac, and carrying out secondary stirring to obtain the cabinet material. According to the invention, the problem of poor performance of the coating layer material of the power distribution cabinet in the prior art is solved.

Owner:西安优信机电工程有限公司

Hot-press molded maintenance-free solid waste-based artificial stone and preparation method thereof

The invention relates to the technical field of building materials, and provides a hot-press molded maintenance-free solid waste-based artificial stone and a preparation method thereof. According to the characteristics that main components of the circulating fluidized bed fly ash contain quartz SiO2 and Al2O3 and main components of the carbide slag contain Ca (OH) 2, the circulating fluidized bed fly ash and the carbide slag are subjected to a pozzolanic reaction in the hot pressing process, and hydrated calcium silicate and hydrated calcium aluminate products are obtained; the fly ash of the circulating fluidized bed is subjected to certain sulfate excitation by utilizing the characteristics that main components in the desulfurized gypsum contain CaSO4. 2H2O and the desulfurized gypsum contains SO4 < 2->, so that the gelling activity of the fly ash of the circulating fluidized bed is improved; and finally, along with the proceeding of the hot pressing process, hydration reaction can be carried out between the three solid wastes of the circulating fluidized bed fly ash, the carbide slag and the desulfurized gypsum and water to generate gelatinous substances such as hydrated aluminosilicate and the like, so that the strength of the artificial stone is improved.

Owner:SHANXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com