Biological carrier for strengthening wastewater treatment, preparation method and application thereof

A biological carrier and wastewater treatment technology, applied in chemical instruments and methods, water/sewage multistage treatment, water/sludge/sewage treatment, etc. Problems such as increased microbial concentration, to achieve the effect of sludge compaction, improved treatment capacity, and increased microbial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

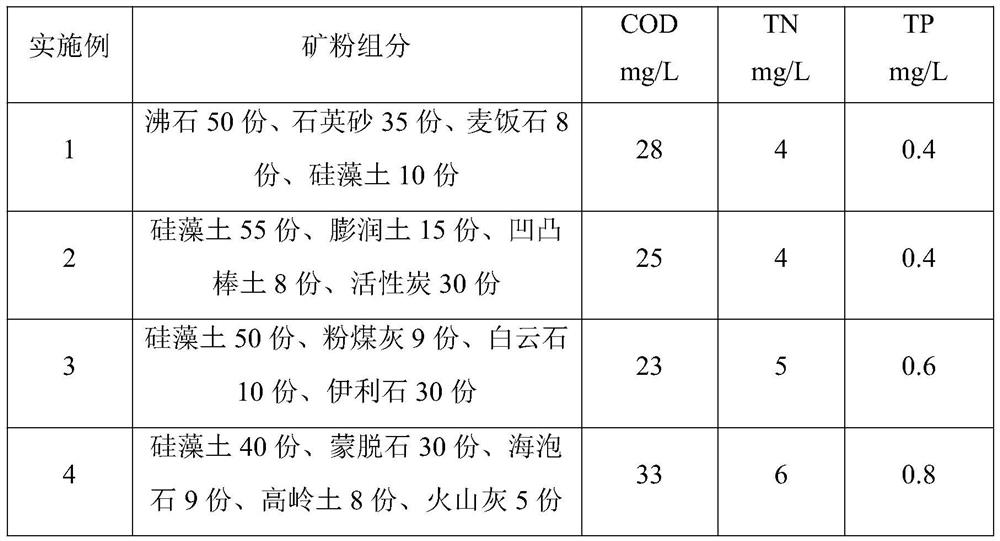

Embodiment 1

[0025] A biological carrier for enhanced waste water treatment, comprising the following components: 50 parts of zeolite, 35 parts of quartz sand, 8 parts of medical stone, and 10 parts of diatomite.

[0026] The preparation method of the biological carrier is as follows:

[0027] (1) The following ingredients are weighed in parts by weight: 50 parts of zeolite, 35 parts of quartz sand, 8 parts of medical stone, and 10 parts of diatomite;

[0028] (2) After mixing zeolite, quartz sand, medical stone, and diatomaceous earth, add them to a crusher for pulverization, and then pass through a 200-mesh sieve to obtain a powder mixture;

[0029] (3) Add an appropriate amount of recycled reclaimed water to the powder mixture, and dissolve the screened powder carrier by stirring to make a slurry, so that the screened powder carrier can completely absorb moisture and no longer agglomerate and float up, and the soaked powder carrier can be obtained powder slurry;

[0030] (4) Adjust th...

Embodiment 2

[0034] A biological carrier for strengthening waste water treatment, which comprises the following components: 55 parts of diatomite, 15 parts of bentonite, 8 parts of attapulgite and 30 parts of activated carbon.

[0035] The preparation method of the biological carrier was the same as that of Example 1, and its pH was finally adjusted to 7.2.

[0036] In the application process step (3) of the biological carrier, the final concentration of the biological carrier dry powder organism is 8g / L, and the treatment time is 6 hours; the remaining operations are the same as in Example 1.

Embodiment 3

[0038] A biological carrier for strengthening waste water treatment, which comprises the following components: 50 parts of diatomite, 9 parts of fly ash, 10 parts of dolomite, and 30 parts of illite.

[0039] The preparation method of the biocarrier was the same as in Example 1, and its pH was finally adjusted to 7.

[0040] In the application process step (3) of the biological carrier, the final concentration of the biological carrier dry powder organism is 10g / L, and the treatment time is 6 hours; the remaining operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com