Flue gas desulfurizing agent as well as preparation method and application thereof

A desulfurizer and flue gas technology, applied in the field of flue gas purification, can solve the problems of easy pulverization, poor crush resistance, low strength of calcium-based desulfurizer, etc., and achieves high porosity and high radial crush resistance. , the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

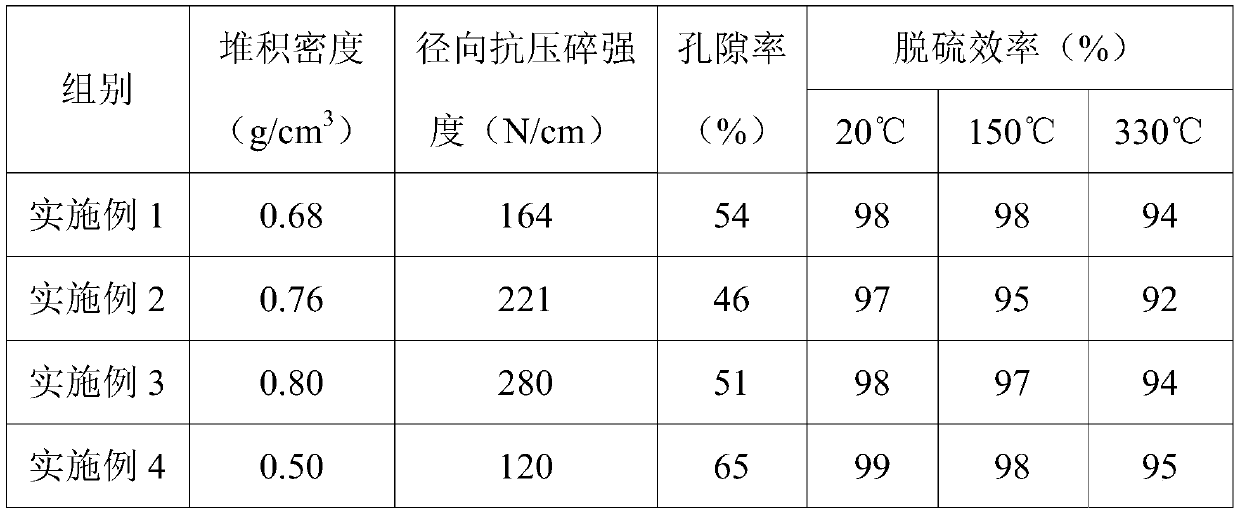

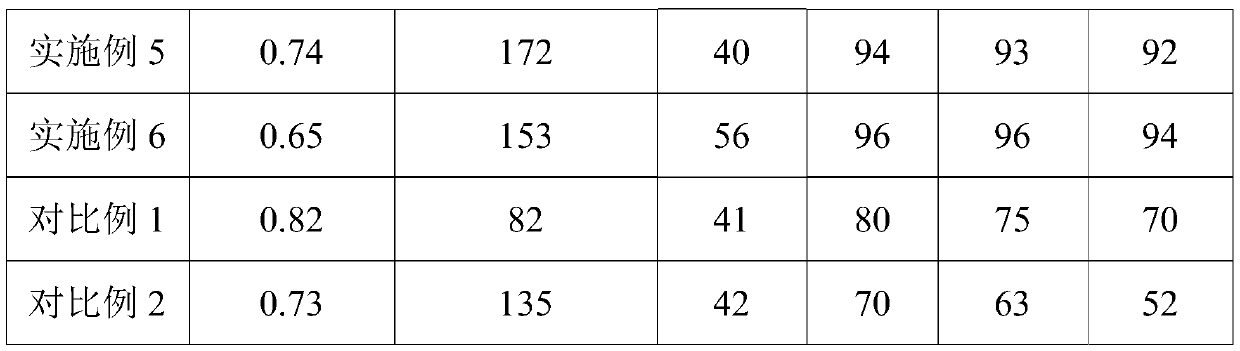

Examples

Embodiment 1

[0033] A flue gas desulfurizer, the raw materials of which are as follows: 30 kg of slaked lime powder, 20 kg of silica fume, 2 kg of cement, 2 kg of kaolinite, 2 kg of montmorillonite, 3 kg of sodium sulfate decahydrate, and 3 kg of calcium chloride dihydrate.

[0034] The preparation method of this flue gas desulfurizer is as follows:

[0035] Put all the above-mentioned raw materials into the mixing equipment and mix them evenly to obtain the mixed powder;

[0036] Add 30% water of the weight of the mixed powder to the mixed powder, seal and stir in the mixing equipment for 20 minutes, and extrude with hydraulic equipment to obtain the molding material;

[0037] Place the molding material in a sealed incubator at 50°C for 14 hours;

[0038] The molded material is taken out from the sealed incubator and roasted at 300°C for 2 hours, taken out and aired to room temperature to obtain a finished granular flue gas desulfurizer with a particle size of 6-8mm.

Embodiment 2

[0040] A flue gas desulfurizer, the raw materials of which are as follows: slaked lime powder 40kg, silica fume 40kg, cement 9kg, illite 10kg, chlorite 5kg, sodium carbonate decahydrate 15kg.

[0041] The preparation method of this flue gas desulfurizer is as follows:

[0042] Put all the above-mentioned raw materials into the mixing equipment and mix them evenly to obtain the mixed powder;

[0043] Add water with 50% of the weight of the mixed powder to the mixed powder, seal and stir in the mixing equipment for 30 minutes, and extrude with hydraulic equipment to obtain the molding material;

[0044] Put the molding material in a sealed incubator at 30°C for 20 hours;

[0045] The molded material is taken out from the sealed incubator and roasted at 200°C for 6 hours, taken out and aired to room temperature to obtain a cylindrical strip-shaped flue gas desulfurizer product with a diameter of 6-8mm.

Embodiment 3

[0047] A flue gas desulfurizer, the raw materials of which are as follows: 60 kg of slaked lime powder, 60 kg of silica fume, 5 kg of cement, 10 kg of kaolinite, 5 kg of ferrous sulfate heptahydrate, and 5 kg of potassium carbonate trihydrate.

[0048] The preparation method of this flue gas desulfurizer is as follows:

[0049] Put all the above-mentioned raw materials into the mixing equipment and mix them evenly to obtain the mixed powder;

[0050] Add water with 60% of the weight of the mixed powder to the mixed powder, seal and stir in the mixing equipment for 10 minutes, and extrude with hydraulic equipment to obtain the molding material;

[0051] Put the molding material in a sealed incubator at 100°C for 4 hours;

[0052] The molding material is taken out from the sealed incubator and baked at 300° C. for 4 hours, taken out and aired to room temperature to obtain a four-leaf clover strip-shaped flue gas desulfurizer product with a diameter of 6-8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com