Patents

Literature

79 results about "Pozzolanic reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

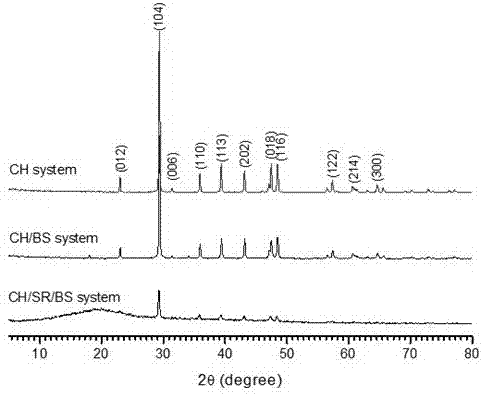

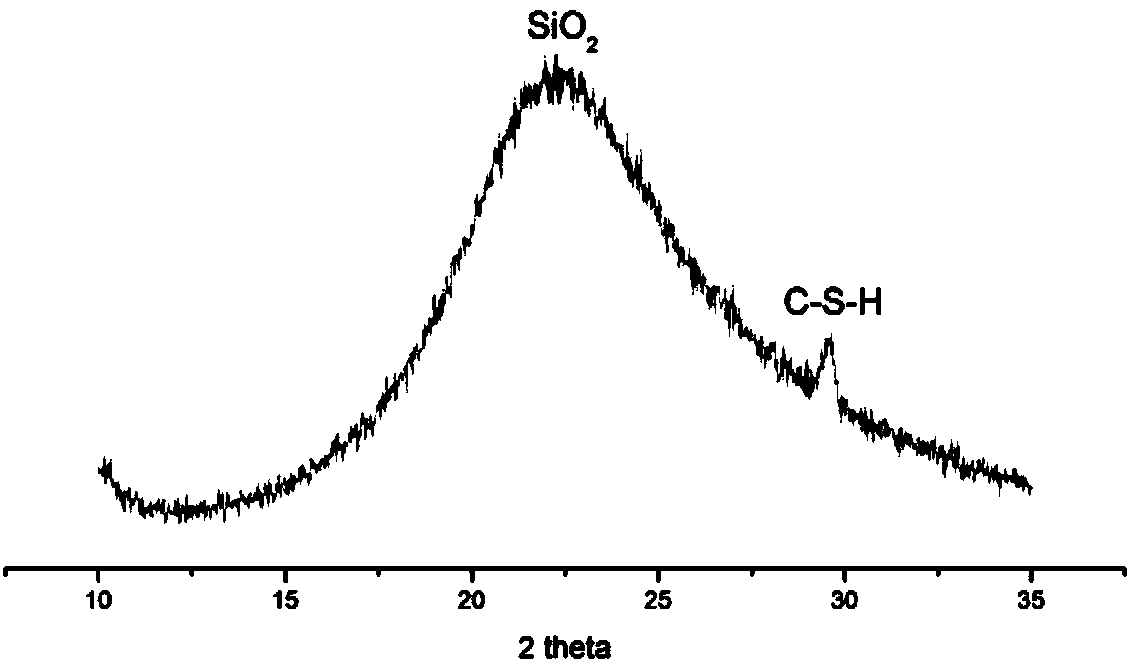

The pozzolanic reaction is the chemical reaction that occurs in portland cement containing pozzolans. It is the main reaction involved in the Roman concrete invented in Ancient Rome and used to build, for example, the Pantheon. At the basis of the pozzolanic reaction stands a simple acid-base reaction between calcium hydroxide, also known as Portlandite, or, and silicic acid. Simply, this reaction can be schematically represented as follows: Ca(OH)₂ + H₄SiO₄ → Ca²⁺ + H₂SiO₄²⁻ + 2 H₂O → CaH₂SiO₄ · 2 H₂O or summarized in abbreviated notation of cement chemists: CH + SH → C-S-H The product of general formula formed is a calcium silicate hydrate, also abbreviated as C-S-H in cement chemist notation, the hyphenation denotes the variable stoichiometry. The ratio Ca/Si, or C/S, and the number of water molecules can vary and the above-mentioned stoichiometry may differ. Many pozzolans contain aluminate, or Al(OH)₄⁻, that will react with calcium hydroxide and water to form calcium aluminate hydrates such as C₄AH₁₃, C₃AH₆ or hydrogarnet, or in combination with silica C₂ASH₈ or strätlingite.

Binder admixture, kaolin product and their manufacture

InactiveUS20050000393A1Improve propertiesImprove the mixing effectClaywaresSolid waste managementFrostKaolin clay

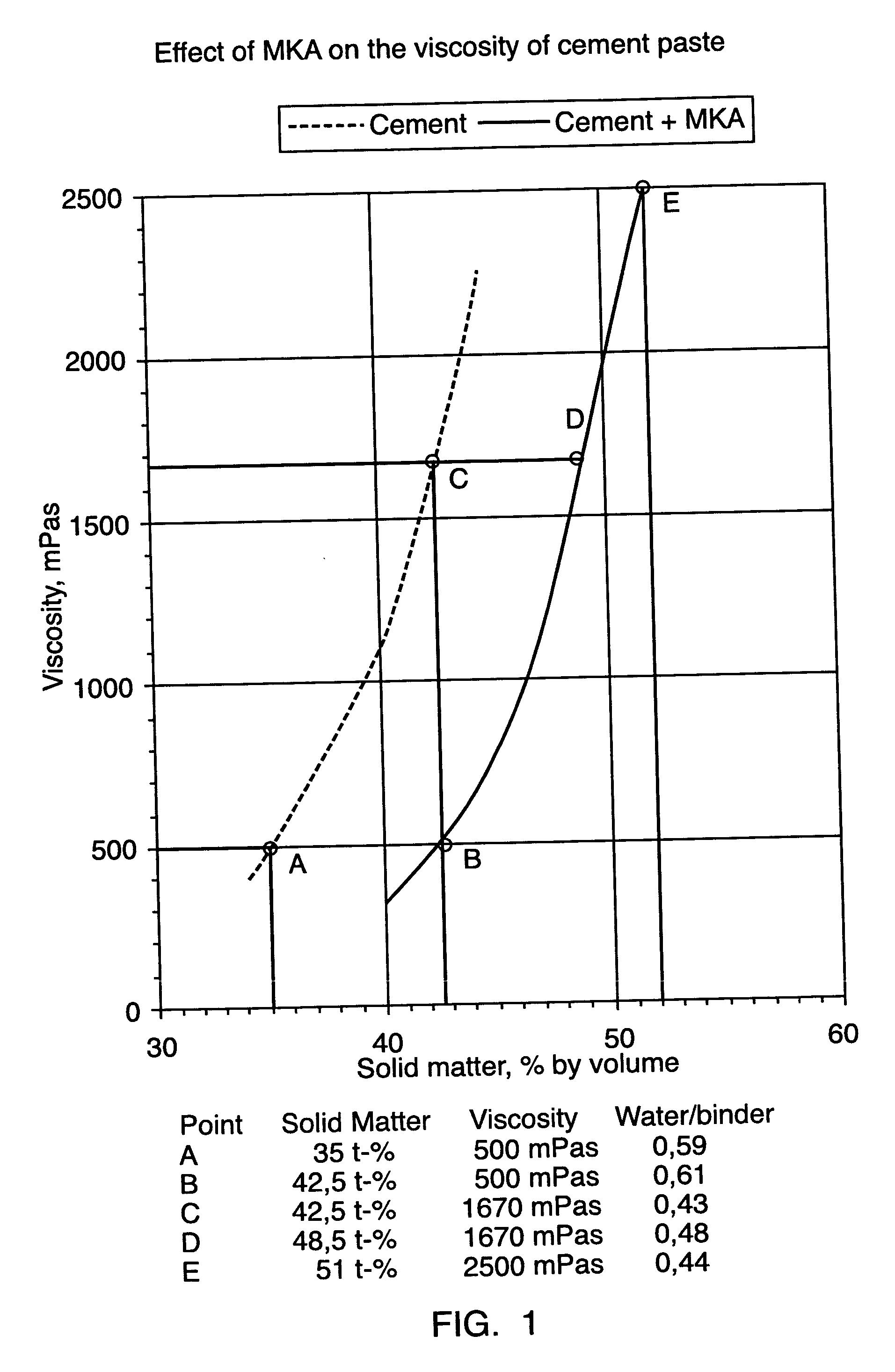

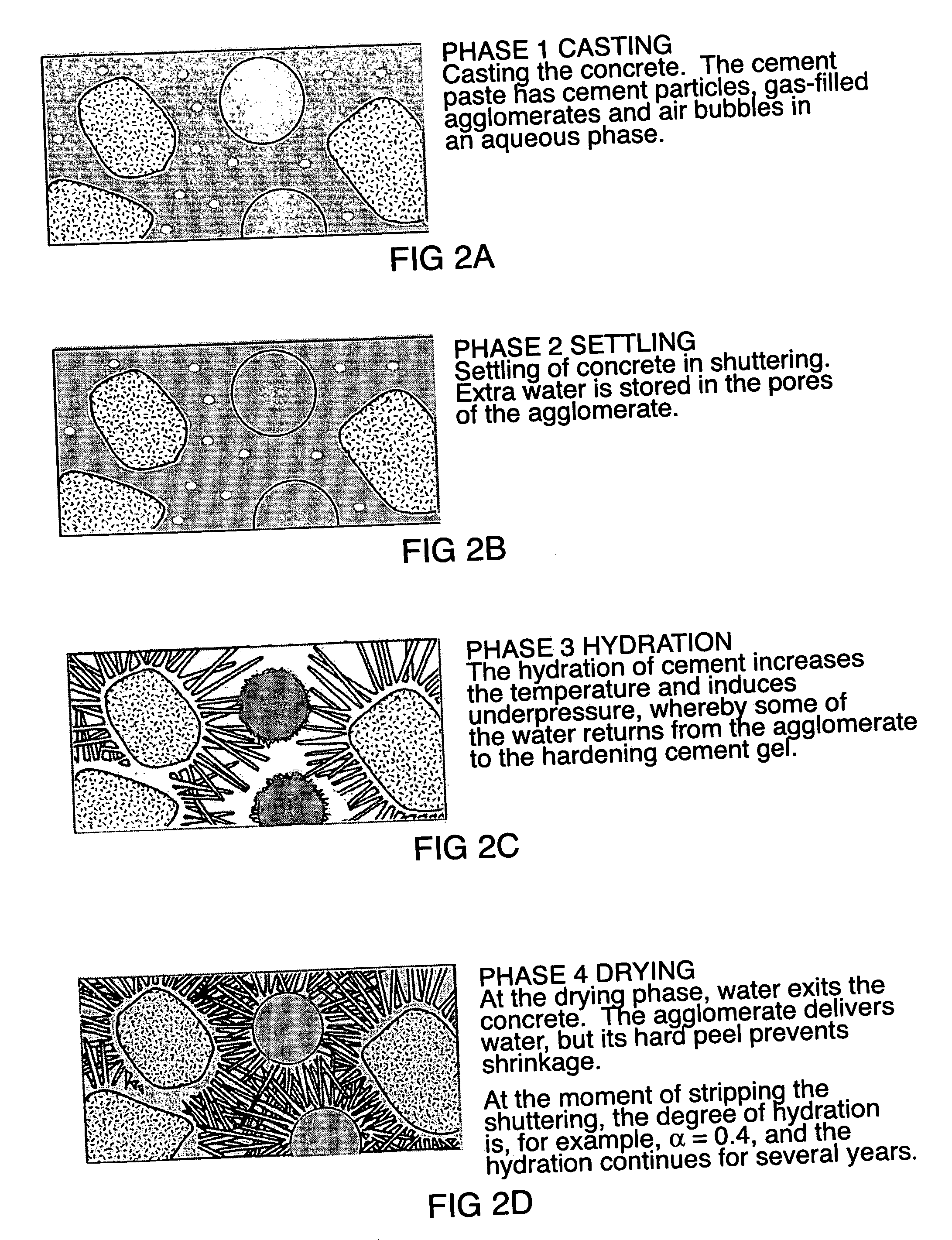

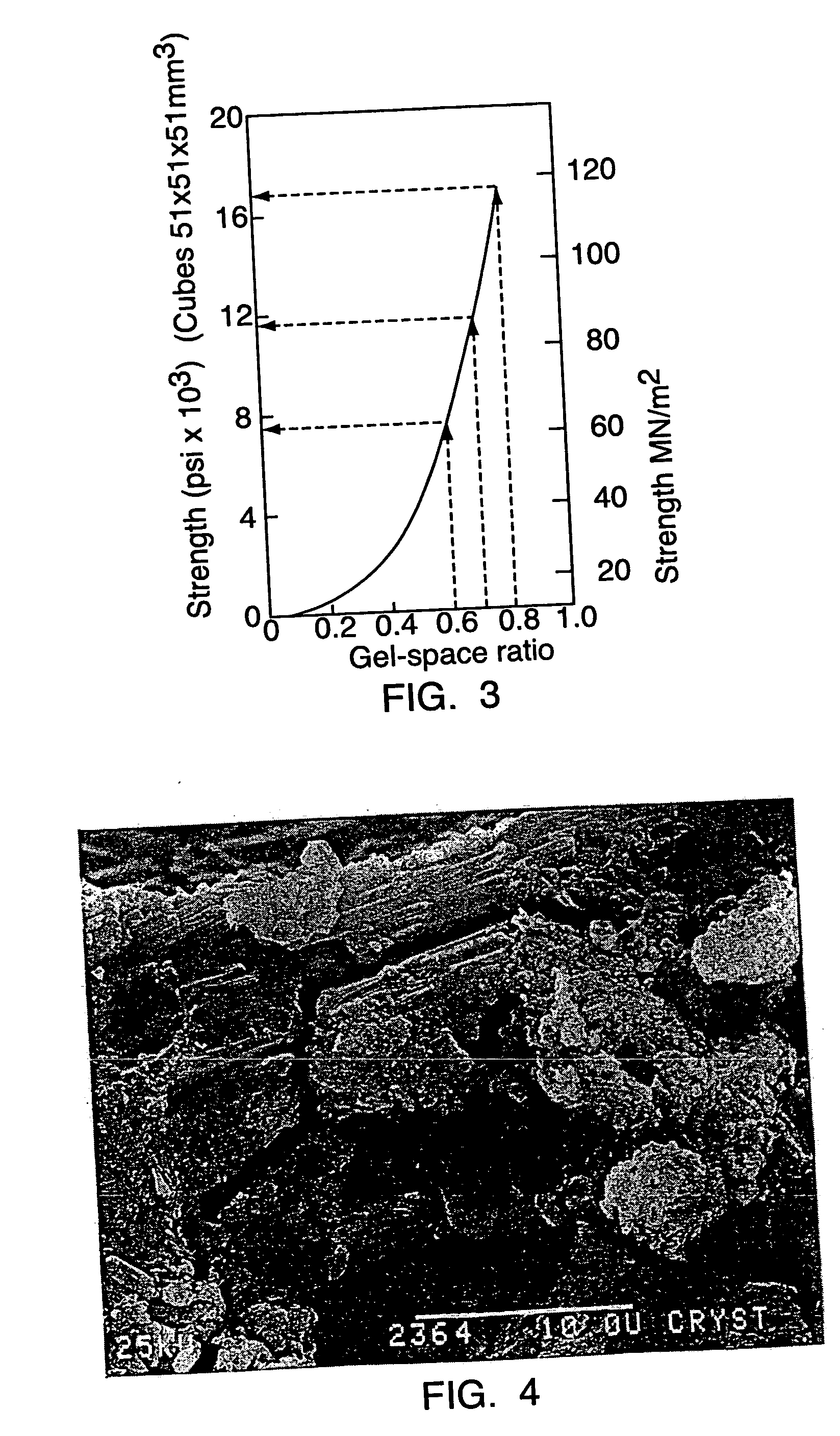

A binder mix containing a hydraulic binding agent and an admixture mixed therewith, a process for preparing a hydraulically hardened binder mass, a calcinated kaolin product and a process for preparing the same. A paste-like composition is formed from the hydraulically hardening binding agent, a pozzolanically reacting admixture and water, which, when so desired, contains stone aggregate or similar filler, the paste-like composition is worked and the worked composition is allowed to harden to form the binder mass. The admixture comprises spherical, porous metakaolin agglomerates, the size of which is 2-200 microns and which have an open pore structure. The invention can be used to improve the manufacturing methods of cast concrete products and shorten the manufacturing times, and to provide concrete with better mechanical and chemical properties, as well as improve the fire and frost resistance of concrete.

Owner:NORDKALK AB

High-performance historic site repair material and preparation method thereof

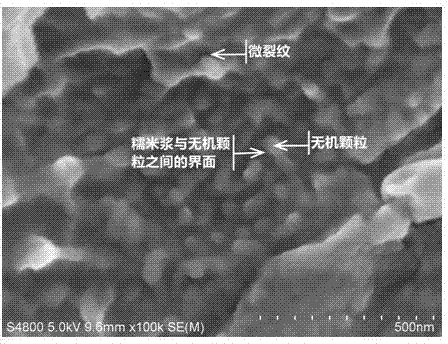

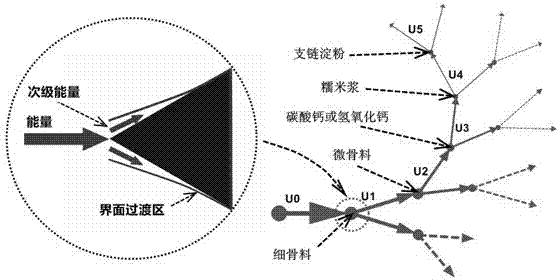

The invention provides a high-performance historic site repair material and a preparation method thereof. The repair material comprises the following raw materials: 191-287 parts of sticky rice pulp, 115-185 parts of lime, 0-4 parts of brown granulated sugar, 344-398 parts of fine aggregates, 204-268 parts of complex mineral admixture, 11-12 parts of reinforcing agent, and 0-19 parts of mineral pigment. The invention further provides a preparation method of the repair material. The preparation method comprises the following steps: weighing all the raw material according to weight, and forcibly stirring evenly to obtain the repair material. Amylopectin in the sticky rice pulp is a highly branched macromolecule, the setting and hardening processes of the lime and the pozzolanic reaction of the complex mineral admixture are influenced, the strength development of the material is similar to biomineralization process, and a microstructure formed in the process endows the repair material with higher strength and toughness. Furthermore, the material has good compatibility with materials of a historic site body.

Owner:WUHAN UNIV

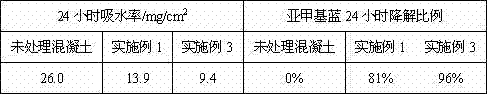

In-situ reaction type concrete protective agent

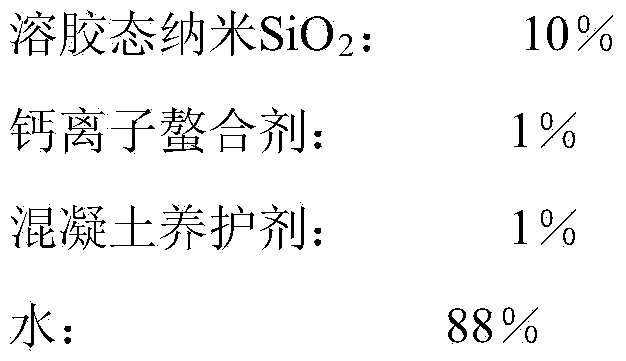

The invention relates to an in-situ reaction type concrete protective agent, belongs to the technical field of building materials, and specifically relates to a hardened concrete surface protective agent prepared by using a sol-state nano SiO2 or a precursor thereof. Raw materials of the concrete protective agent provided by the invention comprises the sol-state nano SiO2 or the precursor thereof, a calcium ion chelating agent, a concrete curing agent and water. A ratio of the above components is 10-40% : 1-5% : 1-5% : 50-88%. A concrete surface structure is compacted and an object for protecting the concrete can be achieved by utilizing the properties that the sol-state ultrafine particles of protective raw materials and a precursor solution can easily permeate into pores and tiny cracks of the hardened concrete surface and generate an in-situ pozzolanic reaction under an alkali environmental condition of the hardened concrete surface pores. The protective agent provided by the invention has the characteristics of small raw material components, convenient construction and the like, and can be widely applied in protection for the hardened concrete surface in different ages.

Owner:UNIV OF JINAN

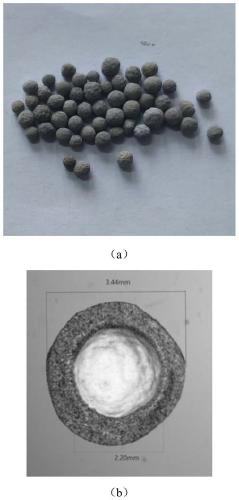

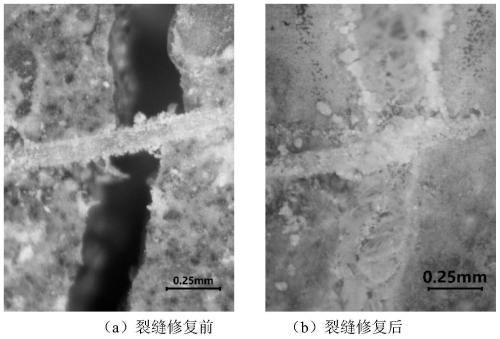

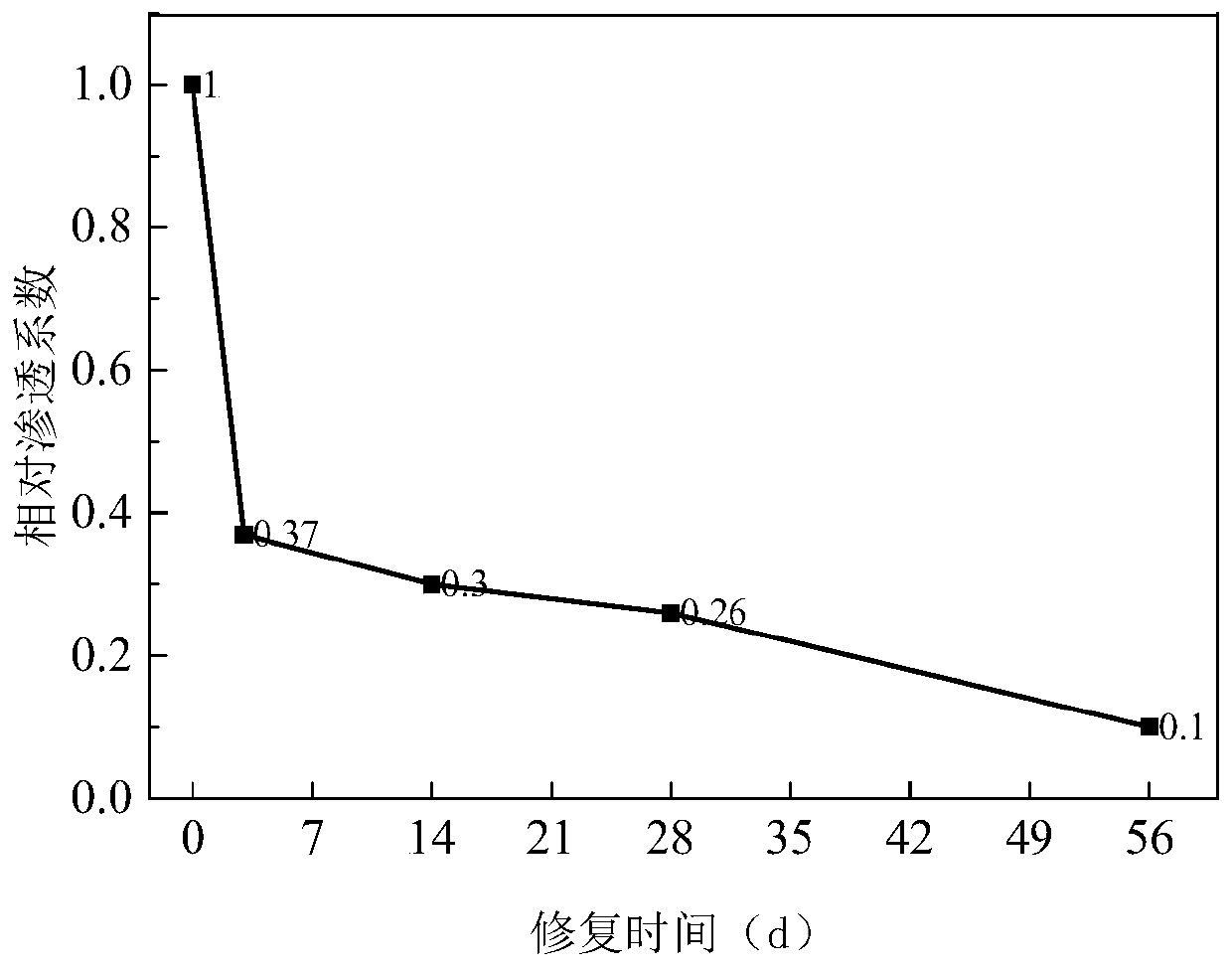

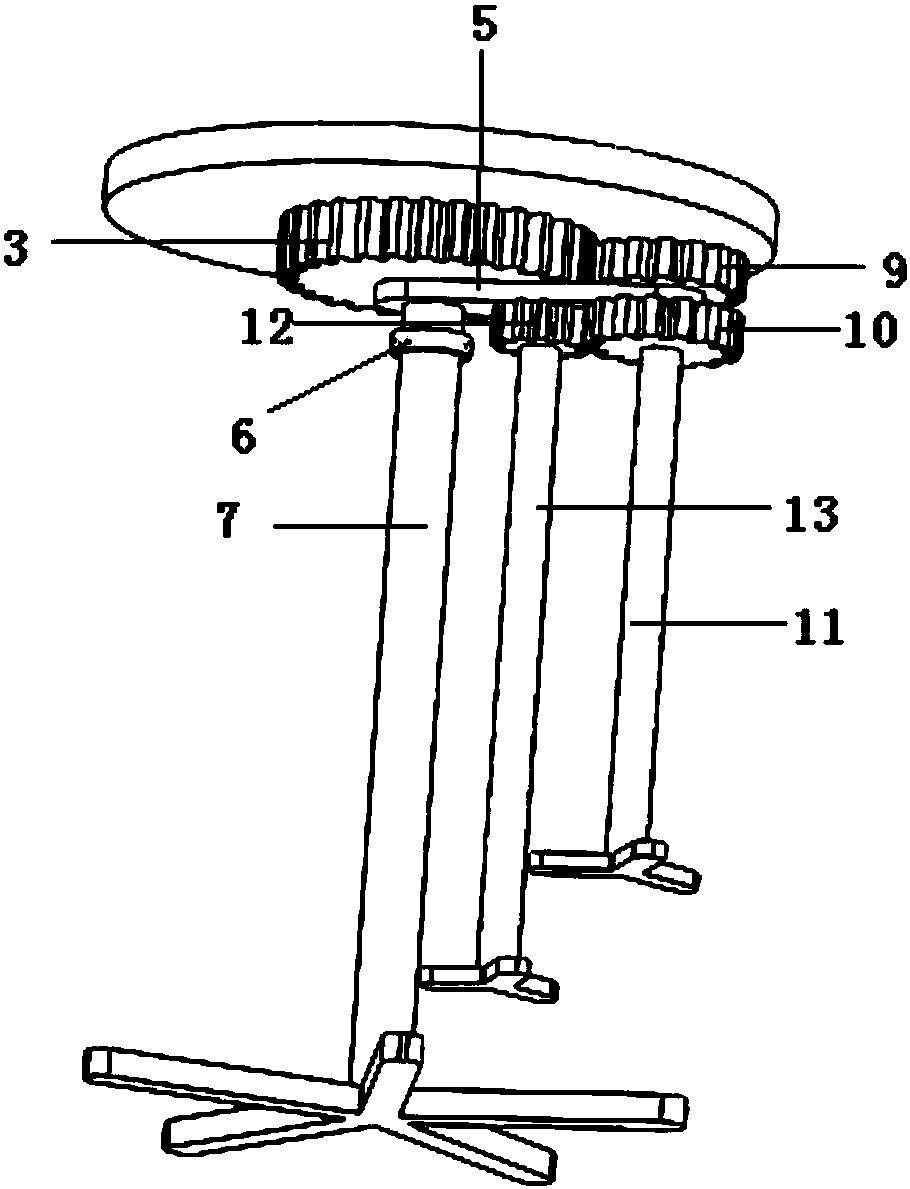

Active multifunctional carrier for microorganism self-repairing concrete and preparation method thereof

ActiveCN111116077APromotes self-healingImprove self-healing abilityMicroballoon preparationMicrocapsule preparationCalcium hydroxideMicroorganism

The invention discloses an active multifunctional carrier for microbial self-repairing concrete and a preparation method thereof. The active multifunctional carrier is composed of a granulation mothernucleus, an internal functional component and an outer protective wall material, wherein the internal functional component comprises a carbonate slow-release component, a volcanic ash active component, an inert filler component and a microbial powder component. The carrier is prepared by a powder granulation technology. The functions of microorganism protection, carbonate slow release and volcanic ash reaction are integrated; firstly, microorganisms are well protected against survival in a harsh concrete internal environment; and secondly, when the crack triggers the carrier to crack, carbonate radicals can be slowly released to compensate the deficiency of carbonate radical formation capability induced by microorganisms in cracks, and meanwhile, the active components in the carrier can be subjected to a pozzolanic reaction with calcium hydroxide dissolved out of the cracks to form C-S-H gel with a gelling effect, so that the self-repairing effect of the cracks is improved through theinterlacing effect of multiple repairing products, and good anti-permeability and mechanical property recovery are achieved.

Owner:YANGZHOU UNIV

Artificial stone and manufacturing method thereof

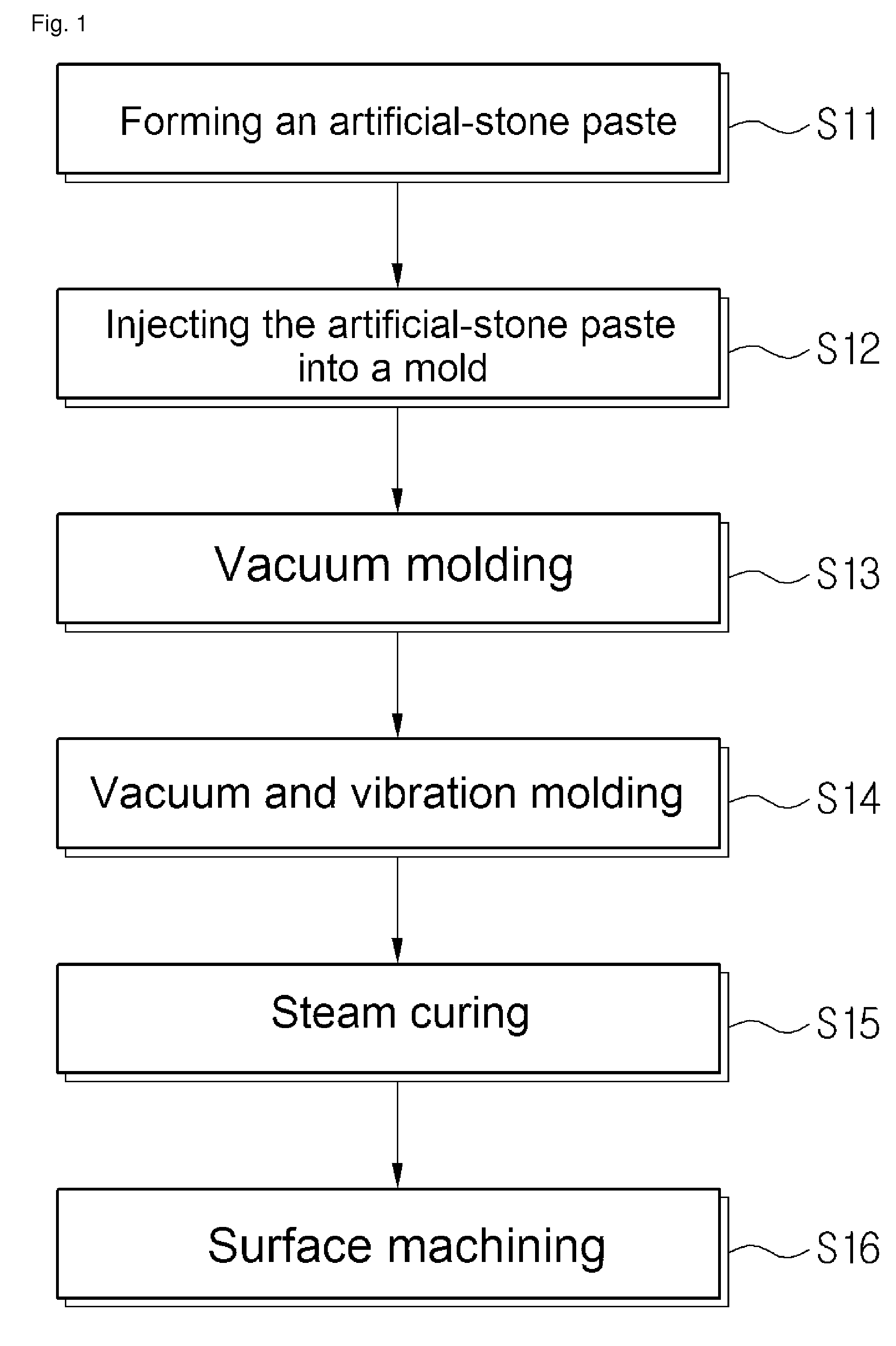

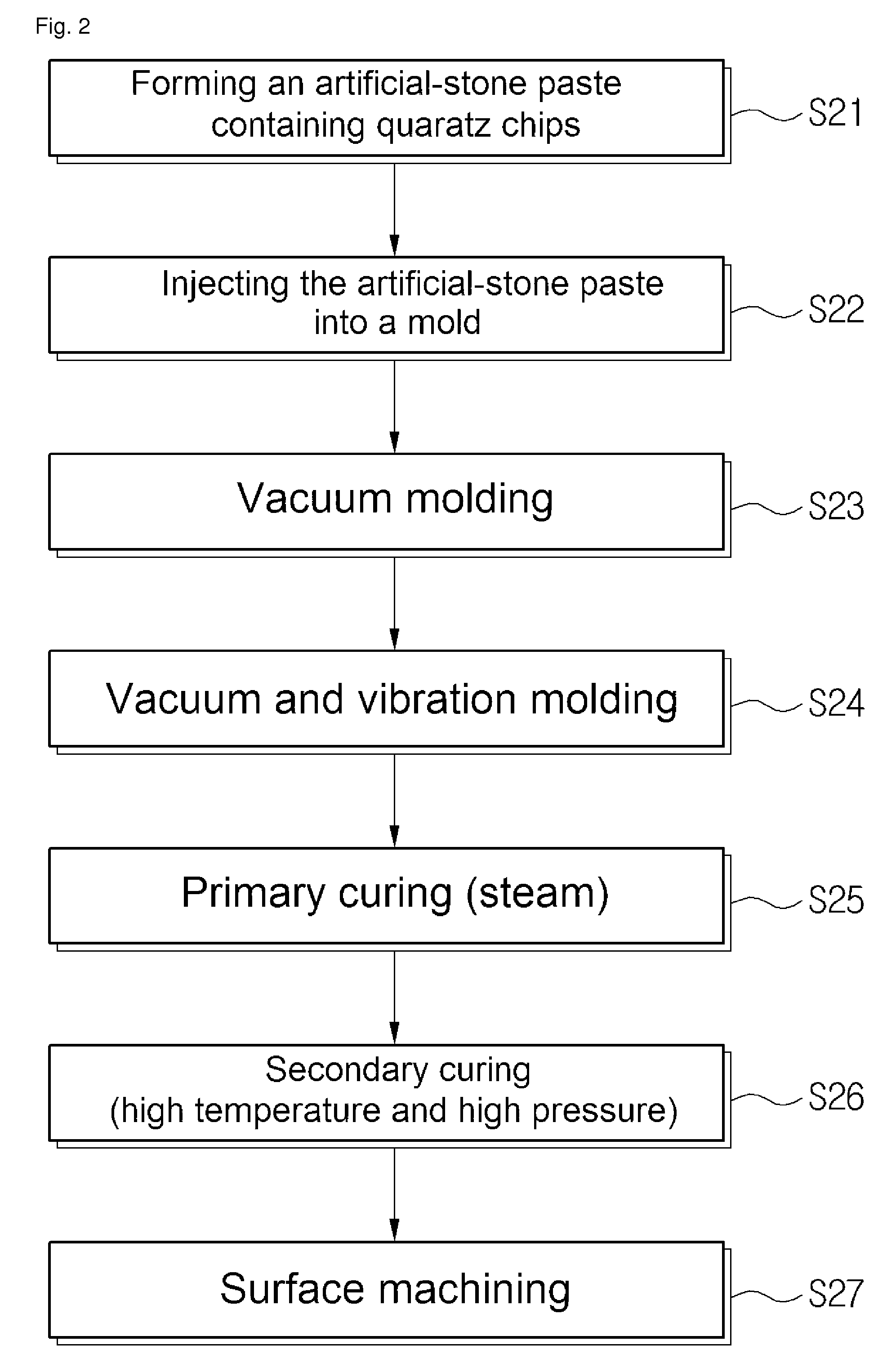

InactiveUS20130284072A1Improve cohesionAvoid separationSolid waste managementSpecial ornamental structuresArtificial stoneGypsum

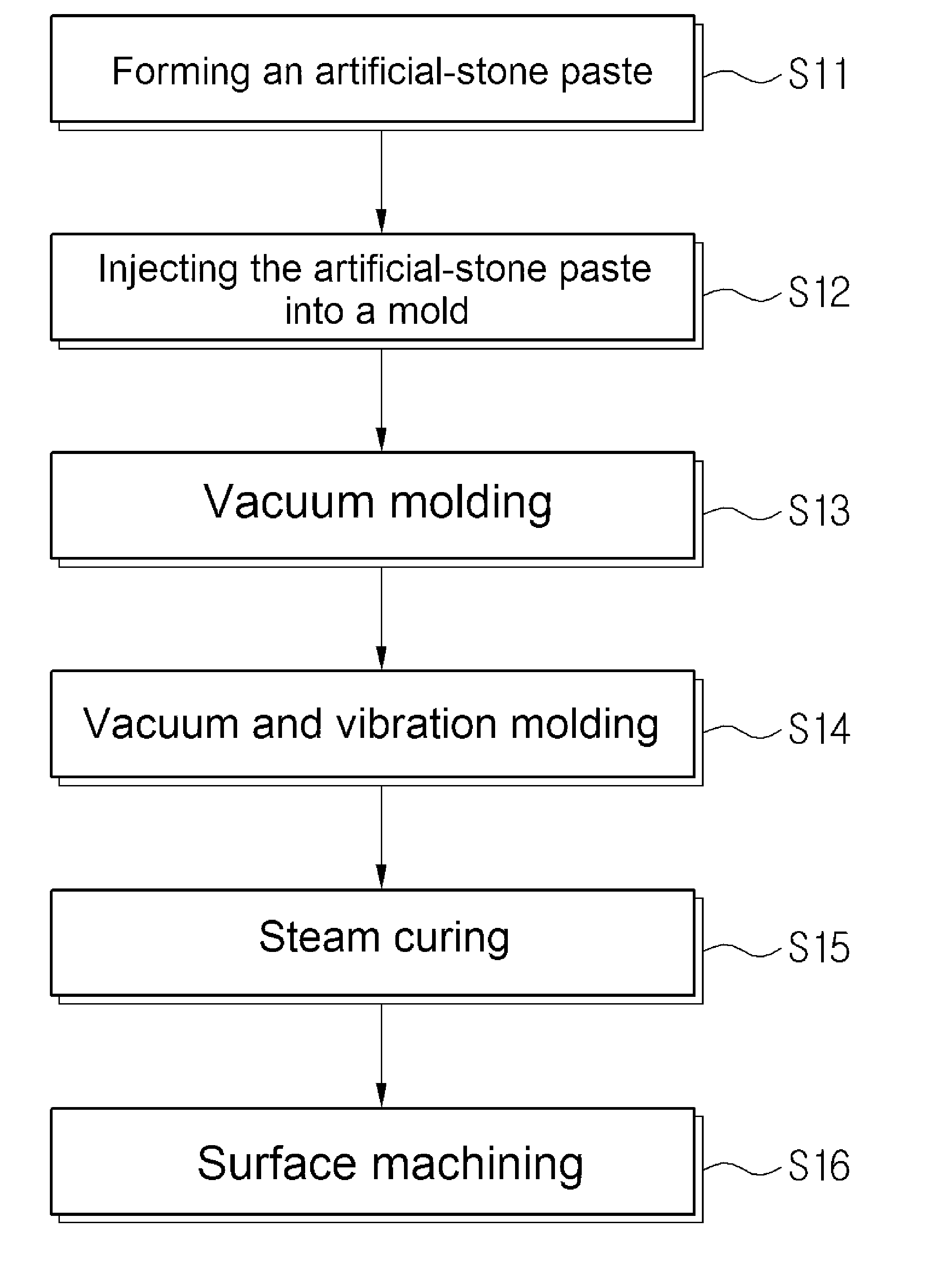

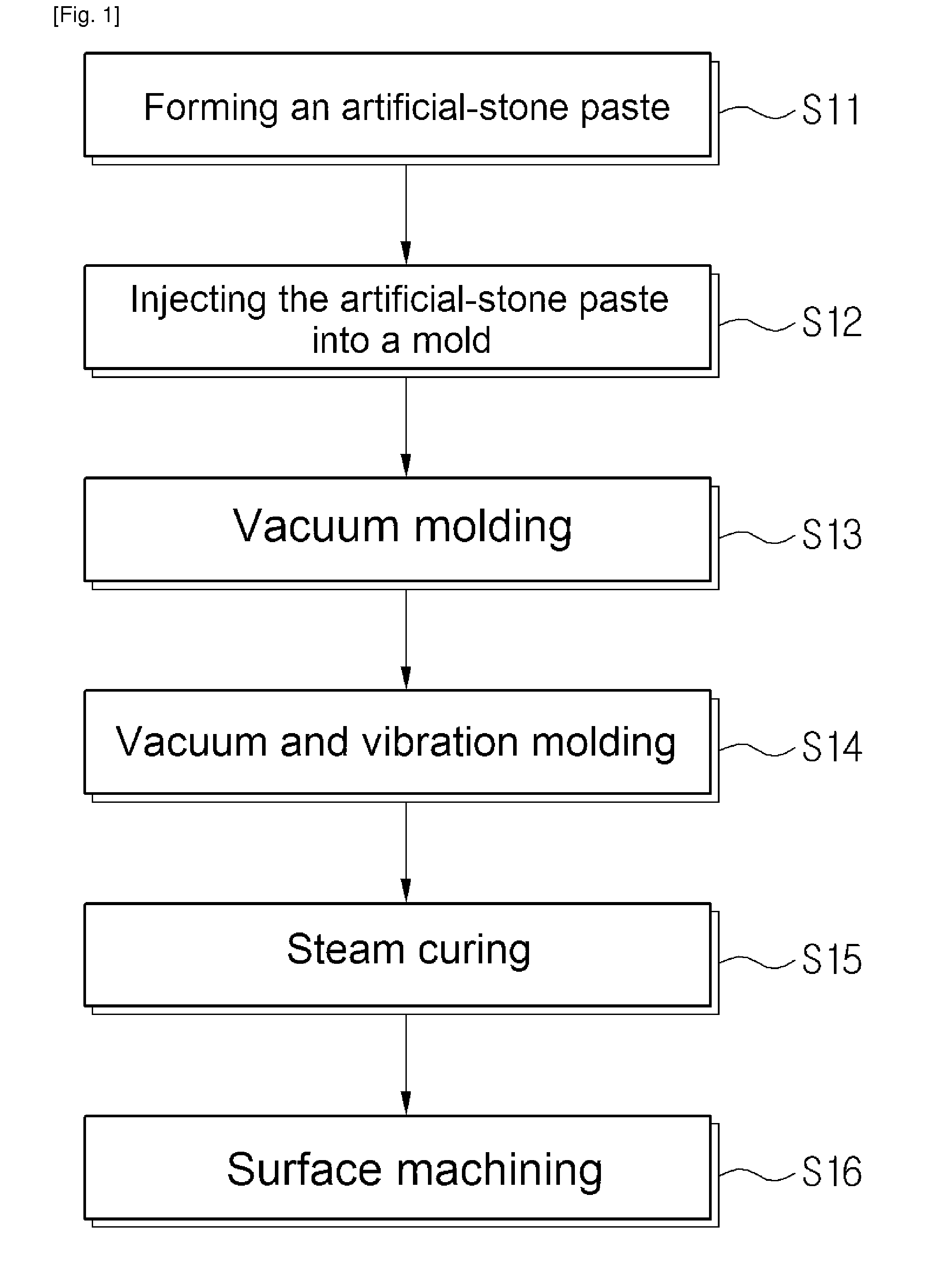

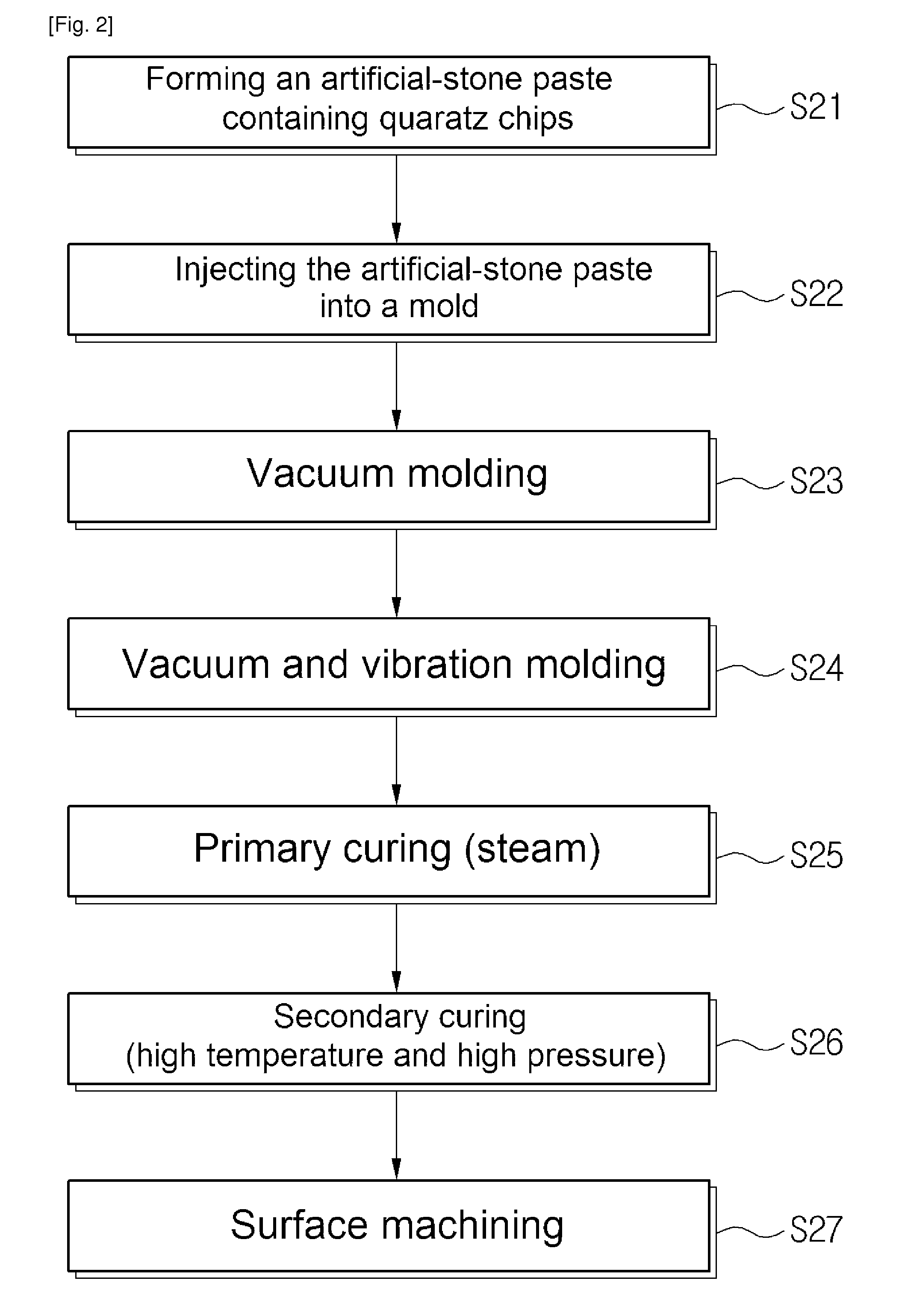

Disclosed is a method of manufacturing an artificial stone, and the method includes forming an artificial-stone paste which comprises 20-20 parts by weight of silica stone, metakaolim or silica fume, 200-300 parts by weight of quartz chips, 30-36 parts by weight if water, 1.5-3 part by weight of water-reducing agent and 0.2-3 parts by weight of pigment with response to 100 parts by weight of white cement; injecting the artificial-stone paste in a mold; primarily vacuum-molding the artificial-stone paste injected in the mold; secondarily vibration-molding the primarily molded artificial-stone paste; primarily curing the secondarily molded artificial-stone paste; secondarily curing the primarily cured artificial-stone paste, which induces a hydrothermal reaction and thus causes a pozzolanic reaction; releasing the secondarily cured artificial-stone paste from the mold; and surface-machining the released artificial-stone paste.

Owner:LG HAUSYS LTD

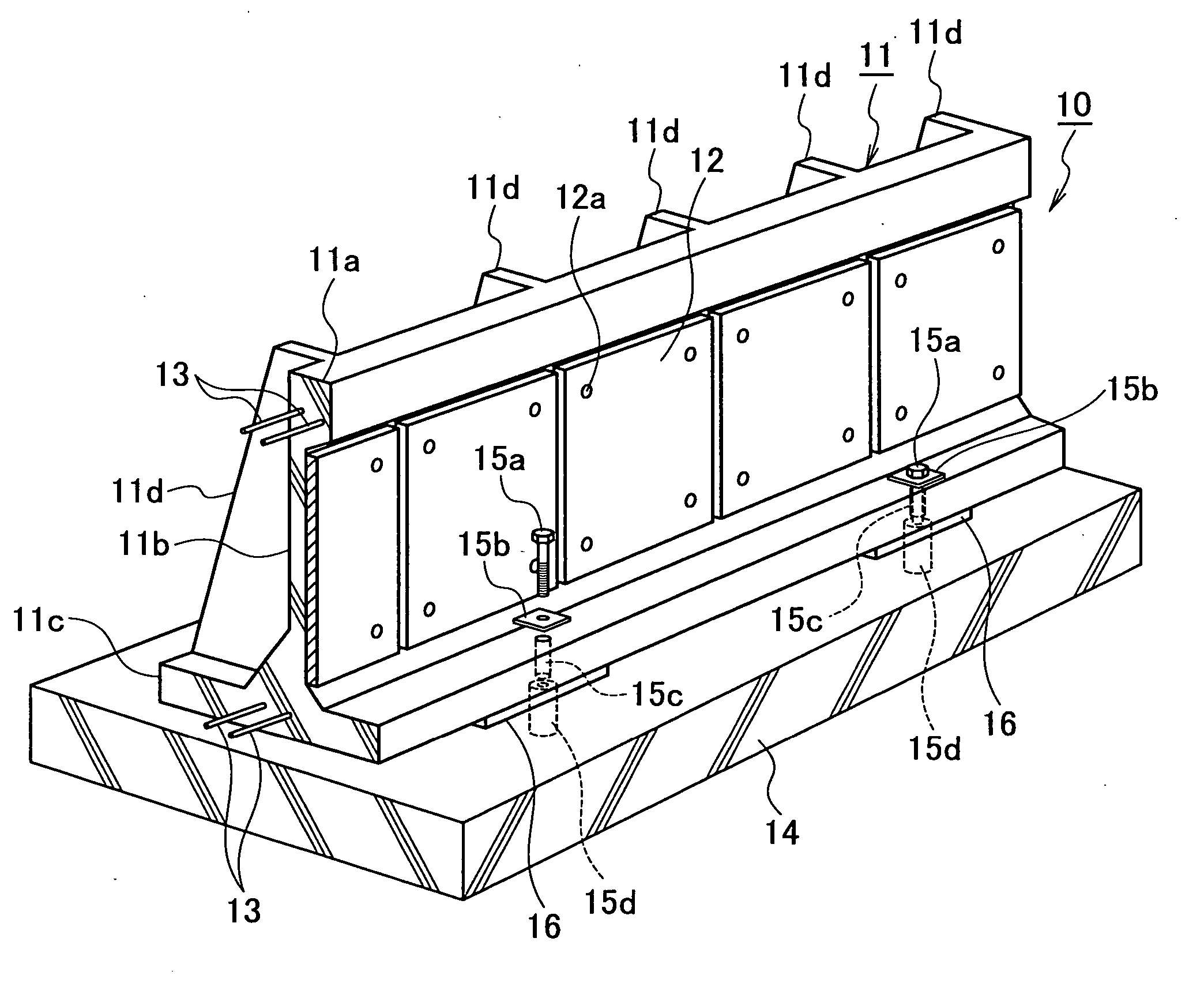

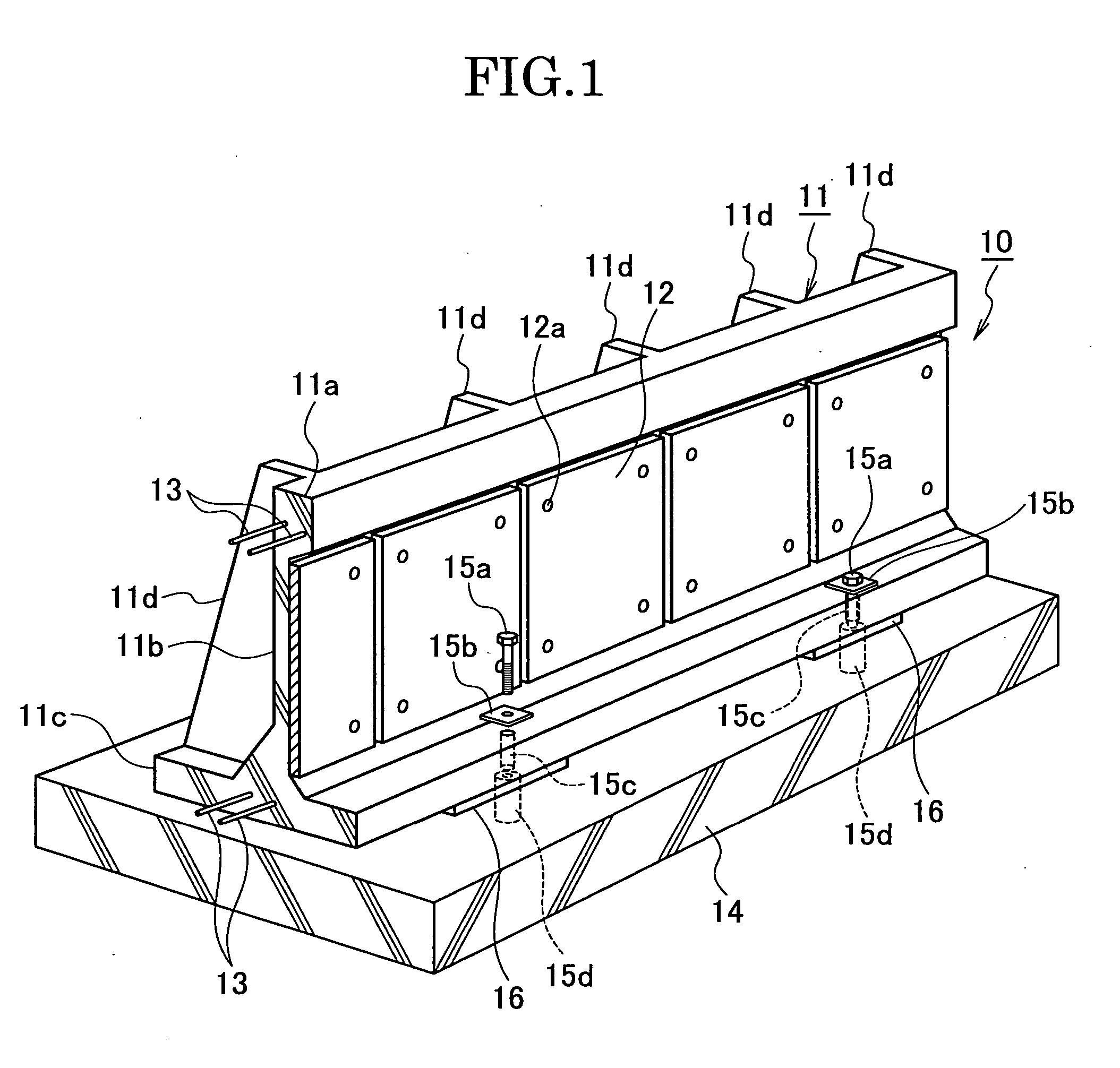

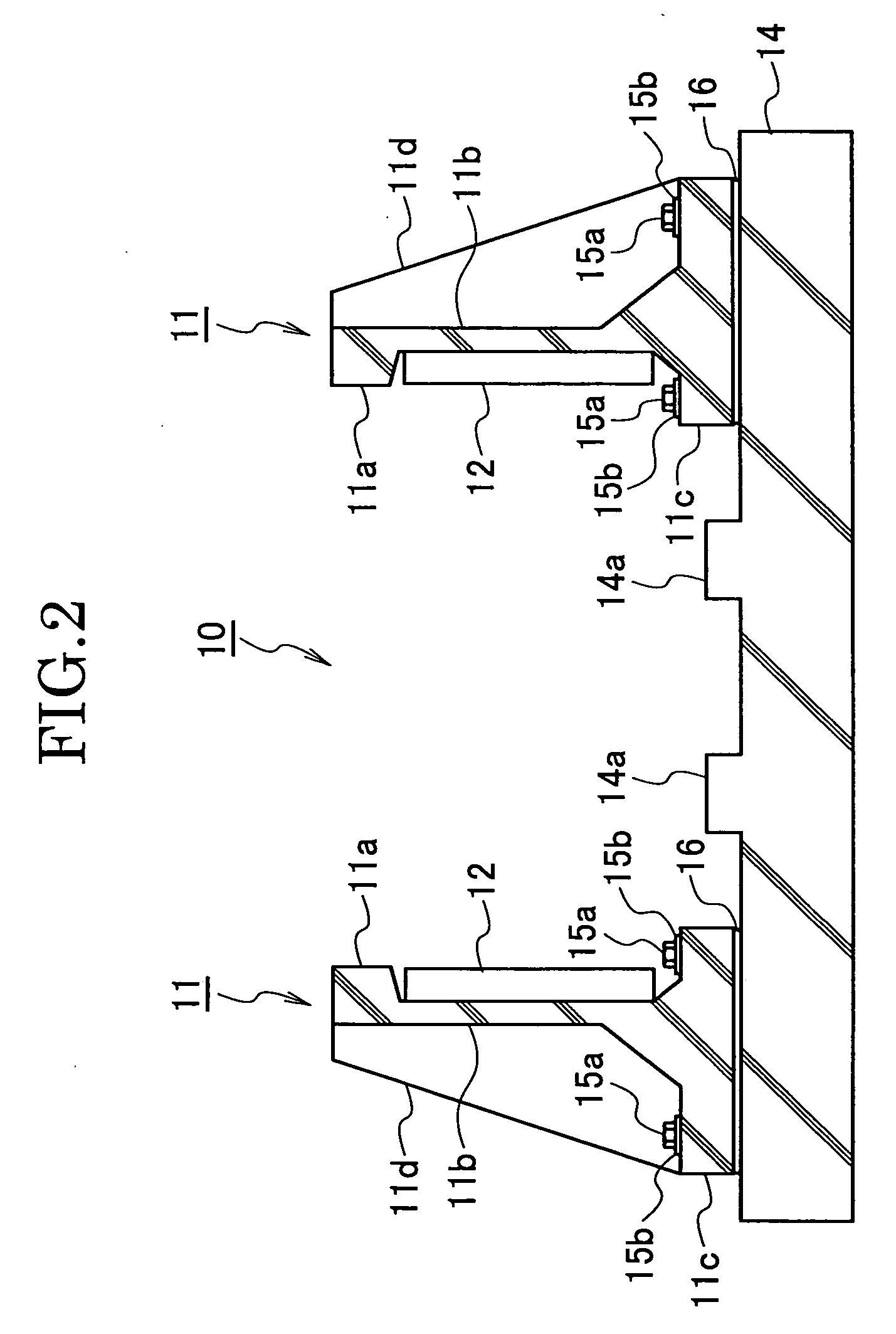

Non-magnetic concrete structure a sidewall for a guideway and a method for installing such a sidewall for the guideway

ActiveUS20070079732A1Small magnetic permeabilityThin thicknessSolid waste managementRailway vehiclesPlasticizerMetal fibers

A non-magnetic concrete structure having no magnetism or a very small magnetic permeability without reinforcing steel bars arranged, a sidewall for a guideway, and a method for installing the sidewall for the guideway are provided. The reinforcing steel bars-free sidewall 11 for the guideway 10 is constructed by using a non-magnetic concrete structure constructed by using a fiber-reinforced cement-based mixed material and having no reinforcing steel bars therein. The fiber-reinforced cement-based mixed material is produced by mixing non-metallic fibers or non-magnetic metal fibers into a cement-based matrix in a mixing amount of 1 to 4% for an entire volume of the cement-based matrix. The cement-based matrix is obtained by mixing a composition with water. The above composition is composed of cement, aggregate grains having a maximum grain diameter of not more than 2.5 mm, pozzolanic reaction particles having particle diameters of not more than 15 μm and supper plasticizer. The fiber-reinforced cement-based mixed material has mechanical properties: a compressive strength of not less than 150 N / mm2 and a tensile strength of not less than 5 N / mm2.

Owner:TAISEI CORP

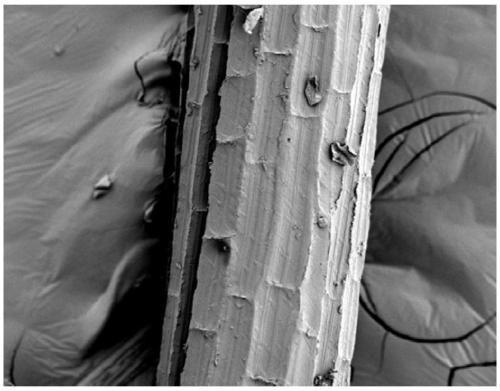

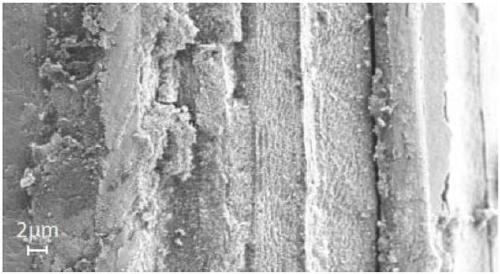

Method for preparing silica nanoparticle-graphene oxide-plant fiber compound

The invention belongs to the technical field of building materials, and discloses a method for preparing a silica nanoparticle-graphene oxide-plant fiber compound. The method comprises the following steps of 1, pretreating natural plant fibers; 2, preparing a graphene oxide dispersion liquid; 3, preparing a silica nanoparticle-graphene oxide dispersion liquid; 4, immersing plant fibers into the silica nanoparticle-graphene oxide dispersion liquid with a certain concentration, and taking out and drying the plant fibers after full and thorough immersion. Silica nanoparticles coating the surfacesof the plant fibers of the compound and a hydrated product calcium hydroxide have a pozzolanic reaction, the alkalinity of a cement matrix can be reduced, and the erosion to the plant fibers is reduced accordingly; generated hydrated calcium silicate can improve the adhesion of the plant fibers and a cement matrix interface, the adhesion strength of the adhesion between the plant fibers and the cement matrix interface can also be improved through a reaction between reactive functional groups of graphene oxide and the hydrated product, and the compound has great application prospects in the aspect of toughening crack-resistant cement-based materials.

Owner:CHANGZHOU INST OF TECH

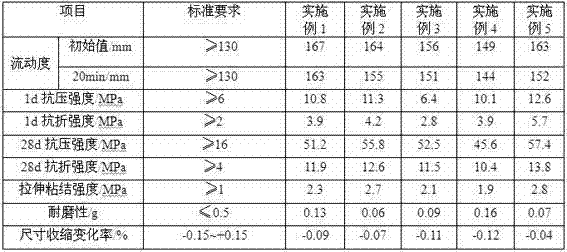

Environment-friendly high-strength wear-resistant self-leveling mortar

Owner:JIANGXI BEIRONG CIRCULAR MATERIALS CO LTD

Magnesium sulphoaluminate cement

The invention discloses magnesium sulphoaluminate cement, which is characterized by comprising the following raw materials in parts by weight: 90-110 parts of light burned magnesium oxide, 45-55 parts of composite sulfate, 25-30 parts of active aluminum sesquioxide, 30-35 parts of active silicon dioxide, 1.0-1.7 pats of phosphoric acid or phosphate and 65-75 parts of water. The magnesium sulphoaluminate cement has the advantages that: no magnesium chloride participates in reaction; and the defects of scumming, metal corrosion and the like of magnesium oxy-chloride cement are avoided. The magnesium sulphoaluminate cement comprises a pozzolanic material containing the active aluminum sesquioxide and the active silicon dioxide; and since the reaction of pozzolana and the structure of a resultant are stable, the service life of a product is long.

Owner:HUBEI ZHONGBAI TECH

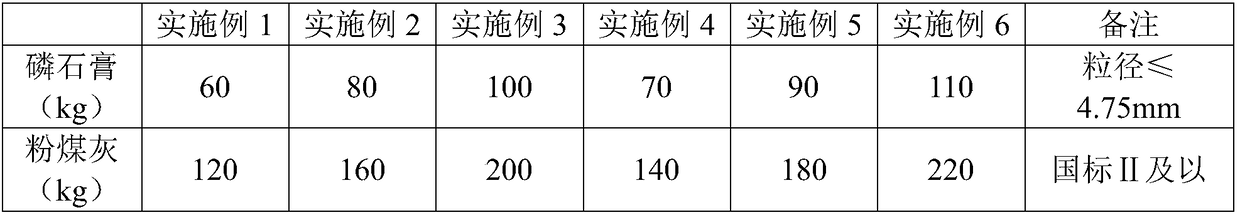

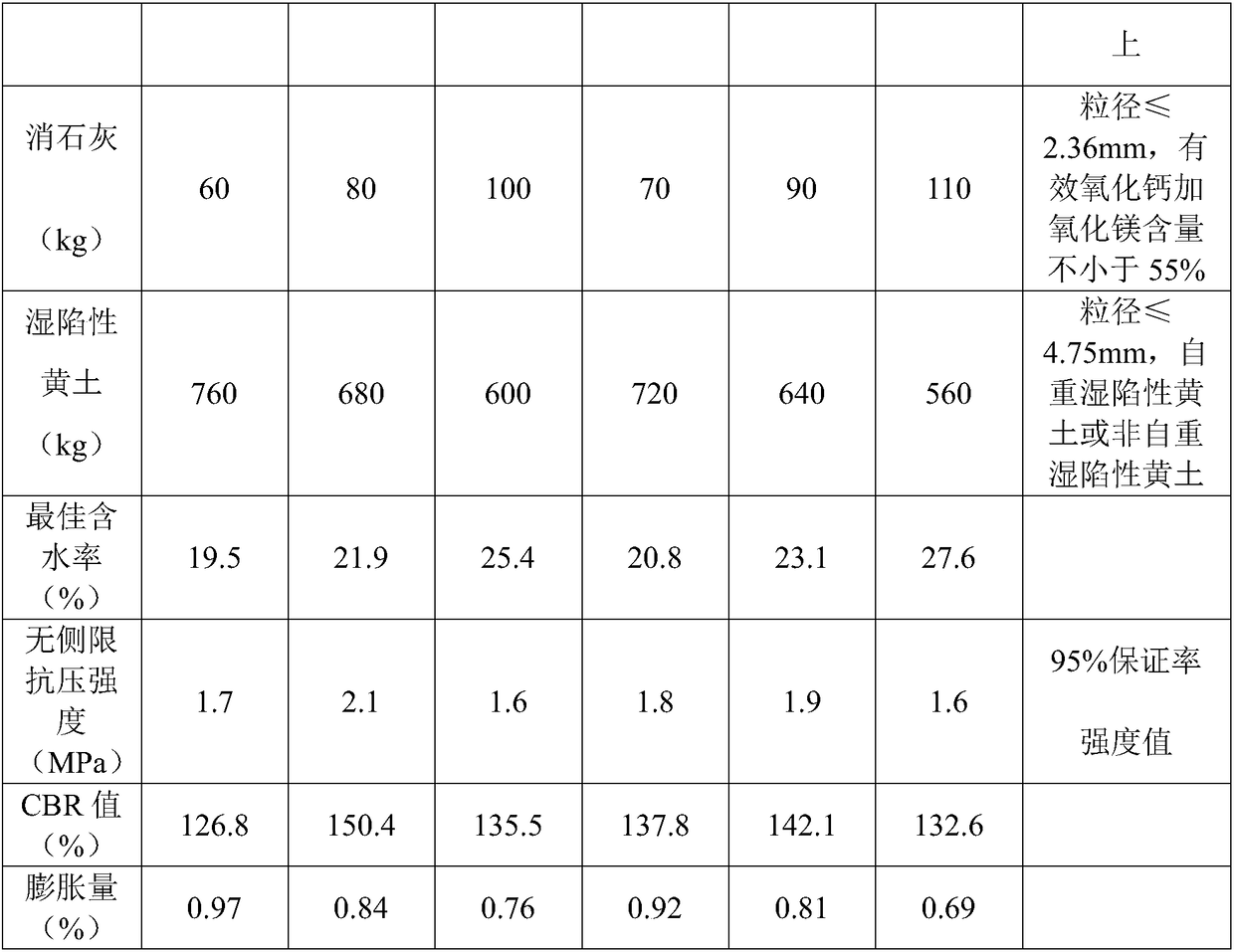

Phosphogypsum stabilized collapsible loess roadbed material and preparation method thereof

InactiveCN108546066ASolve the continuous expansion of stockpileSolve UtilizationCalcium silicatePhosphogypsum

The invention discloses a phosphogypsum stabilized collapsible loess roadbed material and a preparation method thereof. According to the method disclosed by the invention, phosphogypsum is added intoa mixture composed of fly ash, slaked lime and collapsible loess, through addition of the phosphogypsum, main component calcium sulfate contained in the phosphogypsum can activate activity of the inert material fly ash and accelerate a pozzolanic reaction between lime and the fly ash, and needle-shaped ettringite is generated, so that the method has the effect of further enhancing strength of limeand fly ash stabilized collapsible loess, and the loess has higher strength and rigidity and excellent road performance; Ga<2+> contained in the slaked lime and active SiO2 and Al2O3 contained in thefly ash and the collapsible loess act to form water-containing calcium silicate and calcium aluminate, and the water-containing calcium silicate and calcium aluminate are a basis of formation of thelime and fly ash stabilized collapsible loess; and the roadbed material disclosed by the invention has a reasonable formula and the simple preparation method, and the finished product has better strength, rigidity and good road performance, and is suitable for construction of highways in collapsible loess areas.

Owner:CHANGAN UNIV

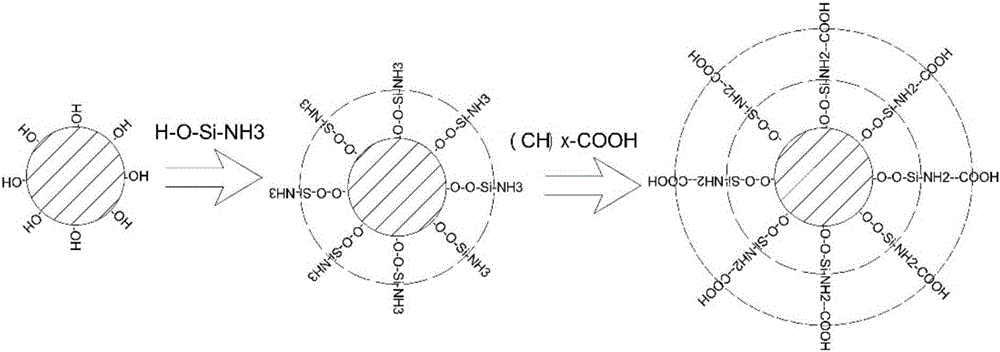

Dispersion and surface treatment method of nano-sized mineral admixture

The invention discloses a dispersion and surface treatment method of a nano-sized mineral admixture. The dispersion and surface treatment method comprises the following steps: (1) fully dispersing the nano-sized mineral admixture to be treated in water to obtain dispersion liquid; (2) adding amino silane into the dispersion liquid in the step (1), so that the hydrolyzed amino silane is combined with a hydroxyl group on the surface of a nano particle of the nano-sized mineral admixture; (3) then adding a polycarboxylic acid polymer containing a carboxyl branched chain, so that an organic group of the hydrolyzed polycarboxylic acid polymer is combined with an amino group on the surface of the amino silane; (4) extracting the nano-sized mineral admixture in the dispersion liquid in the step (3), cleaning the un-reacted amino silane and polycarboxylic acid polymer on the surface, and drying so as to obtain the nano-sized mineral admixture after surface treatment. The nano-sized mineral admixture treated by the method disclosed by the invention has the advantages of stable dispersion effect, full contact with an aqueous solution and smaller resistance to pozzolanic reaction of particles selves.

Owner:SOUTHEAST UNIV

Manufactured natural pozzolan, improved manufactured natural pozzolan-based cement and method of making and using same

Owner:CIUPERCA ROMEO ILARIAN

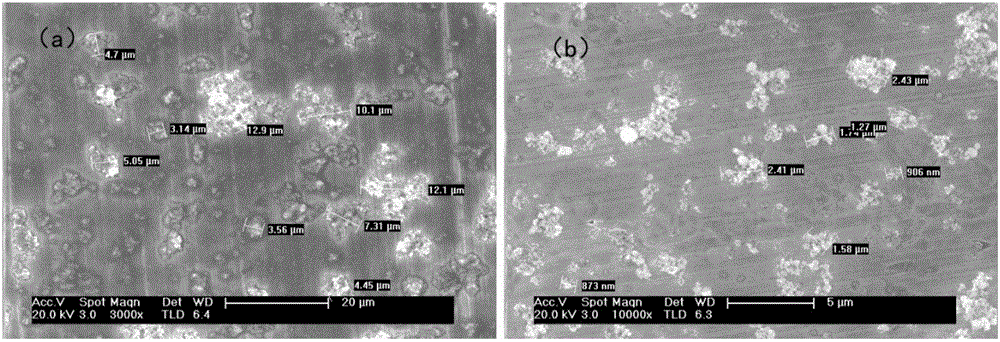

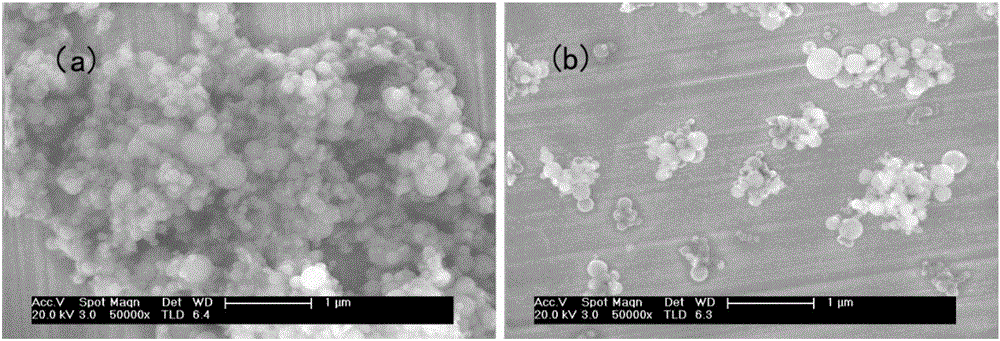

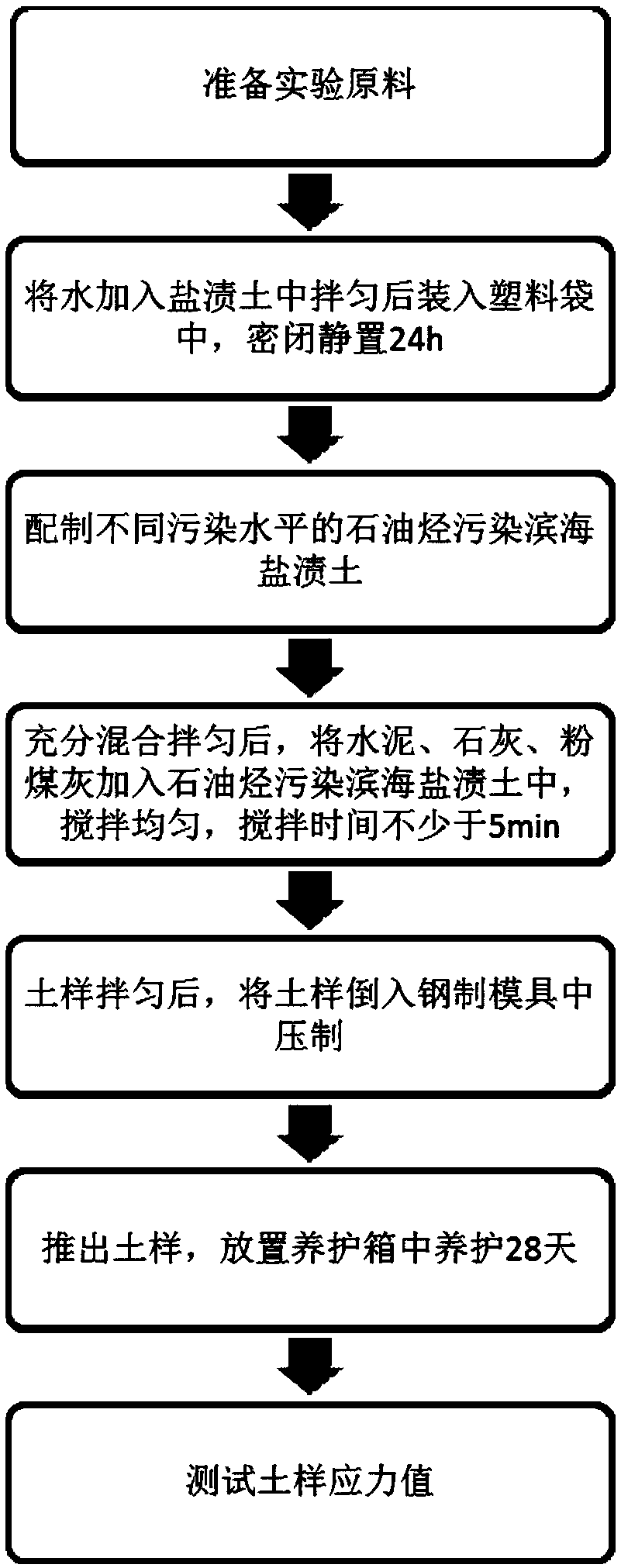

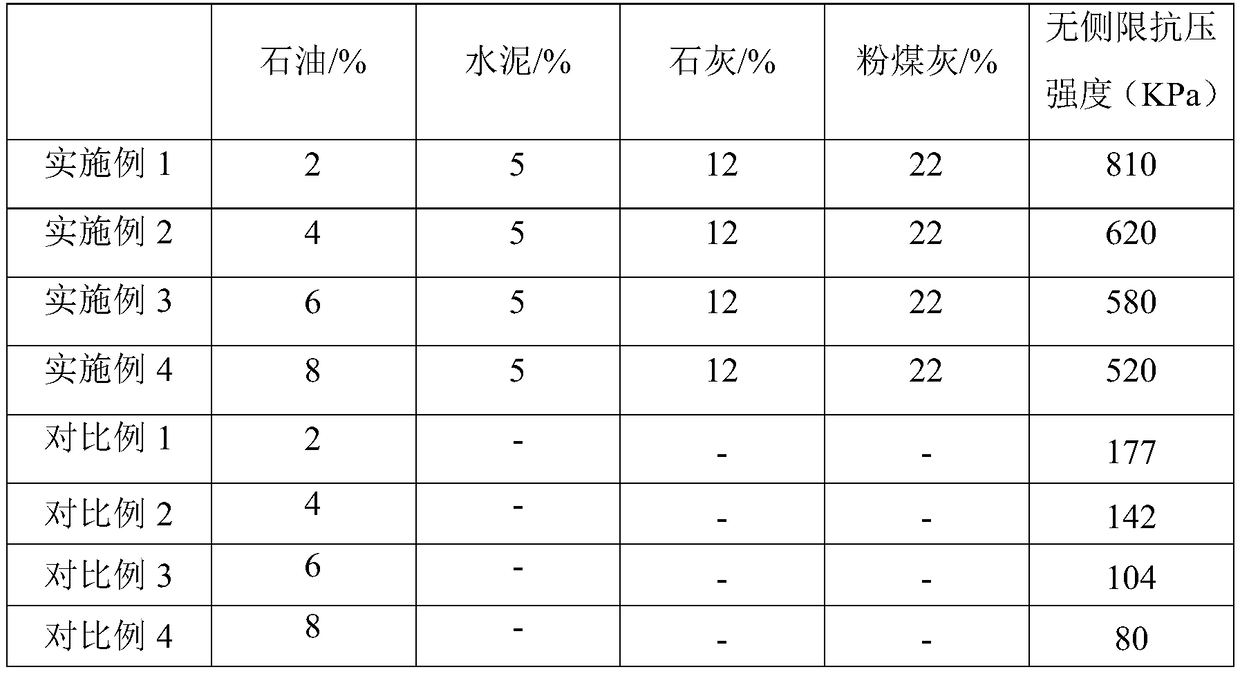

Curing utilization method of petroleum hydrocarbon-polluted coast salty soil

InactiveCN109174955AStrong adsorptionHigh strengthSoil lifting machinesContaminated soil reclamationCalcium silicateHydration reaction

The invention provides a curing utilization method of petroleum hydrocarbon-polluted coast salty soil. The curing utilization method comprises the following steps: preparing coast salty soil, petroleum and a curing material; preparing the petroleum hydrocarbon-polluted coast salty soil; adding the curing material into the petroleum hydrocarbon-polluted coast salty soil, uniformly stirring, pouringa soil sample into a mold, and pressing; and pushing out the sample, and putting the sample into a maintenance tank for maintenance. The hydrocarbon-polluted coast salty soil is processed by virtue of the method, coal ash, lime and cement are added into petroleum-polluted soil, and petroleum is stably adsorbed by virtue of the coal ash, so that the secondary environmental pollution problem in theutilization process of petroleum-polluted soil is solved. Meanwhile, a compound with water-hardening gelation ability is generated by virtue of the pozzolanic reaction and curing reaction between thecoal ash and the lime. A hydration reaction is generated by virtue of AiO2, Al2O3 and Fe2O3 in the coal ash and Ca(OH)2 released during the hydration of the cement so as to generate hydrated calciumsilicate, hydrated calcium aluminate, hydrated calcium carbonate, hydrated calcium ferrite and the like, and the hydrates have a agglutination effect, so that the strength can be further improved.

Owner:TIANJIN CHENGJIAN UNIV

Method for improving expansive soil by means of coal ash

InactiveCN108239974AReduce swell effectLower plasticity indexBuilding constructionsOrganic fertilisersFlocculationActivity index

The invention relates to a method for improving expansive soil by means of coal ash. According to the method, the coal ash is added into the expansive soil, wherein the mass of the coal ash added intothe expansive soil is 20% of that of the expansive soil; the coal ash is an additive for effectively improving the expansive soil, the coal ash is mixed with the expansive soil, an ion exchange effect and pozzolanic reaction exist, and the swell-shrink effect of the expansive soil can be reduced; after the coal ash and the expansive soil are mixed, the coal ash can interact with a soil body undera certain water content condition, the ion exchange effect (high-valence cations in the coal ash replace low-valence cations in the expansive soil) is generated, the plasticity index, the activity index, the swell-shrink characteristic and the like of the expansive soil can be effectively decreased or reduced, and aggregate, containing the fine-grained components, in the soil is made to have relatively-coarse-grained components; the high-valence ions capable of being used for having the ion exchange effect in the coal ash, namely Ca2<+>, Al3<+>, Fe3<+> and the like, can promote flocculation of clay particles; and the coal ash contains a certain amount of amorphous SiO2 and Al2O3, and pozzolanic reaction can occur when the coal ash interacts with the soil.

Owner:HENAN UNIV OF URBAN CONSTR

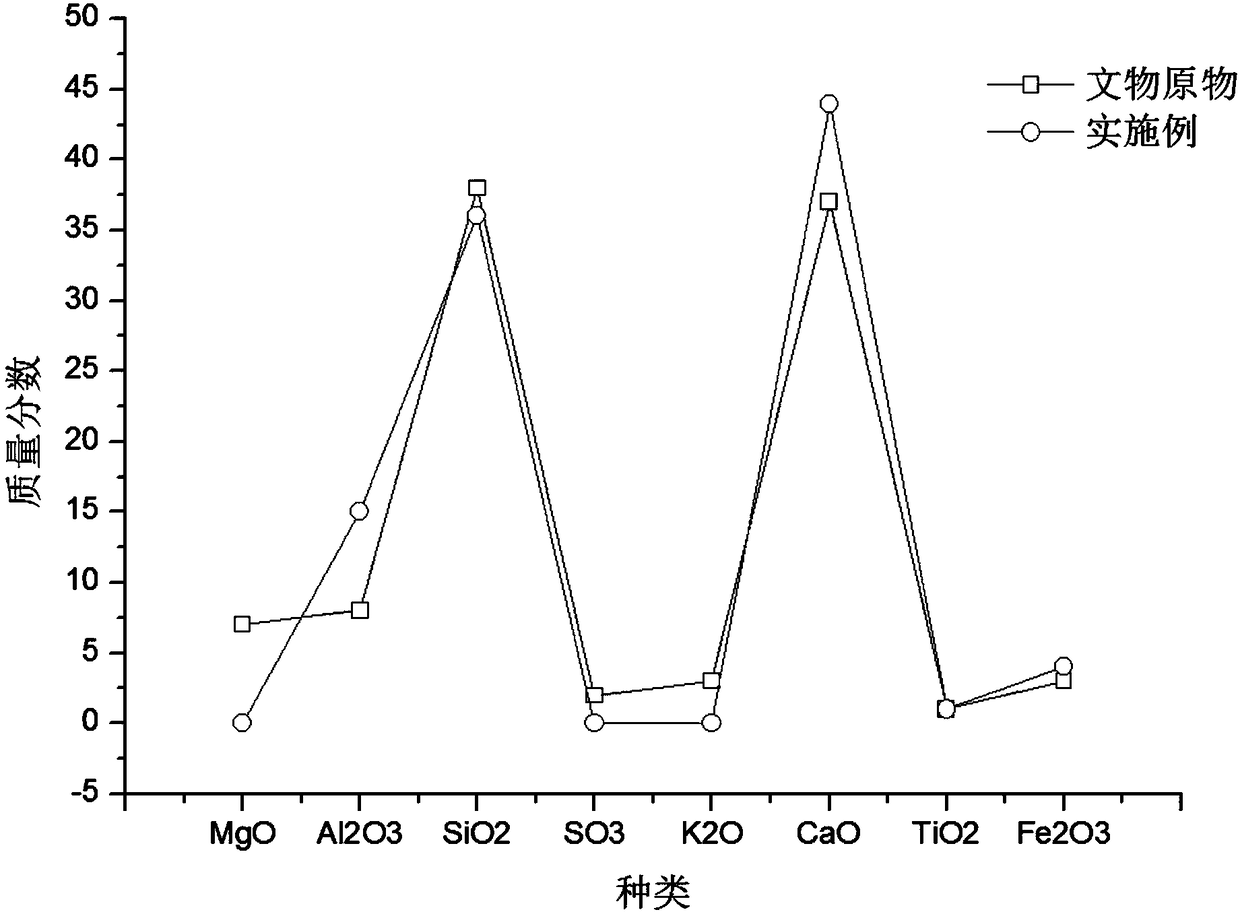

Marl for repairing modern cultural relic architecture decoration

The invention discloses marl for repairing modern cultural relic architecture decoration. The marl is prepared from water, fly ash, quick lime, water-washing medium sand, activated silicon dioxide, activated calcium dioxide, silicic acid, calcium bicarbonate and titanium oxide. According to the marl disclosed by the invention, the activated silicon dioxide, the activated calcium dioxide and the water react to rapidly generate calcium silicate hydrate and the calcium silicate hydrate is subjected to hardening and dry shrinkage to form a hardened framework; the hardened framework can be used forlimiting later-period dry shrinkage of the calcium silicate hydrate generated by the fly ash, the quick lime and the water, calcium aluminate hydrate, calcium alumino-ferrite hydrate and calcium sulfoaluminate hydrate; the dry shrinkage is reduced, so that the marl can be matched with an original cultural relic very well. Moreover, the mineral characteristic value of a material formed by adoptingthe formula provided by the invention is similar with the mineral characteristic value of the original cultural relic, and the material has good compatibility with the original cultural relic. Furthermore, calcium hydroxide generated in a process is consumed in volcanic ash reaction, so that the corrosion resistance and durability of the material formed by adopting the formula provided by the invention can be effectively enhanced.

Owner:黄丽仪 +1

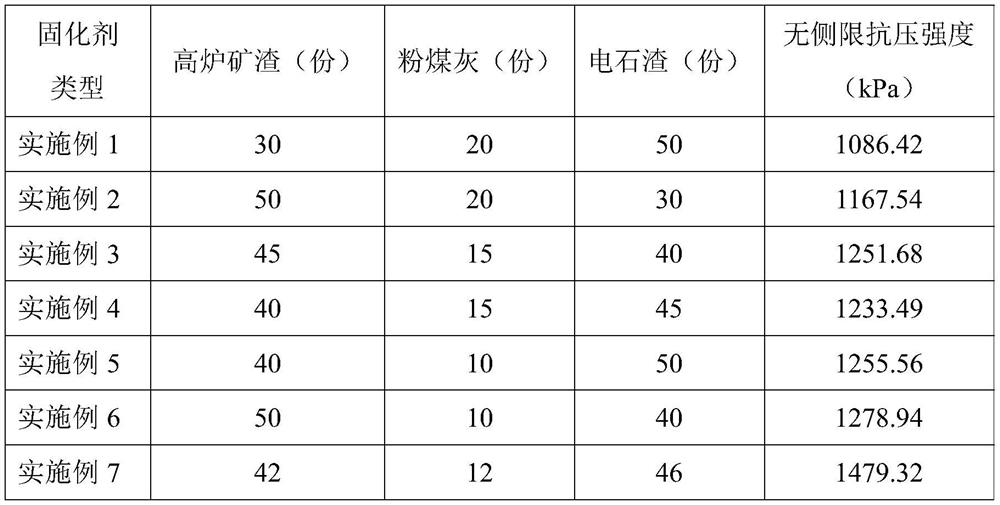

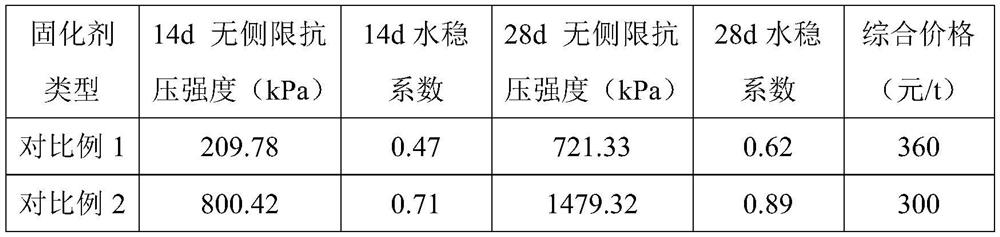

Soil stabilizer for roadbed filling

InactiveCN113214835AWide variety of sourcesLow costRoadwaysBuilding constructionsSlagToxic industrial waste

The invention discloses a soil stabilizer for roadbed filling, which is characterized in that three industrial wastes of granulated blast furnace slag, fly ash and carbide slag are used as raw materials, and Taizhou mucky soil with the water content not less than 50% and the organic matter content not less than 3% is subjected to reinforcement treatment, so that the strength and stability requirements of roadbed filling are met. The invention discloses a construction method for solidifying mucky soil with the soil stabilizer. According to the soil stabilizerdisclosed by the invention, three industrial wastes are combined together according to a proper proportion, and the strength and stability of the soil stabilizer are exerted through a pozzolanic reaction. The soil stabilizer not only can solve the problem that a large amount of mucky soil in Taizhou has no place to stack, but also can solve the problem that industrial waste polluting soil, air and water cannot be directly utilized in industrial production, and meanwhile, roadbed earthwork is saved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +2

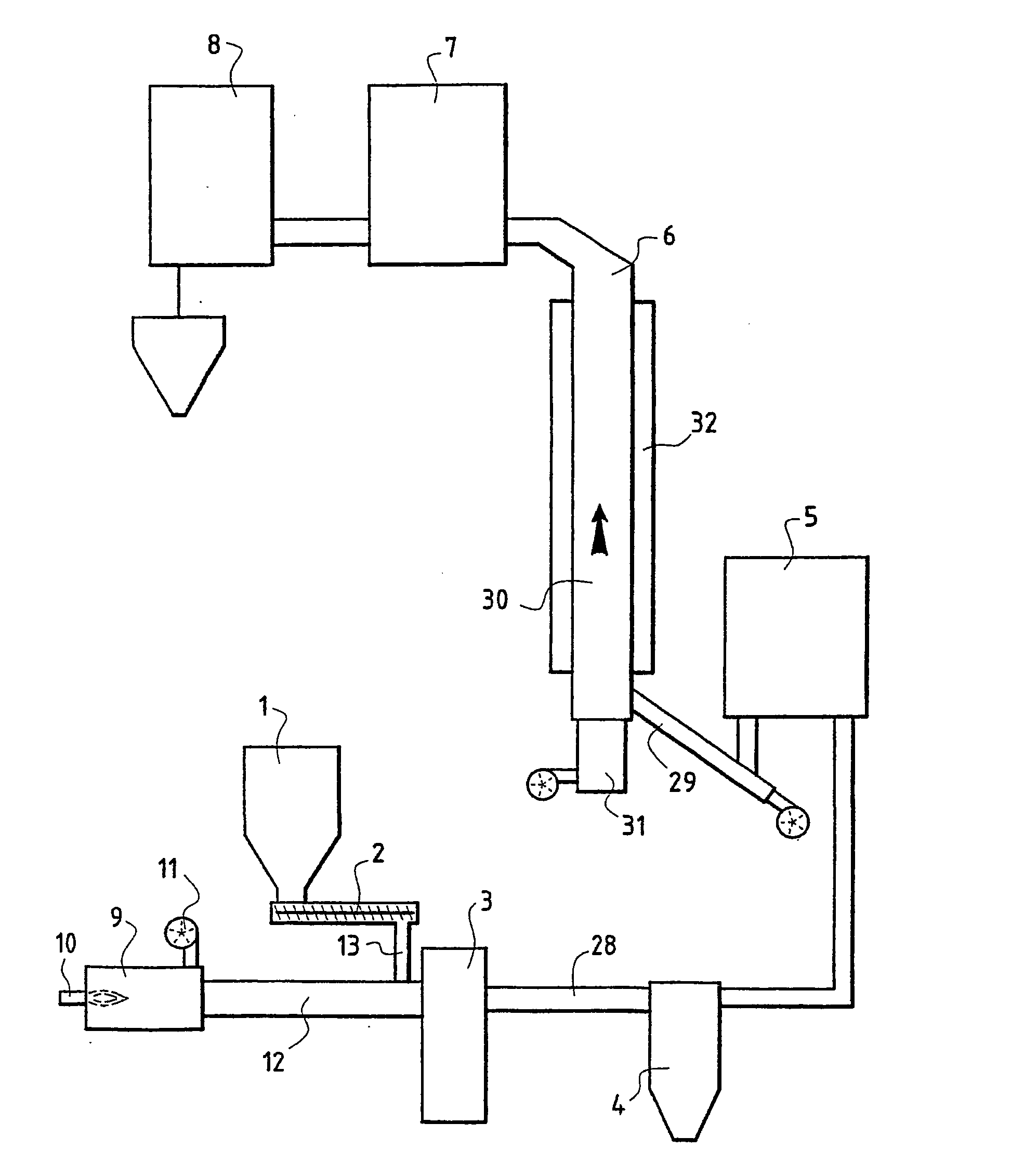

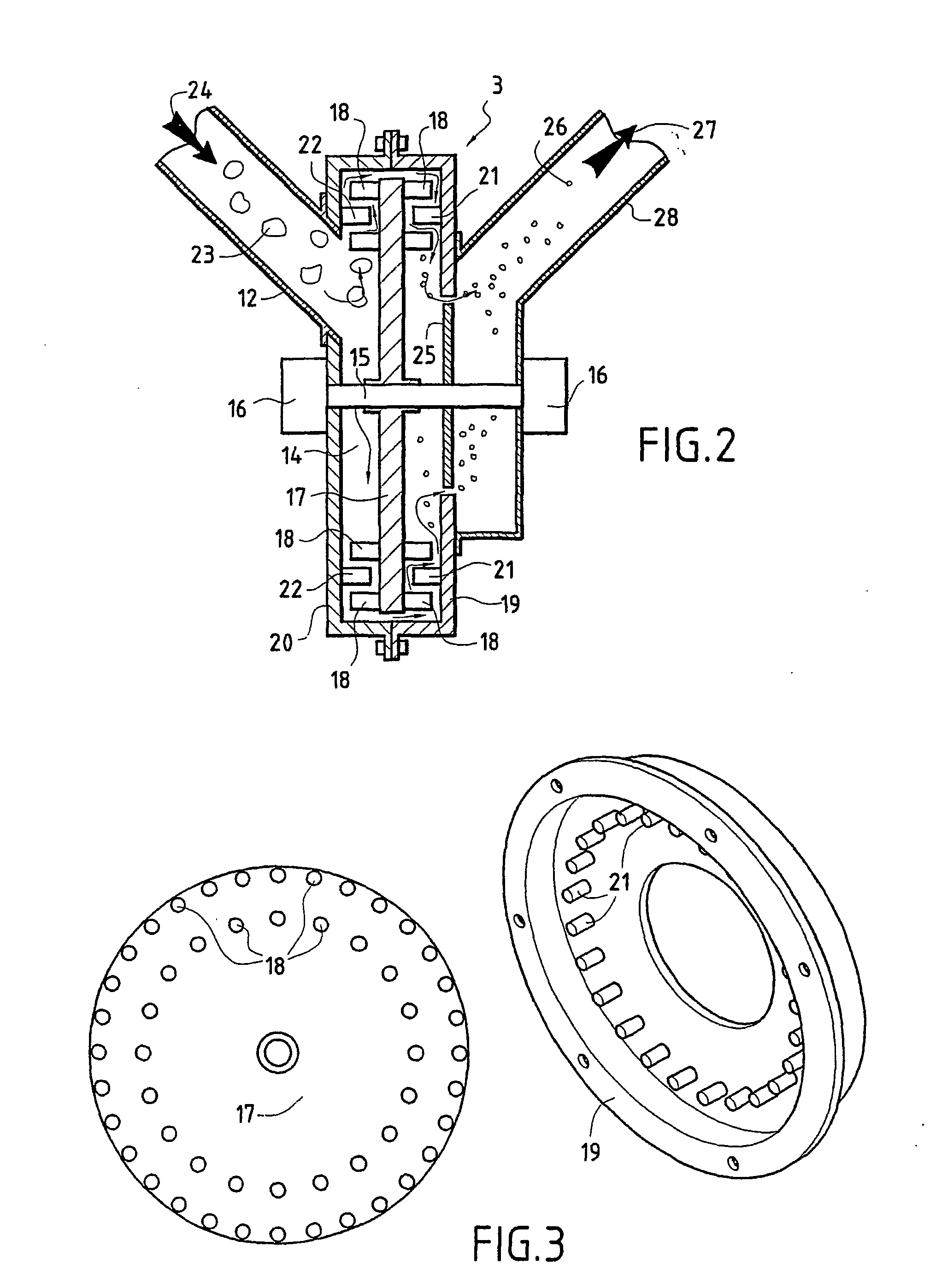

Dehydroxylated aluminium silicate based material, process and installation for the manufacture thereof

InactiveUS20050039637A1Increase motivationHigh strengthAluminium silicatesChemical/physical processesCalcium hydroxideSilicic acid

The invention concerns a dehydroxylated aluminium silicate-based material exhibiting a faster pozzolanic reactivity, characterized in that the amount of reacted calcium hydroxide measured by the pozzolanic reactivity (PR) after a 3-day cure is at least 50%. In a process and an installation for dehydroxylation treatment of aluminium silicate, particles containing aluminium silicate are exposed to a temperature of at least 500° C. The particles are in the form of a dry powder, and the dry powder (26) is optionally transported in a gas stream (30) at a temperature ranging from 600 to 850° C., for a time which is sufficient to achieve the desired degree of dehydroxylation. The powder may be obtained from a hydrated base paste by reducing the base paste into fragments (23), and by disaggregating the fragments (23) of base paste by mechanical action (at 3) in the presence of a hot gas (24) at a temperature ranging from 500° C. to 800° C., in order to form the dry powder (26).

Owner:SAINT GOBAIN MATERIAUX DE CONSTR S COURBEVOIE

Reaction in-situ type concrete protective agent with self-cleaning function

The invention relates to a reaction in-situ type concrete protective agent with a self-cleaning function, belonging to the field of building materials, and particularly relates to a method for protecting surface hardened concrete by ethyl orthosilicate modified nano TiO2. The concrete protective agent provided by the invention comprises the following raw materials in percentage by weight: 10-50% of ethyl orthosilicate, 0-10% of a silane coupling agent, 3-15% of nano TiO2 and 25-87% of water. By means of the character that ethyl orthosilicate in the raw material of the protective agent permeates into surface holes of the hardened concrete and is hydrolyzed in situ to generate nano SiO2, the nano SiO2 has the pozzolanic reaction under an alkaline environment of the surface holes of the hardened concrete, so as to compactly protect the surface of the concrete. The nano TiO2 compounded with ethyl orthosilicate through the coupling agent can be effectively attached to the surface hardened concrete so as to endow the concrete surface with the self-cleaning function. Meanwhile, the physical hole blocking effect of the nano TiO2 particles can further improve the compactness of the surface concrete. The protective agent provided by the invention has the characteristics of less raw material components, convenience in construction and the like, and can be widely applied to protecting and beautifying the hardened concrete surface.

Owner:UNIV OF JINAN

Road and bridge special concrete and preparation method thereof

The invention discloses road and bridge special concrete comprising the following components by weight: 42-47 parts of gravels, 33-38 parts of fine river sand, 11-15 parts of waste ore slag, 8-12 parts of waste broken glass slag, 3 to 7 parts of vesuvianite, 12 to 15 parts of fly ash, 19 to 23 parts of cement, 0.2 to 0.4 part of a weathering filler, 0.2 to 0.3 part of potassium titanate crystal, 5-7 parts of vermiculite, 1.3 to 1.7 parts of a water reducing agent, 2.6 to 3.2 parts of silicon powder, 0.1 to 0.3 part of a curing corrosion inhibitor and 17 to 21 parts of water. The waste ore slagand the fly ash in the concrete have pozzolanic reactivity, and can reduce the permeability of the concrete and increase the strength of the concrete, and the vesuvianite, the vermiculite and the waste broken glass slag all contain inorganic silicon compounds, can effectively improve the strength of the concrete and enhance the impact resistance of roads and bridges, by the addition of the weathering filler, the weather resistance of the concrete can be improved, the roads and bridges can adapt to temperature changes of different seasons, and by the addition of the curing corrosion inhibitor,the bonding performance of the concrete can be improved, surface cracking of the roads and the bridges can be prevented, and the service life of the roads and the bridges can be prolonged.

Owner:广东粤文建筑科技有限公司

Anti-permeability concrete admixture

InactiveCN106007538AImprove water repellencyImprove impermeabilitySolid waste managementPolyvinyl alcoholCombined use

The invention discloses an anti-permeability concrete admixture. The anti-permeability concrete admixture comprises the following components in parts by weight: 0.1 to 0.3 part of white carbon black, 15 to 20 parts of superfine mineral powder, 0.3 to 0.5 part of polyvinyl alcohol, 8 to 10 parts of light calcined magnesia, 1 to 3 parts of aluminium oxide, and 66.2 to 75.6 parts of fly ash, and the total amount of all the components is 100 parts. The anti-permeability concrete admixture disclosed by the invention has the advantages that the prepared admixture utilizes optimized combination of various superfine mineral admixtures to optimize pore structures, and improves a transition region through a secondary pozzolanic reaction, and then combines resin materials to improve the hydrophobicity of concrete so as to comprehensively improve the impermeability of the concrete.

Owner:JIANGSU MINGHE GRP

Method for producing autoclaved brick from foundry waste sand and acetylene sludge

The invention relates to a method for producing an autoclaved brick from foundry waste sand and acetylene sludge, and belongs to the technical field of building materials. According to the method, the foundry waste sand and the acetylene sludge which pollute the environment are prepared into the autoclaved brick, a pozzolanic reaction is generated through the main ingredient Ca(OH)2 of the acetylene sludge and SiO2 and Al2O3 which are formed on the surface of the foundry waste sand under the high-temperature hydrothermal conditions to generate CSH gel, waste sand particles are bonded together, and then a green brick achieves the strength. According to the autoclaved brick prepared from the foundry waste sand and the acetylene sludge, the quality meets the quality requirement of the national standard 'autoclaved sand-lime brick' (GB11945-1999), and the significant social, economic and environment-friendly benefits are achieved.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing inorganic fibers by compounding of slag and coal gangue

InactiveCN107973531AHigh early chemical activityImprove early chemical activityGlass making apparatusFiberSlag

The invention discloses a method for preparing inorganic fibers by compounding of slag and coal gangue. According to the method provided by the invention, firstly, desulfurization gypsum and CaO are used as activators, the coal gangue and fly ash are subjected to chemical / thermal composite excitation treatment, the coal gangue and the fly ash are excited by heat, so that the structure of glass networks of the coal gangue and the fly ash is destroyed, active SiO2 and Al2O3 are dissolved out, the dissolved-out active SiO2 and Al2O3 and CaO are subjected to a solid phase reaction, a new substancewith hydraulic activity is generated, and the activity of a pozzolanic reaction of the material is improved; and then the active material and blast furnace slag are mixed and ground, melt centrifugation drawing is performed, so that the inorganic fibers are prepared, the slag and other raw materials are introduced in the manner of fibers, the fibers can be uniformly distributed into a hardened slurry, and a grid structure can be formed, so that the problem of bleeding of concrete is improved, the compactness of the hardened slurry is improved, and the compressive strength and durability of the concrete are improved.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

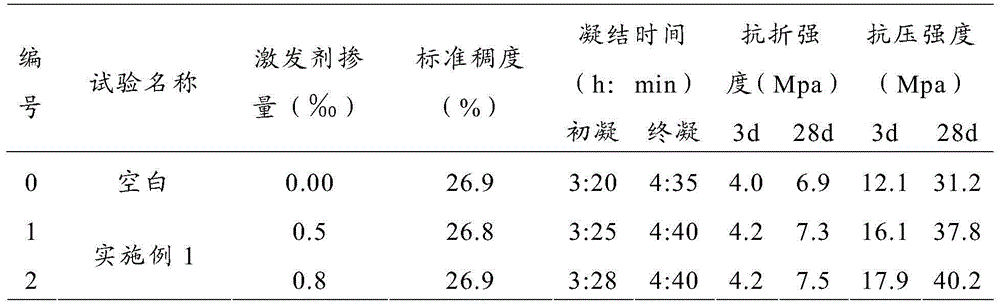

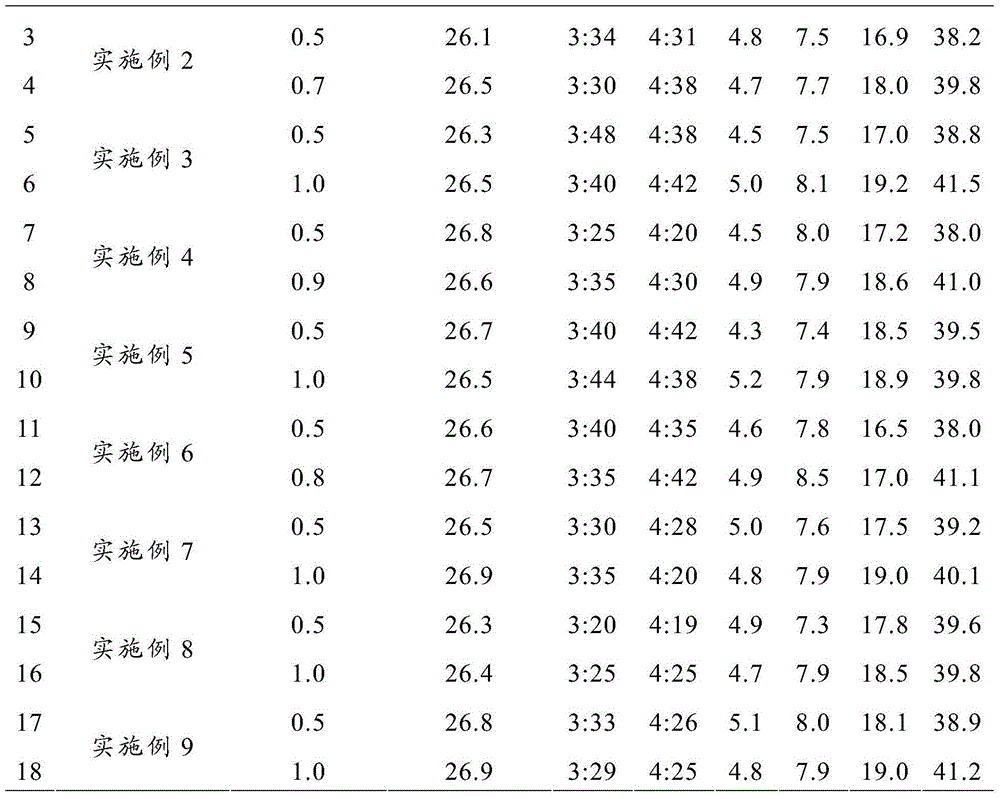

Coal ash activity exciting agent and preparing method of coal ash activity exciting agent

ActiveCN104058621AHigh activityEffective stimulation of activitySolid waste managementAluminateCalcium silicate

The invention provides a coal ash activity exciting agent and a preparing method of the coal ash activity exciting agent. The preparing method includes the step that sodium sulfanilate, water, alkali liquor, acetone, urea and a formaldehyde solution are mixed to react to obtain the coal ash activity exciting agent, wherein the coal ash activity exciting agent has repeated units shown in the first formula (please see the specifications for the formula), and the number-average molecular weight ranges from 5000 to 20000. The coal ash activity exciting agent structurally comprises N bonds with lone pair electrons and C=O double bonds with lone pair electrons, active SiO2 and active Al2O3 in coal ash can be excited to react with calcium ions obtained by ionizing Ca(OH)2, and hydration products, such as hydration calcium silicate and hydration calcium aluminate, of space network structures are generated; in addition, a large amount of hydroxy is contained in molecules of the coal ash activity exciting agent, after the coal ash activity exciting agent is dissolved into water, OH- is obtained through ionizing, the surfaces of vitreous bodies of the coal ash can be corroded, the surface structure of the coal ash is broken up, unsaturated bonds of the coal ash are increased, the pozzolanic reaction is prompted, and the activity of the coal ash can be effectively excited under the condition that the doped amount is small.

Owner:SHANDONG HONGYI TECH

All-solid waste cementing material as well as preparation method and application thereof

InactiveCN113149477AReduce utilizationImprove structural strengthCement productionHydration reactionSlag

The invention relates to the technical field of industrial waste recycling and road base materials, in particular to an all-solid-waste cementing material and a preparation method and application thereof. The all-solid-waste cementing material is prepared from, by mass, 22.5%-27.5% of phosphogypsum, 22.5%-27.5% of carbide slag and 45%-55% of superfine slag powder. The preparation method of the all-solid waste cementing material comprises the following steps: 1) stirring and mixing ardealite and carbide slag, and performing calcining to obtain a calcined product; 2) stirring and mixing the calcined product and the slag micro powder. The proportion design of the materials is reasonable; when the mixed calcined product of the ardealite and the carbide slag is mixed with the superfine slag powder for use, the activity of the mixed calcined product is excited under the action of the superfine slag powder, and the mixed calcined product is subjected to hydration reaction and pozzolanic reaction under the action of water, so that the roadbed and the pavement are cured and hardened by the reactions, the reaction product can also be filled into gaps of the roadbed pavement, so the structural strength of the roadbed pavement is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Manufactured natural pozzolan, improved manufactured natural pozzolan-based cement and method of making and using same

Owner:CIUPERCA ROMEO ILARIAN

Flue gas desulfurizing agent as well as preparation method and application thereof

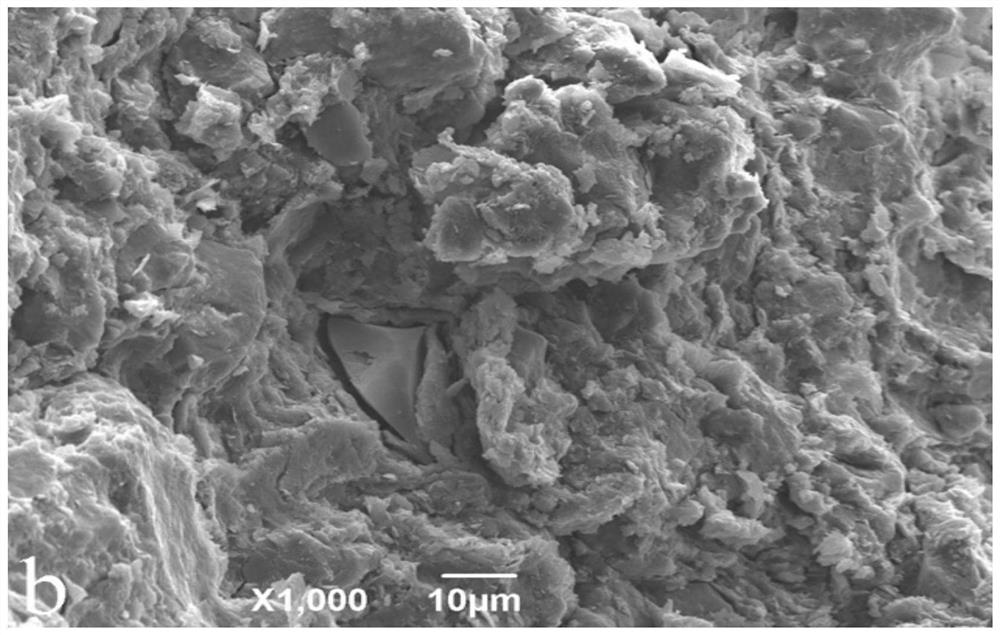

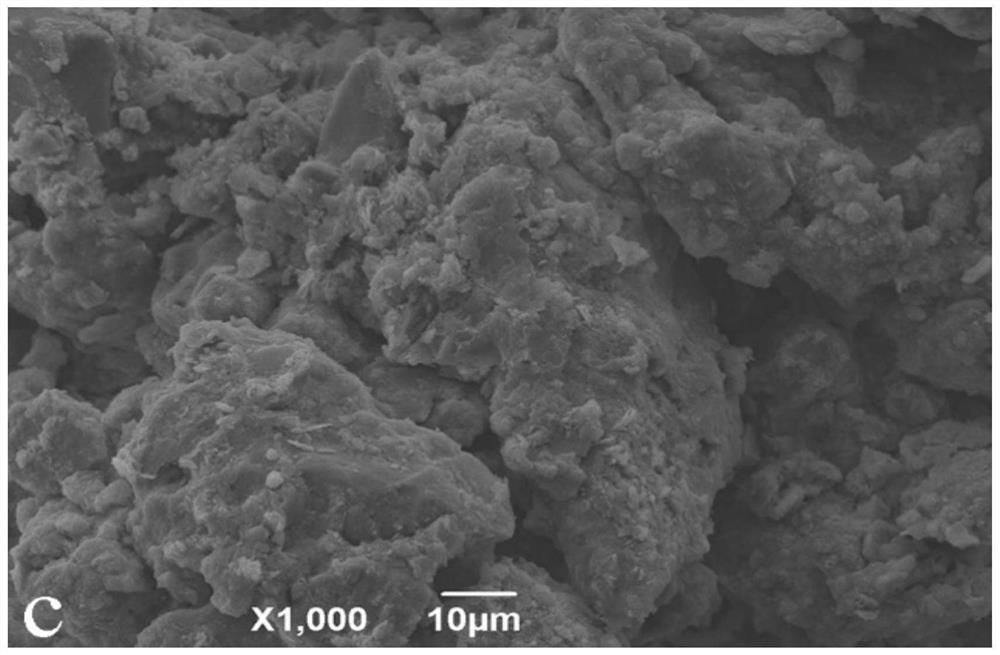

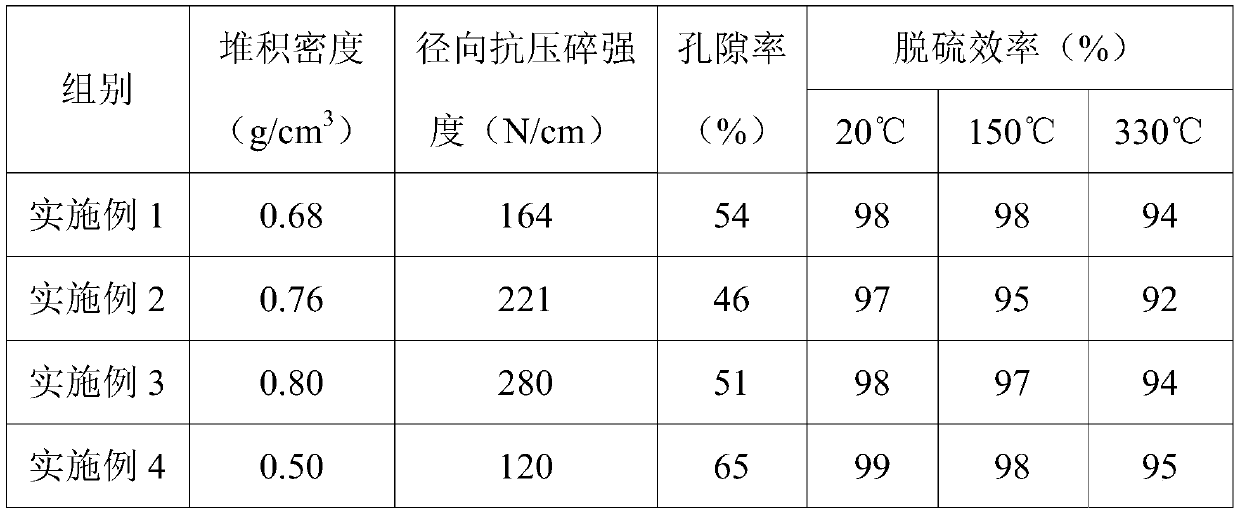

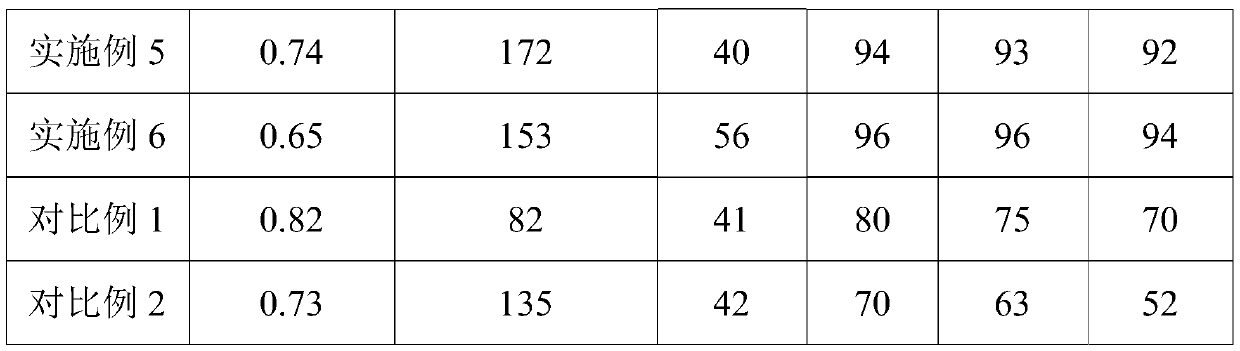

ActiveCN111330424AReduce porosityImprove pore structureGas treatmentDispersed particle separationHydration reactionPozzolana

The invention provides a flue gas desulfurizing agent as well as a preparation method and application thereof. The flue gas desulfurizing agent comprises the following raw materials in parts by weight: 30-60 parts of slaked lime powder, 20-60 parts of silica fume, 6-24 parts of a binder and 6-15 parts of crystalline hydrated salt. According to the flue gas desulfurizing agent, active substances inthe slaked lime powder and the silica fume are subjected to a pozzolanic reaction to generate high-strength hydrated silicate; the binder can bind all the raw material components to improve the strength of the flue gas desulfurizing agent; the crystalline hydrated salt plays a pore-forming role by losing crystalline water in the flue gas desulfurizing agent; mutual cooperation of components, theflue gas desulfurizing agent has relatively small stacking density (0.5-0.8 g / cm<3>), relatively high radial crushing strength (120-280 N / cm) and relatively large porosity (40-65%); the desulfurizingagent can be used for a fixed bed reactor or a moving bed reactor, is suitable for purification treatment of SO2-containing industrial flue gas or waste gas at 20-330 DEG C, has relatively high reaction activity, particularly still has relatively high crushing resistance under a relatively high flue gas temperature condition, and is not easy to pulverize and low in bed pressure.

Owner:北京予知环境工程有限公司

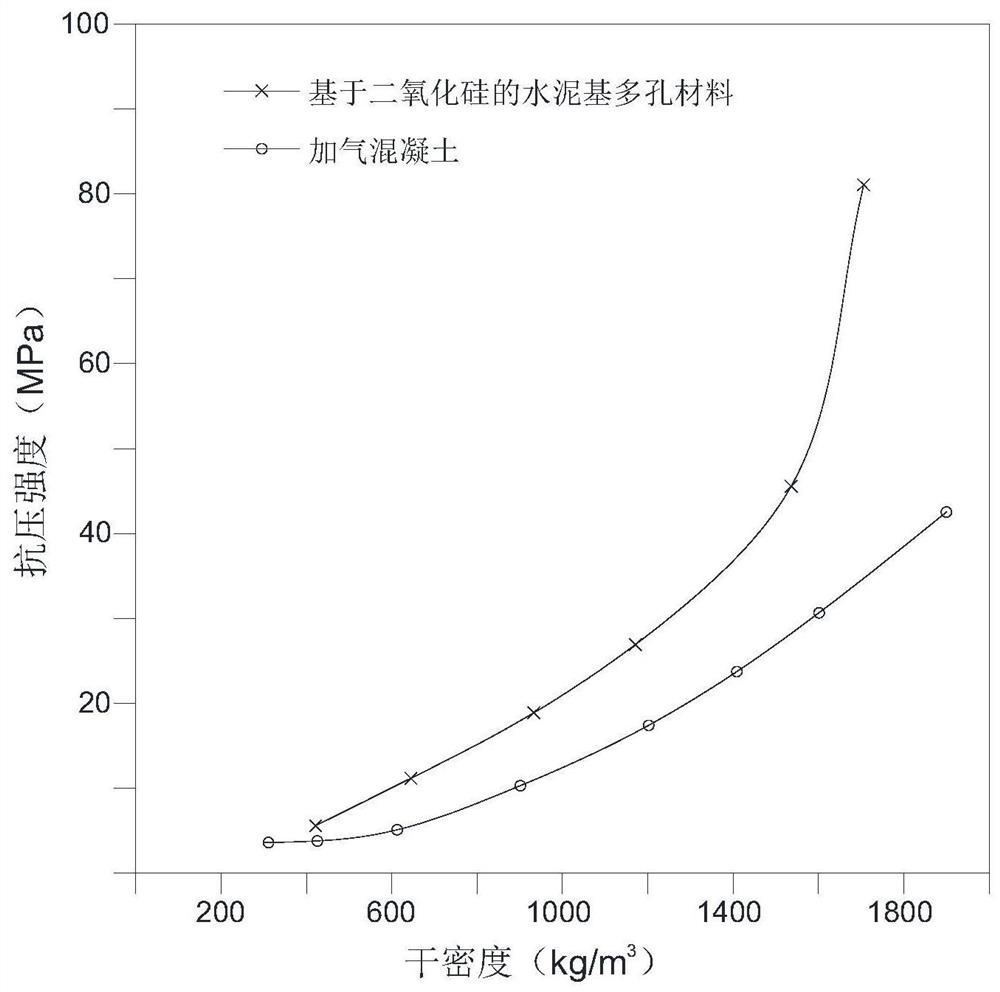

Cement-based porous material based on silicon dioxide and preparation method of cement-based porous material based on silicon dioxide

ActiveCN112408876AIncreased nanopore ratioImprove microstructureSolid waste managementCeramicwareHydration reactionCement composites

The invention relates to the technical field of building materials, and discloses a cement-based porous material based on silicon dioxide and a preparation method of the cement-based porous material based on silicon dioxide. The cement-based porous material is mainly obtained by mixing cement, an admixture, water, an additive and a silicon dioxide dispersion liquid and then condensing and hardening an obtained mixture, the silicon dioxide dispersion liquid is a dispersion system formed by dispersing silicon dioxide particles in water. Due to the fact that introduced water is not completely consumed in a cement hydration reaction, a large number of capillary pore spaces are formed, a cement hydration product and the surface of the spherical silicon dioxide are subjected to a volcanic ash reaction, the cement hydration product grows on the silicon dioxide and is in lap joint with the silicon dioxide, and therefore, the capillary pore spaces can be further divided; a large number of nanopore spaces are constructed in the capillary pore spaces, so that the proportion of nanopores in the cement composite porous material is increased; meanwhile, the capillary spaces are constructed through a nanopore structure, so that the microstructure of the material is strengthened, the development of the strength of the material is facilitated, and the mechanical property of the cement-based porous material is improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Non-heating clay composites for building materials

InactiveUS7097706B2High strengthGood for healthOrganic chemistrySolid waste managementProduction rateSlag

The object of this invention is to provide a non-calcined clay composite used as building materials capable of promoting humans' health and being desirably used irrespective of location, which is improved in terms of strength without calcining clay. Because the non-calcined clay composite is produced without calcining clay, the process of producing it is simplified and its productivity is improved. The non-calcined clay composite includes 50 to 90 wt % clay, 2 to 30 wt % lime, 4 to 48 wt % blast furnace slag, 0.04 to 0.9 wt % alkaline chemical, and water as a balance, and has high compression strength due to an ionic coagulation reaction, a pozzolan reaction, and a latent hydraulic reaction.

Owner:G PLUS

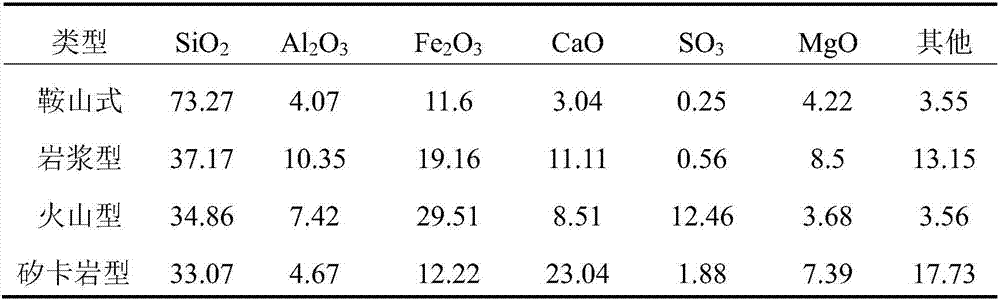

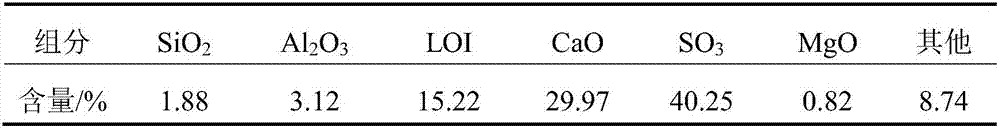

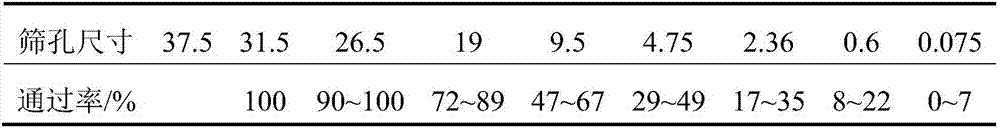

Semi-rigid base material for high grade pavement and preparation method thereof

The invention provides a semi-rigid base material for a high grade pavement and a preparation method thereof. According to the invention, iron tailing waste rock, broken iron tailing waste rock and iron tailing sand are fully utilized and ardealite, quick lime, cement, coal ash, biological agglomeration enzyme and polypropylene fiber are added, so that the optimal mixing proportion scope of the materials is given. The quick lime and the ardealite are stirred and covered for 16 hours and then are milled, so that the activity thereof can be greatly promoted, the active ingredients in iron tailings and coal ash can be stimulated and the pozzolanic reaction can be quickened. The four typical iron tailings, including Anshan, magma, volcano and skarn iron tailings are stabilized and all can meet the requirements of the semi-rigid bases of the high grade pavements. The invention aims to solve the problem of bulk deposition of the iron tailings, reduce the development of gravel building materials, reduce the bulk deposition of the industrial residue ardealite, fully utilize the industrial residue coal ash and greatly reduce the cost of road construction. The material has significance in realizing circular economy and sustainable development.

Owner:HARBIN INST OF TECH

Artificial stone and manufacturing method thereof

InactiveUS8636842B2Improve cohesionAvoid separationSolid waste managementSpecial ornamental structuresArtificial stoneVolcano

Disclosed is a method of manufacturing an artificial stone, and the method includes forming an artificial-stone paste which comprises 20-20 parts by weight of silica stone, metakaolim or silica fume, 200-300 parts by weight of quartz chips, 30-36 parts by weight if water, 1.5-3 part by weight of water-reducing agent and 0.2-3 parts by weight of pigment with response to 100 parts by weight of white cement; injecting the artificial-stone paste in a mold; primarily vacuum-molding the artificial-stone paste injected in the mold; secondarily vibration-molding the primarily molded artificial-stone paste; primarily curing the secondarily molded artificial-stone paste; secondarily curing the primarily cured artificial-stone paste, which induces a hydrothermal reaction and thus causes a pozzolanic reaction; releasing the secondarily cured artificial-stone paste from the mold; and surface-machining the released artificial-stone paste.

Owner:LG HAUSYS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com