Marl for repairing modern cultural relic architecture decoration

A technology for architectural decoration and plaster, applied in the field of cultural relics restoration, can solve the problems of detachment, poor matching of the original cultural relics, large drying shrinkage, etc., to enhance corrosion resistance and durability, reduce drying shrinkage, and reduce drying shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] The invention provides a kind of plaster for repairing the decoration of modern cultural relics, which consists of:

[0043] Solid phase: 40wt%-50wt%,

[0044] Water: 50wt%-60wt%.

[0045] The composition of described solid phase is:

[0046] Fly ash: 25wt%,

[0047] Quicklime: 8wt%,

[0048] Washing medium sand: 59wt%,

[0049] Active silica: 4wt%,

[0050] Activated calcium oxide: 3wt%,

[0051] Silicic acid: 0.6wt%,

[0052] Calcium bicarbonate: 0.2wt%,

[0053] Titanium dioxide: 0.2 wt%.

[0054] The fly ash is primary fly ash.

[0055] The active silicon dioxide is amorphous nano-silicon dioxide, and the amorphous-state nano-silicon dioxide can be dissolved under alkaline conditions.

[0056] The active calcium oxide is nano calcium oxide.

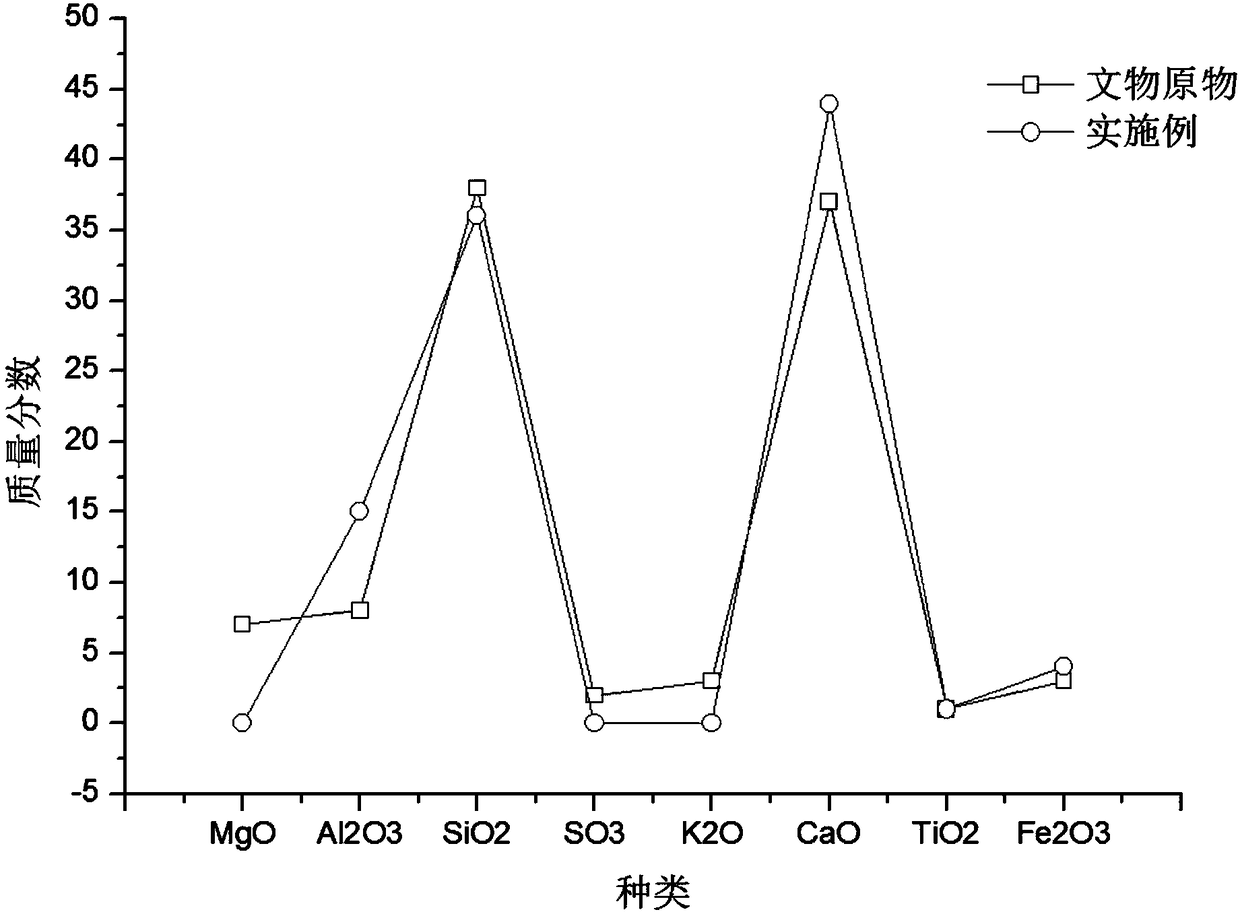

[0057] see figure 1 It can be seen from the figure that the composition of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com