Curing utilization method of petroleum hydrocarbon-polluted coast salty soil

A technology of saline soil and petroleum hydrocarbons, which is applied in the restoration of polluted soil, machinery for lifting soil, application, etc., can solve the problems of time-consuming, long-term physical measures, secondary pollution of soil restoration, etc., to achieve increased strength, The effect of solving the problem of secondary environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

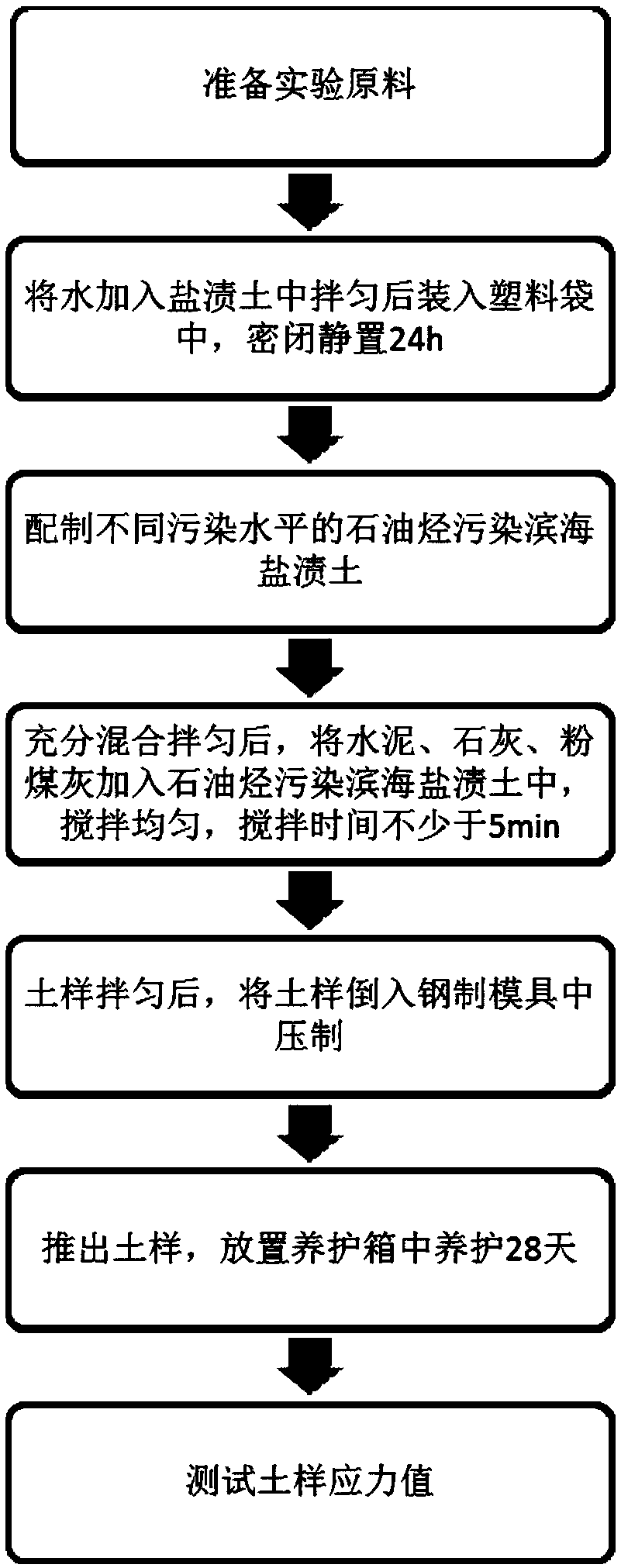

[0048] according to figure 1 As shown in the flow chart, the specific method of treating petroleum hydrocarbon polluted coastal saline soil is as follows:

[0049] (1) Prepare each raw material component in the following manner:

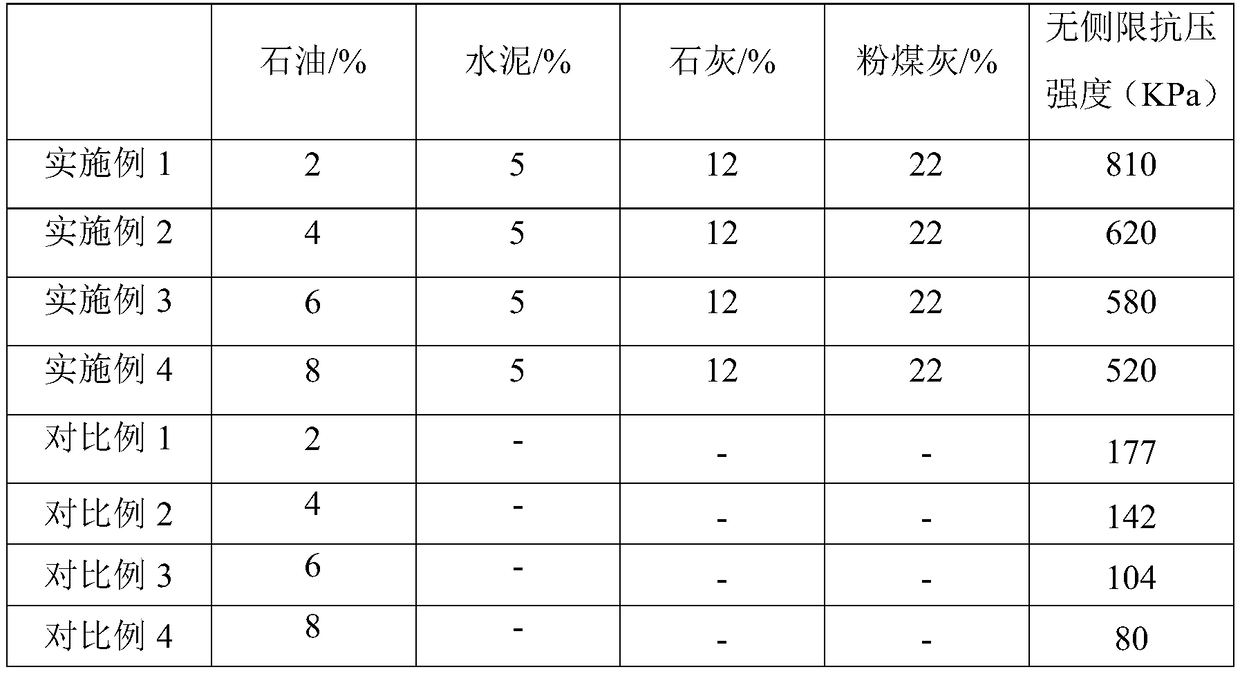

[0050] Weigh the coastal saline soil. In order to ensure the uniformity of the experimental soil particles, air-dry the crushed coastal saline soil and pass it through a 2mm sieve. Based on the dry soil weight, add 10% water to the saline soil and let it stand for 24 hours spare. Based on the weight of the coastal saline soil and water, 2% oil was added to the coastal saline soil on the second day to simulate the outdoor oil pollution environment. Based on the weight sum of coastal saline soil, water and oil, weigh 5% cement, 12% lime and 22% fly ash.

[0051] (2) Add the solidified materials lime, fly ash, and cement into the petroleum hydrocarbon-contaminated coastal saline soil, and stir evenly for no less than 5 minutes.

[0052] (3) After th...

Embodiment 2

[0055] according to figure 1 As shown in the flow chart, the specific method of treating petroleum hydrocarbon polluted coastal saline soil is as follows:

[0056] (1) Prepare each raw material component in the following manner:

[0057] Weigh the coastal saline soil. In order to ensure the uniformity of the experimental soil particles, air-dry the crushed coastal saline soil and pass it through a 2mm sieve. Based on the dry soil weight, add 10% water to the saline soil and let it stand for 24 hours spare. Based on the sum of the weight of coastal saline soil and water, 4% oil was added to coastal saline soil on the second day to simulate the outdoor oil pollution environment. Based on the weight sum of coastal saline soil, water and oil, weigh 5% cement, 12% lime and 22% fly ash.

[0058] Remaining steps are identical with embodiment 1.

Embodiment 3

[0060] With embodiment 2, difference only is that the content of petroleum is different, is 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com