Press-fitting device of battery cover cap

A technology for press-fitting devices and battery covers, which is applied to workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of high manufacturing cost, difficult maintenance and calibration for operators, and difficult maintenance, so as to achieve stable and easy structural transformation The effect of taking out and stabilizing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

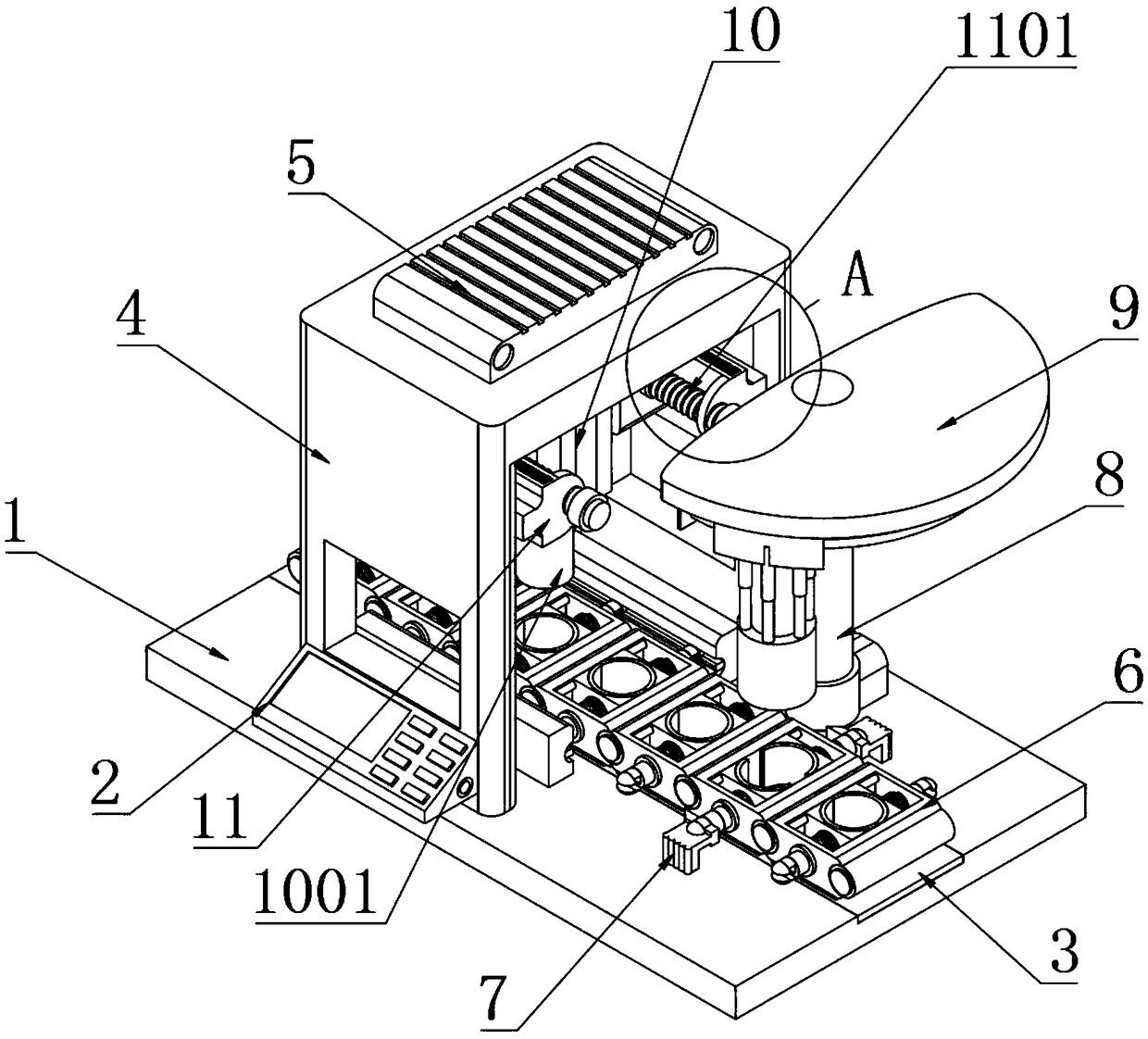

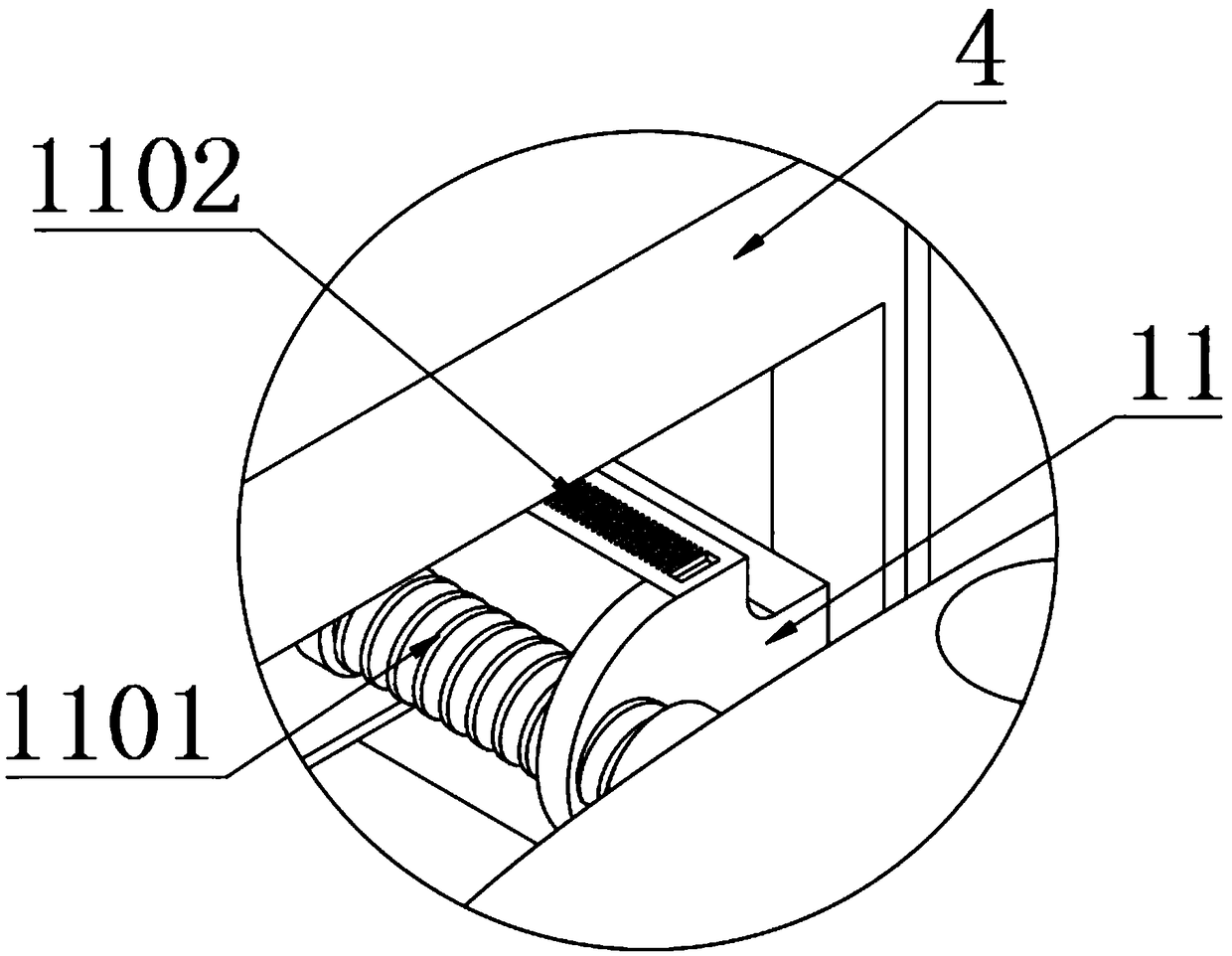

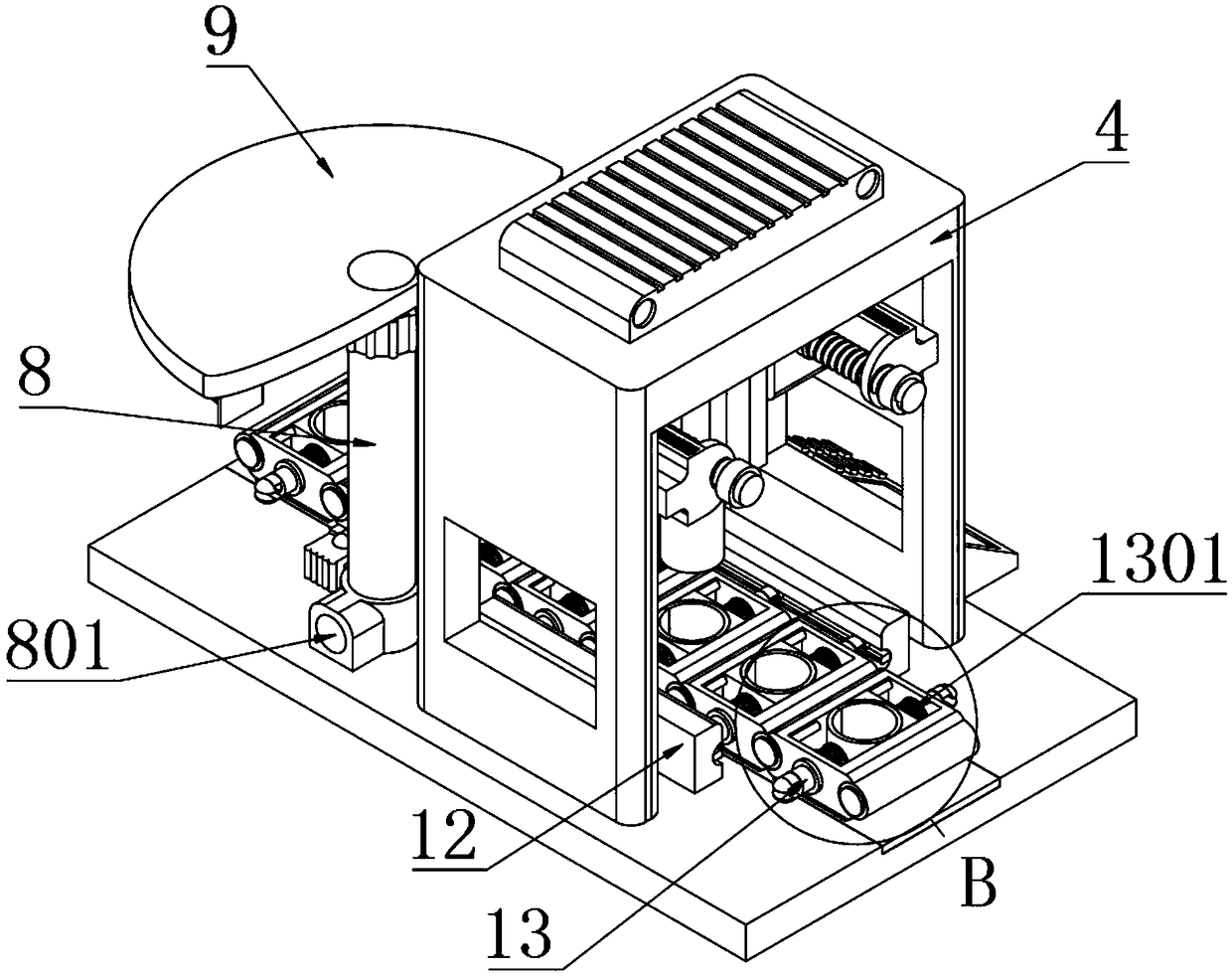

[0050] as attached figure 1 to attach Figure 11 Shown:

[0051] The invention provides a battery cap press-fitting device, which includes an operation table 1, a control panel 2, a conveyor belt 3, a press-fit stand 4, a PLC controller 5, a clamping disc 6, a hinge shaft 601, a guide rail 602, a limit column 603, an expansion Block 7, displacement block 701, support column 8, vacuum pump connector 801, stroke plate 9, arc hanging rail 901, electric push rod 902, hydraulic electric cylinder 10, press-fitting head 1001, clamping block 11, screw screw 1101, precision ruler 1102, guide body 12, guide groove 1201, correction plate 1202, automatic compression column 13, spring 1301, auxiliary shift head 1302, fixing bolt 1303, fixing plate 14, positioning groove 1401, chute 1402, suction head 15. Adsorption sleeve 1501, miniature electric cylinder 16, air pipe 17, rotating disk 1701, slider 18 and adjustment block 19, the conveyor belt 3 is arranged on the console 1; the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com