Patents

Literature

34results about How to "Solve secondary environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

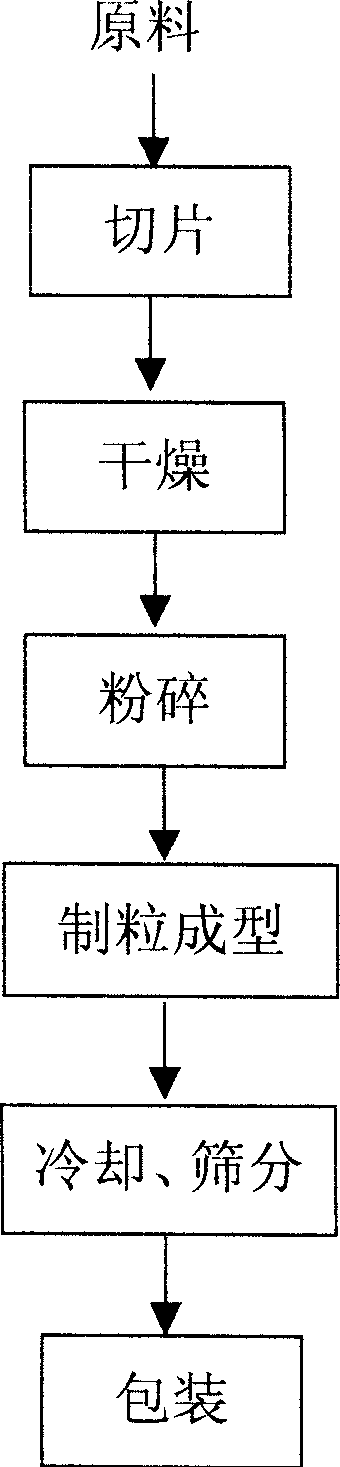

Environment-protecting granular wooden fuel and its production process

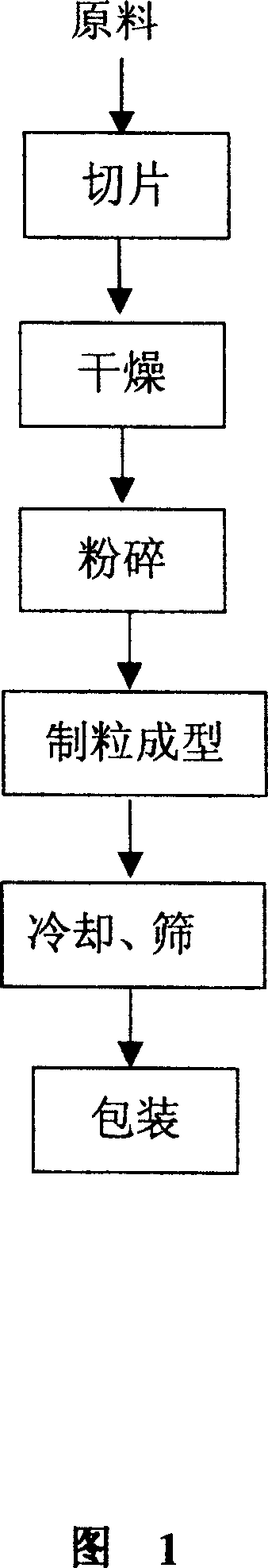

The present invention relates to granular wooden fuel and its production process, and features utilizing waste timber and forest cutting leftover as material. The production process includes cutting the raw material into coarse material, drying in airflow drier to certain water content, crushing into powder, pelletizing, granulating without adding additive through extrusion, cooling and sieving, backing the undersize to pelletizing step, packing the product. The said production process has low cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

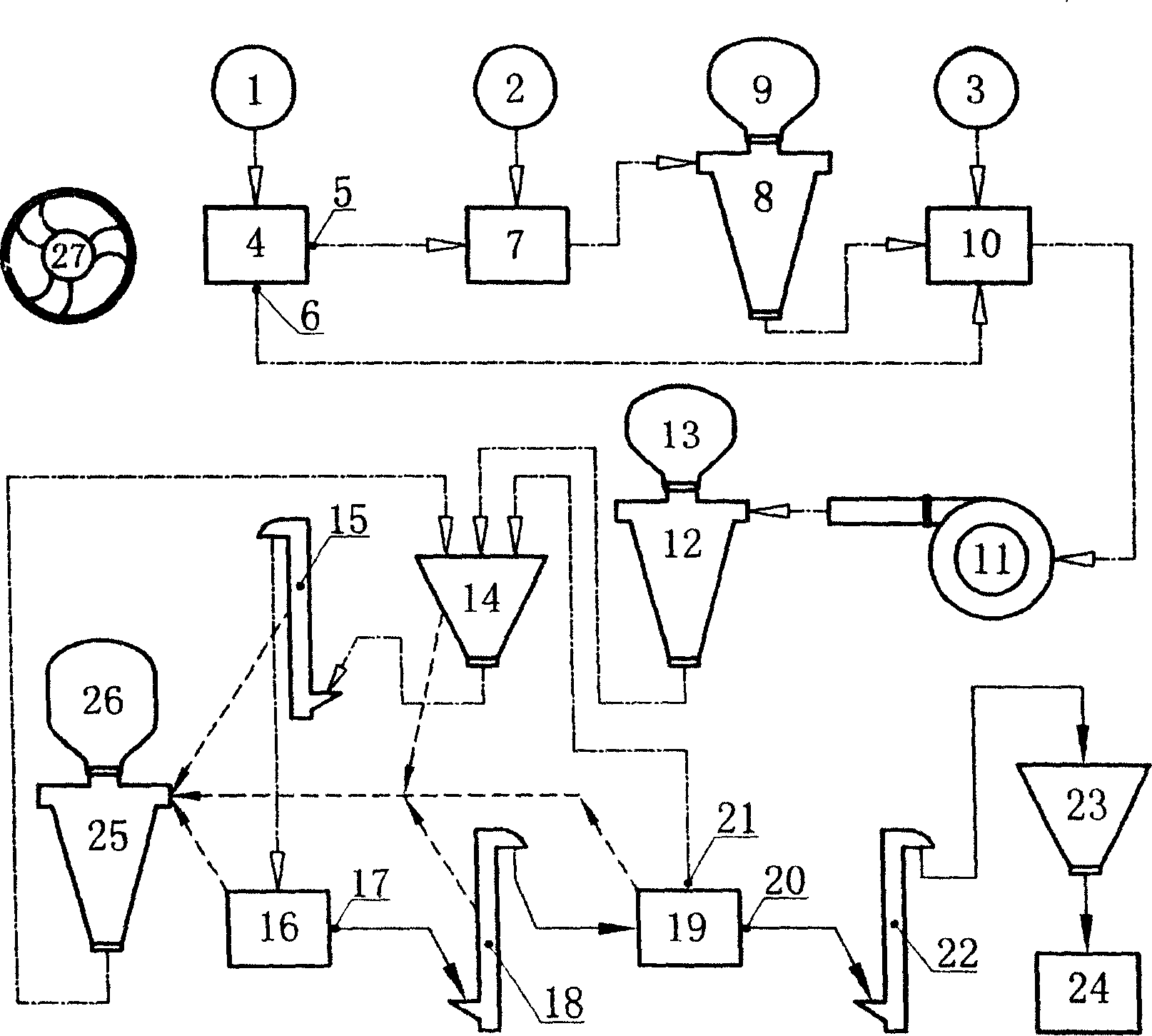

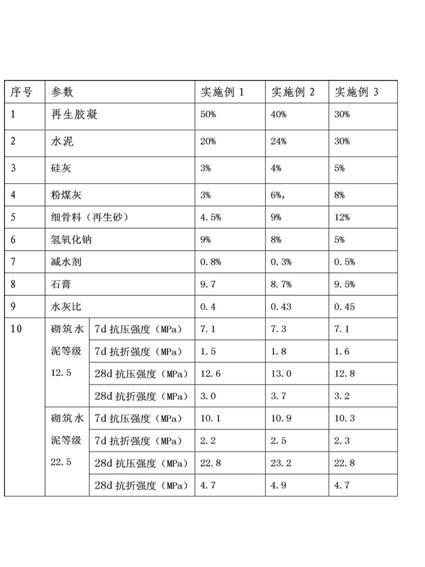

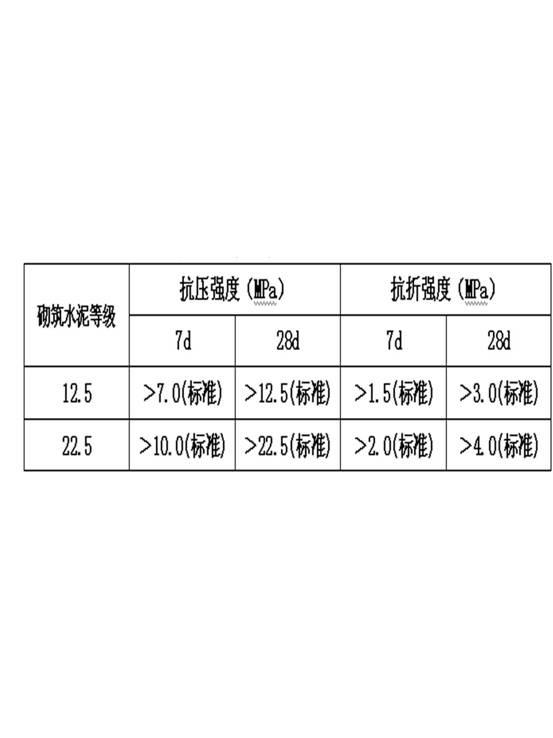

Construction regenerated binding material prepared from construction garbage and preparation method thereof

InactiveCN102432207AGreat renewable valueLarge specific surface areaCement productionSlagPre treatment

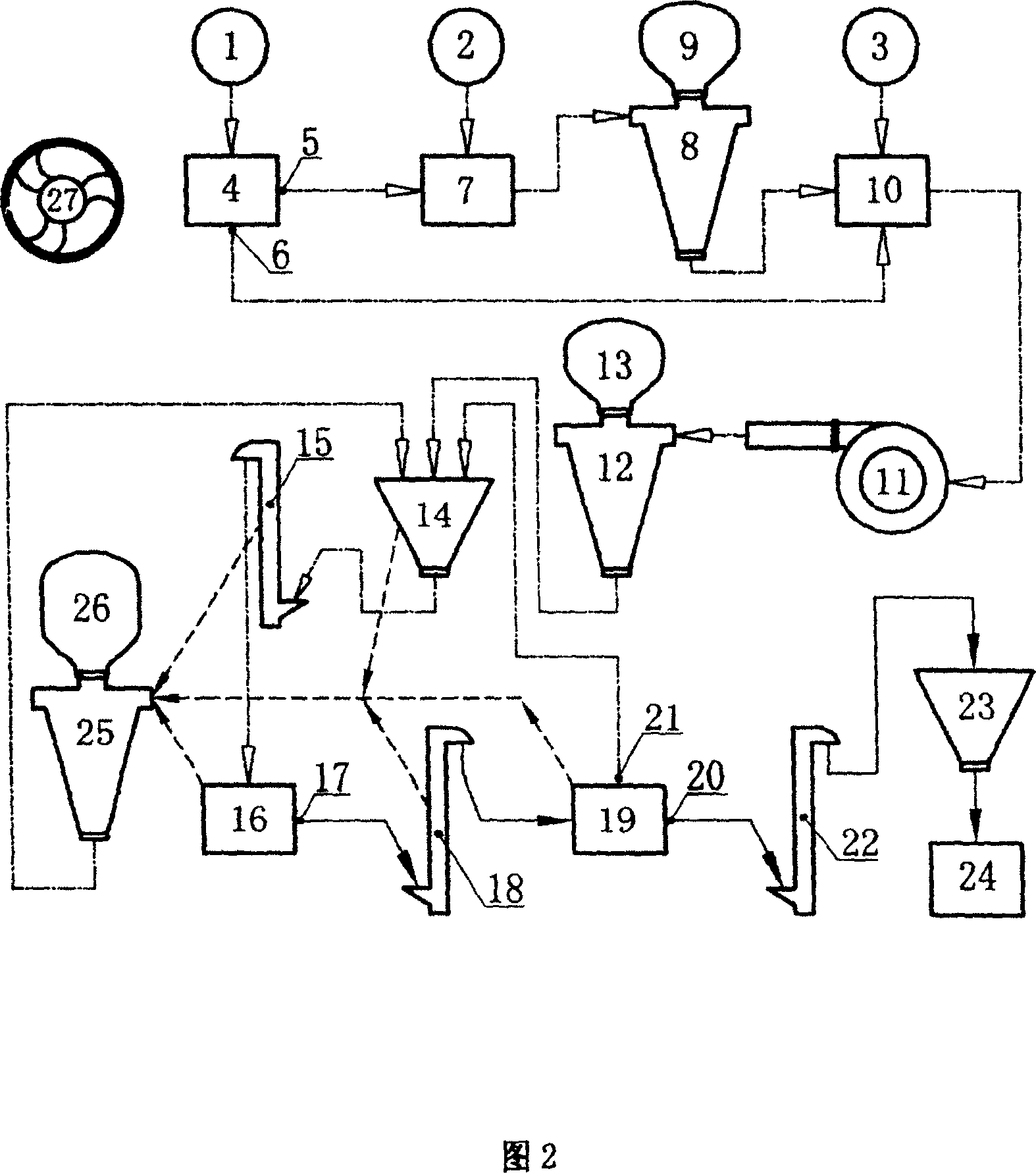

The invention discloses a construction regenerated binding material prepared from construction garbage, prepared by the following steps: putting the construction garbage in a reclamation machine to rub, impact, activate, and modify, using a micro powder extraction device to obtain regenerated micro powder, adjusting the proportion. The invention also discloses a preparation method of the material, comprising the following steps: pretreating construction garbage, reserving waste concrete, waste bricks, waste lime-sand mortar, and waste slag as raw materials; crushing and sieving raw materials to obtain particles; putting the particles in the reclamation machine for processing, removing inert membranes on sand grains, and activating the surface activity of particles; extracting micro powder by a dust collector, sieving the micro powder, and taking undersized parts to obtain regenerated micro powder; continuously crushing the unextracted particles, and extracting the regenerated micro powder when crushing; examining, and adjusting the components to obtain the construction regenerated binding material, wherein, the particles in the reclamation machine are regenerated sand. The construction regenerated binding material is used for replacing 50-70 % of ordinary portland cement to be as masonry cement.

Owner:云南华威废弃物资源化有限公司

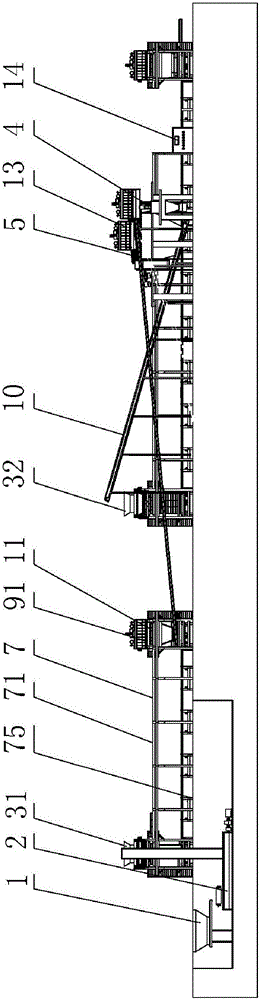

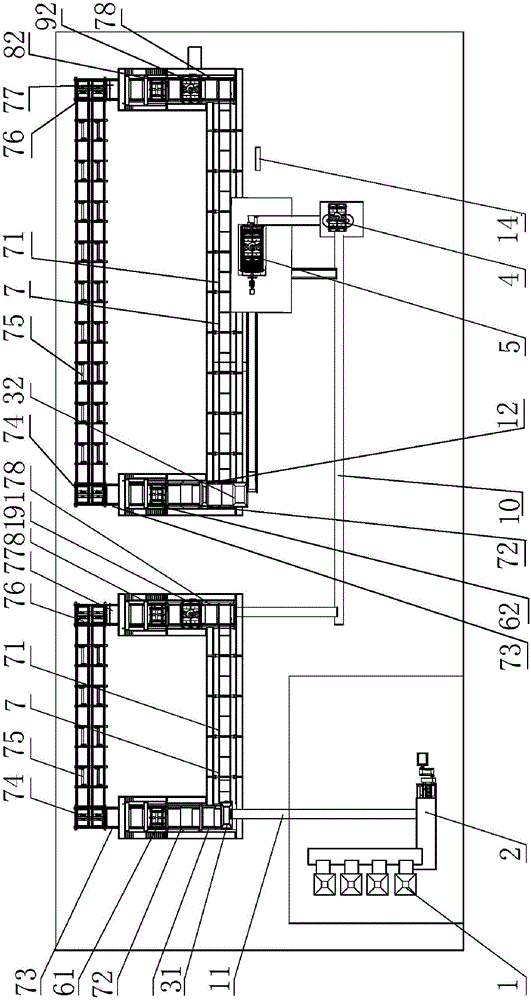

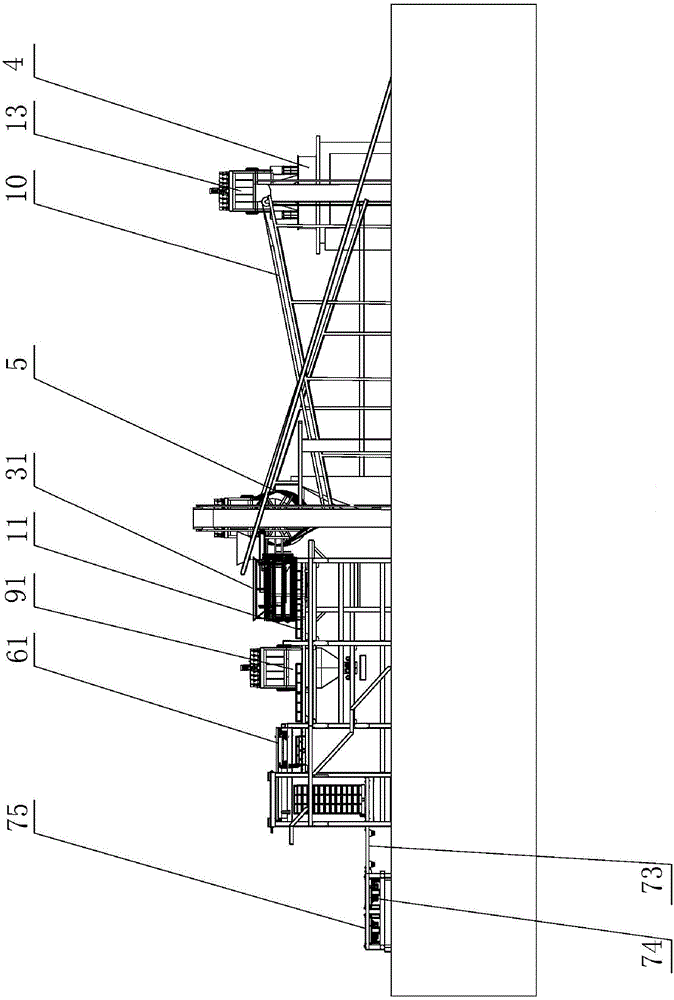

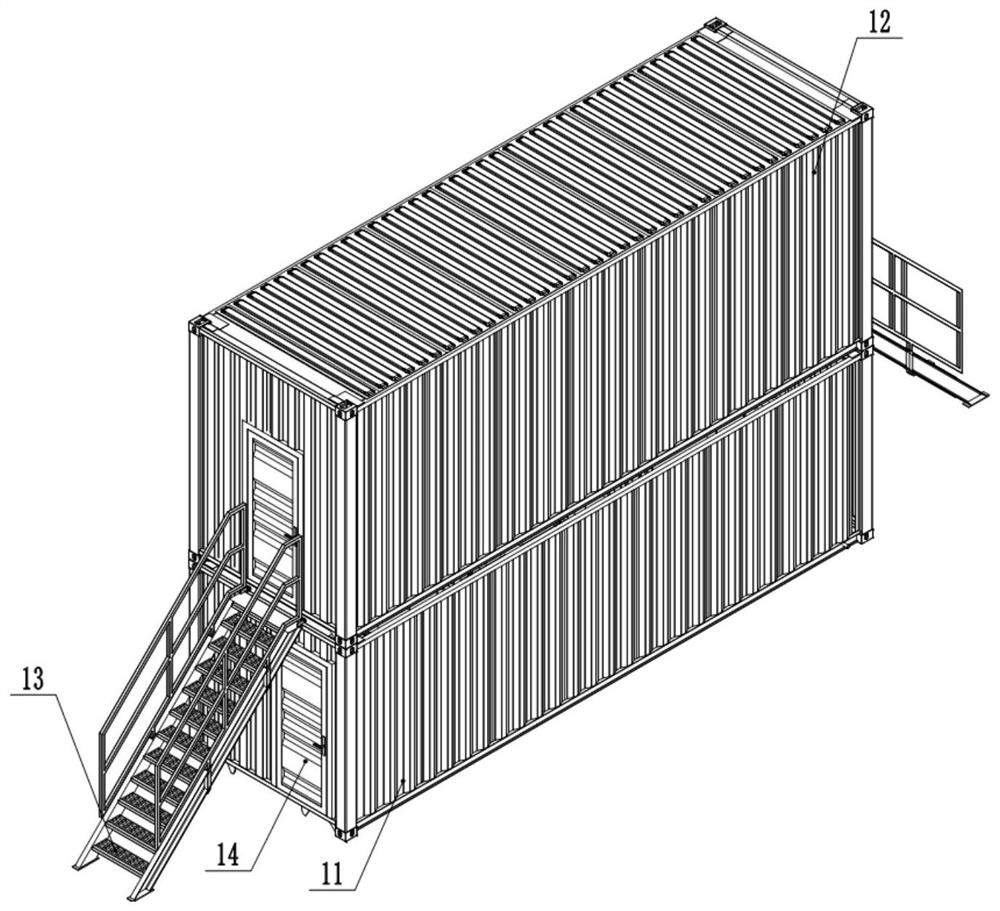

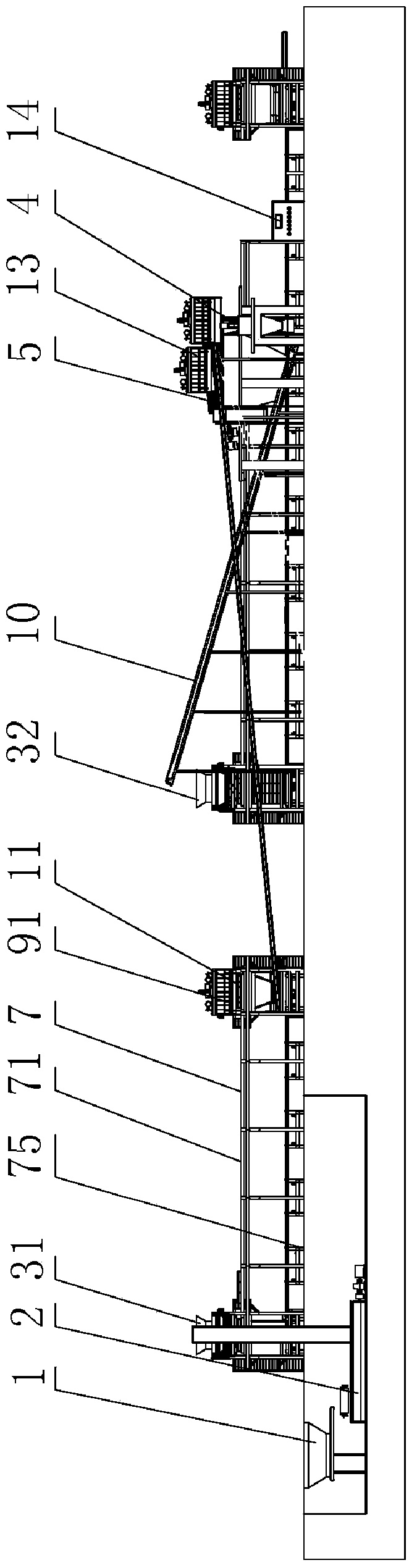

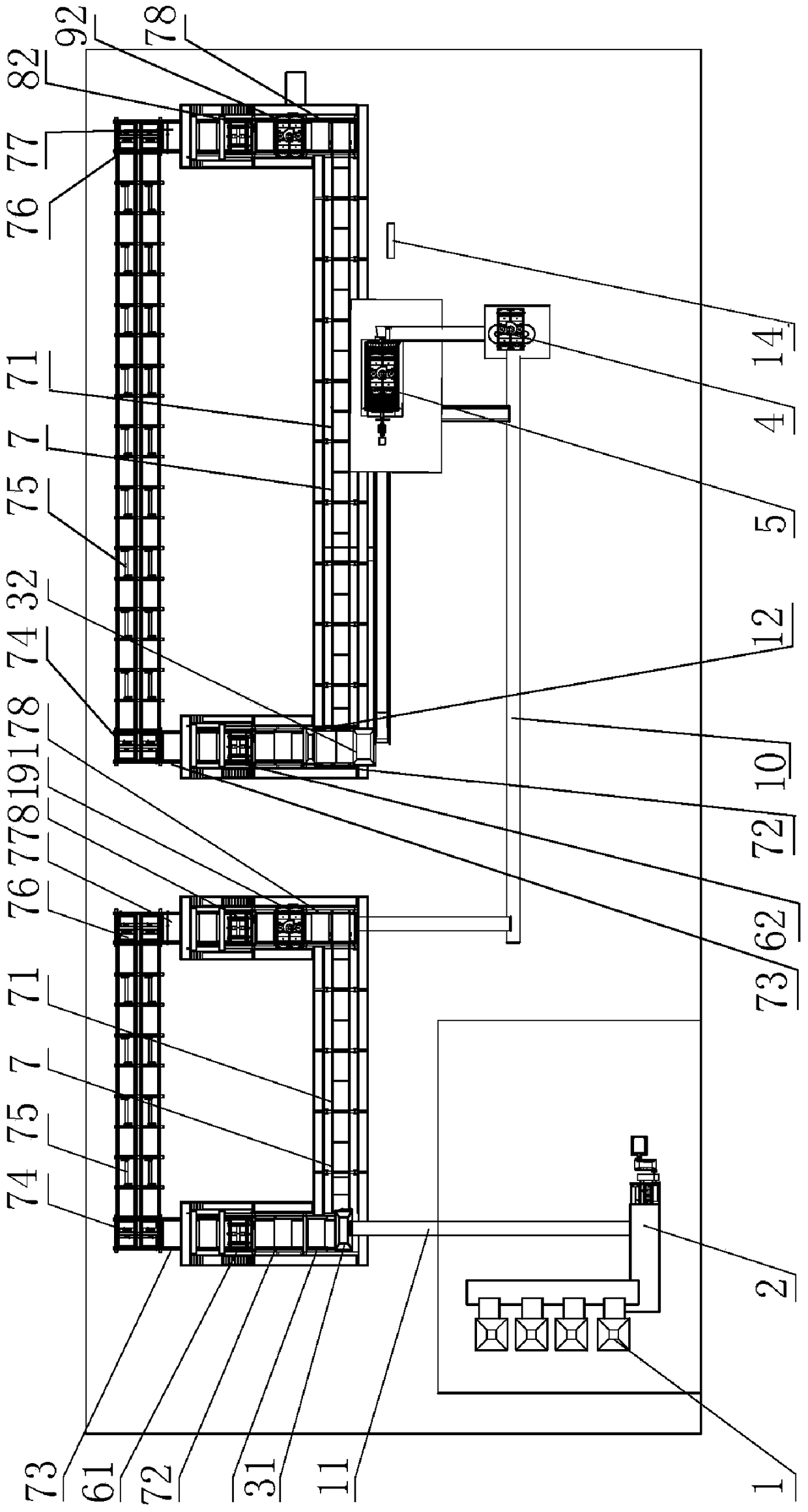

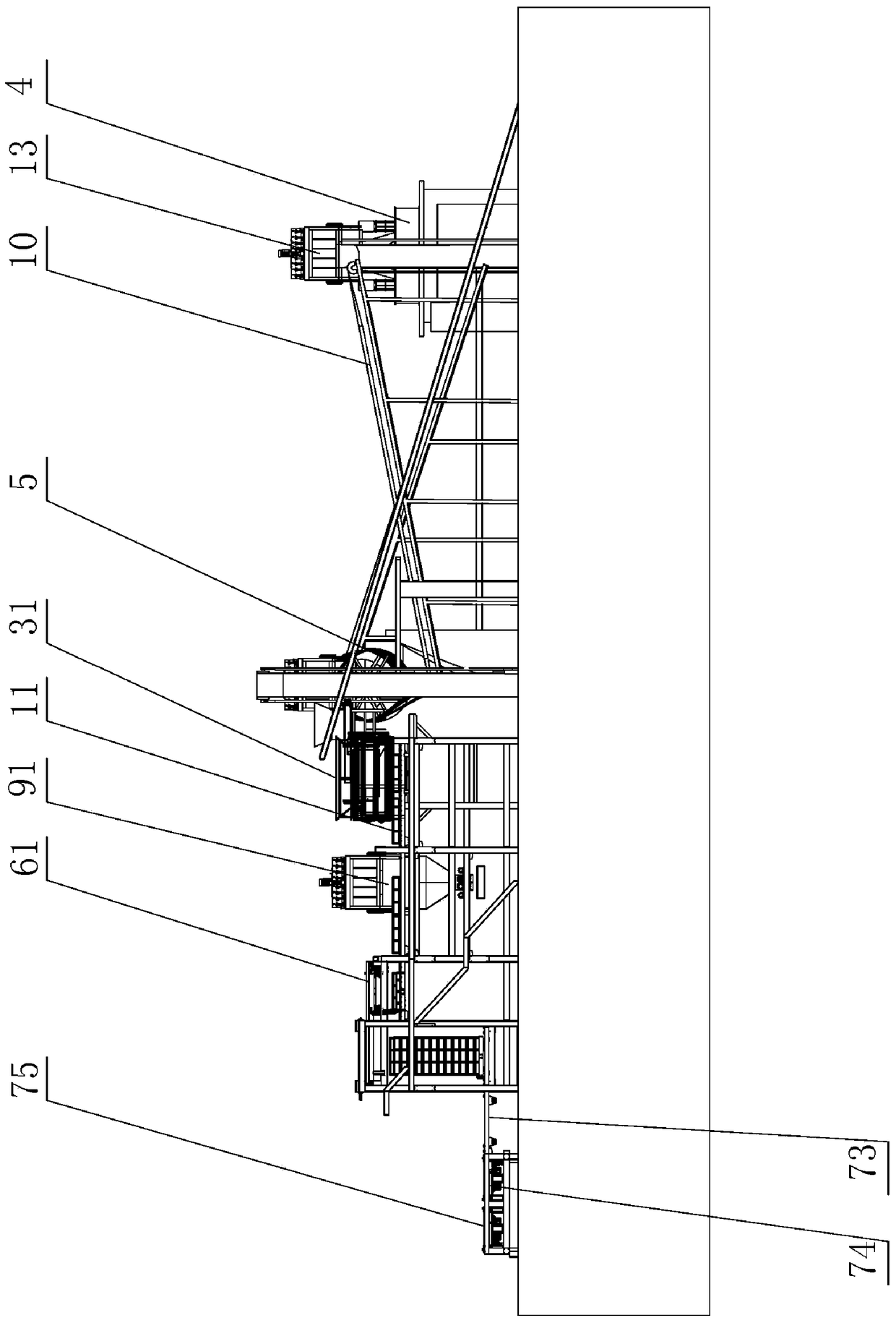

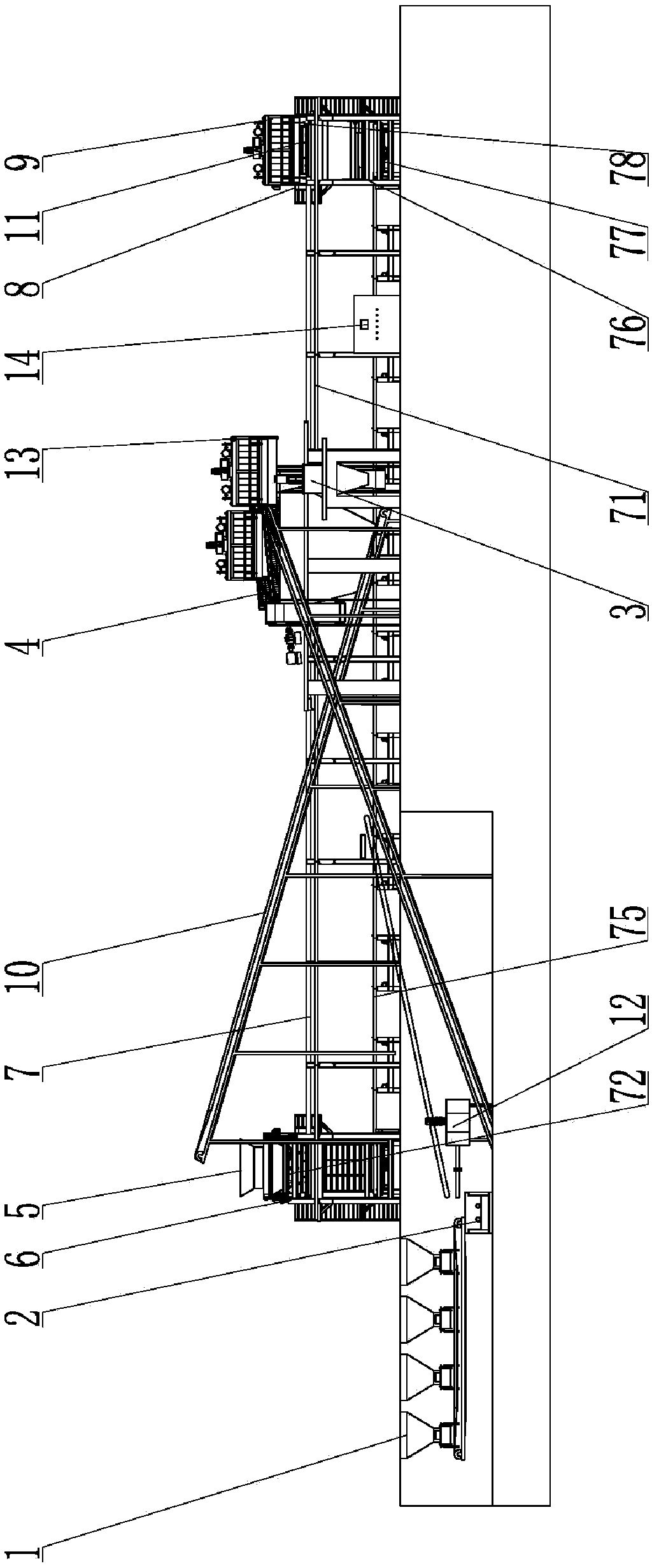

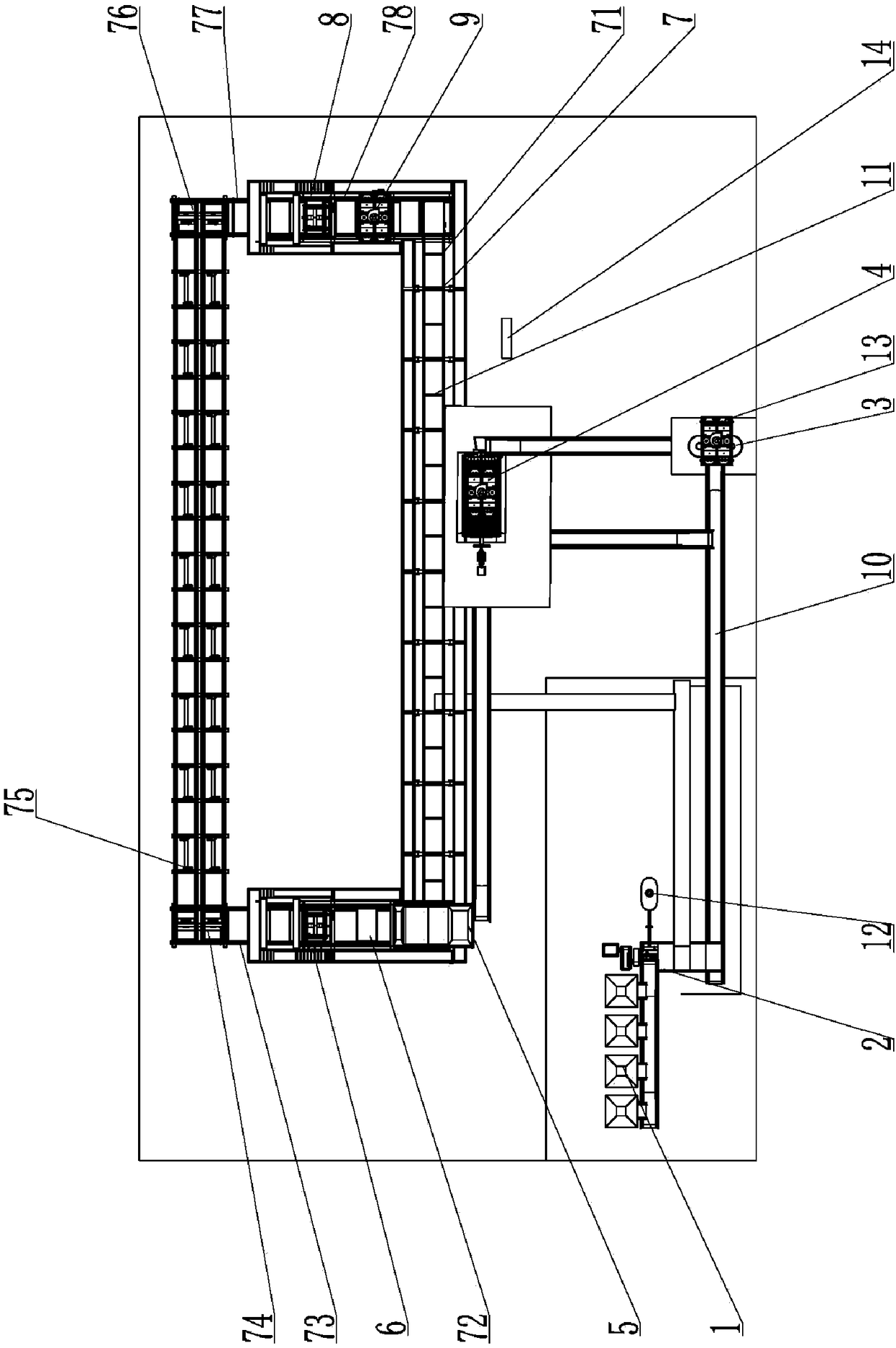

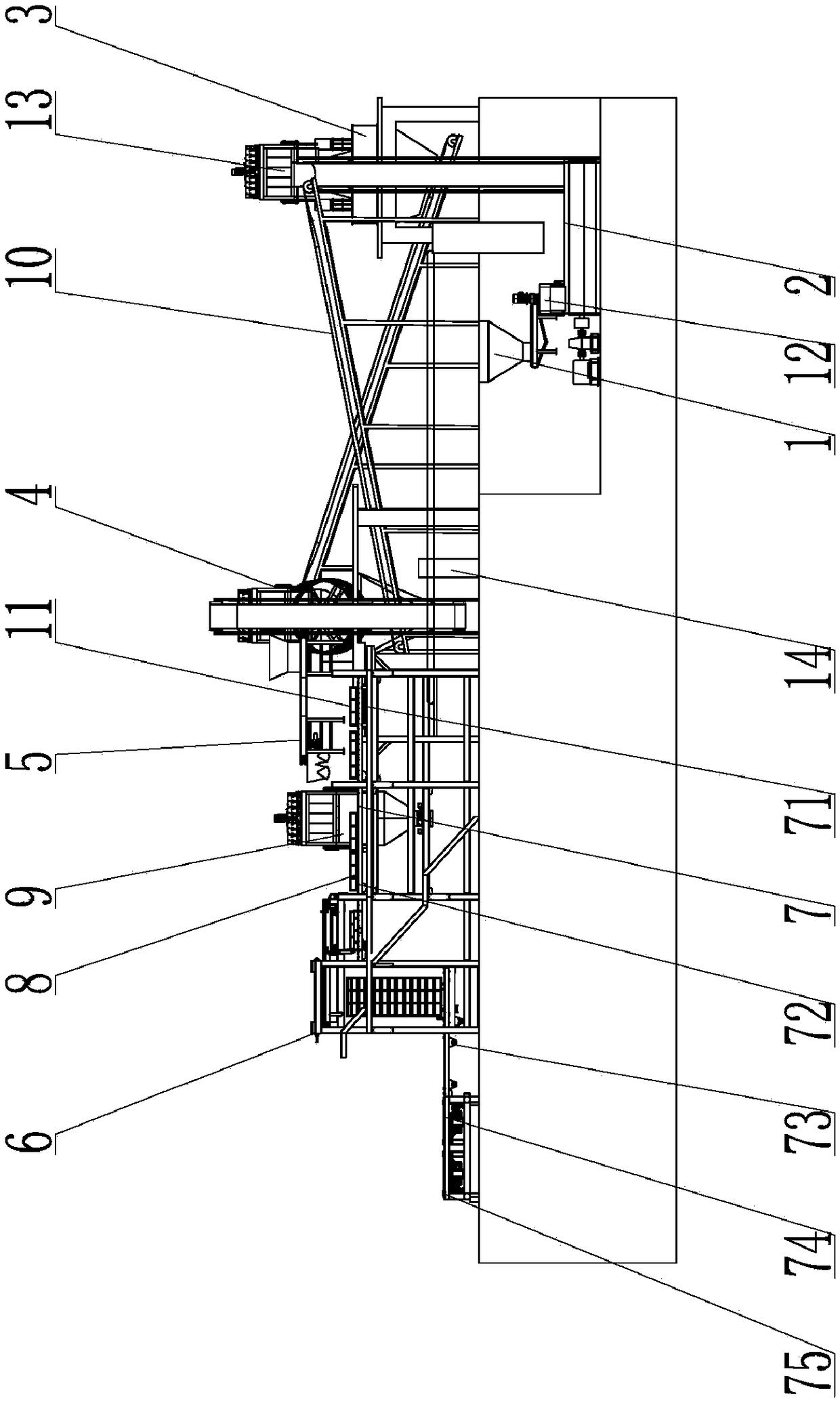

Tray type stereoscopic organic material fermentation system and fermentation method

ActiveCN105060958ASolve the problem of secondary environmental pollutionSave processing and production landBio-organic fraction processingClimate change adaptationStackerFermentation system

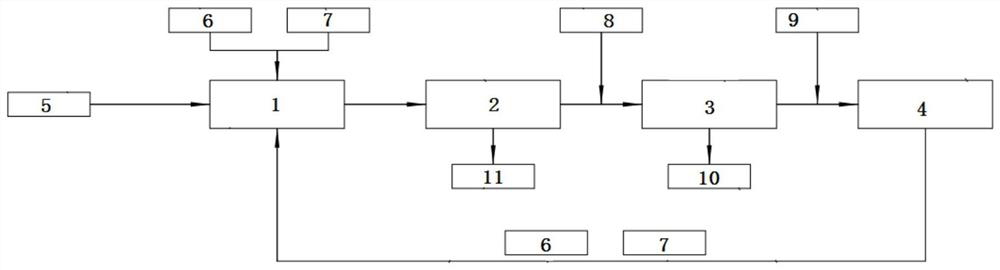

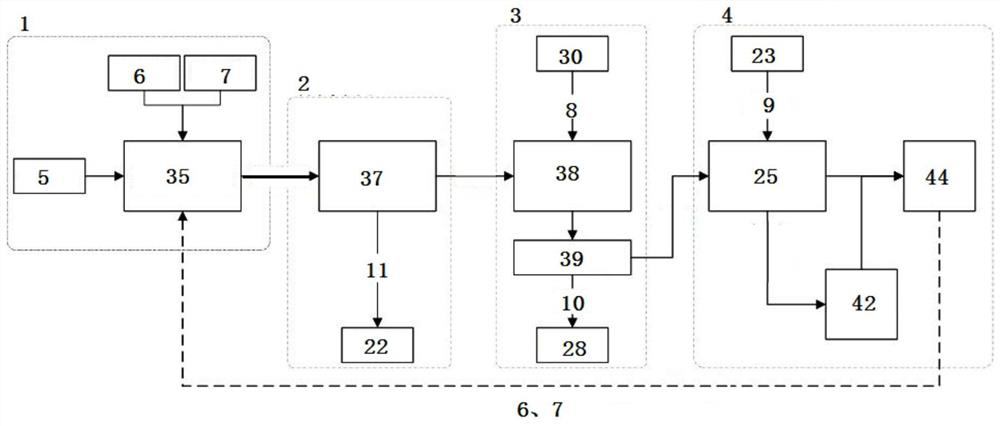

The invention relates to a tray type stereoscopic organic material fermentation system and fermentation method. The fermentation system comprises tray loading equipment, tray stackers, tray unstackers and tray-dumping unloaders which are mounted sequentially as well as rolling equipment mounted on the tray loading equipment, tray conveying equipment connected among the tray loading equipment, the tray stackers, the tray unstackers and the tray-dumping unloaders and fermentation trays moving and circulating among the tray loading equipment, the tray stackers, the tray unstackers and the tray-dumping unloaders through the tray conveying equipment. Organic materials are loaded in the fermentation trays by the tray loading equipment, the fermentation trays are conveyed to the tray stackers by the tray conveying equipment to be stacked to form a tray stack, the organic materials are subjected to aerobic fermentation in the fermentation trays stacked in the tray stack and conveyed to the tray unstackers through the tray conveying equipment, the fermentation trays are taken out from the tray stack, the trays are conveyed to the tray-dumping unloaders by the tray conveying equipment, the materials are poured out from the fermentation trays, and the empty fermentation trays are conveyed back to the tray loading equipment by the tray conveying equipment.

Owner:GUANGXI LIYUANBAO SCI & TECH

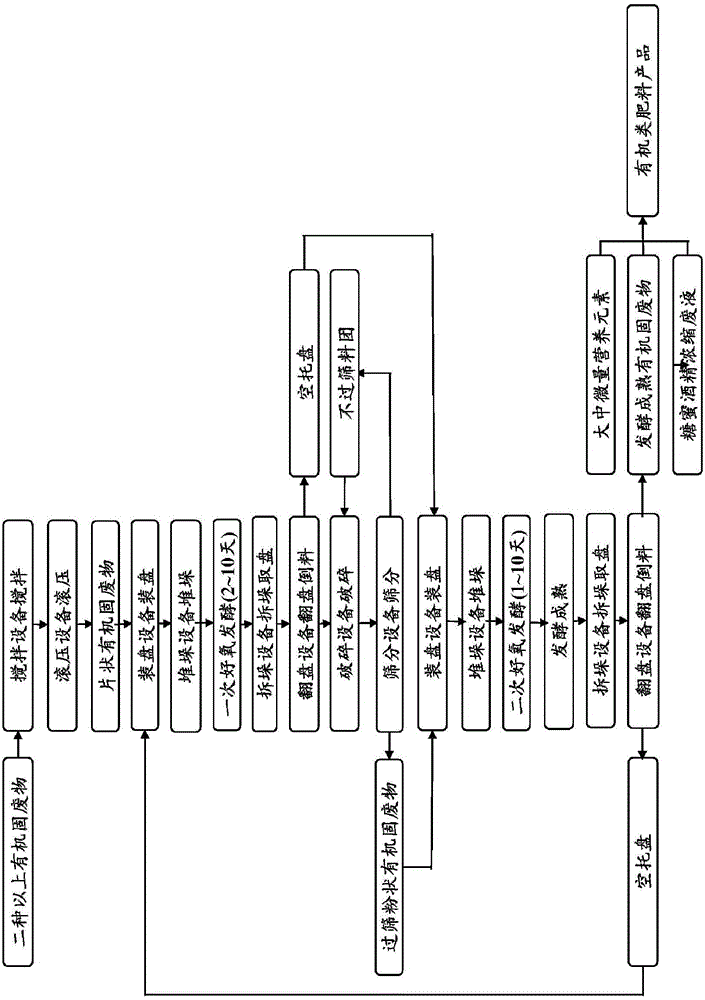

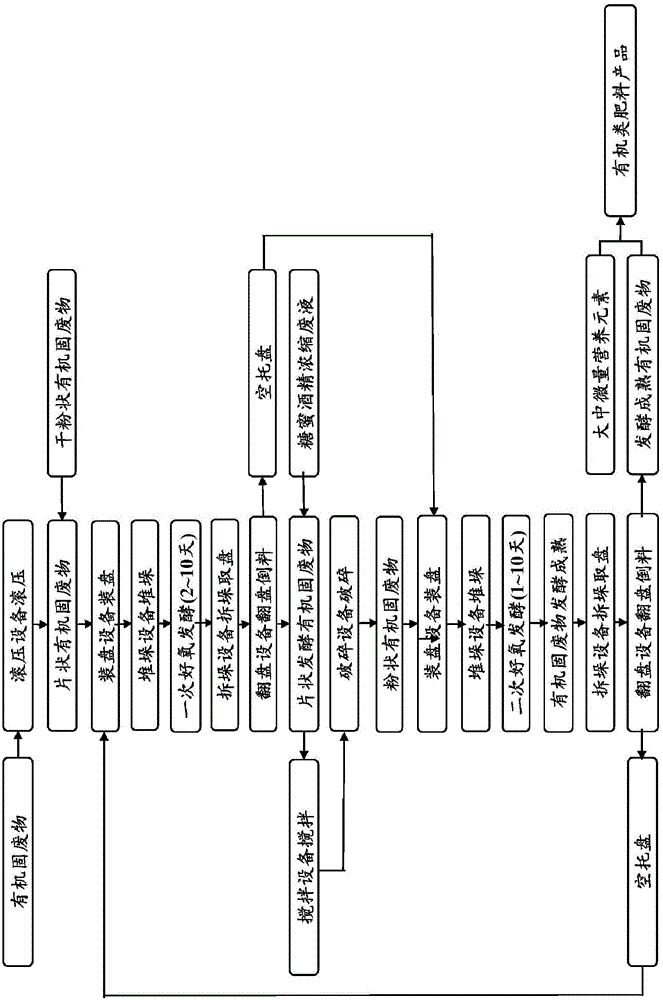

Method for producing organic fertilizer by using sugar refining filter mud and bagasse

ActiveCN104529578ASolve the problem of secondary environmental pollutionGood fermentation air permeabilityBio-organic fraction processingClimate change adaptationNutrientOrganic manure

The invention provides a method for producing an organic fertilizer by using sugar refining filter mud and bagasse. The method comprises the steps of blending the sugar refining filter mud, of which the weight ratio is 90.01-99.9%, and the bagasse, of which the weight ratio is 0.1-9.99%, so as to form a filter mud fermentation material, then, putting the filter mud fermentation material on three-dimensional fermentation equipment, of which the vertical direction comprises 2-40 layers and the horizontal direction comprises 2-40 belt conveyors, carrying out aerobic fermentation, carrying out composting and dehydrating, so as to obtain well-composted organic raw materials, then, applying the well-composted organic raw materials directly as an organic fertilizer, or producing various organic fertilizer products in a manner that the well-composted organic raw materials are matched with macro-, medium- and micro- nutrient elements essential to plants. The method provided by the invention can be used for effectively utilizing the sugar refining filter mud and the bagasse and is good in fermentation effect and small in floor area, meanwhile, secondary pollution resulting from bad smell can be avoided, and the aims of high efficiency and environment-friendliness are achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

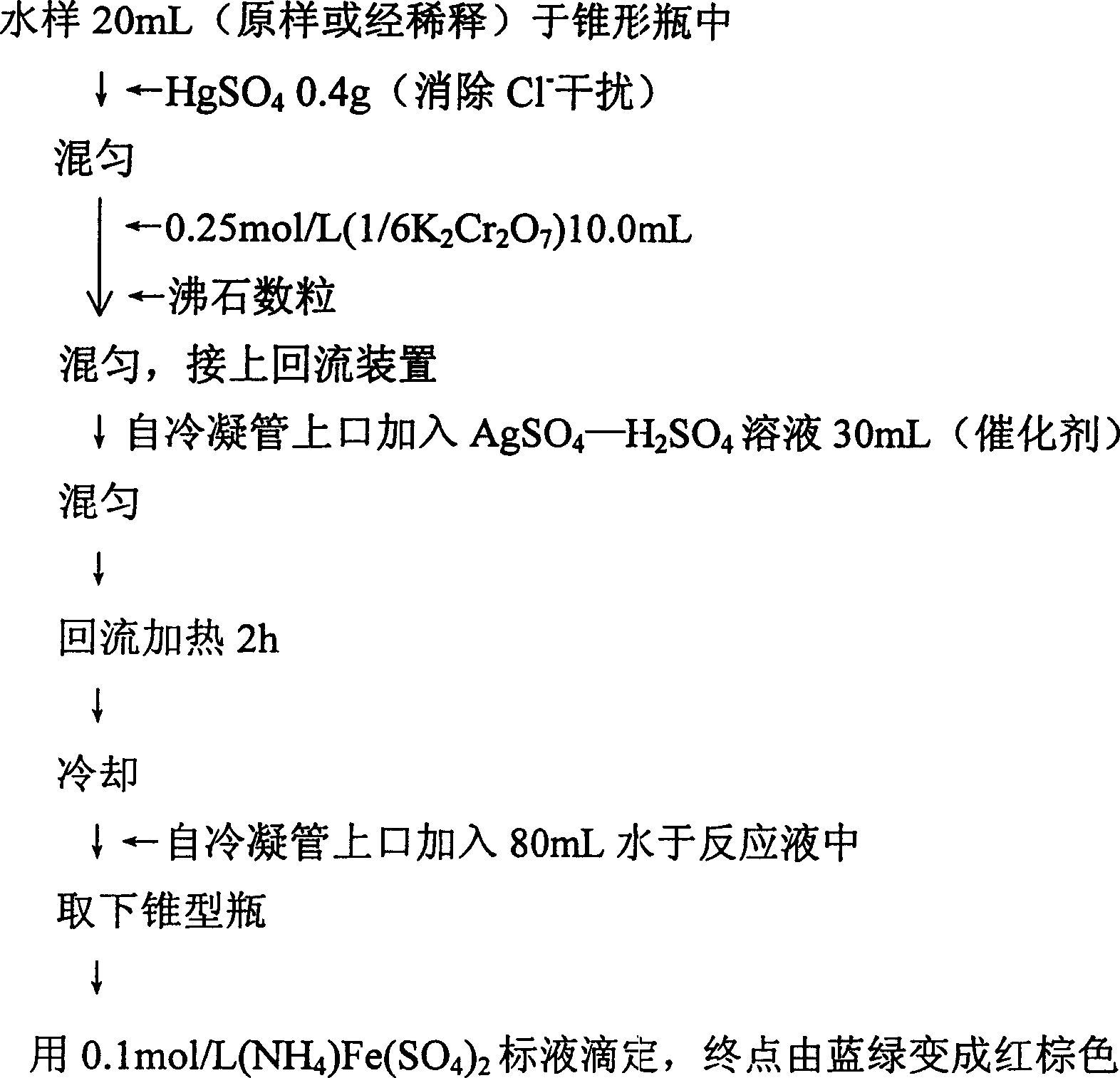

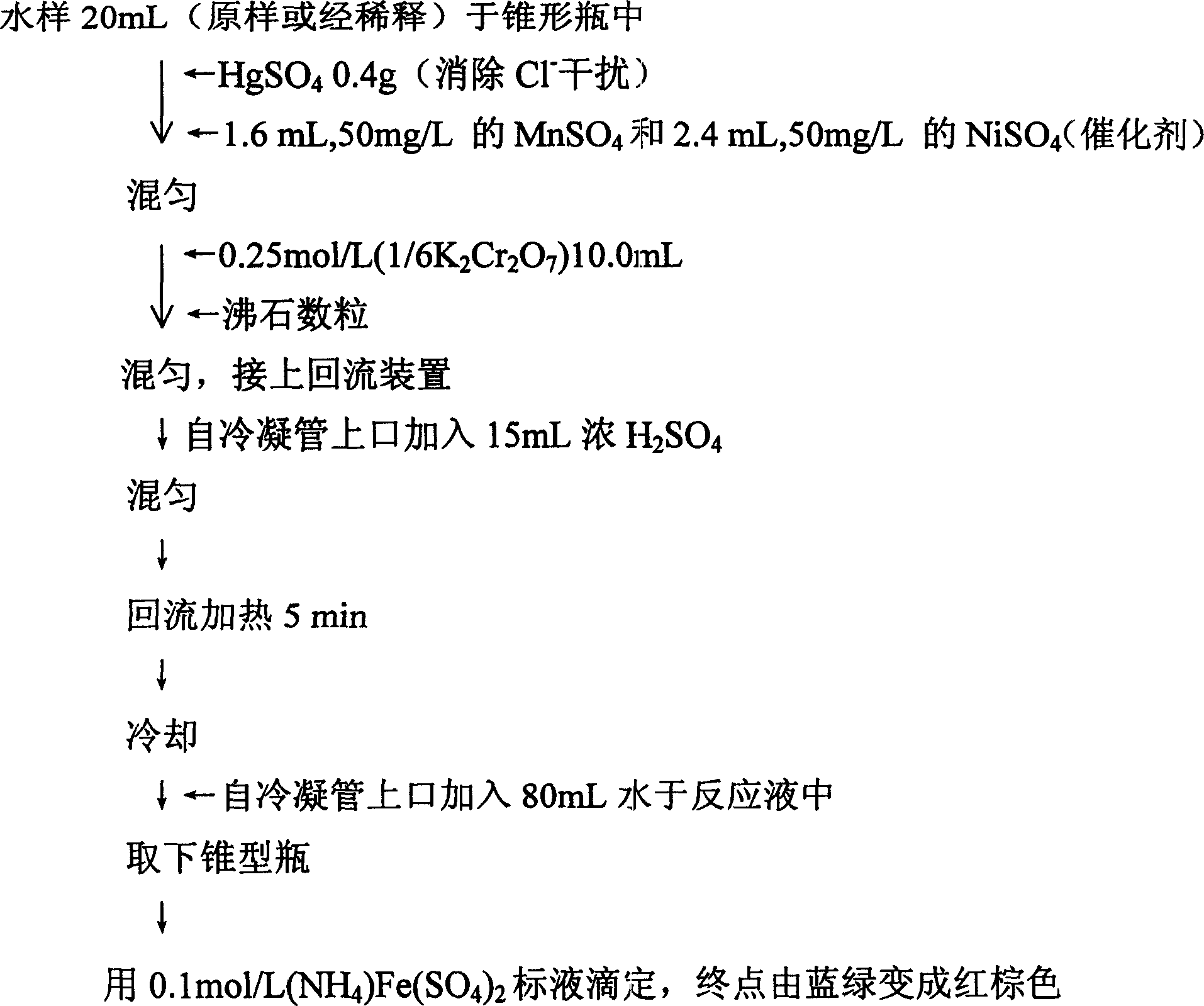

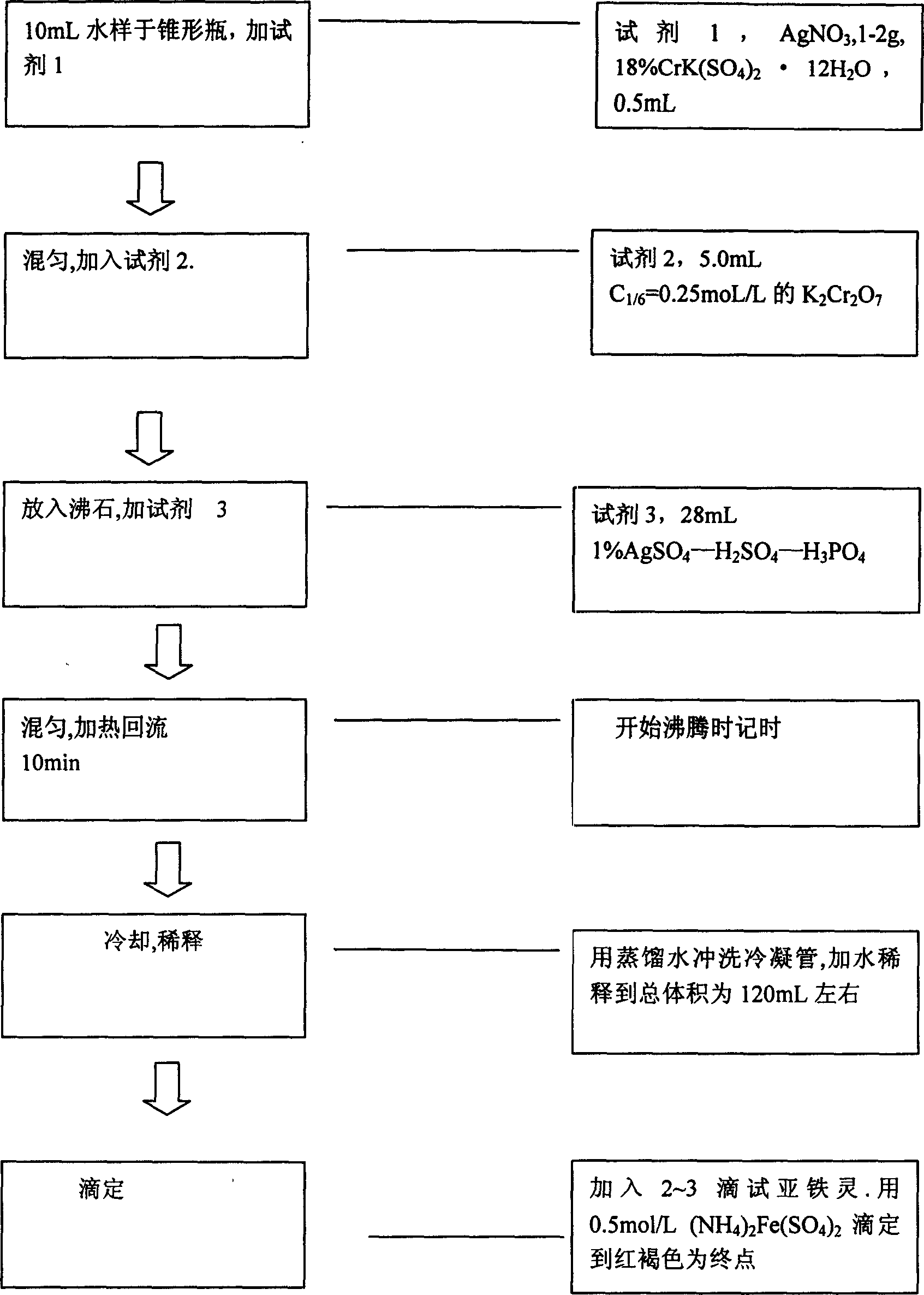

Quick detecting method for needed oxygen COD cr of mercuryless salt high-chlorine waste water chemical

InactiveCN1598548AImprove reliabilityGood reproducibilityMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationOxygenContamination

The invention discloses a quick measuring method for mercury salt less high chlorine waste water chemical oxygen demond quantity CODcr. Its character lies in: the method uses standard potassium dichromate method, uses MnSO4 and NiSO4 to replace Ag2SO4, and checks the CODcr in water sample. The method is reliable, the energy consumption and reagent cost are saved; and because of using AgNO3 and CrK (SO4)2 to replace severe toxici HgSO4 as combined masking agent, solves the secondary contamination to environment.

Owner:DALIAN JIAOTONG UNIVERSITY

Energy-saving and environment-friendly method for treating municipal sludge

ActiveCN104496137AImprove breathabilityNothing producedBio-organic fraction processingSludge treatmentSludgeFermentation

The invention provides an energy-saving and environment-friendly method for treating municipal sludge. The method comprises the following steps: doping municipal sludge with a water content of 70-85% with a regulation material with a certain weight proportion to form a fermented sludge material, and then placing the fermented sludge material on three-dimensional fermentation equipment for dynamic aerobic fermentation, wherein the three-dimensional fermentation equipment is composed of 2-40 layers in the vertical direction and 2-40 groups of belt conveying mechanisms in the horizontal direction, and a rotten dry material which is dried to a water content lower than 50% by biological dehydration is used in further environmental protection treatment or resource utilization. The method provided by the invention is simple, small in occupation area and good in fermentation effect, meanwhile, secondary pollution caused by bad smell can be avoided, and the purposes of high efficiency and environmental friendliness are achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

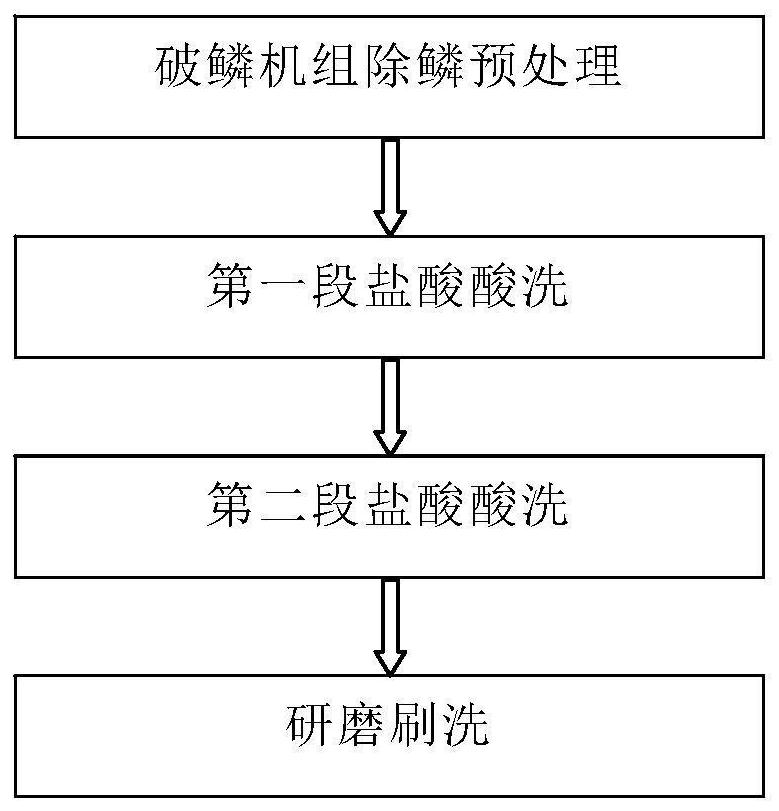

Stainless steel hot rolling strip steel acid pickling process

InactiveCN111604786AImprove surface qualityImprove pickling effectGrinding drivesGrinding machinesCarbide siliconStrip steel

The invention relates to a stainless steel hot rolling strip steel acid pickling process. The process comprises the steps of scale breaking unit scale removal pretreatment, wherein the total extensionrate of strip steel is controlled to be larger than or equal to 3.0%; first-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in first-segment hydrochloric acid acid pickling liquid to be subjected to first-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the first-segment hydrochloric acid acid pickling liquid is controlled to 50 to 300 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 60 to 80 DEG C, and the acid pickling time is controlled to 25 s to 50 s; second-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in second-segment hydrochloric acid acid pickling liquid to be subjected to second-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the second-segment hydrochloric acid acid pickling liquid is controlled to 50 to 250 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 50to 75 DEG C, and the acid pickling time is controlled to 25 s to 50 s; grinding scrubbing, wherein the strip steel is subjected to grinding scrubbing, the diameter of roller brush bristles is controlled to 0.7 to 1 mm, the bristles contain silicon carbide abrasives with meshes being 170 to 200 meshes, the rotating speed of a roller brush motor is controlled to 600 to 1000 rpm, and the current of the roller brush motor is controlled to 100 to 200 A.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Energy-saving and environment-friendly method for treating sewage digested sludge

ActiveCN104529110AImprove breathabilityGood aerobic fermentation stateSludge processingBiological sludge treatmentSmall footprintSewage

The invention provides an energy-saving and environment-friendly method for treating sewage digested sludge. The method comprises the steps of blending the sewage digested sludge, of which the moisture content is 70-85%, with adjusting materials of a certain weight ratio, so as to form a sludge fermentation material, then, putting the sludge fermentation material on three-dimensional fermentation equipment, of which the vertical direction comprises 2-40 layers and the horizontal direction comprises 2-40 belt conveyors, carrying out dynamic aerobic fermentation, carrying out biological dehydration drying until well-composted dry materials, of which the moisture content is lower than 50%, are obtained, and then, carrying out further environment-friendly treatment or resource utilization. The method provided by the invention is simple and is small in floor area and good in fermentation effect, meanwhile, secondary pollution resulting from bad smell can be avoided, and the aims of high efficiency and environment-friendliness are achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Wax paper based sustain-released bio-control agent, preparation method and applications thereof

The invention discloses a wax paper based sustain-released bio-control agent, which comprises the following raw materials: waste and old wax paper, entomogenous fungus spore powder, and an adhesive. The invention also discloses a preparation method of the sustain-released bio-control agent. The preparation method comprises the following steps: step one, grinding waste and old wax paper into fragments with a particle size of 2 to 4 mm, and then evenly mixing the fragments with inoculated fungus spore powder to obtain a material (a); step two, using an adhesive agent to artificially make the material (a) into granular materials; step three, painting pigment on the surface of the granular materials so as to obtain the sustain-released bio-control agent. The invention also discloses applications of the sustain-released bio-control agent. The bio-control agent can be evenly sprayed on farmland or forest through different modes: artificial spraying, mechanical spraying, display shell spraying, aviation spraying, and the like. The preparation method has the advantages that various biodegradable solid wastes are converted into valuable resources, the spore powder can be slowly released, and thus the bio-control effect can last for a long time.

Owner:HUANGSHAN UNIV

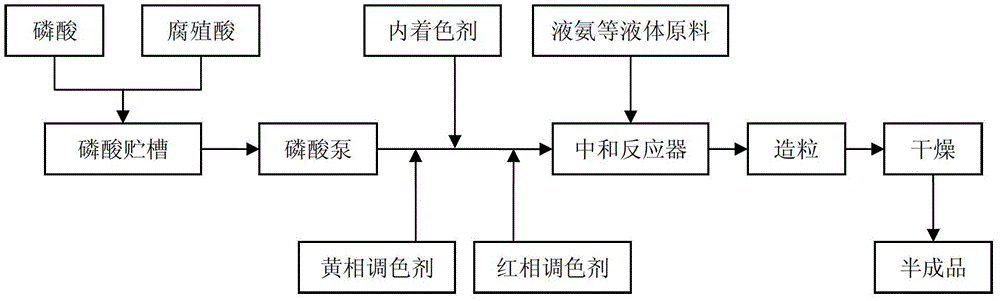

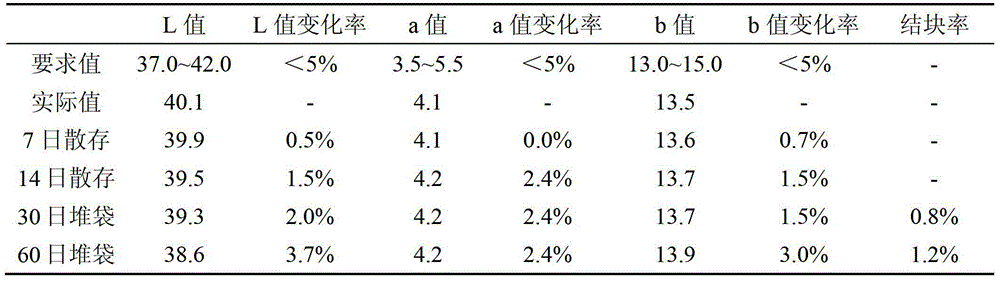

Internally dying method for diammonium phosphate

ActiveCN103408367BSolve secondary environmental pollutionEasy to sendAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersIonHumic acid

The invention discloses an internally dying method for diammonium phosphate, which comprises the following steps: adding humic acid into phosphoric acid and uniformly stirring to obtain mixed raw materials; adding water soluble coloring agent and color matching agent into the mixed materials; enabling the mixed materials to react with liquid ammonia, so as to obtain diammonium phosphate subjected to internally dying. The internally dying method has the advantages as follows: 1, the cost is low as humic acid is taken as the main raw material for internal dying of diammonium phosphate, and the economic benefit is remarkable as the consumption of the traditional water soluble internal coloring agent is reduced from 3-6 / 1000 per ton to 0.5 / 1000 below per ton and the cost of the products is reduced by 40 yuan per ton; 2, the precise adjustment can be realized and the product color is stable and reliable as the method comprises three internal dying stages, namely roughly underpainting, finely underpainting and hue adjusting; 3, the transmission of nutrition elements to crops is facilitated as the humic acid can be separated and combined with metal ions in water, the crop growth is facilitated as the soil structure can be improved, and the humic acid is used for replacing the traditional colorant to solve the secondary environmental pollution problem of the traditional colorant, so as to achieve great significance in environmental protection.

Owner:CHINA NAT OFFSHORE OIL CORP +2

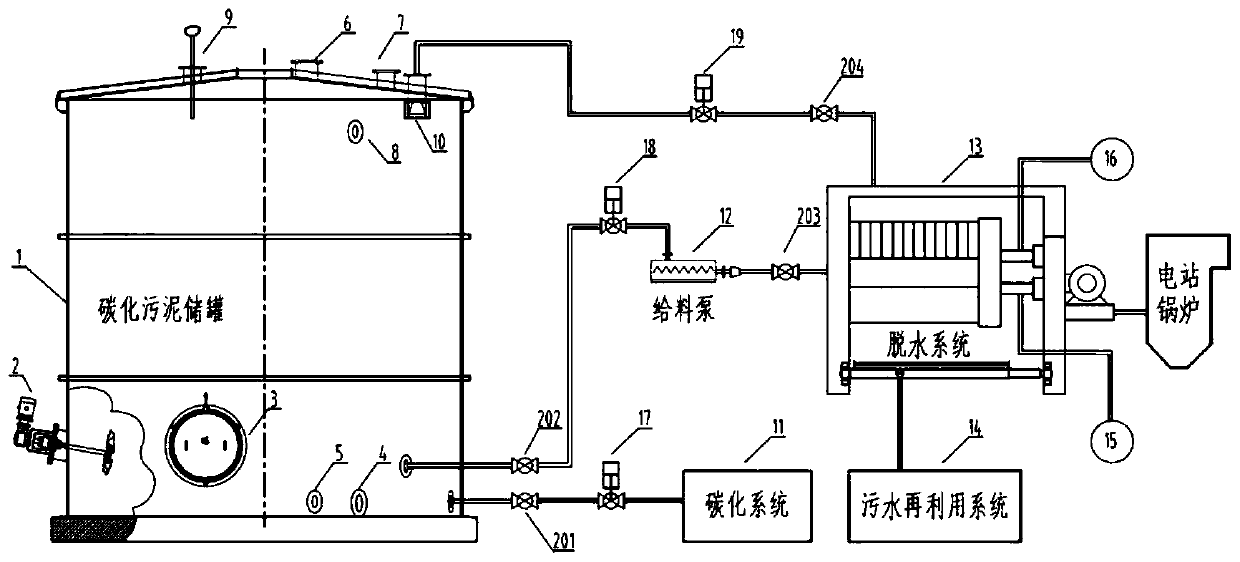

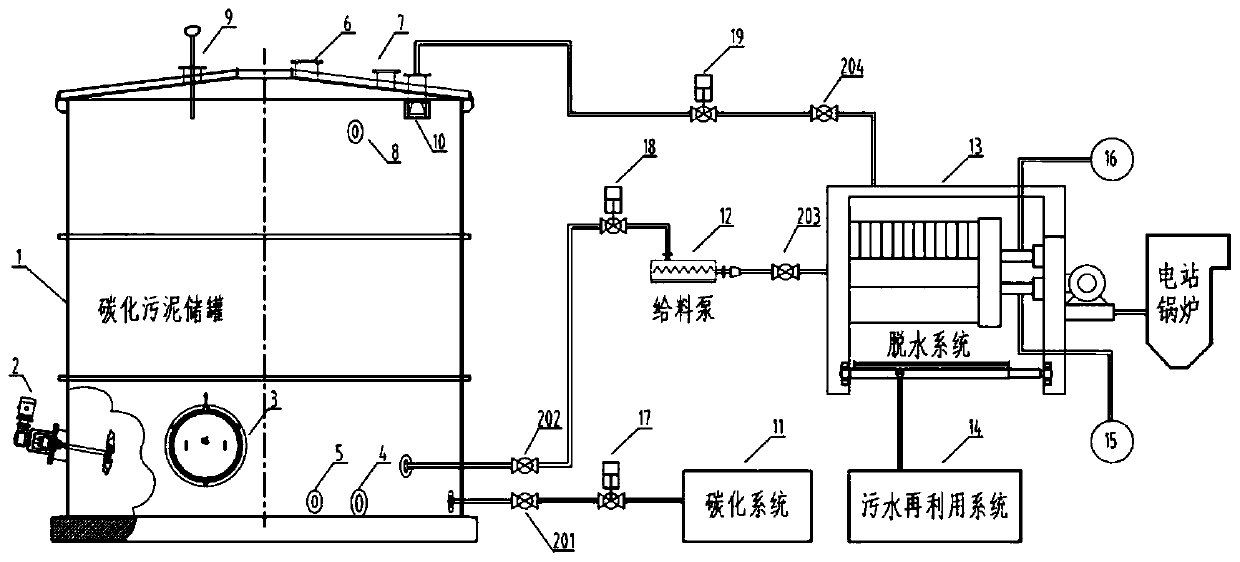

Coal-fired power plant sludge drying and blending combustion system

PendingCN109838789AAvoid influencePrevent proliferationIncinerator apparatusCombined combustion mitigationCombustion systemSludge

The invention discloses a coal-fired power plant sludge drying and blending combustion system. The coal-fired power plant sludge drying and blending combustion system comprises a sludge carbonizing system, a carbonized sludge storage tank, a feeding pump, a dewatering system, a power station boiler and a wastewater recycling system; an outlet of the sludge carbonizing system communicates with an inlet of the carbonized sludge storage tank, an outlet of the carbonized sludge storage tank communicates with an inlet of the dewatering system through the feeding pump, a dried sludge outlet of the dewatering system communicates with a coal feeding belt of the power station boiler, and a wastewater outlet of the dewatering system communicates with the wastewater recycling system; an air exhaust and extraction port, a dosing port and a radar level gauge used for detecting the liquid level of sludge in the carbonized sludge storage tank are arranged at the top of the carbonized sludge storage tank; and a stirrer used for stirring the sludge in the carbonized sludge storage tank is arranged on the side surface of the carbonized sludge storage tank. The coal-fired power plant sludge drying and blending combustion system can solve problem of influence of sediment and carbonized sludge malodor on the environment in the storage, conveying and dewatering processes of the carbonized sludge.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

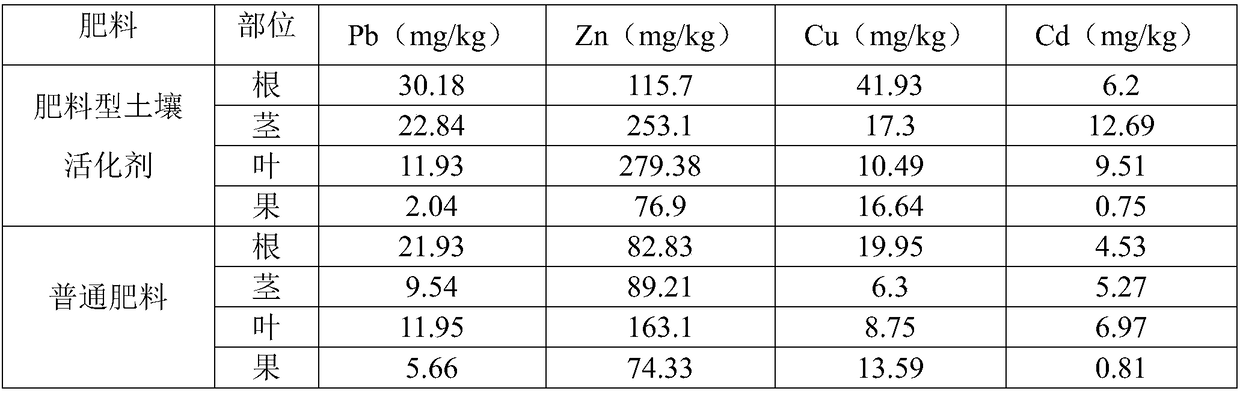

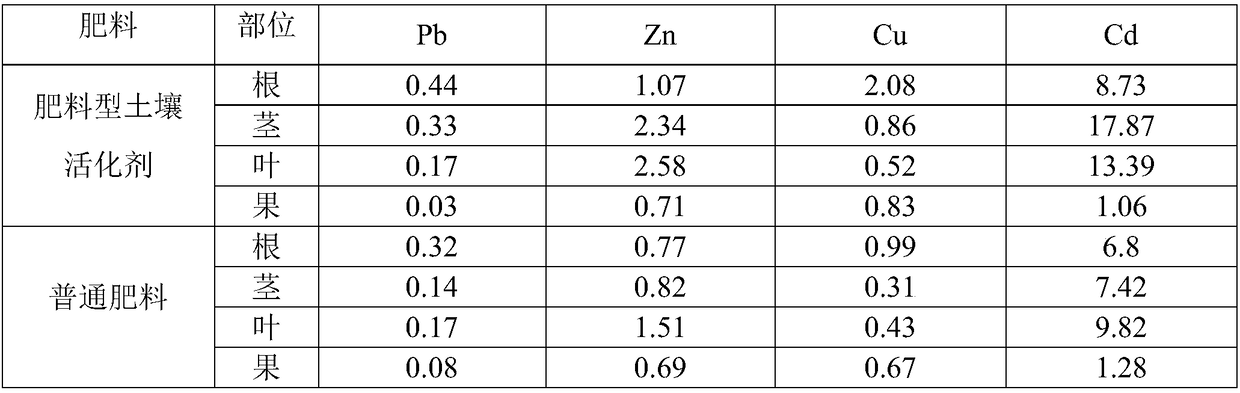

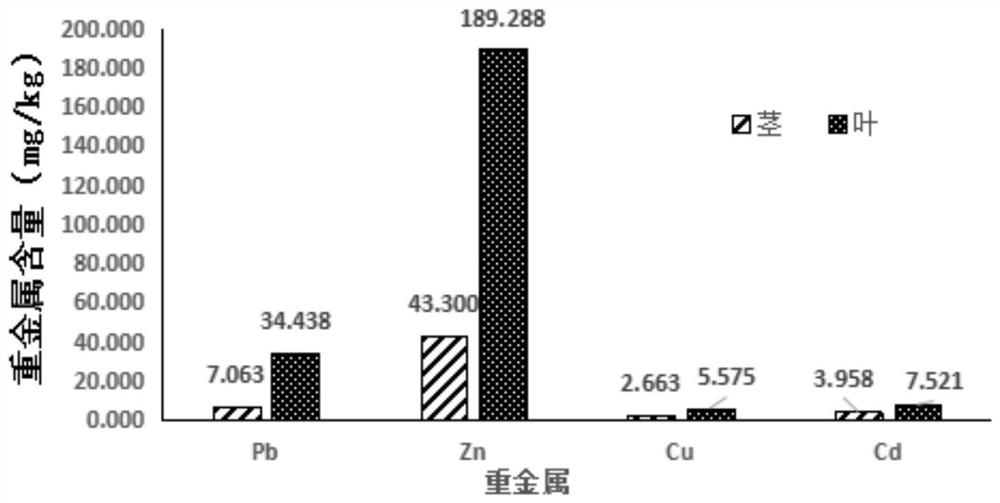

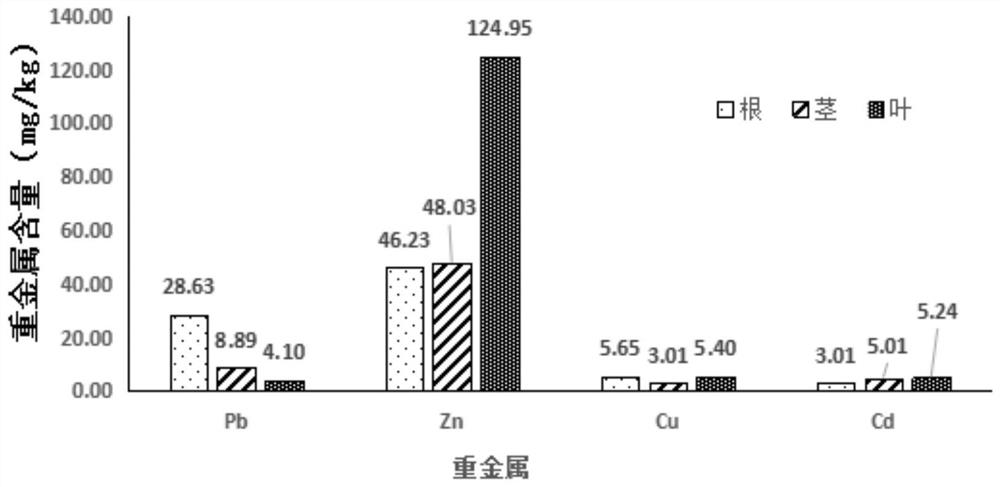

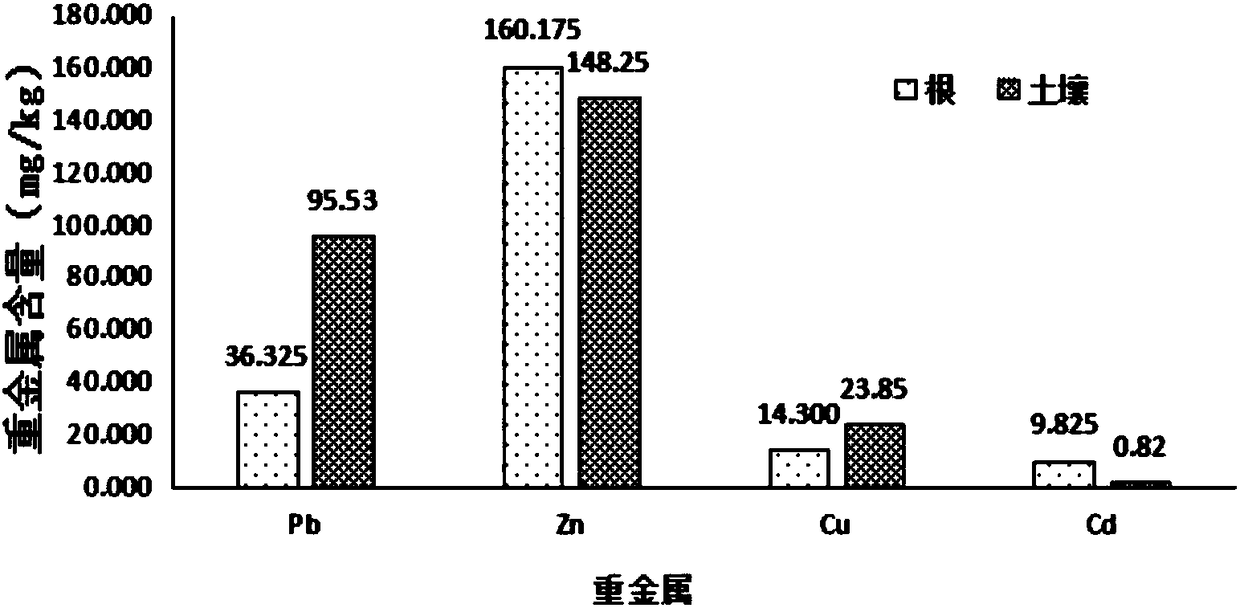

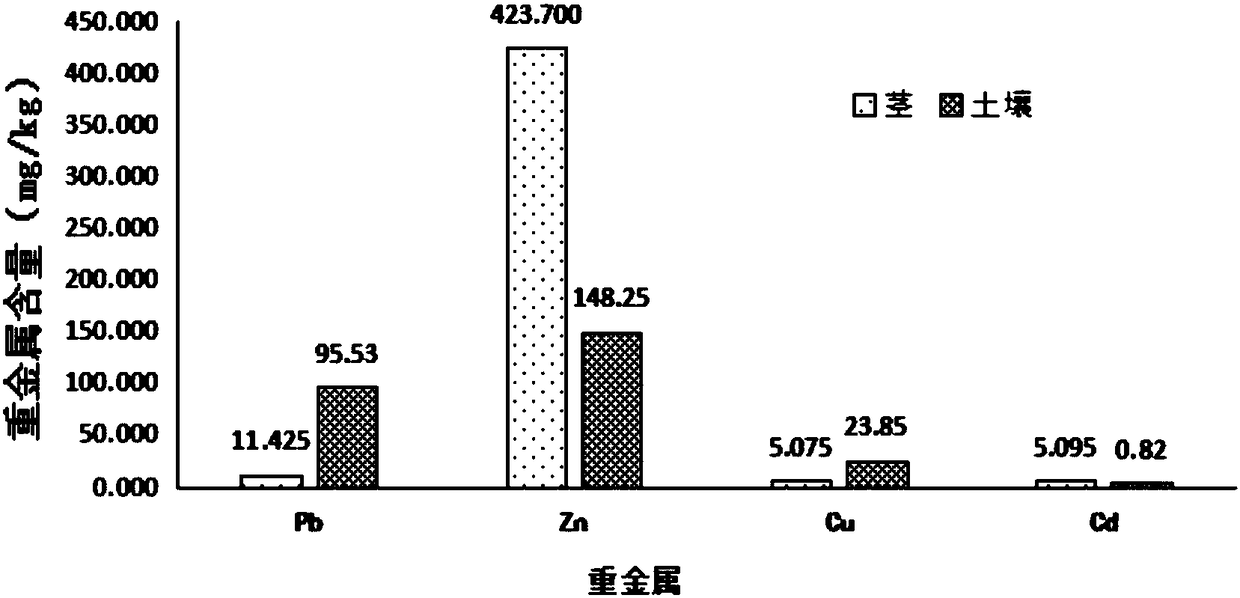

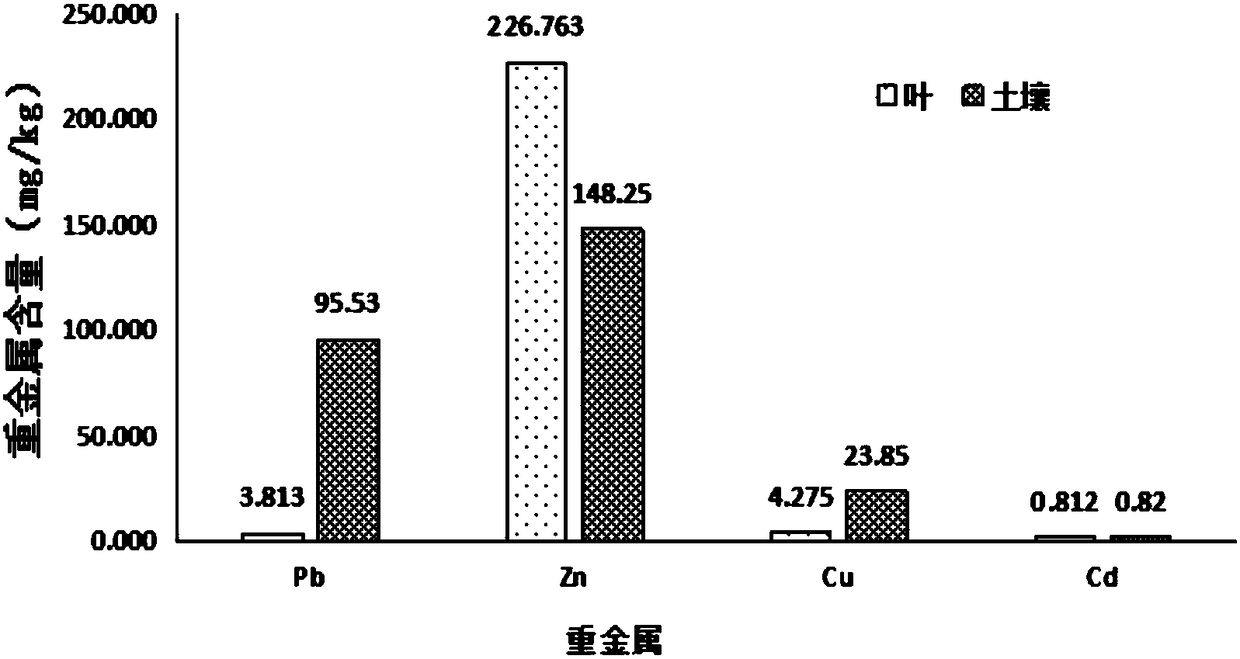

Fertilizer soil activating agent and method for repairing heavy metal polluted soil

InactiveCN108746199AImprove solubilityPromote growthAgriculture tools and machinesContaminated soil reclamationGrowth plantPhytoremediation

The invention discloses a fertilizer soil activating agent and a method for repairing heavy metal polluted soil. The fertilizer soil activating agent comprises ammonium triphosphate and fulvic acid, and the mass ratio of the two is 0.5-1: 0.25-0.5. The method for repairing the heavy metal polluted soil comprises the step of applying the fertilizer soil activating agent in the repair process of theheavy metal polluted soil. The fertilizer soil activating agent has the advantages of high heavy metal dissolving capacity, capability of accelerating the plant growth, capability of prominently improving the capacity of plants absorbing and enriching multiple heavy metal, low cost, reasonable matching of nutrient components, good economical benefit and the like, is a novel soil activating agent,and achieves excellent application value and application prospect. The method for repairing the heavy metal polluted soil by using the fertilizer soil activating agent has the advantages of simple operation, low cost, high economical benefit, good repair effect and the like, and can efficiently and quickly repair the heavy metal polluted soil.

Owner:HUNAN AGRICULTURAL UNIV

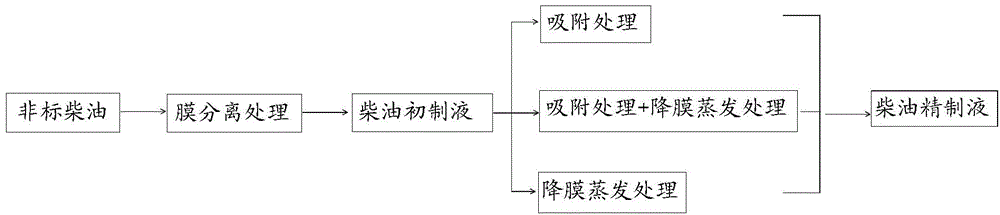

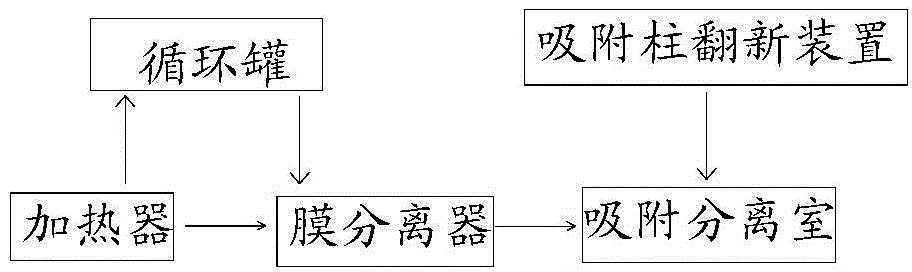

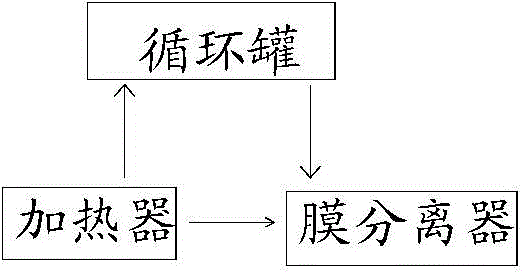

Nonstandard diesel oil treatment technology and apparatus thereof

InactiveCN104152178AWon't happenReduce pressure on environmental protectionTreatment with plural serial refining stagesEvaporationNational standard

The invention relates to a nonstandard diesel oil treatment technology. The technology comprises the following steps: 1, carrying out membrane separation treatment on nonstandard diesel oil at 30-80DEG C under 0.2-0.4MPa in order to obtain a primary treated diesel oil liquid; and 2, carrying out adsorption treatment and / or falling film evaporation treatment on the primary treated diesel oil liquid in order to obtain a purified diesel oil liquid. The invention relates to a nonstandard diesel oil treatment apparatus. The nonstandard diesel oil treatment technology solves the secondary environmental pollution problem of original technologies, and the above obtained product processed through the technology has greatly better chroma and sulfur content index than products obtained through the original technologies, and accords with requirements of national standard diesel oil IV.

Owner:SHENZHEN SENKEYAN TECH

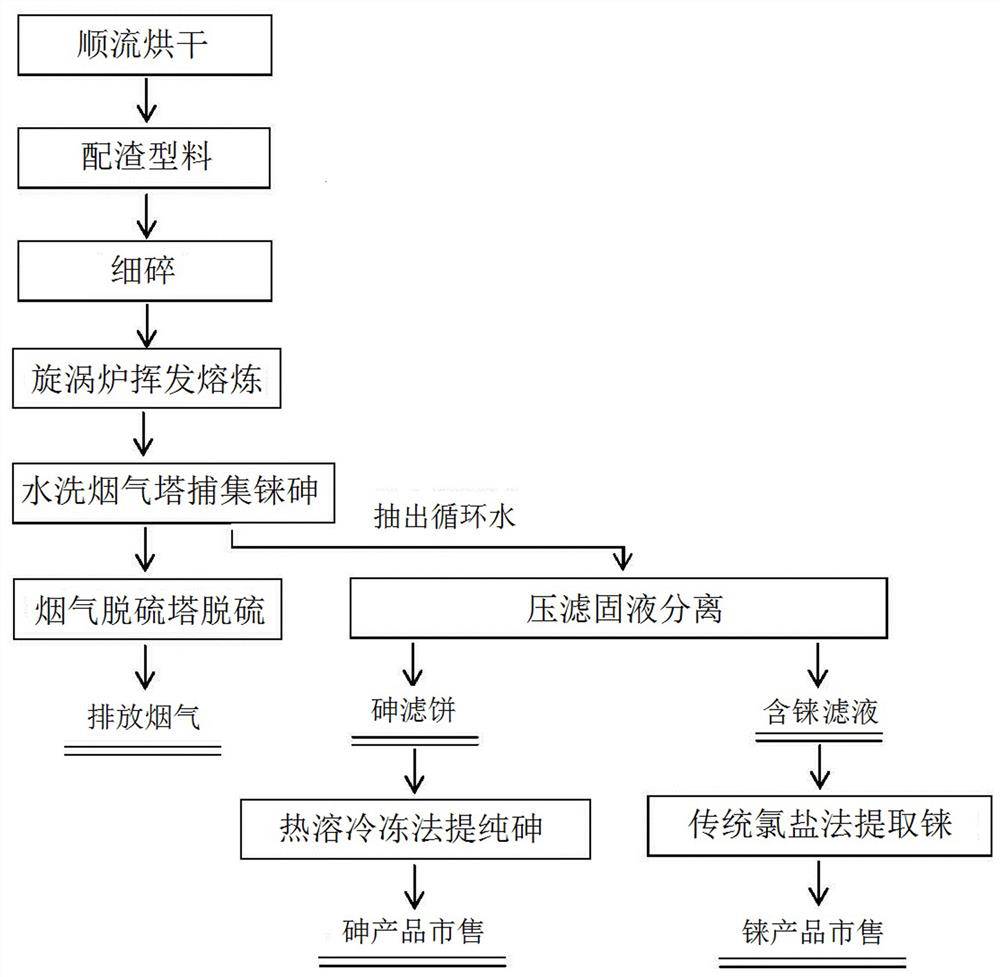

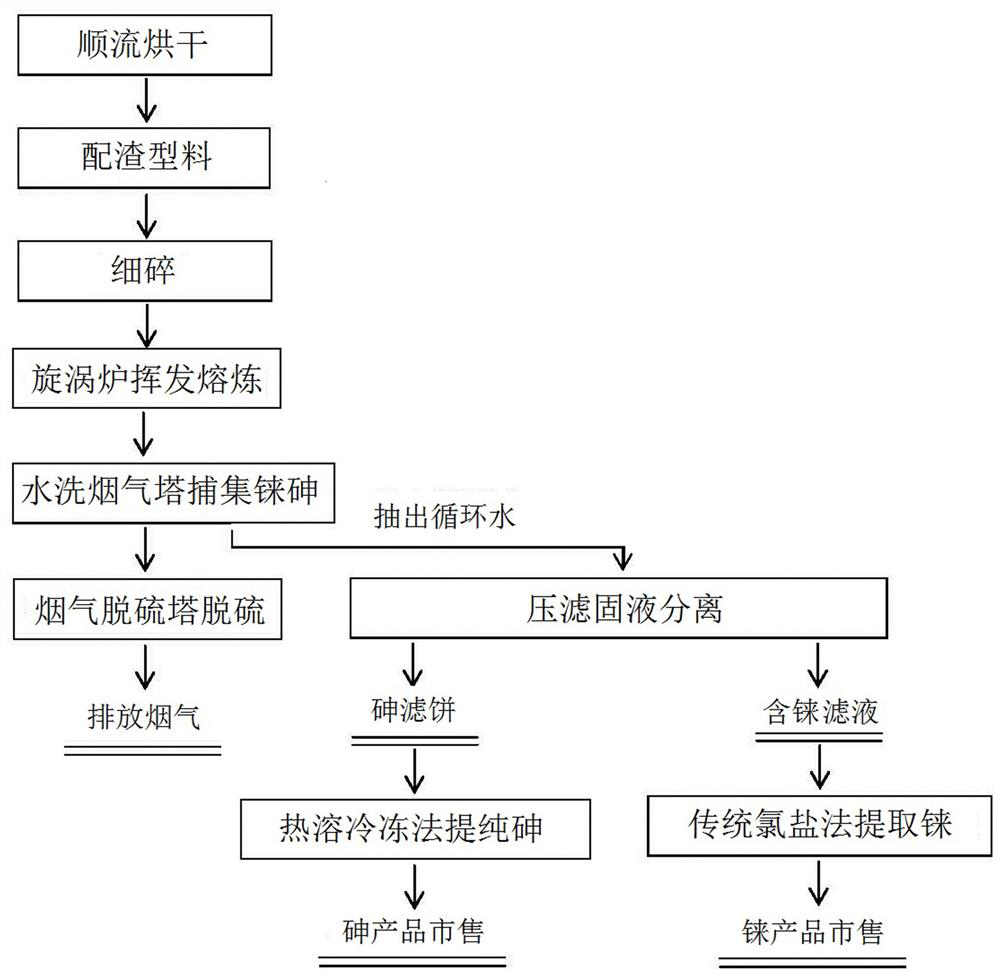

Technological method for comprehensively recovering rhenium, sulfur and arsenic through self-heating volatilization of acid mud containing rhenium, sulfur and arsenic in vortex furnace

ActiveCN112811399AImprove thermal efficiencyImprove direct yieldArsenic oxides/hydroxides/oxyacidsChemical industryRheniumFerrosilicon

The invention provides a technological method for comprehensively recovering rhenium, sulfur and arsenic through self-heating volatilization of rhenium, sulfur and arsenic-containing acid mud in a vortex furnace. The method comprises the following steps: drying a rhenium, sulfur and arsenic-containing acid mud raw material until a material discharged from a kiln is loose, adding a slag material, finely crushing, feeding into a vortex furnace, and carrying out volatilization and smelting, carrying out oxidation and exothermic reaction on the furnace material, wherein under the condition that the temperature is increased to 1400 DEG C or above and in an oxidizing combustion atmosphere, all rhenate in the furnace charge can be decomposed and volatilized, arsenic is oxidized into As2O3 steam, sulfur is oxidized into SO2 steam, and the As2O3 steam and the SO2 steam enter flue gas together; and carrying out rhenium and arsenic enrichment on the high-temperature flue gas in a flue gas washing tower, and feeding SO2 into a subsequent desulfurization tower for sulfur recovery. According to the method, the heat efficiency is high, more than 50% of energy is saved, high-value rare elements are saved, the direct recovery rate is about 10-30% higher, precious resources are effectively saved, the waste slag amount is reduced by about 75-90%, the waste slag is ferro-silicon calcium slag which is free of toxic substances and can be utilized, and the problem of secondary environmental pollution in a traditional method is thoroughly solved.

Owner:LEIYANG YANXIN NON FERROUS METALS

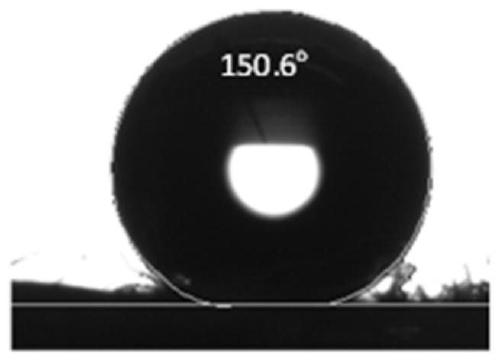

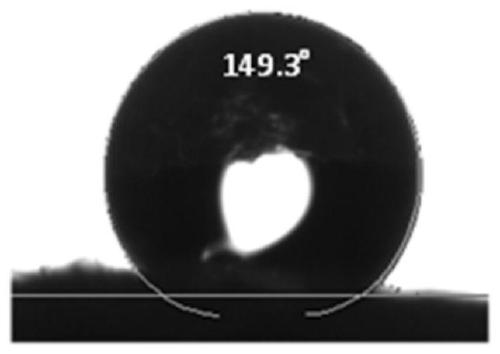

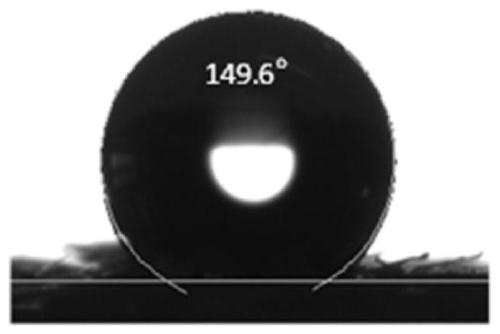

Preparation method of hydrophobic oleophylic adsorbent by taking towel gourd cotton as raw material

PendingCN111569839ASolve the problem of non-degradable secondary environmental pollutionWill not cause secondary pollutionFatty/oily/floating substances removal devicesOther chemical processesSilicic acidSorbent

The invention relates to a preparation method of a hydrophobic oleophylic adsorbent by taking towel gourd cotton as a raw material. The preparation method comprises the following steps: 1, taking towel gourd cotton as a raw material, soaking, cleaning and drying the material; 2, immersing the material in an alkaline solution for pretreatment, then adjusting the material to be neutral with an acid,and carrying out cleaning and drying; 3, immersing the material subjected to alkali treatment into a mixed solution of tetraethyl silicate, absolute ethyl alcohol and pure water, then adding a properamount of ammonia water, and then cleaning and drying with ethyl alcohol; and 4, immersing the material in a mixed solution of hexadecyl trimethoxysilane and pure water, adding a proper amount of acetic acid, cleaning with ethanol, and drying to obtain the modified adsorption material. Compared with the prior art, the adsorbent can be widely applied to petroleum leakage treatment and oily wastewater treatment, and the oil absorption material obtained through modification is high in adsorption rate, low in cost, biodegradable and free of secondary environmental pollution.

Owner:TONGJI UNIV +2

Environment-protecting granular wooden fuel and its production process

The present invention relates to granular wooden fuel and its production process, and features utilizing waste timber and forest cutting leftover as material. The production process includes cutting the raw material into coarse material, drying in airflow drier to certain water content, crushing into powder, pelletizing, granulating without adding additive through extrusion, cooling and sieving, backing the undersize to pelletizing step, packing the product. The said production process has low cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Oil removal treatment device and method for oil-based drill cuttings

ActiveCN111636833ARealize resourcesRealize resource processingConstructionsFluid phaseLiquid storage tank

The invention discloses an oil removal treatment device and method for oil-based drill cuttings. The device is arranged in an upper treatment chamber and a lower treatment chamber and comprises an extraction unit, a solid-liquid separation unit, an extraction oil separation unit and an extraction agent recovery unit. Main equipment of the device is divided into the two treatment chambers, integrated design is adopted, major equipment is placed in the upper treatment chamber, and the lower treatment chamber is mainly used for containing liquid storage tanks of all the units. Through the design,all treated liquid phases can flow into the liquid storage tanks through self weight, a large amount of power is saved, the two treatment chambers are stacked up and down, the occupied area can be reduced, and the equipment can be operated more conveniently.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

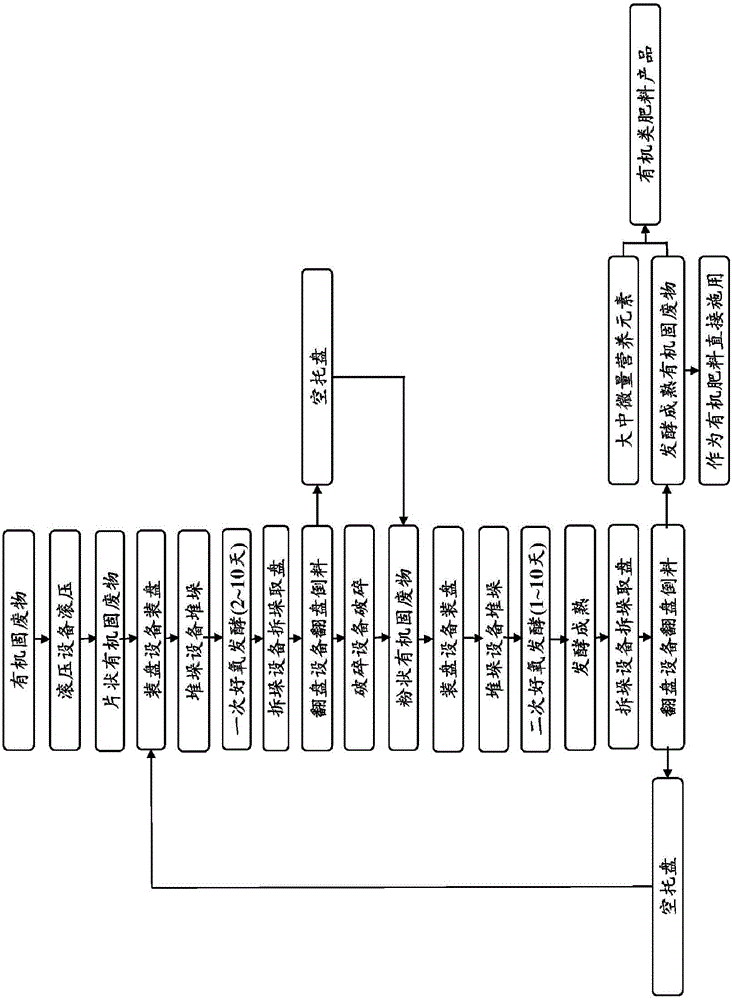

Method for preparing fertilizer by using organic solid waste

InactiveCN105060957AImprove breathabilityInhibitionBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerOxygen

The invention relates to a method for preparing fertilizer by using organic solid waste. According to the method, the organic solid waste with 75%-50% of water content is crushed and / or rolled and is loaded in ventilated fermentation trays, then the fermentation trays filled with the organic solid waste are stacked for aerobic fermentation for 3-20 days, the organic solid waste is composted and dried into a composted organic material with lower than 40% of water content, and the composted organic material is applied directly as organic fertilizer or is matched with macronutrients and secondary and trace nutrient elements required by plants for production of fertilizer products. With adoption of the method, the fertilizer can be prepared from the organic solid waste in more environment-friendly, efficient and low-cost manners.

Owner:GUANGXI LIYUANBAO SCI & TECH

A kind of technical method of self-heating volatilization of rhenium-containing sulfur-arsenic acid mud in a vortex furnace to comprehensively recover rhenium-sulfur-arsenic

ActiveCN112811399BImprove thermal efficiencyImprove direct yieldArsenic oxides/hydroxides/oxyacidsChemical industryRheniumSludge

A technological method for comprehensively recovering rhenium-sulfur-arsenate mud containing rhenium-sulfur-arsenic acid by volatilizing rhenium-containing sulfur-arsenic acid mud by self-heating in a vortex furnace. In volatilization smelting, all the rhenate in the charge will decompose and volatilize, and the arsenic will be oxidized into As when the temperature of the exothermic oxidation reaction of the incoming charge rises above 1400°C and the oxidative combustion atmosphere 2 o 3 Steam, sulfur oxidation to SO 2 The steam enters the flue gas together; the high-temperature flue gas is enriched with rhenium and arsenic in the flue gas washing tower, and SO 2 Then enter the follow-up desulfurization tower to get rid of sulfur recovery. The method has high thermal efficiency, energy saving of more than 50%, and the direct recovery rate of high-value rare elements is about 10% to 30% higher, effectively saving precious resources, reducing the amount of waste residue by about 75% to 90%, and the waste residue is Ferrosilicon-calcium slag, which is non-toxic and available, completely solves the problem of secondary environmental pollution in traditional methods.

Owner:LEIYANG YANXIN NON FERROUS METALS

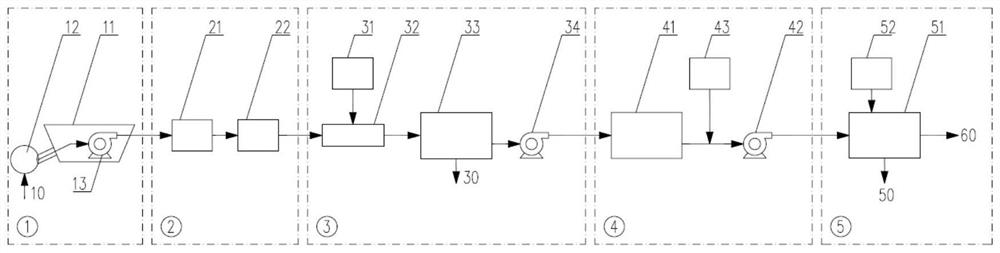

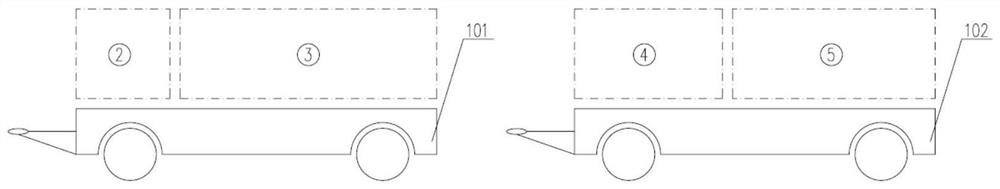

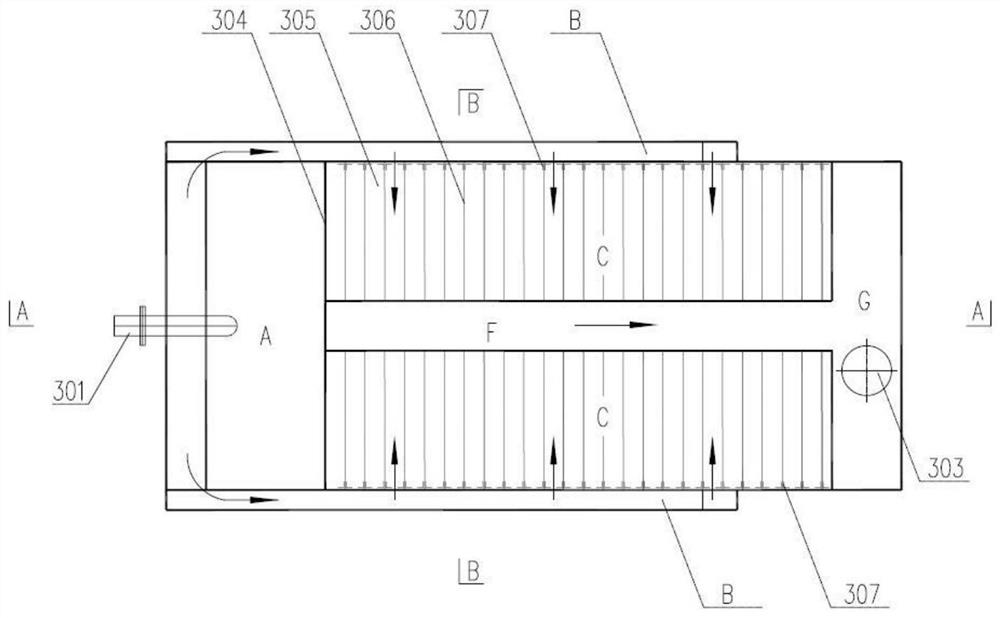

A river channel environmental protection dredging and mobile sludge concentration and dewatering system

ActiveCN107973515BReduce disturbanceThorough dredgingSludge treatment by de-watering/drying/thickeningMechanical machines/dredgersRiver routingPre treatment

The invention belongs to the technical field of environment friendliness, relates to a sludge treatment process system and in particular relates to an environment-friendly riverway dredging and movable sludge concentrating and dewatering system. The environment-friendly riverway dredging and movable sludge concentrating and dewatering system is composed of an environment-friendly dredging unit, apretreatment unit, a sludge concentrating unit, a sludge conditioning unit and a sludge dewatering unit which are sequentially connected by pipelines. Riverway sludge is pumped on the pretreatment unit on the shore by the environment-friendly dredging unit in a riverway and is concentrated by the sludge concentrating unit after large-particle garbage and suspended matters are removed, so that theconcentration of the sludge is further increased; then, the riverway sludge is delivered into the sludge dewatering unit for dewatering after being homogenized and conditioned by the sludge conditioning unit; and finally, the conversion from the riverway sludge to clear water and mud cakes is finished. The system realizes the online flow operation of dredging, conveying and treatment of the riverway sludge; and meanwhile, the system has the characteristics such as good environment-friendly dredging effect, short process flow, high integration level and good movability.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

An energy-saving and environment-friendly method for treating municipal sludge

ActiveCN104496137BImprove breathabilityGood aerobic fermentation stateBio-organic fraction processingSludge treatmentEngineeringSmall footprint

The invention provides an energy-saving and environment-friendly method for treating urban sludge, which comprises mixing urban sludge with a moisture content of 70% to 85% and regulating materials in a certain weight ratio to form sludge fermentation materials, and then placing them in a vertical direction by Dynamic aerobic fermentation is carried out on a three-dimensional fermentation equipment consisting of 2 to 40 floors and 2 to 40 sets of belt conveyors in the horizontal direction, and biological dehydration and drying into decomposed and dry materials with a moisture content of less than 50% for further environmental protection treatment or resource utilization. The method of the invention is simple, and at the same time occupies a small area, has good fermentation effect, can avoid secondary pollution caused by odor, and achieves the goals of high efficiency and environmental protection.

Owner:GUANGXI LIYUANBAO SCI & TECH

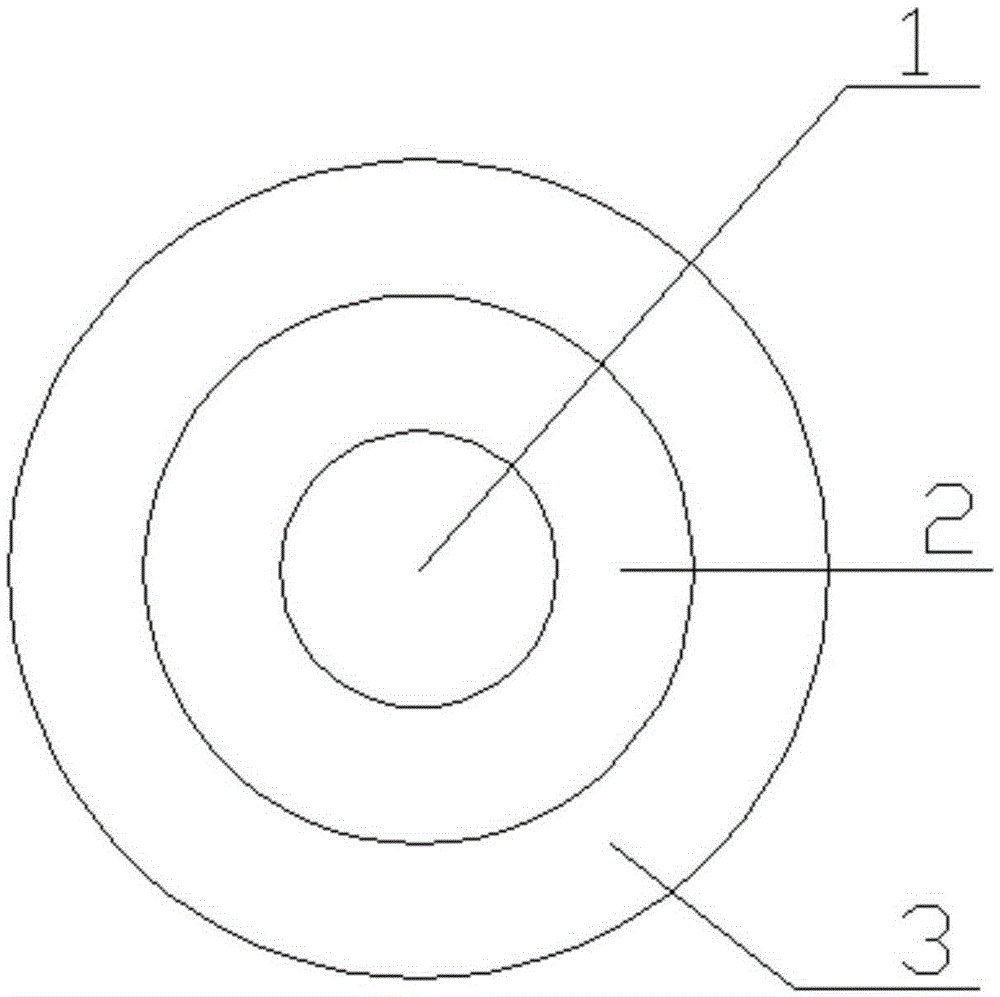

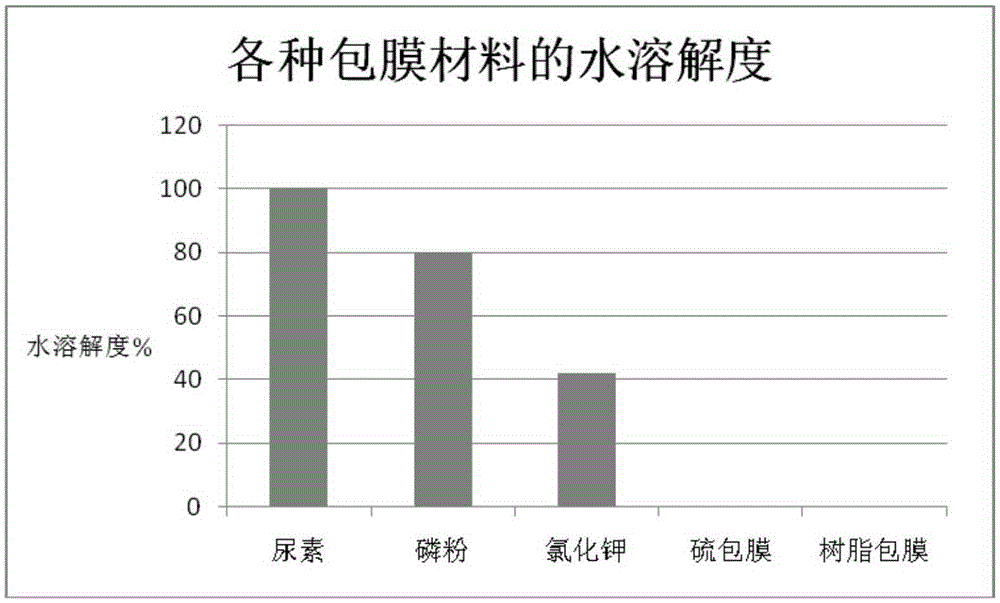

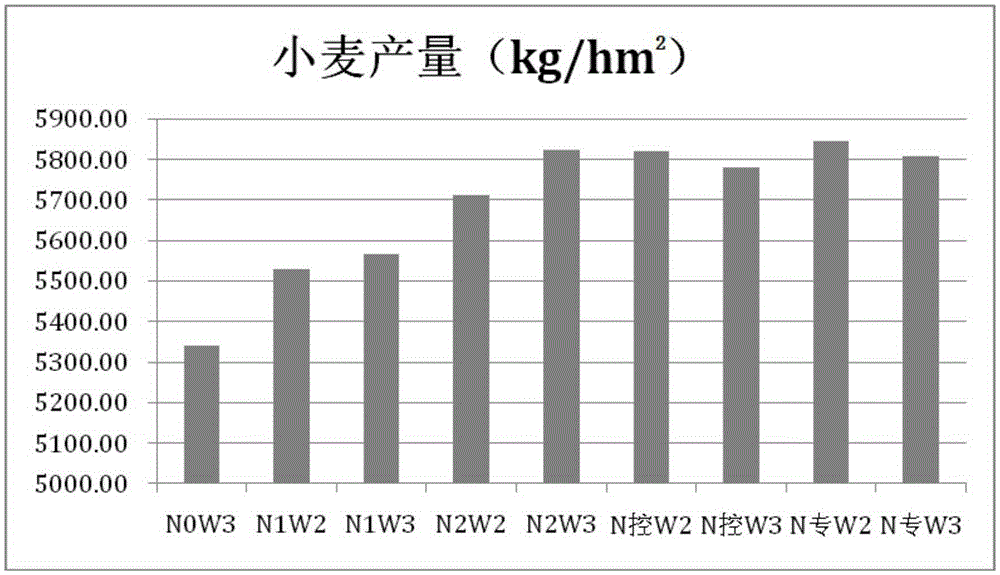

Coated slow-release compound fertilizer and preparation method thereof

The invention discloses a coated slow-release compound fertilizer and a preparation method thereof. The compound fertilizer comprises a urea nuclear as well as a wrapping layer and a hydrophobic layer which coat the urea nuclear from inside to outside, wherein the wrapping layer is formed by performing high-heat mixed melting on powdery nitrogen, powdery phosphorus and powdery potassium, and the powdery nitrogen in the wrapping layer accounts for 15%-25% of the total nitrogen in the coated slow-release compound fertilizer; the hydrophobic layer is made of resin. The coated slow-release compound fertilizer disclosed by the invention can meet nutritional requirements of crops in different stages, is low in cost and has an environment-friendly effect.

Owner:河北丰禾绿光农业科技有限公司

Method for preparing organic fertilizer from sugar filter mud

ActiveCN104496570BImprove breathabilityGood aerobic fermentation stateClimate change adaptationSewage/sludge fertilisersSludgeOrganic manure

Owner:广西田东力源宝科技有限公司

Tray type organic material three-dimensional fermentation system and fermentation method thereof

ActiveCN105060958BImprove breathabilityInhibitionBio-organic fraction processingClimate change adaptationEngineeringStacker

The invention relates to a tray type stereoscopic organic material fermentation system and fermentation method. The fermentation system comprises tray loading equipment, tray stackers, tray unstackers and tray-dumping unloaders which are mounted sequentially as well as rolling equipment mounted on the tray loading equipment, tray conveying equipment connected among the tray loading equipment, the tray stackers, the tray unstackers and the tray-dumping unloaders and fermentation trays moving and circulating among the tray loading equipment, the tray stackers, the tray unstackers and the tray-dumping unloaders through the tray conveying equipment. Organic materials are loaded in the fermentation trays by the tray loading equipment, the fermentation trays are conveyed to the tray stackers by the tray conveying equipment to be stacked to form a tray stack, the organic materials are subjected to aerobic fermentation in the fermentation trays stacked in the tray stack and conveyed to the tray unstackers through the tray conveying equipment, the fermentation trays are taken out from the tray stack, the trays are conveyed to the tray-dumping unloaders by the tray conveying equipment, the materials are poured out from the fermentation trays, and the empty fermentation trays are conveyed back to the tray loading equipment by the tray conveying equipment.

Owner:GUANGXI LIYUANBAO SCI & TECH

Organic material tray type three-dimensional fermentation system and fermentation method thereof

ActiveCN105060963BImprove breathabilityInhibitionBio-organic fraction processingOrganic fertiliser preparationPalletizerBiomedical engineering

The invention relates to a tray-type stereoscopic organic material fermenting system and method which are high in fermenting efficiency, low in cost and very environment-friendly. The fermenting system comprises tray filling equipment, a palletizer, a depalletizer and a tray overturning discharging machine which are mounted in sequence, as well as tray conveying equipment connected among the tray filling equipment, the palletizer, the depalletizer and the tray overturning discharging machine, and fermenting trays circularly flowing among the tray filling equipment, the palletizer, the depalletizer and the tray overturning discharging machine through the tray conveying equipment. The fermenting trays are filled with an organic material in the tray filling equipment, and are conveyed to the palletizer through the tray conveying equipment to be palletized into a tray stack, the aerobic fermentation of the organic material is realized in the fermenting trays palletized into the tray stack, the fermenting trays filled with the fermented organic material are conveyed to the depalletizer through the tray conveying equipment to be taken apart from the tray stack, then the organic material is conveyed to the tray overturning discharging machine through the tray conveying equipment, and is poured out from the fermenting trays, and the empty fermenting trays are conveyed back to the tray filling equipment through the tray conveying equipment.

Owner:GUANGXI LIYUANBAO SCI & TECH

Biological organic fertilizer and preparation method thereof

The invention relates to a biological organic fertilizer and a preparation method thereof. The organic fertilizer is prepared from the following raw materials in parts by weight: (1) 50-80 parts of dewatered sludge, (2) 10-50 parts of protein waste slag, (3) 0-10 parts of urea, (4) 0-10 parts of activated carbon and (5) 0.2-1 part of functional strain microbial inoculum. The preparation method comprises the following steps: (1) preparing a functional strain; (2) fermenting the raw materials; and (3) performing post treatment. According to the invention, the problem of secondary environmental pollution caused by sludge generated in the mycelium CSTR (continuous stirred tank reactor) anaerobic fermentation, organic acid waste water EGSB (expanded granular sludge bed) anaerobic fermentation and aerobic treatment process and protein waste slag generated by organic acid factory microbial fermentation is solved; the waste is changed into valuable substances, thereby meeting the related requirements of circular economy; and the indices of the prepared biological organic fertilizer, such as the organic content, the active viable count and the like, meet the requirements of related industrial standards. Besides, the preparation method provided by the invention is simple and has the advantages of no discharge of three wastes, low investment, quick action and low cost.

Owner:QINGDAO RUIMIN RESOURCE COMPREHENSIVE UTILIZATIONCO

A method of using stevia to remediate heavy metal polluted soil

ActiveCN108480377BStrong toleranceNormal growthContaminated soil reclamationSoil scienceEconomic benefits

The invention discloses a method for repairing heavy metal polluted soil by using stevia. The method comprises the following steps: planting stevia in the heavy metal polluted soil for cultivation, and completing the repair of the heavy metal polluted soil. The method for repairing heavy metal-contaminated soil by using stevia in the present invention has the advantages of simple operation, low cost, high economic benefit, and good repairing effect, and solves the problems of low plant biomass and total absorption and accumulation of heavy metals in the existing heavy metal-contaminated soil repair technology. There are many problems such as small amount, tolerance and enrichment ability only for a single heavy metal, poor economic benefit, complicated plant field management, high management cost, and little comprehensive effect of practical application. No matter from the perspective of ecology or economics, the method of the invention has important practical significance.

Owner:HUNAN AGRICULTURAL UNIV

Method for repairing heavy metal contaminated soil by Chinese yews

PendingCN108435769AStrong toleranceStrong enrichment abilityContaminated soil reclamationContaminated soilsBiomass

The invention discloses a method for repairing heavy metal contaminated soil by Chinese yews. The method includes the step: planting the Chinese yews into the heavy metal contaminated soil for cultivation to finish repairing the heavy metal contaminated soil. The method for repairing the heavy metal contaminated soil by the Chinese yews has the advantages of simplicity in operation, low cost, higheconomic benefit, good repairing effect and the like, and solves the problems that plants in an existing heavy metal contaminated soil repairing technology are low in biomass, less in absorbed and accumulated heavy metal total amount, poor in enrichment capacity and economic benefit, complex in plant field management, high in management cost and little in practical application comprehensive effect and only has resistance to single heavy metals. Regardless of ecological point of view and economic point of view, the method has vital practical significance.

Owner:HUNAN AGRICULTURAL UNIV

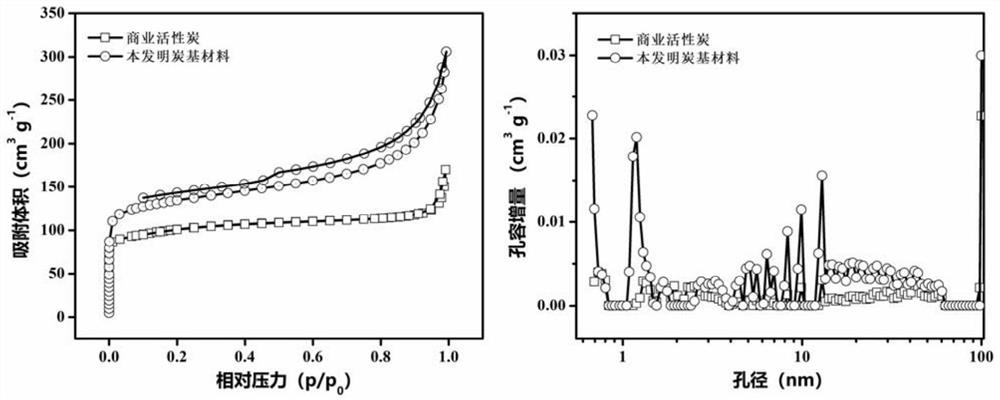

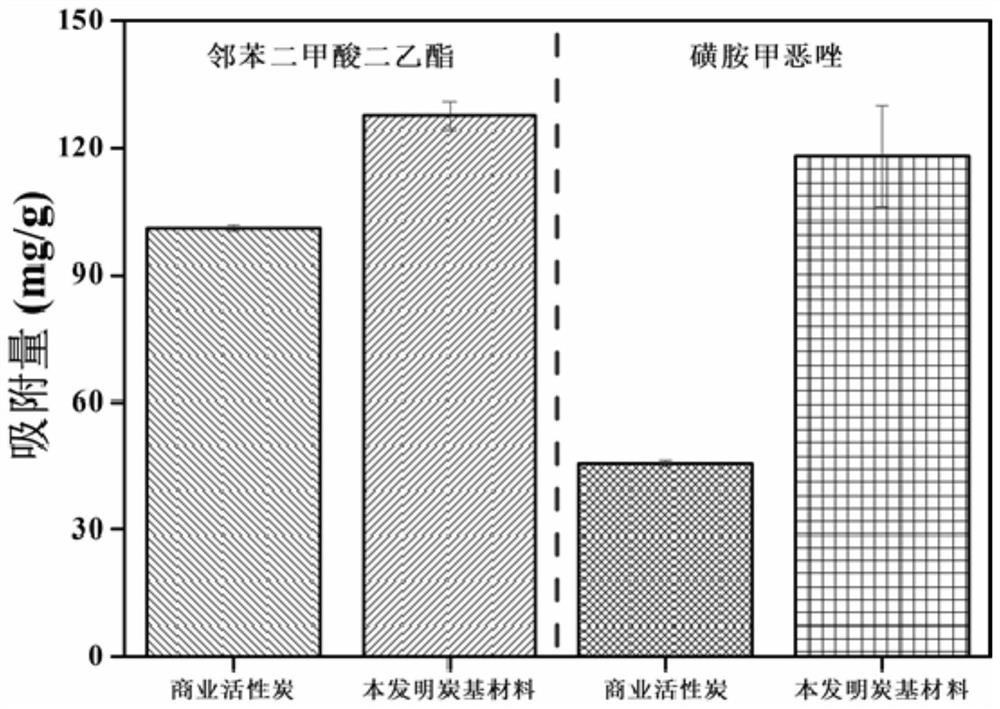

Alkaline residue recycling method, product and application

ActiveCN111921498AEfficient resource utilizationLow costOther chemical processesActivated carbonEnvironmental engineering

The invention discloses an alkaline residue recycling method, a product and application, and belongs to the field of solid waste recycling. The method comprises the following specific steps: a) respectively preparing alkaline residue powder and agriculture, forestry and animal husbandry biomass powder, and uniformly mixing to obtain a mixture; b) carbonizing the mixture under the protection of aninert gas, specifically, raising the temperature to 600-900 DEG C, carbonizing for a certain time under the condition of 600-900 DEG C, and then cooling to room temperature to obtain grey black residues; c) crushing the grey black residues, and cleaning the grey black residues; and d) drying the grey black residues, and grinding the grey black residues into powder to obtain the product. The carbon-based material which is more developed in pore structure and more excellent in adsorption performance than commercial activated carbon is obtained by utilizing the preparation method, and efficient removal efficiency is shown for organic pollutants. According to the method, efficient recycling of the alkaline residues and the biomass is achieved, and meanwhile the low-cost and efficient organic pollutant adsorbing and removing product is prepared.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Method for repairing heavy metal contaminated soil by using Stevia Rebaudiana Bertoni Rebaudiana Bertoni

ActiveCN108480377AStrong toleranceStrong enrichment abilityContaminated soil reclamationBiomassContaminated soils

The invention discloses a method for repairing heavy metal contaminated soil by using Stevia Rebaudiana Bertoni. The method comprises the following steps: Stevia Rebaudiana Bertoni is planted in heavymetal contaminated soil, and is cultivated to complete the repairing of the heavy metal contaminated soil. The method for repairing heavy metal contaminated soil by Stevia Rebaudiana Bertoni has theadvantages of simplicity in operation, low cost, high economic benefit and good repairing effect, and solves the problems of low biomass, small total amount of absorbed and accumulated heavy metals, tolerance and enrichment ability to only single heavy metal, poor economic benefit, complex plant field management, high management cost, poor practical application comprehensive effect and other problems of plants in existing heavy metal contaminated soil repairing technologies. The method has great practical significance ecologically and economically.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com