Coal-fired power plant sludge drying and blending combustion system

A technology for sludge drying and coal-fired power plants, which is applied in the direction of combustion type, combustion method, combined combustion mitigation, etc., can solve the problems of environmental secondary pollution, easy stratification, and easy precipitation during storage and transportation, so as to avoid Secondary environmental pollution and the effect of preventing the spread of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

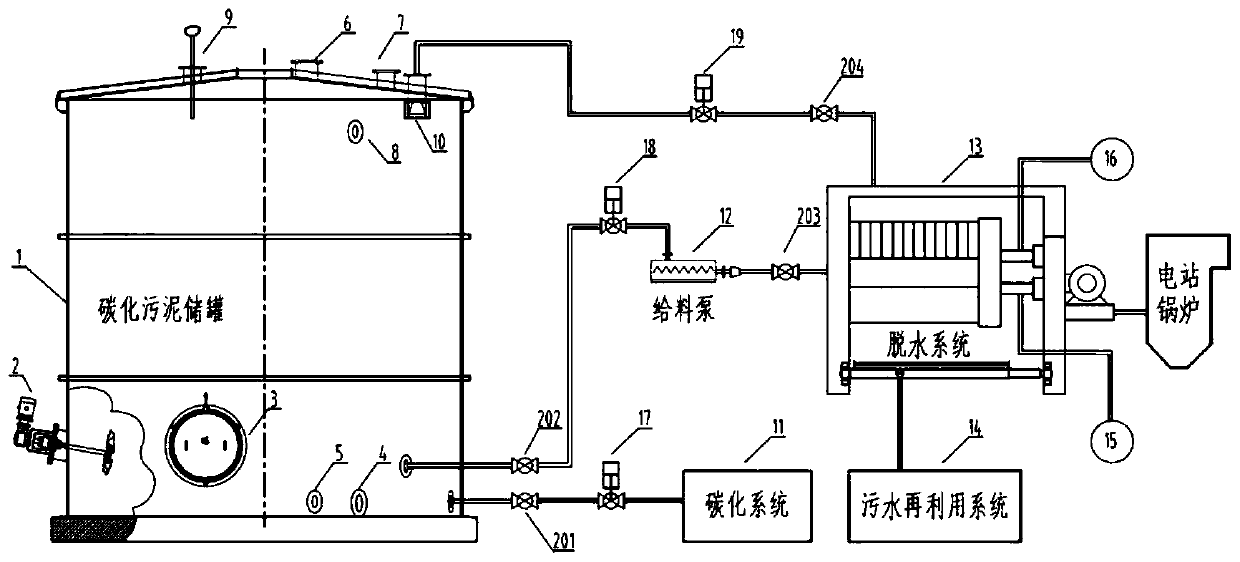

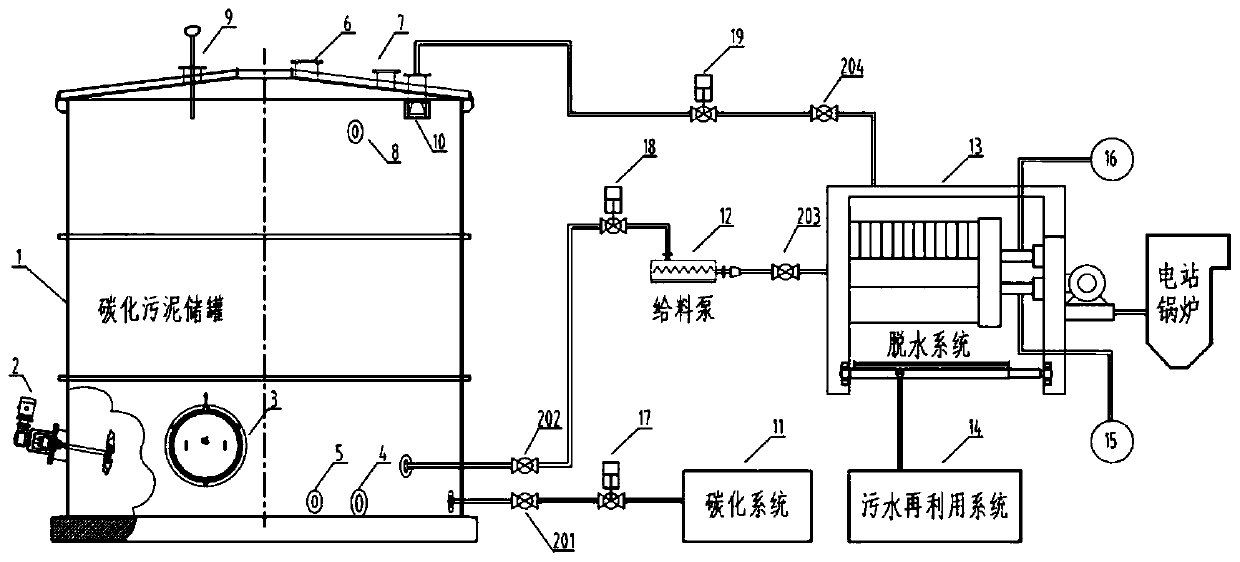

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

[0019] refer to figure 1 The coal-fired power plant sludge drying and blending system of the present invention includes a sludge carbonization system 11, a carbonized sludge storage tank 1, a feed pump 12, a dehydration system 13, a sewage reuse system 14 and a power plant boiler; The outlet of the sludge carbonization system 11 is connected with the inlet of the carbonized sludge storage tank 1, the outlet of the carbonized sludge storage tank 1 is connected with the inlet of the dehydration system 13 through the feed pump 12, and the dry mud outlet of the dehydration system 13 is connected with the power plant boiler The coal feeding belt is connected, the sewage outlet of the dehydration system 13 is connected with the sewage reuse system 14, and the top of the carbonized sludge storage tank 1 is provided with an exhaust port 7, a dosing port 6 and is used to detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com