Vacuum pipeline docking technology and high-speed permanent maglev train system

A technology of vacuum pipelines and high-speed trains, applied in tunnel systems, sliding/floating railway systems, tracks, etc., can solve the problems of maglev high-speed and fast advantages, underground failures, and surprisingly high costs, etc., to avoid air leakage The problem of pressure loss, fast speed, and the effect of reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will now be described in further detail in conjunction with the accompanying drawings.

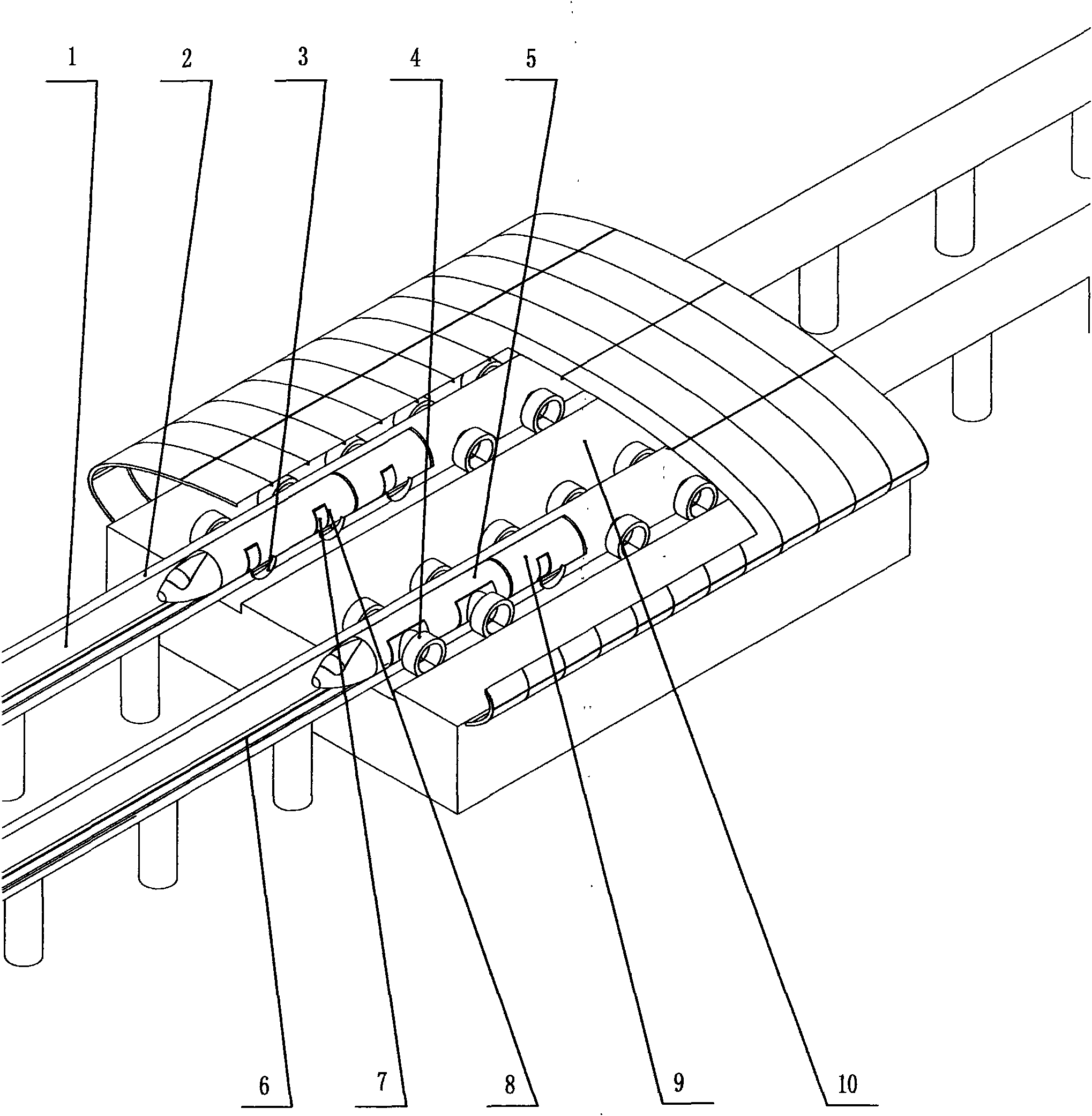

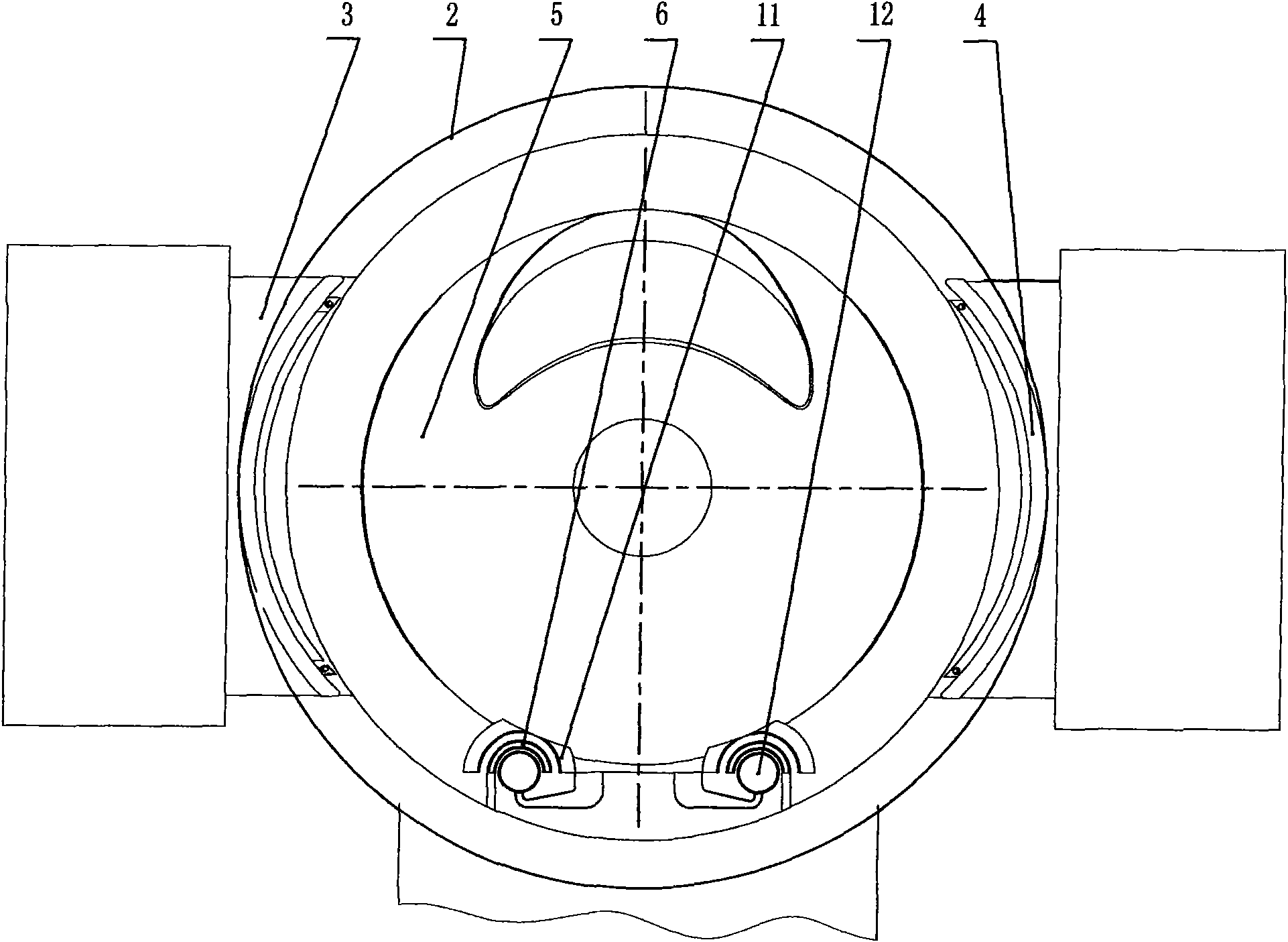

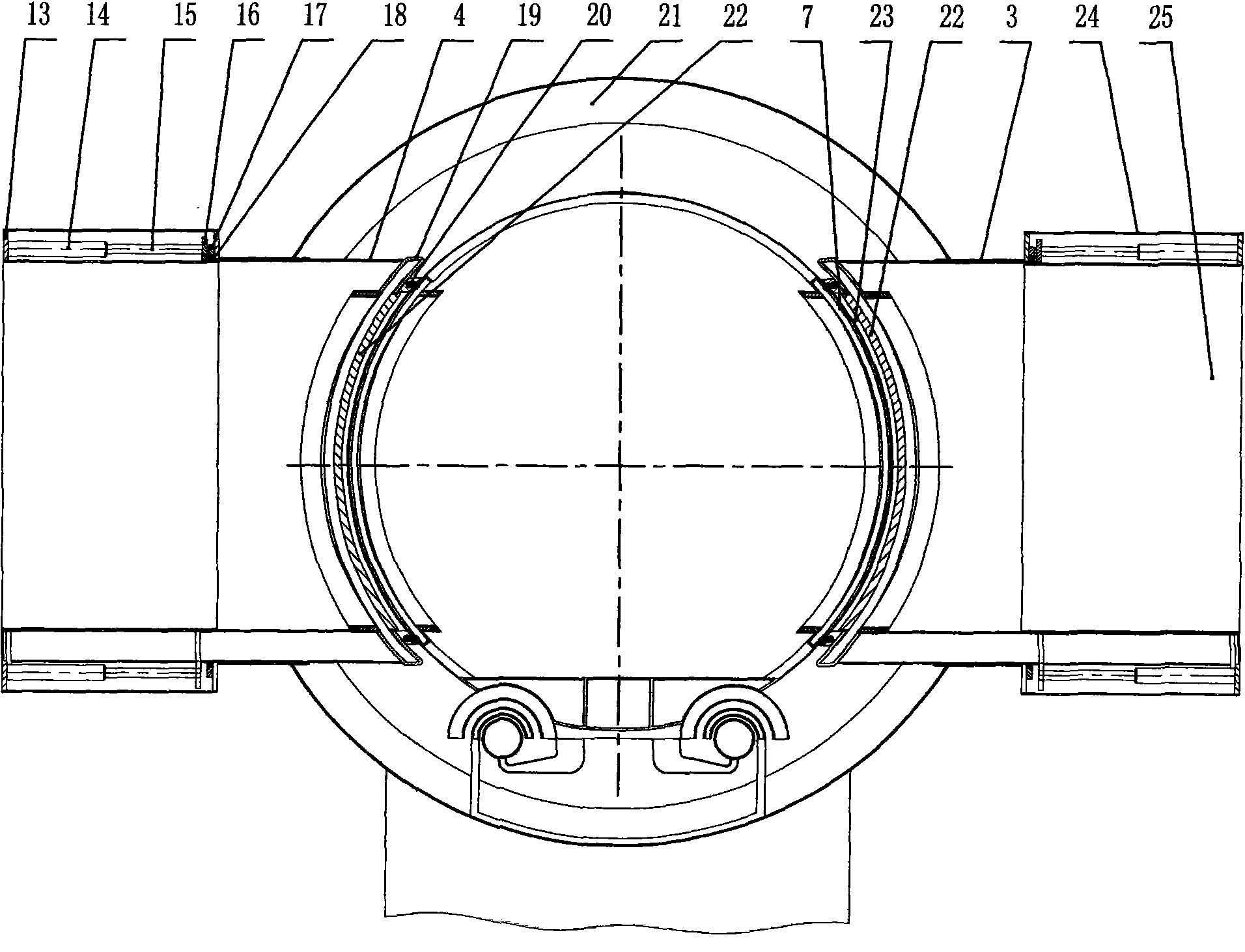

[0064] like figure 1As shown, the vacuum pipeline (1) of the present invention is internally pumped into a sub-vacuum state under the shielding of the external vacuum cover (2). state. The vacuum pipeline (1) can be provided with branch pipelines as required along the way, and a bypass pipeline (3) can be laterally arranged at the vacuum pipeline (1) that needs to be discharged from the warehouse, and a telescopic channel (4) can be arranged in the bypass pipeline (3). The maglev train (5) is suspended on the maglev track (6) laid in the vacuum pipeline (1). Train doors (7) are arranged on both sides of the maglev train (5), and the train doors (7) are surrounded by door frames (8). The train door (7) tightly seals the maglev train (5) and the intermediate carriage (9), and maintains a pressure of 1 standard atmosphere. Since the air resistance of the train...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com