Preparation method of hydrophobic oleophylic adsorbent by taking towel gourd cotton as raw material

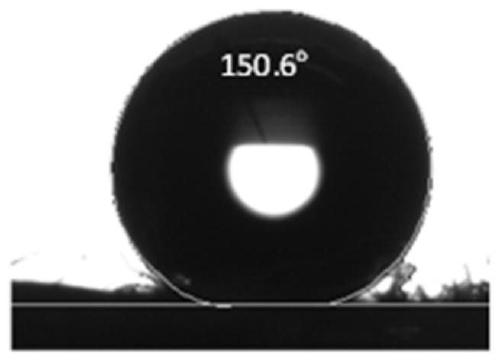

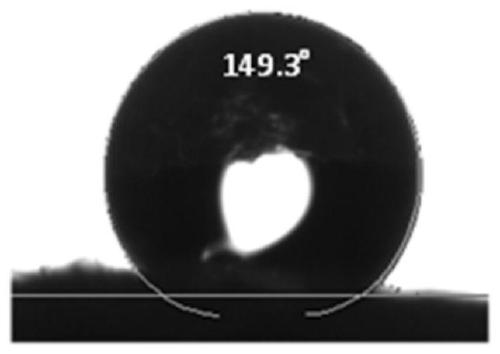

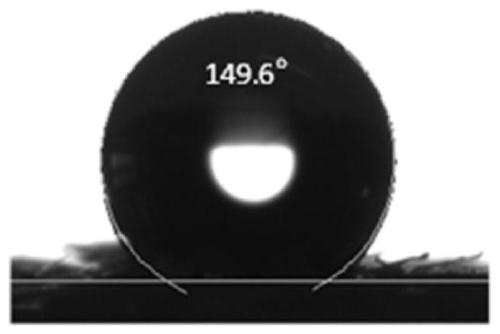

A technology of adsorbent and loofah cotton, which is applied in the field of preparation of hydrophobic and lipophilic adsorbents, can solve the problems of troublesome waste disposal in adsorption and recovery work, slow natural degradation speed, and inability to generate naturally, and achieves convenient and fast acquisition, good quality Effect of oil adsorption and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]The first step: pretreatment: Soak the ready-to-use loofah cotton raw material with ultrapure water at room temperature (20-25°C) for 24.0h, wash with pure water three times, and dry in a vacuum oven at 70°C until the quality is constant;

[0043] The second step: alkali treatment: immerse the loofah cotton pretreated in the first step in the alkaline solution, at room temperature (20-25°C), stir with a magnetic stirrer for 8.0h, and the above-mentioned alkaline solution is 5%wt NaOH solution, then adjusted the pH to 7.0 with hydrochloric acid, washed several times with pure water, and dried in a vacuum oven at 70°C until the mass was constant;

[0044] The third step: silicon-loaded surface treatment: add 20.0mL pure water to 100.0mL absolute ethanol, then add 2.0mL tetraethyl silicate under stirring condition, and stir for 10 minutes to obtain a mixed solution 1, the loofah cotton treated with alkali Immerse 2.0 g in mixed solution 1, stir at room temperature for 10 mi...

Embodiment 2

[0055] The first step: pretreatment: Soak the ready-to-use loofah cotton raw material with ultrapure water at room temperature (20-25°C) for 24.0h, wash with pure water three times, and dry in a vacuum oven at 70°C until the quality is constant;

[0056] The second step: pretreatment: immerse 2.0g of pretreated loofah cotton in the mixed solution, and stir with a magnetic stirrer for 5.0h at 70°C. The above alkaline solution is 1%wt NaOH+1%wt H 2 o 2 solution, then adjust the pH to 7.0 with hydrochloric acid, wash several times with pure water, and dry in a vacuum oven at 70°C until the quality is constant;

[0057] The third step: silicon-loaded surface treatment: add 20mL pure water to 100mL ethanol solution, then add 2mL tetraethyl silicate under stirring conditions, stir for 10min to obtain a mixed solution, and immerse 2.0g of alkali-treated loofah cotton into the mixed solution , stirred at room temperature for 10 min, then added 1.0 mL of ammonia water, stirred at room...

Embodiment 3

[0061] The first step: pretreatment: Soak the ready-to-use loofah cotton raw material with ultrapure water at room temperature (20-25°C) for 24.0h, wash with pure water three times, and dry in a vacuum oven at 70°C until the quality is constant;

[0062] The second step: pretreatment: immerse 2.0g of the pretreated loofah cotton in 100mg / L NaClO solution, stir with a magnetic stirrer for 24.0h at room temperature (20-25°C), then adjust the pH to 7.0 with hydrochloric acid, Wash several times with pure water, and dry in a vacuum oven at 70°C until the quality is constant;

[0063] The third step: surface silicon-loaded treatment: add 20.0mL pure water to 100.0mL ethanol solution, then add 2.0mL tetraethyl silicate under stirring conditions, stir for 10min to obtain a mixed solution, and add 2.0g of alkali-treated loofah cotton Immerse in the mixed solution, stir for 10 min at room temperature, then add 1.0 mL of ammonia water, stir for 5.0 h at room temperature, then wash with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com