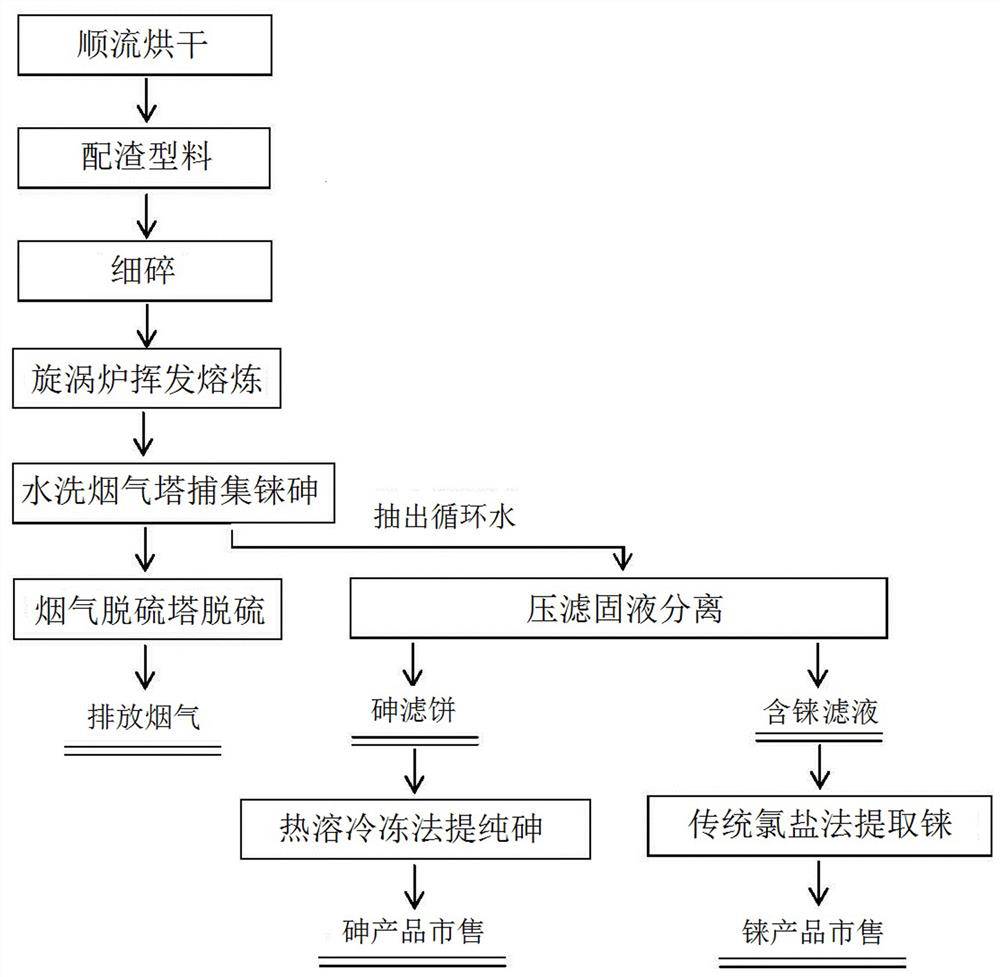

Technological method for comprehensively recovering rhenium, sulfur and arsenic through self-heating volatilization of acid mud containing rhenium, sulfur and arsenic in vortex furnace

A technology of sulfuric arsenic acid sludge and a process method, applied in the field of volatilization smelting technology, can solve the problems of secondary environmental pollution, high arsenic, large amount of leaching slag, etc., achieves high thermal efficiency, saves valuable resources, and solves the problem of secondary environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a certain smelting enterprise in Leiyang, Hunan, according to the method of the present invention, the following concrete implementation has been done.

[0019] Step 1: Downstream drying and dehydration. A downstream rotary kiln with a diameter of Φ1m×L10m is adopted, the flue gas temperature at the tail end of the rotary kiln is controlled at 60-80°C, the kiln body rotates at 6 revolutions per minute, the inclination angle is 4.5°, the feed water content is 55%, and the feed rate is 1T / hour. The moisture content of the kiln material is about 19.5%, and it is in the form of loose lumps. It can process 20-24T / day of raw materials every 24 hours.

[0020] Step 2: Mixing slag molding materials. The total slag-forming ingredients in the rhenium-containing sulfur-arsenic acid mud raw materials are very small. In order to ensure the smooth operation of the vortex furnace, the raw materials are mixed with 15% slag material. In the slag material: river sand (containing SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com