Patents

Literature

127 results about "Arsenic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arsenic acid is the chemical compound with the formula H₃AsO₄. More descriptively written as AsO(OH)₃, this colorless acid is the arsenic analogue of phosphoric acid. Arsenate and phosphate salts behave very similarly. Arsenic acid as such has not been isolated, but is only found in solution, where it is largely ionized. Its hemihydrate form (H₃AsO₄·¹⁄₂H₂O) does form stable crystals. Crystalline samples dehydrate with condensation at 100 °C.

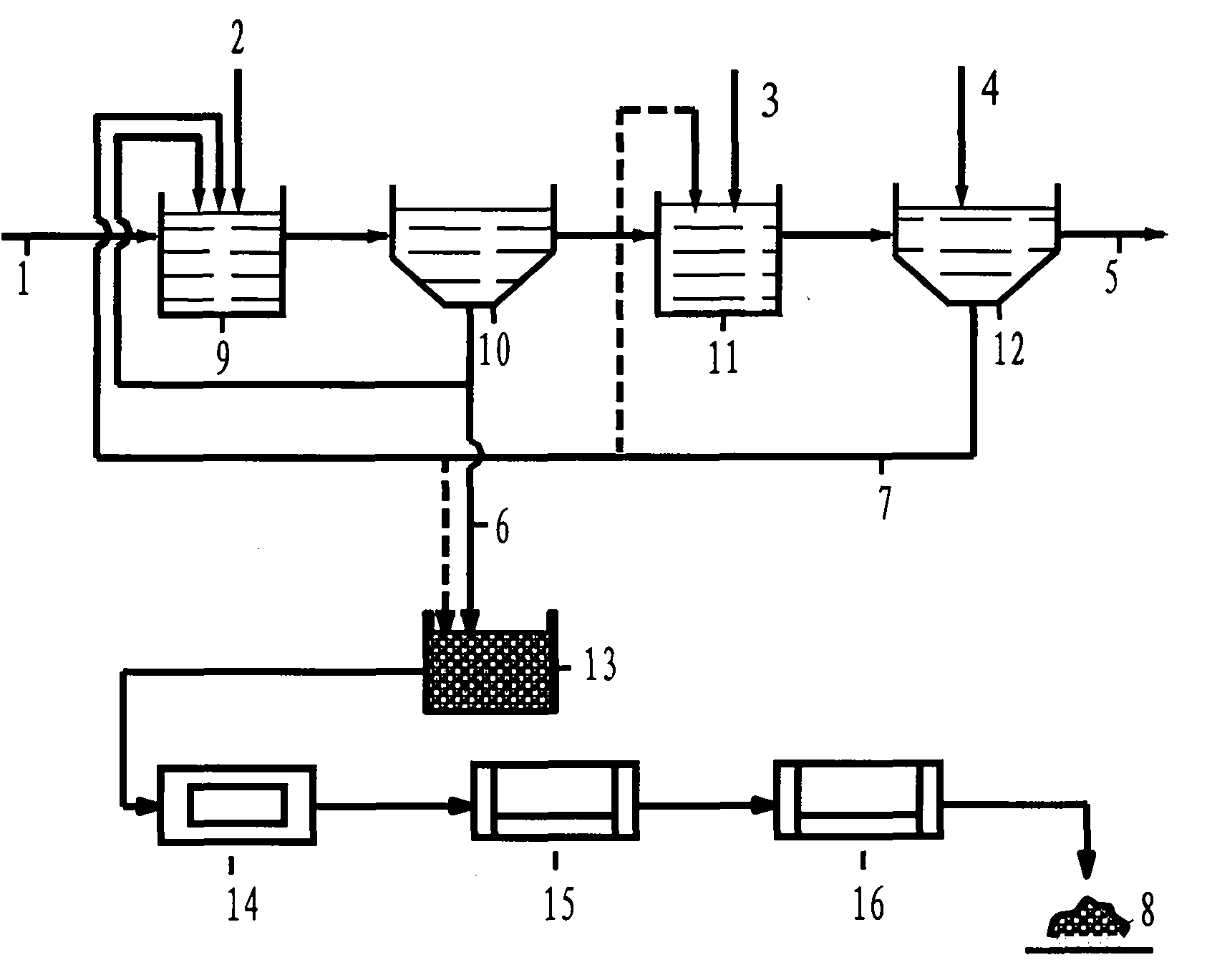

Advanced treatment method for arsenic-containing wastewater

InactiveCN103043812AImprove removal efficiencyConducive to aggregation and settlementMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeFerrous salts

The invention relates to a method for treating arsenic-containing wastewater by a process of preoxidation-composite coagulation deposition-filtering, and belongs to the technical field of wastewater treatment. The method comprises the steps of adding a certain amount of an oxidizing agent in a reaction tank for preoxidation in a condition that the wastewater contains trivalent arsenic so as to transform the trivalent arsenic into pentavalent arsenic completely, while for the wastewater only contains the pentavalent arsenic, the preoxidation process is not needed; adding a certain amount of a ferrous salt water solution; controlling a molar ration of Fe to As being 5-50; adding acid or alkali to adjust a pH value being 6-8; stirring for 0.1-1 min rapidly, so that a ferric arsenate precipitate is formed, at the same time, the ferrous salt is hydrolyzed into ferrous carbonyl to promote coagulation deposition of the ferric arsenate; adding a solution of 0.1-10 mg / L organic polymer flocculant; stirring for 0.1-1 min rapidly; stirring for 5-10 min slowly, precipitating for 10-30 min, discharging sludge from the bottom, introducing supernatant into a sand filter tank, a filter film or a filter bag, filtering and discharging the effluent. Arsenic content in water after treatment is lower than that of a drinking water standard (less than 10 [mu]g / L) regulated by the world health organization. The method has low sludge production and low cost, and can be used for advanced treatment of the arsenic-containing industrial wastewater and treatment of arsenic polluted underground water and drinking water.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

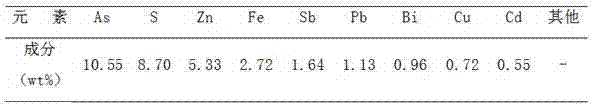

Method for treating arsenic pollution of copper smelt industry

InactiveCN101037725AAchieve separationProcess efficiency improvementWater/sewage treatment by oxidationArsenic pollutionZINC SULFATE HEPTAHYDRATE

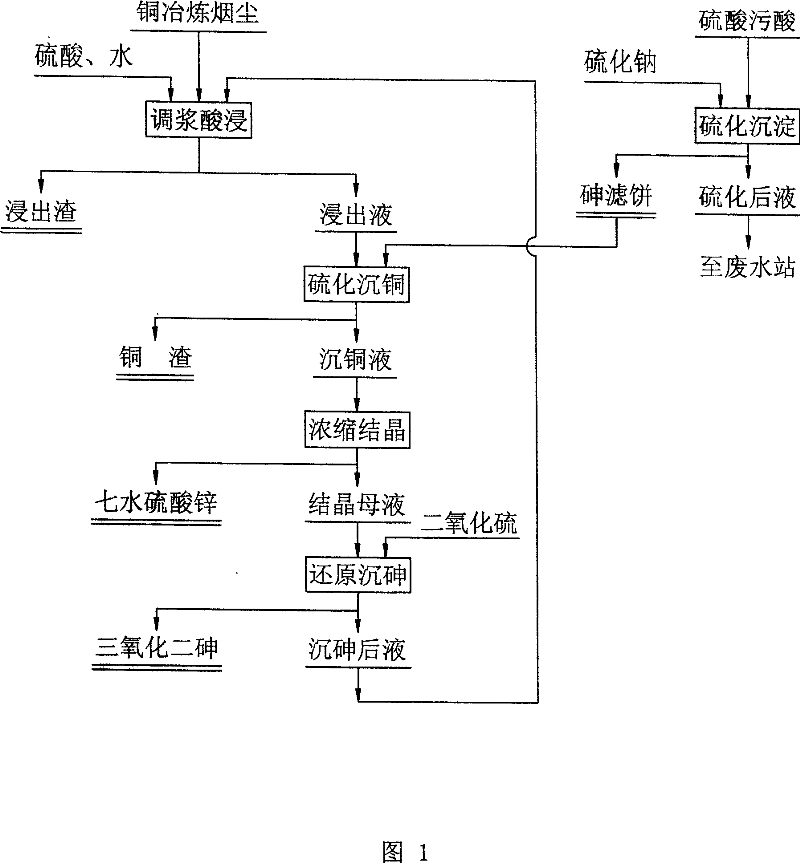

The invention provides a method for controling arsenic pollution in the copper metallurgy industry, is characterized in that arsenic acid filtering case is added as vulcanized agent in sulphuric acid extract of copper metallurgy smoke to precipitate copper, copper slag and the solution containing copper are obtain by separation; the solution containing copper is contracted to 60-100 g / l of arsenical concentration and then cooled to the room temperature, heptahydrate zinc sulphate and crystal mother liquor are obtained after separation; sulfur dioxide is added to crystal mother liquor, thereby arsenic is dissolved out in the form of arsenic trioxide, arsenic trioxide and the solution after precipitating arsenic are obtained after separation, the solution after precipitating arsenic is back to smoke extract. The separature of the main component such as copper, arsenic, zinc and cadmium is performed in sulphuric acid extract of copper metallurgy smoke and arsenic acid filtering case with an objective for controling arsenic pollution economically and effectively, while provided with an advantage for further recycling valent metal synthetically.

Owner:朱永文

Method for preparing arsenic trioxide from arsenic sulfide waste

InactiveCN102115166ALow costNothing producedSolid waste disposalArsenic compoundsSolubilityArsenic sulfide

The invention provides a method for preparing arsenic trioxide from arsenic sulfide waste. The arsenic sulfide waste is soaked in a sodium hydroxide solution to extract arsenic sulfide, arsenic sulfide mixes with an excessive amount of arsenic acid, and the mixture reacts at a temperature ranging from 40 DEG C to 95 DEG C for 0.5 to 3 hours, to produce a mixture containing arsenous acid and elemental sulfur; the mixture containing arsenous acid and elemental sulfur mixes with 2 to 5 times (by mass) of water and then oxygen gas is introduced so that arsenous acid is oxidized into arsenic acid, and the reaction product is filtered to remove elemental sulfur and thus to produce an arsenic acid solution; and the arsenic acid solution is reduced by sulfur dioxide gas to arsenous acid with a lower solubility, the reaction liquid is distilled under a reduced pressure to produce a saturated solution of arsenous acid, the saturated solution of arsenous acid is cooled so that arsenous acid is crystallized and then filtered to produce a filter cake of arsenous acid, and the filter cake of arsenous acid is dried and pulverized to obtain an arsenic trioxide product. The method has a short process flow, increases the recovery rate of arsenic, avoids the production of secondary pollutants, adopts simple equipment, greatly reduces the cost of arsenic recovery and is worthy to be widely applied.

Owner:JIANGSU ZHONGKE MACHINERY

Non-ferrous metal smelting high-arsenic contaminated acid arsenic fixing process

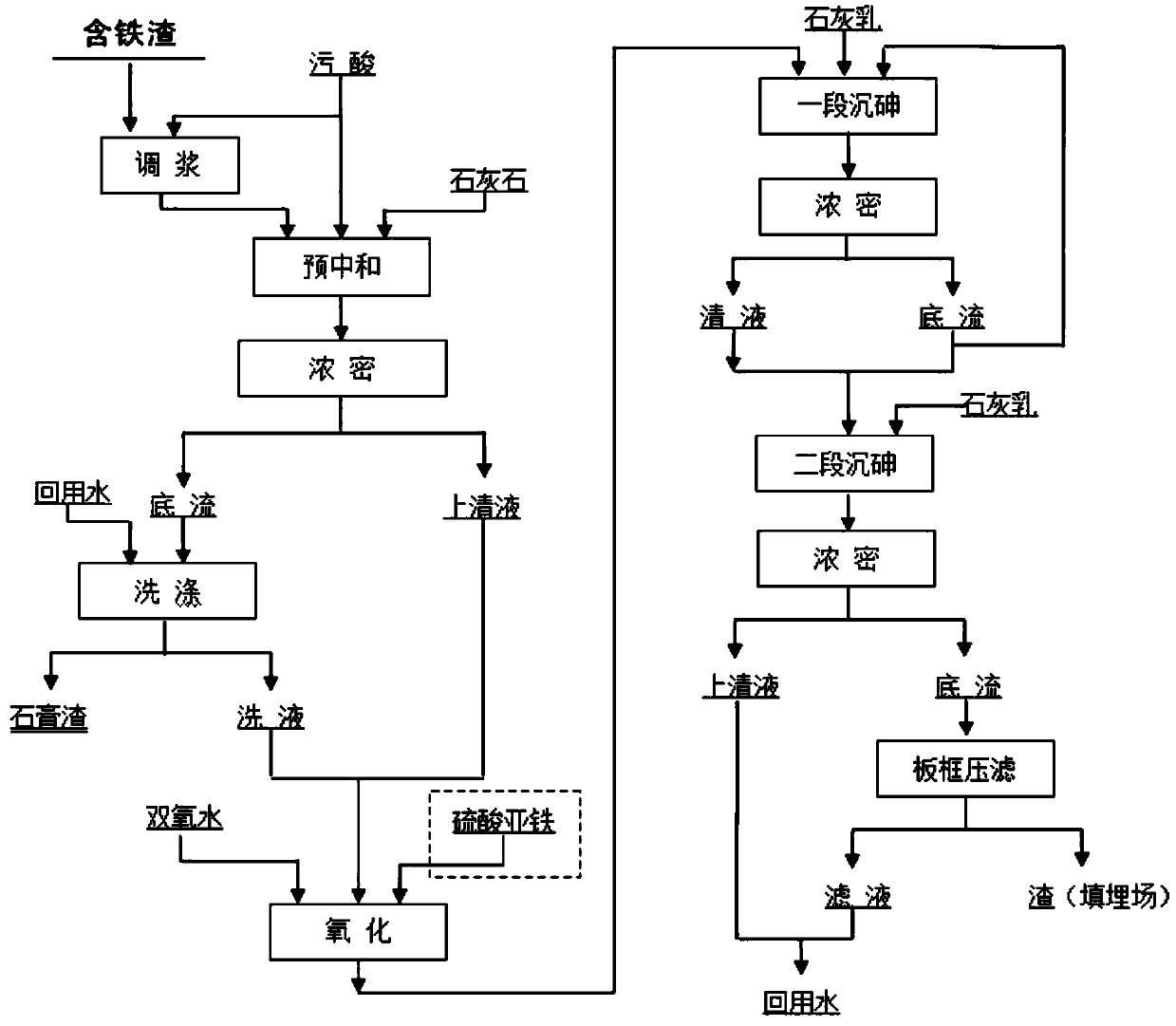

ActiveCN109574319AMild responseSimple processTreatment involving filtrationWaste water treatment from metallurgical processIron sulfateTreatment effect

The invention relates to a non-ferrous metal smelting high-arsenic contaminated acid arsenic fixing process which sequentially includes the steps: pre-neutralization, to be specific, mixing iron-containing slag or iron-containing reagents and smelting contaminated acid, controlling Fe / As molar mole ratio, throwing mixed slurry and the contaminated acid into a pre-neutralization tank, performing reaction, controlling the pH (potential of hydrogen) value of solution, thickening pre-neutralization slag slurry to obtain bottom flow, supernate and gypsum slag, and using the gypsum slag as a cementretarder for sales; oxidation, to be specific, supplementing iron sulfate serving as an iron source reagent as required, heating the pre-neutralized supernate, adding hydrogen peroxide serving as an oxidizing agent for oxidation, controlling oxidation-reduction potential, and completely oxidizing trivalent arsenic into pentavalent arsenic; crystal form iron arsenate precipitation arsenic fixing, to be specific, controlling reaction temperature, adding seed crystals, controlling reaction endpoint pH values by adding lime milk, and conveying bottom flow subjected to two-stage arsenic precipitating reaction to a landfill through filter-pressed crystal form iron arsenate solids. The arsenic fixing process has the advantages of simple process, low cost, good treatment effects, low environmentalpollution risk and the like and is applicable to non-ferrous metal metallurgy industries.

Owner:ZIJIN MINING GROUP +1

Method for preparing quaternary ammonium salt cationic absorbing agent by using manioc straw/ manioc waste and application

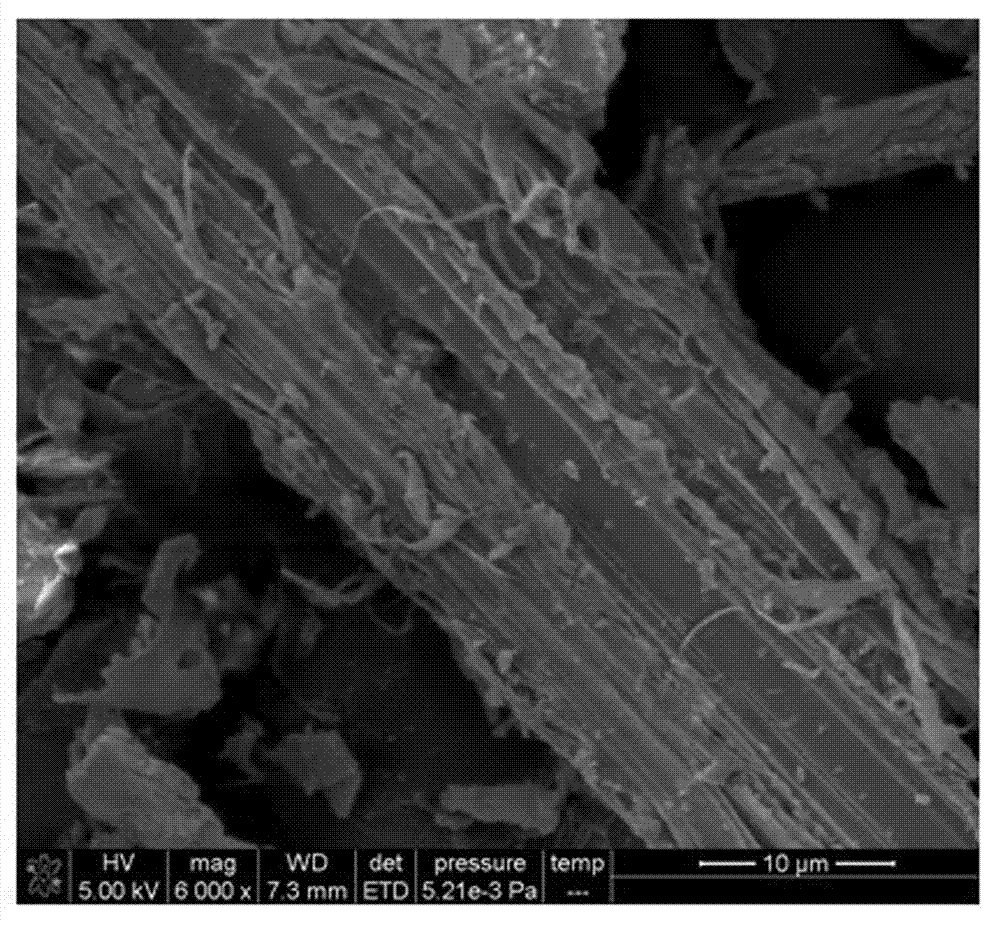

InactiveCN102764635ASimple production processReduce secondary pollutionOther chemical processesWater/sewage treatment by sorptionCross-linkCellulose

The invention discloses a method for preparing a quaternary ammonium salt cationic absorbing agent by using manioc straw / manioc waste. The method comprises that ground manioc straw and manioc waste are preprocessed by using alkali, N,N-dimethylformamide serves as a reaction medium, quadrol serves as a cross-linking agent, the manioc straw, the manioc waste and epichlorohydrin are subjected to reaction, cellulose ester is generated, the reaction activity is improved, the the manioc straw, the manioc waste and the quadrol are subjected to reaction, a quaternary amine group is introduced, and an cationic ion exchanger is prepared. Under conditions of a room temperature and oscillation, the pH value of waste water is adjusted to be no more than 12, the cationic absorbing agent is added, the solid-to-liquid ratio of the absorbing agent and the waste water is no less than 1g / L, the oscillating time is no less than 30 min, filtering is conducted, and the cationic absorbing agent is separated. According to the method and application, source of raw materials is numerous, the cost is low, the process is simple, and the absorbing agent is economical and applicable, reproducible, high in weight gain and good in stability and absorbing effect and can be used widely in processing of waste water of water body eutrophication, anionic dye and negative ions such as arsenic acid radical, sulfate radical and Cr (VI).

Owner:GUANGXI NORMAL UNIV

Treatment technology for high-arsenic acid industrial wastewater

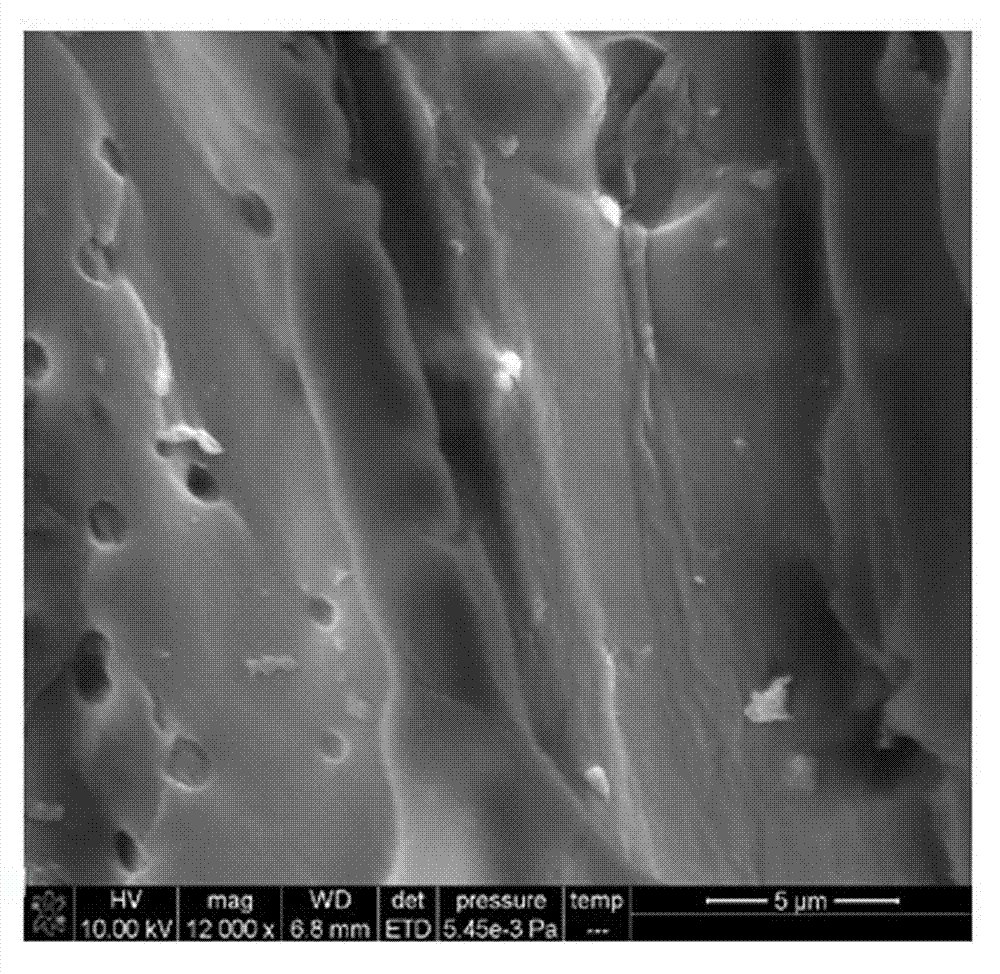

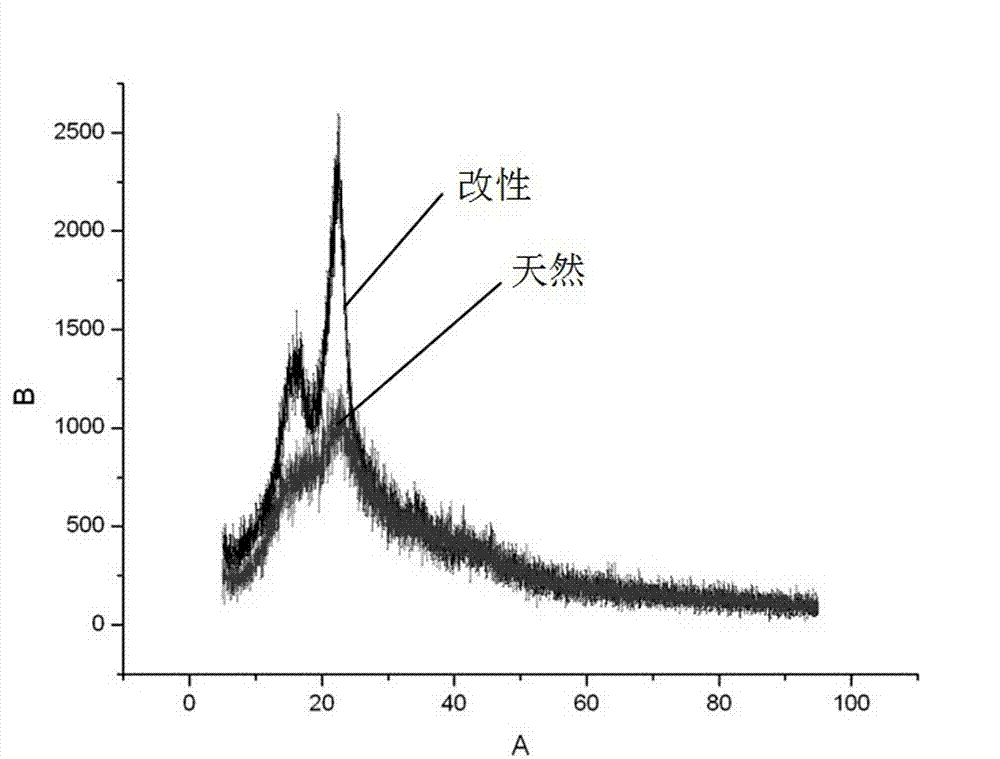

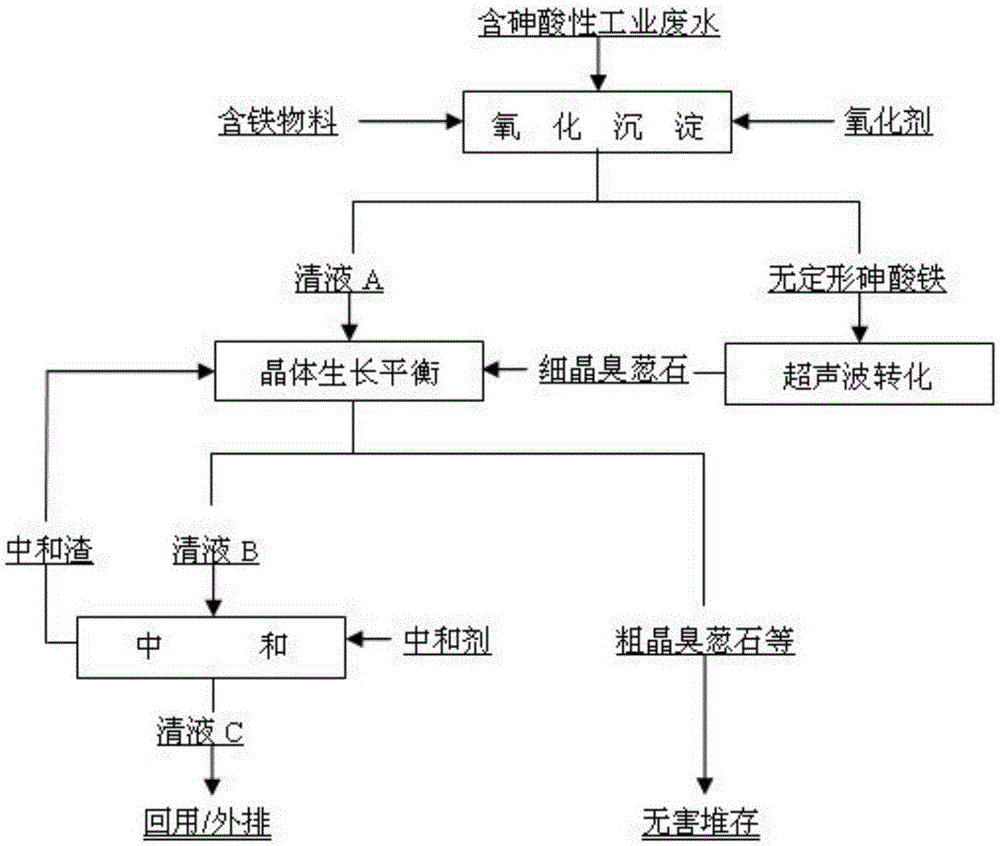

InactiveCN105461110AReduce processingReduce energy consumptionWater contaminantsWaste water treatment from gaseous effluentsSludgeSlurry

The invention provides a treatment technology for high-arsenic acid industrial wastewater. The technology comprises steps as follows: Step 1: an iron-containing material is added to the arsenic-containing acid industrial wastewater, and amorphous ferric arsenate sediment and a clear liquid A are formed; Step 2: the amorphous ferric arsenate sediment obtained in Step 1 is placed in a reactor with an ultrasonic wave source, and a slurry material is converted into fine-grain scorodite under the action of ultrasonic waves; Step 3: the fine-grain scorodite and the clear liquid A are led into a reaction tank and stirred to have reaction equilibrium for 0.5-8 h, and coarse-grain-scorodite-containing sediment (for harmless stockpiling) and a clear liquid B are obtained; Step 4: a neutralizer is added to the clear liquid B, the pH is adjusted to be neutral, a clear liquid C is produced (for reuse / discharge), and neutralization sludge produced in a neutralization reaction returns to Step 3 for reaction equilibrium. According to the treatment technology, an ultrasonic wave technology is applied to the grain form transformation process, a precipitation technology is designed again, contaminated acid treatment energy consumption is obviously reduced, and the self-cleanliness of the treatment process is improved.

Owner:昆明泉淳环保科技有限公司 +1

Harmless treatment method of arsenic-containing flue dust

ActiveCN103551025AImprove leaching rateReduce consumptionDispersed particle separationWaste water treatment from gaseous effluentsSolubilityPregnant leach solution

The invention relates to a harmless treatment method of arsenic-containing flue dust, and belongs to the environment engineering and science field. The method comprises the following steps: adding a dilute acid and hydrogen peroxide in a water extracting process of the arsenic-containing flue dust to realize acidic oxidation extraction, adding high valence iron having a weight 0.8-2.5 times the weight of arsenic to the obtained extraction liquid to form insoluble arsenic acid iron slag, carrying out high valence iron salt dearsenification, adding high valence iron having a weight 3-6 times the amount of arsenic to the obtained dearsenified high valence iron salt filtrate, adjusting the pH value to 6-9 by using ammonia water, and carrying out depth adsorption dearsenification to obtain a filtrate having an arsenic content lower than a discharge standard of 0.5mg / L to realize the harmless treatment method of arsenic-containing flue dust. The method fully utilizes the high solubility characteristic of pentavalent arsenic, allows the water consumption in the extraction process to be lower than that in the prior art and the temperature of the reaction process to be lower than a boiling temperature, realizes the high extraction rate of arsenic, and reduces the water consumption and the energy consumption.

Owner:KUNMING UNIV OF SCI & TECH

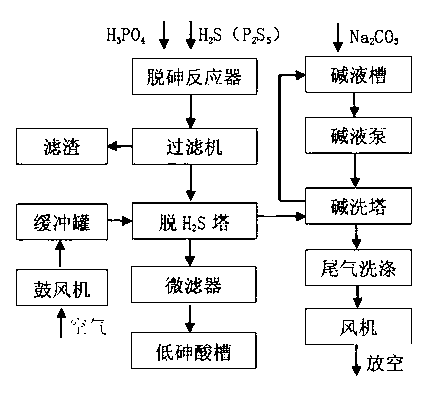

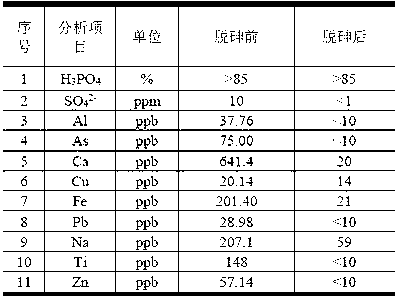

Method for removing arsenic from electronic grade phosphoric acid generated by wet-process phosphoric acid

The invention discloses a method for removing arsenic from electronic grade phosphoric acid generated by wet-process phosphoric acid. The method comprises the following steps of: firstly, adding H2S and phosphoric acid in an arsenic-removed reactor and maintaining the reaction temperature at 80 DEG C for stirring; secondly, filtering concentrated liquor from the arsenic-removed reactor through a filter to separate arsenic slag from clear solution; thirdly, after the clear solution is heated to a certain temperature, pumping the heated clear solution into an H2S-removing tower and blowing to remove residual hydrogen sulfide gas in the acid by using an air bubbling and negative-pressure sucking mode; fourthly, enabling the acid subjected to H2S removal to enter a storage groove for later use by a microstrainer and ensuring that the arsenic content of low arsenic acid to reach below 1mu g / g and controlling the granularity to below 5mu m; and fifthly, absorbing H2S gas blown in the arsenic-removed process with Na2CO3, wherein the obtained Na2S solution is used for producing phosphate with low sulfur content requirement. According to the method disclosed by the invention, the arsenic in the phosphoric acid can be effectively removed and the industrial standard is reached.

Owner:WENGFU (GRP) CO LTD

Mercury ion test paper as well as preparation method and use method thereof

InactiveCN103487431AEasy to useEasy to makeMaterial analysis by observing effect on chemical indicatorDistilled waterFilter paper

The invention discloses mercury ion test paper as well as a preparation method and a use method thereof. The test paper is prepared by immersing filter paper in an immersion solution, taking out and drying; the immersion solution comprises an immersion solution I prepared by dissolving 0.35-0.7 g of a cadmium reagent in 100 ml of absolute ethanol and uniformly mixing, and an immersion solution II prepared by dissolving 5 ml of arsenic acid in 20 ml of distilled water, adding 20 ml of a 40% sodium hydroxide solution and finally fixing the volume to 100 ml by the distilled water. The test paper is simple to prepare, low in cost, convenient to use, free from environmental pollution, favorable for environmental protection and wide in test range, does not need to be operated by professionals and is especially suitable for quickly detecting the mercury content on site.

Owner:KUNMING BOYIN SCIANDTECH CO LTD

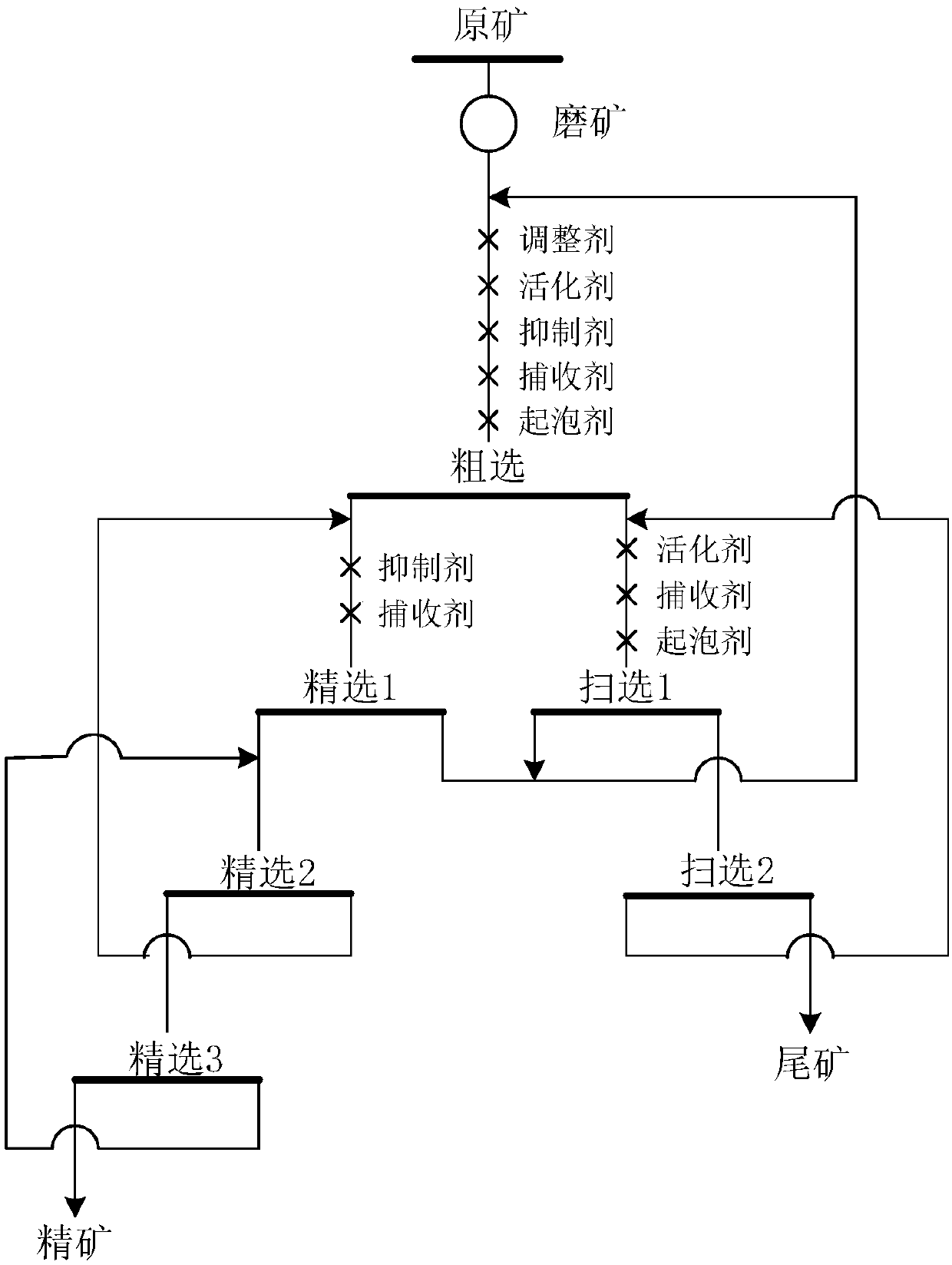

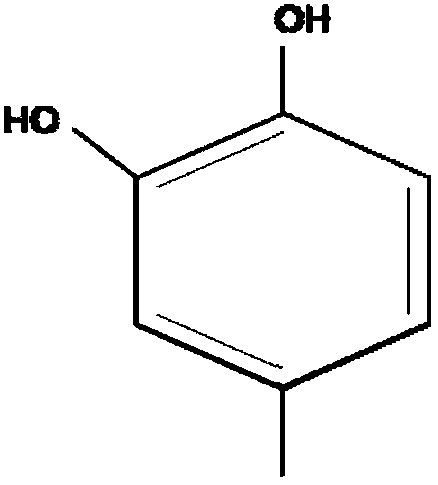

Composition and flotation method for flotation collecting of rutile from ores

The invention provides a composition for flotation collecting of rutile from ores. The composition for flotation collecting of the rutile from the ores comprises an activating agent used for activating the rutile, and / or an inhibitor used for inhibiting gangue, and a collecting agent, namely 3,4-dihydroxytoluene. The invention further provides a flotation method for flotation collecting of the rutile from the ores. The flotation method comprises the step that the 3,4-dihydroxytoluene is used as the collecting agent. According to the composition and the flotation method for flotation collectingof the rutile from the ores, oxygen atoms of every two adjacent pieces of hydroxyl on a benzene ring are bonded with the rutile, so that the collecting agent has high collecting performance; comparedwith an arsenic acid collecting agent and a phosphonic acid collecting agent, the collecting agent is low in price, free of toxic and side effects and little in environmental pollution; compared witha hydroximic acid collecting agent, the collecting agent has the advantages that the cost is low, water solubility is good, and pipeline blocking is avoided; and meanwhile, the collecting agent is short in flotation time and small in using amount, and thus separation of the rutile and a gangue mineral can be well achieved under the neutral condition and under the weak-base condition.

Owner:CENT SOUTH UNIV

Method for recycling rhenium, arsenic and copper from sulfuric acid wastewater of copper smelting flue gas purification system

ActiveCN103695961AAchieve enrichmentAchieve separationElectrolysis componentsPhotography auxillary processesRheniumElectrodialysis

The invention belongs to the technical field of metal extraction, and particularly relates to a method for recycling rhenium, arsenic and copper from sulfuric acid wastewater of a copper smelting flue gas purification system. The method comprises steps of a. putting highly acid sulfuric acid wastewater generated in flue gas purification into an electrolytic cell, and respectively separating an anode region and a cathode region by a sulfo group anion selective membrane and a polysulfone cation selective membrane; b. preparing peroxymonosulfuric acid in the anode region to be used as a strong oxidant, wherein the concentration of peroxymonosulfuric acid is 30-60g / L, and rhenium and arsenic ions in the highly acid sulfuric acid wastewater are oxidized into high valence rhenium acid radical and arsenic acid radical by peroxymonosulfuric acid; c. enriching and separating arsenic, rhenium and copper under the condition of reaction temperature of 10-40 DEG C, reaction time of 2-5 hours, and conversion between anode and cathode through frequent changeover. The method uses an electroosmosis technology for enriching and separating substances such as arsenic, rhenium and copper in highly acid sulfuric acid wastewater efficiently, and has the characteristics of simple equipment, easy operation, short processes, low energy consumption and comprehensive utilization of all resources.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for rapidly removing arsenic in high arsenic zinc oxide through zinc ash and sodium carbonate peroxide in iron and steel plants and producing zinc sulfate

InactiveCN103274449ATo achieve the purpose of comprehensive recycling at the same timeTo achieve the purpose of comprehensive recyclingZinc sulatesFiltrationHydrolysis

The invention discloses a method for rapidly removing arsenic in high arsenic zinc oxide through zinc ash and sodium carbonate peroxide in iron and steel plants and producing zinc sulfate, which rapidly removes arsenic in high arsenic zinc oxide through zinc ash and sodium carbonate peroxide in iron and steel plants and simultaneously also produces zinc sulfate. By adopting the property that Fe(OH)3 can produce FeAsO4 with arsenic acid when the pH value of Fe(OH)3 is 3.0 to 5.4, iron in raw material is leached out, and Fe(OH)3 is produced through oxidation reaction and hydrolysis reaction, so that the purpose that arsenic is removed from solution is realized. The method comprises the concrete steps of calculating usage amount of high arsenic zinc oxide and zinc ash in iron and steel plants according to laboratory reports of arsenic, iron and zinc elements in the high arsenic zinc oxide and the zinc ash in iron and steel plants, mixing the raw material, slurrying, leaching, pH value adjusting, removing iron and arsenic trough sodium carbonate peroxide oxidation, neutralization, pressure filtration, purification, evaporative crystallization, and finally obtaining qualified zinc sulfate products. Arsenic is subjected to smelting waste solidification during the smelting process, so that hazard-free treatment is realized.

Owner:HENGYANG NORMAL UNIV

Method for preparing arsenic trioxide by arsenic-containing waste water

InactiveCN102115165AHigh recovery rateLow costSolid waste disposalArsenic compoundsCopper sulfateArsenic sulfide

The invention provides a method for preparing arsenic trioxide by arsenic-containing waste water, which comprises the steps of: mixing arsenic sulfide waste residue with water, and extracting arsenic sulfide by sodium hydroxide solution; mixing the obtained arsenic sulfide with the water with 2-5 times of the weight of the arsenic sulfide to be sizing agent, and reacting with copper sulfate solution to obtain arsenous acid and copper sulphide-containing precipitate and sulfuric acid solution; mixing the arsenous acid and copper sulphide-containing precipitate with the water to feed the oxygen, oxygenizing arsenious acid to generate arsenic acid which is easy to dissolve in water, and filtering to obtain arsenic acid solution and copper sulphide precipitate; restoring the obtained arsenic acid to be arsenious acid by sulfur dioxide to obtain arsenious acid; and distilling the arsenious acid, concentrating, filtering and drying to obtain an arsenic trioxide product. The method is short in technological process, high in arsenic recovery rate, free of the generation of secondary pollutant, simple in equipment, and extremely lower in arsenic recovery cost, thereby being a method which is worth to popularize and apply.

Owner:马艳荣

Method for recovering arsenic from scrap material containing arsenic and copper produced in process of copper smelting

InactiveCN101767822AImprove oxidation efficiencyShorten the timeArsenic compoundsPregnant leach solutionSlurry

The invention provides a method for recovering arsenic from scrap material containing arsenic and copper produced in process of copper smelting, comprising the following steps: mixing waste acid containing 18 / L of arsenic solution with arsenic filter cake according to proportion by weight of 8:1 and stirring the mixture; preheating the mixture and sucking size into a reaction kettle, warming and pressurizing the size by conveying compressed air by an air compressor, then separating the pressurized leaching agent; injecting sulfur dioxide after carrying out secondary filtration on filter liquor to reduce arsenic acid to arsenoxide for seedout. The method of the invention features simple technique, saved copper powder consumption and improved arsenic recovery rate.

Owner:JIANGXI COPPER CORP

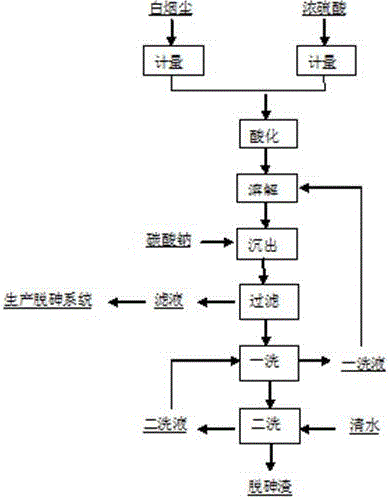

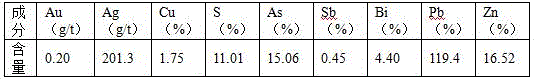

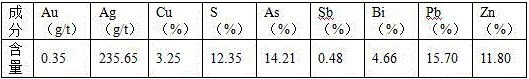

Method for copper smelting white smoke dust arsenic removal

ActiveCN106756056ASolve the shortcomings of low arsenic dissolution rateLarge production capacityProcess efficiency improvementSlagDissolution

The invention discloses a method for copper smelting white smoke dust arsenic removal. White smoke dust collected by a copper smelting electric dust remover is used as a raw material, arsenic is converted into arsenic acid through a concentrated sulfuric acid acidification method, the arsenic acid is dissolved with water for 1-1.5 hours, and the water adding amount is 4-5 times the weight of the white smoke dust; after dissolution, solid sodium carbonate is added to adjust the pH value to 8.0-8.5, soluble metallic sulfate is converted into settlement, after being filtered to be separated from sodium arsenate salt, the settlement is washed twice with clear water, and an obtained filter cake is an arsenic-removed filter cake rich in valuable metal, wherein the arsenic content of the filter cake is lower than 0.5%; and filter liquor enters a main produced lime-molysite arsenic removal system, and newly adding of waste water treatment equipment is not needed. According to the method, the equipment is simple, heating is not needed, operation is convenient, the arsenic removal rate is high, and the arsenic content of acidized slag meets the third-level quality standard requirement of bing ore; and convenience is provided for recovery of other acid-soluble valuable metals in the white smoke dust, and the method has good application and popularization value.

Owner:KUNMING UNIV OF SCI & TECH

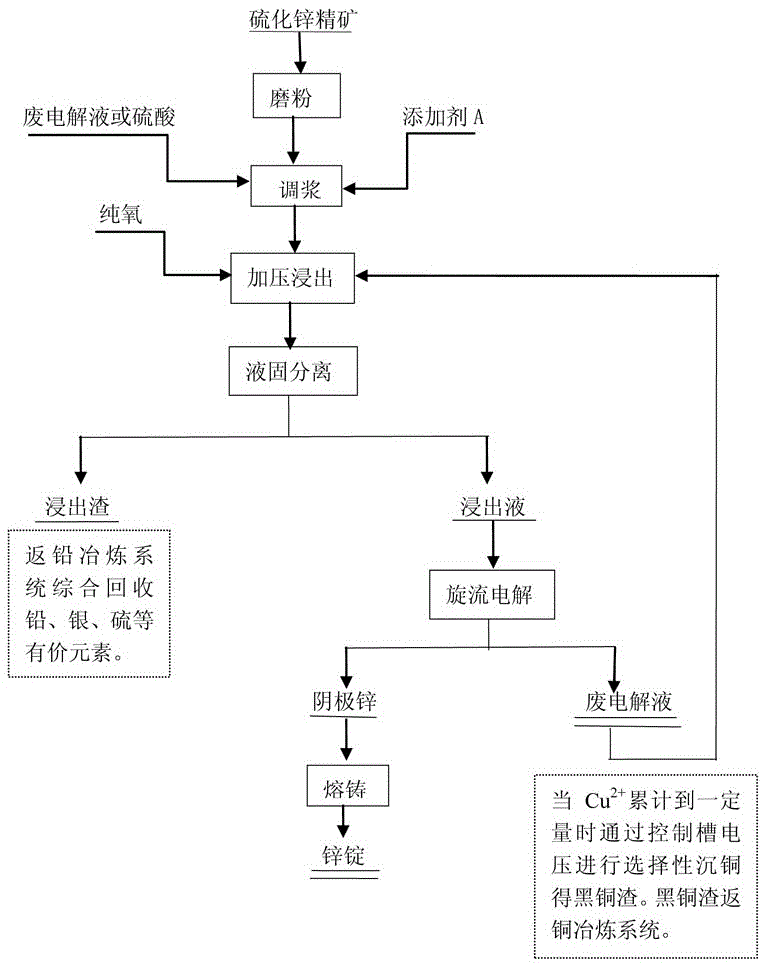

Technology for efficiently and selectively separating zinc in zinc sulfide concentrate

ActiveCN105603186ANo pollution in the processAdaptablePhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a technology for efficiently and selectively separating zinc in zinc sulfide concentrate. The technology includes the steps that the zinc sulfide concentrate serves as a raw material and is wetly ground, then the wetly-ground concentrate and sulfuric acid or waste electrolyte are mixed into a slurry and poured into a high-pressure kettle for leaching, an adjusting agent A is added, pure oxygen is led in, the proper final acidity is controlled, and most Fe and most As in the zinc sulfide concentrate enter slag in the hematite mode, the iron vitriol mode and the ferric arsenate salt mode. Leached liquid is subjected to acidity regulation to be directly electrolyzed in a rotational flow mode, zinc in the leached liquid is extracted, and an electric zinc product meeting the national standard can be obtained. According to the technology, the traditional purification working procedure is omitted, the technological process and a device are simplified, the technology is simple, operation is easy and convenient, energy consumption is reduced, the leaching rate and the recovery rate of the zinc are increased, resources are saved accordingly, and cost is reduced.

Owner:XIANGNAN UNIV +1

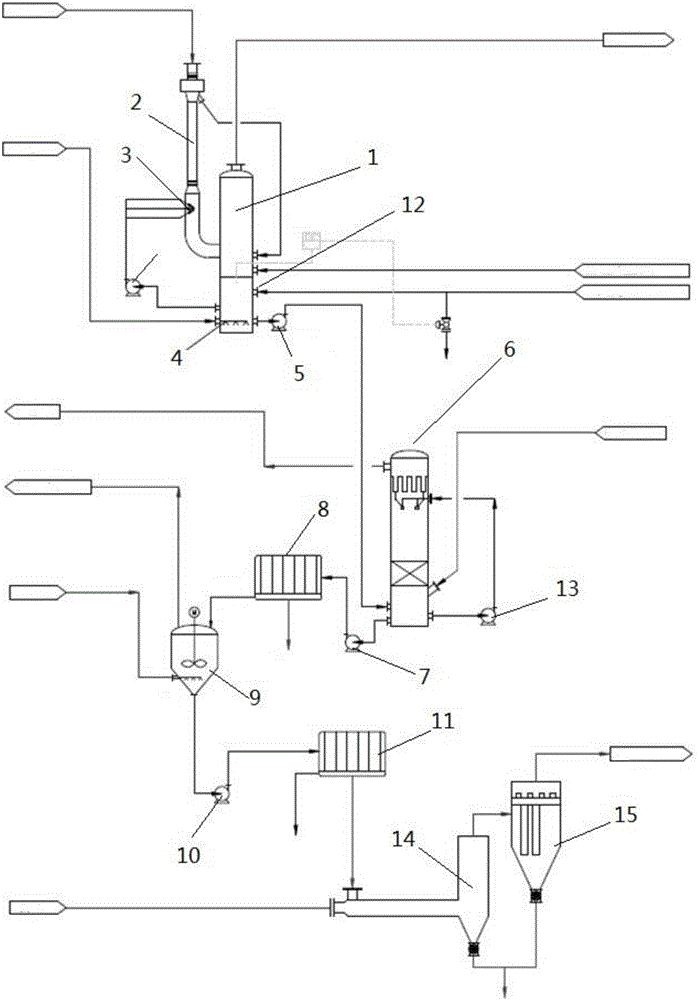

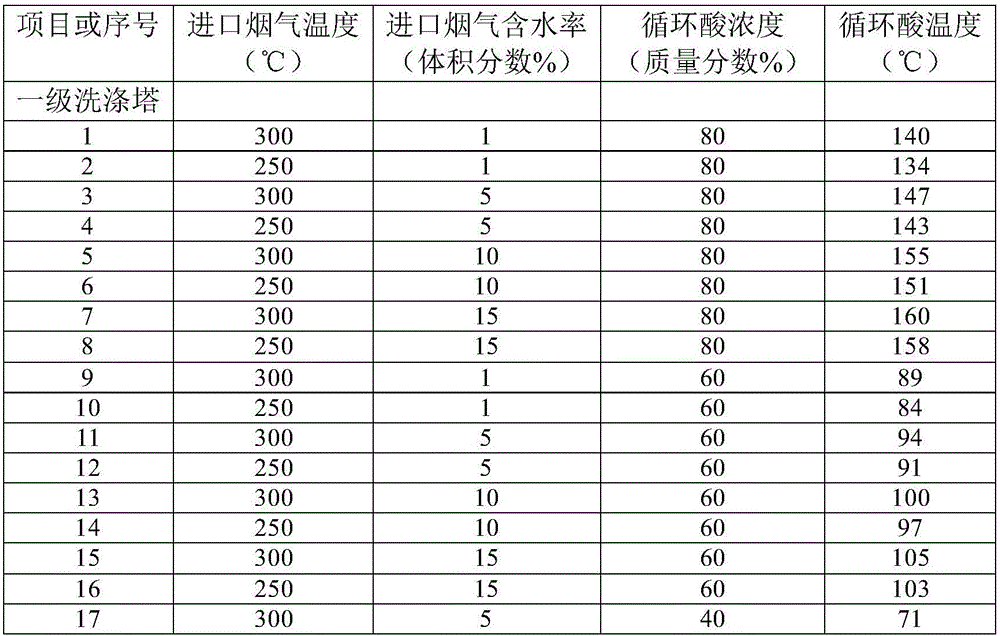

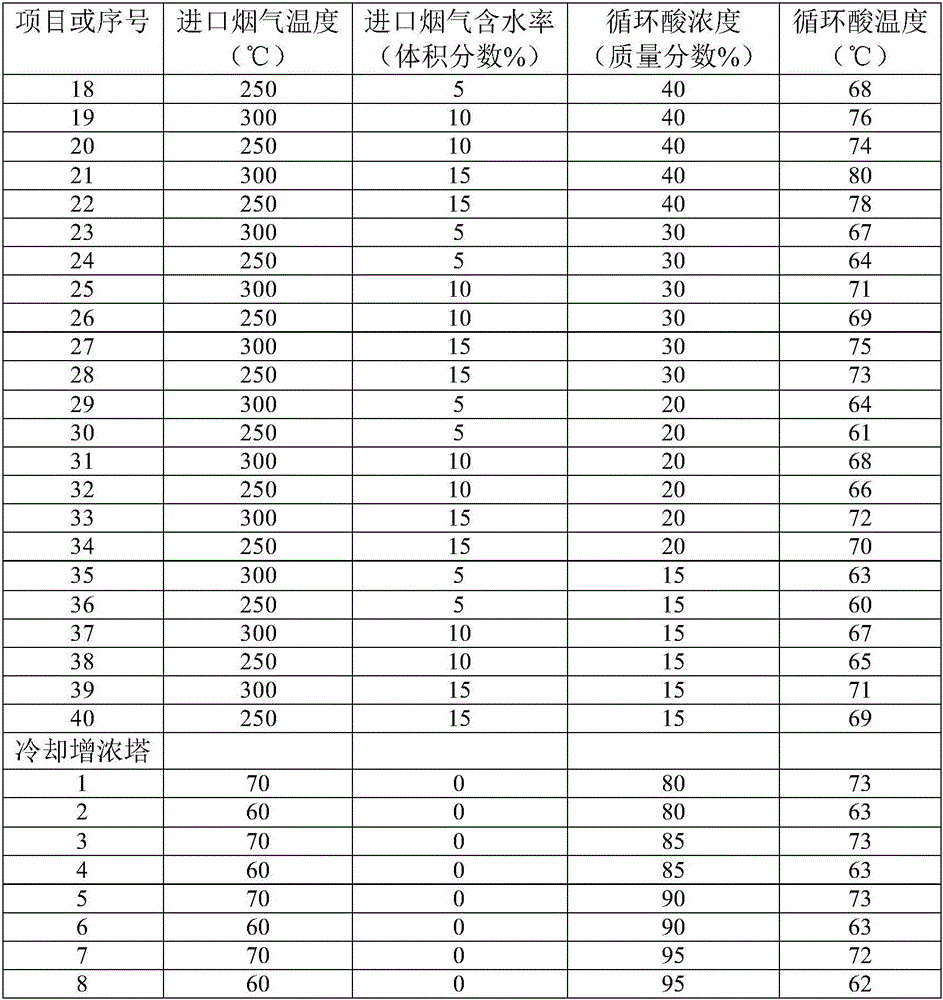

Energy saving process and system for comprehensively recycling waste acid of sulfuric acid purification

ActiveCN106268179ALow running costReduce solubilityGas treatmentArsenic oxides/hydroxides/oxyacidsHigh concentrationSlag

The invention discloses an energy saving process for comprehensively recycling waste acid of sulfuric acid purification. The energy saving process comprises the following steps: high-temperature flue gas is fed into a first-stage washing tower; acidic liquor at the bottom of a tower is pumped to an acid discharging spraying head in a gas inlet pipeline of the first-stage washing tower, and the acidic liquor is in contact with the high-temperature flue gas reversely to absorb SO3 in the flue gas; the flue gas washed by the acidic liquor is cooled and then enters a subsequent conventional purification process for continuous cooling, and condensed diluted acid generated in the subsequent cooling process is returned into the first-stage washing tower to keep the SO3 and water in the tower balanced; heavy metal dust and arsenic elements in the flue gas form sulfate and arsenious acid after being washed by the acidic liquor; a compressed air aeration device oxidizes the arsenious acid in the acidic liquor into arsenic acid; the acidic liquor containing the arsenic acid and the heavy metal acid salt is conveyed into a cooling and thickening tower; concentrated acid from the cooling and thickening tower is filtered by a slag filter to filter out heavy metal sulfate slag; filtrate enters an SO2 reducing tank, and high-concentration SO2 gas is fed into the tank, so that the arsenic acid is reduced into arsenious acid precipitates which can be slightly dissolved in the sulfuric acid; the acidic liquor containing the arsenious acid precipitates is subjected to solid-liquid separation to obtain an arsenious acid filter cake.

Owner:中铝环保节能集团有限公司

High-efficiency method for treating arsenic-containing wastewater

InactiveCN102107981ANo secondary impactReduce solubilitySludge treatment by oxidationWater contaminantsAfter treatmentSludge

The invention discloses a high-efficiency method for treating arsenic-containing wastewater, solves the problems in the prior art, and provides a complete method for treating the arsenic-containing wastewater. Arsenic (As3 plus) can be catalytically oxidized in advance through self-oxidation iron oxide flow bacilli; arsenious acid ions are oxidized to arsenic acid ions; then calcium compounds are added to gather arsenic-containing waste in the water; solid-liquid separation is conducted twice; and sludge can enter the wastewater again to circularly remove arsenic. After treatment, the arsenic content in the wastewater is very low, the discharged arsenic-containing sludge becomes non-toxic matters to be land-filled after being dried and roasted, and the water needing to be discharged can be discharged directly.

Owner:湖南布鲁斯凯碳资产管理有限公司

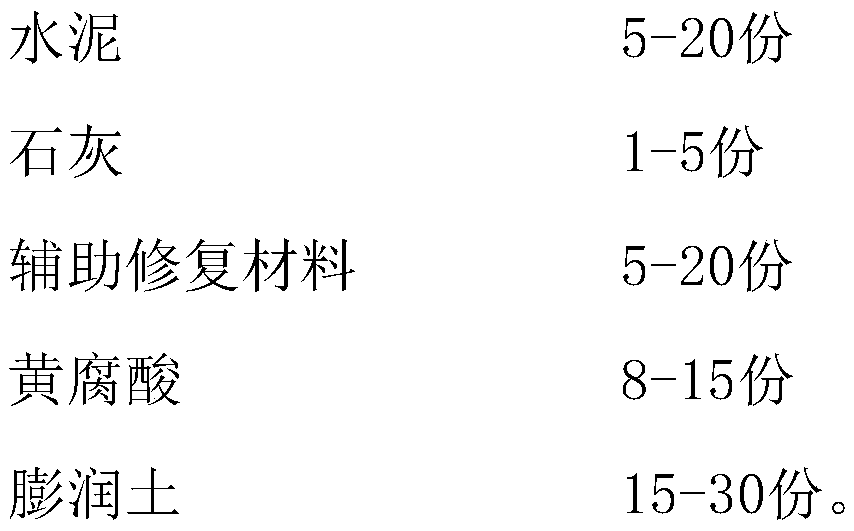

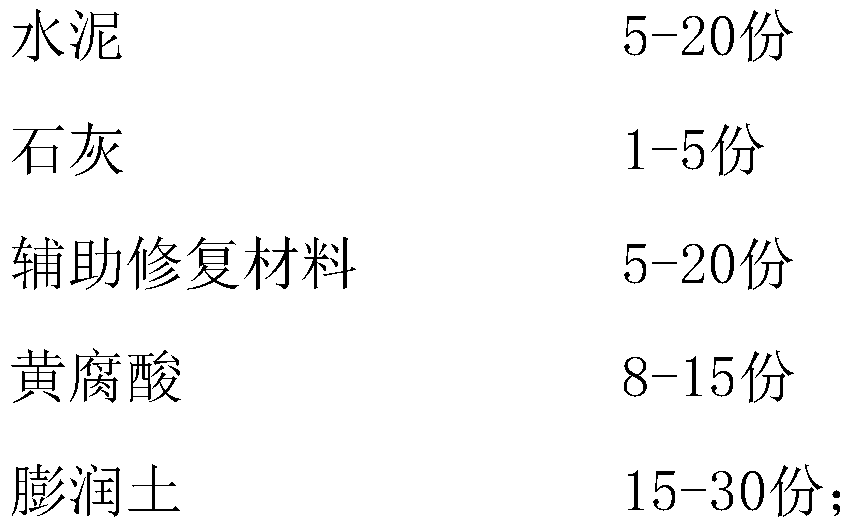

Heavy metal cadmium and arsenic combined contaminated soil remediation agent and preparation method thereof

ActiveCN109762569AReduce leaching concentrationEasy to operateOther chemical processesContaminated soil reclamationSodium BentoniteBiological activation

The invention relates to the technical field of soil remediation agents, in particular to a heavy metal cadmium and arsenic combined contaminated soil remediation agent and a preparation method thereof. The remediation agent is prepared from raw materials in parts by weight as follows: 5-20 parts of cement, 5-15 parts of lime, 5-20 parts of an auxiliary remediation material, 8-15 parts of fulvic acid and 15-30 parts of bentonite. The preparation method of the remediation agent is simple and easy to operate, mass production can be realized, a small quantity of remediation agent is used during soil remediation, soil structures and properties are not affected, Fe<3+> in a used Fe-based compound can be subjected to a reaction with OH- in water to produce Fe(OH)3, activation of arsenic acid ions due to high pH value of soil after immobilization is inhibited, so that pH value of sediment and leaching of arsenic after soil passivation are reduced, and the remediation agent has long-acting stability and can make pH value of the soil weakly alkaline.

Owner:GUANGDONG KAIYUAN ENVIRONMENT TECH

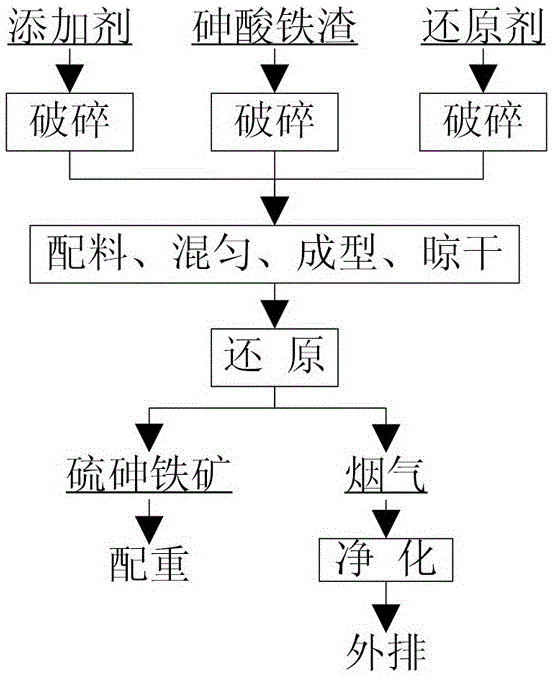

Stable arsenic acid iron slag solidifying method

The invention discloses a stable arsenic acid iron slag solidifying method. The stable arsenic acid iron slag solidifying method comprises the steps that arsenic acid iron slag, an additive and a reducing agent are mixed evenly, geierite is obtained through forming and reduction, and stable solidifying treatment is completed. The method can be used for directly producing geierite, dissolution of arsenic in waste slag can be effectively prevented, bounce does not occur with time, the geierite obtained after stable solidifying is high in strength, large in specific gravity and good in hydrolytic resistance, can be used for balance weight, the environmental environment caused by arsenic-containing slag stockpiling is eliminated, and stable solidifying of arsenic slag is achieved.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Process for producing 2-methyl-8-nitryl quinoline

The invention provides a method for preparing 2-methyl-8-nitroquinoline. The method comprises the following steps: o-nitroaniline reacts in hydrochloric acid and benzene solution to form hydrochloride of the o-nitroaniline; the o-nitroaniline hydrochloride and aldehyde are subjected to cyclization at a temperature between 10 and 100 DEG C; oxidation reaction is performed by use of oxidant at a temperature between 10 and 100 DEG C; and finally the 2-methyl-8-nitroquinoline with high purity is obtained through separation, neutralization, washing and drying. The method has the advantages that the method uses low-toxicity paraldehyde as a raw material to replace virulent crotonaldehyde, and uses iodine as the oxidant to replace virulent arsenic acid so as to reduce toxic effects on human and environment; inorganic acid and inorganic base used in the reaction are common acid and base; and the method is low in cost, little in pollution and high in product purity, and reaches the yield of 80 percent.

Owner:CINIC CHEM SHANGHAI

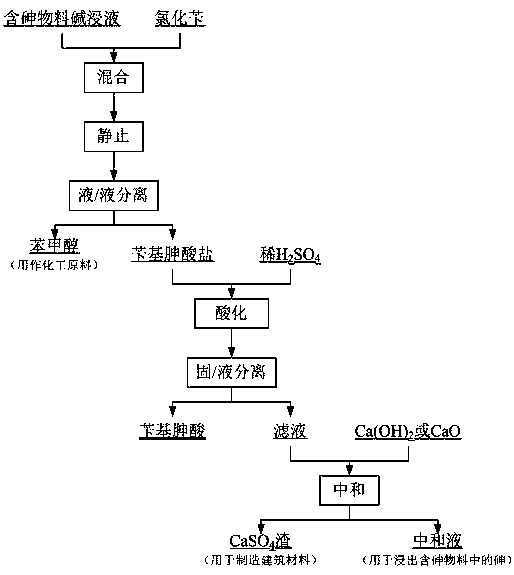

Method for recycling arsenic in arsenic-containing material alkali leaching arsenic removal liquid

ActiveCN108276448ASolve pollutionAddressing Arsenic HazardsGroup 5/15 element organic compoundsArsenateArsenic pollution

The invention relates to a method for recycling arsenic in arsenic-containing material alkali leaching arsenic removal liquid and belongs to the technical fields of metallurgy and environmental protection. The method comprises the following steps: mixing arsenic-containing material alkali leaching arsenic removal liquid and benzyl chloride to perform arsenic reaction, allowing standing still for 30 minutes or longer after the reaction is completed, and performing liquid / liquid separation to obtain an intermediate product benzyl arsenate and a byproduct benzyl alcohol, wherein benzyl alcohol serves as a chemical raw material; adjusting the pH of the benzyl arsenate to 1 to 3 by using dilute sulfuric acid, separating out precipitate, performing liquid and solid separation to obtain a productbenzyl arsenic acid and filtrate, enabling the benzyl arsenic acid to be applied to mineral separation, neutralizing the filtrate and filtering to obtain neutralization residue and neutralization liquid, enabling the neutralization residue to be applied to manufacture a building material, and returning the neutralization liquid to leach the arsenic in the arsenic-containing material. According tothe method, the problems that by the conventional treatment technology of the arsenic-containing material alkali leaching arsenic removal liquid, arsenic pollution, arsenic harm and poor market are unavoidable are solved.

Owner:KUNMING UNIV OF SCI & TECH

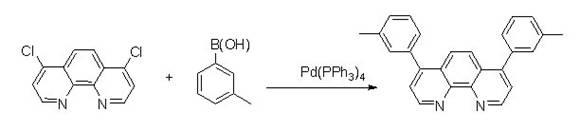

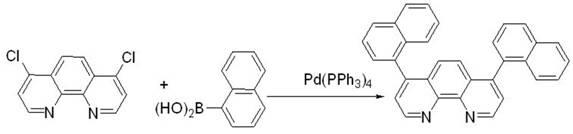

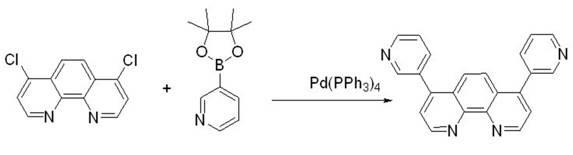

Electron transport material for organic electroluminescent devices and preparation method of electron transport material

ActiveCN102443003ASimple reaction preparationHigh reaction yieldOrganic chemistrySolid-state devicesArylSuzuki reaction

The invention relates to an electron transport material for organic electroluminescent devices and a preparation method of the electron transport material. The preparation method comprises the following steps of taking 4,7-dihalogen-1,10-phenanthroline as a starting material, and carrying out a Suzuki reaction on the starting material and arylboronic acid or arylboronate to obtain 4,7-diaryl-1,10-phenanthroline and derivates thereof as the electron transport material. The method provided by the invention has shorter synthetic route, simpler technology and higher reaction yield, obtains end-products with various types of different substituent groups, and has more easiness in material structure design and performance optimization in comparison with the conventional Skraup preparation method; meanwhile, no highly toxic materials such as arsenic acid and the like are in the reaction process, so that the reaction condition is milder, and the reaction process is safer and more environment-friendly. The preparation method provided by the invention is suitable for laboratorial preparation in gram scale and kilogram scale as well as industrial mass production in ton scale.

Owner:苏州纳凯科技有限公司

Method for quickly removing arsenic in zinc oxide with high arsenic content and producing zinc sulfate by using zinc ash and sodium peroxycarbonate of iron and steel plant

InactiveCN103466686ATo achieve the purpose of comprehensive recycling at the same timeTo achieve the purpose of comprehensive recyclingZinc sulatesSulfate zincSmelting process

The invention discloses a method for quickly removing arsenic in zinc oxide with high arsenic content and producing zinc sulfate by using zinc ash and sodium peroxycarbonate of an iron and steel plant. The purpose of removing arsenic in liquor is realized by leaching iron in a raw material and then carrying out oxidizing and hydrolyzing reactions to generate Fe(OH)3 by means of a characteristic of Fe(OH)3 which is reacted with arsenic acid at the pH of 3.0-5.4 to generate FeAsO4 precipitates. The method specifically comprises the following steps: calculating the use levels of the two raw materials according to the laboratory reports of arsenic, ferrum and zinc elements in zinc oxide with high arsenic content and zinc ash of the iron and steel plant; proportioning the raw materials; pulpifying; leaching; adjusting the pH value; oxidizing to remove iron and arsenic by sodium peroxycarbonate; neutralizing; carrying out filter pressing; purifying; then, carrying out evaporative crystallization, thereby obtaining a qualified zinc sulfate product. Arsenic enters into smelting waste to be cured in the smelting process, so that harmless treatment is realized.

Owner:HENGYANG NORMAL UNIV

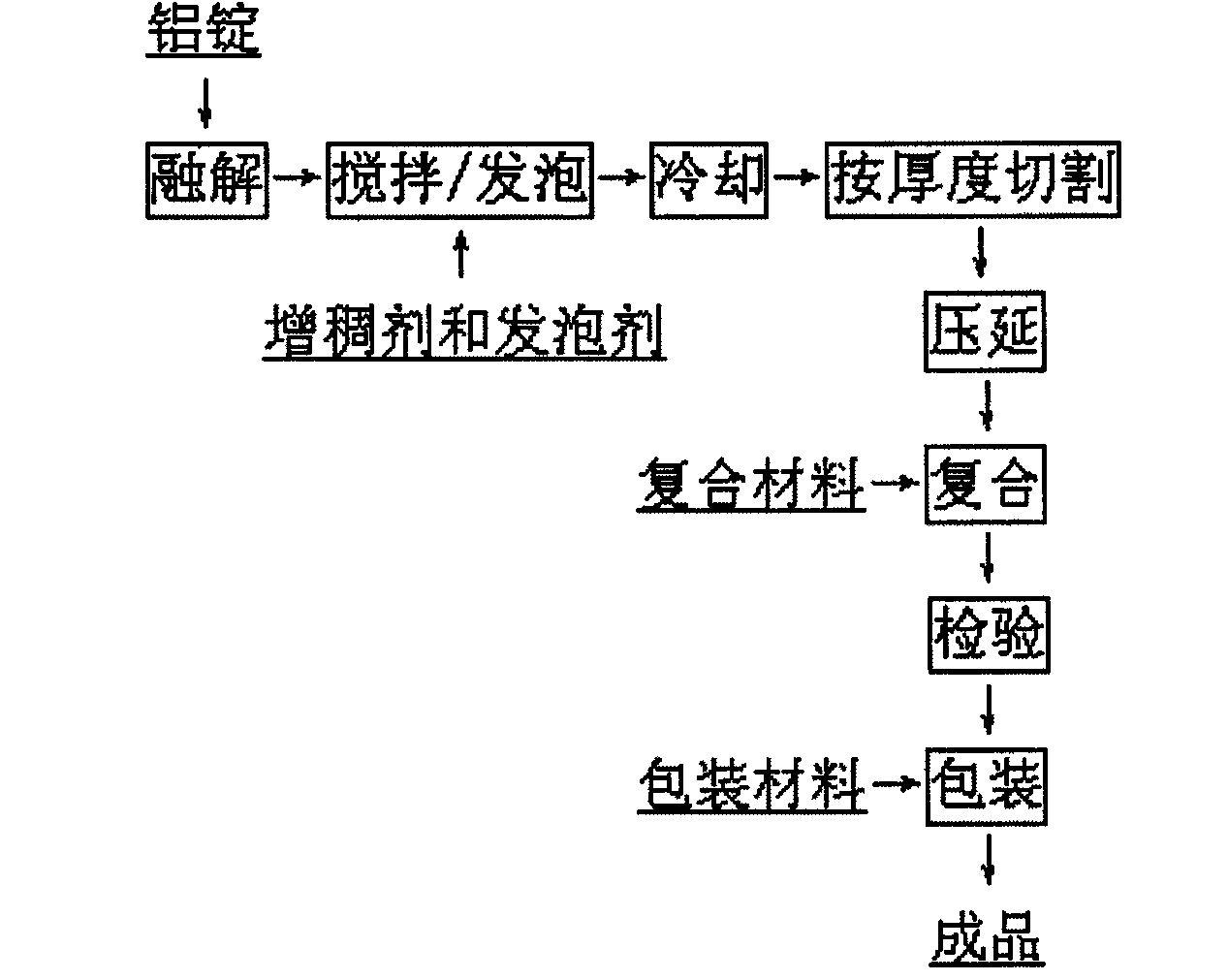

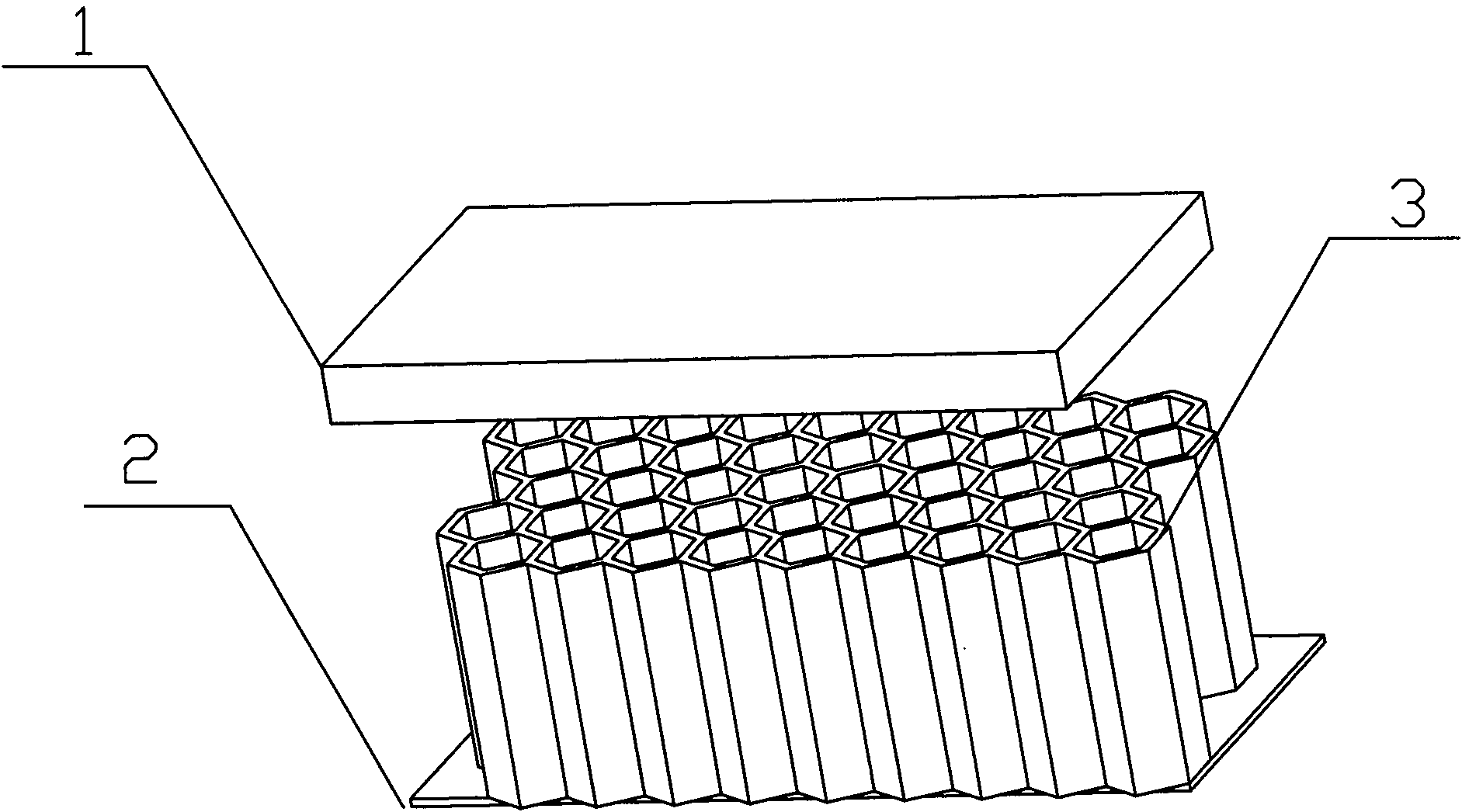

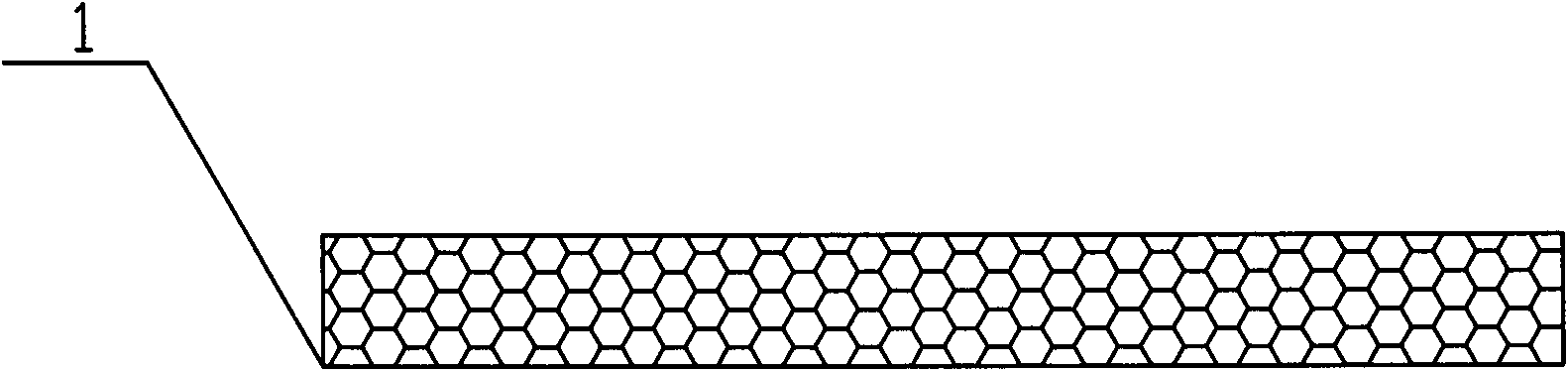

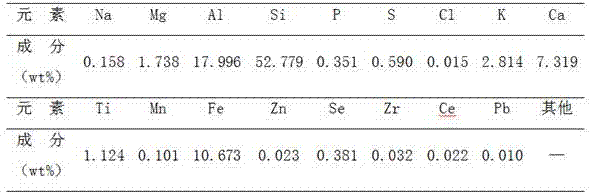

Production process for foamed aluminum, foamed aluminum and noise-reducing and sound-absorbing panel

InactiveCN101914700AHas semi-permanent sound-absorbing propertiesEffective energy absorptionRailway roofsUnderground chambersProduction lineFoaming agent

The invention discloses a production method for foamed aluminum. The method sequentially comprises the following steps of: feeding an aluminum ingot serving as a raw material into a foamed aluminum production line; placing the aluminum ingot into a heating crucible; heating and melting the aluminum ingot and pouring the molten aluminum ingot into a foaming box; adding a foaming agent into the foaming box for foaming; conveying the aluminum ingot out by using a conveyor belt after the foaming is finished; placing the foamed aluminum ingot on ground and naturally cooling the foamed aluminum ingot; cutting the cooled aluminum ingot into slices according to requirements of a customer; placing the sliced aluminum ingot on an oil press to compress by a certain height; cutting edges according to the specification of the customer; and packaging the aluminum slices to obtain the foamed aluminum. Because a porous structure is adopted, the foamed aluminum has semi-permanent sound-absorbing performance, is made of metallic material, fire-resistant completely and is completely free from hazard of noxious gases; the porous structure can effectively absorb energy and has a remarkable energy-absorbing effect in high-impact deformation rate; and the foamed aluminum does not have toxicity or smell or produce dust, peculiar smell or harmful substances to human body such as arsenic acid and the like and can be completely recycled and prepared from waste aluminum.

Owner:王占清

Mildew-proof dealcoholization type organic silicon sealant and preparation method thereof

InactiveCN105505296AReduce yellowingImprove mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesArsanilic acidZinc

The invention discloses a mildew-proof dealcoholization type organic silicon sealant. The mildew-proof dealcoholization type organic silicon sealant is prepared from the following components in parts by weight: 100 parts of 107 silicone oil, 10 to 150 parts of reinforcing filler, 0.3 to 1 parts of silane coupling agent, 0.01 to 0.5 part of catalyst, 5 to 7 parts of crosslinking agent, and 0.1 to 0.5 part of mildew-proof agent, wherein the mildew-proof agent is o-Arsanilic acid or methyl arsenic acid zinc using polyether glycol as a carrier. The mildew-proof dealcoholization type organic silicon sealant has the advantages that the mildew-proof effect is realized, and the anti-yellowing property is achieved.

Owner:西卡(江苏)工业材料有限公司

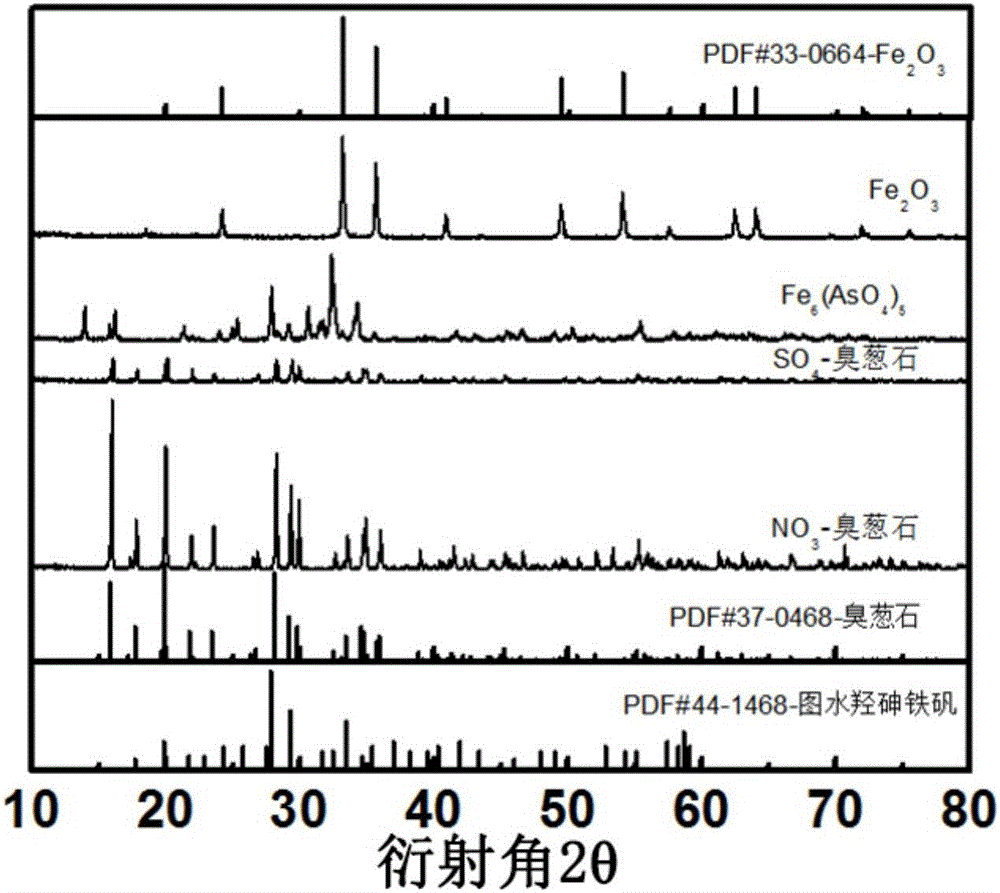

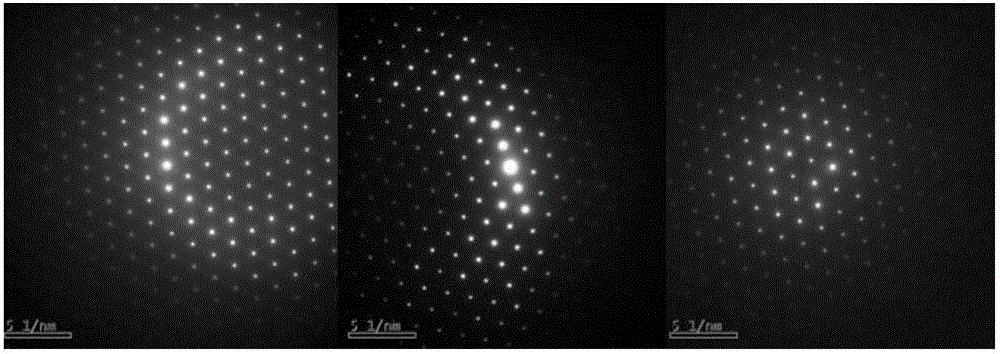

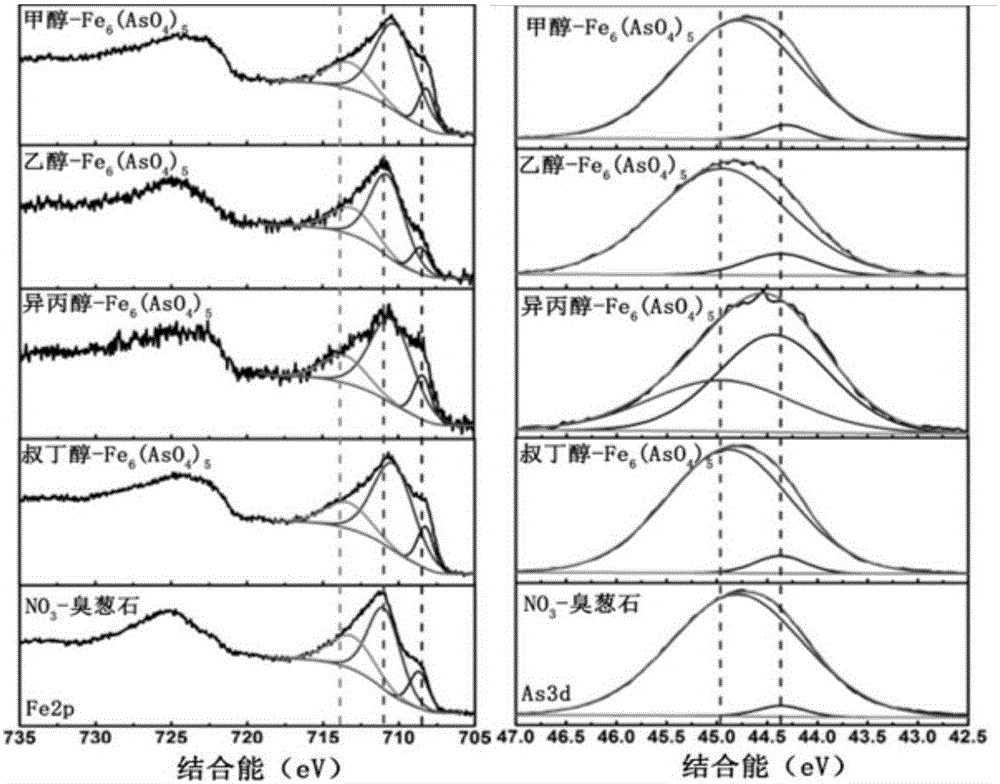

Black ferric arsenate crystal and synthesis method thereof

The invention discloses a black ferric arsenate crystal. The black ferric arsenate crystal is a micrometer petal-shaped particle, the particle size is 10 to 20mu m, and the appearance feature is black powder; a chemical formula of the black ferric arsenate crystal is Fe6(AsO4)5; diffraction peaks 2theta are equal to 13.9, 16.0, 21.2, 24.9, 25.2, 27.8, 28.4, 29.1, 30.5, 32.3, 34 and 34.2. The invention also discloses a synthesis method of the black ferric arsenate crystal. The synthesis method comprises the following steps of using ferric nitrate, sodium arsenate, nitric acid and deionized water to prepare a synthesis solution; mixing alcohol and the synthesis solution according to a volume ratio, so as to obtain a mixed solution; adding the mixed solution into a high-pressure reaction kettle to react for 8 to 24 hours at the temperature of 160 to 200 DEG C; after reacting, centrifuging, flushing solids by alcohol and water, and drying, so as to obtain the black ferric arsenate crystal. The synthesis method has the advantage that after the black ferric arsenate crystal is synthesized, the removal rates of Fe and As are respectively greater than 97%, so that the application potential in an As removal field is very large.

Owner:CENT SOUTH UNIV

Method for recovering tellurium from low-concentration tellurium-containing liquid

ActiveCN104591104ALower requirementAccelerated corrosionElemental selenium/telluriumIron sulfateSulfite salt

The invention relates to a method for recovering g tellurium from a low-concentration tellurium-containing liquid. The method comprises a mixing step and a settling step, wherein the mixing step comprises the processes of heating the tellurium-containing liquid, adding a ferric sulfate solution, stirring at constant temperature, adding an arsenic acid solution, stirring at constant temperature, adding a copper sulfate solution and stirring at constant temperature to obtain mixed liquor; the settling step comprises the processes of adding the obtained mixed liquor into dilute sulfuric acid to control the pH value, stirring at constant temperature, slowly adding a sodium sulfite settling agent, stirring at constant temperature and filtering to obtain a rich-tellurium product. According to the method, the treatment time is shortened, the equipment corrosion is reduced and the recovery rate is high.

Owner:JIANGXI COPPER

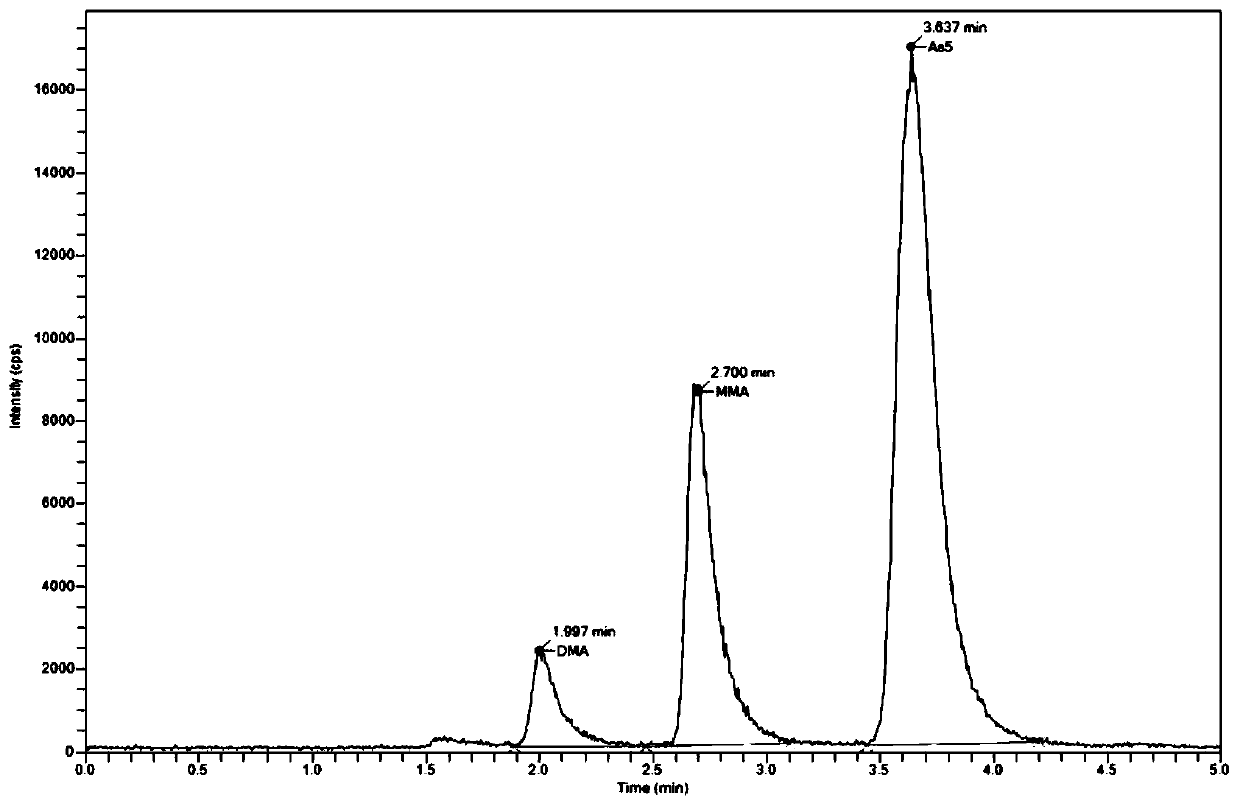

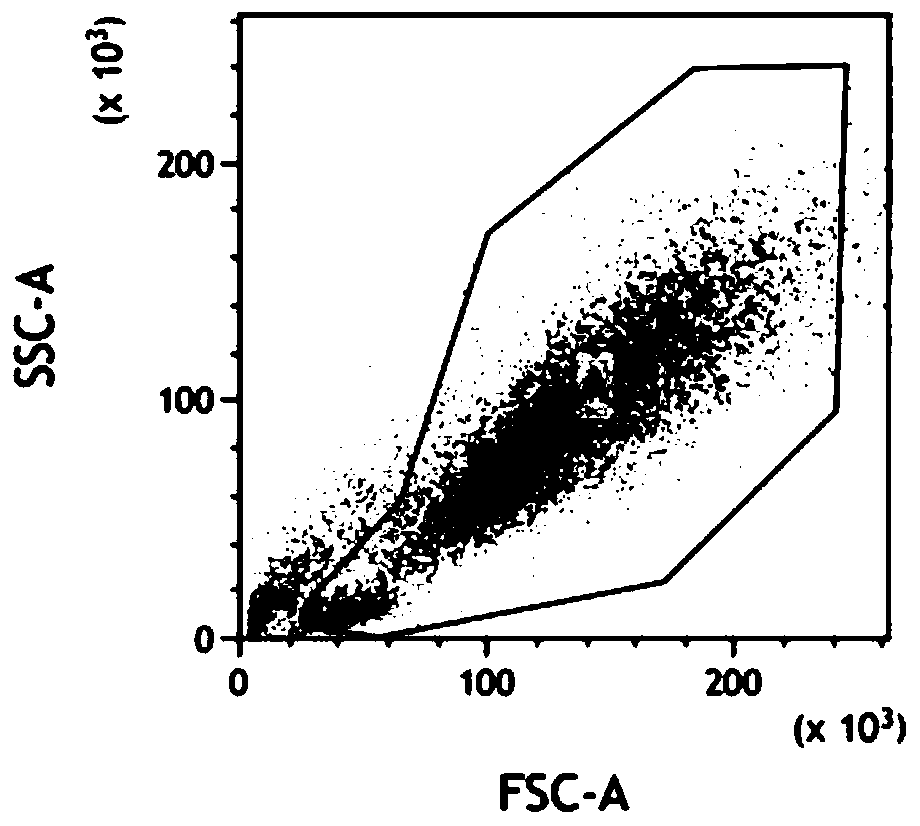

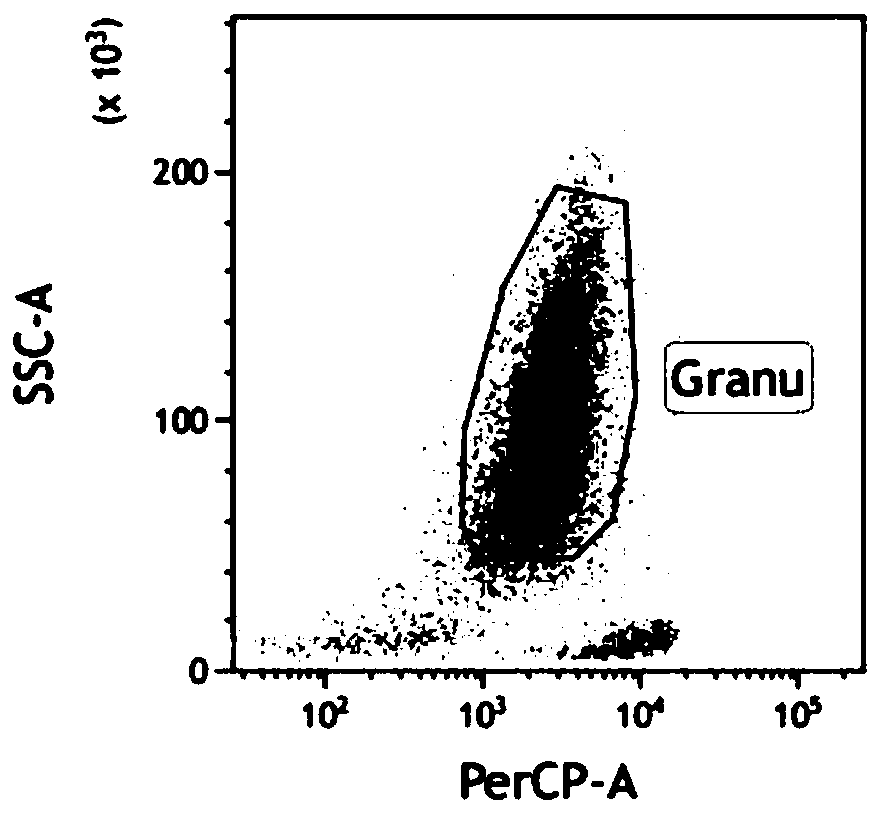

Method for measuring concentrations of four arsenic compounds in granulocytes by using HPLC (High Performance Liquid Chromatography)-ICP (Inductively Coupled Plasma)-MS method and application

ActiveCN110632217AMeet the sensitivity requirementsHigh precisionComponent separationInductively coupled plasmaToxic reaction

The invention relates to a method for measuring the concentrations of four arsenic compounds in granulocytes by using an HPLC (High Performance Liquid Chromatography)-ICP (Inductively Coupled Plasma)-MS method and an application, and belongs to the technical field of blood sample detection. In order to solve the problem that the existing method cannot accurately measure the concentrations of fourdifferent arsenic compounds AsIII, AsV, DAV and MMVA in granulocytes, the invention provides a method for measuring the concentrations of four arsenic compounds in granulocytes by using the HPLC-ICP-MS method. The method comprises the steps of determining a detection condition, preparing a standard solution, drawing a standard curve, collecting and processing a granulocyte sample, performing sample detection and data processing. According to the method for measuring the concentrations of four arsenic compounds in granulocytes by using the HPLC-ICP-MS method and the application, each arsenic compound in granulocytes can be effectively extracted and accurately quantified. When the method is applied to the detection of the concentrations of four arsenic compounds in peripheral blood granulocytes of a patient suffering from APL (Acute Promyelocytic Leukemia, the metabolism and distribution characteristics of each arsenic form can be clarified, a technical basis is provided for revealing ofthe action mechanism of arsenic acid and reduction of toxic reactions, and when the method is used for assisting clinics, personalized medicine and targeted therapy are implemented.

Owner:HARBIN MEDICAL UNIVERSITY

Method for co-processing arsenic-containing sludge and lake sediment

InactiveCN106927657ASolve stacking problemsSolve curing problemsSludge treatment by de-watering/drying/thickeningWater contaminantsSteam pressureDry weight

The invention relates to a method for co-processing arsenic-containing sludge and lake sediment and belongs to the technical field of solid waste resource utilization in environmental engineering. The method comprises the following steps: firstly, controlling the moisture content of the acquired arsenic-containing sludge to be below 15% after treating the arsenic acid wastewater and lime according to a ferric salt method; controlling the moisture content of the lake sediment containing more than 50% of SiO2 and Al2O3 in dry weight to be above 50%; ball-milling and uniformly mixing the pre-processed arsenic-containing sludge, lake sediment, cement, lime, excitant and additive, thereby acquiring a dry base; adding water into the acquired dry base, uniformly stirring and then pressing into a cured building block; placing the cured building block and standing by for 4-6h; maintaining for 6-12h under 0.8-2.0Mpa steam pressure; safely storing the standard cured building block or applying to industrial buildings. The method provided by the invention not only can solve the problem of stockpiling of the lake sediment but also can solve the problem of curing of the arsenic-containing sludge and the problem of secondary pollution to the environment.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com