Composition and flotation method for flotation collecting of rutile from ores

A composition and flotation technology, applied in flotation, solid separation, etc., can solve the problems of expensive collectors, poor water solubility, and environmental hazards, and achieve the effects of no toxic side effects, little environmental pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Mineral raw materials

[0027] Flotation of pure rutile minerals (rutile:quartz = 1:1) is carried out. The single minerals are obtained by crushing, ceramic ball milling and sieving of high-purity minerals. The particle size is -200+400 mesh.

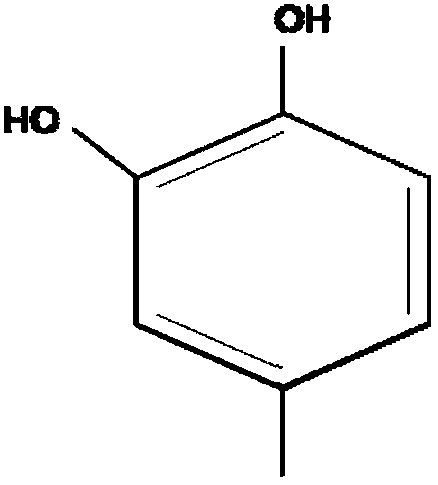

[0028] 2. Experimental protocol

[0029] The artificial mixed ore flotation experiment was carried out on the XFG hanging trough flotation machine. The 2.0g raw ore sample weighed is a mixture of rutile and quartz in a ratio of 1:1. Put it into a 40mL flotation tank, add 35mL distilled water, and adjust the slurry for 2 minutes. Add a pH adjuster to adjust the pH of the slurry. Join 1×10 -4 mol / L Pb(NO 3 ) 2 As an activator, add the collector 3,4-dihydroxytoluene 4×10 of the present invention -5 mol / L and foaming agent No. 2 oil, each agent is added and stirred for 3 minutes before adding the next agent. After 3 minutes of flotation, the collector can be obtained in the range of pH=6-9.5, the recovery rate of rutile in the concentr...

Embodiment 2

[0033] 1. Mineral raw materials

[0034] Take argillaceous schist rutile ore from a certain area in Henan, TiO after grinding and desliming 2 The grade is about 2.69% as the actual flotation feed of rutile ore, and its main gangue minerals are amphibole and garnet.

[0035] 2. Total dosage of flotation reagent:

[0036] pH adjuster: 1500g / t of sodium carbonate

[0037] Activator: rough selection of lead nitrate 500g / t, sweep selection 200g / t+100g / t

[0038] Inhibitor: rough selection of sodium fluorosilicate 600g / t, selection 80g / t

[0039] Collector: 3,4-Dihydroxytoluene for rough selection 500g / t, selection 60g / t, sweep selection 100g / t

[0040] Foaming agent: No. 2 oil coarse selection 40g / t sweep selection 20g / t

[0041] The operating steps and technical conditions are as follows:

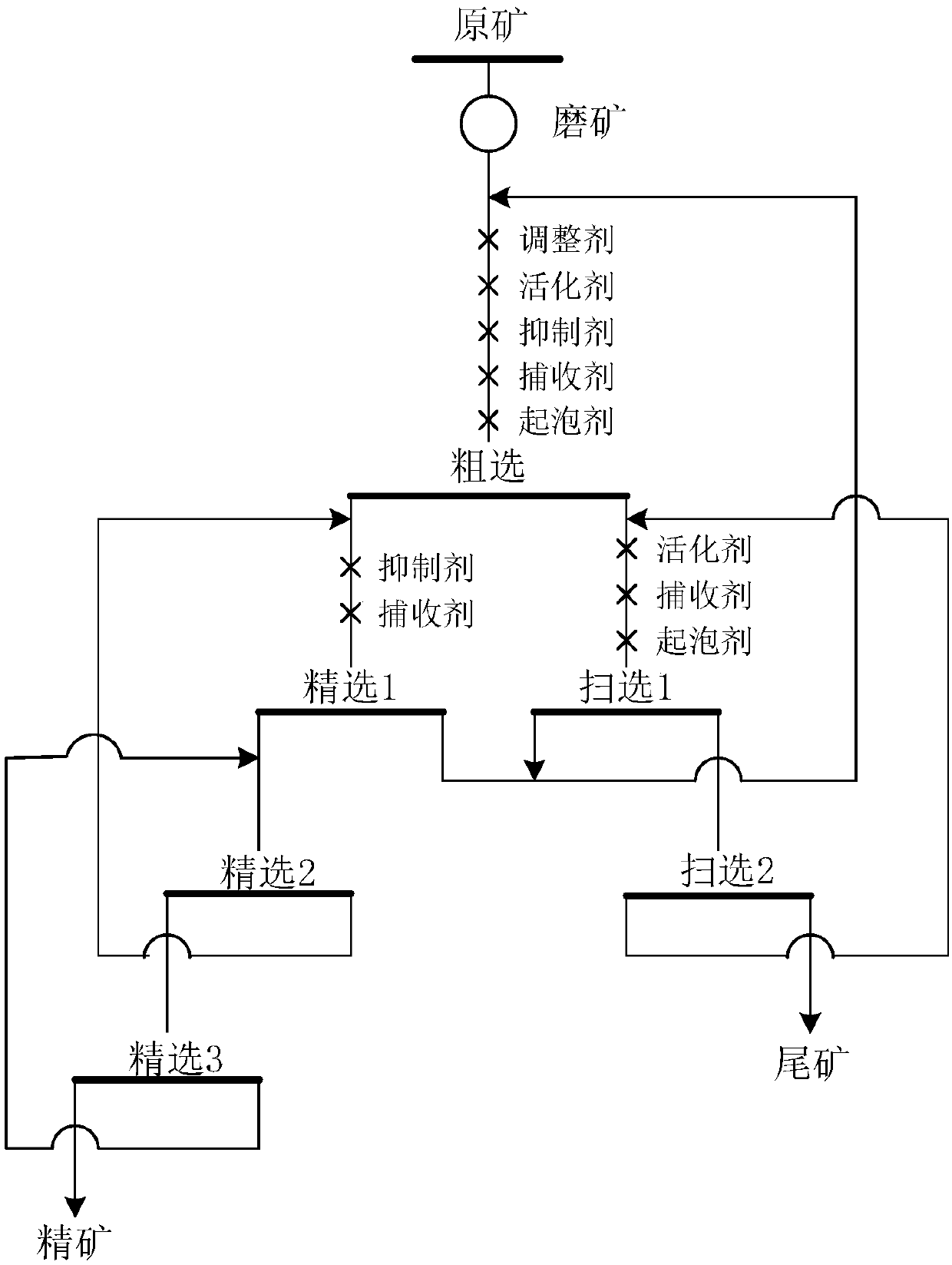

[0042] During the flotation process, the ore is added to the mill to grind the ore until the mineral monomers dissociate, the fineness of the ore is controlled -74μm not to exceed 82%, the pH value of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com