Production process for foamed aluminum, foamed aluminum and noise-reducing and sound-absorbing panel

A foamed aluminum, production line technology, applied in the field of foamed aluminum noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

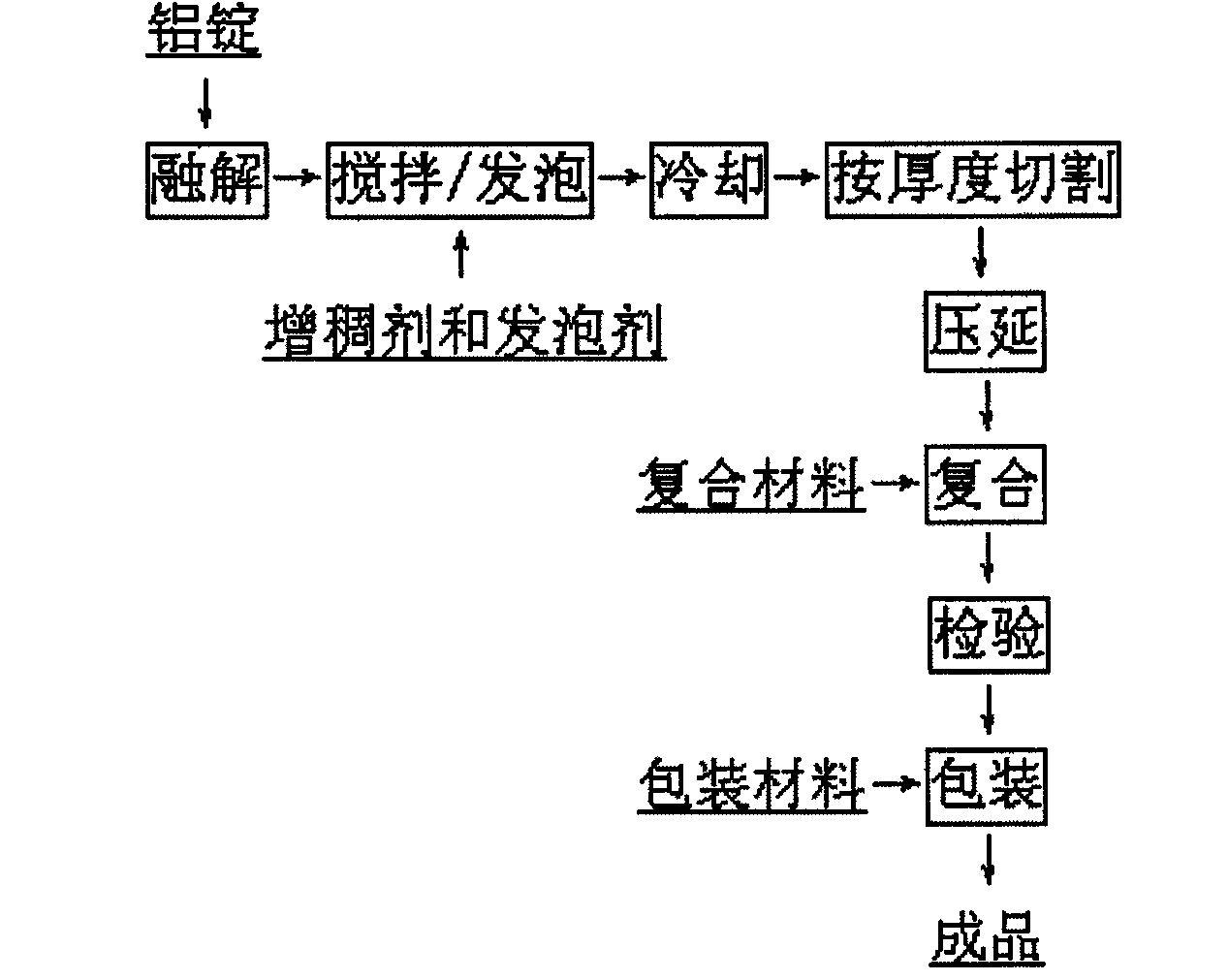

[0016] like figure 1 Shown is the process flow chart of the foamed aluminum manufacturing method of the present invention. The raw material aluminum ingots are sent to the foamed aluminum production line, put into a heating pot, heated and melted, poured into the foaming box, and added into the foaming box. Paoji foaming--sent out by the conveyor belt after foaming, placed on the ground to cool naturally--cut into pieces according to customer requirements after cooling--after cutting, put them on a hydraulic press to compress to a certain height--according to customer specifications Edge trimming--packaging--completion, the foaming agent uses titanium hydride.

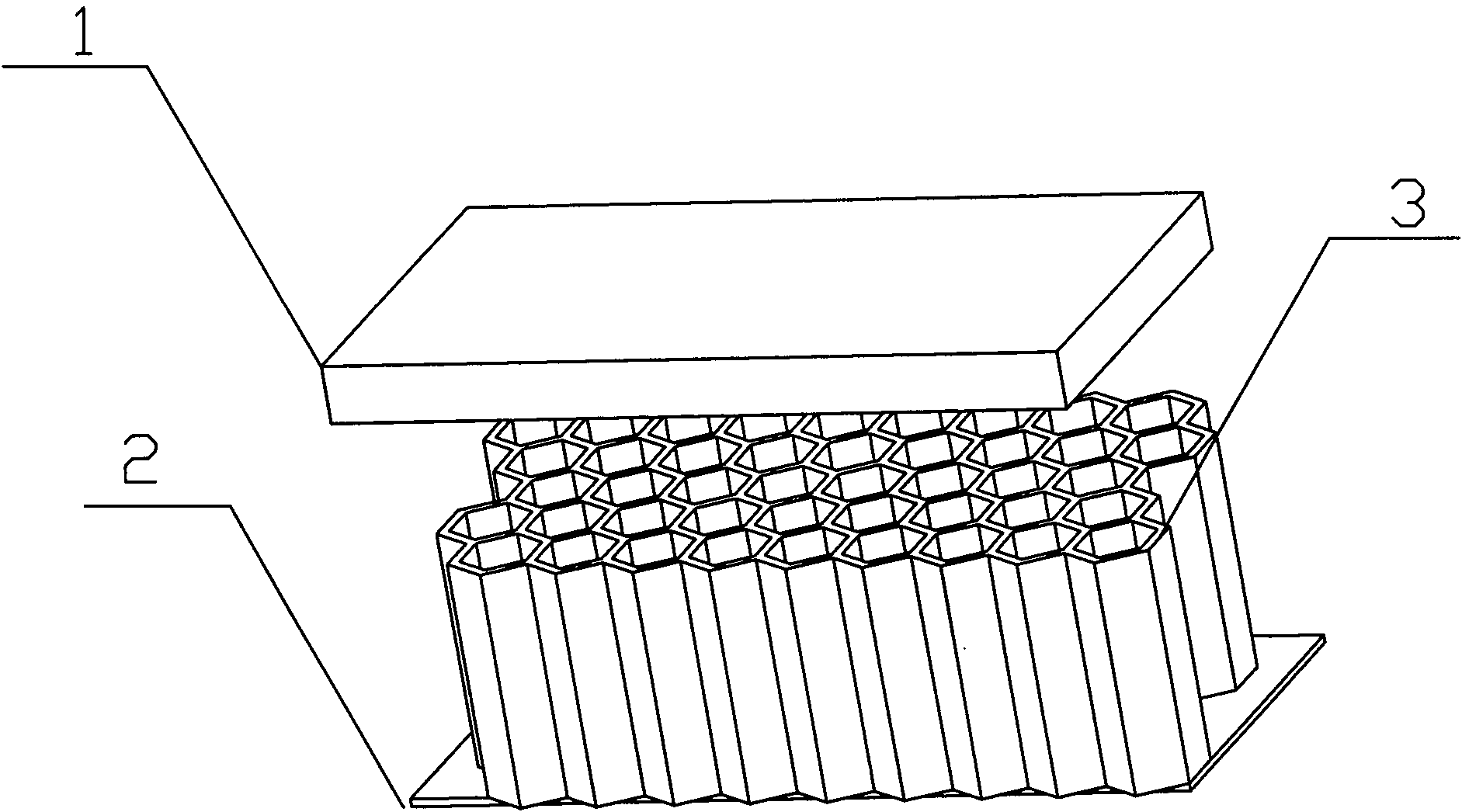

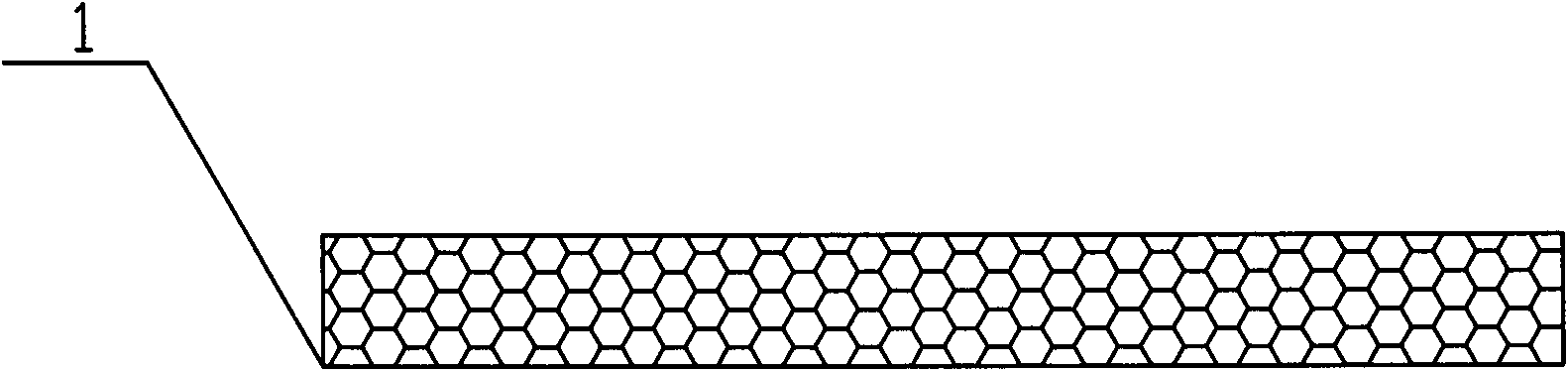

[0017] figure 2 A schematic diagram of the structure of a noise-reducing and sound-insulating panel provided by the present invention, including a foamed aluminum layer 1, a honeyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com