Lightweight high-explosion-resistant unit plate and protection product thereof

A unit board, high-resistance technology, used in earthquake-proof, protective buildings/shelters, building components, etc., can solve the problems of secondary splashing of bulk materials, low resistance, and doors that cannot be opened, and achieve good energy absorption. effect, energy absorption efficiency improvement, energy absorption improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

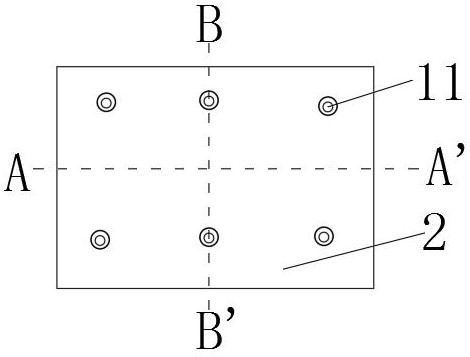

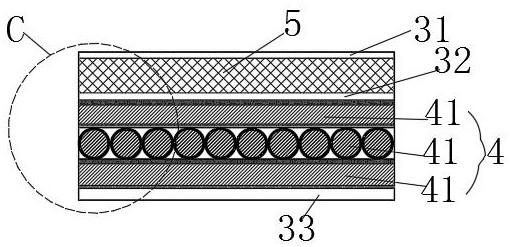

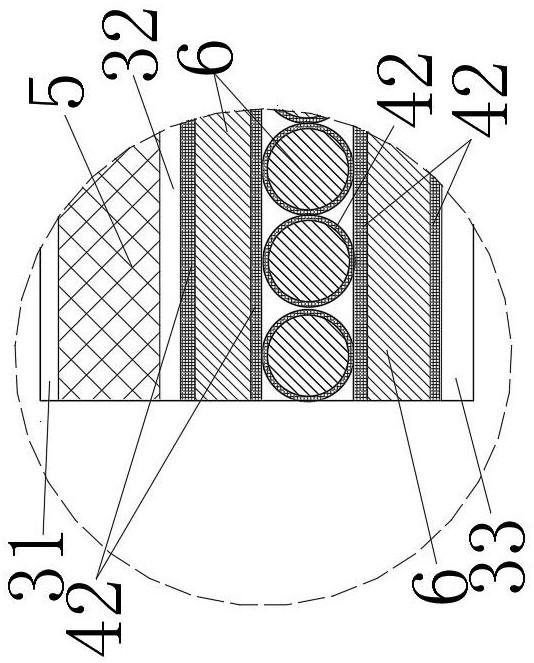

[0070]Example 1. Such asFigure 1-5 As shown, a lightweight high anti-proof unit plate includes an outer metal plate layer 33 that is arranged in parallel to each other, a metal plate layer 32, an inner metal plate layer 31, a suction layer 4, a foam metal sheet layer. 5, the suction layer 4 includes a number of suction hierarchical 41, each of which includes a number of absorbent tubes 42 arranged in parallel to each other;

[0071]The suction tube 42 of each sucking layer 41 is filled with a first sucking material 6.

[0072]The suction tube 42 of the adjacent two suction tierators 41 is perpendicular to each other; the outer metal plate layer 33 is provided with a suction layer 4 between the metal plate layer 32, and there is a metal plate layer 32 and the inner metal plate layer 31. The foam metal plate layer 5; the outer metal plate layer 33, the metal plate layer 32, the inner metal plate layer 31, each of the adhesive tube 42, and the outer surface of the foam metal plate layer 35 a...

Embodiment 2

[0093]Example 2. Such asFigure 6-7 As shown, the present embodiment differs from the first embodiment in that the second sucking material 61 is filled between the suction tube 42 of each suck layer 41.

Embodiment 3

[0094]Example 3. Such asFigure 8-9 As shown, the present embodiment differs from the second embodiment in that the first sucking material is filled in the suction tube 42 of each suck. A second sucking material 61 is filled between the suction tube 42 of each sucking layer 41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com