Capless multiaxial screw and spinal fixation assembly and method

a multi-axial screw and screw technology, applied in the field of spinal fixation assembly and method, can solve the problems of spinal rod threading, spinal rod threading, number of parts and components, etc., and achieve the effect of improving spinal fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

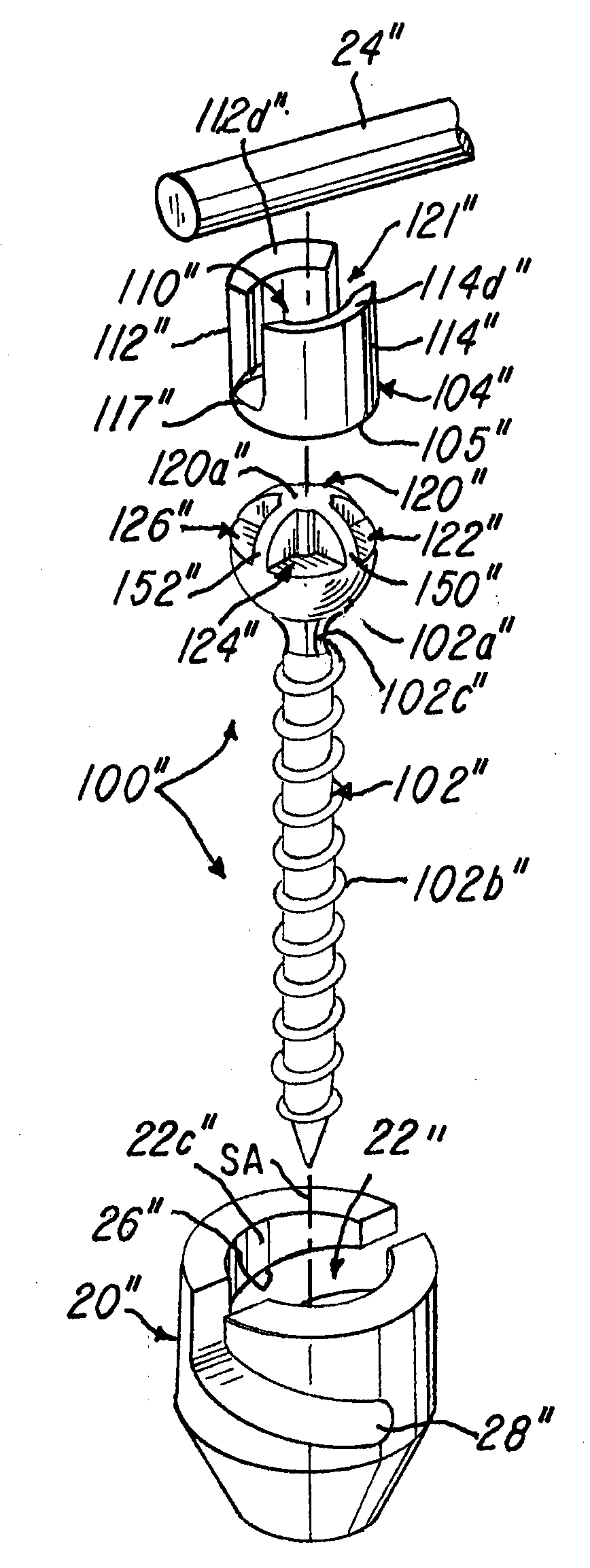

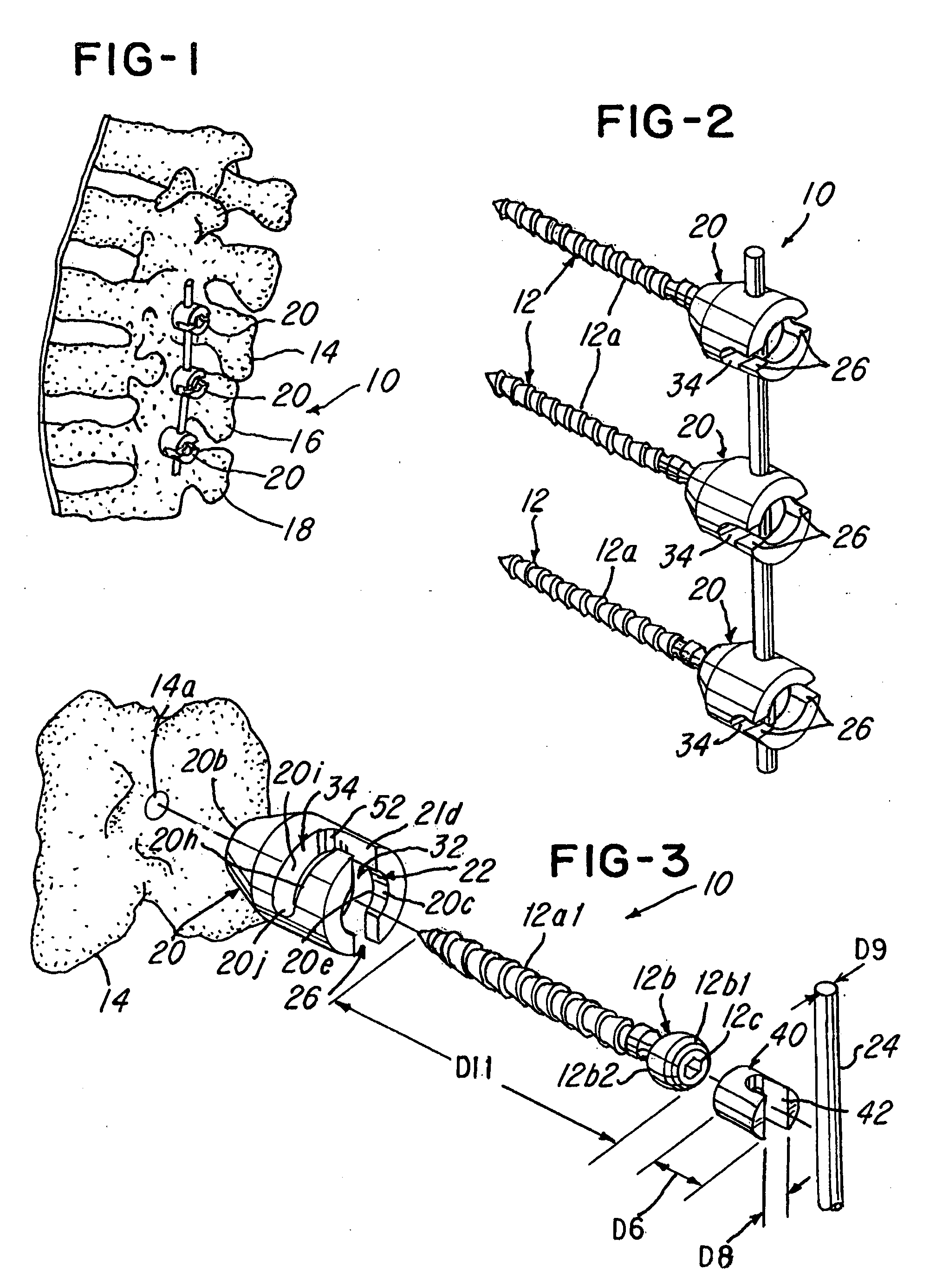

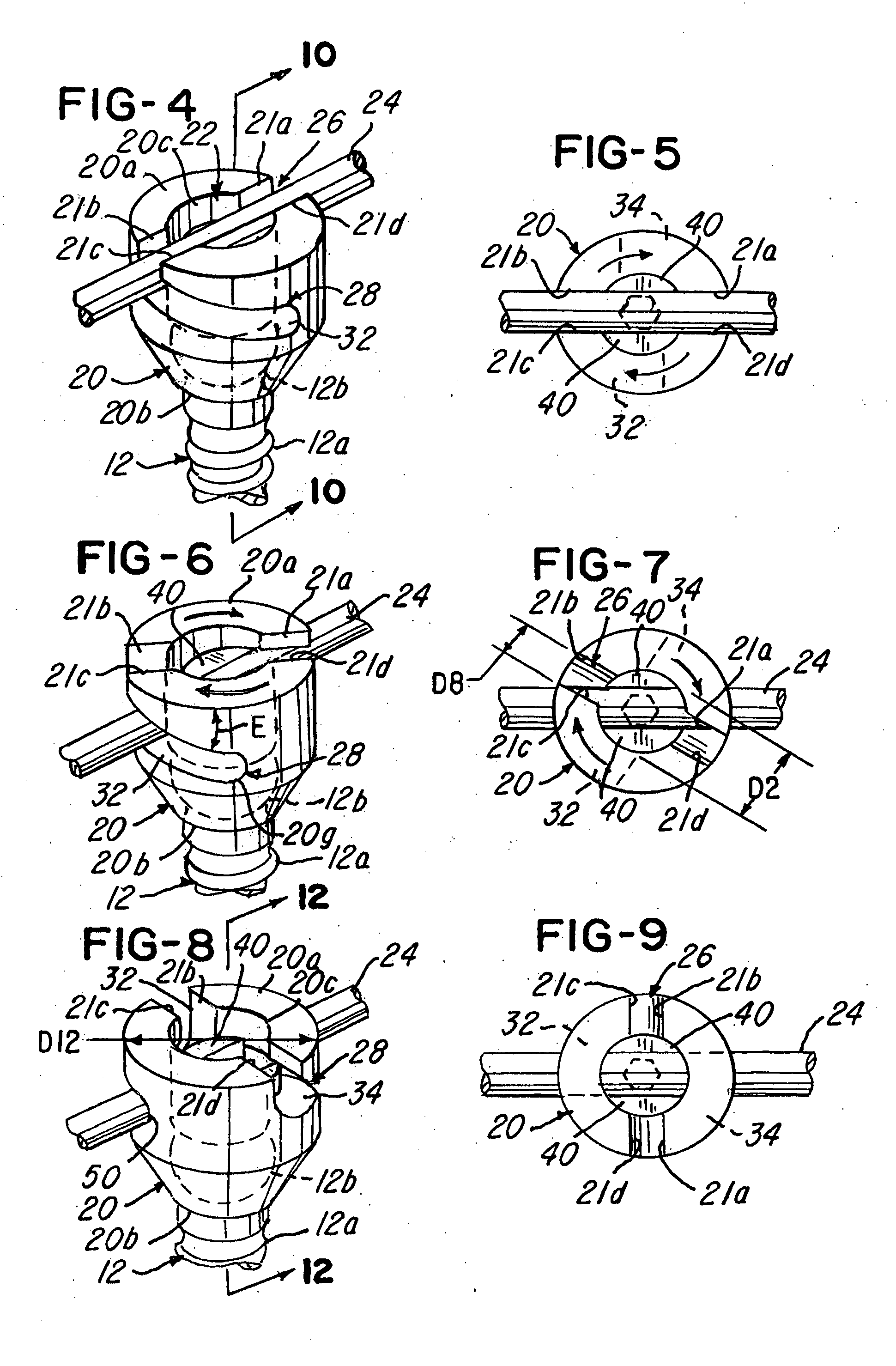

[0066] Referring now to FIGS. 1-3, a capless multi-axial screw and spinal fixation assembly 10 and method are shown. The assembly 10 comprises a screw 12 having a threaded portion 12a and a head 12b that in the embodiment being described, has a rounded profile or curvature, as best illustrated in FIGS. 3 and 10-13. The screw head 12b comprises a hex female opening 12c for receiving a tool (not shown) for screwing the screw 12 into an aperture 14a of a spinal bone 14, such as a vertebra of a spine.

[0067] As illustrated in FIGS. 1 and 2, one feature of the invention is that it enables a user to fix a relative position of a plurality of vertebrae, such as vertebrae 14, 16 and 18 in FIG. 1, in a fixed and stabilized position.

[0068] The system 10 comprises a retainer or receiver 20 having a generally cylindrical receiver wall 20c (FIG. 4) that defines an aperture or bore 22 that traverses or extends along a receiver axis A (FIG. 11) the entire length of the receiver 20, as best illustr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com