Foamed aluminum noise-reducing acoustic board and application thereof

A technology of foamed aluminum and sound-absorbing panels, applied in the field of foamed aluminum noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

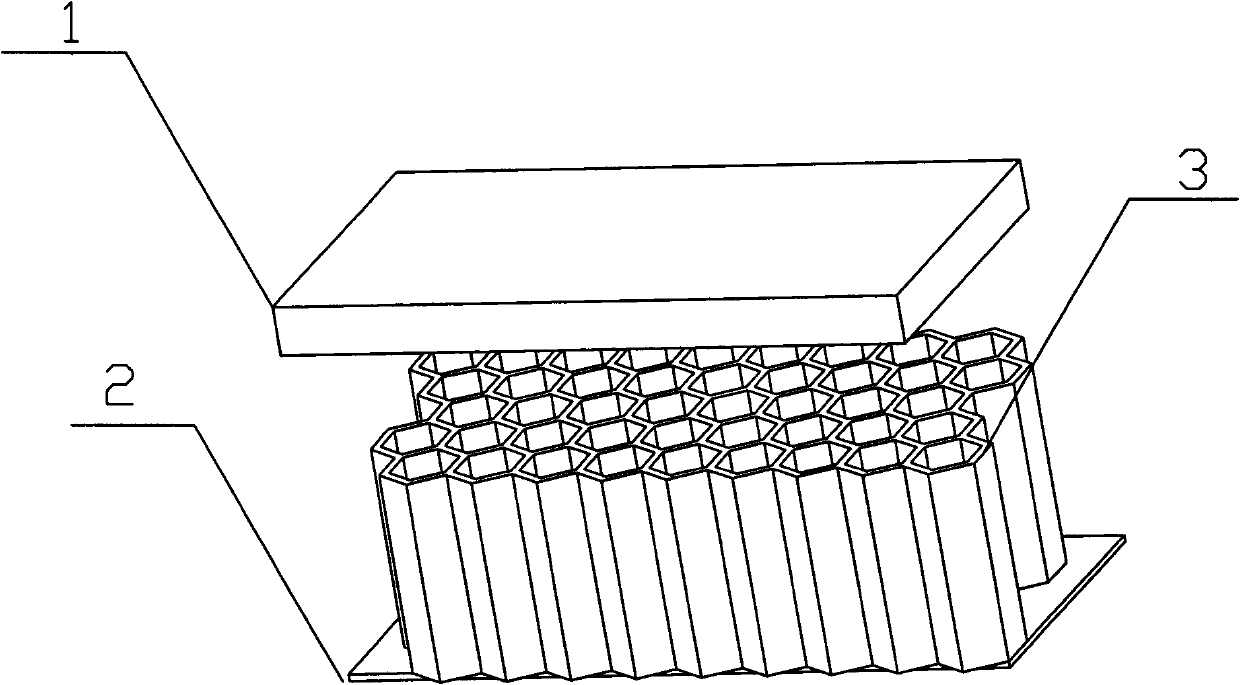

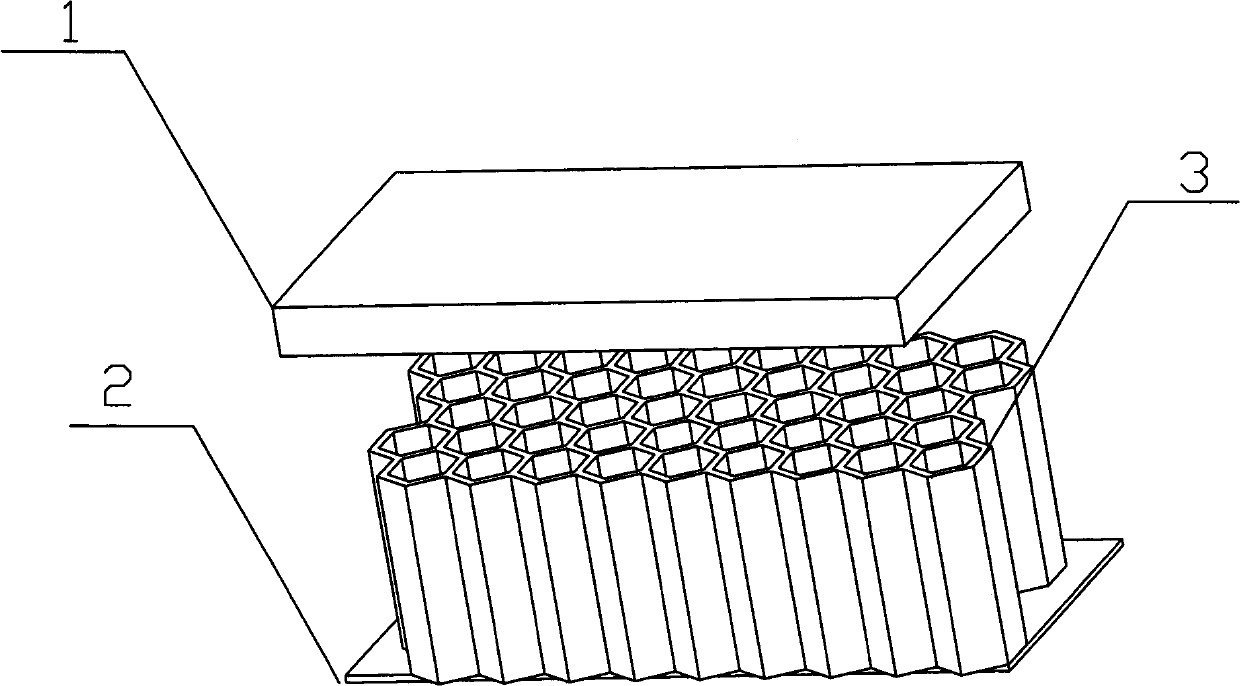

[0017] Such as figure 1 Shown is a schematic structural diagram of the noise-reducing and sound-insulating panel of the present invention, which includes a foamed aluminum layer 1, a honeycomb aluminum layer 2 and a solid aluminum layer 3. The above three layers of plates are fixed and stacked together in sequence, and can be bonded together with a high-strength adhesive.

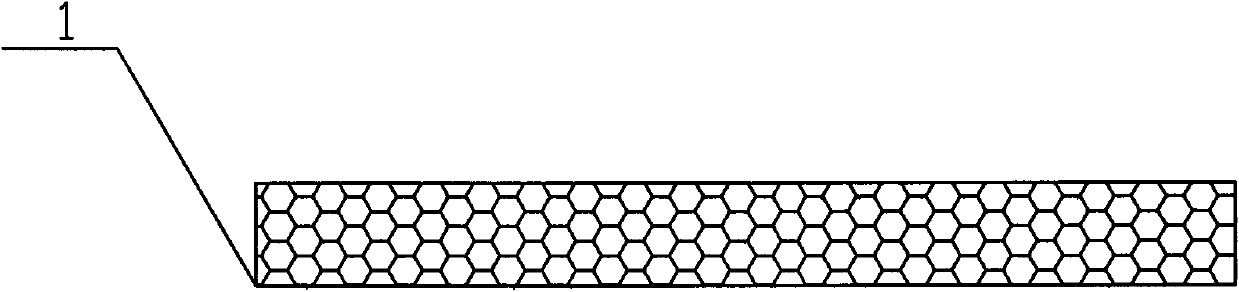

[0018] figure 2 Shown is a cross-sectional view of the foamed aluminum layer, and a large number of sponge-like structures can be seen in the cross-section.

[0019] The aluminum foam layer 1 is a foam material made by melting an aluminum ingot, adding a foaming agent and a thickener, and foaming.

[0020] The density of the foamed aluminum is 0.2-0.4g / cm 3 .

[0021] The foamed aluminum noise-reducing and sound-absorbing board of the invention can be applied in tunne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com