Overload impact resistant planetary reducer, robot joint and quadruped robot

A planetary reducer, anti-overload technology, used in springs/shock absorbers, mechanical equipment, components with teeth, etc., can solve the problems of large size, inability to be compact, and high manufacturing costs of reducer robots, and achieve the solution Feasible, compact, and low-cost to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

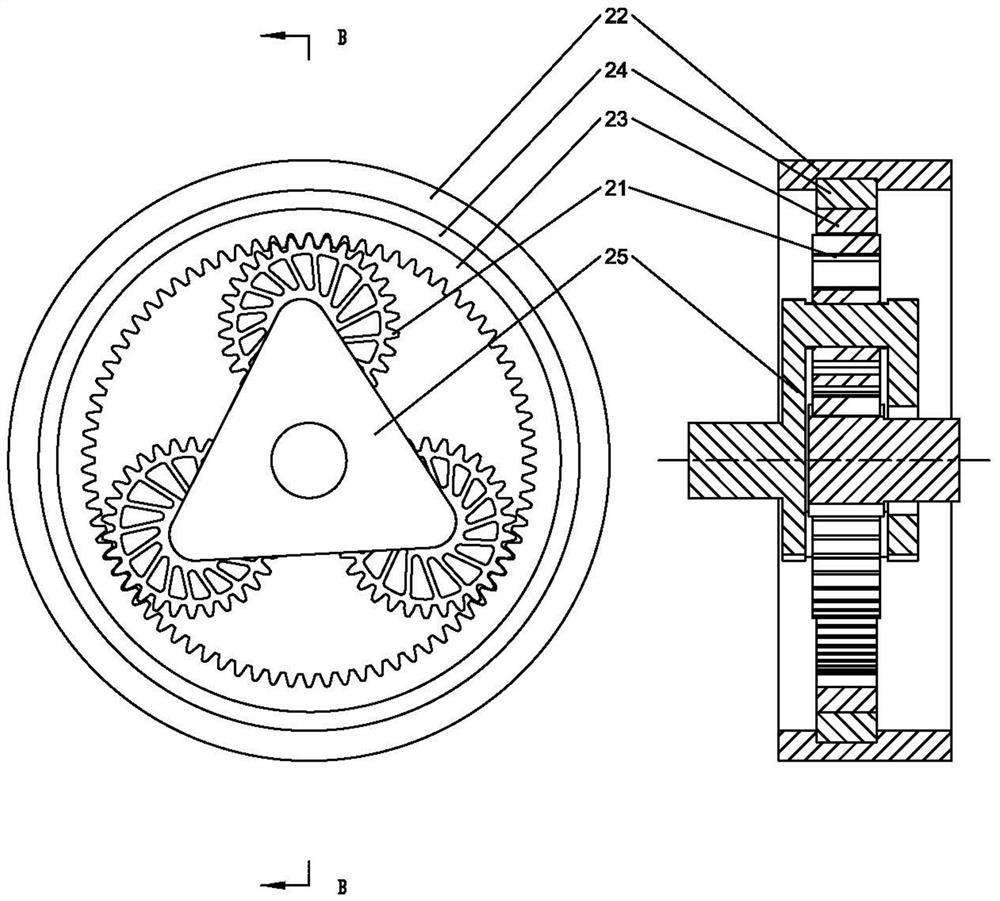

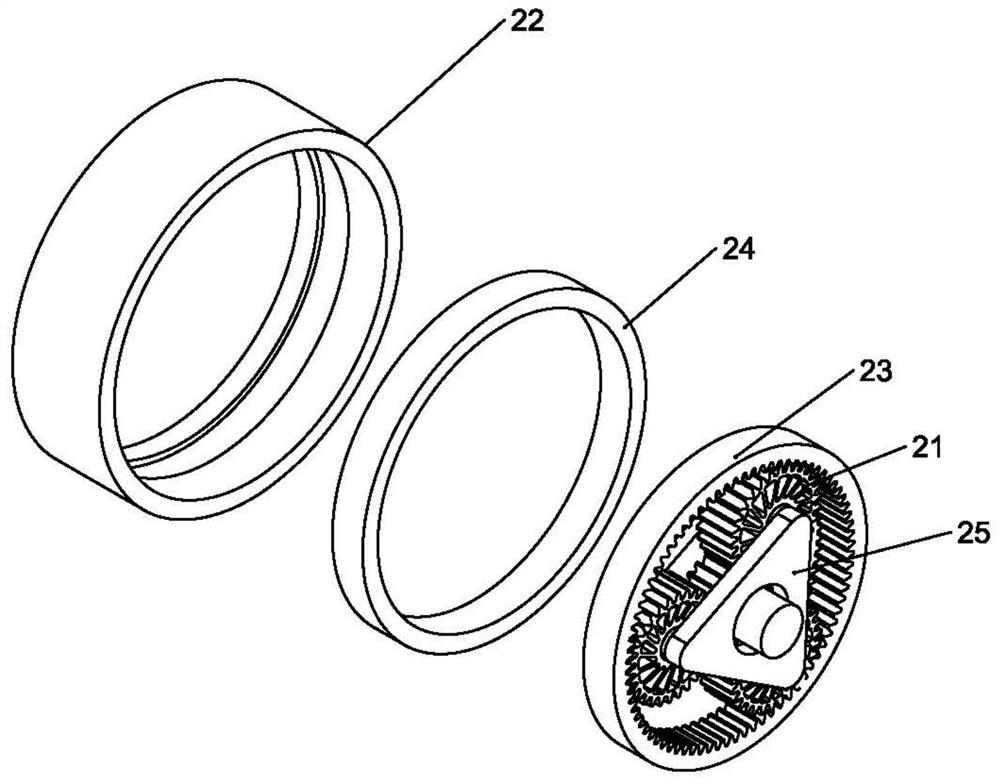

[0062] The reducer component is a planetary gear 21;

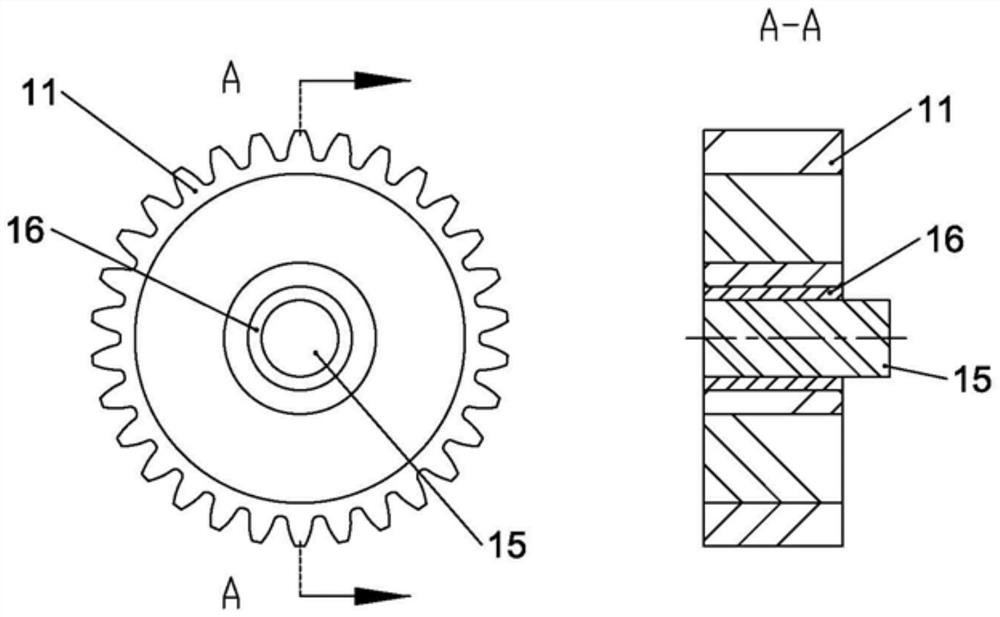

[0063] The tooth surface portion is the outer tooth portion 11 of the planetary gear 21,

[0064] The buffer portion is the buffer layer 16 assembled on the inner side of the outer tooth portion 11;

[0065] When the external tooth portion 11 is subjected to an impact force, the buffer layer 16 is deformed, so that the external tooth portion 11 is displaced relative to the planetary gear shaft 15;

[0066] When the impact force received by the external teeth 11 disappears, the deformation generated by the buffer layer 16 disappears, so that the external teeth 11 are reset relative to the rotating shaft. The structure is simple, practical, and easy to manufacture.

[0067] A specific embodiment of the deformation through hole 14 provided in the buffer layer 16 of the present invention:

[0068] The buffer layer 16 defines at least one deformation through hole 14 capable of being deformed by impact force;

[0069] The def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com