Casing head for thermal recovery of thick oil

A technology of heavy oil thermal recovery and casing head, which is applied in the field of casing head, can solve problems such as expansion of telescopic pipes, potential safety hazards of wellhead weld seams, and threats to the life safety of staff, and achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The conception, specific structure and technical effects of the invention will be clearly and completely described below in conjunction with the embodiments and drawings, so as to fully understand the purpose, features and effects of the invention. The various technical features in the invention can be combined interactively on the premise of not conflicting with each other.

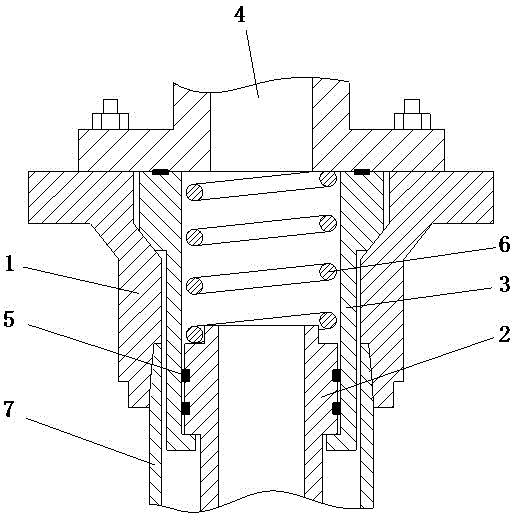

[0012] refer to figure 1 , a casing head for heavy oil thermal recovery, including a hollow shell 1 and a telescopic tube 2, and also includes a hollow suspension body 3, the inner wall of the shell 1 and the outer wall of the suspension body 3 are provided with movable The inclined surfaces that cooperate with each other, the suspension body 2 is suspended inside the housing 1 through the cooperation of the inclined surfaces, a flange 4 is fixedly connected to the top surface of the housing 1 and the suspension body 3 is pressed down, the lower end of the suspension body 3 The opening is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com