High-efficiency method for treating arsenic-containing wastewater

A waste water and oxidation treatment technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low arsenic removal efficiency, secondary pollution, and low arsenic removal efficiency , to achieve the effect of improving the efficiency of arsenic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

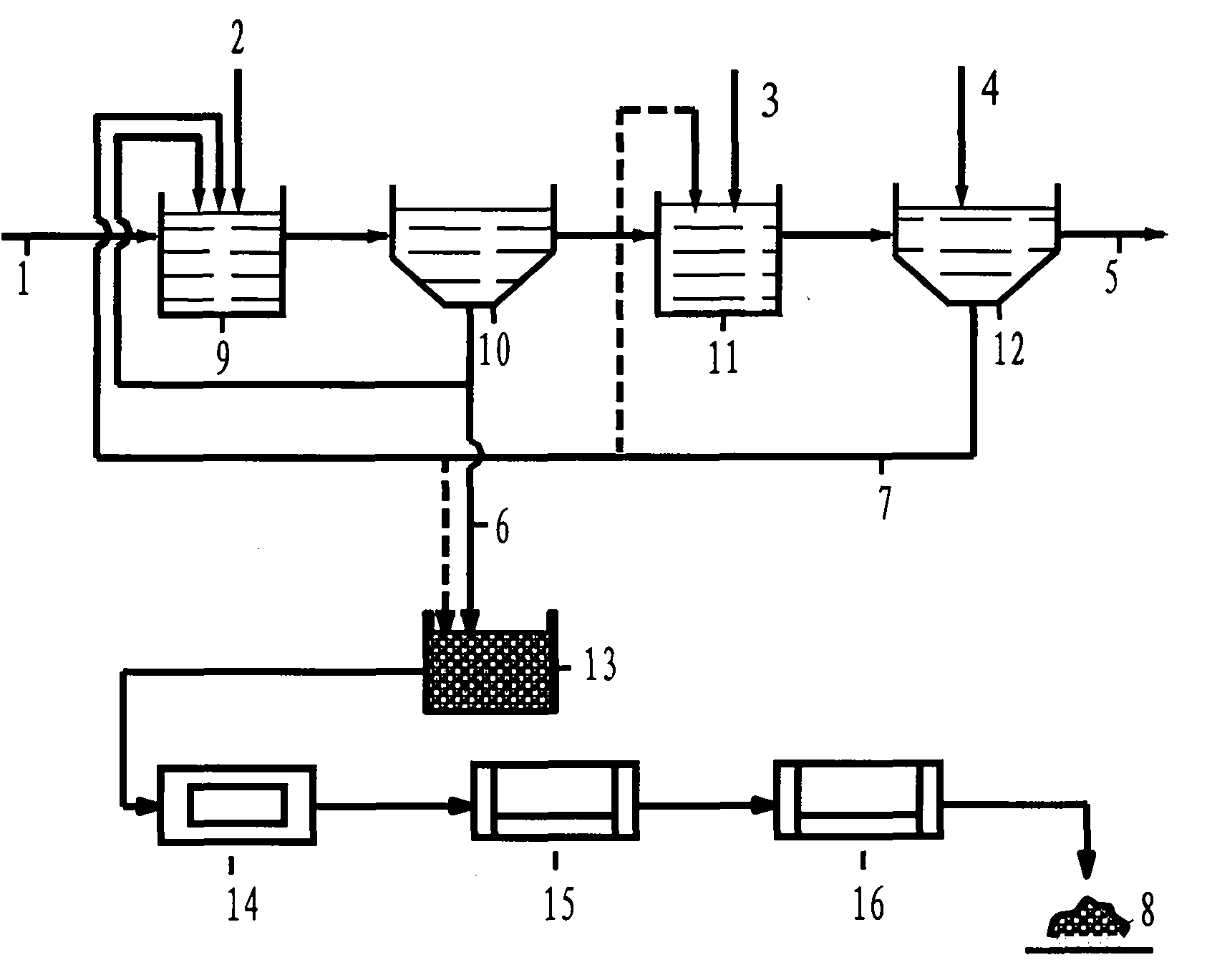

[0014] figure 1 It is a brief explanatory diagram of an embodiment of the method for treating arsenic-containing wastewater according to the present invention.

[0015] figure 1 Among them, 9 is the first reaction tank, waste water 1 is added, and at the same time, bacterial oxidant 2′ composed of ferrooxidans is added to pre-oxidize As3+, and then slaked lime 2 is added to adjust the pH value; 10 is the first aggregation sedimentation tank, in the reaction The aggregates formed in the tank are precipitated and separated here; 11 is the second reaction tank, the supernatant discharged from the first aggregation sedimentation tank 10 is added, and flocculant is added to adjust the pH value; 12 is the second aggregation sedimentation tank , the aggregate that generates in the second reaction tank 11 is precipitated and separated here; 13 is a sludge storage tank, and the arsenic-containing sludge (a The first-level aggregate sedimentation sludge 6 and the second-level aggregat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com