Electromagnetic transient unloading test system and method

An electromagnetic transient and test system technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of slow unloading speed, high cost, and inability to unload the load, etc., to achieve good results buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

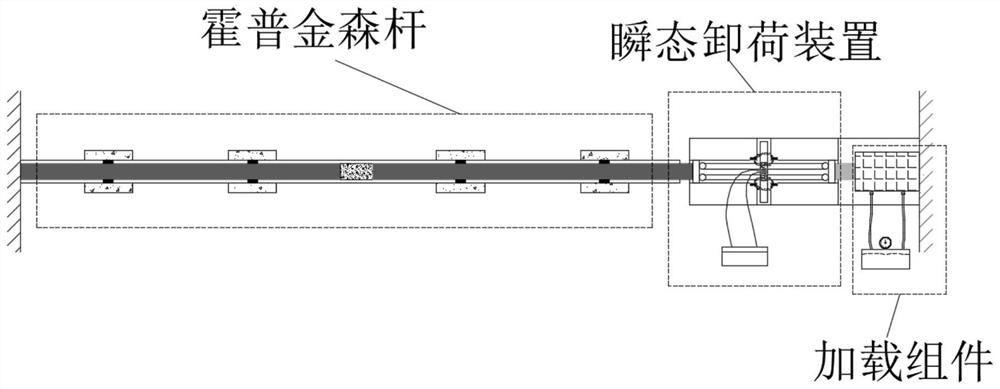

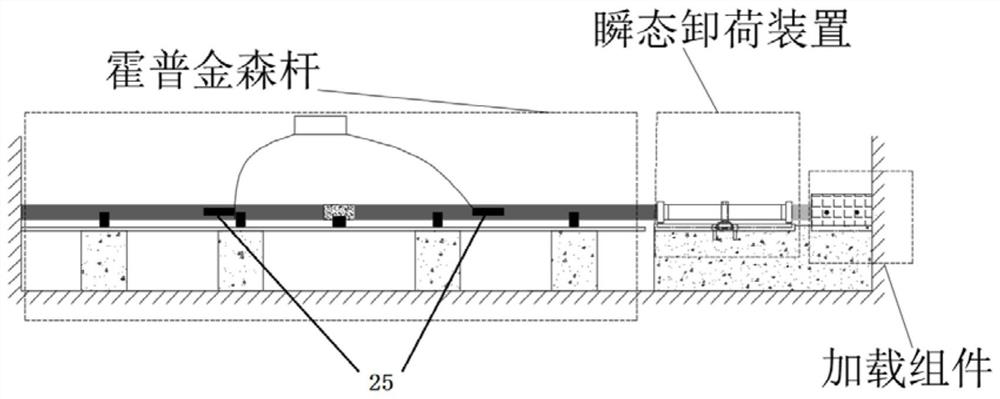

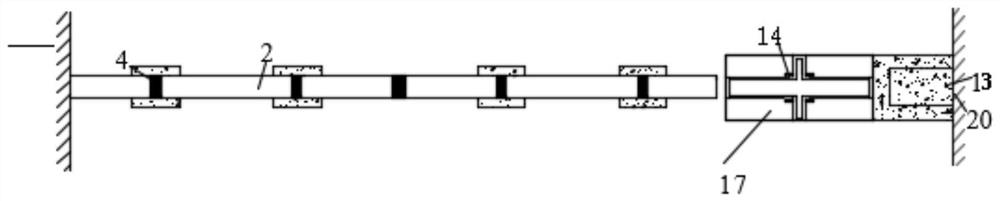

[0047] A kind of test system of electromagnetic transient unloading that the present invention proposes, such asfigure 1 , figure 2 As shown, the system mainly includes rock mass sample 1, Hopkinson rod 2, transient unloading device, loading component and monitoring component.

[0048] Two Hopkinson rods 2 are coaxially arranged, the end of the Hopkinson rod 2 at the front end is fixed, and it is set as a projection rod, and the end of the Hopkinson rod 2 at the rear end is provided with an unloading assembly, which is set as an injection projection rod , the two Hopkinson rods 2 are respectively provided with resistance strain gauges 25 . A rock mass sample 1 is fixed between two Hopkinson rods 2 . The front end of the projection rod of the Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com