Concrete formwork supporting device for floor slab concreting

A concrete formwork and support device technology, which is applied to the connection parts of formwork/formwork/work frame, construction, building structure, etc., can solve the problems of uneven pouring of the bottom plate, long maintenance and removal time, complicated process, etc., to achieve The construction is convenient, the cross construction is safe and reliable, and the effect of ensuring the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings.

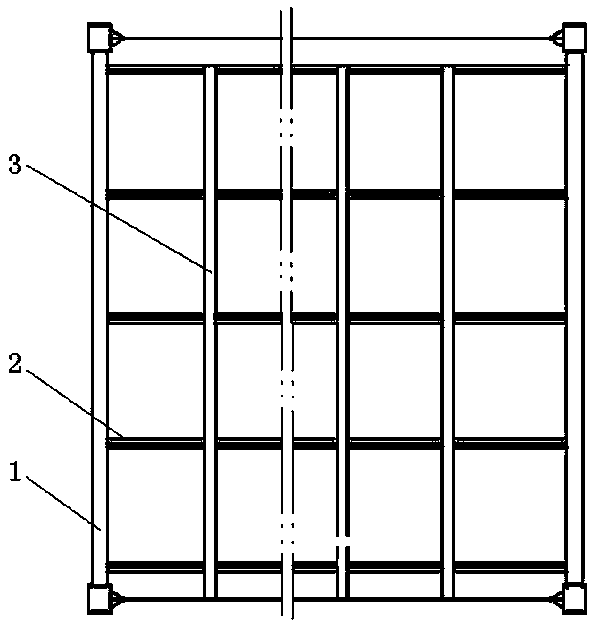

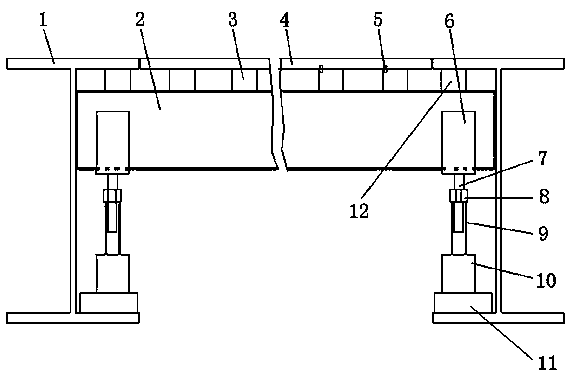

[0016] The concrete formwork support device for floor slab pouring provided by the present invention includes a main steel frame beam 1 and a formwork 4. The main steel frame beam 1 is H-shaped steel, and the formwork 4 is a conventional wooden formwork, which is located between two opposed main steel beams 1 The main keel with adjustable height is arranged at intervals, and the auxiliary keel 3 is arranged at intervals on the main keel, and the template 4 is placed on the auxiliary keel 3; The support 6 is connected below the support 6 with a vertical screw 7 with a nut 8 on it. The lower end of the vertical screw 7 is placed in the hollow column 9, and the lower end of the hollow column 9 is fixed on the base 10; the horizontal beam 2 is A square beam, the square beam is a steel square tube, the support 6 below the two ends of the square beam is a trough with an opening facing upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com