Patents

Literature

459 results about "Steel square" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The steel square is a tool used in carpentry. Carpenters use various tools to lay out structures that are square (that is, built at accurately measured right angles), many of which are made of steel, but the name steel square refers to a specific long-armed square that has additional uses for measurement, especially of various angles. Today the steel square is more commonly referred to as the framing square or carpenter's square. It consists of a long, wider arm and a shorter, narrower arm, which meet at an angle of 90 degrees (a right angle). It can also be made of aluminum or polymers, which are light and resistant to rust.

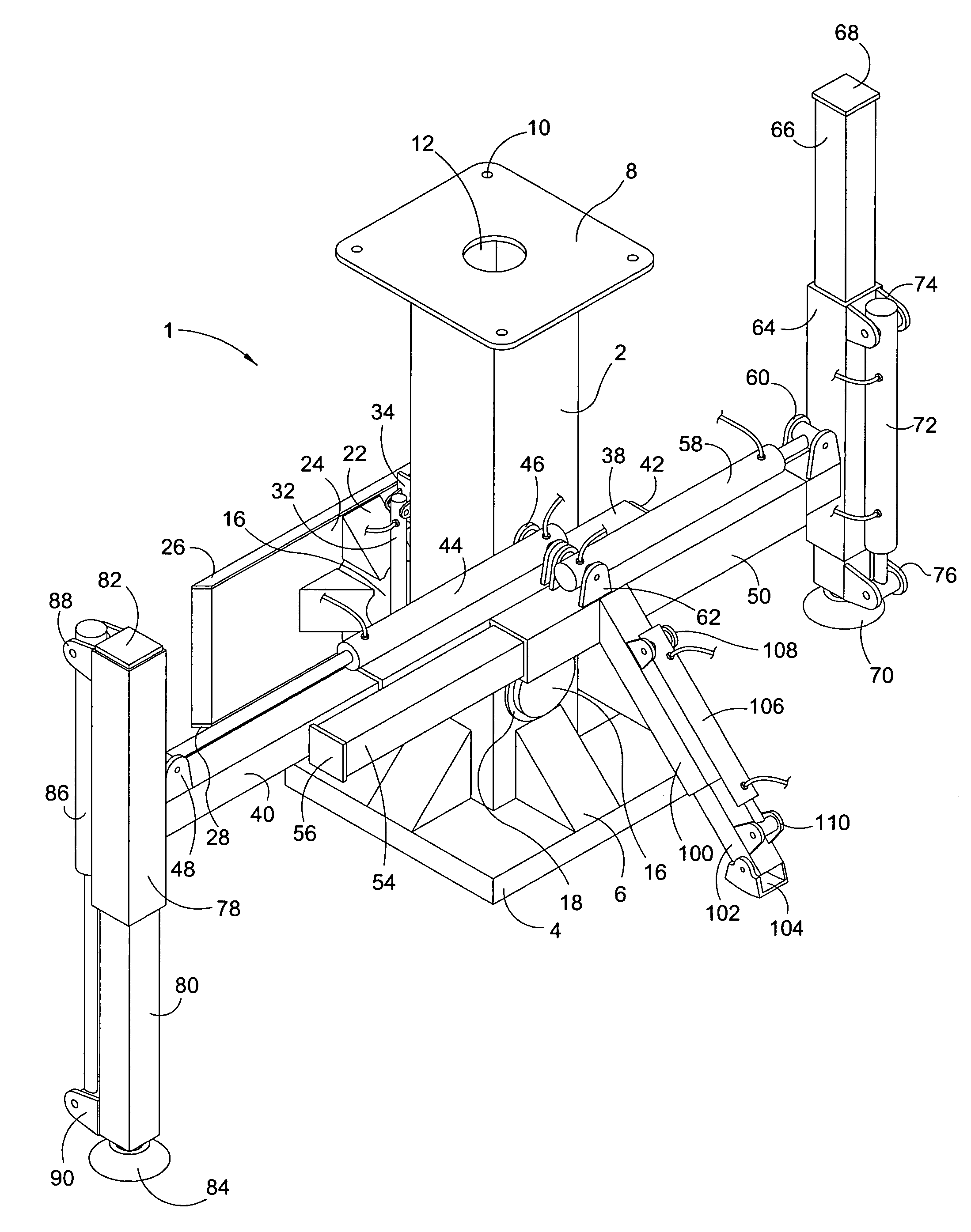

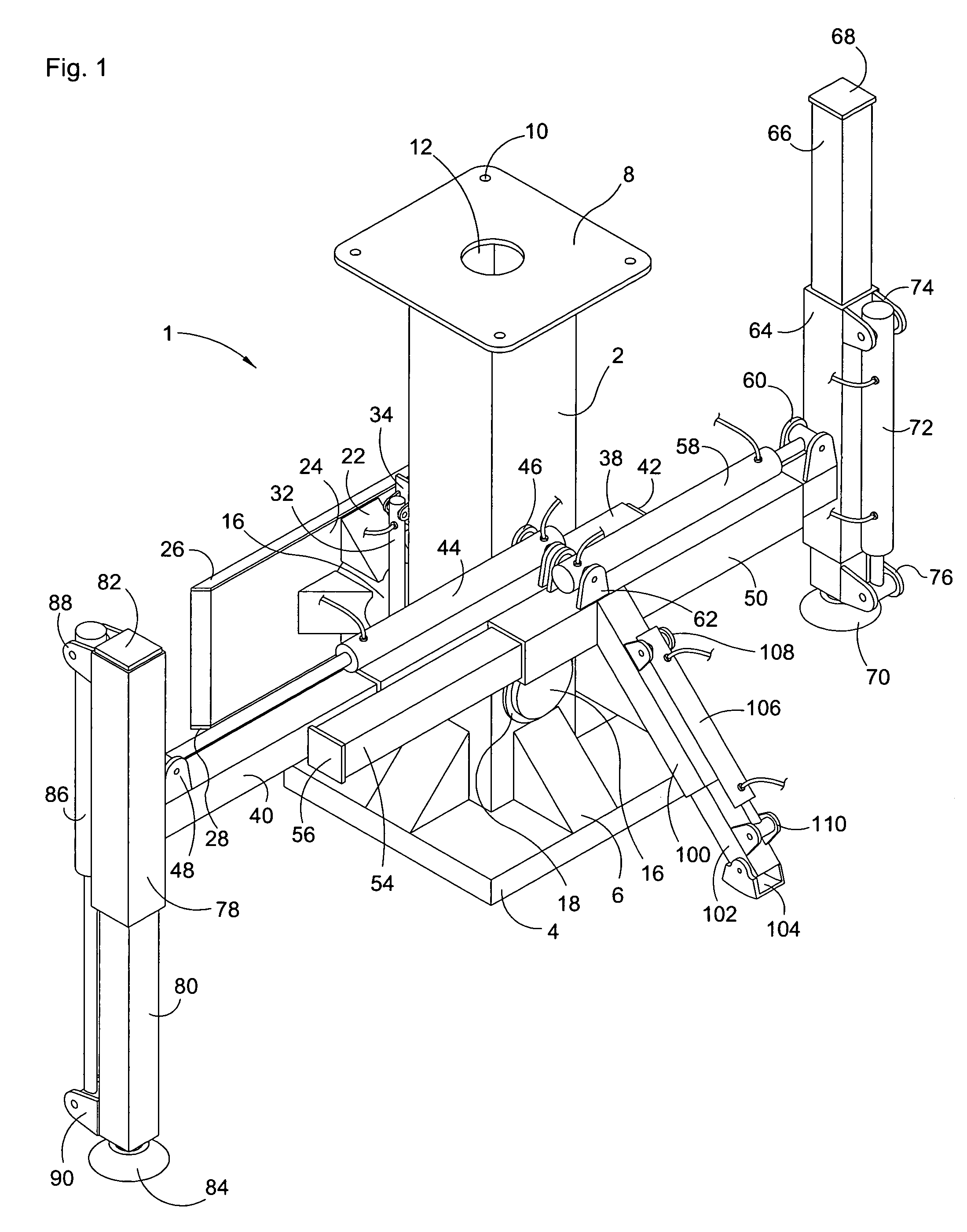

Crane supporting apparatus

InactiveUS7328810B1Easy to installAccurate vertical positionCranesHydraulic cylinderMechanical engineering

A crane support consisting of a steel square tubing pedestal having an apertured mounting plate fixedly attached to its upper end, and having an enlarged base fixedly attached to its lower end; an axle, the pedestal being mounting rotatably upon the axle; an auxiliary implement mounting frame fixedly attached to a rearward end of the axle, such mounting plate being adapted for attachment to skid steer loader lift arms and bucket dumping rams; a pair of telescoping outriggers fixedly attached to and extending laterally from the pedestal, each outrigger arm having downwardly extendable and upwardly retractable foot fixedly attached to its distal end; a plurality of hydraulic cylinders operatively connected to the telescoping outriggers and to the feet for alternating lateral and vertical extensions and retractions; and a hydraulic cylinder connected operatively to the pedestal for alternately locking the pedestal against rotation with respect to the mounting frame and permitting such rotation.

Owner:RHODES LESTER KENT

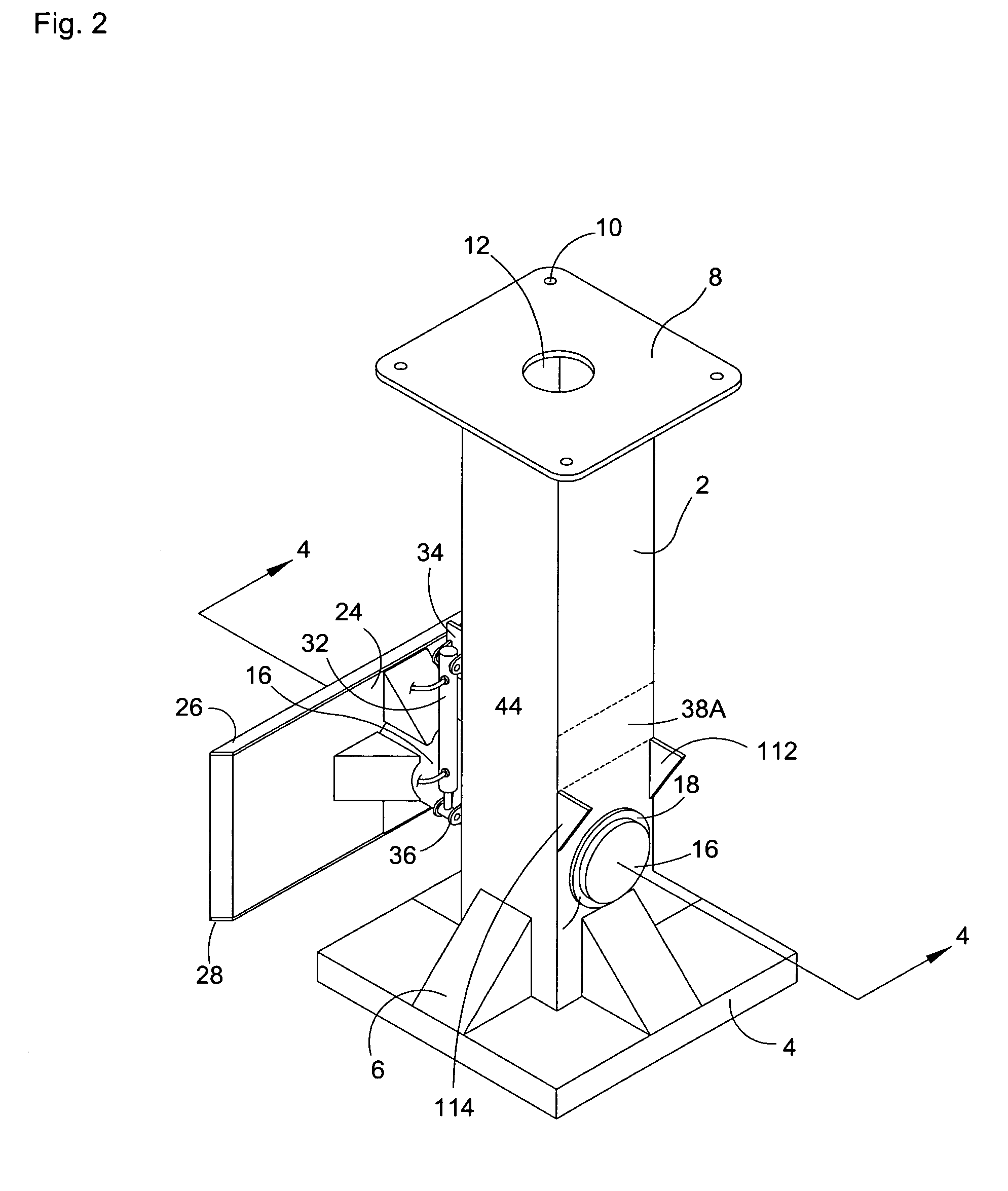

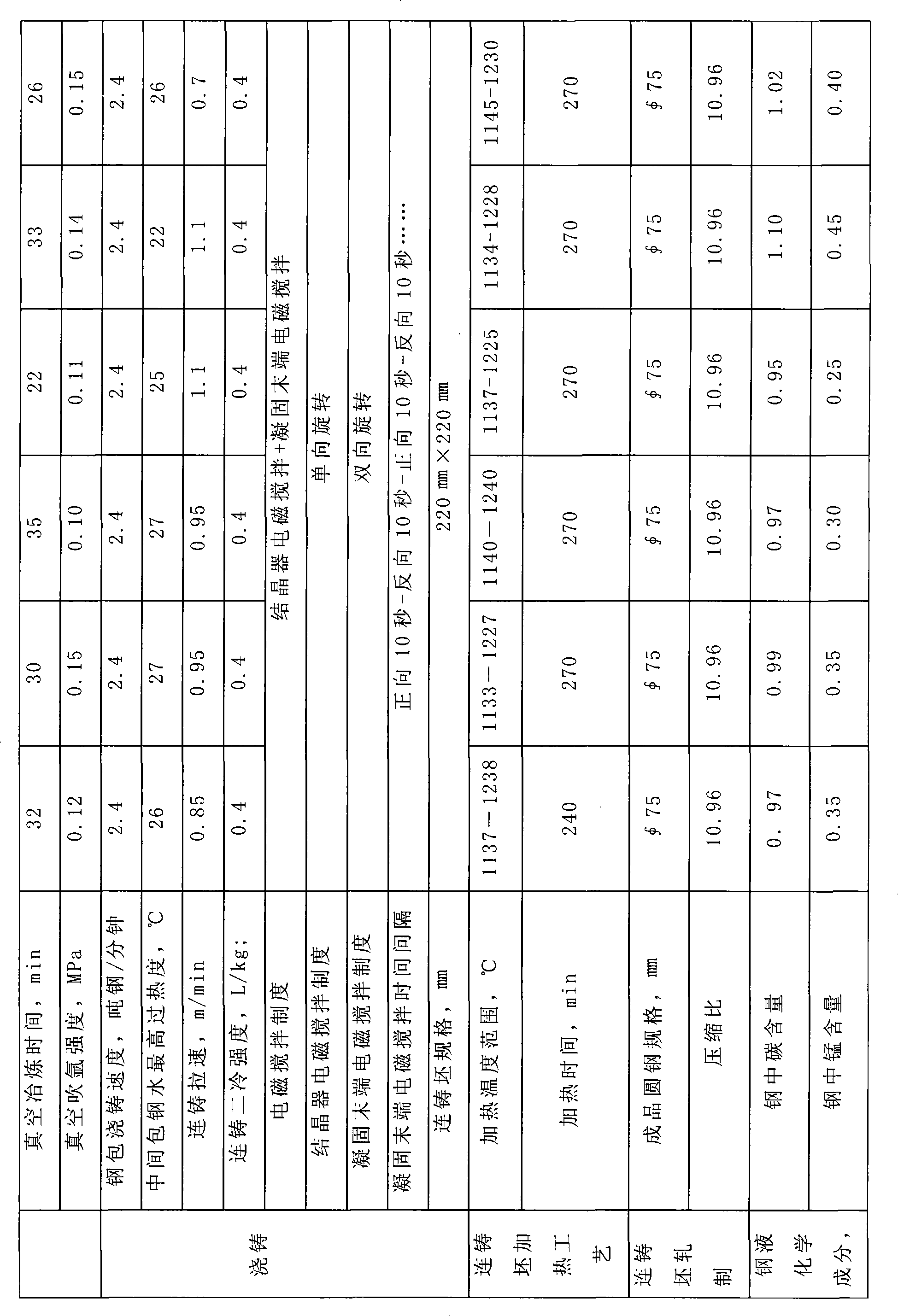

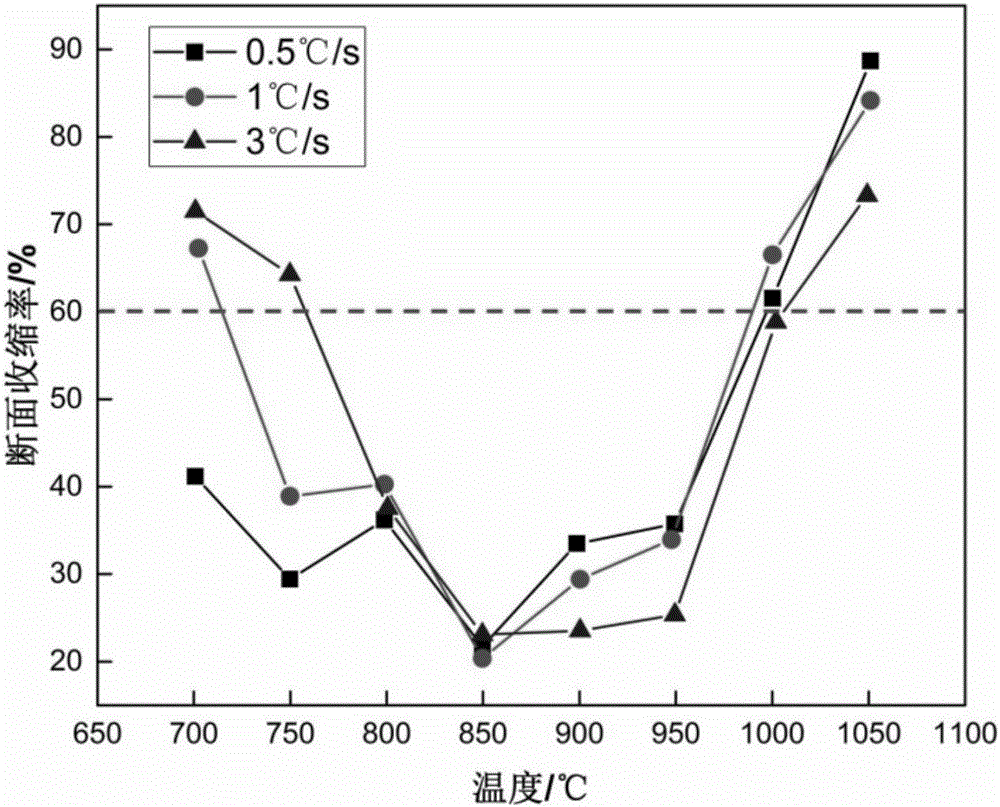

Continuous casting bearing steel round steel and method for producing the same

The invention relates to a continuous casting bearing steel round steel with small compression ratio and high cleanliness, the chemical components according to weight percentage are: 0.90 to 1.10 percent of C, 0.20 to 0.50 percent of Mn, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Cr, being equal to or less than 0.0007 percent of oxygen, being equal to or less than 0.008 percent of phosphorus, being equal to or less than 0.005 percent of sulfur, being equal to or less than 0.0025 percent of titanium, being equal to or less than 0.25 percent of copper, being equal to or less than 0.10 percent of nickel, and the rest of Fe and inevitable impurities. The manufacturing method of the continuous casting bearing steel round steel with small compression ratio and high cleanliness comprises the following steps: the selection of liquid steel for steel-making, ladle pouring, pouring box continuous casting bearing steel square billet, heating continuous casting bearing steel square billet in a heating furnace, and rolling the continuous casting bearing steel round steel with the specification Phi from 20 to 75mm(compression ratio can reach the minimum 10.96) in a rolling mill. The nonuniformity of the eliquation carbide and the ribbon carbide of the obtained continuous casting bearing steel round steel reaches China national standards and meets the requirements of bearing manufacturer.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

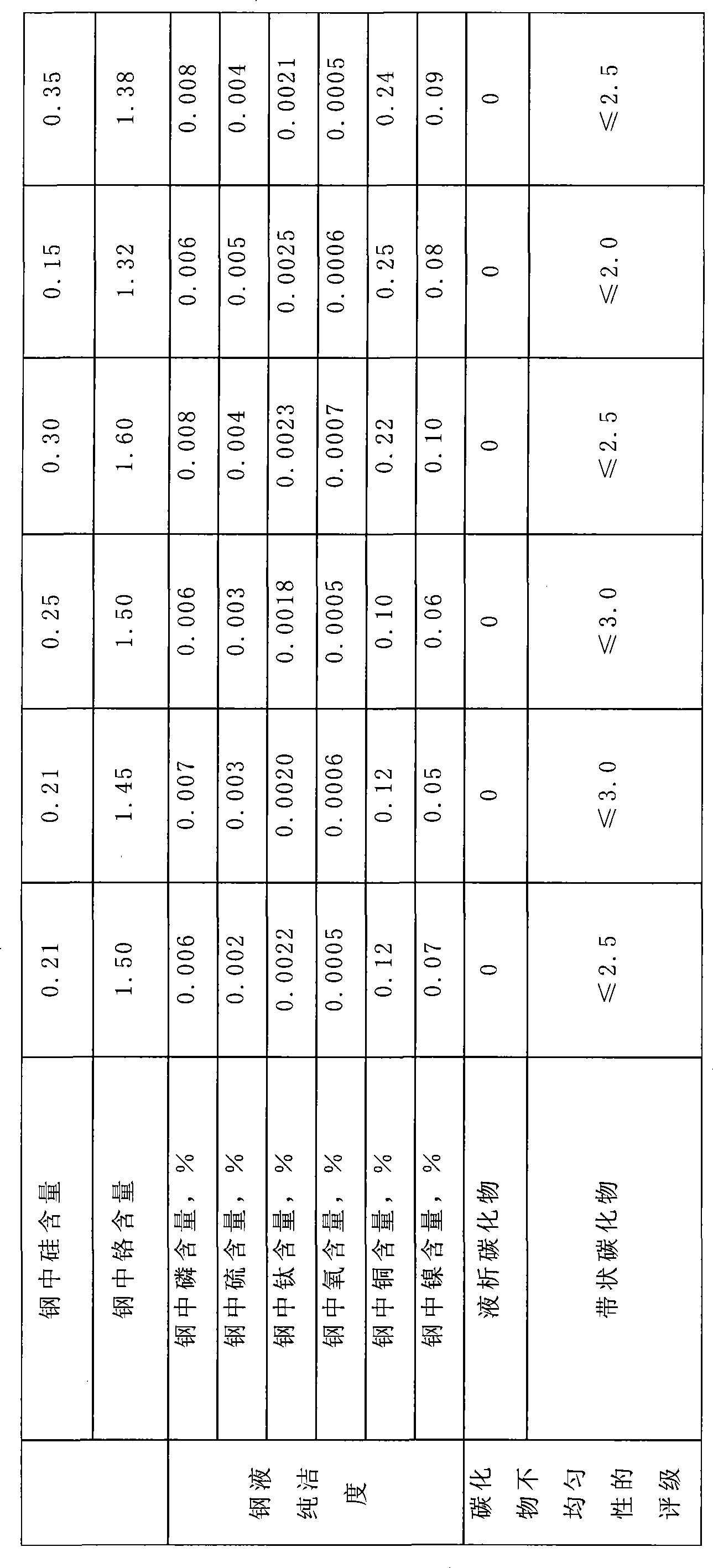

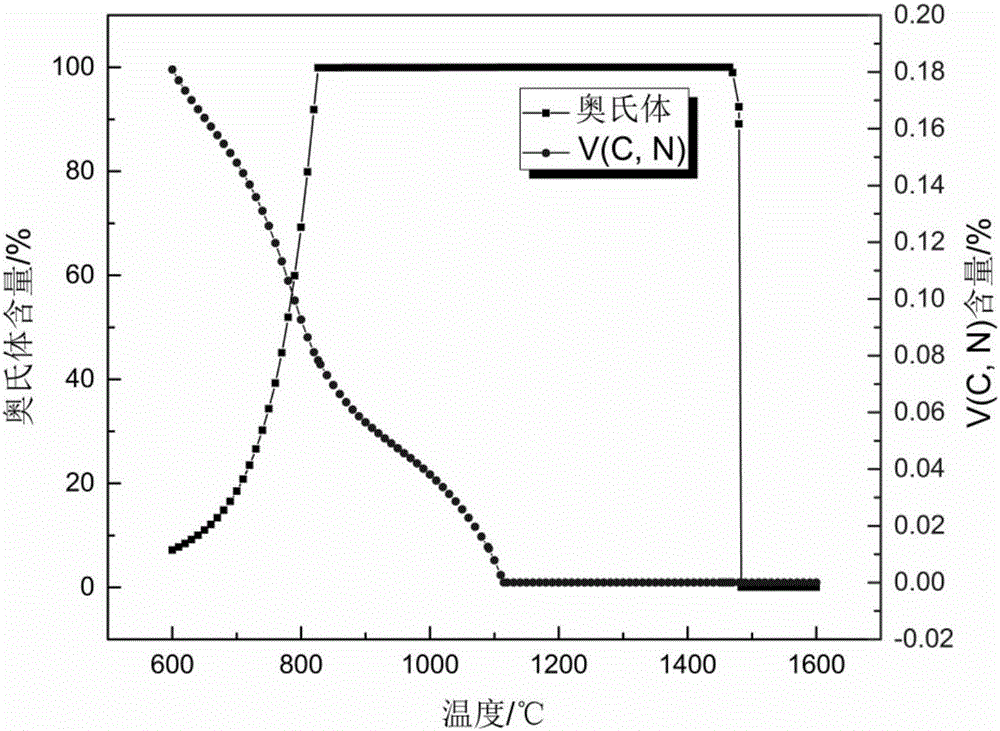

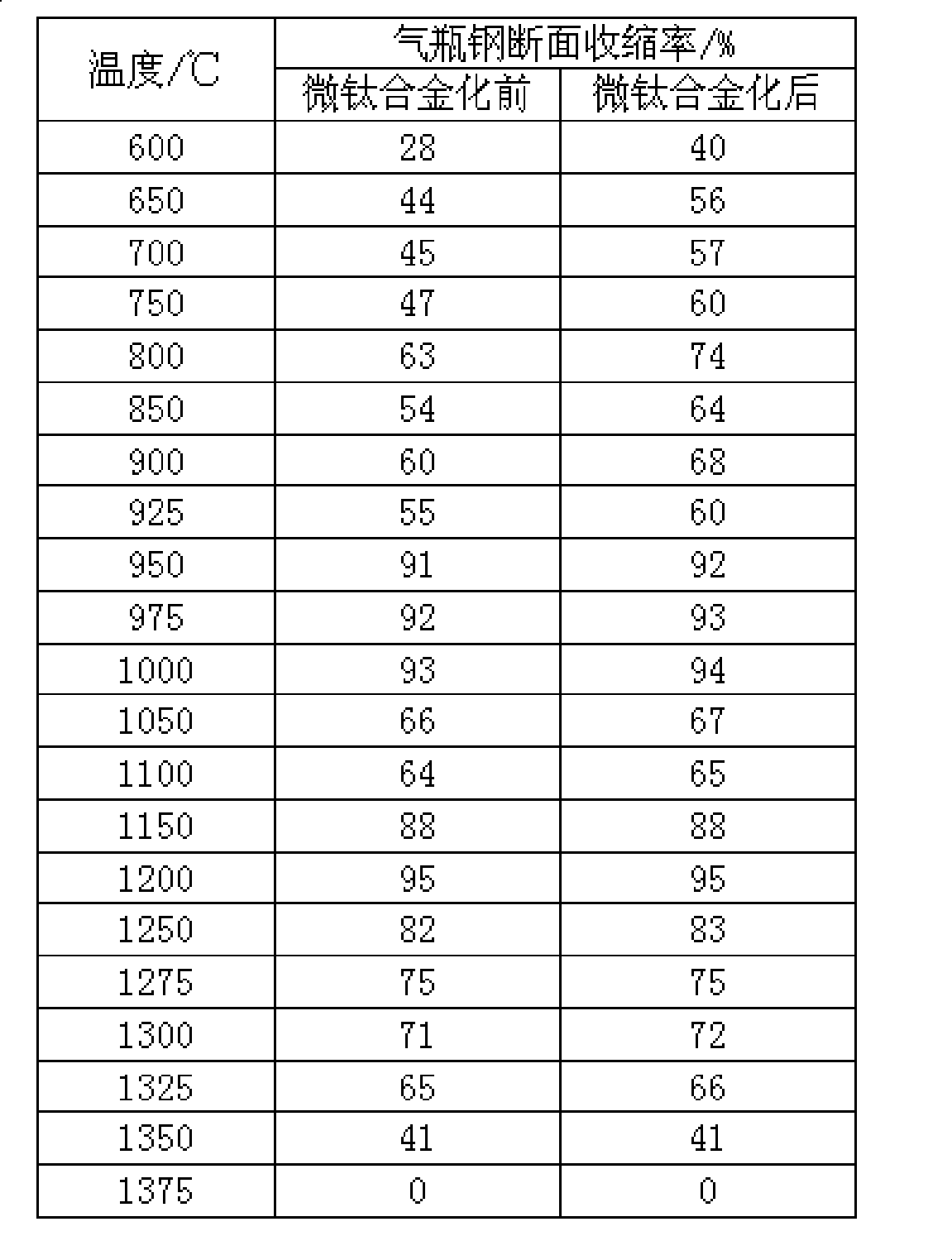

Microalloyed steel continuous casting cooling control method based on steel grade solidification characteristic and evolution of microstructures

The invention relates to a microalloyed steel continuous casting cooling control method based on the steel grade solidification characteristic and evolution of microstructures. The critical technical contents of the microalloyed steel continuous casting cooling control method comprise steel grade solidification characteristic experimental analysis, continuous cast blank solidification structure numerical simulation, continuous casting cooling process water amount regulation and control and the like. Change rules of the thermoplasticity and a third brittle temperature range of a target steel grade at different cooling rates are determined through experiments at first, then the influences of the cooling rates on austenite / ferrite transformation and the microalloy element second-phase particle precipitation law are comprehensively analyzed with te combination with the experiments, and finally, the microalloyed steel square blank continuous casting cooling precise control strategy of "low superheat pouring, low cooling of a third secondary cooling zone and high cooling of a fourth secondary cooling zone" is provided, relevant regulation and control schemes, that is, the superheating temperature is 23 DEG C (the original value is 37 DEG C), the water amount of the third secondary cooling zone is 2.6 L / min (the original value is 51.5 L / min), and the water amount of the fourth secondary cooling zone is 165.6 L / min (the original value is 18.4 L / min) are made a new continuous casting secondary cooling regulation and control mechanism based on the microalloyed steel characteristic is built, a cast blank solidification structure is optimized, and the strength of a surface microstructure of the solidification structure is improved.

Owner:UNIV OF SCI & TECH BEIJING

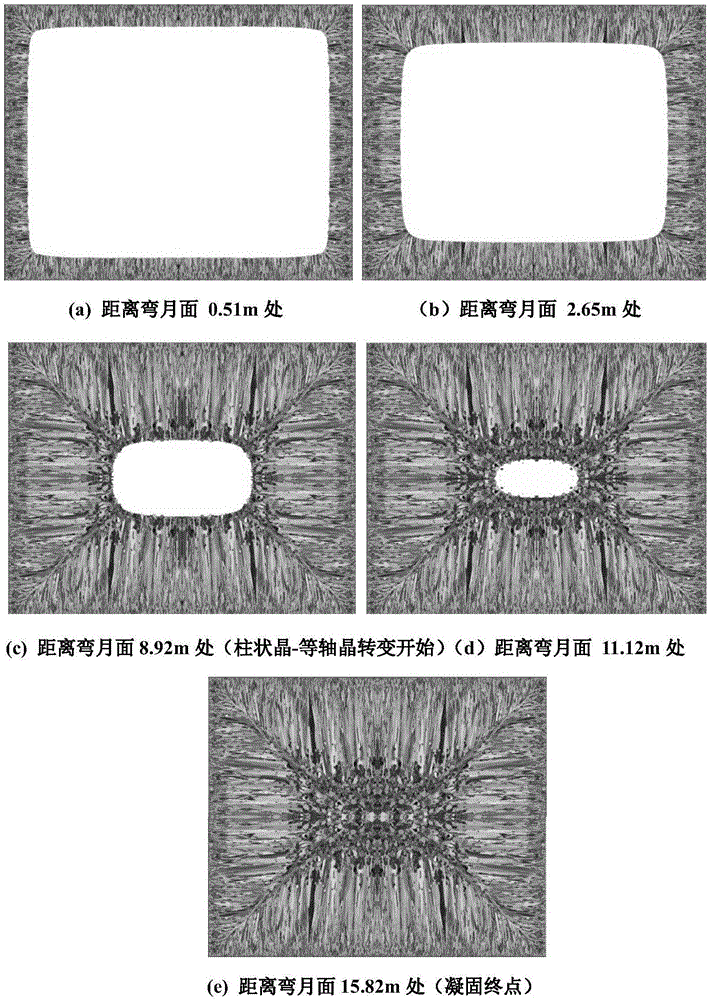

Continuous casting method for improving central shrinkage cavity of small high-carbon steel square billet

ActiveCN103506586AConducive to cost controlSimplified means of operationElectromagnetic stirringSteel square

The invention discloses a continuous casting method for improving a central shrinkage cavity of a small high-carbon steel square billet. According to the continuous casting method for improving the central shrinkage cavity of the small high-carbon steel square billet, the degree of superheat, the amount of blown argon of a submersed nozzle and full-protection casting are controlled, the cooling specific water flow for secondary cooling and casting speed are adjusted, and soft reduction of the final stage of electromagnetic stirring and solidification of each crystallizer is carried out. The specific technological parameters are that the amount of blown argon of the submersed nozzle is controlled to be 15-20L / min under the condition that the full-protection casting is adopted, the average casting speed of a casting blank corresponding to each crystallizer is 2.6-3.0m / min, the cooling specific water flow of cooling water in the secondary cooling section of each crystallizer is 0.8-1.2L / kg, and aerosol cooling is carried out; casting with the low degree of superheat is adopted in the whole process, the degree of superheat is 20-40 DEC C, and soft reduction of the final stage of the crystallizer electromagnetic stirring under the condition of 460-480 A and 5-7Hz and solidification under the 0.4-4.5m condition is adopted. The continuous casting method for improving the central shrinkage cavity of the small high-carbon steel square billet has the advantages that the flow of the inlet gas and the specific water flow can be accurately controlled, cost is reduced, and products meeting all specifications are produced through adjustment of all parameters.

Owner:ANGANG STEEL CO LTD

Method for sticking cakes in plastering engineering by using laser

InactiveCN102071792AEasy to operateLow skill level requiredSurveying instrumentsBuilding constructionsControl lineLaser

The invention discloses a method for sticking cakes in plastering engineering by using laser. The method comprises the step that: the cakes are stuck by taking a crossed vertical laser surface output by a laser marking gauge as a reference surface for sticking the mud cakes, namely, a control line is set on a floor of a building which is required to be subjected to plastering construction in a conventional mode, and the laser marking gauge is placed on the control line to keep a straight line projected to laser cross on the floor coincided or parallel with the control line; thus the mud cakes can be stuck by taking the laser surface which is coincided or parallel with the control line as the reference surface for sticking the cakes, the distance from the end face of each mud cake to the laser surface serving as the reference surface is measured by using an angle steel ruler, and the distance from the end face of each stuck mud cake to the laser surface serving as the reference surface is kept same. The method has the advantages of high construction efficiency, good quality, low construction cost, low requirement on the technical level of the construction personnel and the like, and is easy and convenient to operate, and the raw materials are saved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

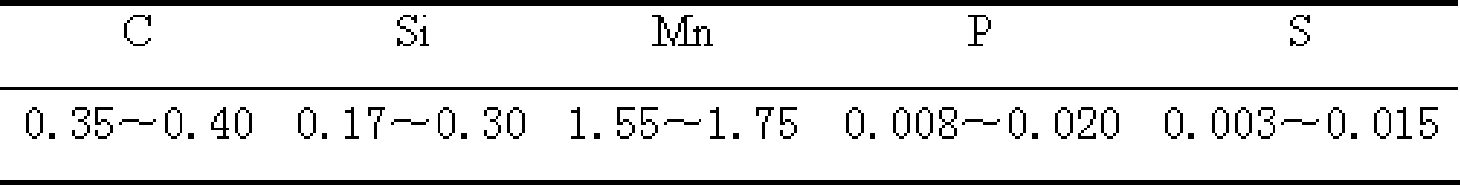

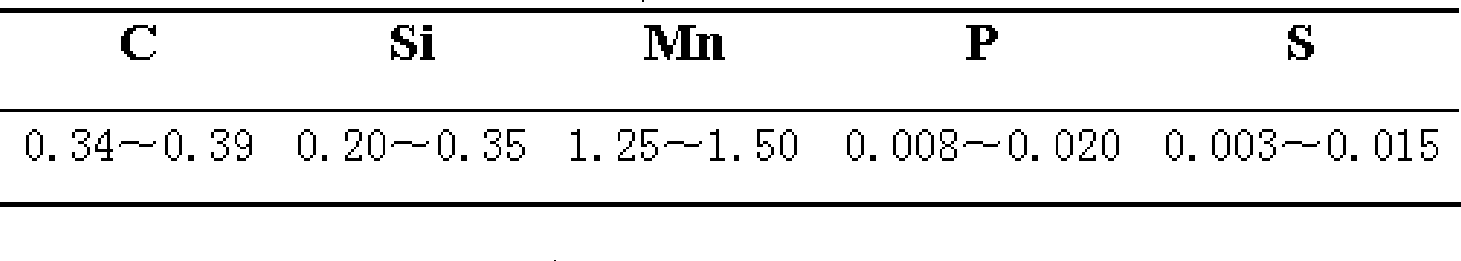

Production method for preventing cracks on medium-carbon high manganese steel

The invention belongs to the technical field of ferrous metallurgy and particularly relates to a production method for preventing the cracking of mid-carbon high manganese steel. The method solves the technical problem of preventing the cracking of mid-carbon high manganese steel square billet during the continuous casting process production. The method for preparing the mid-carbon high manganese steel square billet comprises the following steps: rotary furnace smelting, LF+RH refining and square billet continuous casting; the method is characterized in that: during the continuous casting, the continuous casting pulling rate is controlled to be between 0.3 and 0.7m / min, and the cooling intensity is between 0.37 and 0.53L / kg; and simultaneously, at the RH refining station, after the Al content of steel is controlled to be between 0.010 and 0.050 percent, the ferrotitanium is added, and the Ti content of steel is controlled to be between 0.015 and 0.045 percent. By the improvement, the cracking of the mid-carbon high manganese steel big square billet which is strong in crack sensitivity is eliminated.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

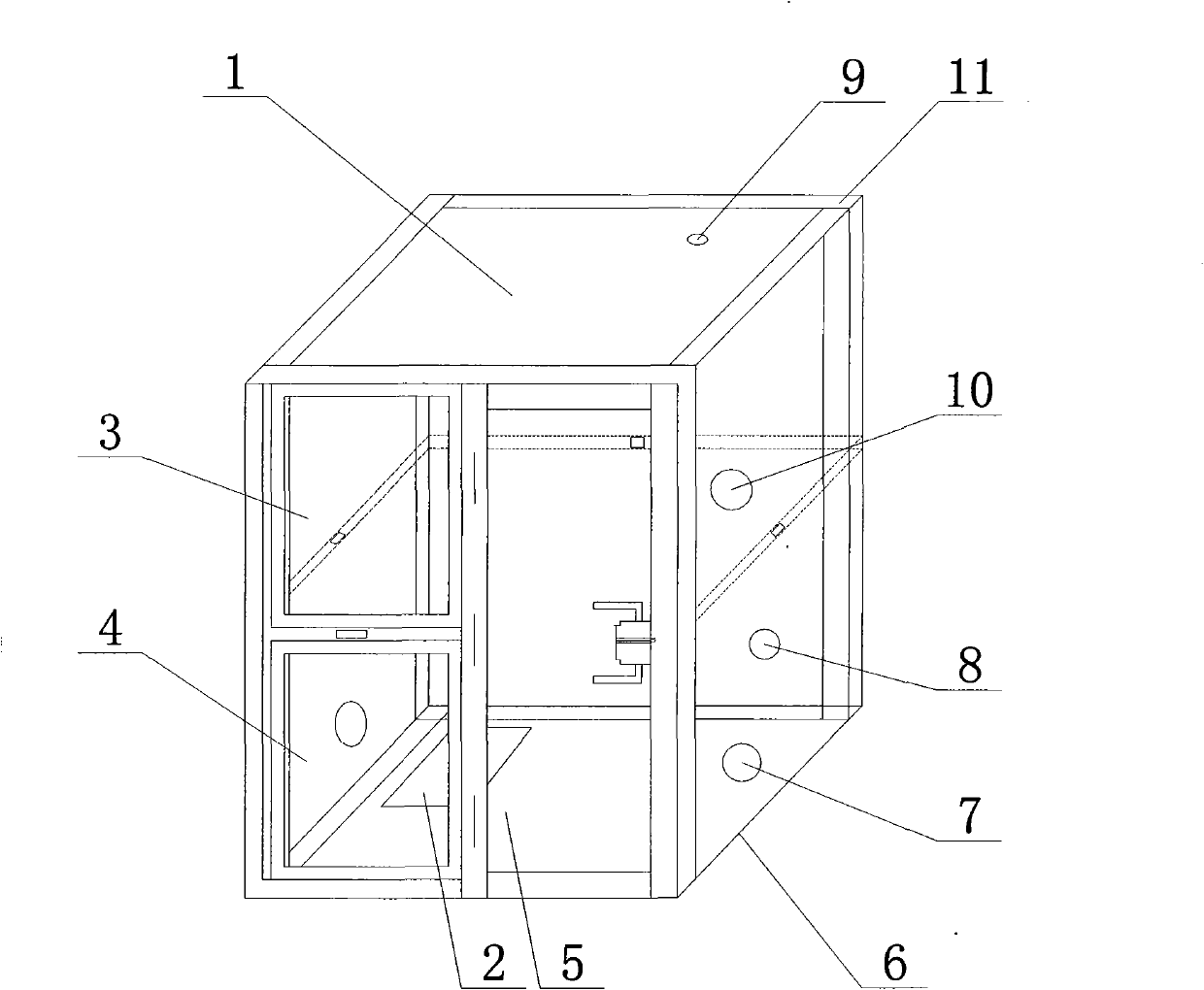

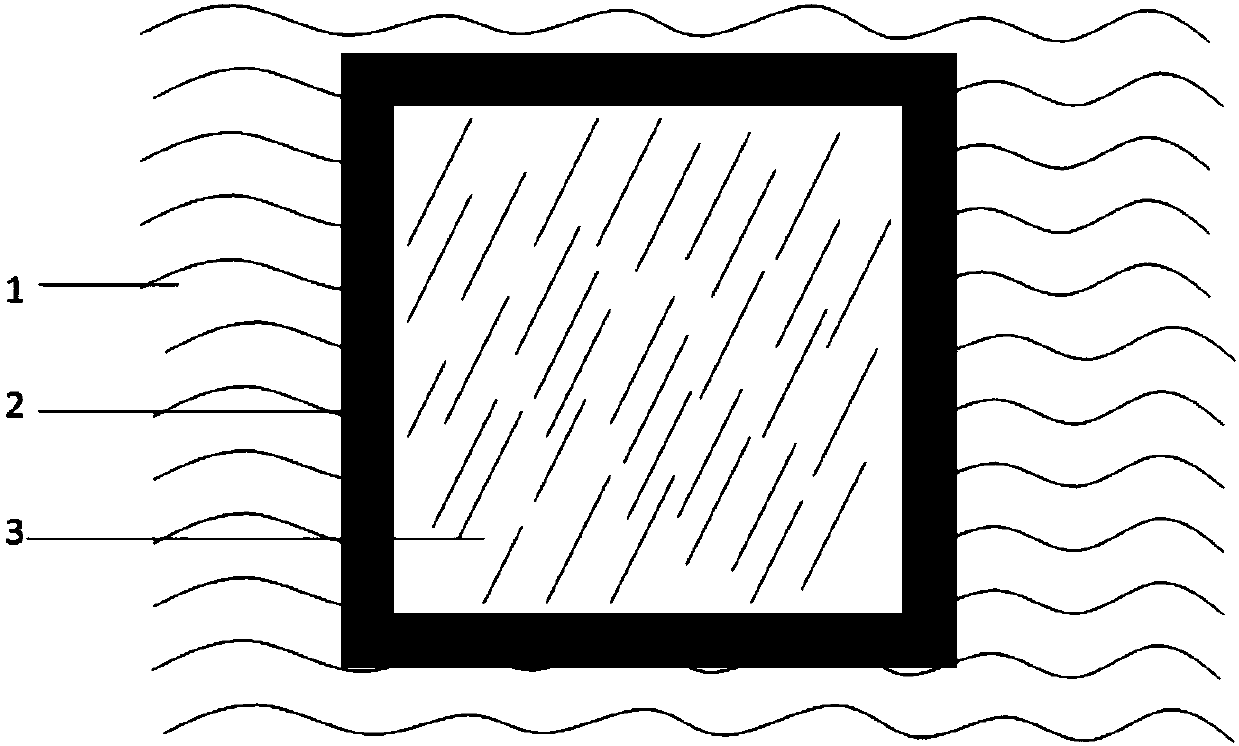

Explosion-proof sentry box

InactiveCN101793104AProtect life and property safetyComplete internal facilitiesWallsProtective buildings/sheltersMaterials scienceWall plate

The invention discloses an explosion-proof sentry box, which is composed of a framework, a top board, an explosion-proof composite glass wallboard, an explosion-proof composite glass door and a floor; the explosion-proof composite glass wallboard consists of a bulletproof composite transparent glass, a polycarbonate transparent board, interlayer transparent glass, a molecular sieve rack, a molecular sieve, double-sided sponge adhesive tapes, sealing agent and a U-shaped clamping groove, wherein the framework is formed by welding section steels and is provided with a plurality of screw holes, a hinge base connected with the explosion-proof composite glass door, a steel.-made plane bonded with the periphery of the explosion-proof composite glass wallboard and screw holes connected with the floor, the top board is composed of three layers of galvanized iron boards arranged in a parallel, superposed and combined manner, the peripheries of hollow cavities between corresponding planes in the top board are provided with steel square tubes, and a steel board of each plane is fastened with the steel square tube via a sunk head rivet. The explosion-proof sentry box can be extensively applied to important places, such as military base, scientific research site, prison, customs, frontier, etc., and public security places, and lives and properties of staff on duty can be effectively protected by using multi-layer composite glass.

Owner:河南恒鑫丰安防科技有限责任公司

Waterwheel-type aerator

ActiveCN102687686AOutstanding FeaturesHighlight significant progressClimate change adaptationWater aerationImpellerDrive shaft

The invention belongs to an aquaculture machine and relates to a waterwheel-type aerator. The waterwheel-type aerator comprises an impeller, a floating body, a main machine, a transmission shaft and a bearing seat, wherein the floating body is connected by virtue of a thin-wall stainless steel square tube; the square tube is provided with holes through which bolts cab pass; more than two floatingboats are combined by passing the bolts through square tube holes so as to form the floating body; a reinforcing plate is arranged above the square tube holes; two sides of the floating boats are provided with grooves and the bolts are fixed in the grooves; the impeller is composed of a blade and an impeller disc; the impeller disc is provided with a retaining mechanism which is molded by injection; one end of an elastic retaining strip and the straight edge of the impeller disc are molded into a whole body by virtue of injection and the other end of the elastic retaining strip is suspended; and after the blade is assembled in place, the retraining strip is reset and the blade is prevented from being moved out.

Owner:ZHEJIANG FORDY MACHINERY

Swinging self-resetting dual-deck bridge bent pier based on energy-dissipation angle steel with vertical joints

ActiveCN106087702AReduce congestionReduce the residual displacement after the earthquakeBridge structural detailsBridge materialsEngineeringFiber-reinforced concrete

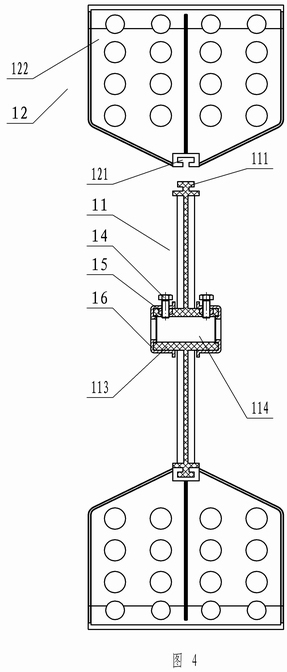

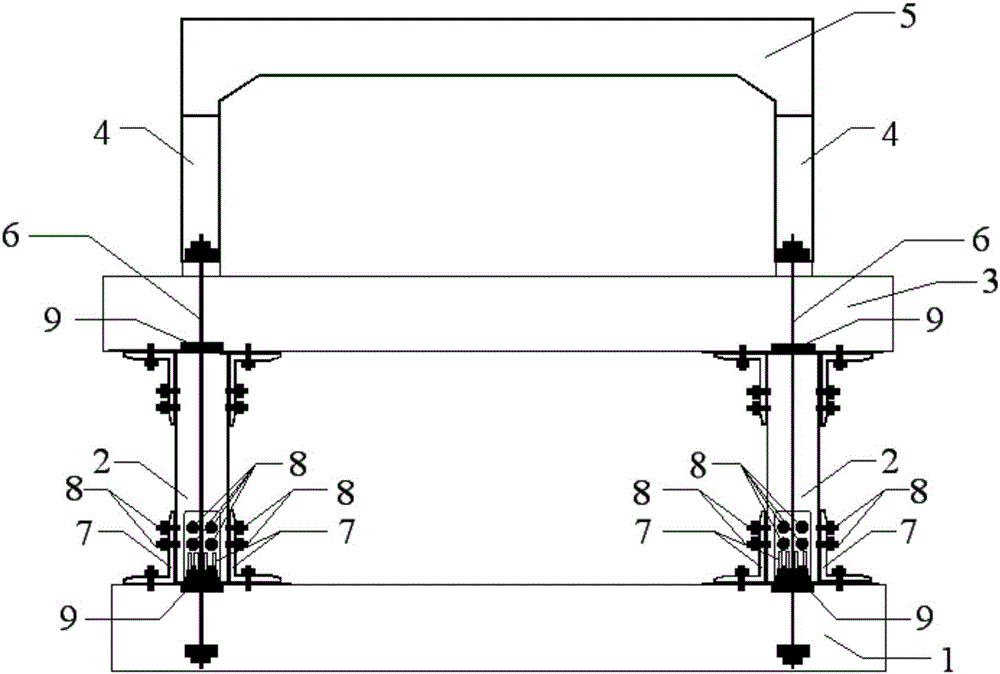

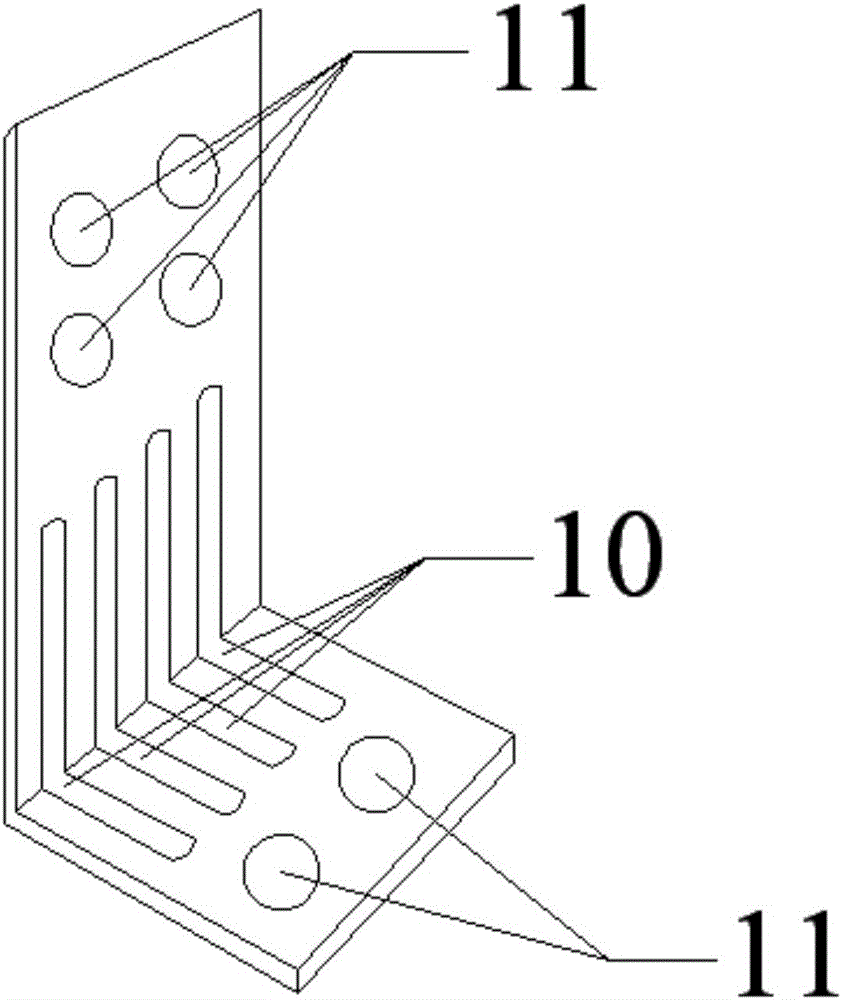

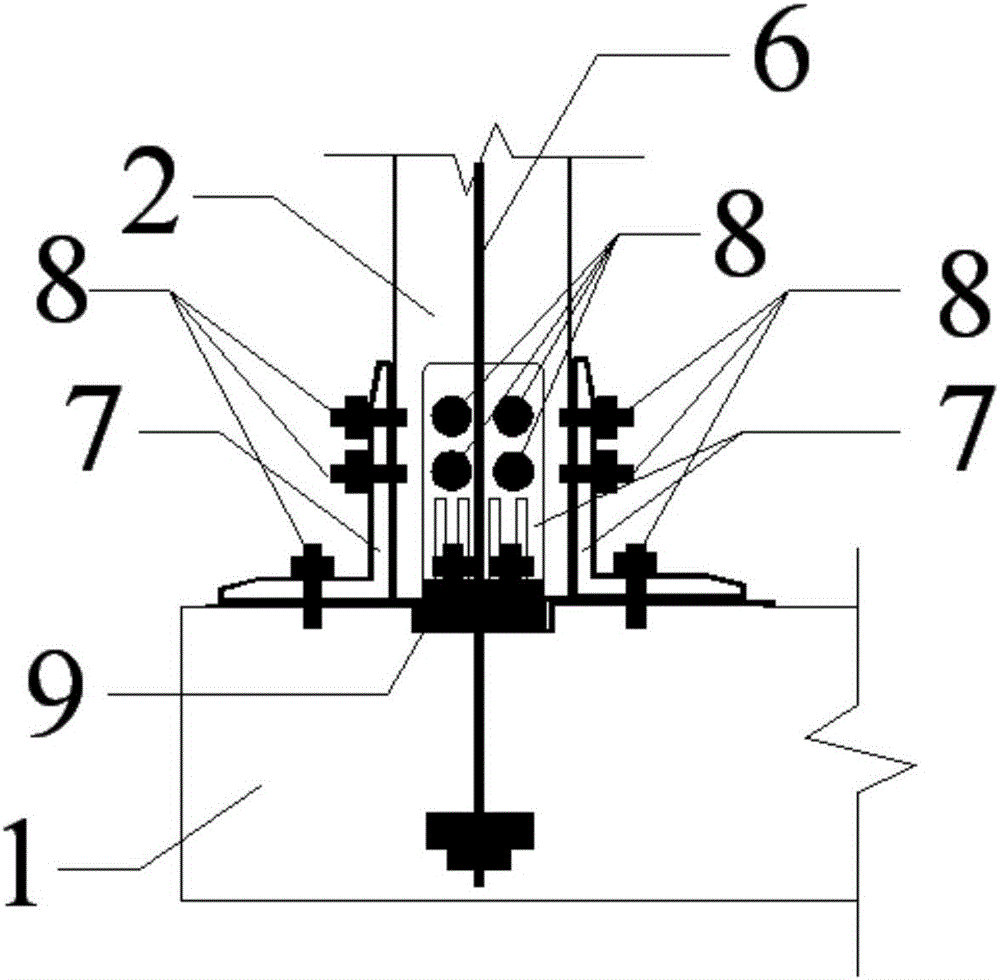

A swinging self-resetting dual-deck bridge bent pier based on energy-dissipation angle steel with vertical joints comprises a bent pier foundation, bottom-layer prefabricated concrete filled steel tube pier bodies arranged on the bent pier foundation and filled with self-compacting steel fiber reinforced concrete in a pouring mode, a bottom-layer prefabricated bent cap arranged at the top ends of the bottom-layer prefabricated concrete filled steel tube pier bodies, top-layer prefabricated pier bodies on the bent cap, a top-layer prefabricated bent cap arranged at the top ends of the top-layer prefabricated pier bodies, unbounded prestressed tendons penetrating through the bottom-layer prefabricated concrete filled steel tube pier bodies, the energy-dissipation angle steel with the vertical joints, bolts, steel square keys and the like. All the energy-dissipation angle steel with the vertical joints enables the bottom-layer prefabricated concrete filled steel tube pier bodies to be connected with the bent pier foundation and the bottom-layer prefabricated bent cap through the bolts, and the steel square keys are arranged at swinging joint portions. Under a strong earthquake, the bottom layer of the double-deck bent pier shakes, and the unbounded prestressed tendons provide self-resetting capability. Earthquake damage is concentrated in the energy-dissipation angle steel with the vertical joints, and the energy-dissipation angle steel with the vertical joints can be replaced when damaged after the earthquake and becomes fuses in the structure.

Owner:INST OF DISASTER PREVENTION

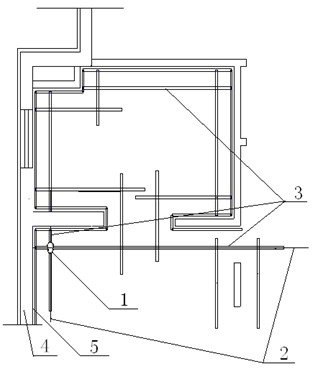

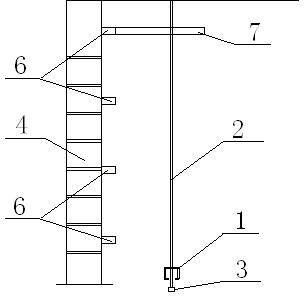

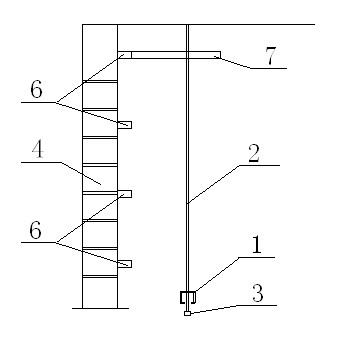

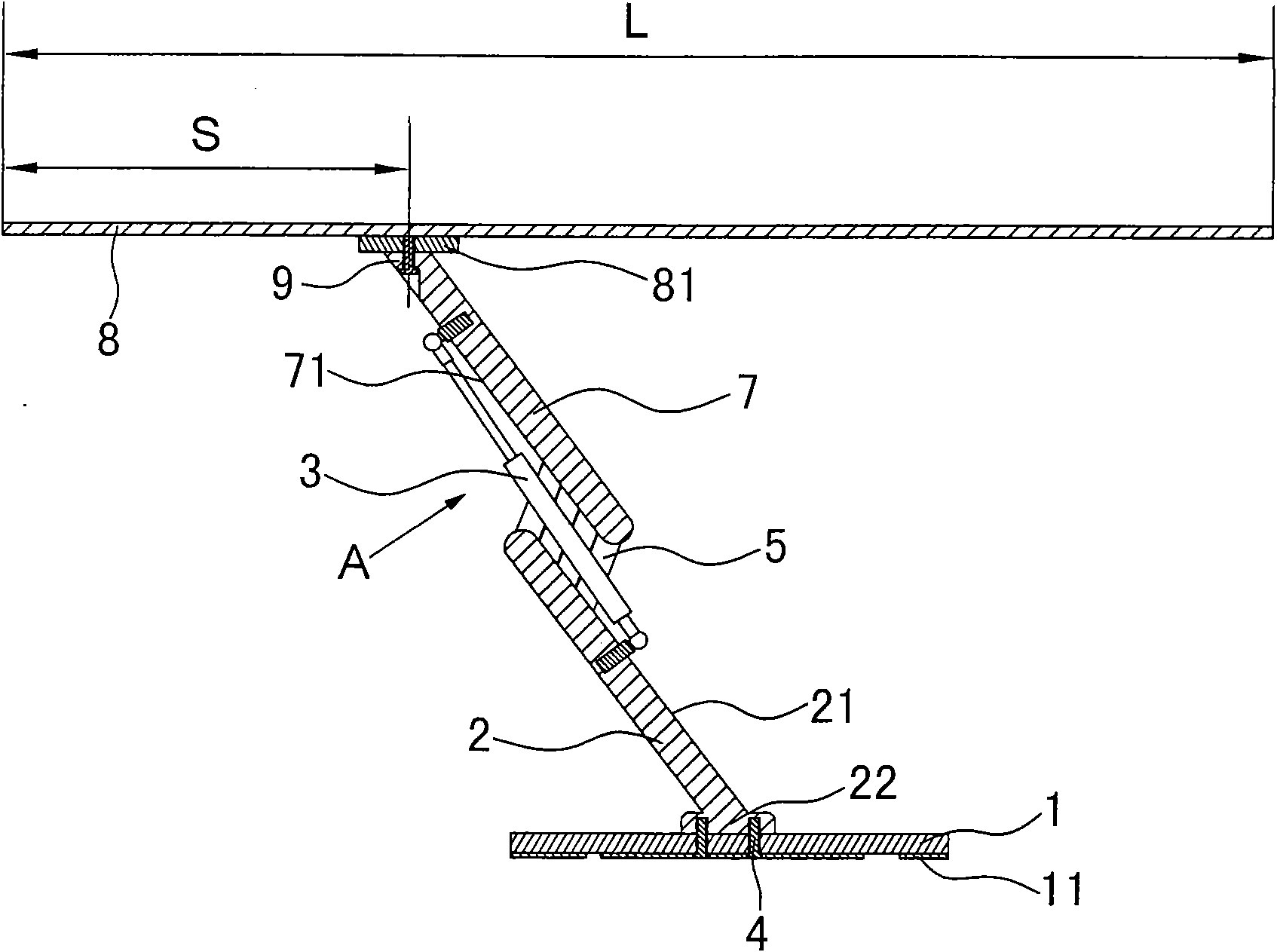

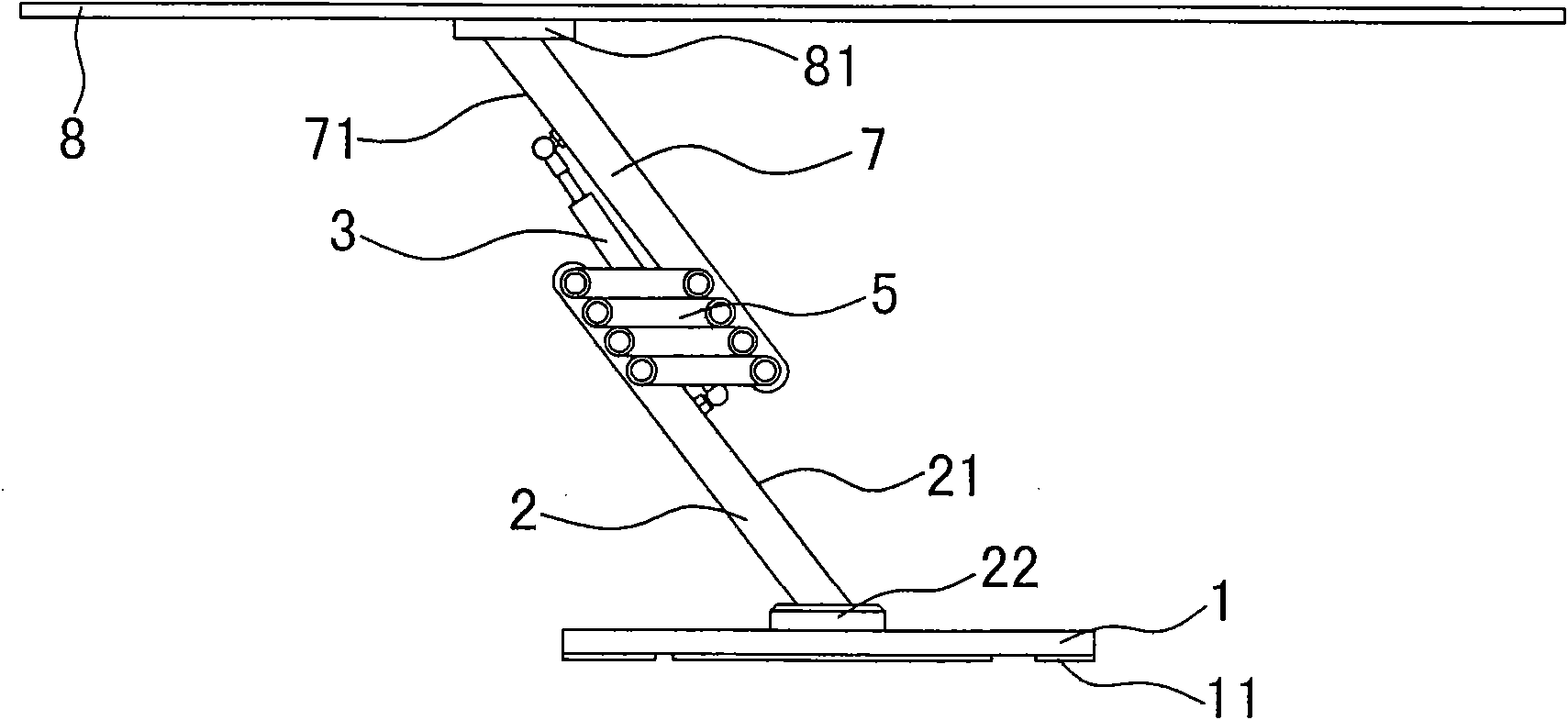

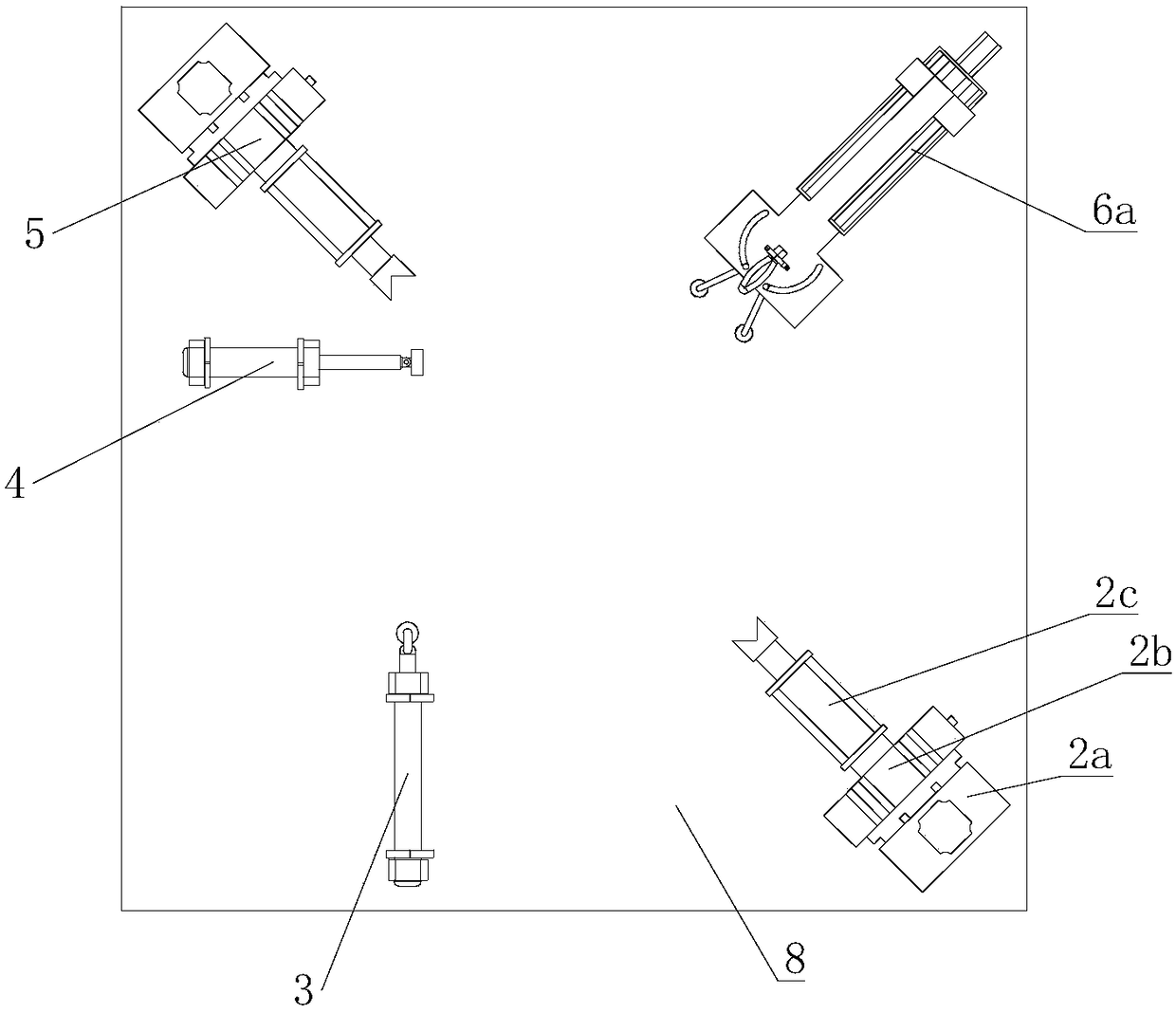

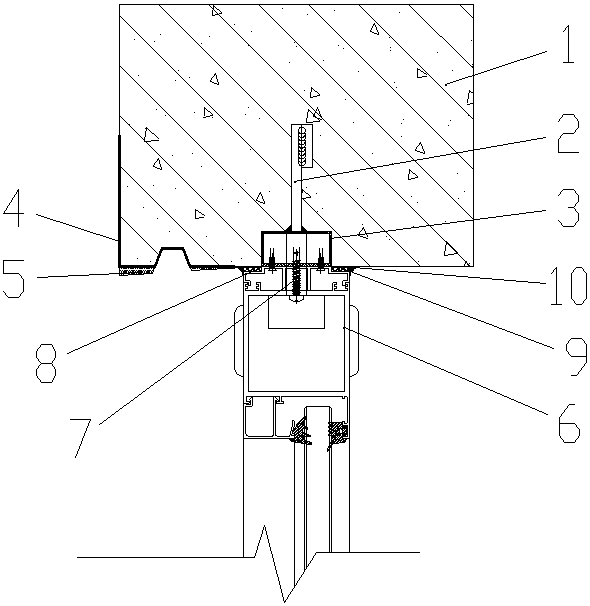

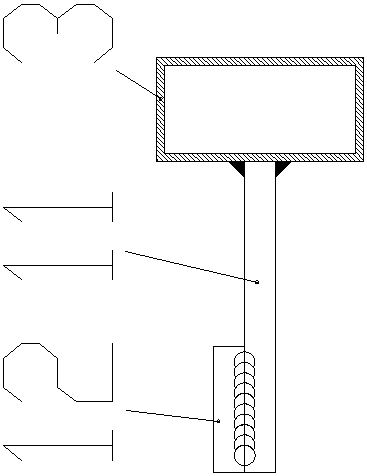

Lift-mounting tool and using method thereof

InactiveCN101537959ASimple structureEasy to useElevatorsMechanical measuring arrangementsProtractorSize determination

The invention relates to a lift-mounting tool and a using method thereof. The tool is a rail-calibrating rule and comprises a straight strip rule body and a boot sleeve which is perpendicular to the rule body and is used for sleeving a guide rail. The construction also needs matching tools, such as a door side frame calibrating support, a frame calibrating line support and a rectangle protractor. The using method comprises the following steps: arranging the side plumb surface of the door side frame calibrating support on a side plumb vertical operation surface of a lift car sill, namely on a datum plane; arranging edges of the frame calibrating line support on a plumb surface dichotomizing a lift car in parallel to the datum plane and a centring gap, namely on a rail-calibrating surface; confirming the installation drawing size of the vertical surface of the lift car sill, namely the datum plane by the aid of a door frame calibrating support and two door side vertical lines thereof; confirming the installation drawing size of the rail-calibrating surface in parallel to the datum plane by the datum plane, the frame calibrating support and four accessory vertical lines; confirming the corresponding positions of a main rail, an auxiliary rail and other lift fittings according to the installation drawing sizes, the rail-calibrating surface, the rail-calibrating rule and the rectangle protractor. The invention has the advantages of simple structure and accurate measurement and improves the labor efficiency.

Owner:韦浩

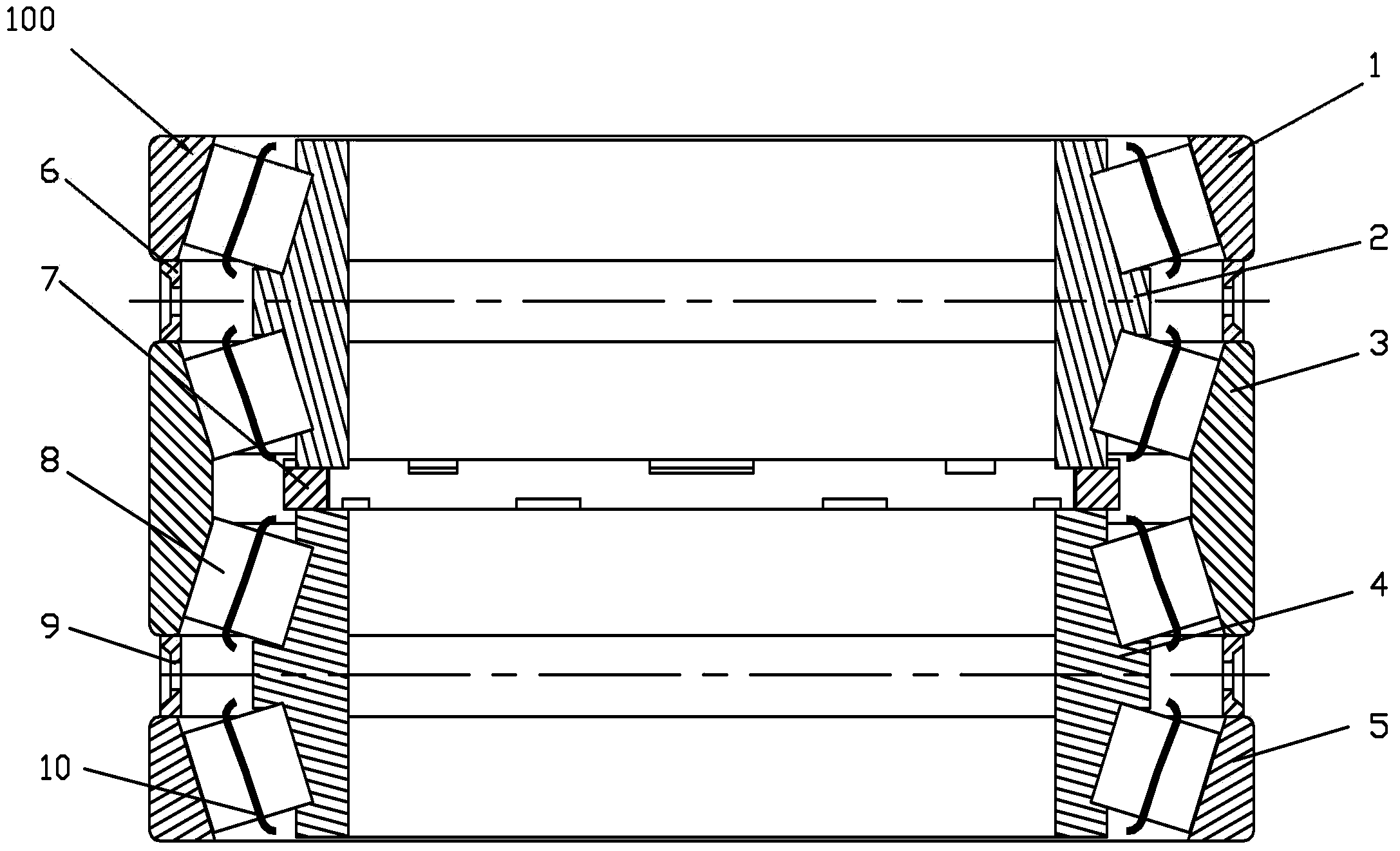

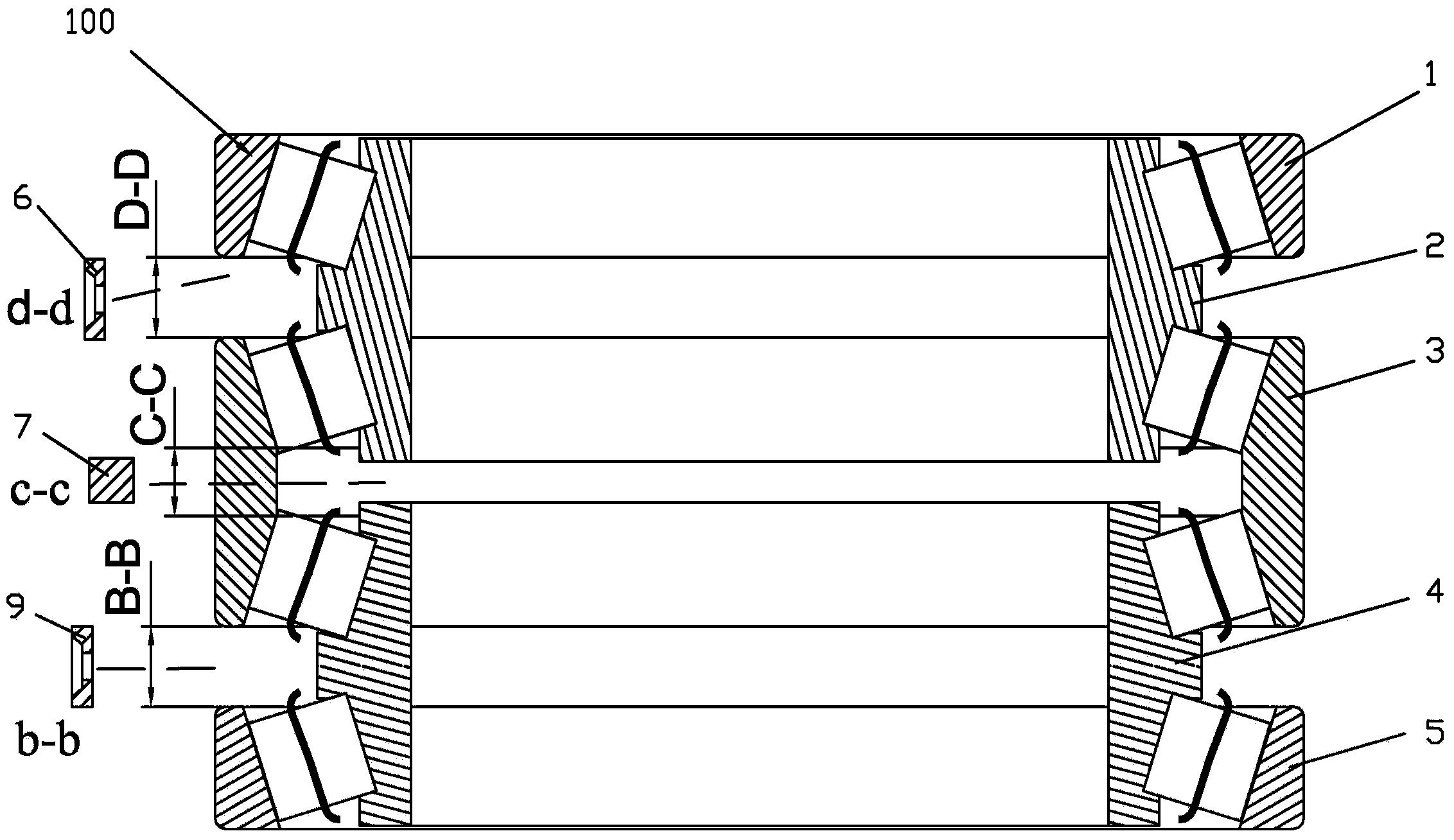

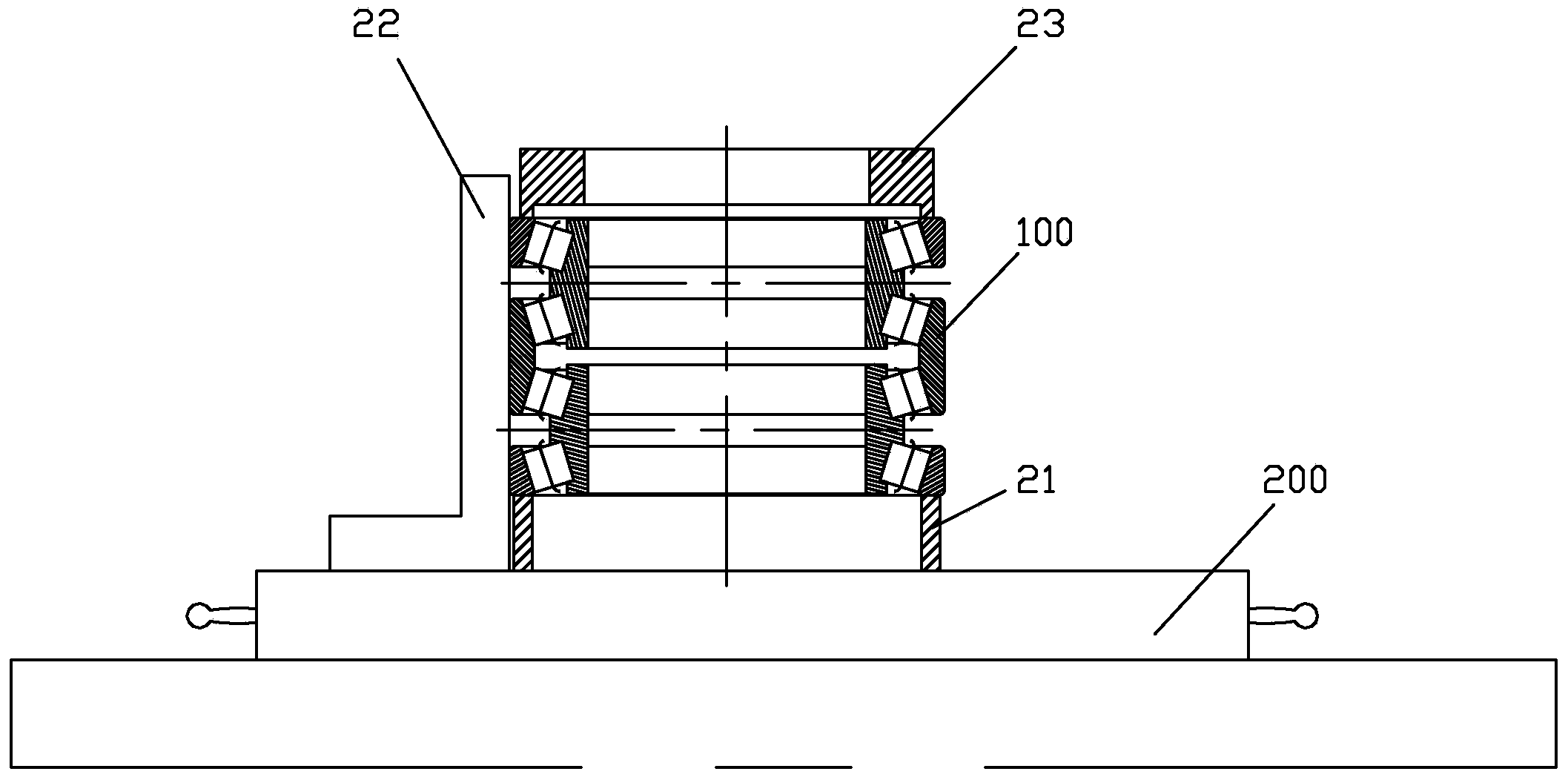

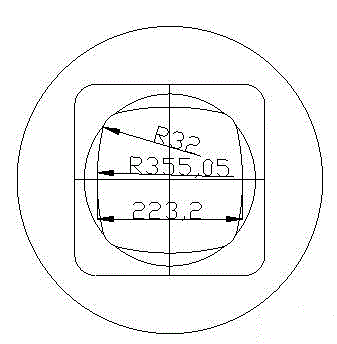

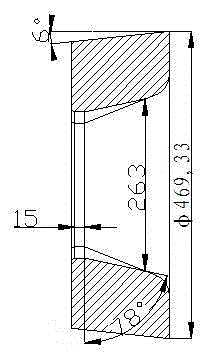

Method for adjusting working clearances of antifriction bearings of rolling device of seamless steel tube cold rolling mill

ActiveCN103722018AReasonable workmanshipSimple and fast operationRolling equipment maintainenceMetal rolling arrangementsObservational errorVernier scale

The invention provides a method for adjusting working clearances of antifriction bearings of a rolling device of a seamless steel tube cold rolling mill. According to the method, a standard plate, a 90-degree angle square, a bottom gasket, a top weight, a vernier caliper, a gauge and a filler gauge are adopted to form measurement tools. The standard plate serves as the measuring basis, the 90-degree angle square serves as a vertical check tool, the bottom gasket is used for supporting the end face of a lower side outer ring of a lower side bearing, and the top weight is pressed on the end face of an upper side outer ring. Three axial distances of the bearings are measured one by one from bottom to top through the vernier caliper or the gauge, the antifriction bearings are arranged upside down, and then distances between the bearing outer rings are measured one by one from bottom to top again. Measurement errors can be corrected through four measuring points and two times of measurement, the thickness of a spacer can be determined through computation, and the working clearances can be adjusted quickly and accurately.

Owner:宝武特种冶金有限公司

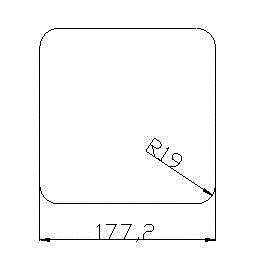

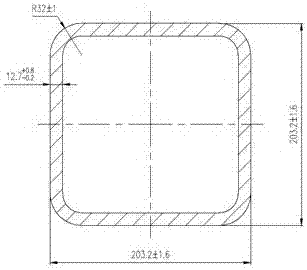

Method for forming large-diameter stainless steel square tube

The invention discloses a method for forming a large-diameter stainless steel square tube, and belongs to the field of processing and manufacturing of stainless steel seamless tubes. The method includes technological processes of raw material selecting, primary surface lubricating, tube end stripping, drawing head welding, primary drawing, primary pickling and degreasing, primary solid-liquid treatment, primary pickling, secondary surface lubricating, secondary drawing and head cutting, secondary pickling and degreasing, secondary solid-liquid treatment, straightening, secondary pickling, head flattening, dimension checking, ultrasonic flaw detection and packaging. Deformation in a drawing process tends to be alleviated, stabilizing time is short, and instability degree of an end surface is low. In addition, a formed product is high the dimensional precision and fine in flatness, and influence of the outer diameter of a circular tube billet is low before the product is formed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Manufacturing method of stainless steel square pipe

The invention discloses a manufacturing method of a stainless steel square pipe. A forged round ingot is adopted as a pipe billet and subjected to hot extrusion, cold deformation, heat treatment and surface treatment to form a finished product. The method comprises the specific steps that 1, a semi-finished round pipe corresponding to the finished product in size is prepared from the stainless steel pipe billet through the seamless forming technology comprising hot extrusion and cold rolling / cold drawing; 2, a square pipe meeting size requirements is prepared from the semi-finished round pipe through a two-pass drawing method, wherein the first pass is sink drawing, and the second pass is short mandrel liner drawing; and 3, heat treatment is carried out, wherein a roller bottom type heat treatment furnace is adopted for the finished product for solid solution heat treatment, and the heat treatment process comprises four stages. The stainless steel square pipe can be applied to waste heat exhaust heat exchangers of third-generation nuclear reactors such as AP1000, CAP1000, CAP1400 and Hualong One, has the special section shape, high corrosion resistance, high surface smoothness and high boundary dimension precision and is required to pass strict ultrasonic flaw detection and liquid penetrating tests.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

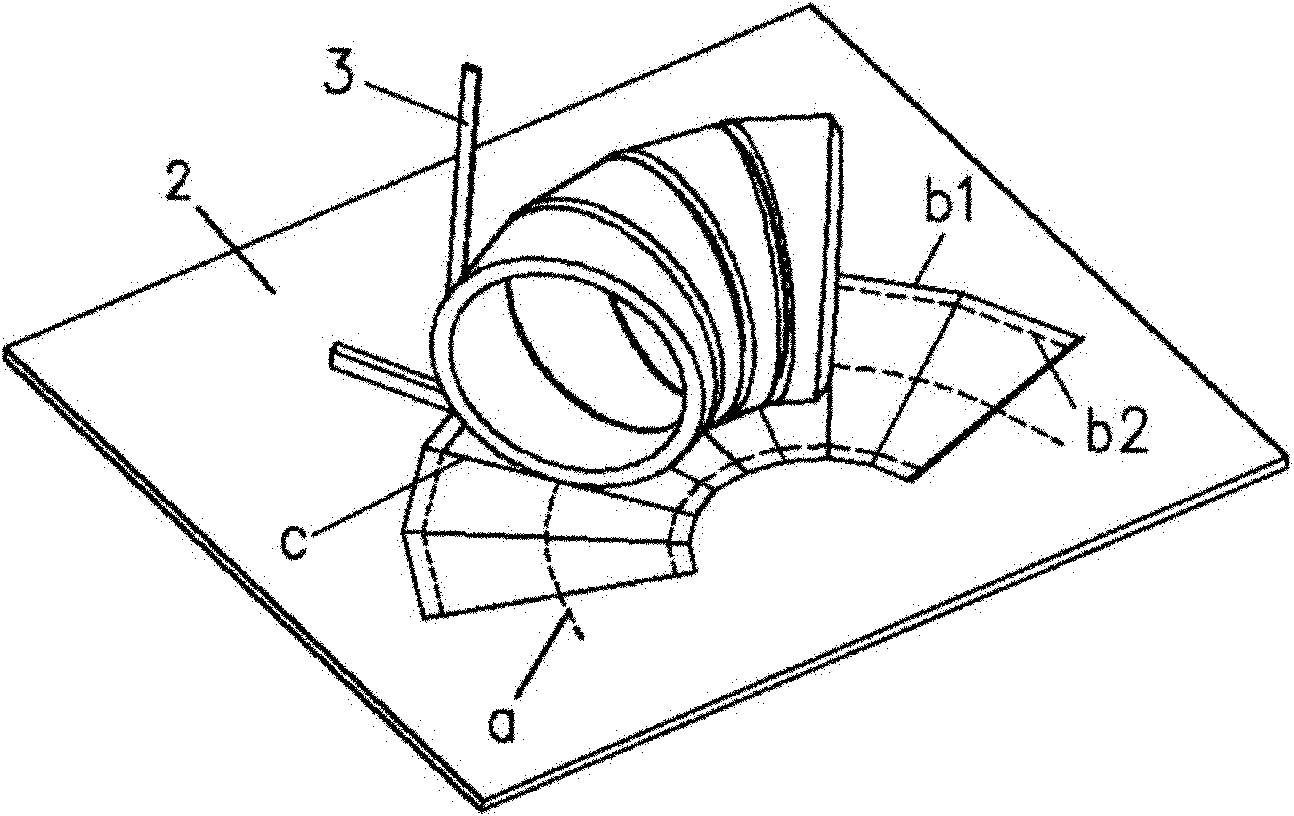

Continuous casting method for controlling center carbon segregation of small high-carbon hard-wire steel square billet

The invention discloses a continuous casting method for controlling center carbon segregation of a small high-carbon hard-wire steel square billet. Crystallizer electromagnetic stirring is adopted in the method. According to the process of the method, the superheat degree of molten steel ranges from 10 DEG C to 35 DEG C, the current of crystallizer electromagnetic stirring ranges from 320 A to 350 A, and the frequency ranges from 3 Hz to 4 Hz; aerial fog cooling is adopted for secondary cooling and the specific water flow ranges from 0.5 L / kg to 0.7 L / kg; and the casting speed ranges from 1.5 m / min to 1.7 m / min. By the adoption of the method, process parameters in the continuous casting process are reasonably adjusted and optimized, the center segregation of the high-carbon hard-wire steel small square billet is obviously improved, a cast blank is sampled for detection, a carbon segregation coefficient KC is controlled between 0.95 and 1.05, and therefore it can be guaranteed that the accidents, caused by center segregation, of net-shaped cementite appearing and breaking are not generated in the following rolling process of the steel billet. Under the conditions that tail-end electromagnetic stirring and soft press are not available, the proper parameters are selected for reasonable adjustment so as to control the continuous casting process, the cast blank defects of center segregation and the like of the small square billet are overcome, and the continuous casting method has the beneficial effects of being simple in process and effective.

Owner:HEBEI IRON AND STEEL

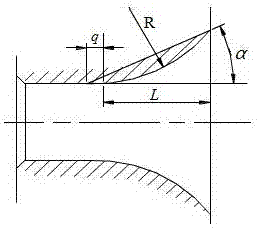

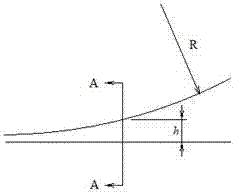

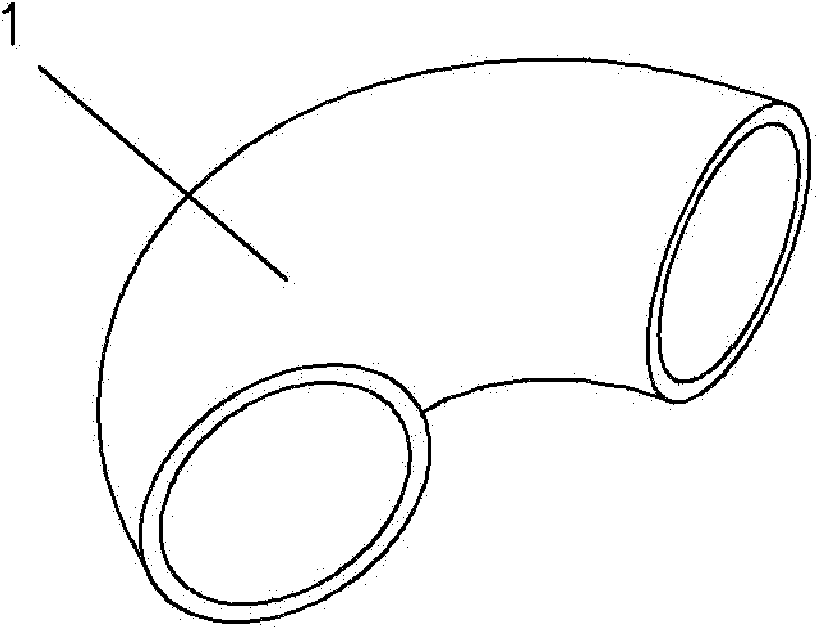

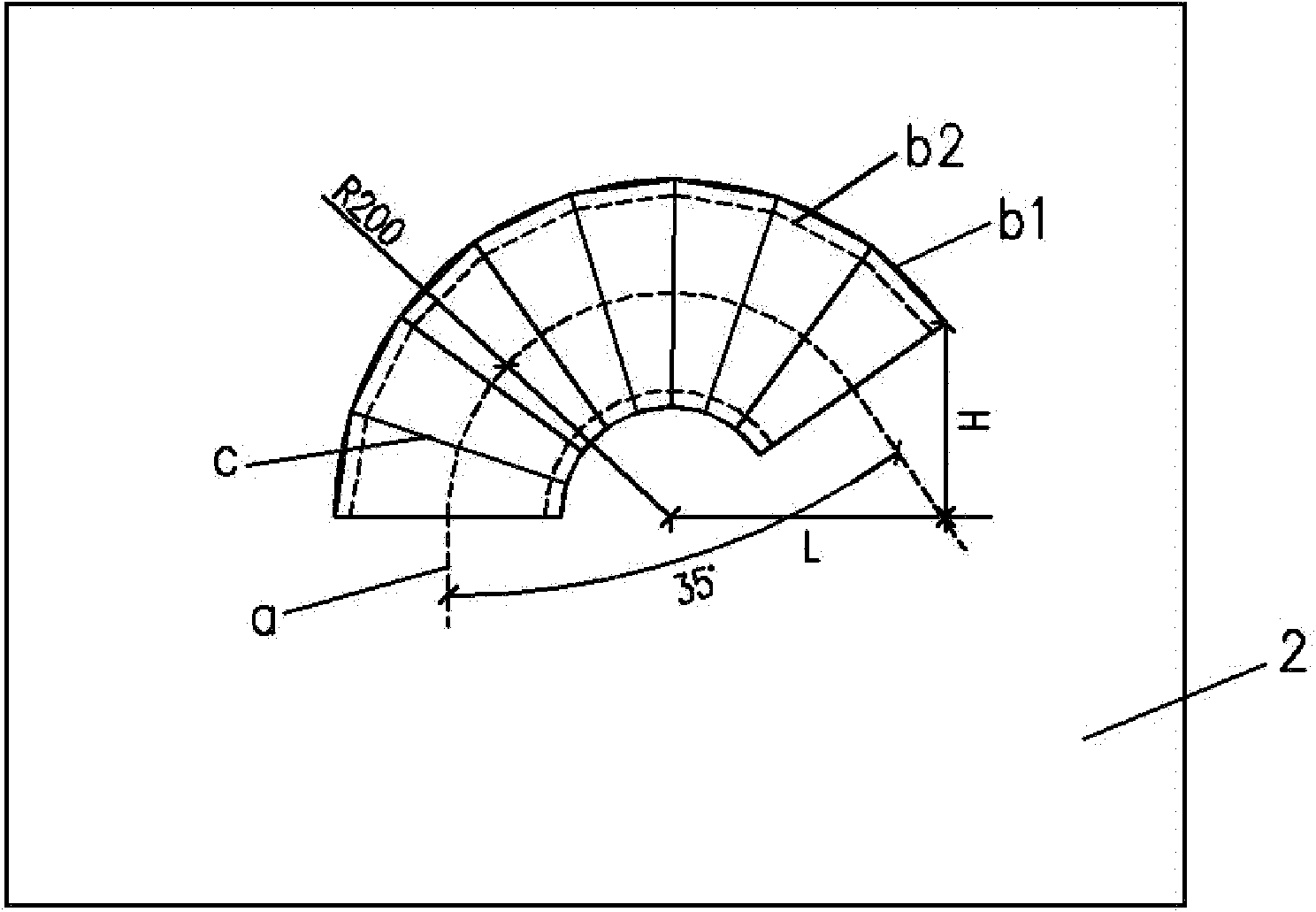

Processing method of small-curvature and small-angle bent pipe

The invention discloses a processing method of a small-curvature and small-angle bent pipe, which is characterized by comprising the following steps of: firstly replacing each straight pipe-section shrimp pipe by a circular-arc section, and segmenting the processed bent pipe into straight-pipe sections; marking a projection center line a, an outer side contour line b1, an inner side contour line b2 and a port line c of each straight pipe-section shrimp pipe for assembling the bent pip by using the processed member on a steel plate platform; sequentially positioning each straight pipe-section shrimp pipe from middle to both sides by using an angle rule; finally welding the neighboring straight pipe-section shrimp pipes in the integrally positioned straight pipe-section shrimp pipes to accomplish the connection between the neighboring straight pipe-section shrimp pipes; and then polishing edges of welding lines into smooth transition. In the method, the plurality of straight pipe-section shrimp pipes replace the circular-arc sections, the assembly of the small-curvature and small-angle bent pipe is accomplished by cutting, scribing and positioning, therefore the method is simple and rapid, and the processed small-curvature and small-angle bent pipe is especially suitable for serving as a transition section at the crossed position of two small-angle steel pipes.

Owner:ANHUI FUHUANG STEEL STRUCTURE

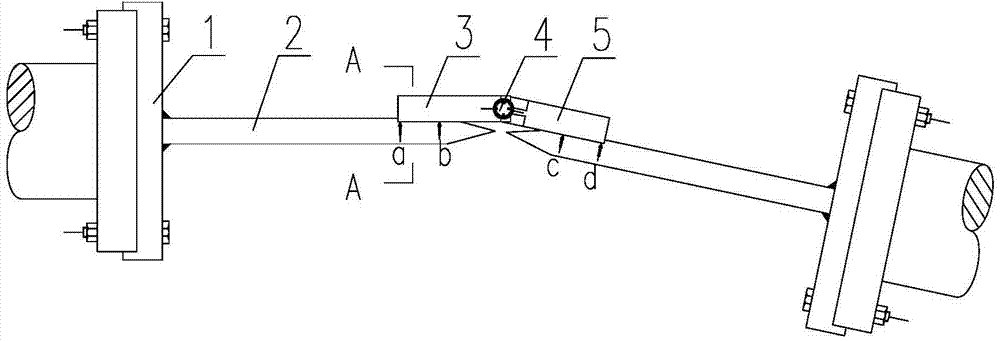

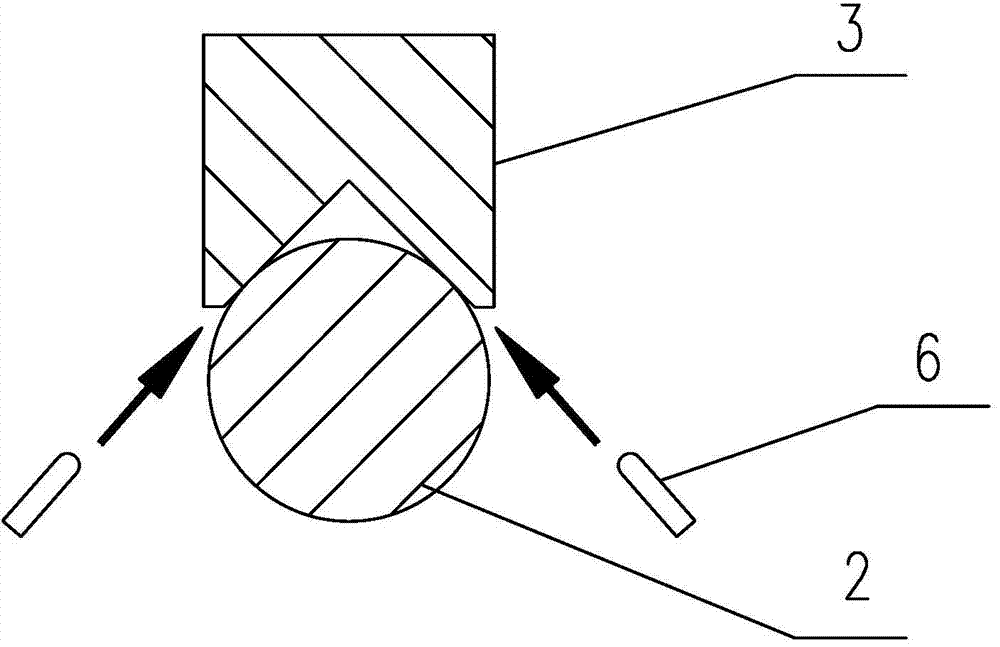

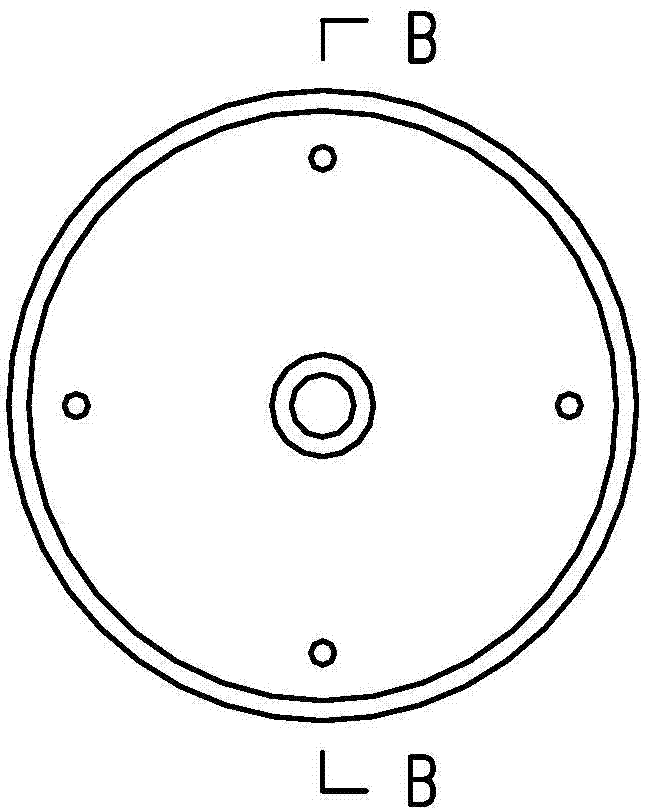

Manufacturing method for zigzag shafting alignment tool

ActiveCN103542797AIntuitive measurement resultsImprove Manufacturing AccuracyAngles/taper measurementsSteel barShaft alignment

The invention discloses a manufacturing method for a zigzag shafting alignment tool, and relates to the field of alignment of zigzag shafting. The manufacturing method includes respectively manufacturing a pair of alignment pointers between an input shaft and an output shaft, wherein the input shaft and the output shaft are adjacent and an included angle is formed between the both, and each alignment pointer is a mechanical member formed by welding of a flange and a straight steel bar with a tapered tip; manufacturing a set of alignment right-angle ruler comprising a first right-angle ruler arm, an angle indicating bolt and a second right-angle ruler arm, wherein a screw hole is formed at the ruler arm end of each of the first right-angle ruler arm and the second right-angle ruler arm, the angle indicating bolt penetrates the screw hole to fix the first right-angle ruler arm and the second right-angle ruler arm together, and the first right-angle ruler arm and the second right-angle ruler arm rotate around the angle indicating bolt which displays included angle between the first right-angle ruler arm and the second right-angle ruler arm. By the method, both angle and offset can be measured, measuring results are visual, measuring accuracy is high, construction is simple and convenient, the tool is convenient to demount, and production efficiency can be improved.

Owner:WUCHANG SHIPBUILDING IND

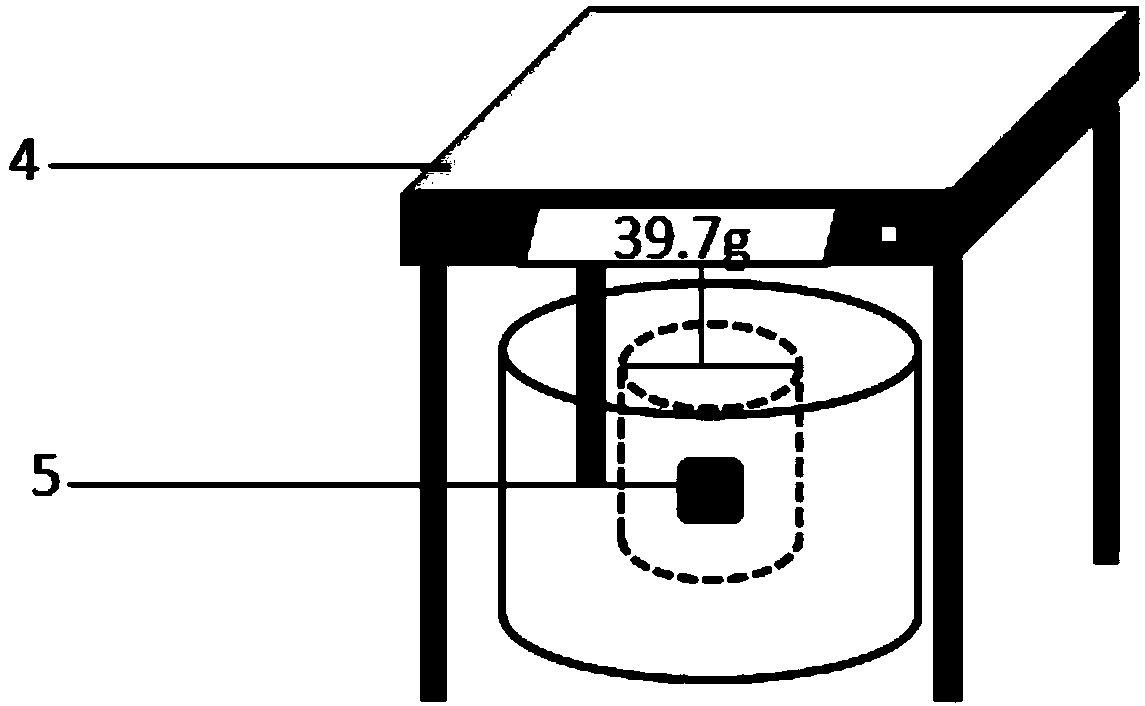

Roughness detecting method for combined surface of concrete prefabricated part

ActiveCN107621250AEffective means of controlFast measurementMeasurement devicesDistilled waterSurface roughness

The present invention discloses a roughness detecting method for the combined surface of a concrete prefabricated part. The method comprises the following steps of 1) cleaning sundries on the surfaceof a to-be-measured part before the test, selecting a suitable area, painting a layer of demoulding oil on the selected area, and fixing a stainless steel square frame on the area; 2) filling the stainless steel square frame by adopting the plasticine to enabling the parallel and level state of the surface of the stainless steel square frame; 3) removing the stainless steel square frame, and taking down the plasticine attached on the surface of the part; 4) kneading the plasticine into a whole block, weighing the plasticine in the air as m1 and accurate to 0.01 g, placing the plasticine in a mesh basket, placing the plasticine in the distilled water together with the mesh basket, weighing the plasticine in the water as m2 and accurate to 0.01 g, and calculating the roughness of the plasticine. According to the roughness detecting method for the combined surface of the concrete prefabricated part, the roughness of the concrete prefabricated part, in the horizontal, vertical and inclineddirections, can be tested.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

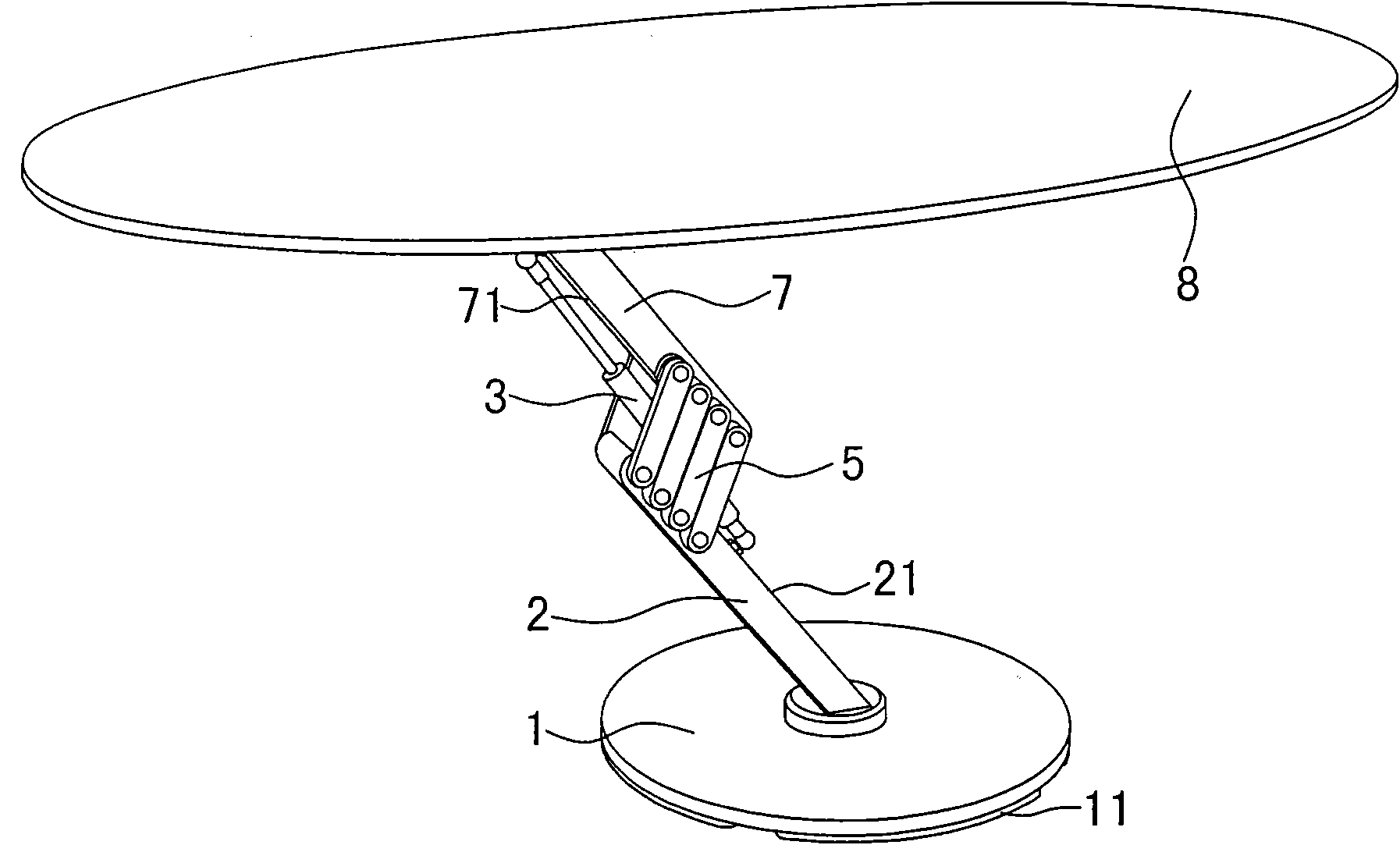

Inclined height-adjustable lifting table

InactiveCN102068114AAbility to withstandEasy to convertVariable height tablesArchitectural engineeringEngineering

The invention relates to an inclined height-adjustable lifting table. The table comprises a base, an oval table panel, and a lifting table leg for connecting the base with the oval table panel, and is characterized in that: the lifting table leg comprises a steel square declivitous support rod connected to the upper surface of the base, and a steel square acclivitous support rod connected to the lower surface of the oval table panel away from the center; the acclivitous support rod and the declivitous support rod are parallel to each other; the two sides of the acclivitous support rod and the two sides of the declivitous support rod are provided with steel connecting rods respectively, and at least two connecting rods are arranged on each side; and the inclined plane upper wall of the declivitous support rod and the inclined plane lower wall of the acclivitous support rod are provided with a cylinder. Through the technical scheme, the table only can be adjusted to a high position and a low position and is subjected to two-stage adjustment, but the height of the table can be adjusted conveniently and instantaneously; the steel square acclivitous support rod, the steel square declivitous support rod and the steel connecting rods have high strength and bearing capacity, so the table is stable; and the table is inclined, stands on one table leg, is like a galloping horse, and has a concise and elegant shape and attractive appearance.

Owner:叶根林

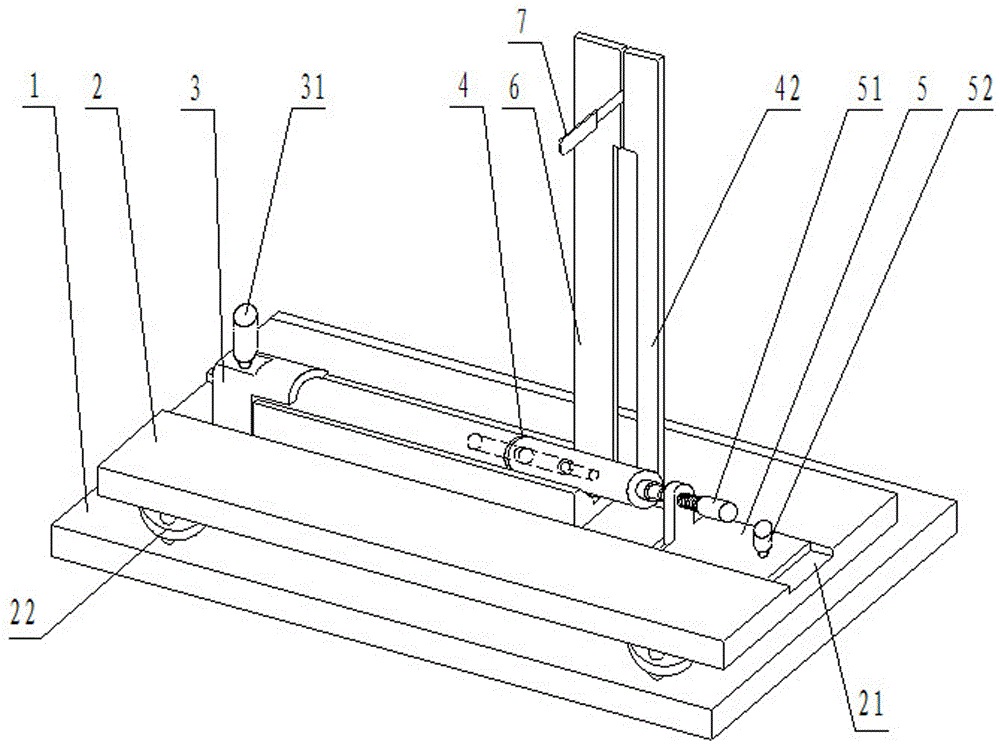

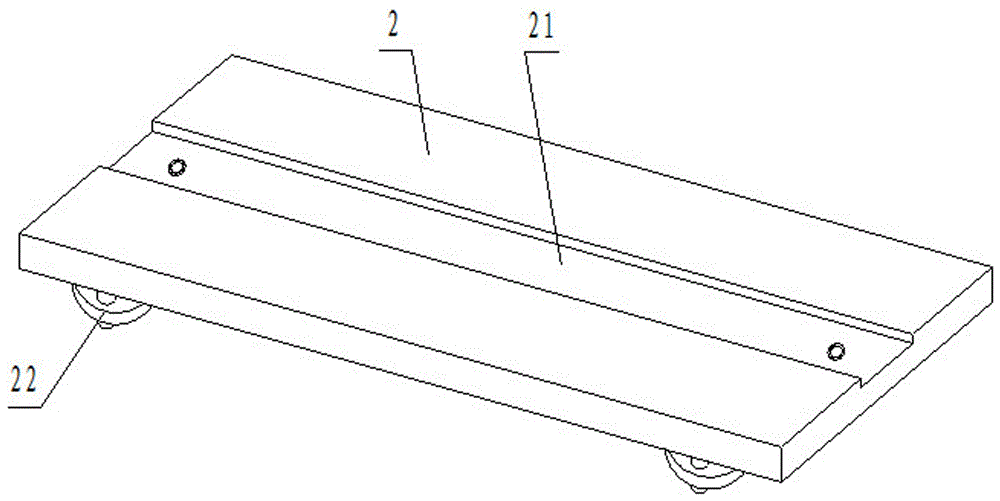

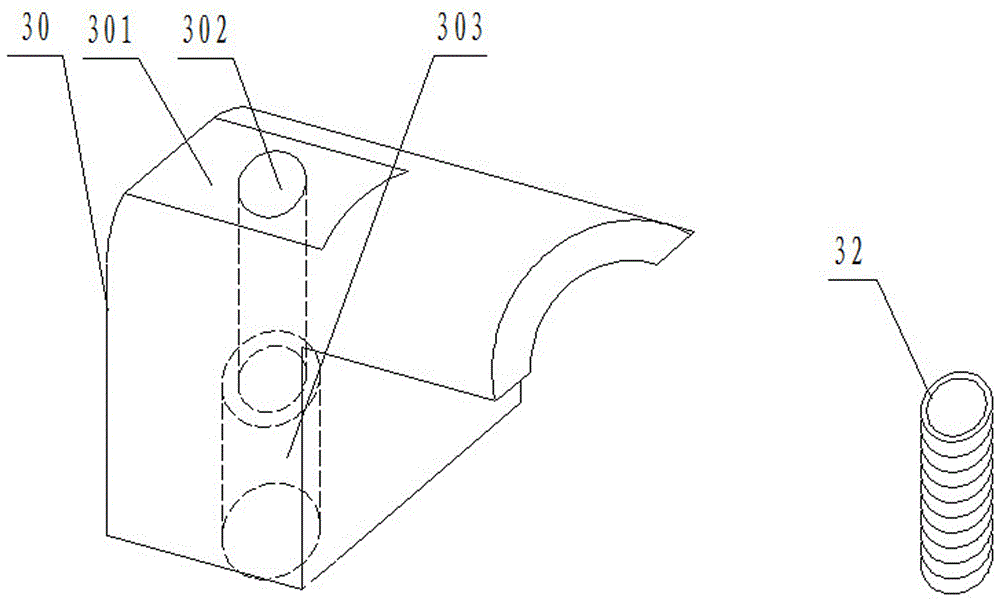

Arbitrary dip angle jointed rock sample coring chassis adjusting device

InactiveCN104458324AEasy to manufactureImprove drilling accuracyWithdrawing sample devicesProtractorCoupling

The invention discloses an arbitrary dip angle jointed rock sample coring chassis adjusting device. The device comprises a base, wherein vertical steel plates are arranged on two side surfaces of the base; an automatic lifting hydraulic jack is arranged on the base; the automatic lifting hydraulic jack is connected with a coupling plate by virtue of a shaft pin; the coupling plate is connected with a coupling support by virtue of a shaft pin; a steel plate tray with a fixed convex groove is arranged on the top of the coupling support; rigid transverse supporting rods are arranged on the vertical steel plates on the two side surfaces of the base by virtue of a shaft sleeve; two ends of the rigid transverse supporting rods are locked by virtue of a locking nut; and a protractor and a rock fixing device are arranged on the steel plate tray. According to simple automatic operation, rock samples containing different jointed rock angles are directly drilled by utilizing a conventional indoor rock drilling sampler, the instrument is easy to manufacture, the drilling precision is high, and the operation is convenient and reliable.

Owner:CHINA THREE GORGES UNIV

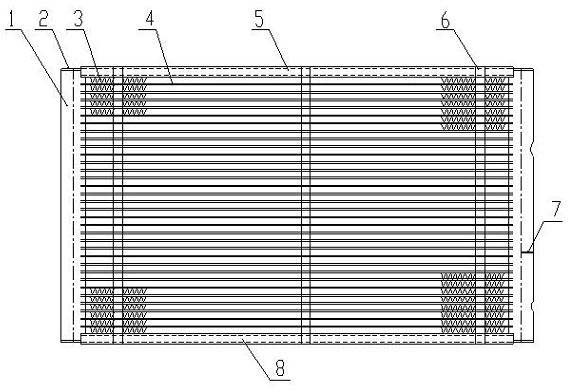

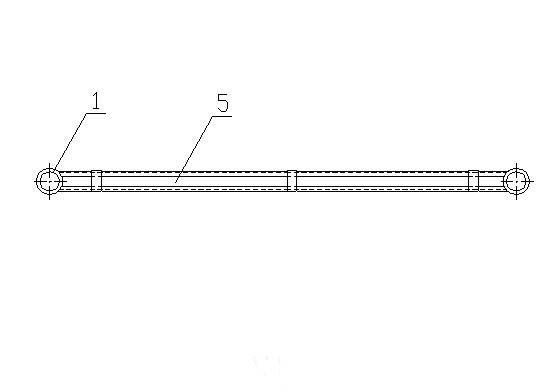

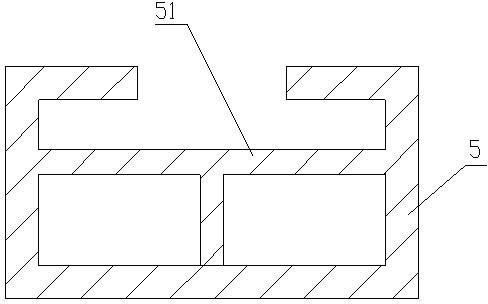

Method for producing and assembling micro-channel heat exchanger

ActiveCN102628654ALow costSolve the defect of deformationStationary conduit assembliesHeat exchanger casingsPlate heat exchangerNitrogen

The invention relates to a micro-channel heat exchanger technology, in particular to a method for producing and assembling a micro-channel heat exchanger. According to the method, the problems of deformation of a core body protective plate and oxidized black residues attached to the protective plate caused by that the core body of the micro-channel heat exchanger is reinforced by a stainless steel square pipe before braze welding are solved. The method is characterized in that porous flat pipes are arranged between collecting pipes on two sides uniformly in parallel; a radiating belt is arranged between the adjacent porous flat pipes; the end parts of the parallel and symmetrical collecting pipes are plugged by end covers; partition boards are arranged in the collecting pipe; the porous flat pipes are arranged on the inner sides of the radiating belts on the edge of the length direction of the collecting pipes; upper protective plates or lower protective plates are arranged on the outer sides of the radiating belts; the protective plates and the lower protective plates are bundled by a plurality of steel belts; the core body, bundled by the steel belts, of the micro-channel heat exchanger is conveyed to a nitrogen protection high-temperature brazing furnace to be welded; and after the core body of the micro-channel heat exchanger moves out of the nitrogen protection high-temperature brazing furnace, the steel belts are removed. According to the method, no deformation defect exists, the surface is smooth, clean and attractive, and production efficiency is high.

Owner:浙江康盛热交换器有限公司

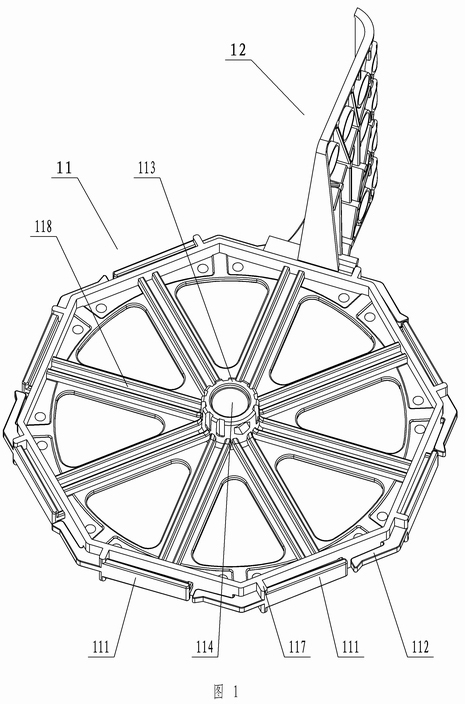

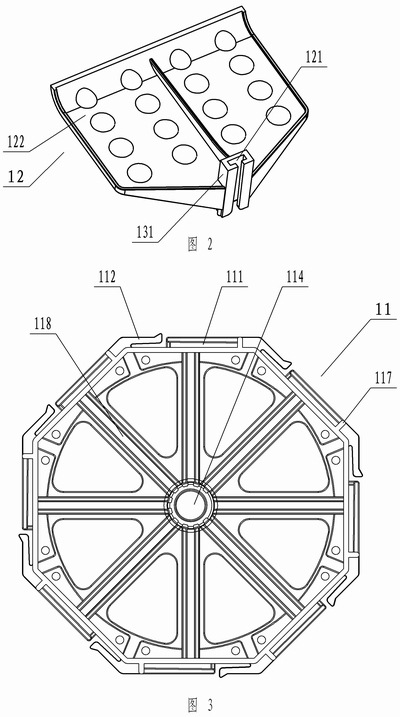

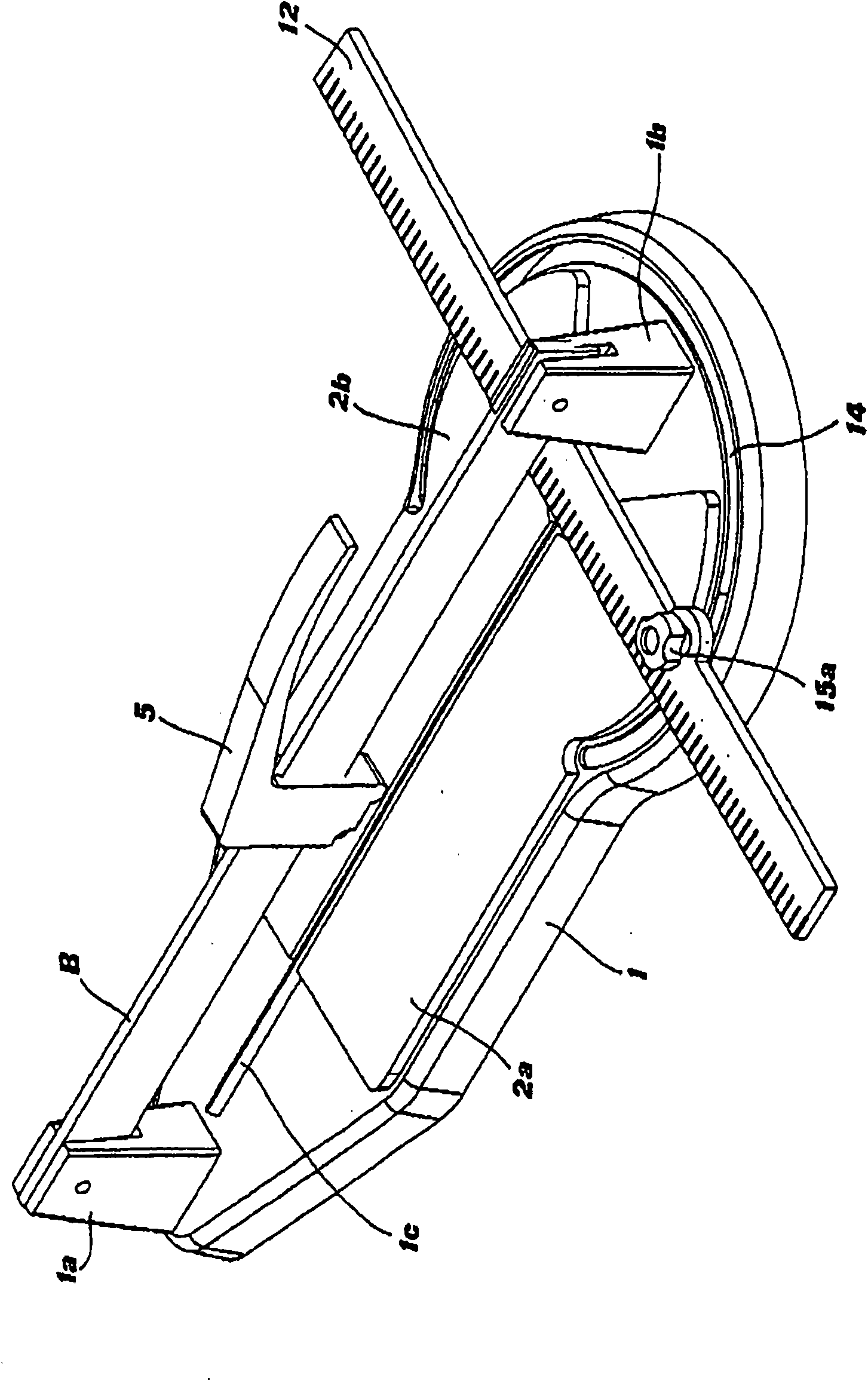

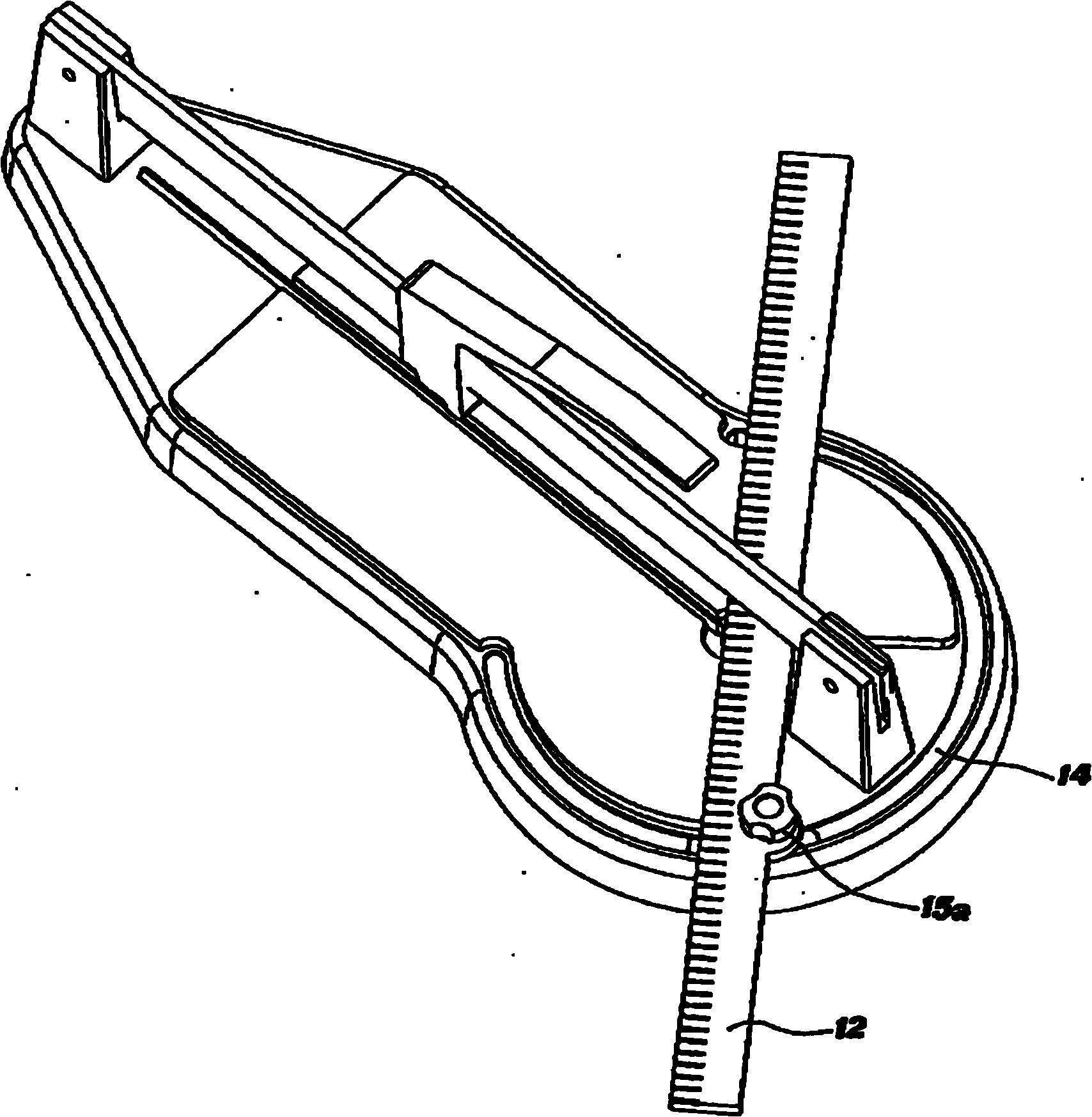

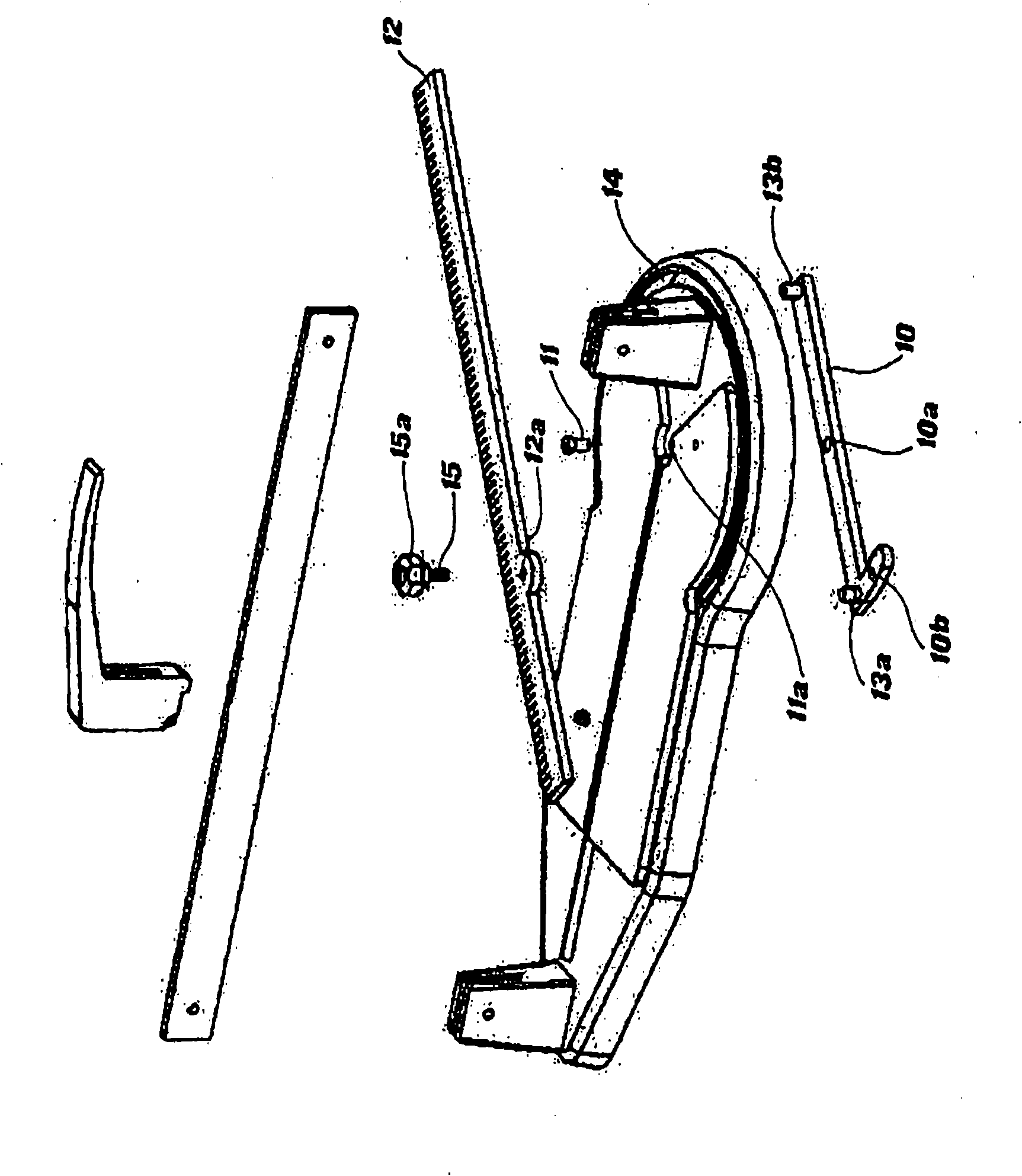

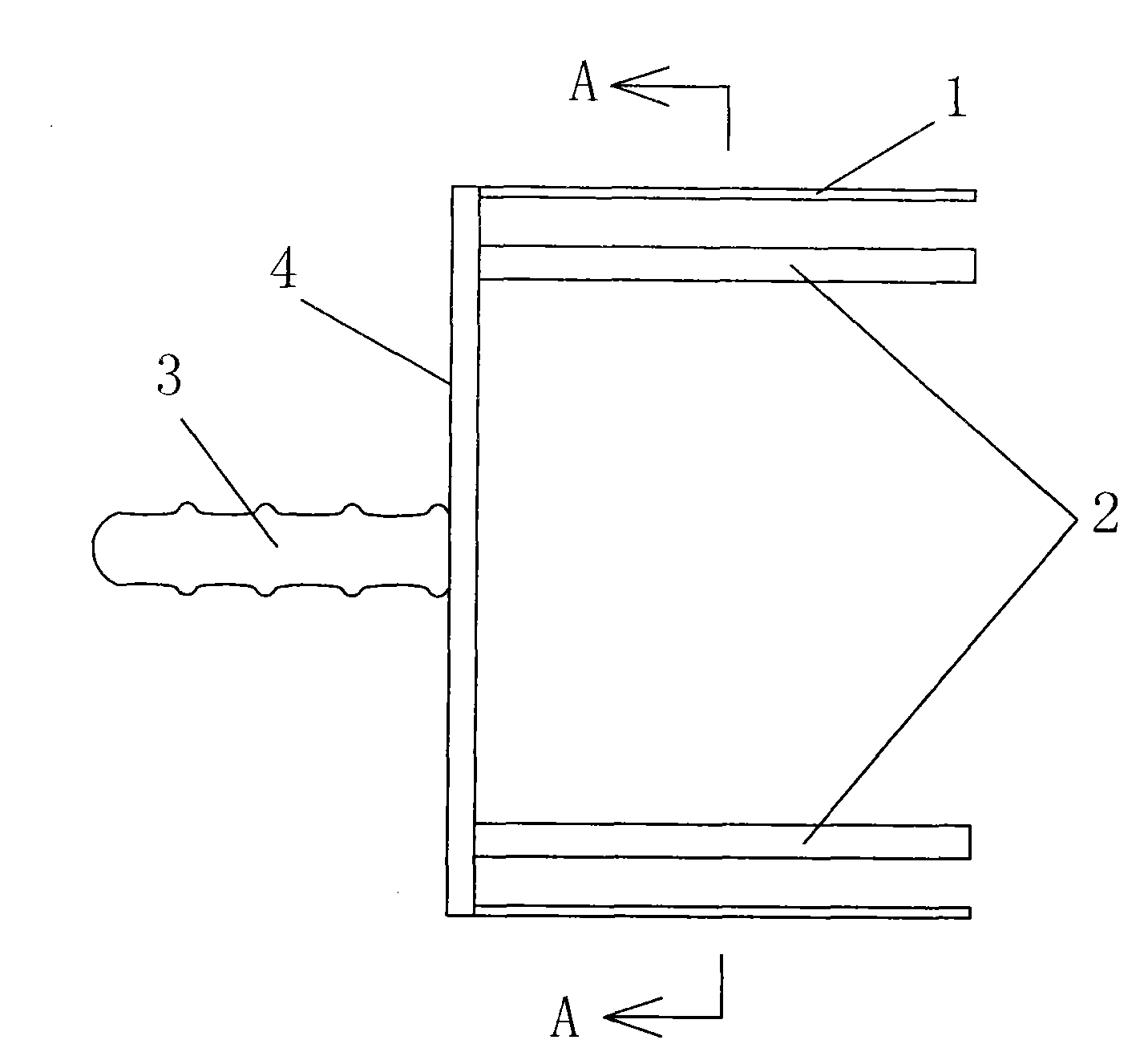

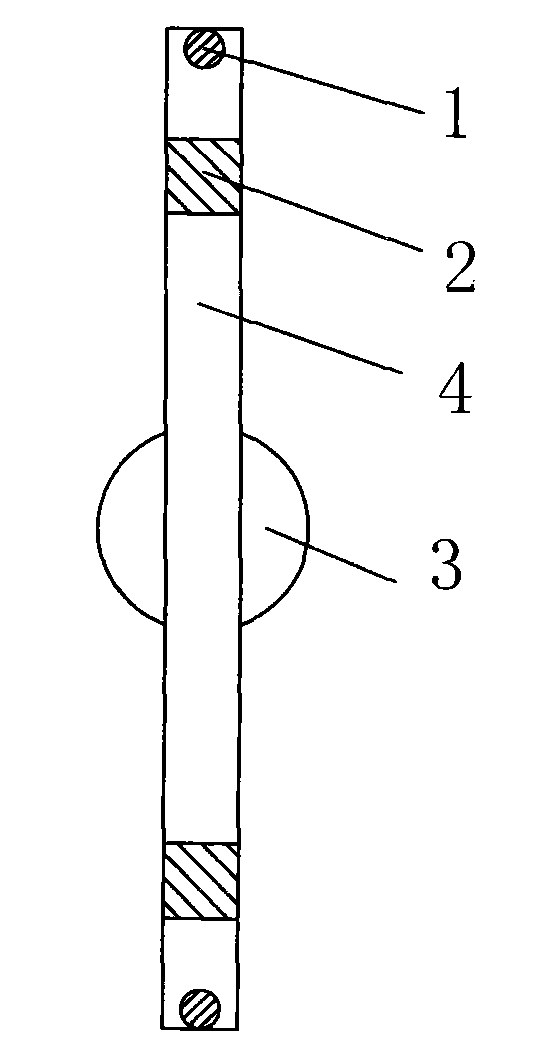

Manual tile cutter with improved rotating square

A manual tile-cutting machine is disclosed, of the type comprising a basement (1), a translation rail (B) for guiding a tool-carrying member (5) equipped with a cutting tool, and an abutment square, rotatably mounted on said basement, which consists of a lower rocker arm (10), rotatably mounted below a support plane of the basement (1), and an upper rectilinear ruler (12), arranged above the support plane and which may be coupled with said rocker arm (10) through mounting means (13a, 13b) which cross said support plane.

Owner:BREVETTI MONTOLIT

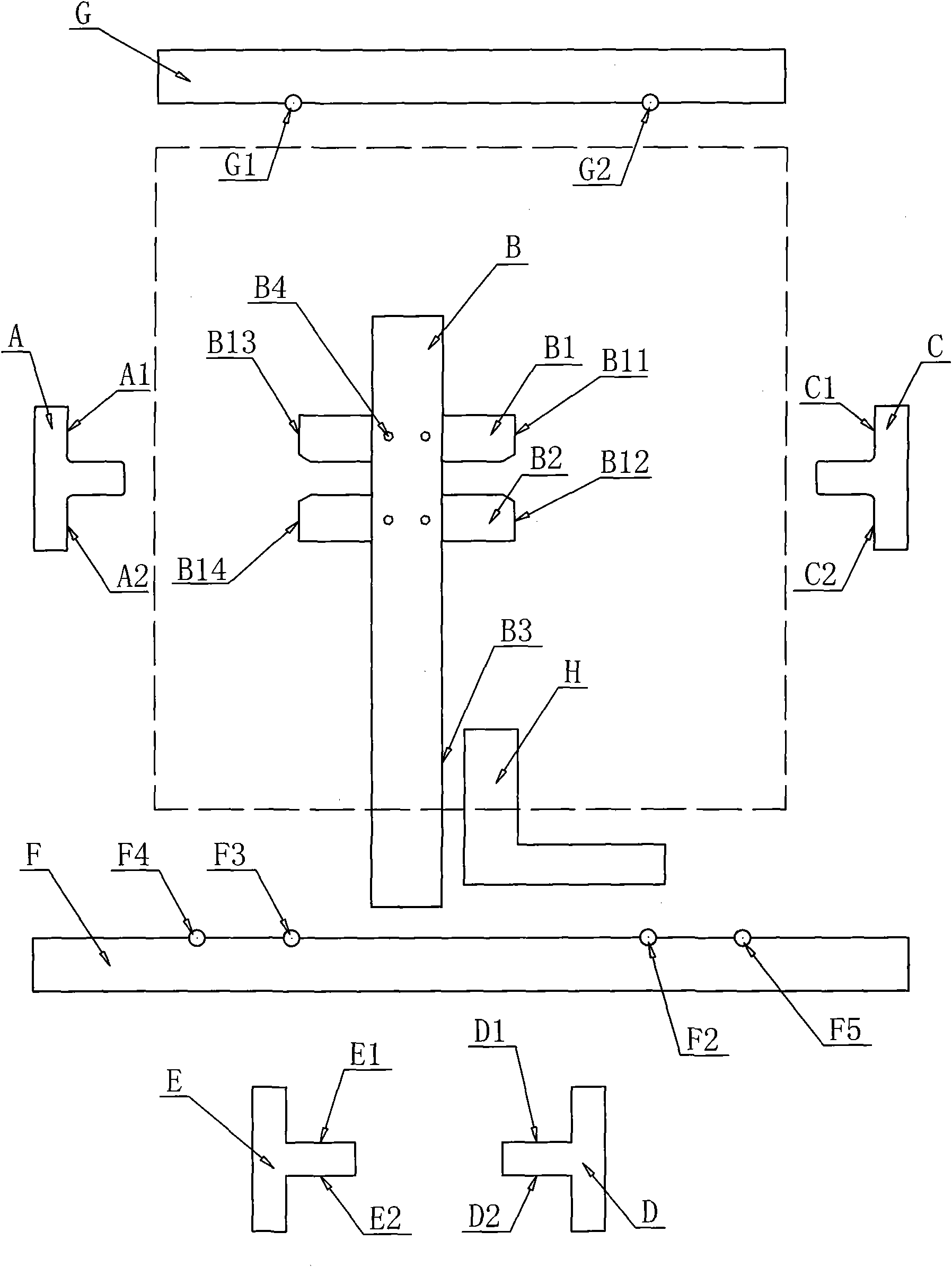

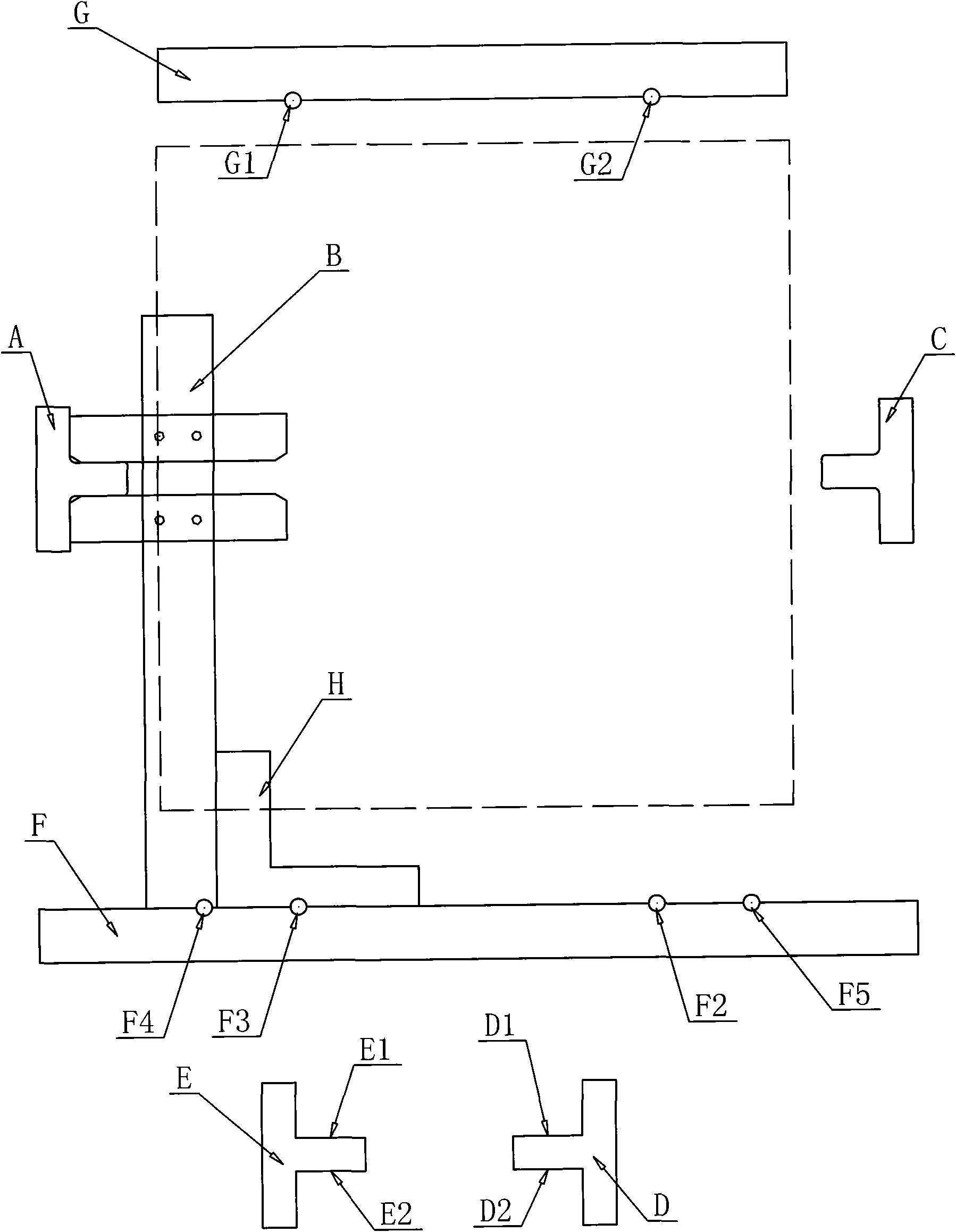

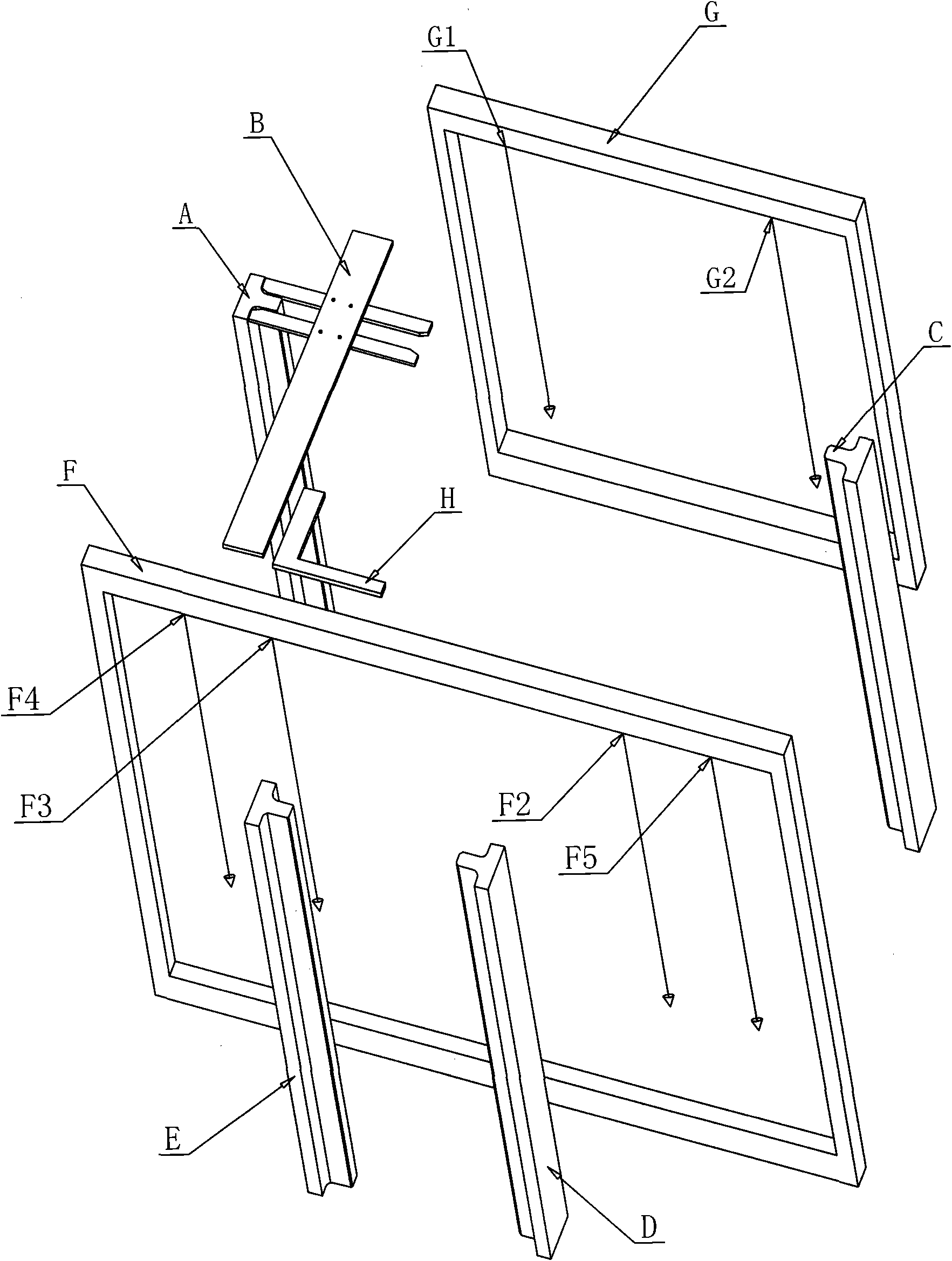

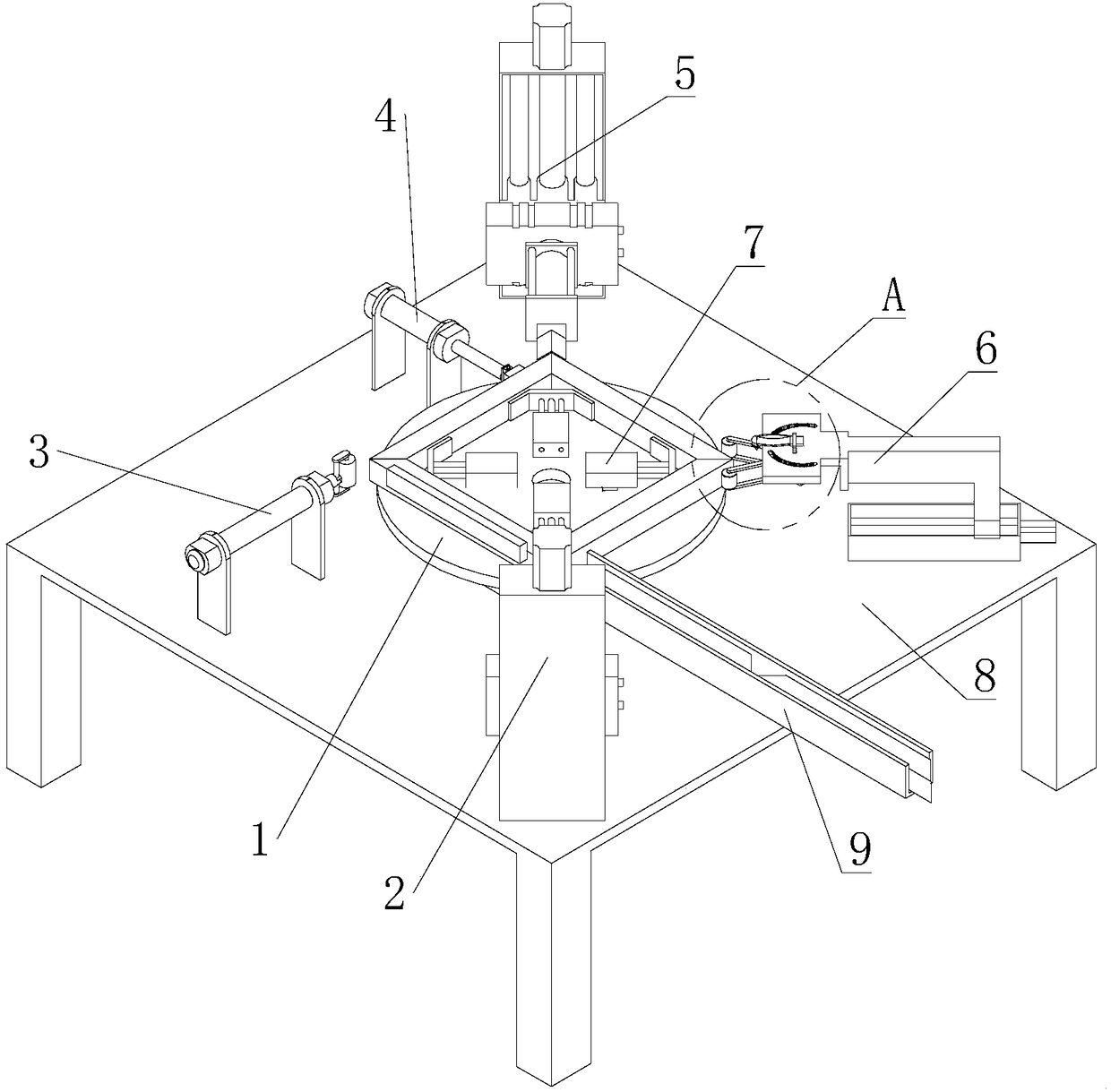

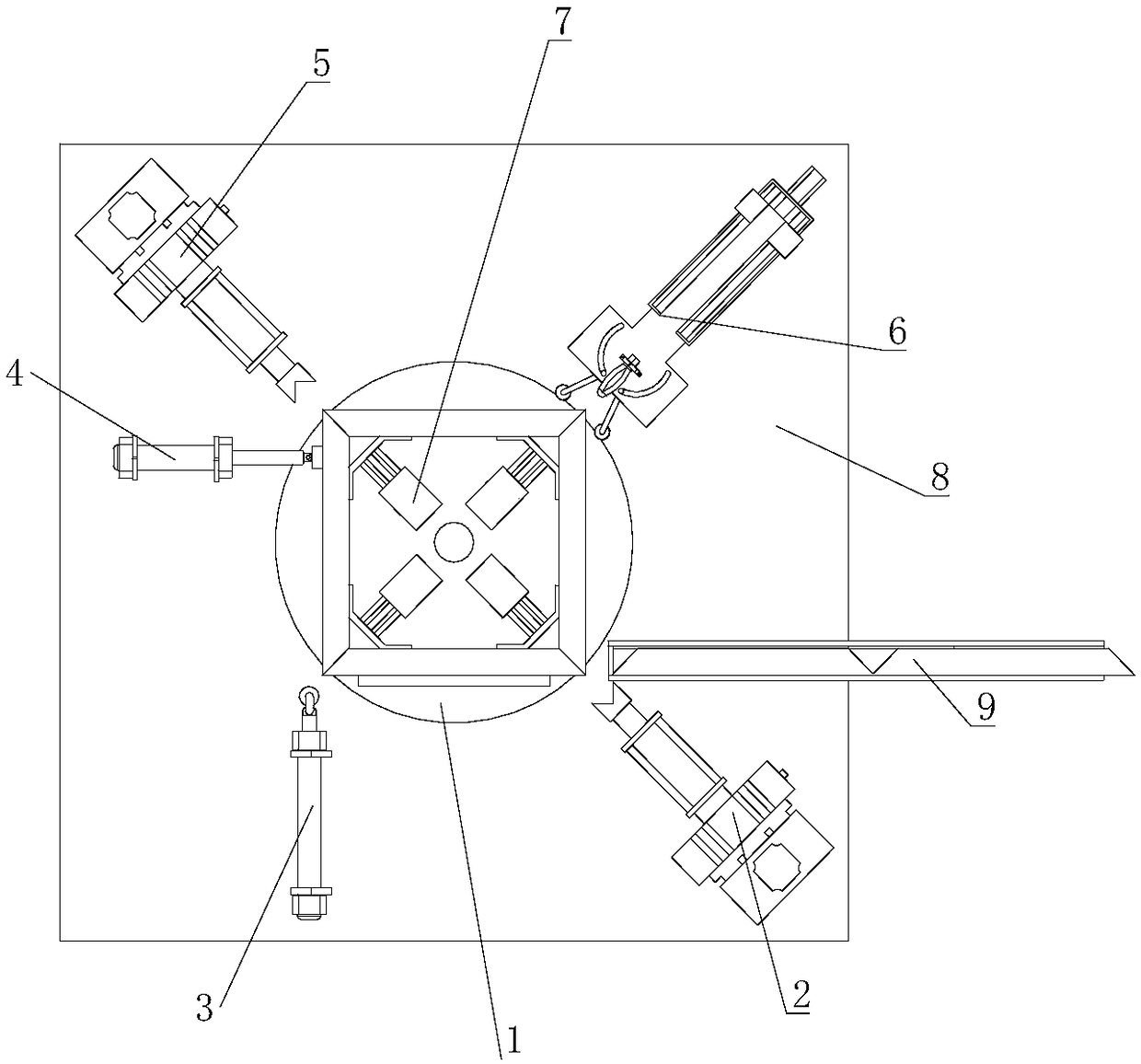

Automatic bending and welding equipment for door and window pipe materials

ActiveCN108581498AWill not deformWeld firmlyOther manufacturing equipments/toolsCircular discEngineering

The invention relates to the field of automatic machining, in particular to automatic bending and welding equipment for door and window pipe materials. The automatic bending and welding equipment comprises a base and further comprises a rotary workbench, a first overturning mechanical arm, a first bending assembly, a second bending assembly, a second overturning mechanical arm and a welding assembly. The rotary workbench comprises a stepping type index plate and a rotary disc. The rotary disc is provided with a clamping assembly used for fixing a square pipe. The first overturning mechanical arm, the first bending assembly, the second bending assembly, the second overturning mechanical arm and the welding assembly are sequentially arranged in the output direction of the rotary disc, and the first overturning mechanical arm, the first bending assembly, the second bending assembly, the second overturning mechanical arm and the welding assembly are all arranged on the base. The output endof the first overturning mechanical arm and the output end of the second overturning mechanical arm are arranged oppositely and extend in the axis direction of the rotary disc. By means of the automatic bending and welding equipment, bending of the stainless steel square pipes and the right angle welding work are achieved.

Owner:济南萨博特种汽车有限公司

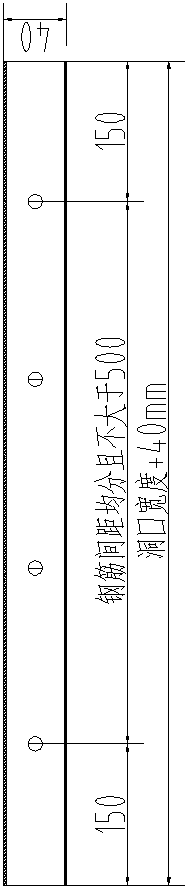

Waterproof node structure for door-window cave and construction method of external door-window pre-buried steel auxiliary frame

PendingCN107620543AWaterproof quality is reliableReduce hollowingFrame fasteningSealing arrangementsEngineeringCorrosion

The invention relates to a waterproof node structure for a door-window cave. The waterproof node structure is arranged at the door-window cave and comprises an anchoring part, wherein a steel auxiliary frame is fixed on the door-window cave through the anchoring part, a JS waterproof coating layer is arranged at one side of the joint of the steel auxiliary frame and the door-window cave, and an external facing layer is arranged on the outer surface of the JS waterproof coating layer. The periphery of the external door-window cave is optimized into a full-concrete structure by virtue of a detailed design of a drawing, 20mm*40mm*1.6mm hot-dip galvanized steel square tubes are pre-buried into the side surface of the periphery of the cave in the construction process of a main body structure, are cut according to a door-window size discharging list, the anchoring part is welded to the square tubes, and two sides of the square tubes are blocked by virtue of polystyrene foam, so that the flow-in of the concrete is avoided; the square tubes are fixed with an aluminum alloy template by virtue of self-tapping screws and are poured into a main body structure together with the concrete, and the steel square tubes are pre-buried, so that the pollution, damage and corrosion caused by later-period civil construction to doors and windows are avoided, the formation of a leakage channel is completely eradicated, the construction quality is guaranteed, and meanwhile, the cost is saved.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

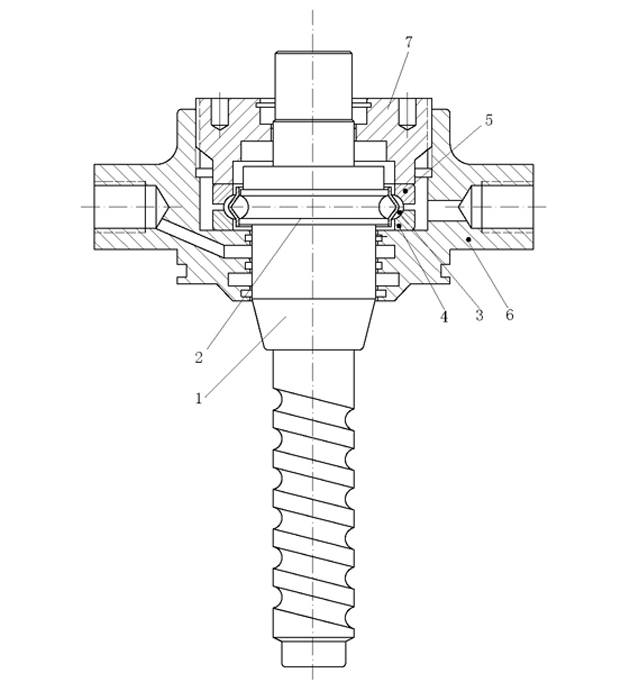

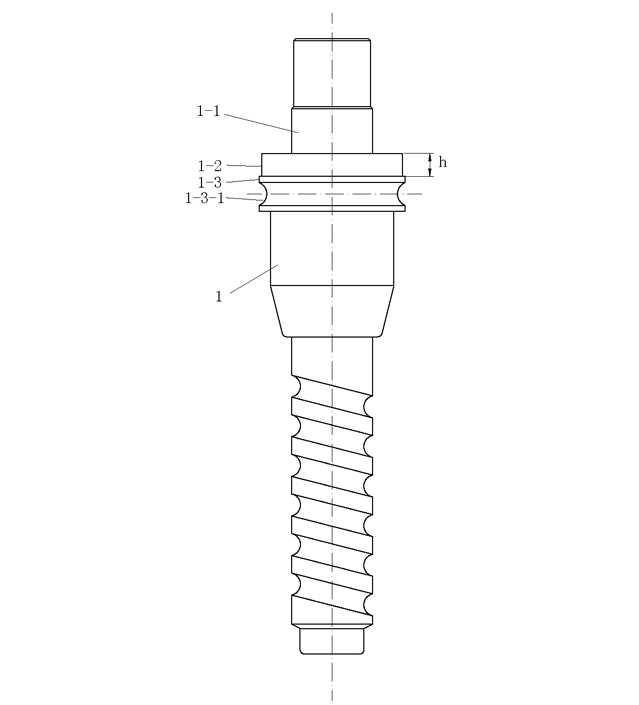

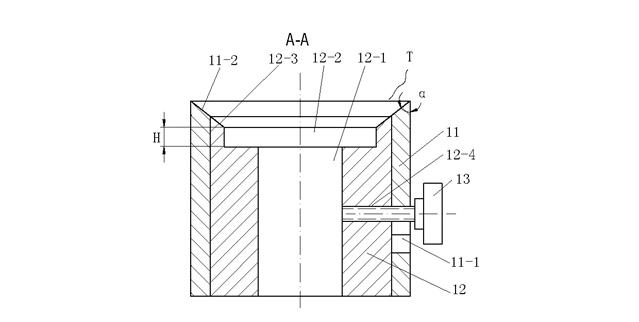

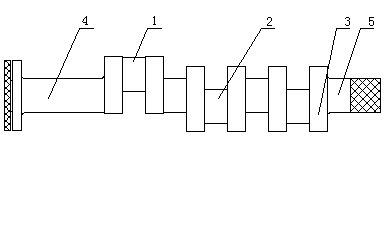

Assembly tool and assembly process for screw bearing of automobile steering device

ActiveCN102000968AEasy to take outIngenious designMetal working apparatusTransverse grooveSteel ball

The invention provides an assembly tool for a screw bearing of an automobile steering device. The assembly tool comprises an outer sleeve and an inner sleeve which is connected with the outer sleeve in a sliding way, wherein a flat bottom expansion hole is reserved on the upper part of a through hole of the inner sleeve; the orifice of the flat bottom expansion hole is provided with a chamfer; the outer sleeve is higher than the inner sleeve; the orifice of the higher end of the outer sleeve is provided with a chamfer; the chamfer part of the orifice of the outer sleeve and the chamfer port of the orifice of the inner sleeve form a feed hopper; a radial screwed hole is reserved on the lower part of the inner sleeve; an angle-square shaped groove consisting of an upper upright groove and a lower transverse groove is formed on the lower part, corresponding to the radial screwed hole of the inner sleeve, of the outer sleeve; and a locking screw is screwed into the radial screwed hole of the inner sleeve through the angle-square shaped groove on the outer sleeve. By using the assembly tool disclosed by the invention, a steel ball can automatically roll into each ball pocket of a retaining frame through the feed hopper which is formed by the orifices of the inner sleeve and the outer sleeve; and the steel ball can be wrapped in the outer sleeve by lifting the outer sleeve. The assembly tool has an ingenious design and a simple structure, and is convenient to use; moreover, the assembly time of the screw bearing is greatly reduced; and the product quality is stable.

Owner:常州市武滚轴承有限公司

Forging process of engine crankshaft

InactiveCN103691873ANo distortionGood quality forgingsEngine componentsEconomic benefitsMetal fibers

The invention discloses a forging process of an engine crankshaft. The forging process includes the following steps: 1), for first fire, holding a bar by a pressing clamp, biting the bottom, upsetting and drawing; 2), for second fire, upsetting, drawing and performing number printing, wherein number printing depth is 120; 3), for third fire, using a 120-degree up-down V-shaped anvil to perform turn grinding, finishing and straightening, wherein grinding shift amount is 170; 4), pressing a turn (2), using an angle square to determine an angle, pressing a turn (3), and pressing a turn (1); 5), performing number printing, pressing out a bottom end small shaft (5), and pressing out a small shaft (4) between a flange and the turn (1); 6), rounding the flange to be in a process size, using the angle square to check relative angle of all turns after reaching the required size, using a wrench to adjust the relative angle of the turns by taking a middle turn as a reference, chamfering sides of each turn, finishing, straightening and completing. Metal fibers of a forged crankshaft are continuous and free of distortion, the forged crankshaft is high in quality, long in service life, few in tool aid input, high in additional value and obvious in economic benefit, and the forging process is applicable to forging production of various crankshafts.

Owner:JIANGSU JINYUAN FORGE

Perpendicularity checking device for roller stand angle square positioning gauge of spinning machine

ActiveCN105806190AMeet toleranceGuaranteed to be accurateMechanical measuring arrangementsPulp and paper industrySteel square

Owner:ANHUI HUAMAO TEXTILE

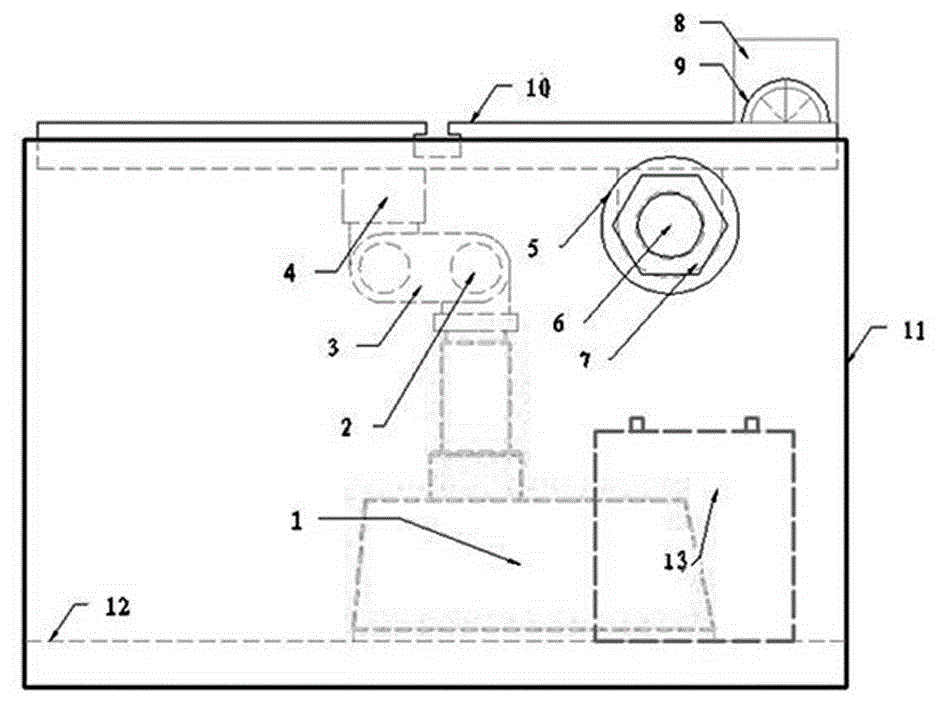

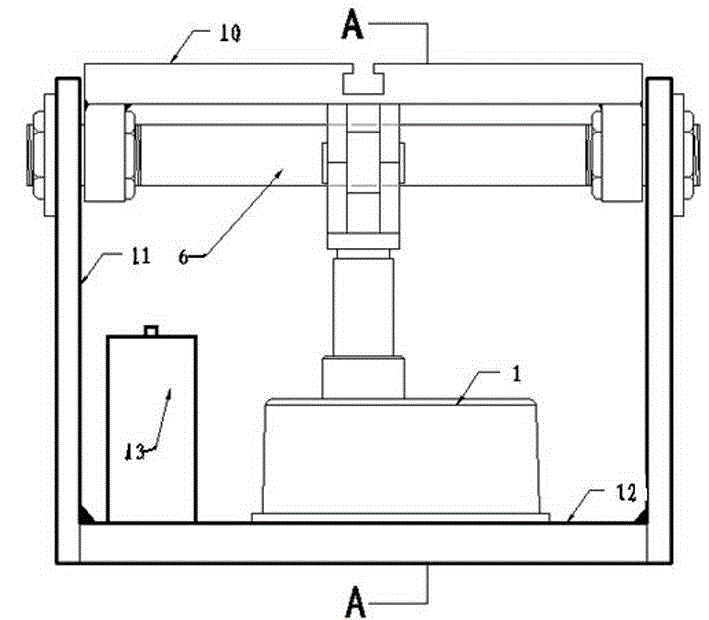

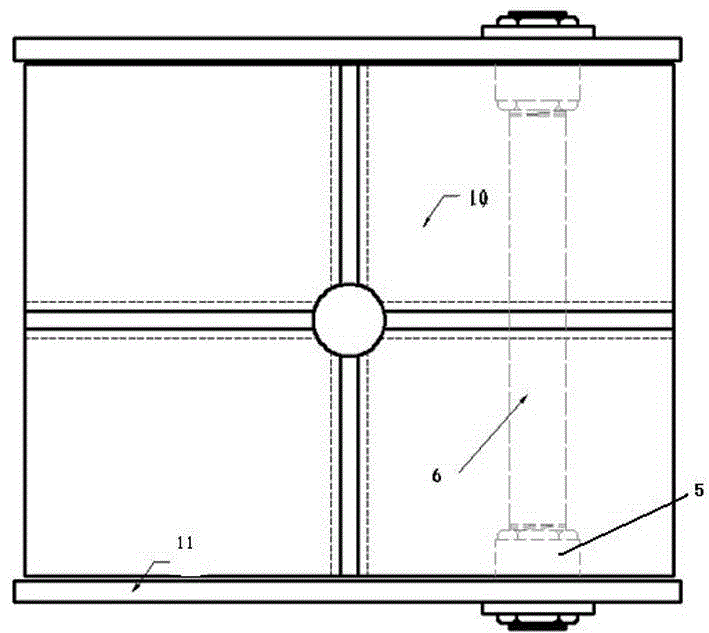

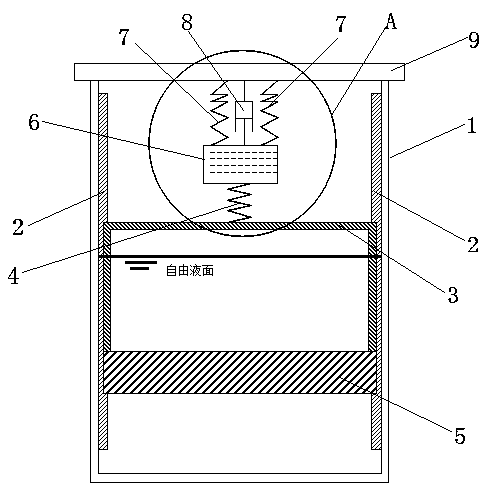

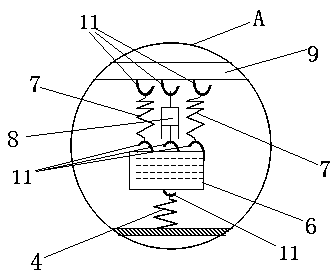

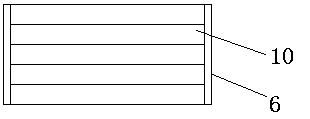

Vortex-induced vibration suppression experimental device based on nonlinear energy trap

ActiveCN110715782ASuppression of vortex induced vibrationSimple structureHydrodynamic testingVibration testingEngineeringMechanical engineering

The invention discloses a vortex-induced vibration suppression experimental device based on a nonlinear energy trap. The vortex-induced vibration suppression experimental device comprises an experimental water tank, a connecting and fixing device and a vibration damping device, wherein a water tank cover is arranged on the top of the experimental water tank; the connecting and fixing device comprises guide rails, a test piece, a support and a first spring, the guide rails are fixed on the inner walls of two opposite sides of the experimental water tank, the lower end of the support is connected with the test piece, the upper end of the support is connected with the first spring, and the cylindrical test piece and the support slide up and down along the guide rails; the vibration damping device comprises a stainless steel square box, a nonlinear spring and a linear damper, and the bottom surface of the stainless steel square box is connected with the first spring downwards; the bottom of the nonlinear spring and the bottom of the linear damper are connected with the stainless steel square box, and the top of the nonlinear spring and the top of the linear damper are connected with the water tank cover; a plurality of slots are formed in the side surface of the stainless steel square box, and mass sheets are selectively inserted into the slots. The vortex-induced vibration suppression experimental device provided by the invention is simple in structure, various adjustable parameters such as design mass, rigidity and damping are designed, and vortex-induced vibration can be effectively suppressed.

Owner:HOHAI UNIV

Nonmagnetic soft stainless steel wire rod or stainless steel plate and method of manufacturing same

The invention relates to a nonmagnetic soft stainless steel wire rod or stainless steel plate and a method of manufacturing the same. The stainless steel wire rod or stainless steel plate comprises the following components: C which is more than 0 percent and is less than or equal to 0.050 percent, Si which is more than 0 percent and is less than or equal to 1.00 percent, Mn which is equal to 8.00-15.00 percent, P which is less than or equal to 0.045 percent, S which is less than or equal to 0.030 percent, Cr which is equal to 13.00-18.00 percent, Ni which is equal to 4.00-8.00 percent, Cu which is equal to 1.50-4.00 percent and N which is more than 0 percent and is less than or equal to 0.050 percent. The method of manufacturing the nonmagnetic soft stainless steel wire rod or stainless steel plate comprises the following steps: A, steel billet is made by the alloy of the molten iron, the Cr, the Ni, the Mn and the Cu, and the steel billet is cast continuously into the stainless steel square billet or the stainless steel slab; B, heating the stainless steel square billet or the stainless steel slab to 1240-1260 DEG C and preserving the temperature of the stainless steel square billet or the stainless steel slab at 1240-1260 DEG C for 1.5-3 hours; C, rolling the stainless steel square billet into the stainless steel wire rod which has a diameter of 5.5-20 mm, or rolling the stainless steel slab into the stainless steel plate which has a thickness of 3-8 mm and a width of 1000-1300 mm; D, reeling the stainless steel wire rod or the stainless steel plate; and E, cooling the stainless steel wire rod or the stainless steel plate. The stainless steel wire rod or the stainless steel plate which is manufactured with the method has good cold processing performance and low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Device for quickly forming orthodontic ligature wire

The invention provides a device for quickly forming an orthodontic ligature wire. Two ends of a stainless steel side frame are respectively connected with stainless steel round wires; two stainless steel square wires the cross sections of which are in round rectangles are respectively positioned at the inner sides of the stainless steel round wires and are connected with the stainless steel side frame; the two stainless steel round wires and the two stainless steel square wires are mutually parallel; and a handle which is in the same direction with the stainless steel round wires and is connected with the stainless steel side frame in the vertical direction is arranged at the middle part of the other side of the stainless steel side frame. The tip of the ligature wire formed by the invention is in a semicircle (about 2mm), thus the ligature wire can be conveniently hung on a hook with a ring in the back ligaturing process of canine teeth. When a bracket is ligatured, an approximately square part in the middle of the formed ligature wire is arranged parallel to an arch wire and is placed below a bracket wing and then pulled to the other direction along the traveling direction of the arch wire, so that the ligature wire can be placed below the bracket wing for ligaturing.

Owner:王兰磊

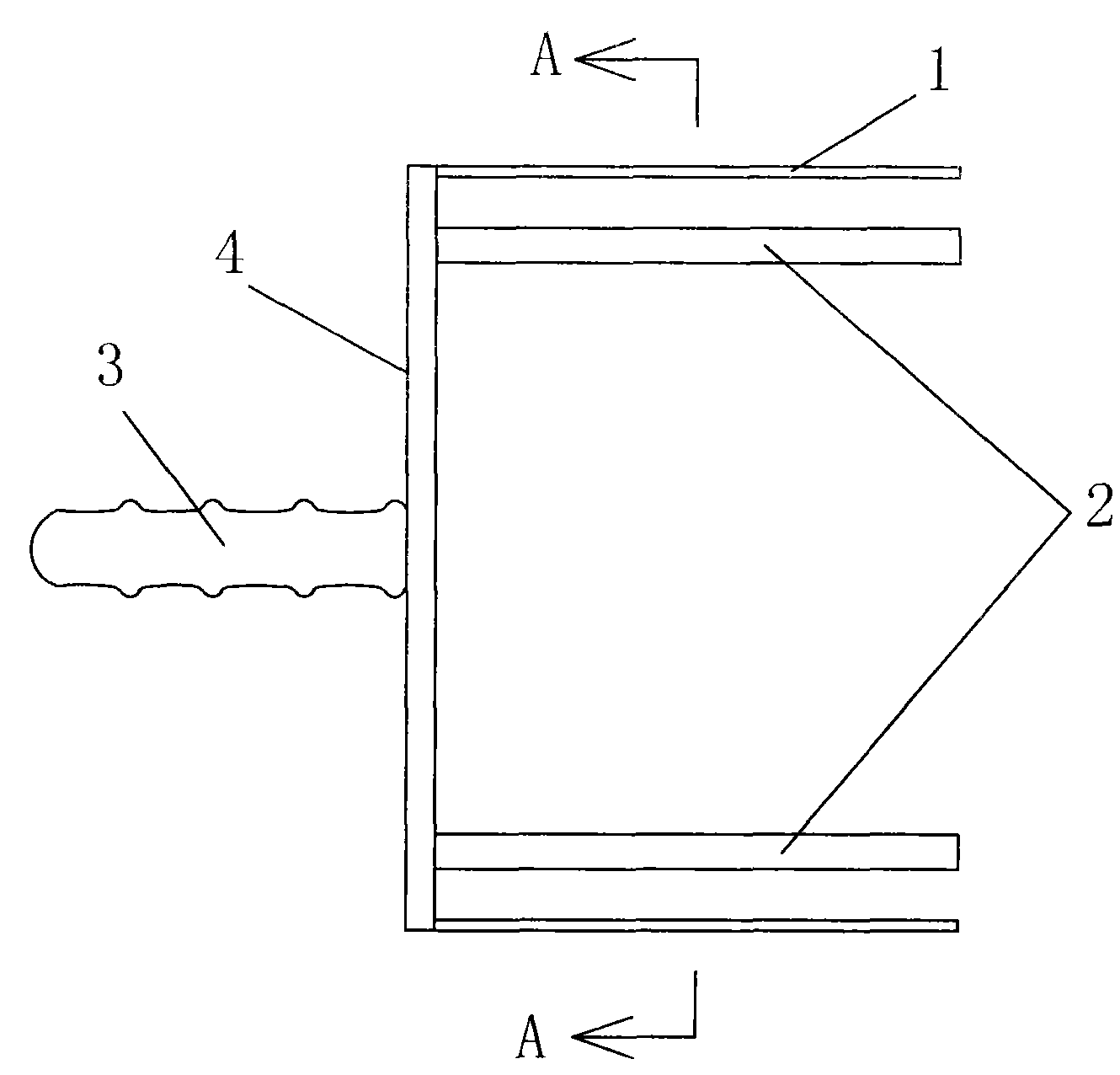

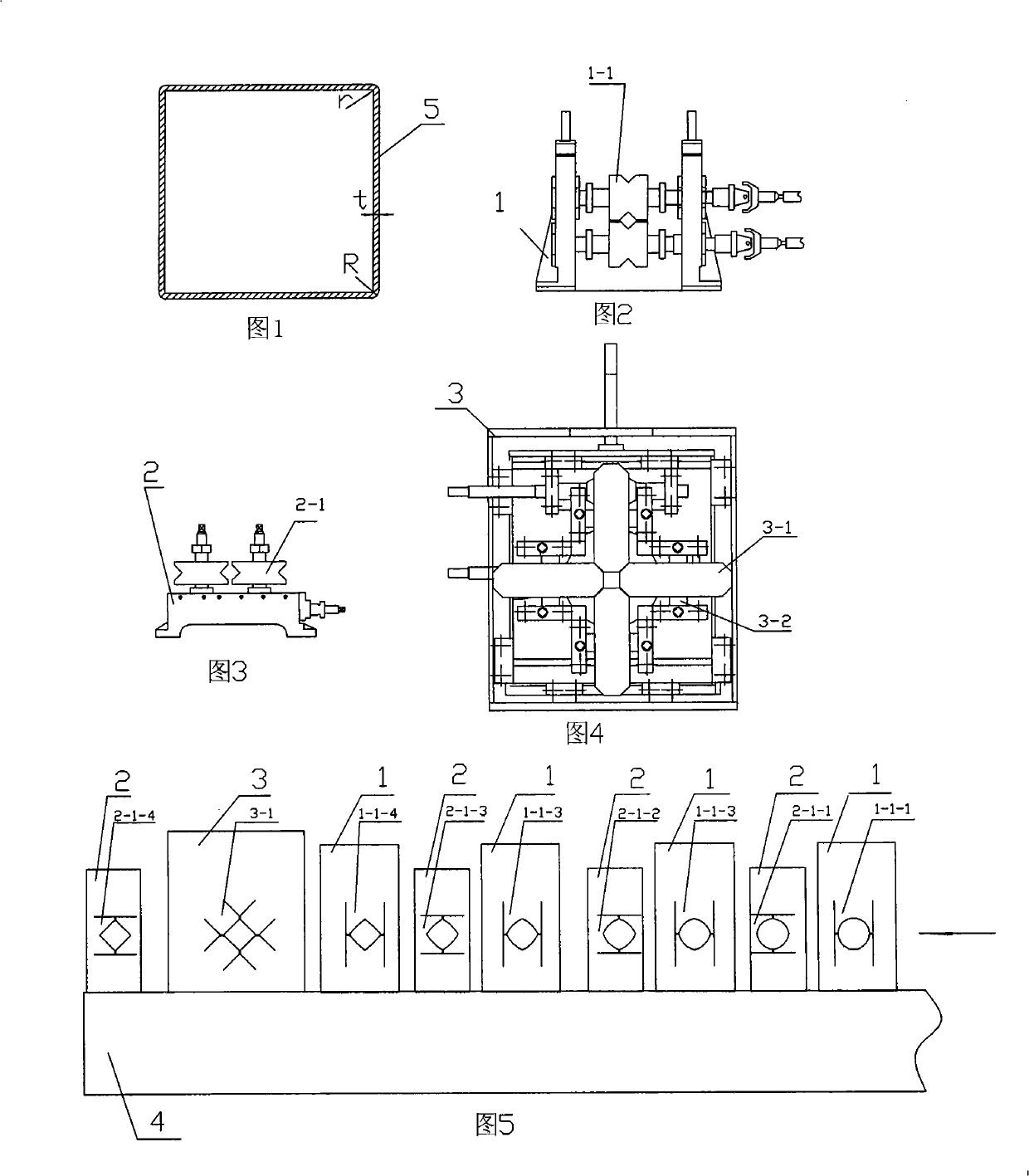

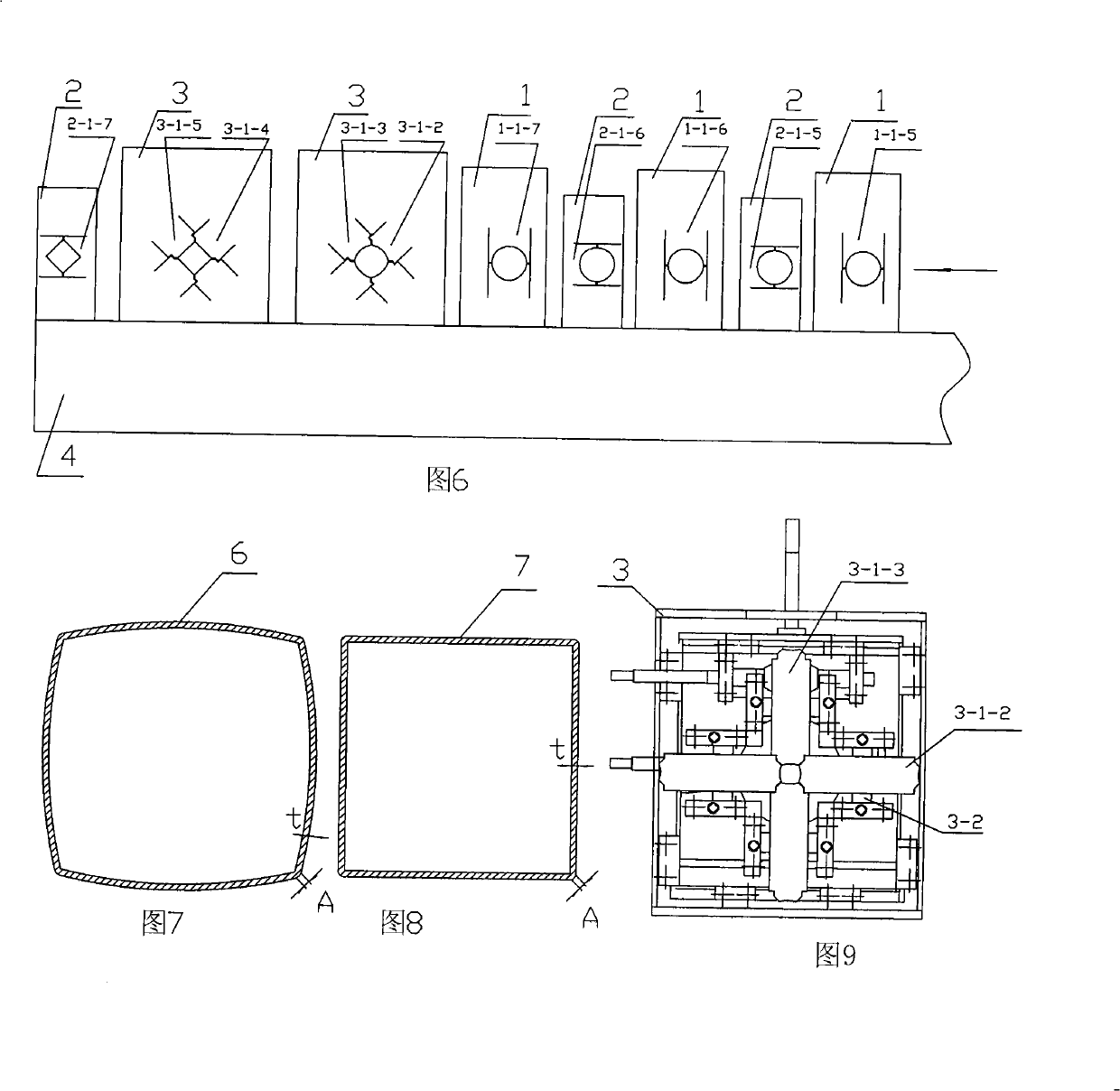

Thin wall non-corrodible steel sharp corner square, rectangular pipe and its production facility

InactiveCN101334120AHigh positioning accuracyHigh dimensional accuracyRollsRigid pipesVertical edgeMaterials science

The invention discloses a thin wall stainless steel taper angle square or rectangular pipe and the production equipment thereof. Four angles of the thin wall stainless steel taper angle square or rectangular pipe are all taper angles and substantially identical, thus the interchangeability is good when the pipes are butted. The production equipment and process route for manufacturing the thin wall stainless steel taper angle square or rectangular pipe adopt the following steps that at least a first plain barreled roll machine frame, a second vertical edging roll machine frame, a third plain barreled roll machine frame, a fourth vertical edging roll machine frame, a fifth plain barreled roll machine frame, a sixth Turkish head machine frame, a seventh Turkish head machine frame and an eighth vertical edging roll machine frame are installed and arranged in sequence, circular hole type rollers are installed in the plain barreled roll machine frames and the vertical edging roll machine frames in front of the Turkish head machine frames, four square or rectangular hole type rollers mutually positioned with the rollers are respectively installed in the two Turkish head machine frames, and a square or rectangular hole type roller is installed in the vertical edging roll machine frame installed at the back of the Turkish head machine frames. The thin wall stainless steel square or rectangular pipe of the invention can be widely applied in fields of various construction and decoration projects.

Owner:金奎文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com