Patents

Literature

149results about How to "Intuitive measurement results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

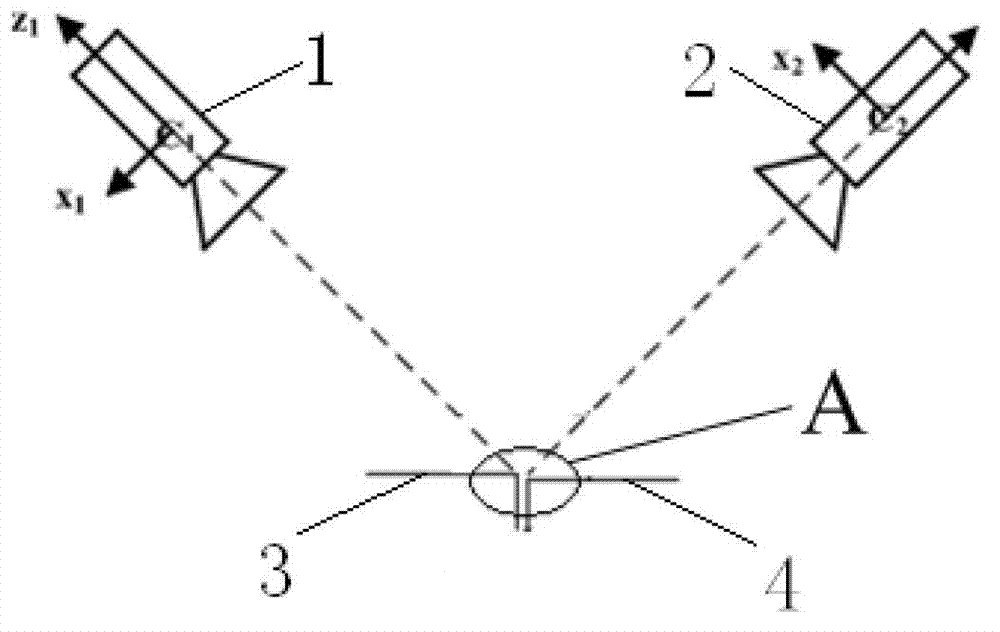

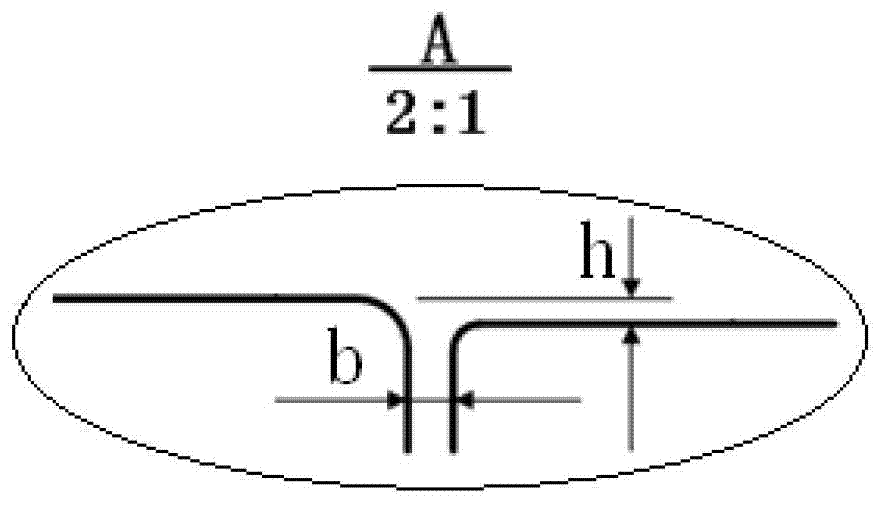

Non-contact online inspection method for automobile body gap size

InactiveCN103075973AEasy to operateSmall amount of calculationImage enhancementUsing optical meansIn planeCalibration result

The invention discloses a non-contact online inspection method for automobile body gap size, aiming at overcoming the problems that the size of equipment is large, the equipment is inconvenient to carry, influences are apt to cause by external factors due to contact-type measurement, and online measurement and large-size covering part gap measurement cannot be realized in the prior art. The non-contact online inspection method comprises the following steps of: 1. camera calibration; 2. image acquisition: placing a gap part of an automobile body covering part in the view field of a camera to take images; 3. stereoscopic matching; and 4. three-dimensional reconstruction, which comprises the steps of: 1) according to a calibration result of a binocular stereoscopic visual system, determining three-dimensional space coordinates of gap edge points of the covering part according to stereoscopic matching points; 2) reconstructing an automobile body gap three-dimensional curve according to the determined three-dimensional space coordinate points; 3) spatially rotating the reconstructed three-dimensional curve according to included angles and directions between the curve and an x-axis, y-axis and a z-axis; and 4) respectively projecting gap curves in planes after rotation to determine the width value and the plane difference value of the gap.

Owner:JILIN UNIV

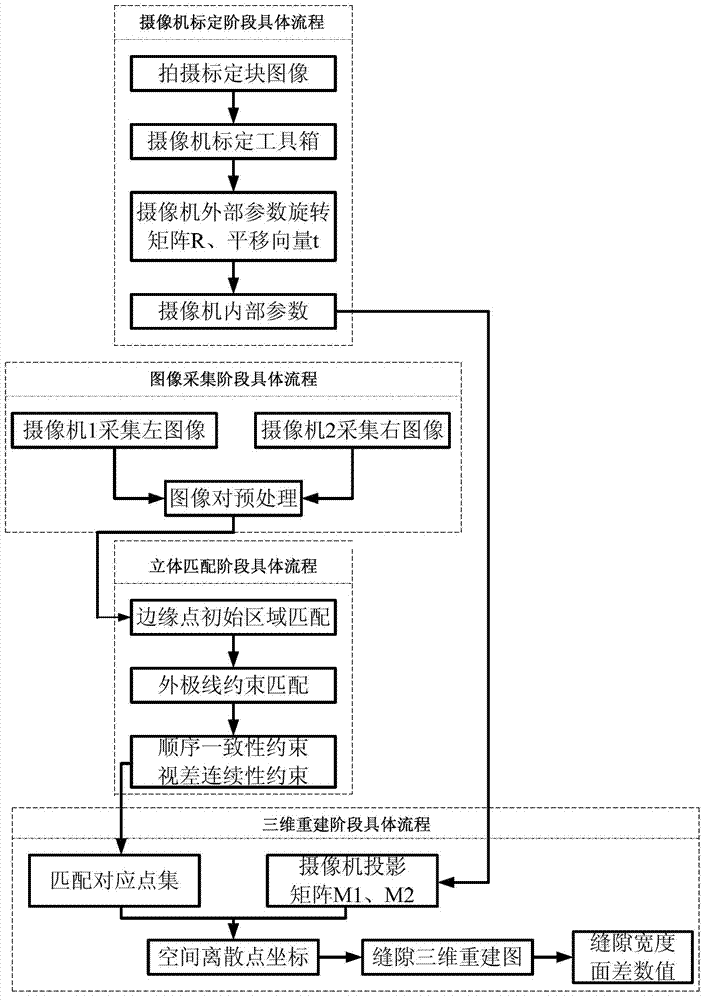

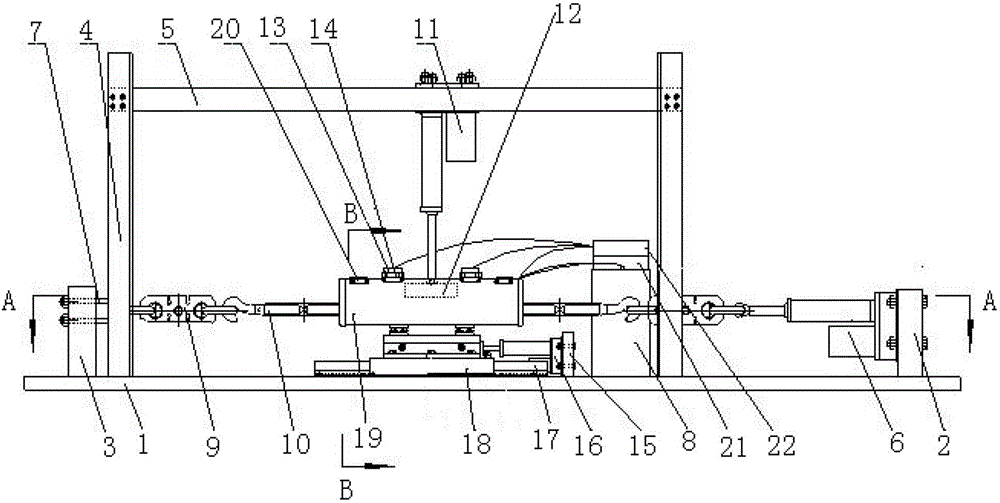

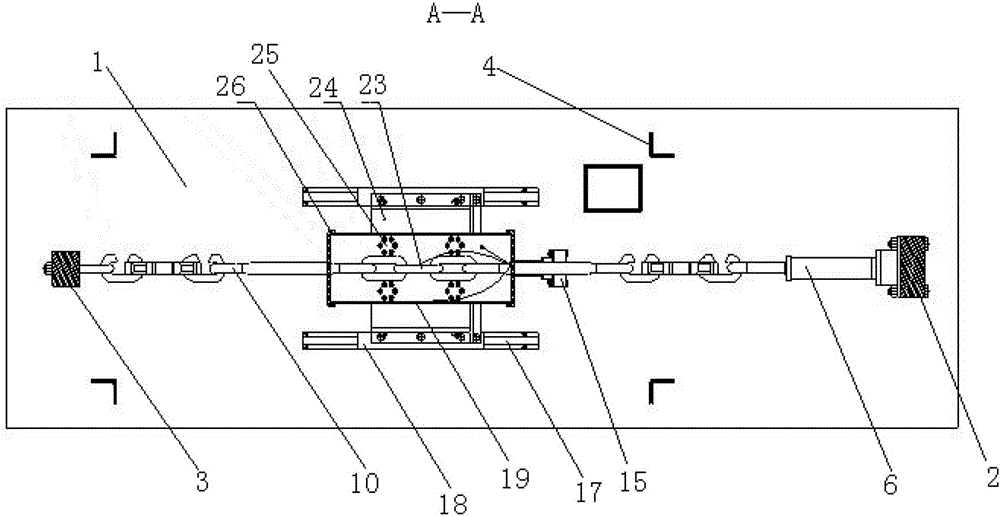

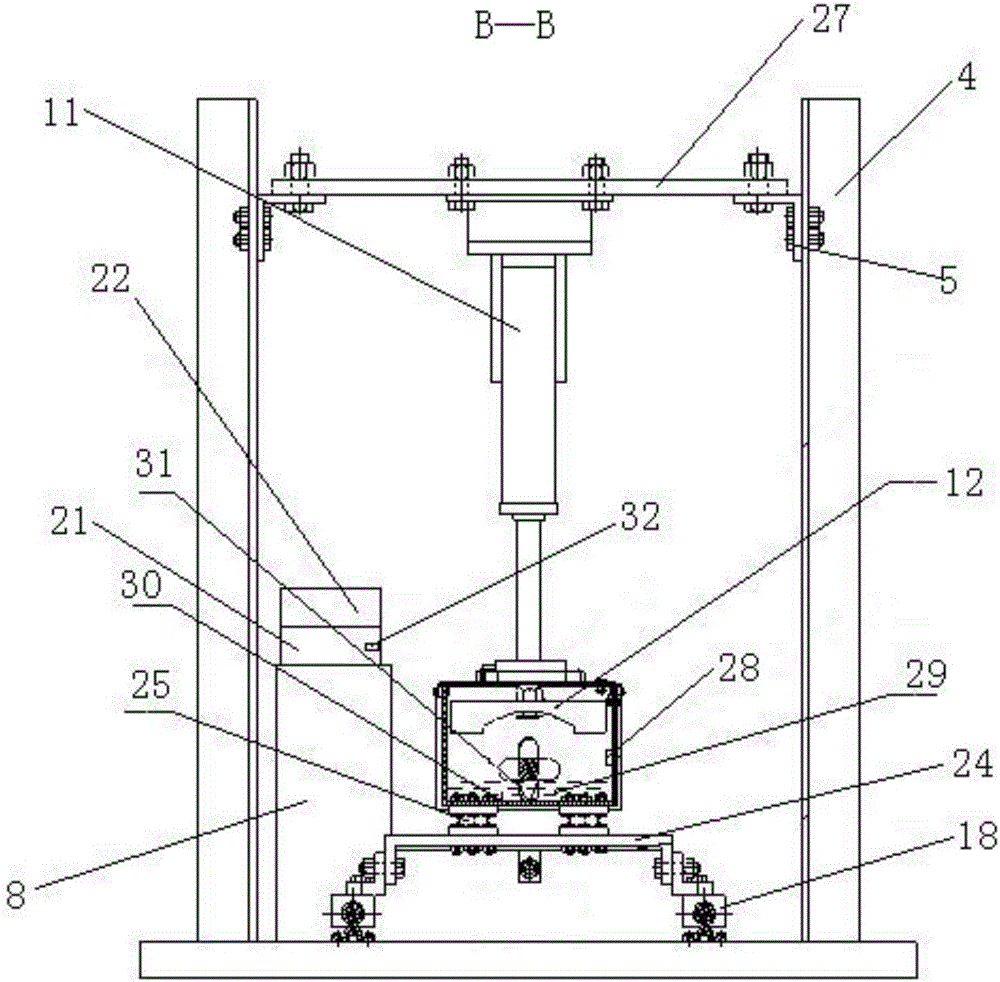

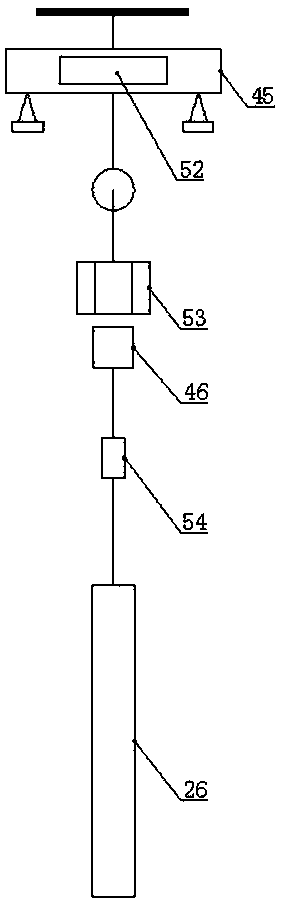

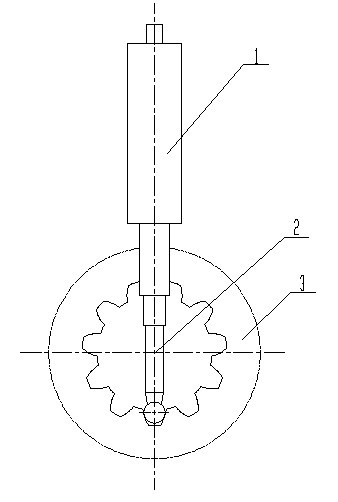

Measuring apparatus and method for transmission accuracy of gear pair

InactiveCN101271038AEasy to adjustEasy clampingMachine gearing/transmission testingTurn angleElectric machine

The invention relates to a gear pair transmission precision measuring device and a method, which belongs to the technical field of gear pair transmission precision measurement. The device essentially includes a turning angle input part, a turning angle output measuring part and a computer data collecting, analyzing and processing part, wherein, the turning angle input part and the turning angle output measuring part respectively include an angle sensor. The method includes the following steps: (a) a computer controls the rotating angle and speed of a servo motor (2) according to the speed ratio of a gear pair, and collects the data from an input angle sensor (1) and an output angle sensor (15) at the same time; (b) the computer completes the peak removal, value filtration and error curve outline extraction of the data from the sensors, and adopts the right-angle coordinate and the polar coordinate to display the transmission error, backlash and deviation tendencies of each point of the gear pair. The device and the method have the advantages of good reliability, fast measuring speed, high measuring precision and wide scope of measurement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

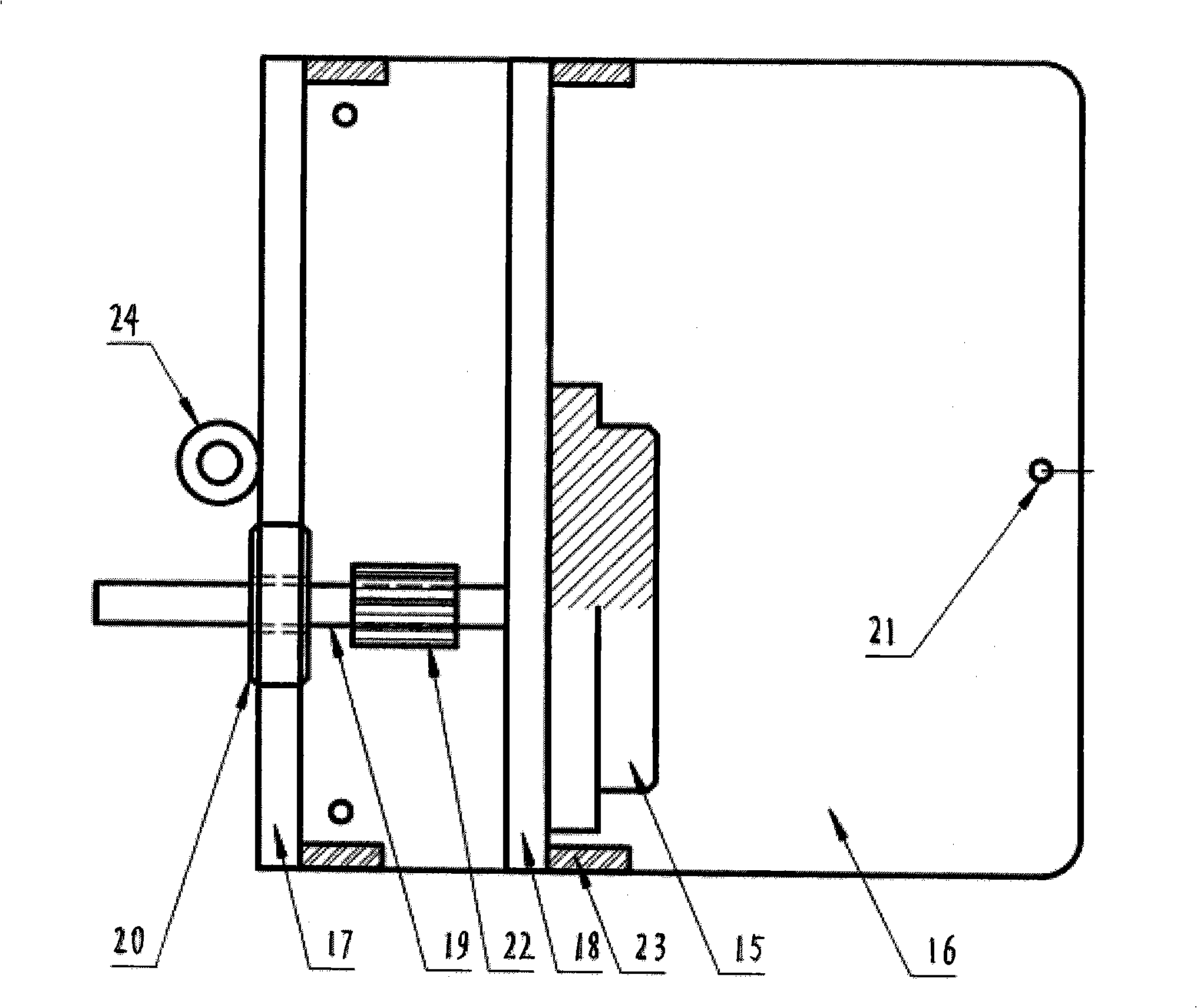

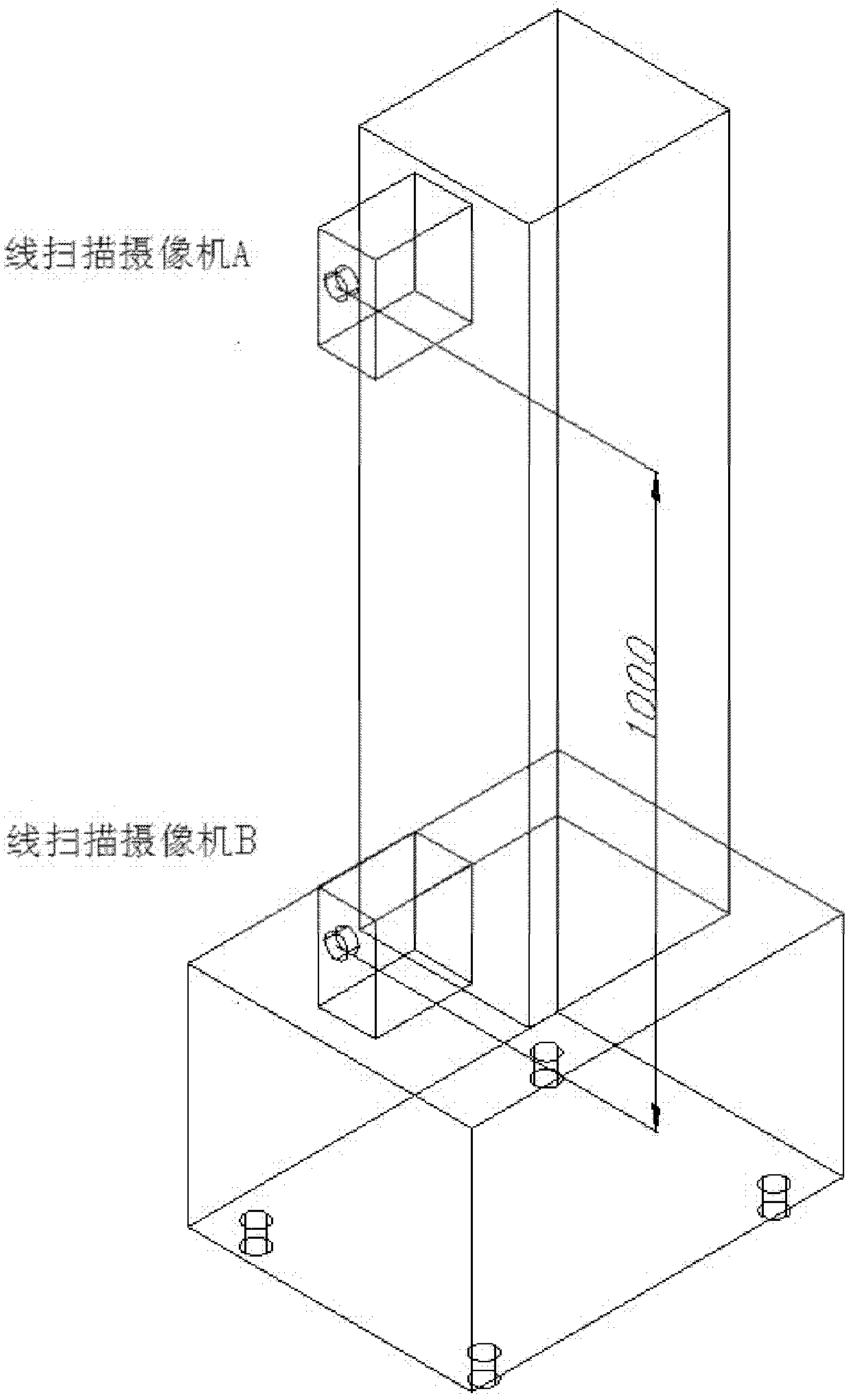

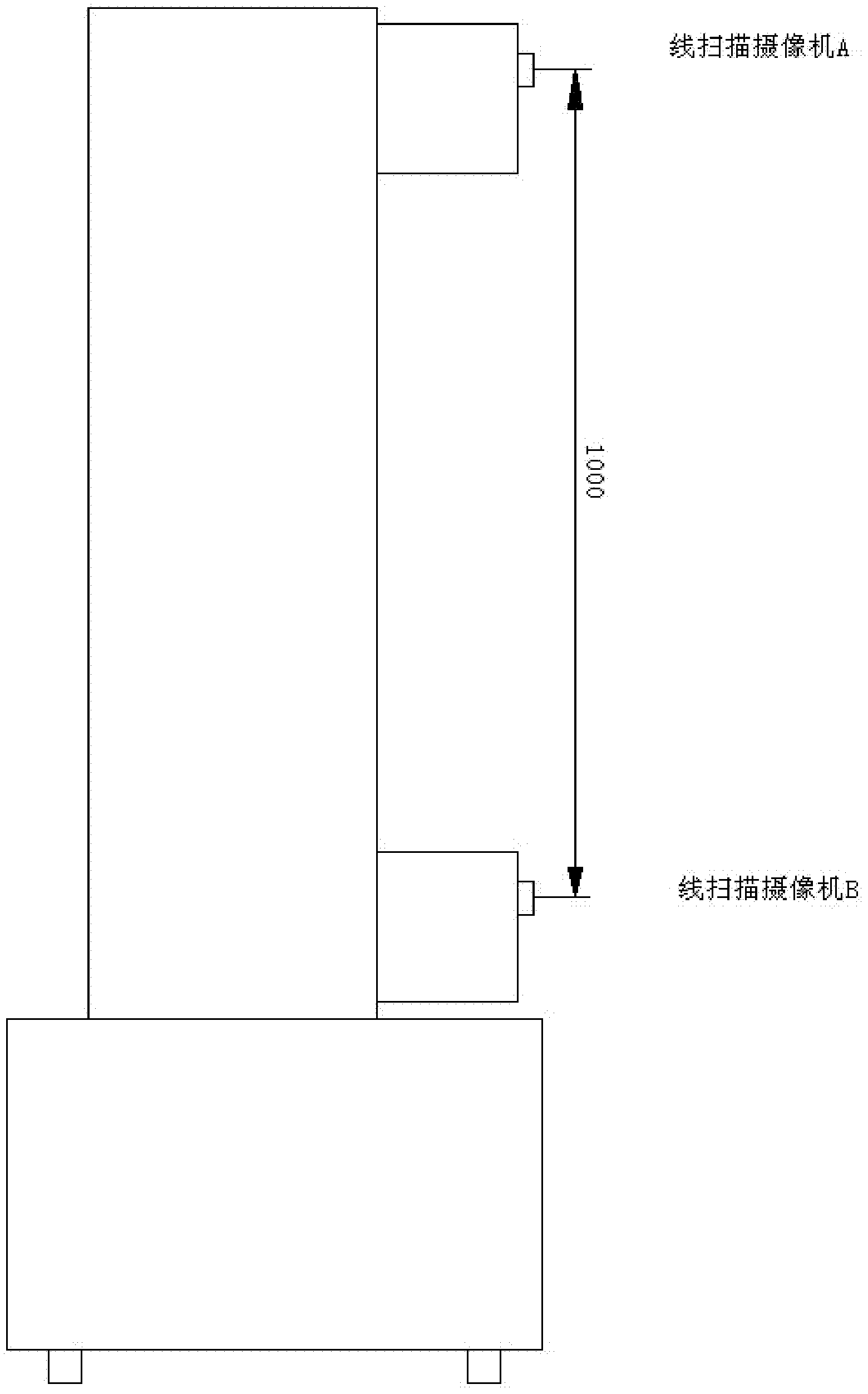

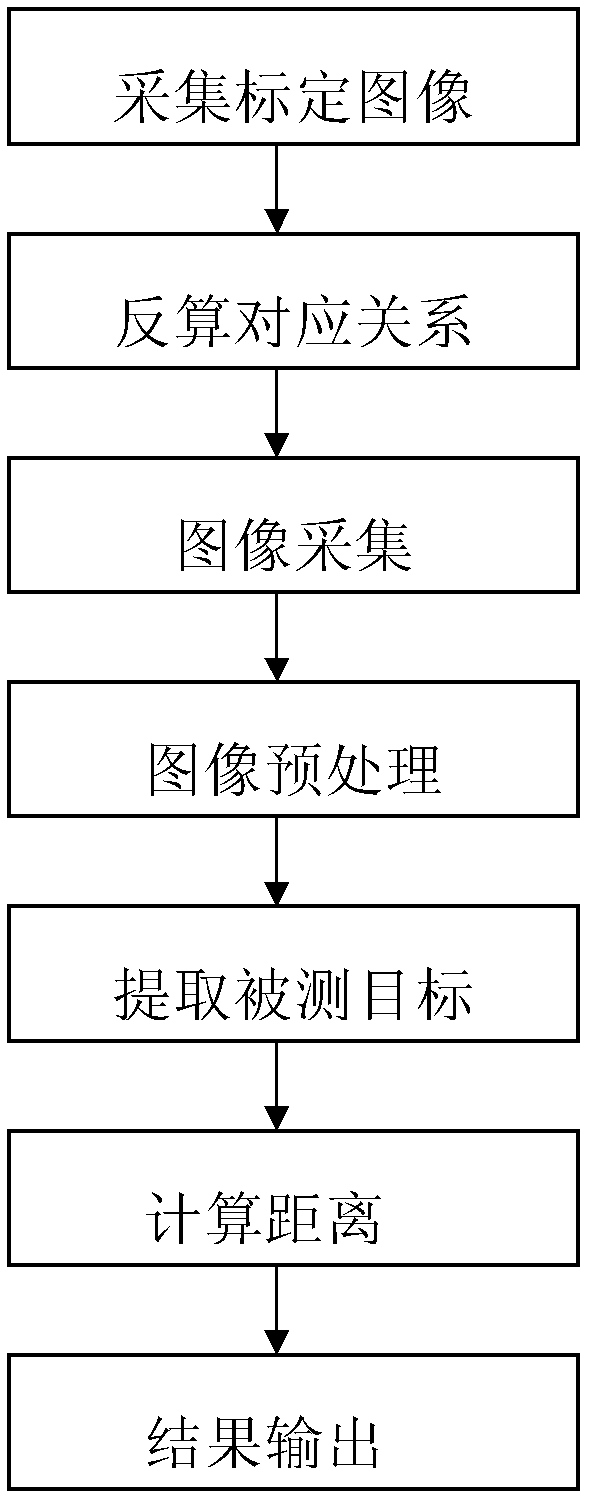

Dynamic distance measuring system based on binocular line scan cameras

ActiveCN102589516ASimple structureEasy to operateOptical rangefindersPhotogrammetry/videogrammetryChemical industrySignal generator

The invention discloses a dynamic distance measuring system based on binocular line scan cameras. The system comprises an image acquiring device, a computer and a signal generator, the image acquiring device comprises a camera support and a pedestal thereof, and a movable objective table, and the two line scan cameras are symmetrically arranged on the camera support. The measuring method of the measuring system comprises the following steps: acquiring a calibration image, carrying out inverse computation to obtain a corresponding relation, carrying out image acquisition, carrying out image preprocessing, extracting circle centers of the detected object circle, and obtaining the real distance of the detected object circle through calculating according to the corresponding relation. The system can be widely applied to the instantaneous space position filed and the like of moving objects of the railway industry, the medicine industry, the chemical industry, the food industry, the building industry and the like.

Owner:CHANGAN UNIV

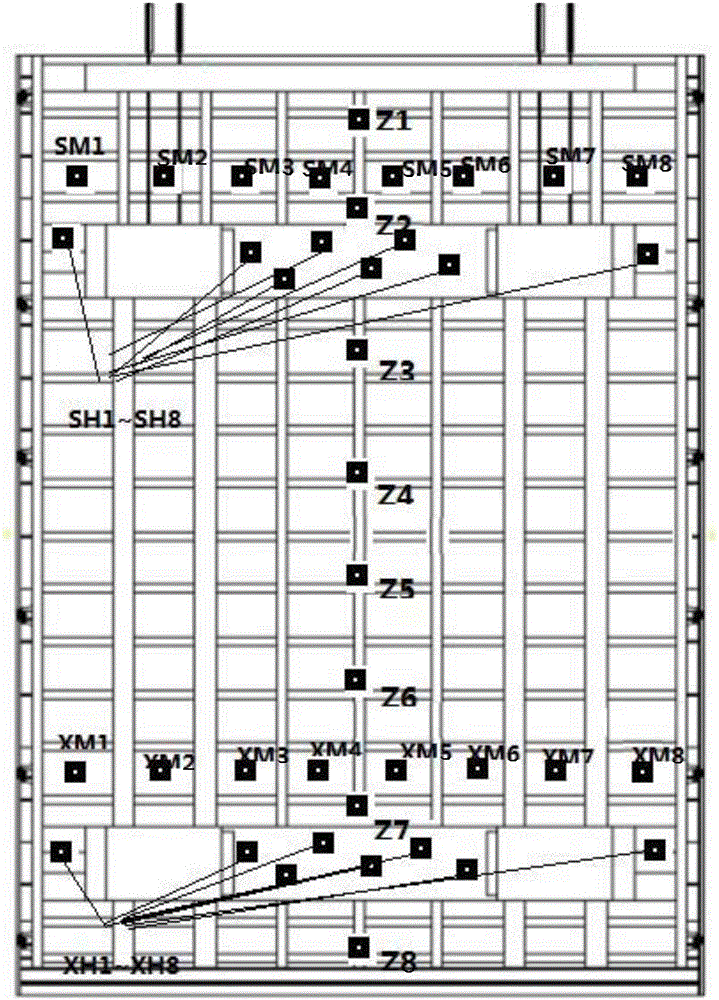

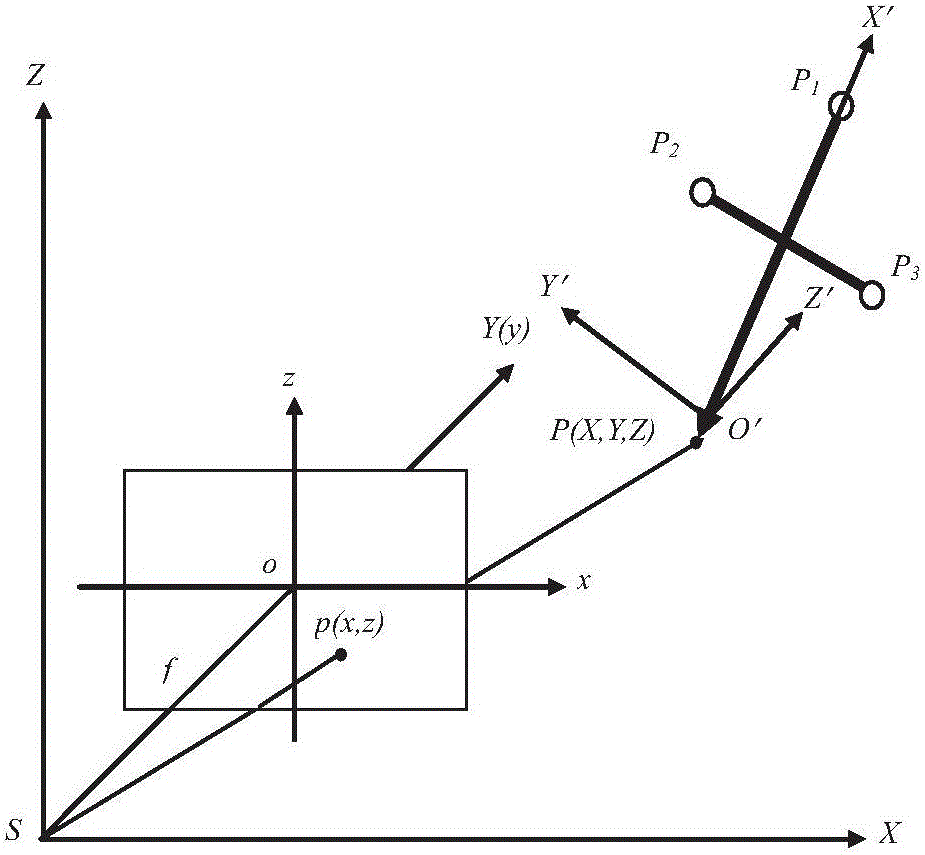

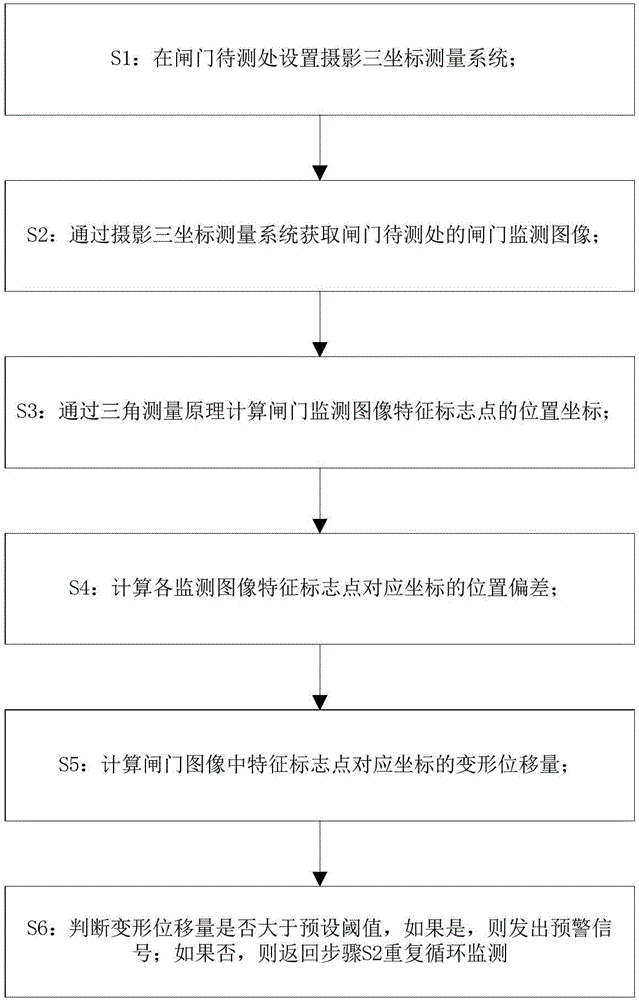

High-dam large-reservoir hydropower station flood discharge gate dynamic monitoring method and system

ActiveCN105783752AEasy to operateEasy data collectionUsing optical meansField conditionsTriangulation

The invention discloses a high-dam large-reservoir hydropower station flood discharge gate dynamic monitoring method. The method comprises the steps of: firstly, placing a shooting three-coordinate measuring system at the position to be detected of a gate; obtaining a gate monitoring image of the position to be detected of the gate; then utilizing a triangulation principle to calculate position coordinates of characteristic mark points of the gate monitoring image; then calculating position deviations and deformation displacement amounts of the coordinates corresponding to each characteristic mark point of the gate monitoring image; and finally, judging whether the deformation displacement amounts exceed a prescribed requirement. According to the invention, the three-dimensional shooting measuring system is adopted to detect the deformation state of the hydropower station gate, the problem that the deformation measurement of hydraulic metal structural gate prototype observation is limited by field conditions and restricted by measurement precision is solved, and the three-dimensional shooting measuring system detects the deformation of the hydropower station gate based on a three-dimensional visual imaging technology; in addition, the method is applicable to the deformation measurement of a hydropower station flood discharge tunnel arc-shaped gate, and the method has the advantages that the usage and operation are simple, the data collection is convenient, and the measurement result display is visual.

Owner:HUANENG LANCANG RIVER HYDROPOWER

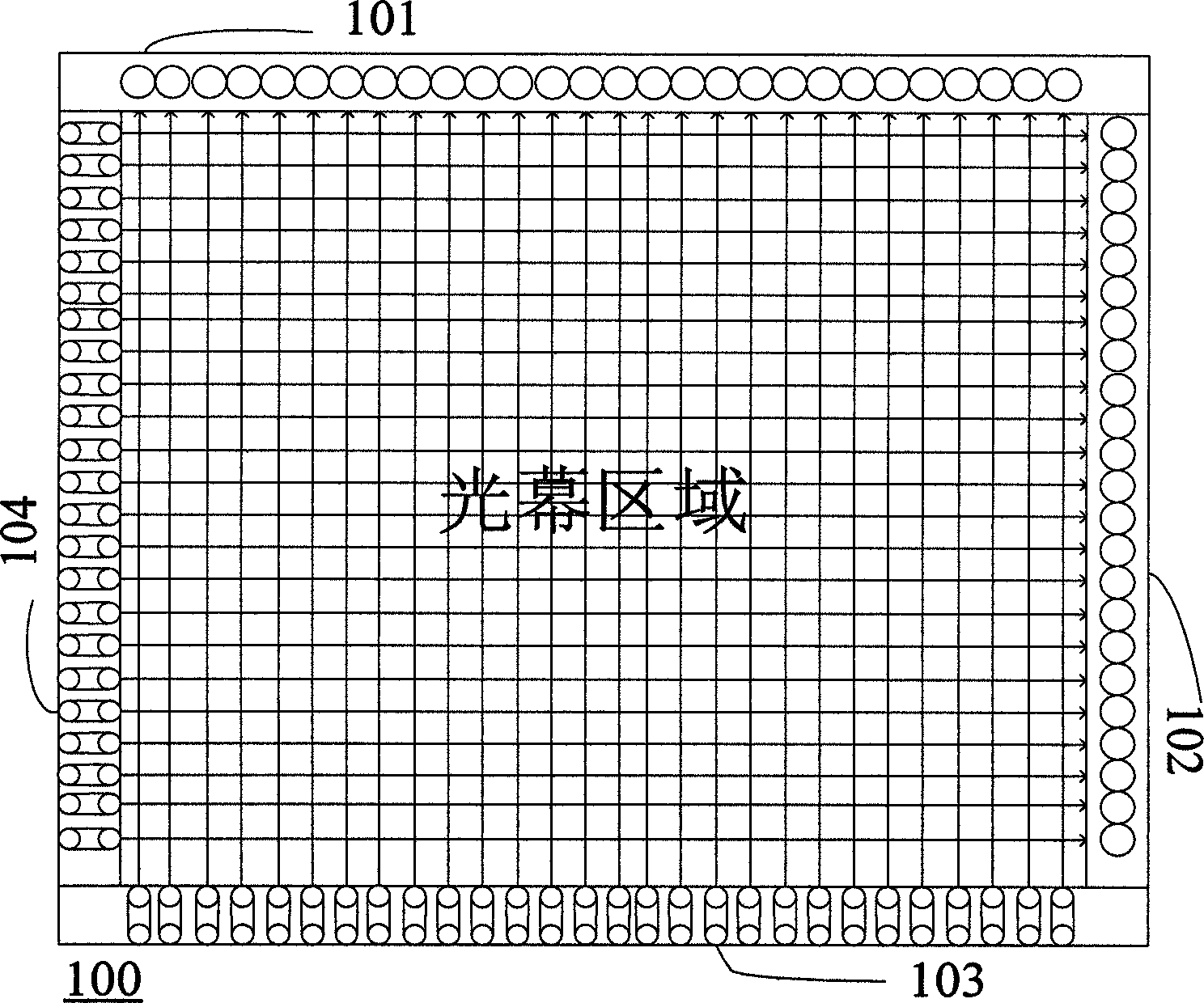

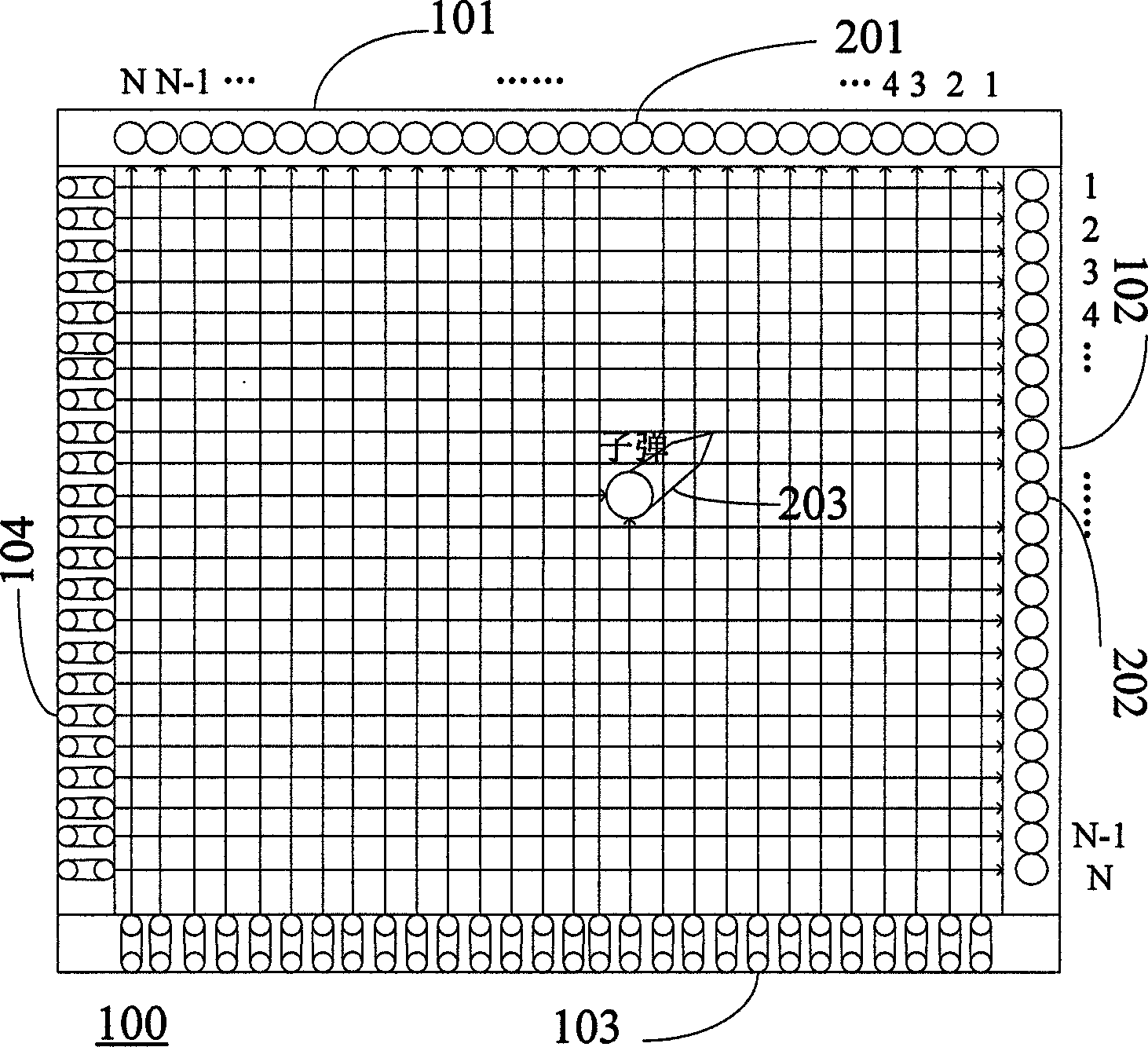

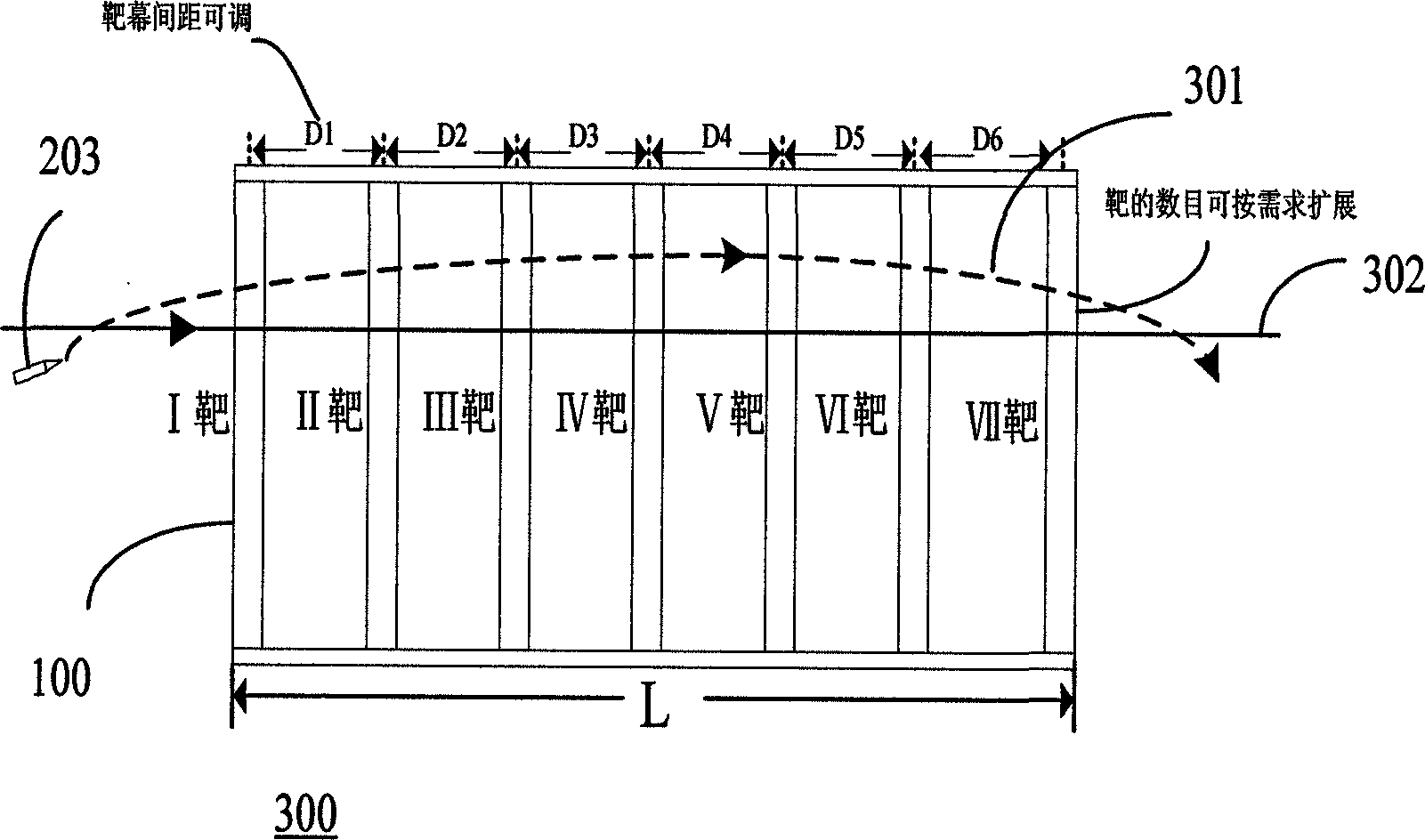

Laser screen target tachymeter and ballistic trajectory capturing method

InactiveCN104020312AImprove detection accuracySimple device structureDevices using time traversedElectromagnetic wave reradiationBallisticsVisibility

The invention relates to a laser screen target tachymeter and a ballistic trajectory capturing method, wherein the laser screen target tachymeter and the ballistic trajectory capturing method are applied to velocity measurement of a bullet. The laser screen target tachymeter is characterized by comprising a microprocessor unit, a display touch screen unit for display and operation, an X-axis laser screen transmitting unit, a laser receiving unit of an X-axis receiving laser screen, a Y-axis laser screen transmitting unit, a laser receiving unit of a Y-axis receiving laser screen and a signal processing circuit unit. The ballistic trajectory movement locus of the bullet can be traced out in the space through multiple points while velocity is measured, and compared with a ballistic trajectory measuring method in the prior art, the ballistic trajectory capturing method is low in cost, simple in principle, high in efficiency, free of influences of visibility of external environment and visual in measuring result.

Owner:XIANGTAN UNIV

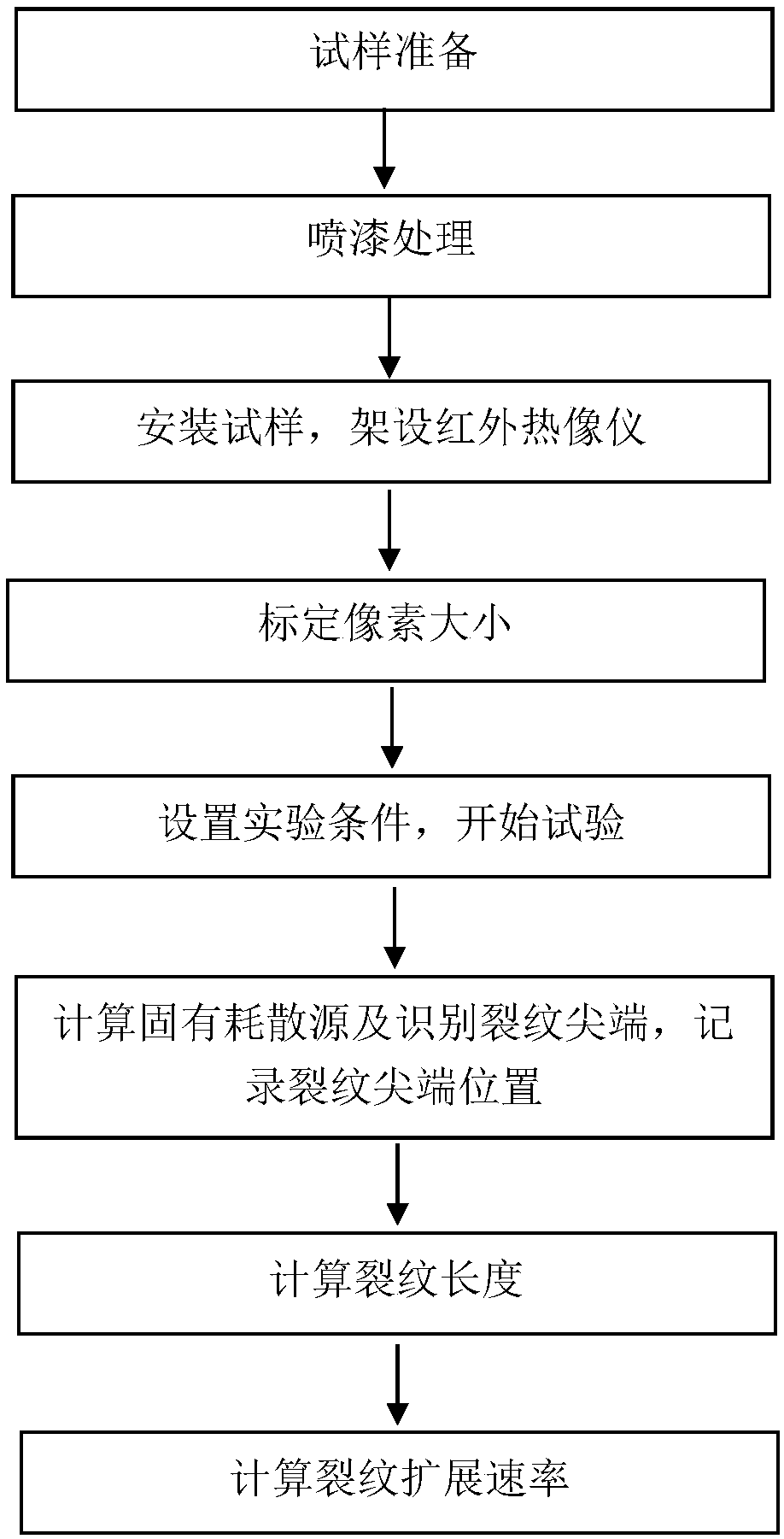

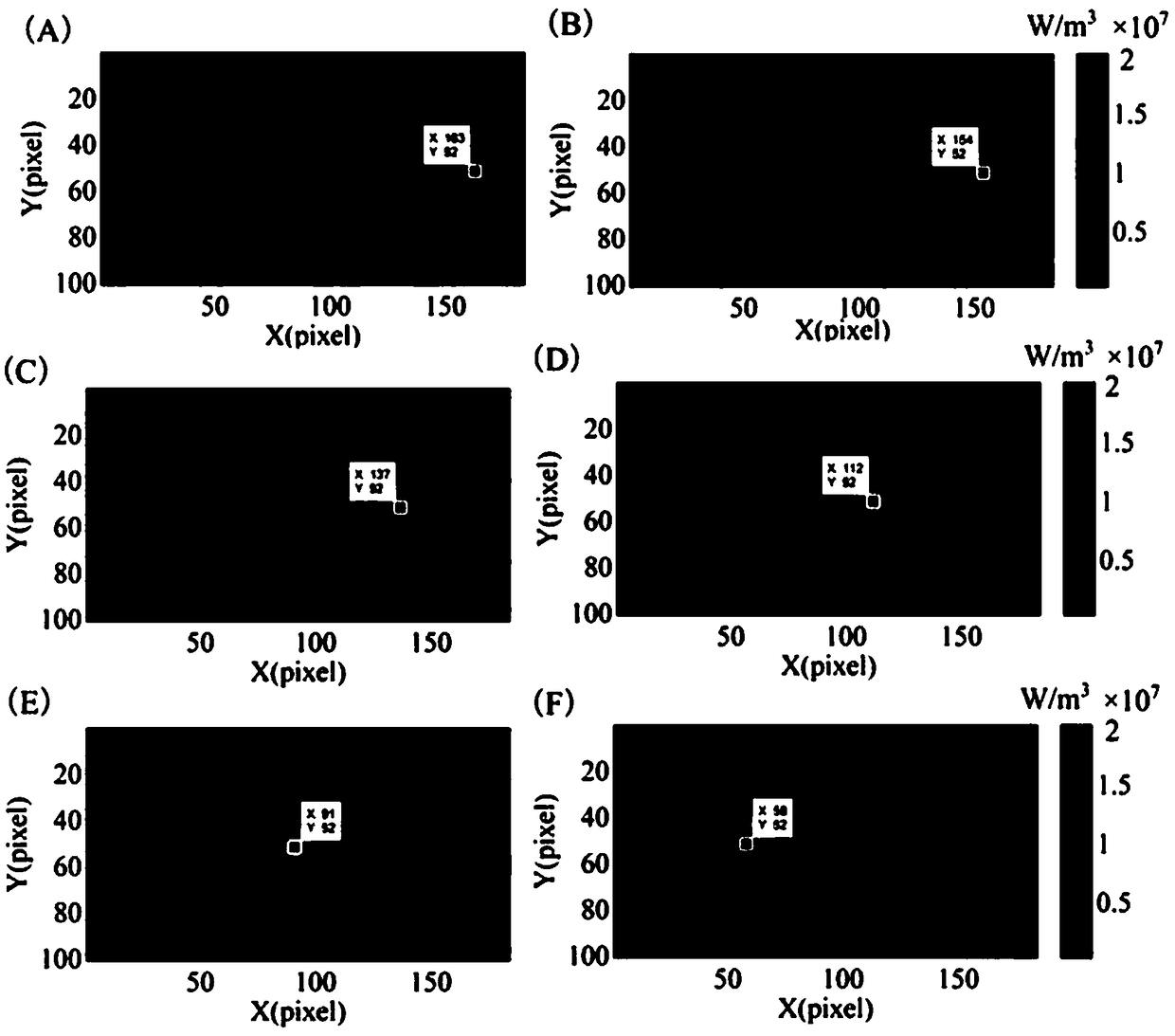

Fatigue crack growth rate measurement method based on infrared thermal imaging technology

ActiveCN108760546ALow influence on mechanical behaviorIntuitive measurement resultsMaterial strength using repeated/pulsating forcesFatigue loadingLacquer

The invention discloses a fatigue crack growth rate measurement method based on infrared thermal imaging technology, including the following steps: spraying a black flat lacquer on a sample satisfyinga required geometric size and surface roughness to improve the surface emissivity of the sample; installing the sample, setting up an infrared thermal imager, determining an observation area, and calibrating the spatial resolution of an infrared image; setting fatigue loading parameters and infrared thermal imager sampling parameters, starting the fatigue test, and recording the temperature fieldevolution process in a fatigue crack tip region in real time; acquiring a corresponding heat source field through temperature field calculation with a two-dimensional heat transfer model, and automatically identifying the fatigue crack tip position in the heat source field; according to the change of the fatigue crack tip position, determining a crack propagation path, acquiring the fatigue cracklength at each moment, and calculating to obtain the fatigue crack growth rate. The method can be used to obtain accurate and reliable measuring results, has low requirements on test environment, iseasy to operate, and can realize non-contact measurement, full field measurement and automatic measurement.

Owner:HUNAN UNIV

Friction corrosion fatigue test device and friction corrosion fatigue test method of heavy-load scraper plate conveyor circular chain

ActiveCN106289759AEasy to operateIntuitive measurement resultsMachine gearing/transmission testingAuxiliary electrodeDynamic Tension

Owner:CHINA UNIV OF MINING & TECH

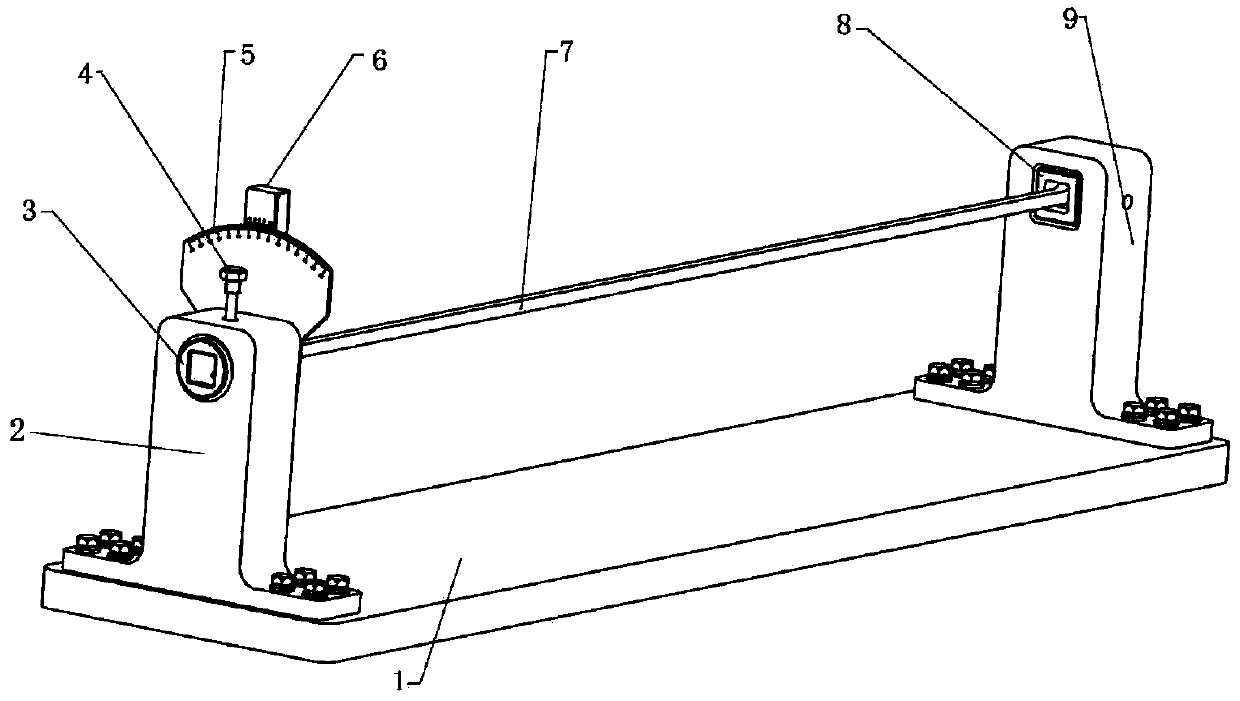

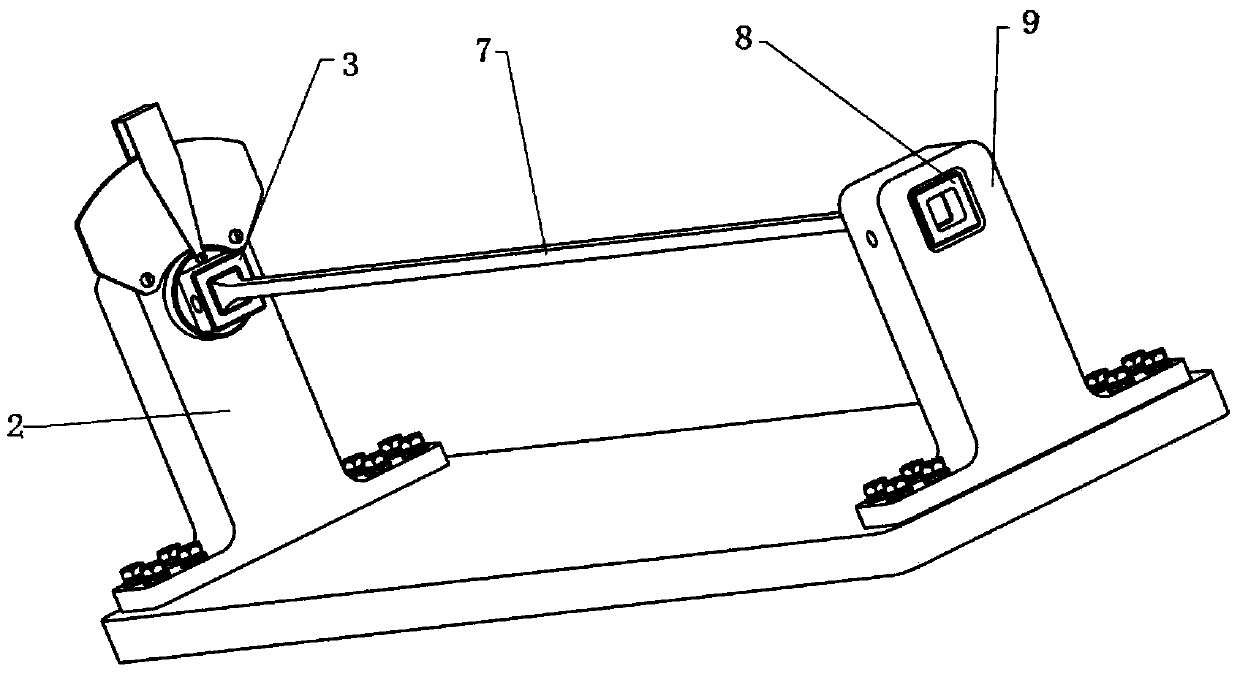

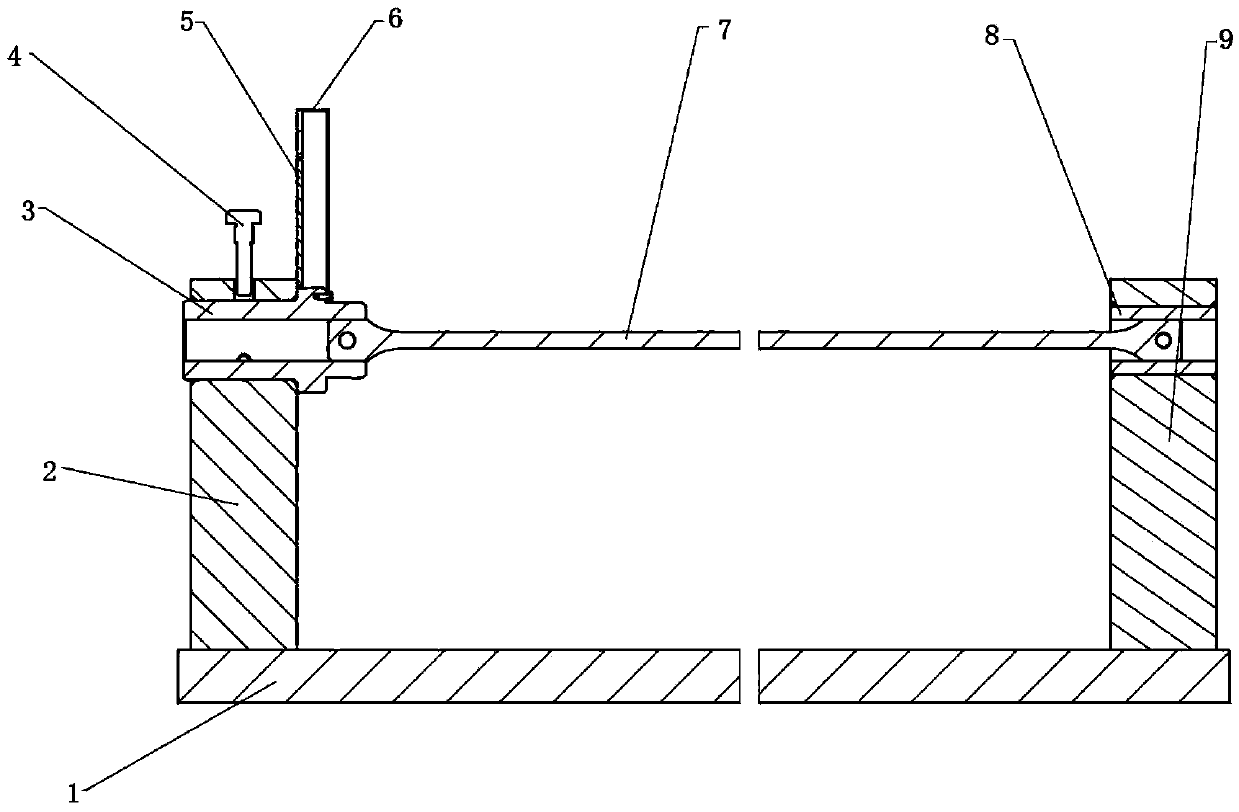

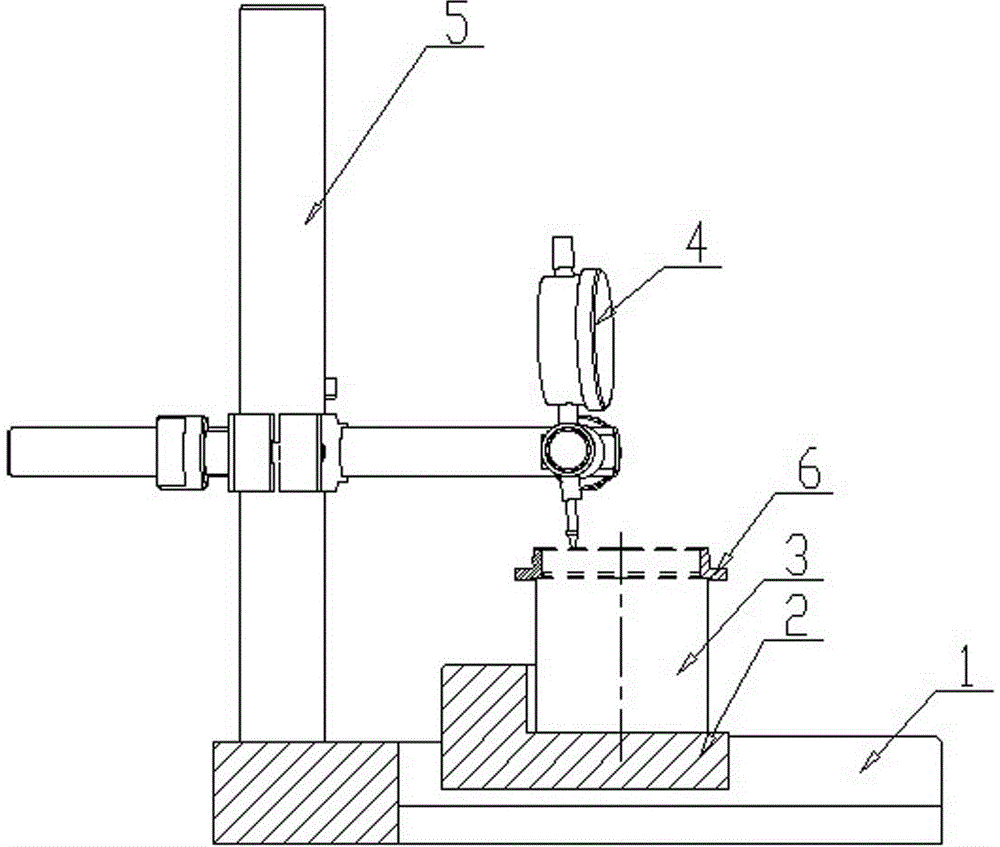

Device for measuring creep of torsion bar

ActiveCN104198303AGood estimateGuaranteed measurement accuracyStrength propertiesMechanical engineeringFixed angle

The invention discloses a device for measuring creep of a torsion bar. The device for measuring creep of the torsion bar comprises a base, a front bracket, a rear bracket, a front joint, a rear joint, a limiting screw, an index dial and a pointer, wherein the front bracket and the rear bracket are symmetrically mounted on two ends of the base; a threaded through hole is formed in the upper end surface of the front bracket; the two ends of the torsion bar are inserted into through holes of the front joint and the rear joint respectively; the front joint is not fixed at the periphery of the front bracket; the rear joint is fixed at the periphery of the rear bracket; a through hole is radially formed in the front joint; when the torsion bar rotates along with the front joint, the through hole of the front joint is just coaxially aligned at the threaded through hole in the upper end surface of the front bracket; the limiting screw is screwed into the threaded through hole and the through hole of the front joint, so that the torsion bar maintains a fixed angle; the index dial is mounted on the front end surface of the front bracket; the pointer is mounted at the end part of the front joint; the pointer rotates along with the rotation of the torsion bar; the creep is read by the index dial which is indicated by the pointer. The device for measuring the creep of the torsion bar is simple in structure, small in occupation area, easy to manufacture, easy in measurement and high in accuracy; a pure mechanical measurement manner is adopted; the measured results are intuitive.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

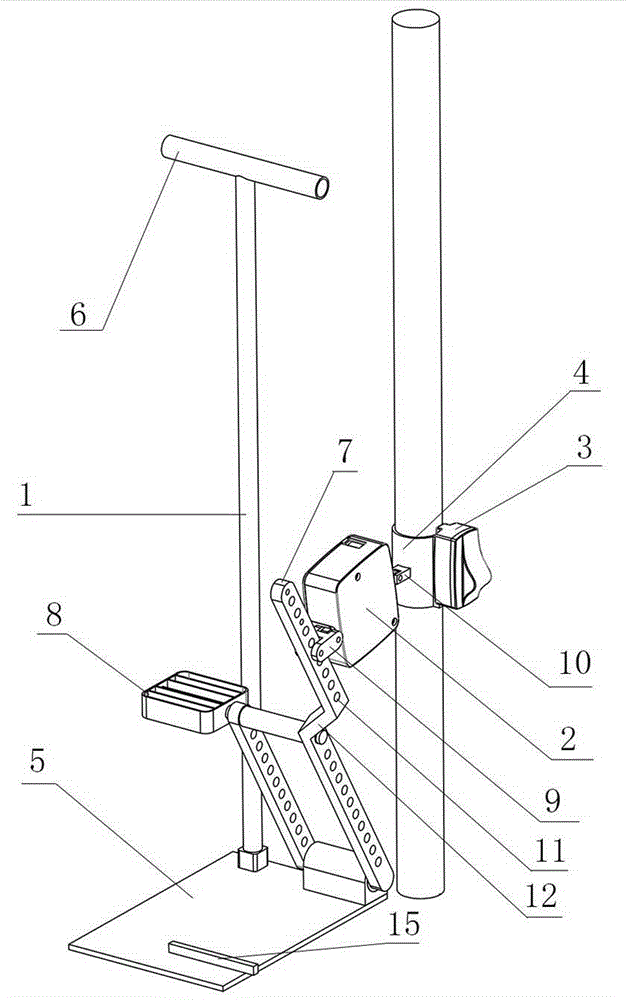

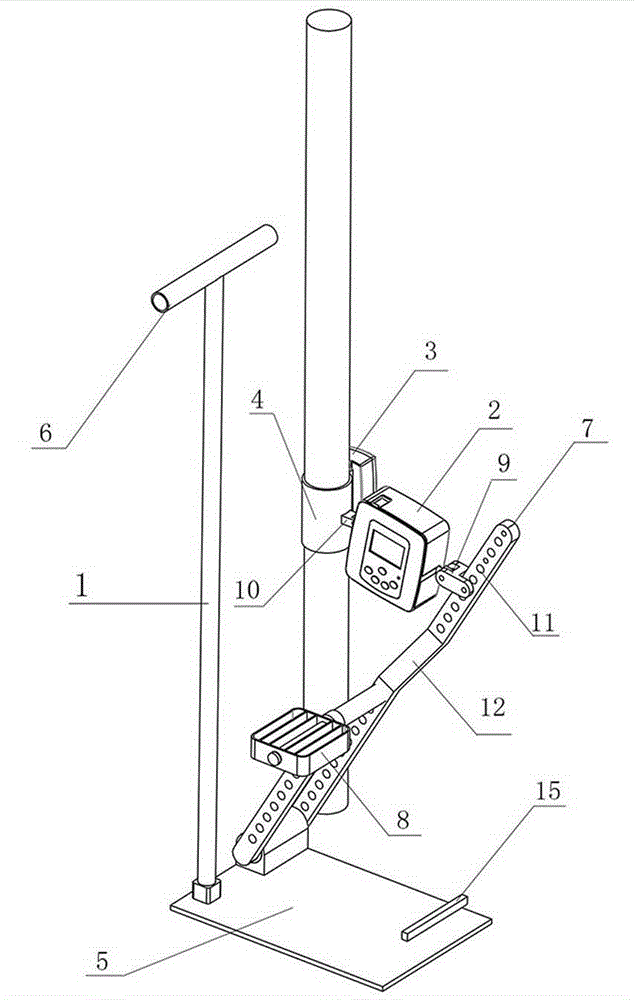

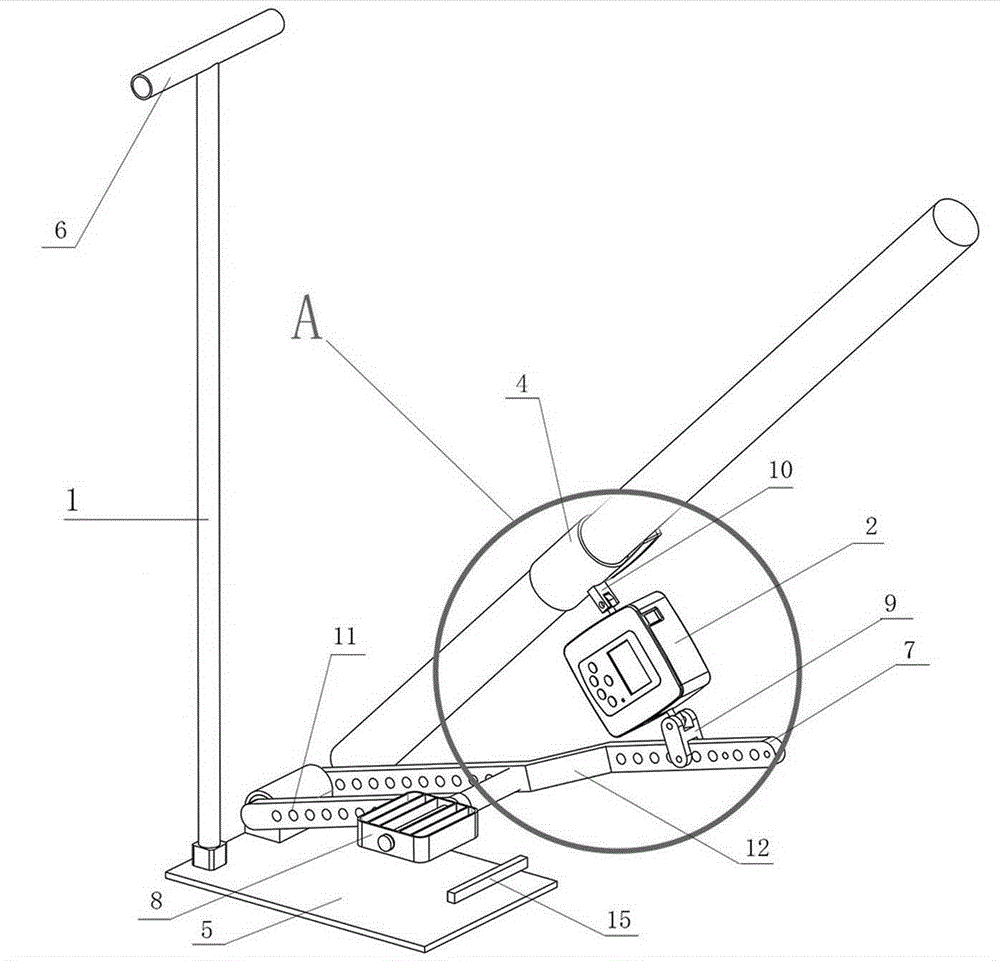

Device and method for measuring crop stem lodging resistance strength

InactiveCN105241756AAchieve outputMeasurement data is stableMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention discloses a device for measuring crop stem lodging resistance strength and a method for measuring stem lodging resistance strength by using the device. The device includes a force application mechanism, a tensile mechanism, a stem inclination collection mechanism and a stem fixture which is fixed on a crop stem. The force application mechanism comprises a base and a mobile tensile component installed on the base through a hinge; the mobile tensile component includes a tension rod, pedals and a mobile fastening part arranged on the tension rod; and a tension sensor is arranged on the tensile mechanism. The device for measuring crop stem lodging resistance strength can realize storage of a large amount of measured data in measurement of crop stem lodging resistance strength, and can realize the output of the measurement data; and repeated and convenient measurement can be carried out in the measurement of crop stem lodging resistance strength, and stable measurement data can be obtained. The method for measuring crop stem lodging resistance strength can obtain more accurate and reliable tensile strength measurement data in the measurement of crop lodging resistance.

Owner:HENAN AGRICULTURAL UNIVERSITY

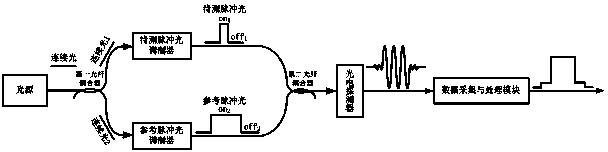

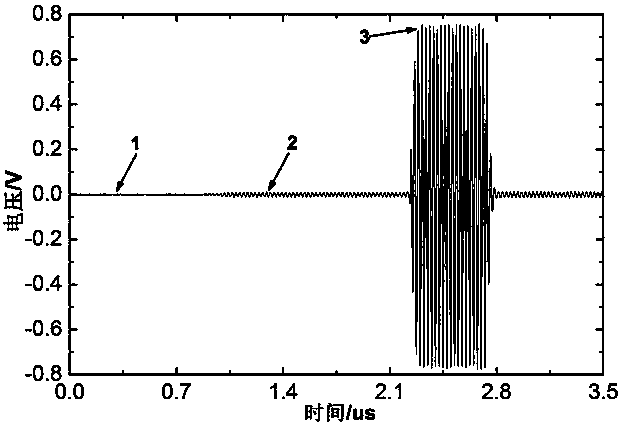

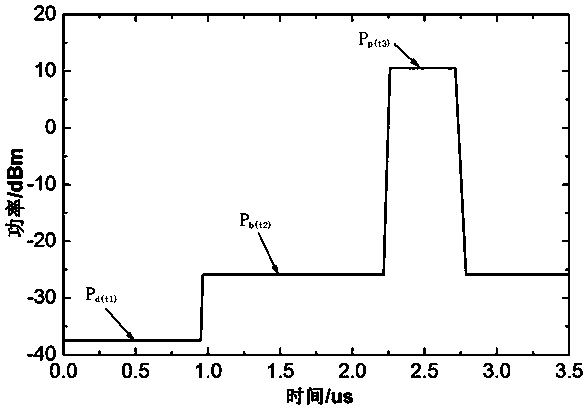

Device and method for measuring dynamic extinction ratio of pulsed light with high dynamic range

ActiveCN103414513AInhibition effectIntuitive measurement resultsElectromagnetic transmissionContinuous lightPeak value

The invention discloses a device and method for measuring the dynamic extinction ratio of pulsed light with a high dynamic range. The device comprises a light source, a first optical fiber coupler, a modulator of pulsed light to be measured, a modulator of reference pulsed light, a second optical fiber coupler, a photoelectric detector and a data collecting and processing module. Two beams of continuous light divided from continuous light are modulated into the pulsed light to be measured and the reference pulsed light, beat frequency optical signals produced after the pulsed light to be measured and the reference pulsed light are in coherent coupling are converted into beat frequency current signals, the beat frequency current signals are processed, electric power of pulse peak optical power and electric power of substrate optical power of the pulsed light to be measured, and electric power of PD dark current noise are obtained, and the dynamic extinction ratio of the pulsed light to be measured is calculated according to the obtained electric power. Through single measurement, the power of the peak and the power of the substrate of the pulsed light to be measured and the power of the dark current noise of the photoelectric detector are obtained at the same time, the dynamic extinction ratio of the pulsed light is measured, the measurement efficiency is high, the precision is high, and the dynamic range is large.

Owner:NANJING UNIV

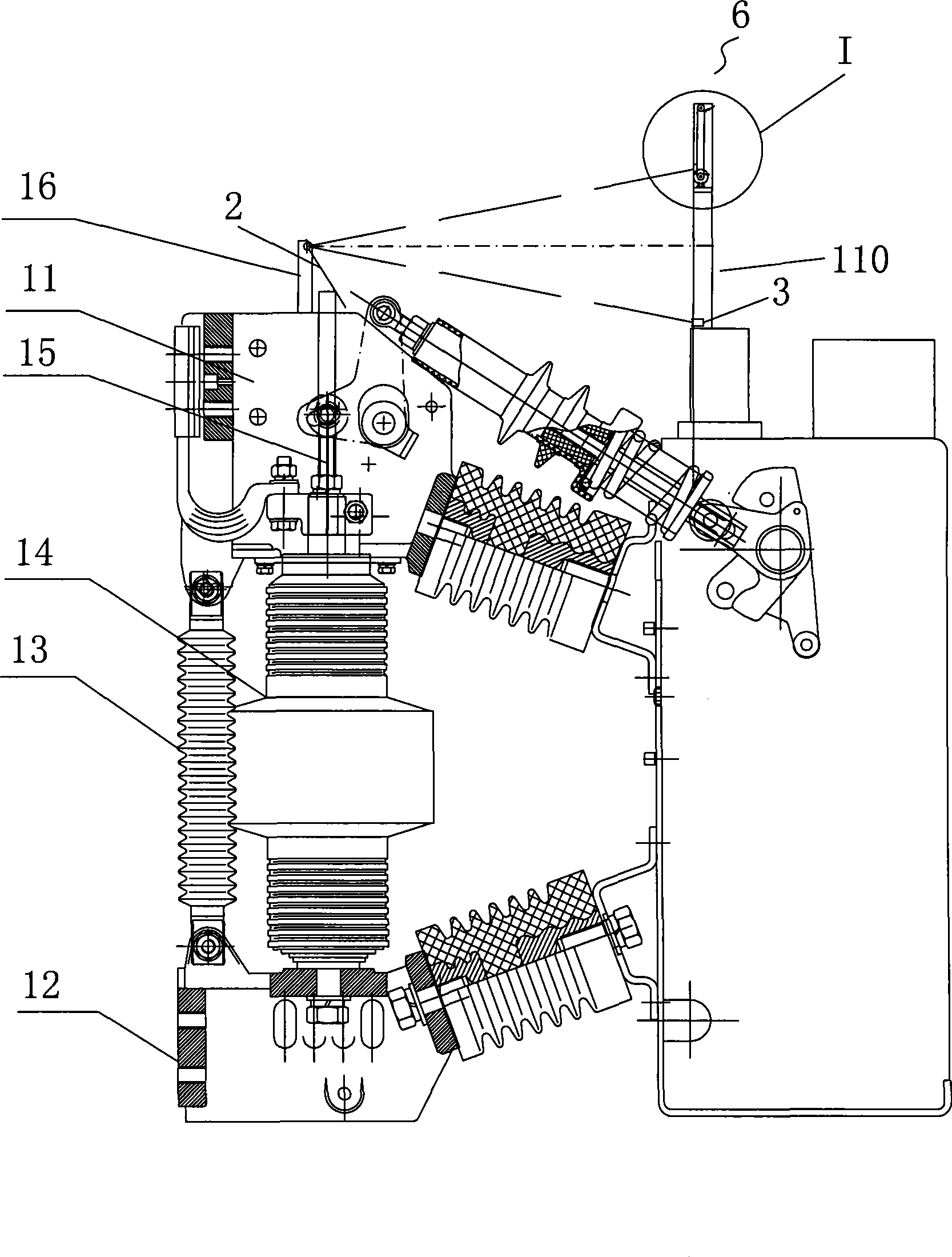

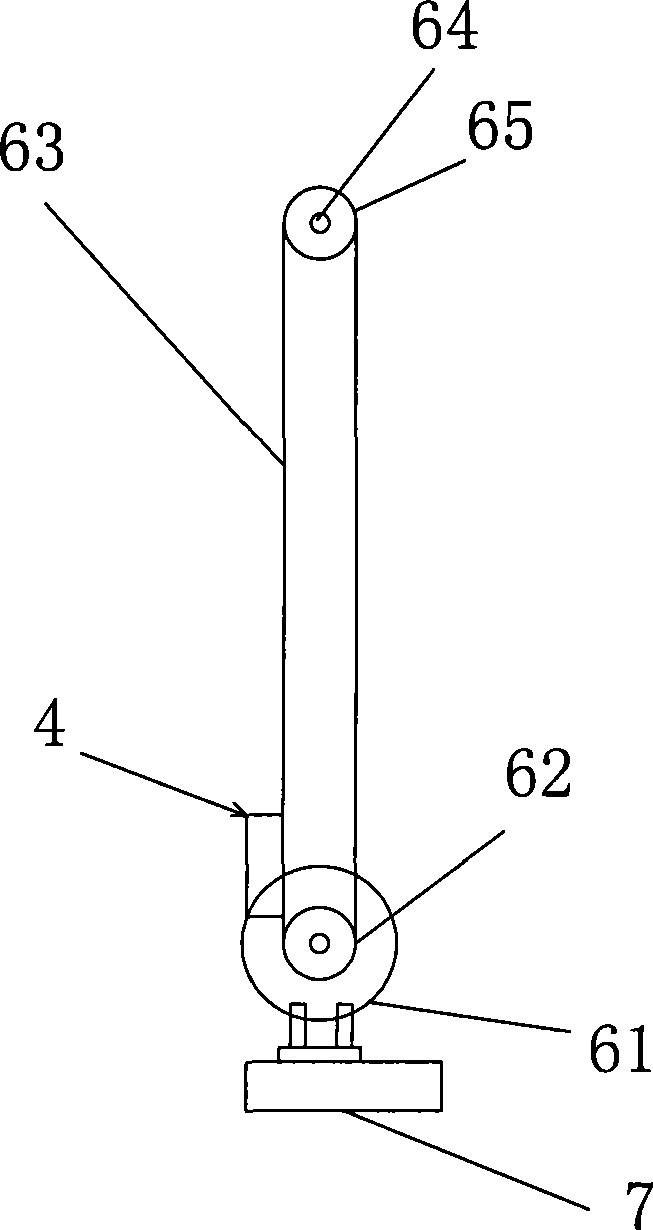

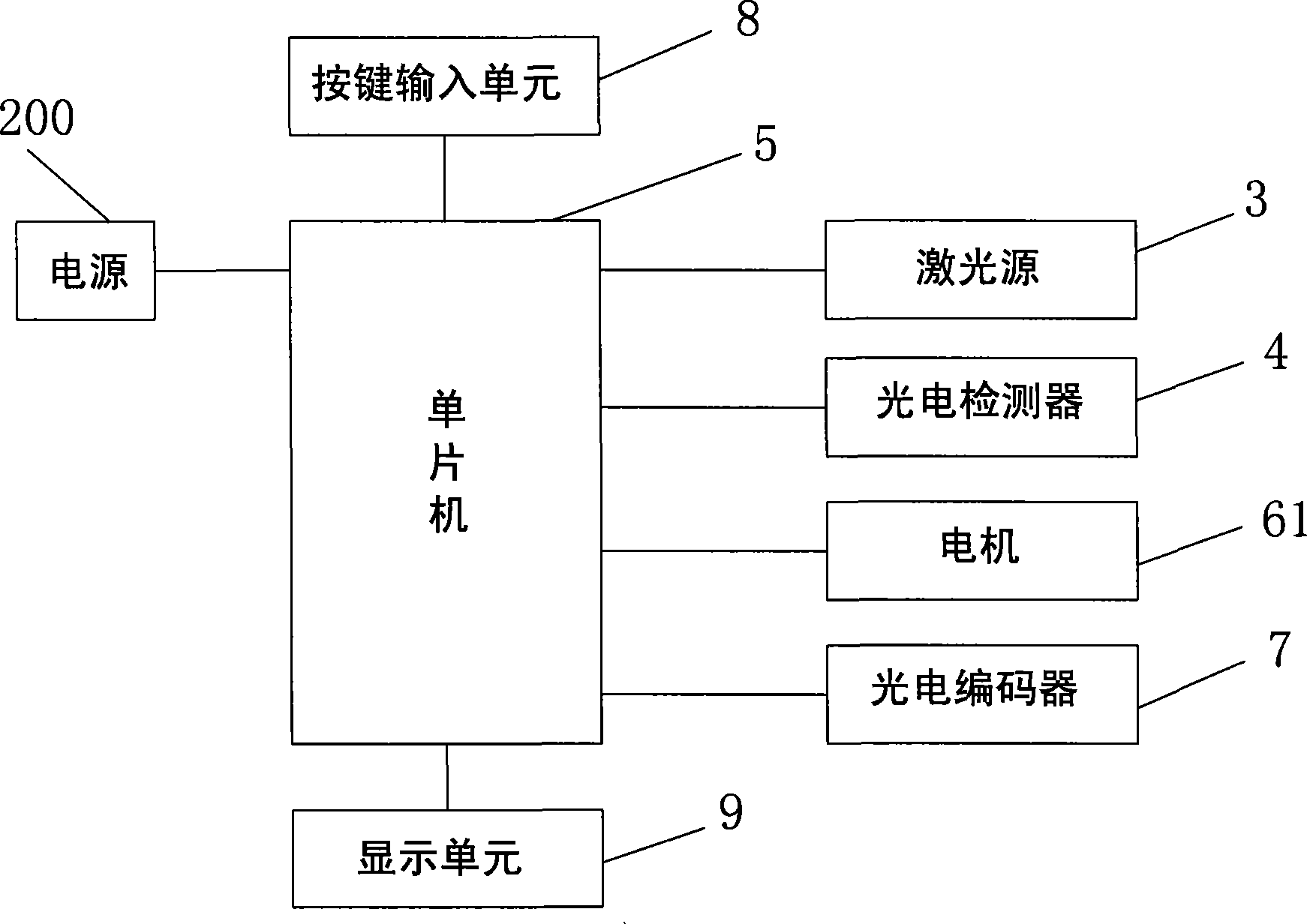

Method and apparatus for detecting contact head abrasive loss of vacuum circuit breaker

InactiveCN101469971AImprove measurement accuracyEasy to operateUsing optical meansLight beamSingle chip

The invention discloses a method for detecting the abrasion amount on the contactor of vacuum circuit breakers, and a device thereof, wherein one end of the dynamic conductor pole of a vacuum circuit breaker is arranged with a reflecting device, the reflecting surface of the reflecting device is oppositely arranged with an incident light source and a reflected light receiver, the reflected light receiver receives the light emitted from the incident light source and reflected by the reflecting device. When the contactor is abraded, the angle position of the reflecting device changes, to cause the change of the receiving position of the light beam reflected by the reflecting device, the method measures the receiving position change of the reflected light beam, and utilizes the trigonometric function among the abrasion amount of the contactor, the incident light source, the reflected light receiver and the reflecting device, to calculate the abrasion amount of the contactor via a single chip and display the result on a display unit. The invention has the advantages of simple and fast operation, visual displayed measurement result and high measurement precision.

Owner:SHANGHAI WESTHOUSE SWITCHGEAR

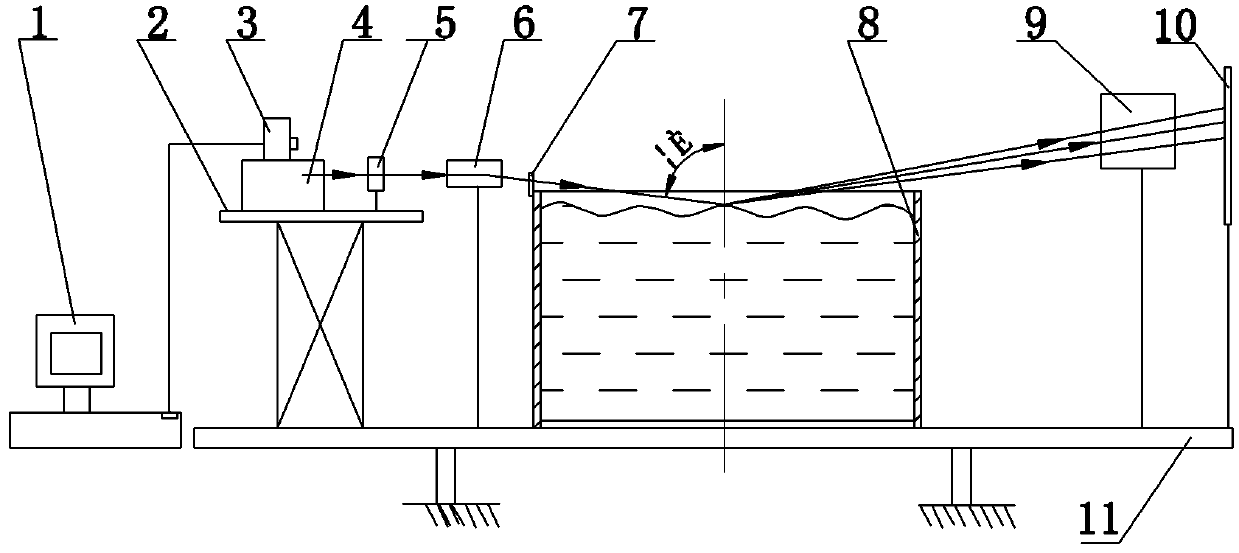

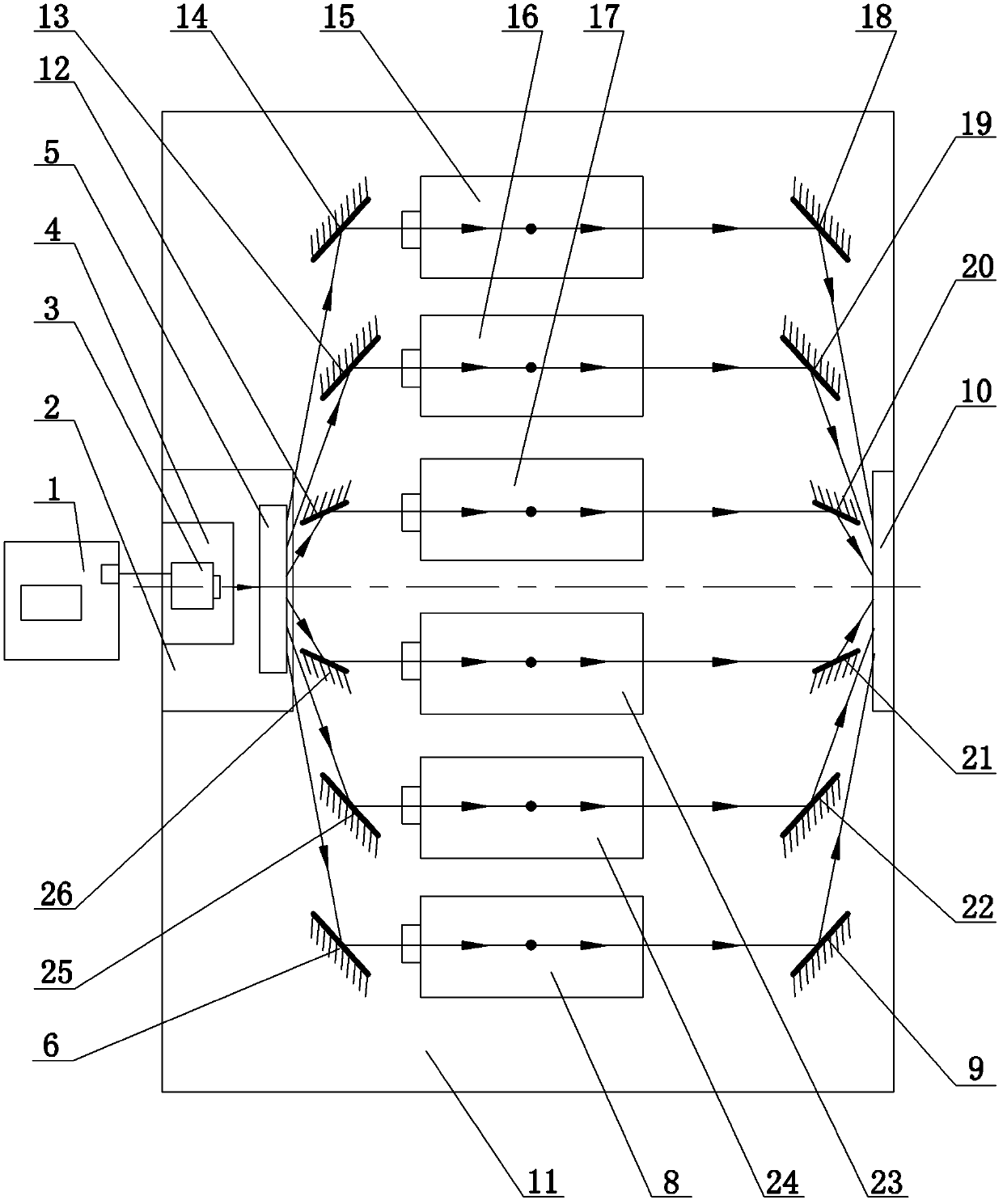

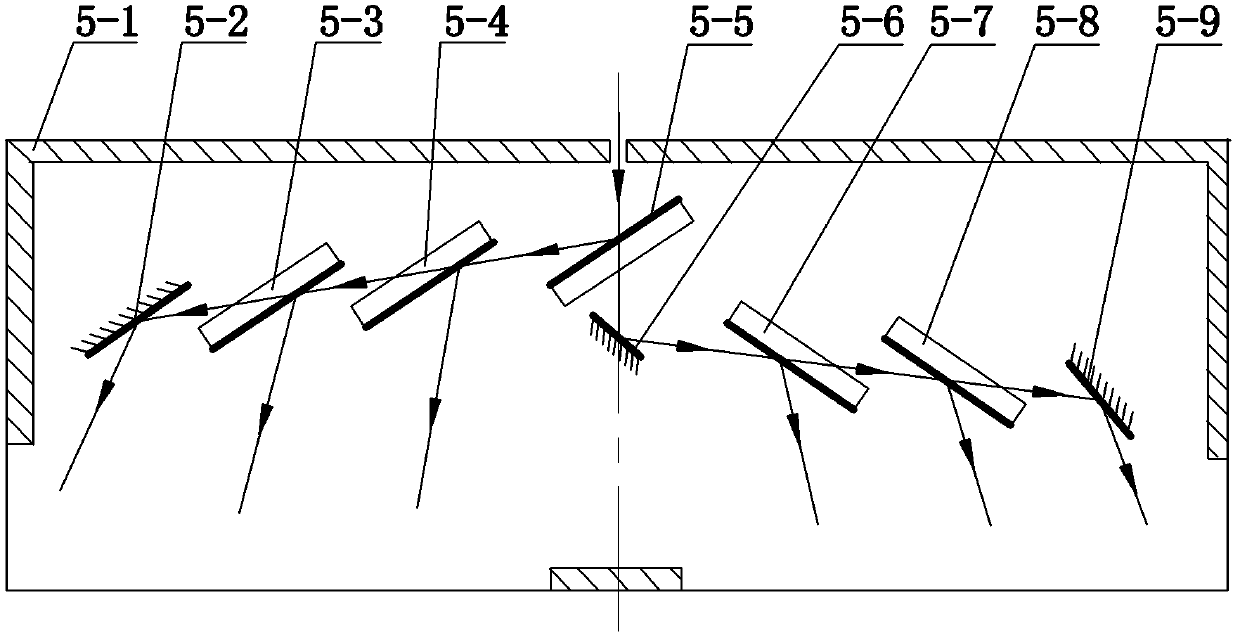

Device and method for detecting vibration isolation performance consistency of oversized optical platform

InactiveCN102607788AReasonable designSimple structureSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansBeam splitterOptical table

The invention discloses a device for detecting the vibration isolation performance consistency of an oversized optical platform. The left end of a central line on the optical platform is provided with a bracket; the right end of the central line on the optical platform is provided with a display screen; the left side of the bracket is provided with a laser; the wavelength of the laser is 632.8 nanometers; the laser is provided with a CCD (Charge Coupled Device) camera which is connected with a computer through a lead; the right side of the laser is provided with a beam splitter along a central line emitting direction bracket in the length direction of the optical platform; at least six even number left reflecting mirrors are arranged in the laser emitting direction of the beam splitter on the optical platform; the optical platform along the light reflecting directions of the left reflecting mirrors is provided with water-filled water grooves of which the quantity is the same as that of the left reflection mirrors; a light diaphragm is arranged in the light reflecting direction of the left reflecting mirror at the upper end of the central line of the left side wall of each water groove; the optical platform in the inner water surface light reflecting direction of each water groove is provided with right reflecting mirrors of which the quantity is the same as that of the left reflecting mirrors; and a display screen is arranged at the right end of the central line of the optical platform in the light reflecting directions of six right reflecting mirrors.

Owner:XIAN AERONAUTICAL UNIV

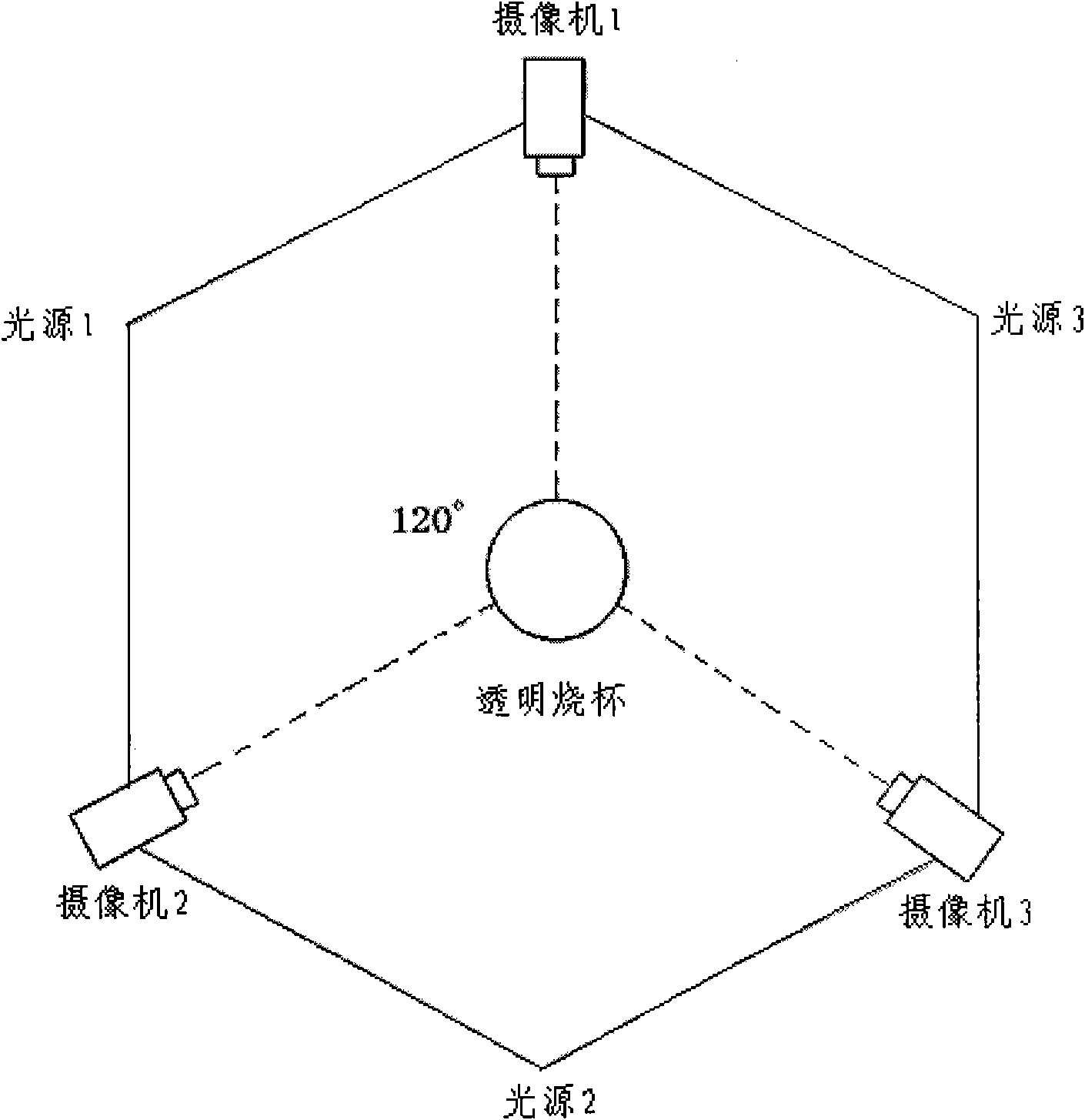

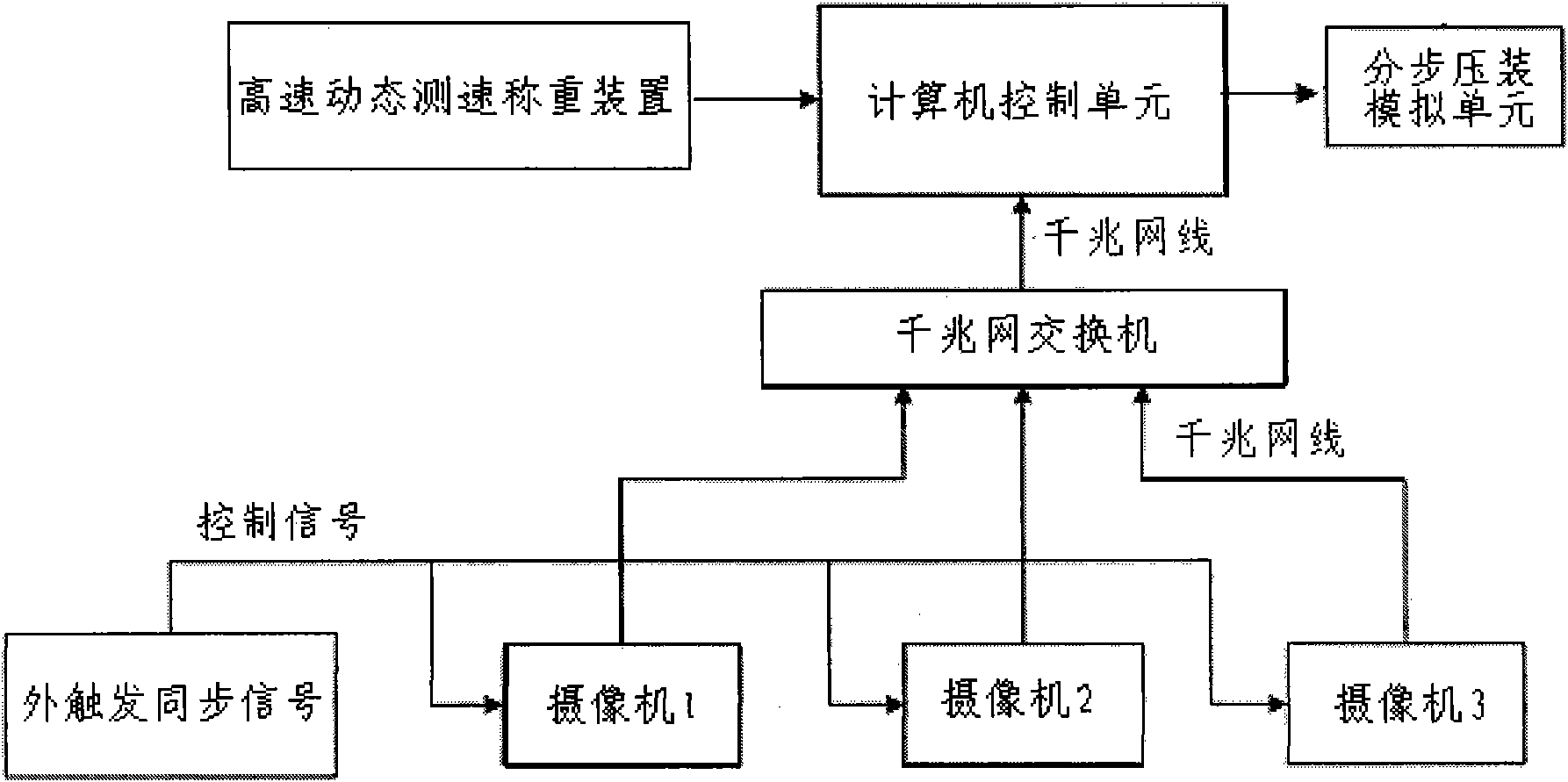

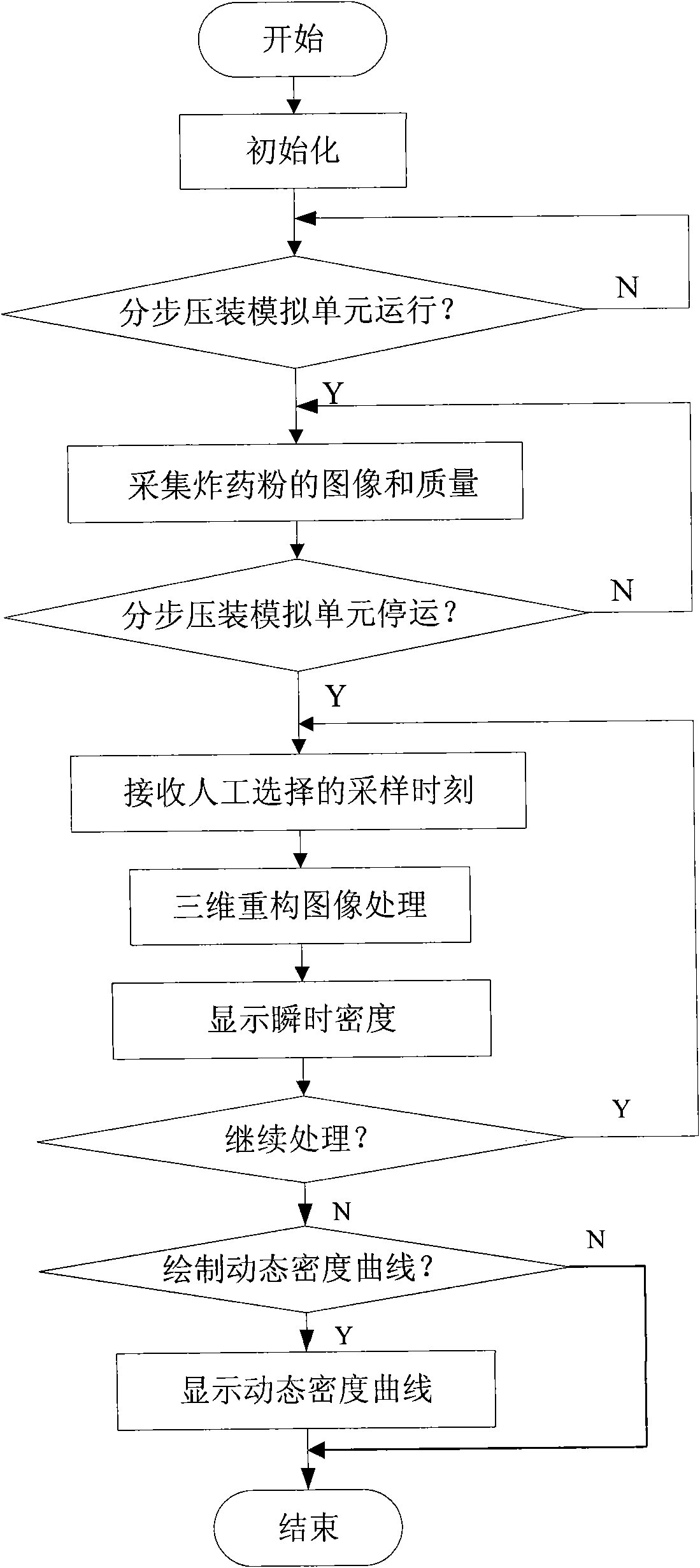

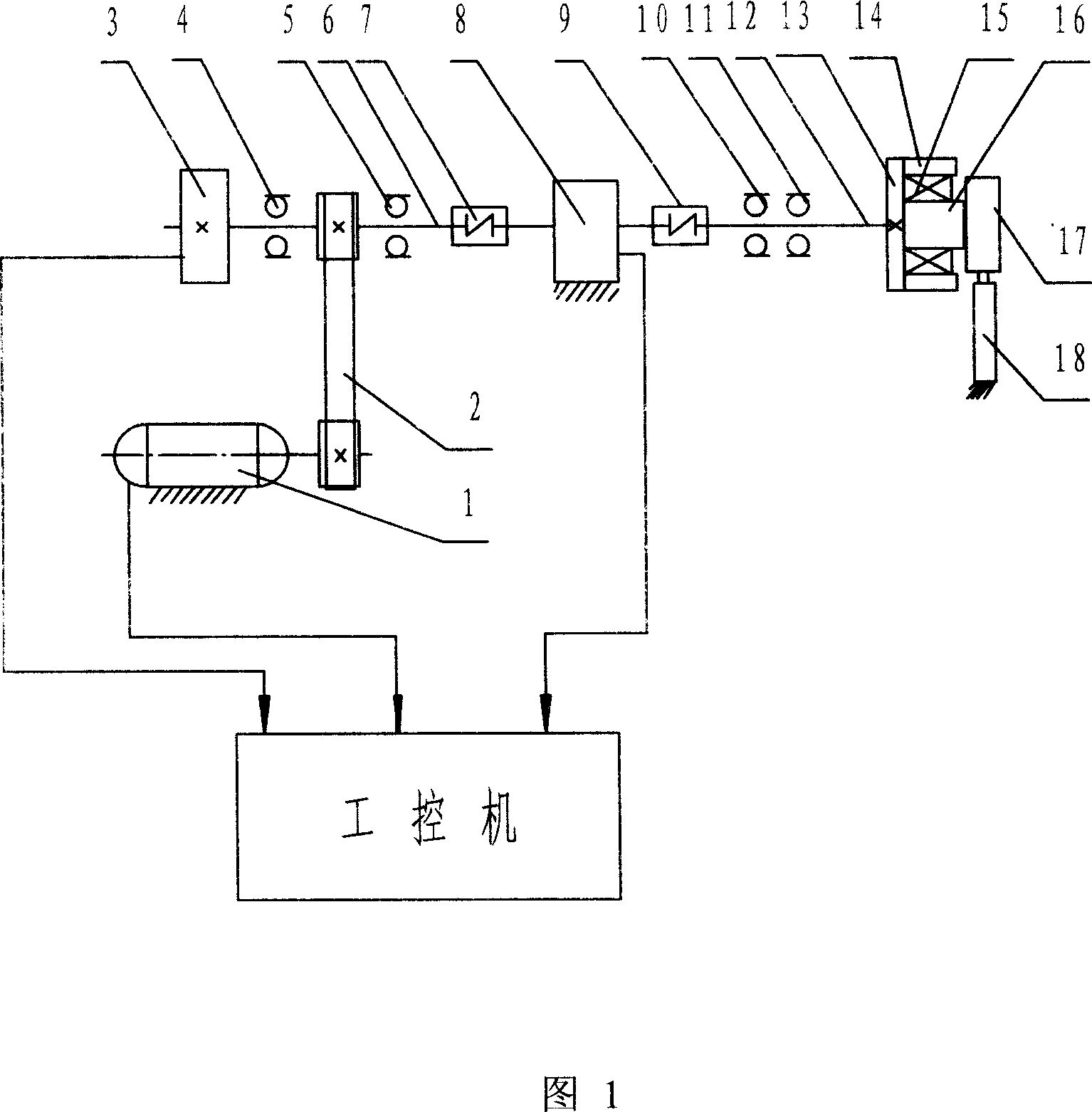

Three-dimensional reconstruction based explosive fluidity measuring method

InactiveCN101571492AImprove real-time performanceEasy to operateImage analysisMaterial analysis by optical meansMeasurement deviceVoxel

The invention discloses a three-dimensional reconstruction based explosive fluidity measuring method, which comprises the following main operation steps: acquiring explosive frame image data shot by three cameras and explosive dynamic mass data weighted by an electronic balance in an explosive fluidity measuring device in real time and synchronously; and performing treatment such as filtering, feature value extraction, stereo matching, 3D reconstruction by a voxel method in sequence on three images in a frame of image at a manually selected sampling moment, obtaining an instantaneous density value of explosive falling into a standard transparent cup at a corresponding moment, performing the treatment on frame images at different moments, obtaining a group of explosive instantaneous density values changing with time, and drawing an explosive fluidity curve according to the group of explosive instantaneous density values. The method makes the explosive fluidity measuring device really realize automatic and objective measurement function on the explosive fluidity, and has the remarkable advantages of strong real-time, quick calculation speed, intuitive measuring results and high precision.

Owner:CHANGAN UNIV +1

Freewheeling clutch dynamic friction torque tester

ActiveCN101144743ASimple structureFriendly interfaceMachine gearing/transmission testingWork measurementFriction torqueBand shape

The invention discloses a dynamic frictional force torque test set of a free wheeling clutch, and the dynamic frictional force torque test set comprises a controlling system, a testing system, and a testing device; wherein, a computer of the controlling system controls a motor of a drive mechanism through a sensor and a velometer; the motor is connected with a drive axle through a synchronous belt, the drive axle is connected with a chief axle through a clutch, the output end of the chief axle is connected with a fixed tray, an inner sleeve and an outer sleeve are arranged between the fixed tray and a relative supporting tray, and the supporting tray is fixed by a double supporting block; the tested piece is arranged between the inner sleeve and the outer sleeve and is used for three testing states: an inner frictional force torque test, an outer frictional force torque test, and a banding frictional force torque test. The complete machine has simple structure, friendly interface, and convenient operation; the invention can set the parameters such as the testing rotating speed, the sampling time, and the sampling frequency; the testing data is correct and reliable, and the testing precision is high; after being analyzed and processed by a computer software, therefore, not only the test result can be displayed in dynamic state and in visible state, but also the relative data can be analyzed and collated, and the finished testing result can be stochastically displayed, output, and archived.

Owner:LUOYANG BEARING RES INST CO LTD

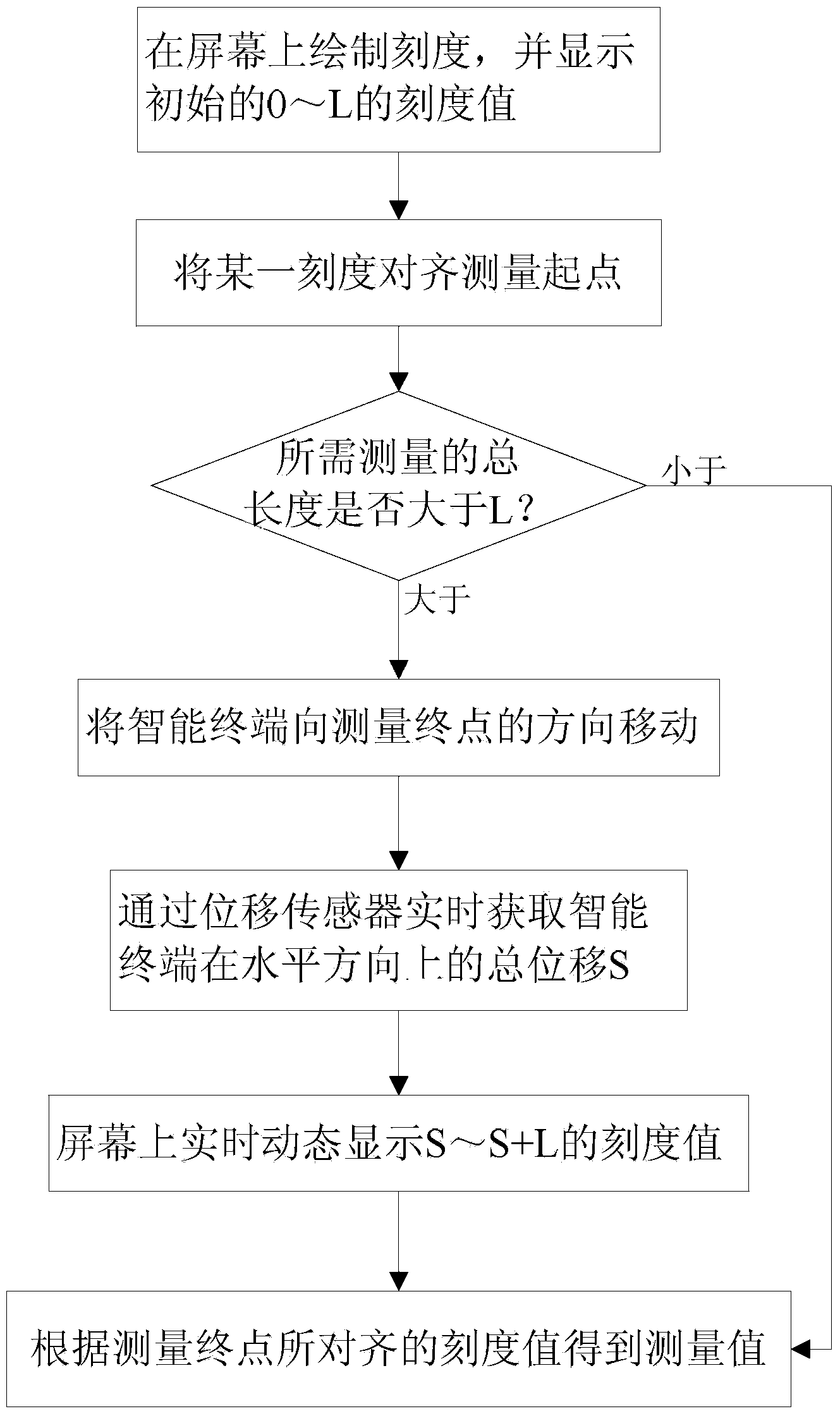

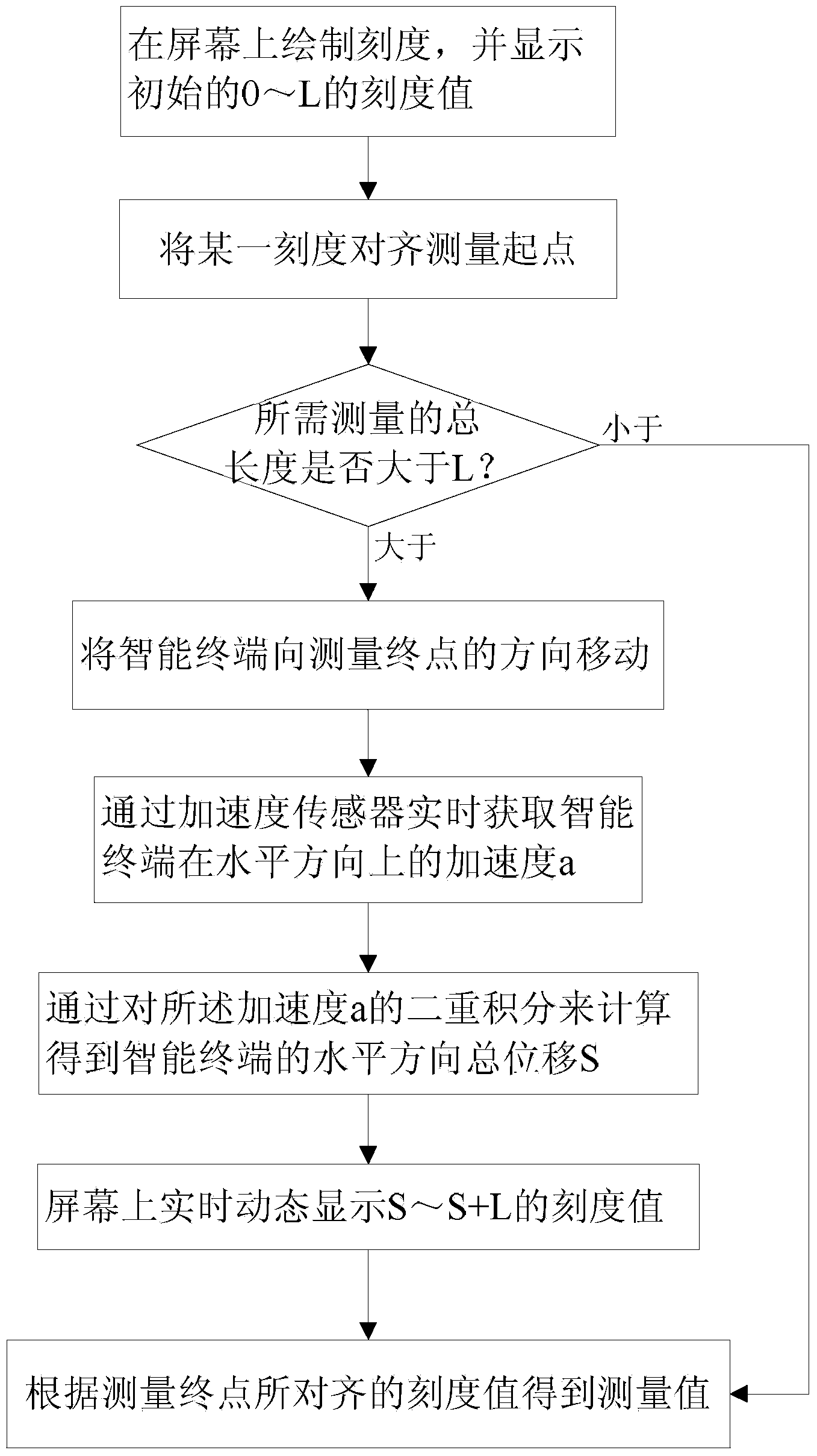

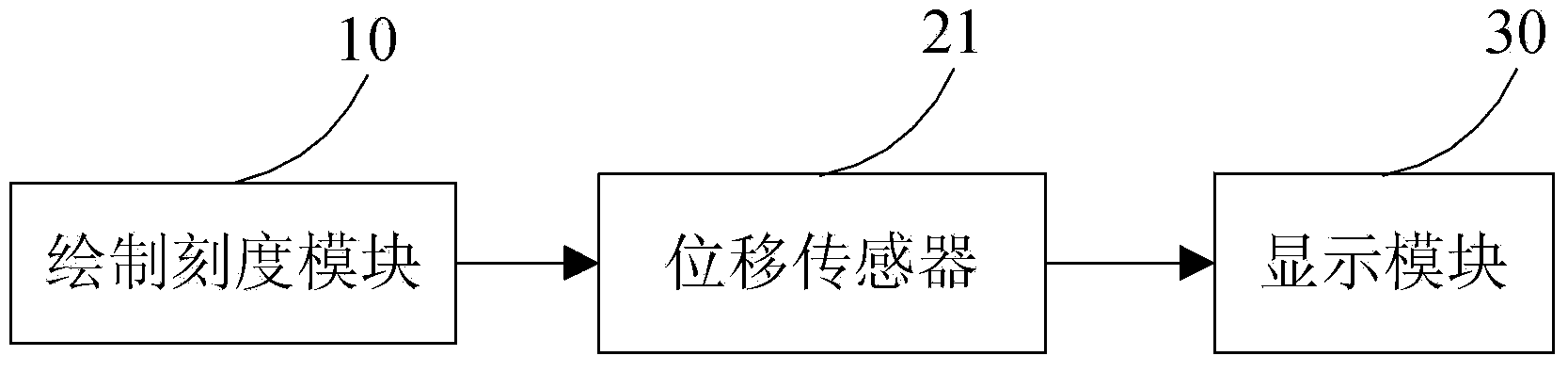

Method for measuring by means of intelligent terminal and intelligent terminal

InactiveCN103512528AImprove user experienceLong measuring distanceMeasurement devicesReal-time computing

The invention discloses a method for measuring by means of an intelligent terminal and the intelligent terminal. The method includes the following steps of drawing scales on a screen and displaying original scale values ranging from 0 to L, aligning a certain scale to a measurement starting point, moving the intelligent terminal to the direction of a measurement end point if the total length needing to be measured is larger than L, obtaining the total displacement S of the intelligent terminal in the horizontal direction in real time, displaying the scale values ranging from S to S+L on the screen dynamically in real time, and obtaining a measurement value according to the scale value aligned to the measurement end point when the intelligent terminal moves to the measurement end point. Therefore, when the intelligent terminal measures, the length limit of the intelligent terminal itself can be eliminated, a larger length distance can be measured, a user can flexibly, easily and conveniently measure lengths, heights and widths of different objects and the distance between two points by means of the intelligent terminal, the function of the intelligent terminal is enriched, use convenience of the intelligent terminal is improved, and use experience of the user is optimized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

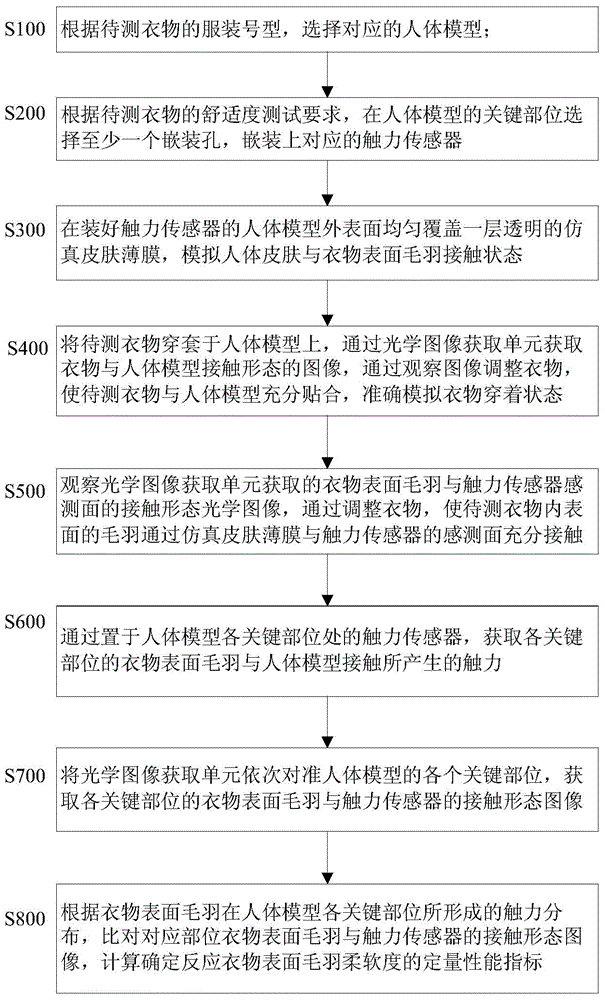

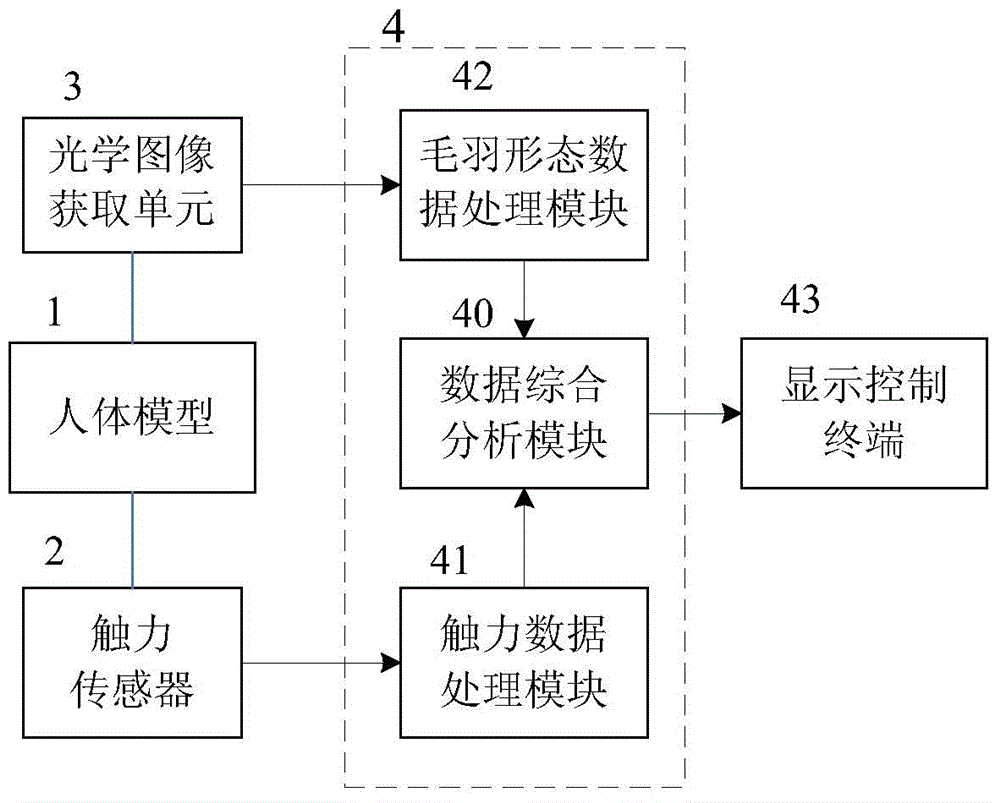

Method for detecting softness of hairiness on surface of clothing and detection apparatus thereof

The invention relates to a method for detecting softness of hairiness on surface of clothing and a detection apparatus thereof, and relates to a method for detecting quality of a weaving product and an apparatus thereof, and especially relates to a method for detecting quantity and softness of hairiness on surface of clothing and the detection apparatus thereof. The method comprises the following steps: selecting a model of human body, embedding a touch force sensor, obtaining the touch force data and contact form image data generated by contact of hairiness on the surface of clothing and the model of the human body, and quantification performance index for reflecting softness of hairiness on surface of clothing and evaluating wearing comfort level of the clothing is constructed through data analysis. According to the method and the apparatus, the high-precision touch force sensor is employed for obtaining the data, a contact state image of the hairiness on the surface of the clothing and the model of human body can be obtained by an optical image collection unit, operation is convenient and simple, experiment data is objective, precision is high, and reliability is strong; the touch force sensor is used for directly obtaining contact force of fiber and skin but not frictional force, and the contact force is closer to the contact force influence of real wearing hairiness of the clothing and the human body.

Owner:HENGYUANXIANG GRP

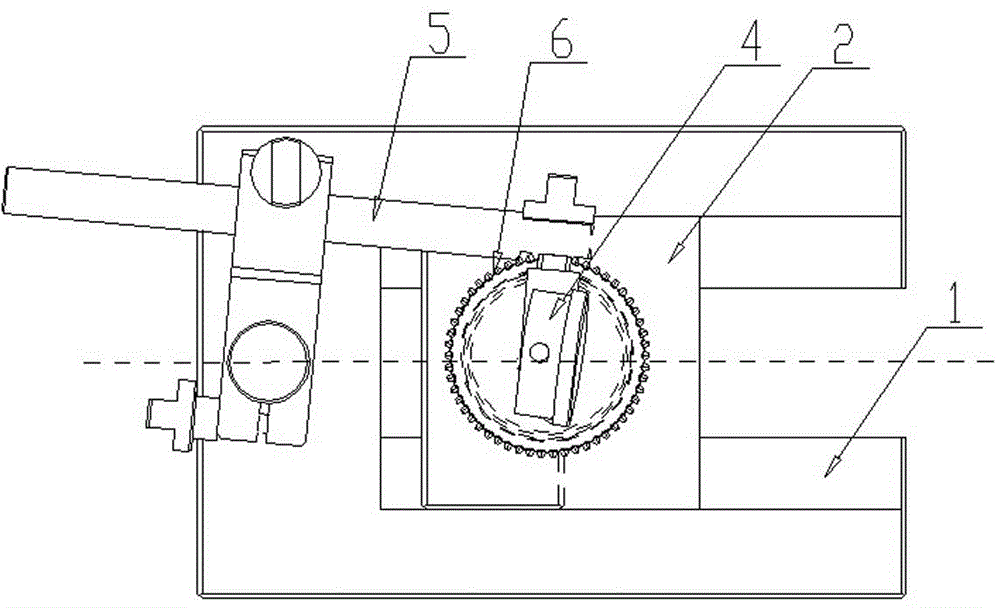

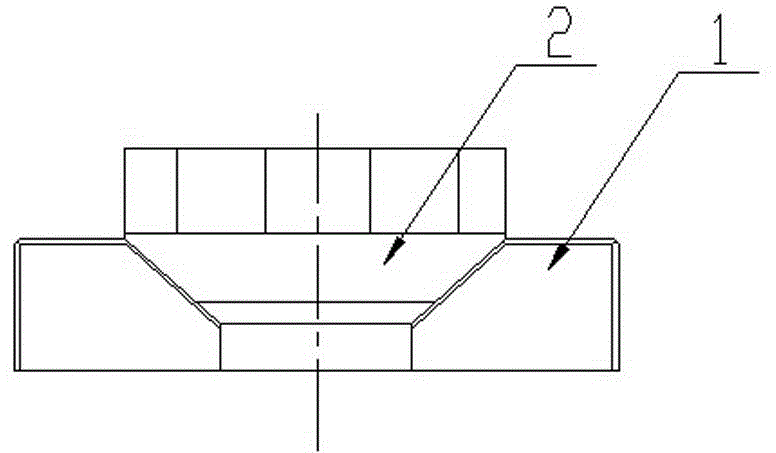

Gear ring length dimension gauge

InactiveCN104390558AEasy to moveLow detection conditionMechanical measuring arrangementsCross connectionEngineering

The invention discloses a gear ring length dimension gauge. The gauge comprises a base, a slider, a shaft seat, an instrument and an instrument frame. The instrument frame is mounted on the base and consists of a vertical rod and a horizontal rod which are intersected with each other; the instrument is assembled at the end of the horizontal rod. An internal open groove is formed in a plate surface of the base; the two sides of the open groove are provided with upward bevels. The bottom surface of the slider is matched with the upward bevels on the two sides of the open groove of the base to form a straight rail structure; the inner side surface of one upwards-bent side is provided with a V-shaped groove vertical to the straight rail. A circular bead is arranged at the top end of the shaft seat and has clearance fit with an inner hole of a work-piece; the shaft seat is moved so that the outer wall of a main shaft section is located close to the bevel of the vertical V-shaped groove of the slider. The gear ring length dimension gauge disclosed by the invention belongs to mechanical measurement and is low in requirements on detection condition, quite simple in structure but precise in measurement results, convenient to operate and especially suitable for being arranged in a production field. One-line detection is beneficial for finding out quality deviation in time, and occurrence of batch scrap accidents is prevented.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

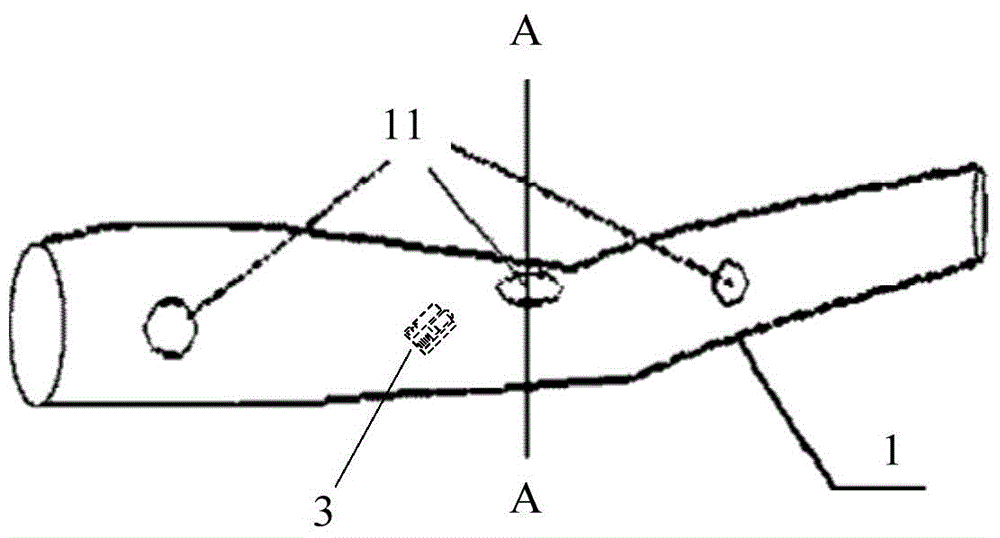

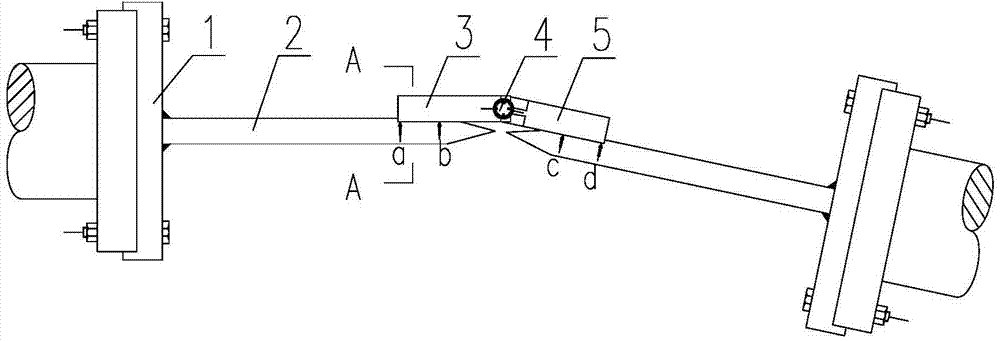

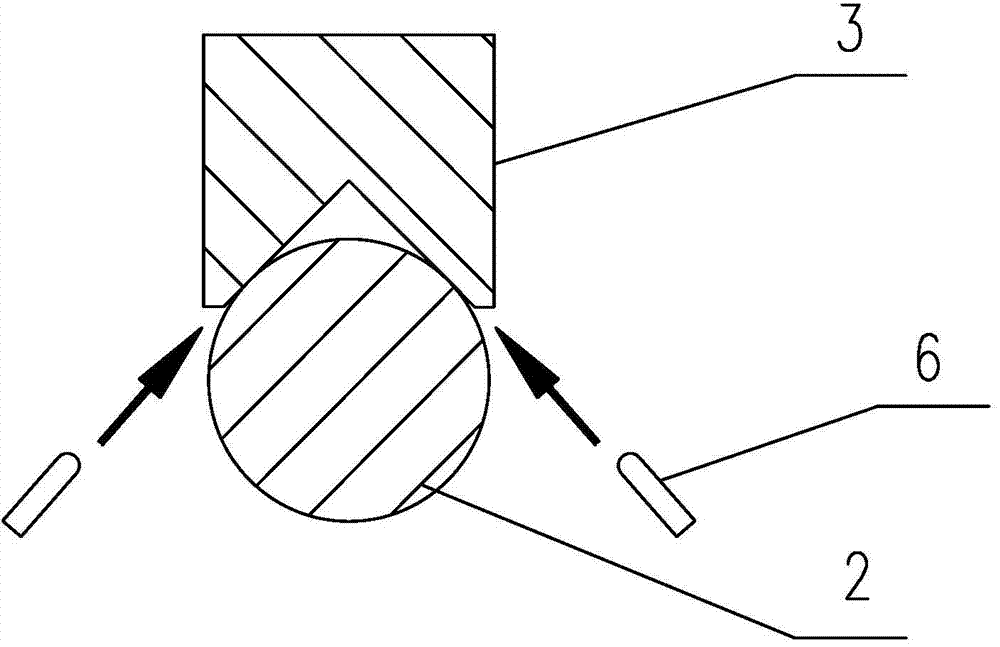

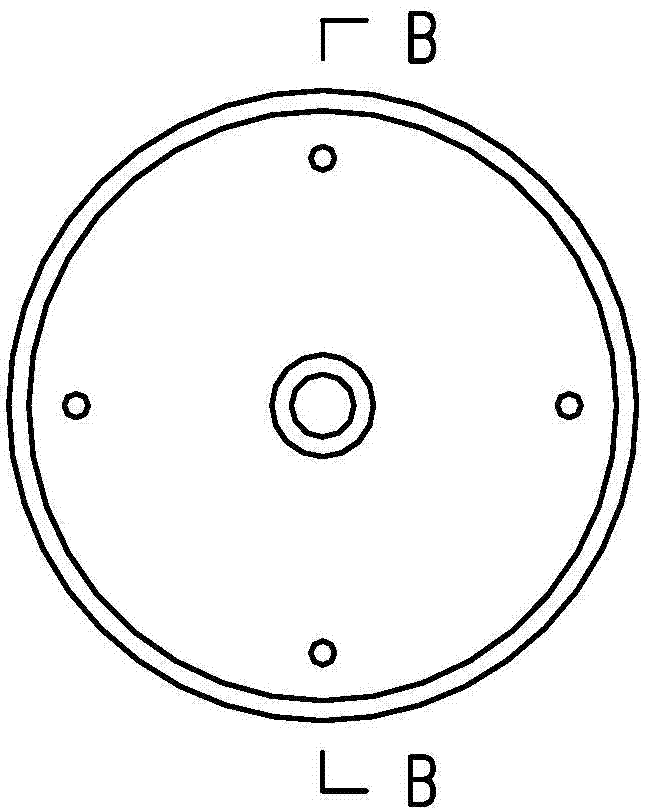

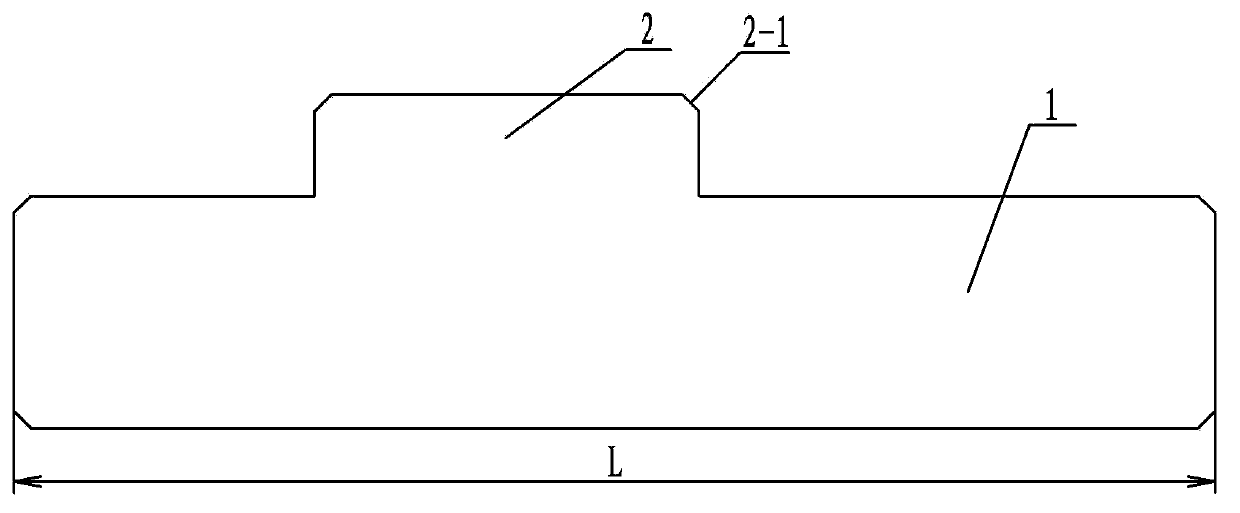

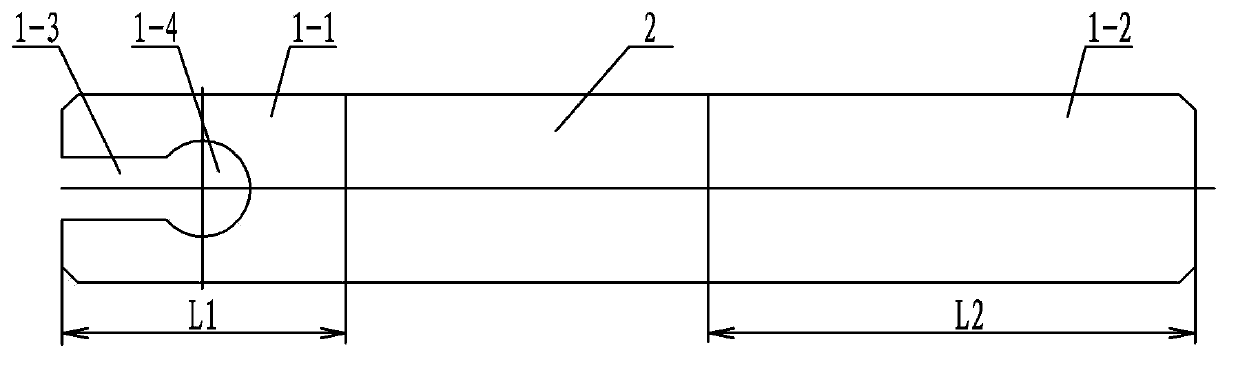

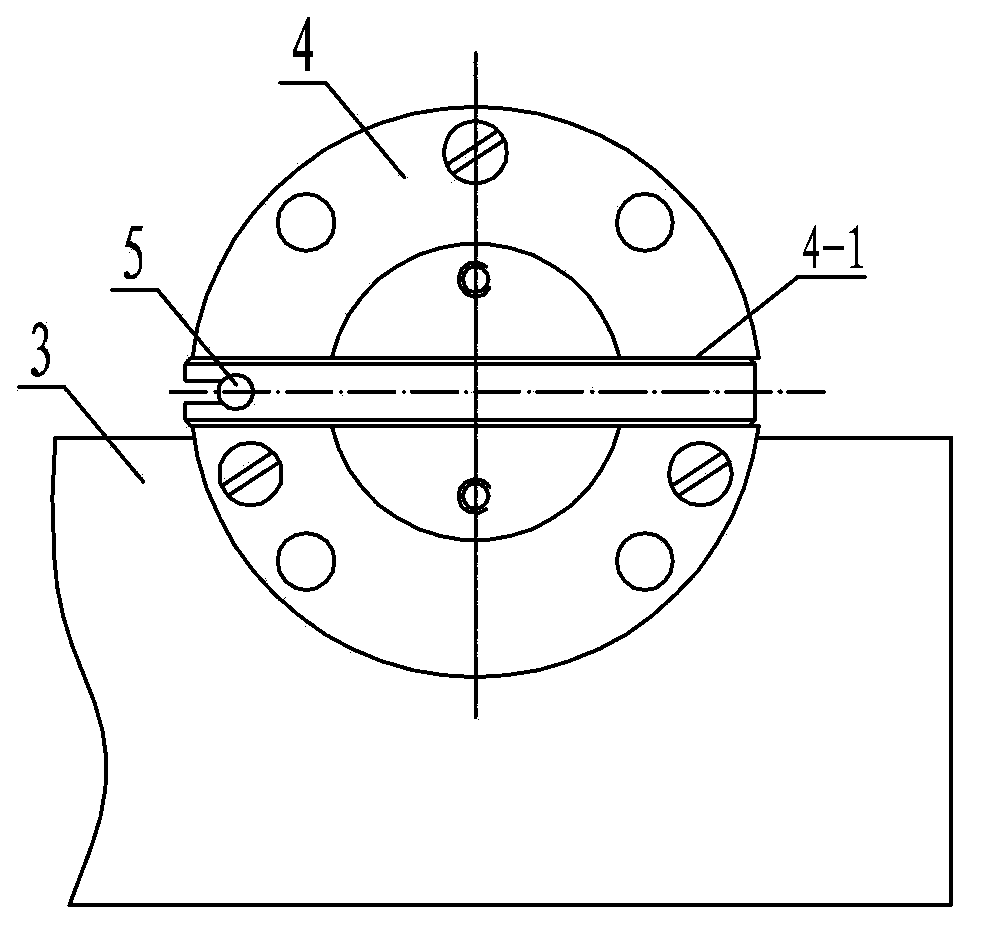

Manufacturing method for zigzag shafting alignment tool

ActiveCN103542797AIntuitive measurement resultsImprove Manufacturing AccuracyAngles/taper measurementsSteel barShaft alignment

The invention discloses a manufacturing method for a zigzag shafting alignment tool, and relates to the field of alignment of zigzag shafting. The manufacturing method includes respectively manufacturing a pair of alignment pointers between an input shaft and an output shaft, wherein the input shaft and the output shaft are adjacent and an included angle is formed between the both, and each alignment pointer is a mechanical member formed by welding of a flange and a straight steel bar with a tapered tip; manufacturing a set of alignment right-angle ruler comprising a first right-angle ruler arm, an angle indicating bolt and a second right-angle ruler arm, wherein a screw hole is formed at the ruler arm end of each of the first right-angle ruler arm and the second right-angle ruler arm, the angle indicating bolt penetrates the screw hole to fix the first right-angle ruler arm and the second right-angle ruler arm together, and the first right-angle ruler arm and the second right-angle ruler arm rotate around the angle indicating bolt which displays included angle between the first right-angle ruler arm and the second right-angle ruler arm. By the method, both angle and offset can be measured, measuring results are visual, measuring accuracy is high, construction is simple and convenient, the tool is convenient to demount, and production efficiency can be improved.

Owner:WUCHANG SHIPBUILDING IND

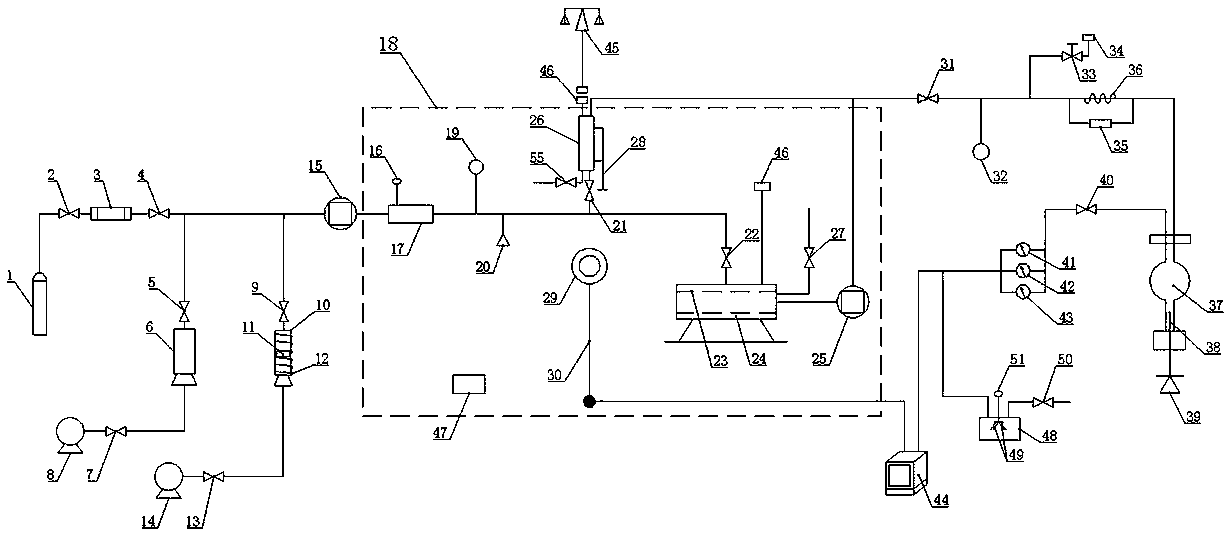

High-precision visual testing device and method for influence factors of wellbore sulfur precipitation

ActiveCN109060616AImprove test accuracyReal-time calculation of deposition volumeMaterial analysisData acquisitionHigh pressure

The invention discloses a high-precision visual testing device and method for the influence factors of wellbore sulfur precipitation. The high-precision visual testing device comprises a supply system, a wellbore condition simulation system, a magnetic suspension balance measuring system, a visual data collecting system and a tail gas treatment system. The high-precision visual testing device andmethod have the beneficial effects that the device can truly simulate any types of wellbores, the temperature and pressure of any positions and different phase states of sulfur, the sulfur precipitation influence factors can be measured and analyzed qualitatively by changing temperatures, pressure, precipitation time, hole deviation angles, the content of hydrogen sulfide and the content of water,the testing precision of sulfur precipitation quantity and precipitation speed can be greatly improved, and the precipitation dynamic condition and the sedimentation dynamic condition of sulfur in awellbore are observed through high-power microscope in real time; and when sulfur elements suspend in the wellbore, the critical suspended velocity and the minimum sulfur carrying gas production rateof the sulfur under different states can be calculated. The high-precision visual testing device and method have the advantages of good safety, high measuring precision, high temperature and pressureresistance, high corrosion resistance and the like, thereby having very important significance to research of high sulfur content gas wellbore sulfur precipitation laws.

Owner:SOUTHWEST PETROLEUM UNIV

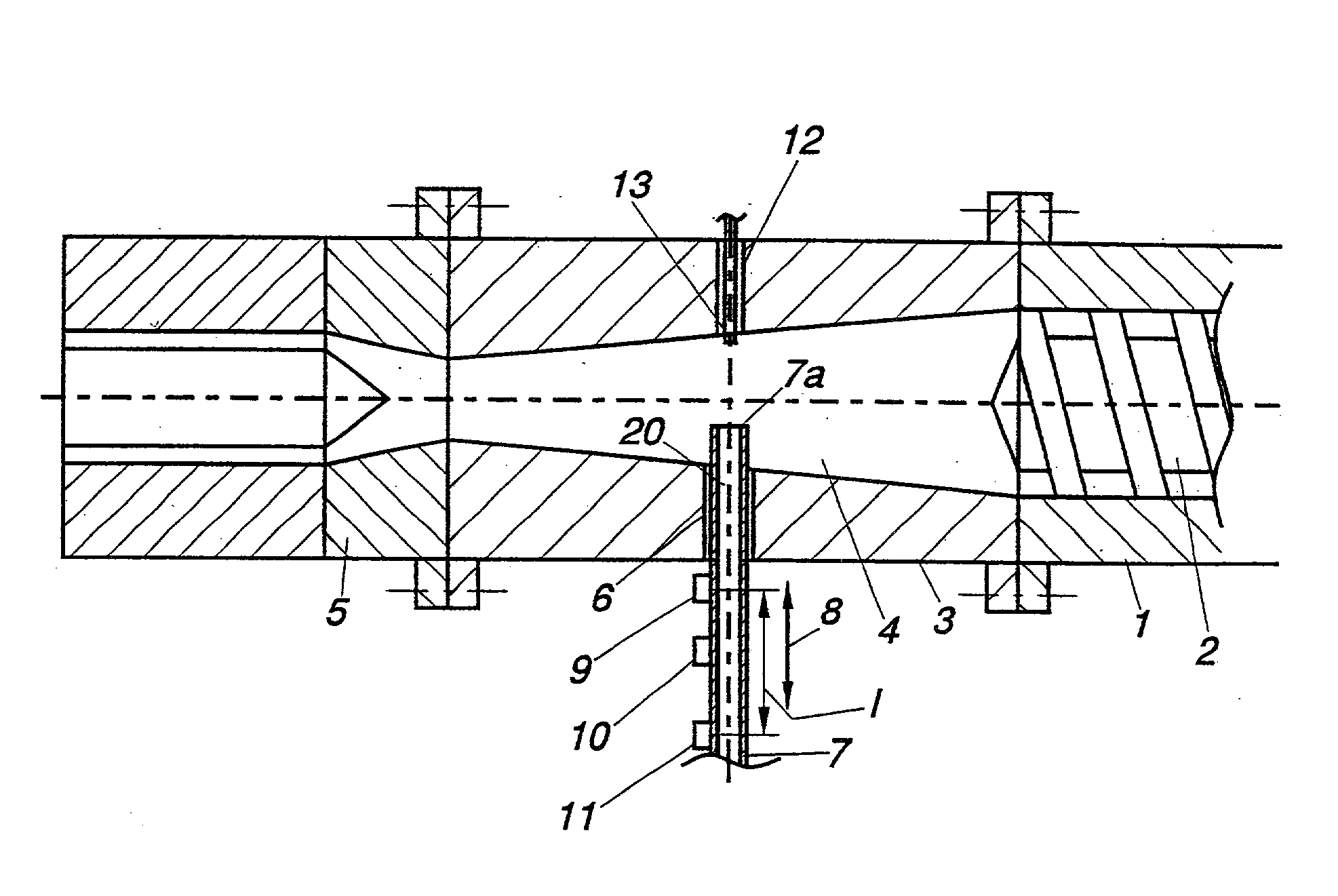

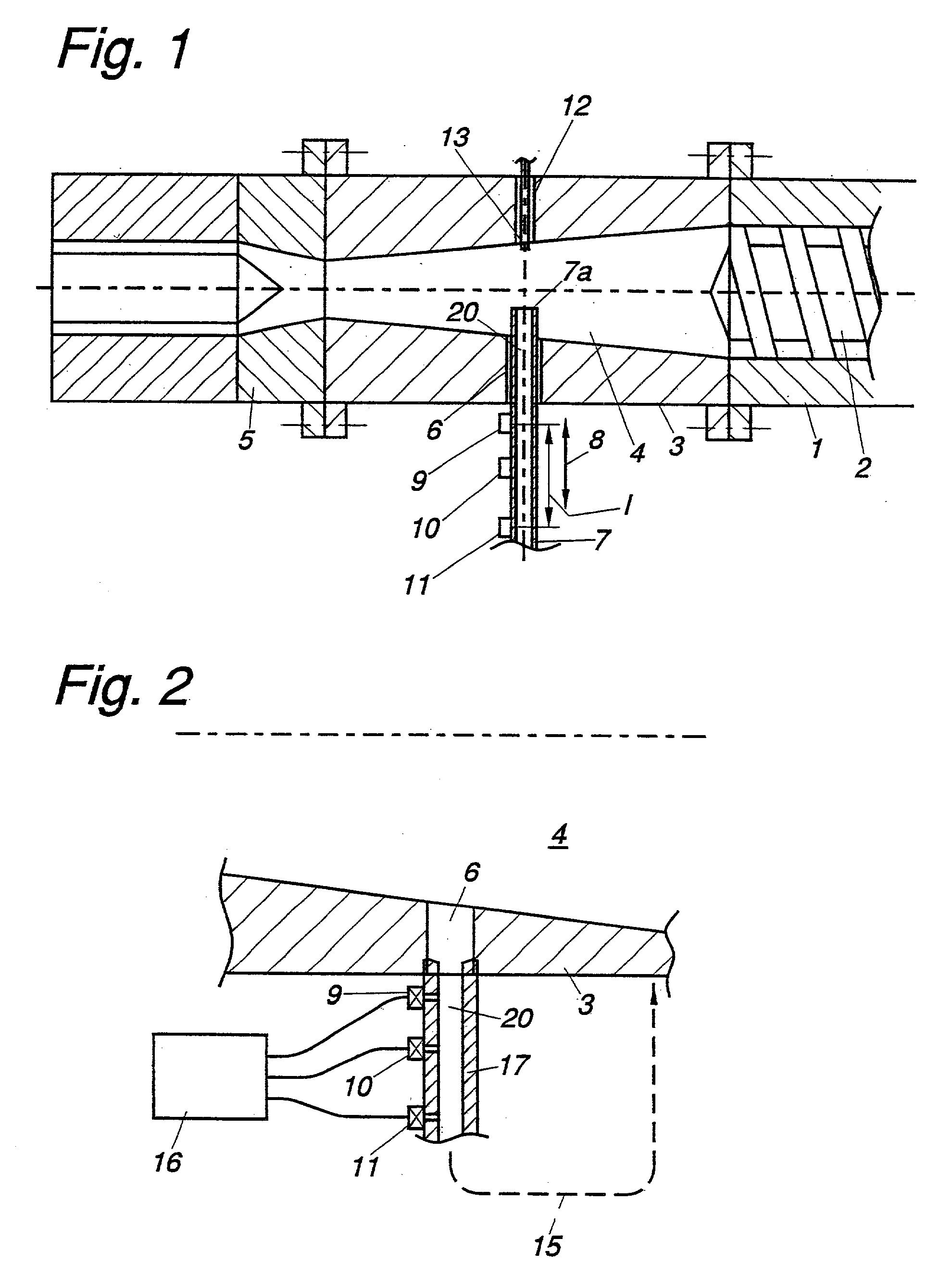

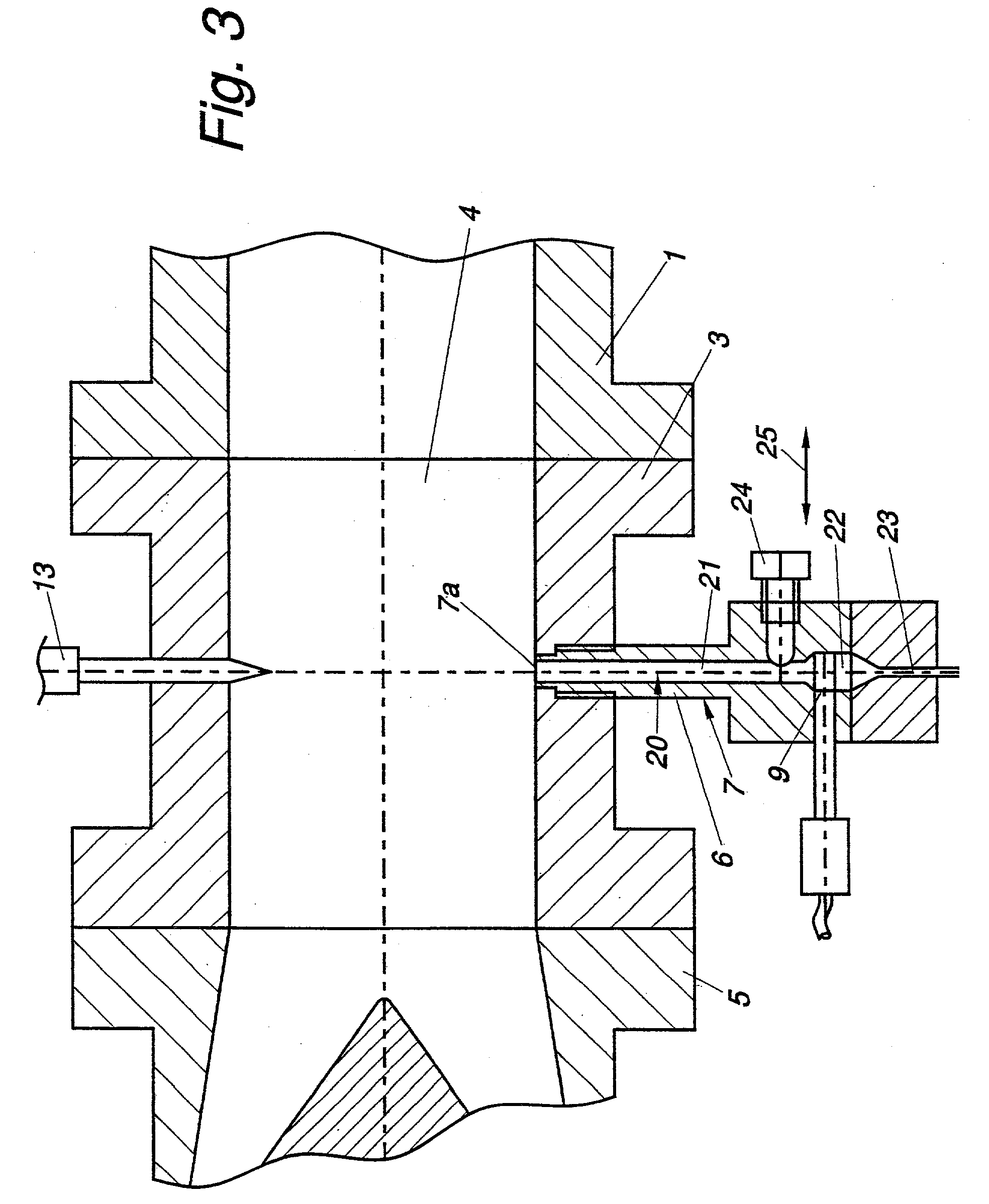

Method and an apparatus for adjusting an extrusion die in an extruder

InactiveUS20020185765A1Minimise measureIntuitive measurement resultsMouldsConfectioneryFlow curveEngineering

The invention relates to a method for adjusting an extrusion die in an extruder by recording at least one master flow curve (40, 41) in a first extruder to which the extrusion die is optimized, in which curve the volume flow is entered over the pressure, which master flow curve (40, 41) is obtained in a measuring channel (20) which branches off in the extruder, the extrusion die or in any interposed adapter part from the flow channel (4), and the repeated recording of flow curves (30, 31) in the same or similar measuring channels (20) as in the first extruder after the assembly of the extrusion tool in the extruder to be checked and adjusted, and the purposeful change of process parameters for such a time until the flow curves (30, 31) correspond to the master flow curves (40, 41) within predetermined tolerance ranges.

Owner:TECHNOPLAST KUNST GES

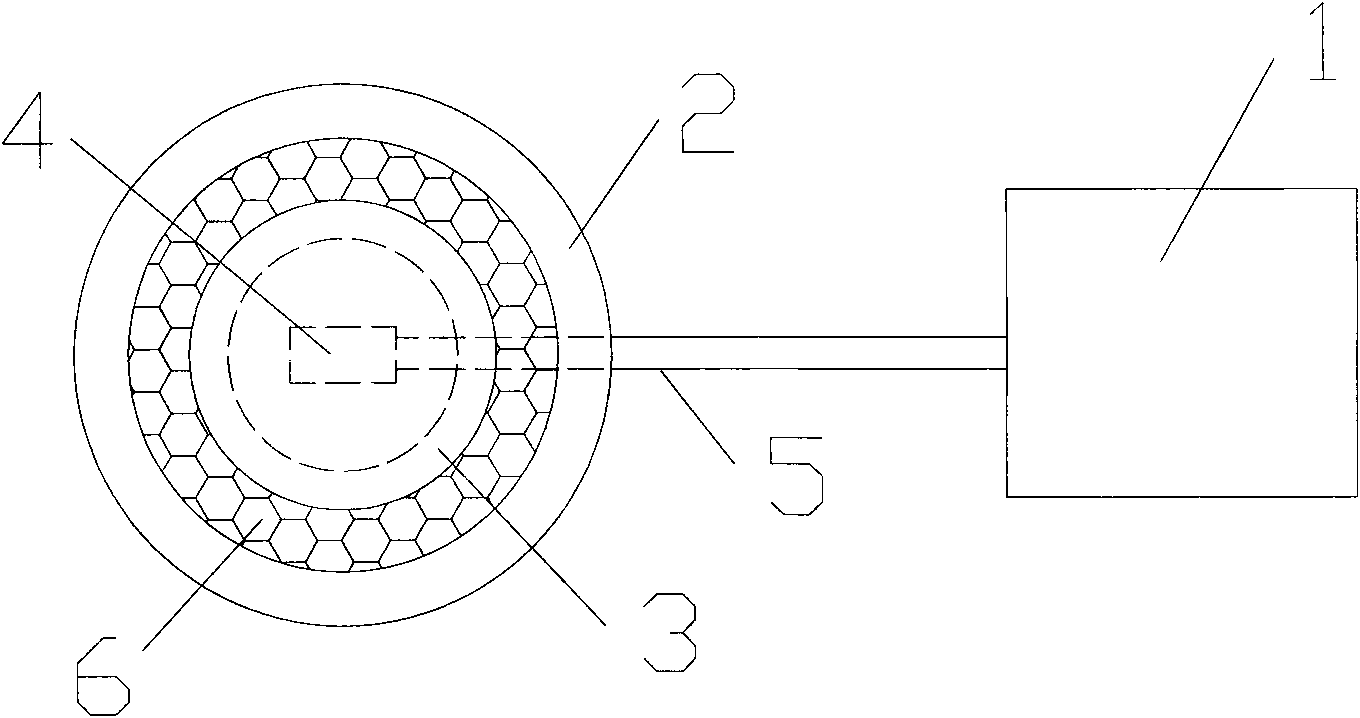

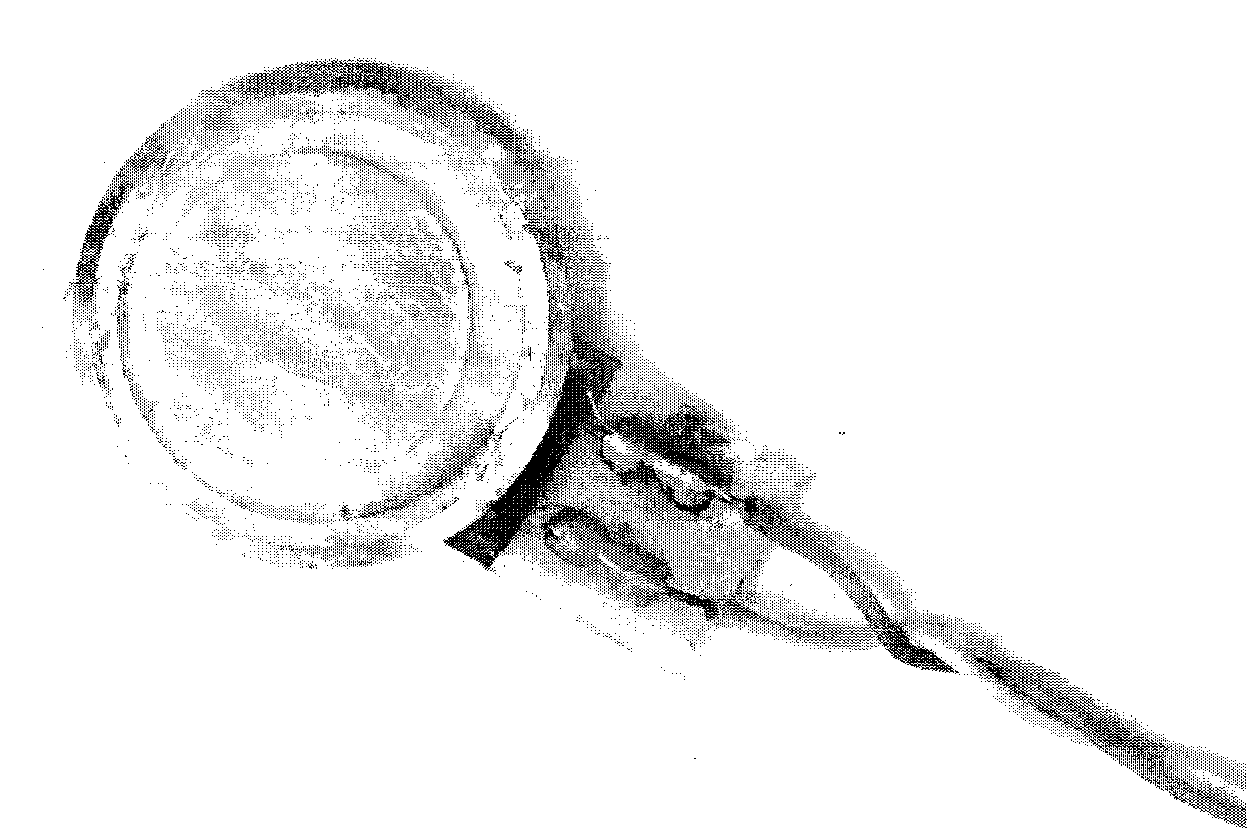

Test method and test device of confining pressure in steel tube concrete

InactiveCN101881673AIntuitive measurement resultsAccurate measurementForce measurementSteel tubeDeformation strain

The invention relates to a test method and a test device of confining pressure in steel tube concrete. The test method of the confining pressure of a steel tube to core concrete is characterized in that a miniature waterproof pressure gauge is fixedly arranged on the inner wall of the steel tube, and the core concrete transversely deforms under a loading action and generates corresponding deformation strain through a pressure slice arranged on the miniature waterproof pressure gauge to directly obtain the confining pressure thereof. The test device thereof comprises an outer circle steel ring, the pressure slice, a resistance strain gauge, a data line, a waterproof sealing layer and a data collection system, wherein the pressure slice, the back of which carries the resistance stain gauge, is arranged at one side of a groove of the outer circle steel ring, wrapped completely for waterproofing and sealing and connected to the data collection system through the data line. A test result thereof is intuitive and accurate, and the test device has the advantages of simpleness, convenience and low cost.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST +1

Mechanical zero adjusting device of steering engine

InactiveCN103968726AMeet the overall performance requirementsSimple structureMechanical measuring arrangementsEngineeringMechanical engineering

Owner:HARBIN JIANCHENG GRP

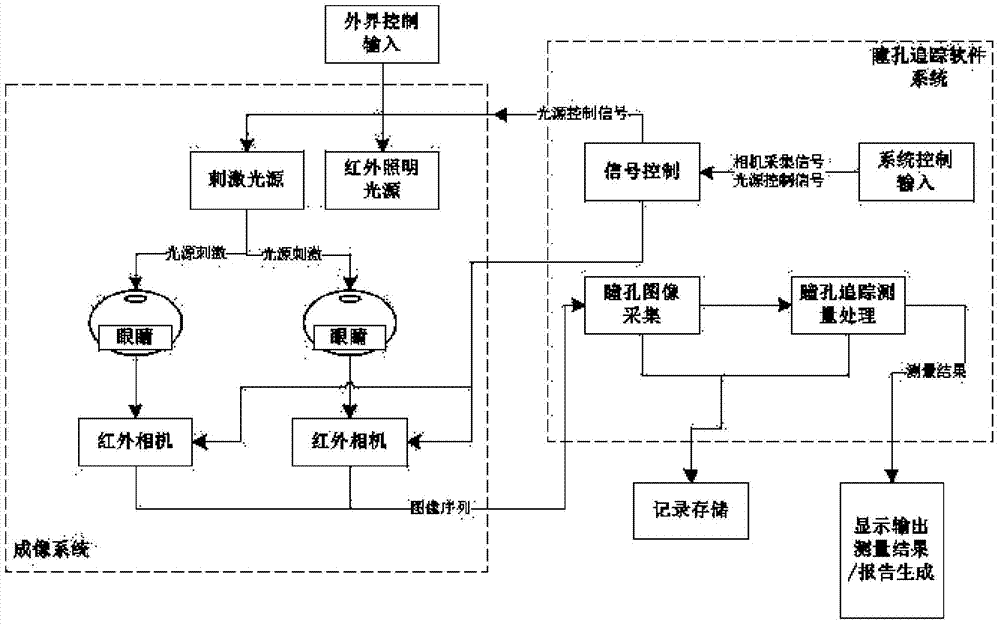

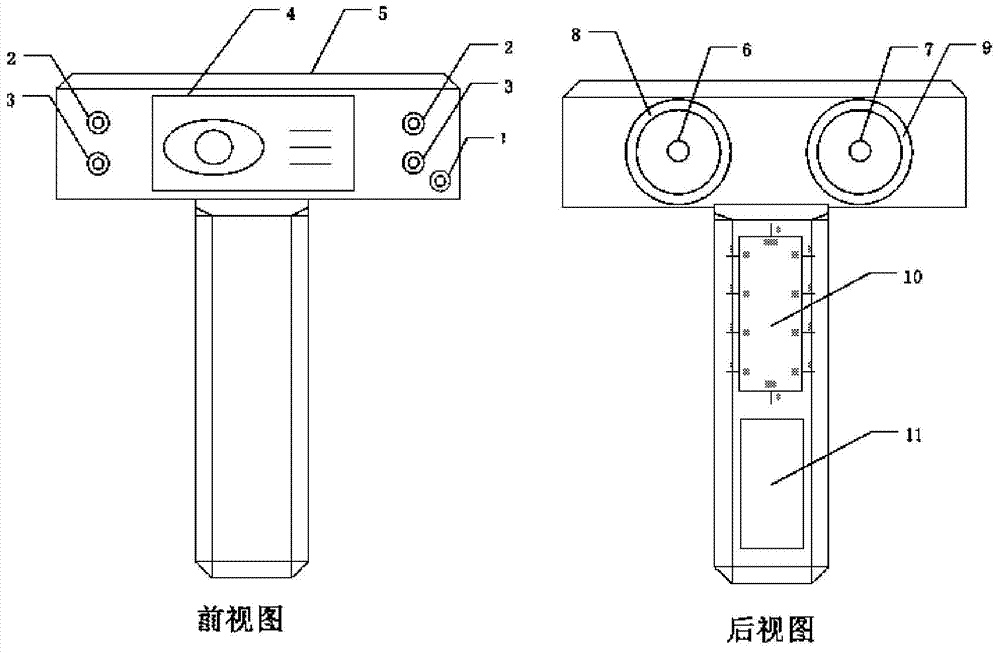

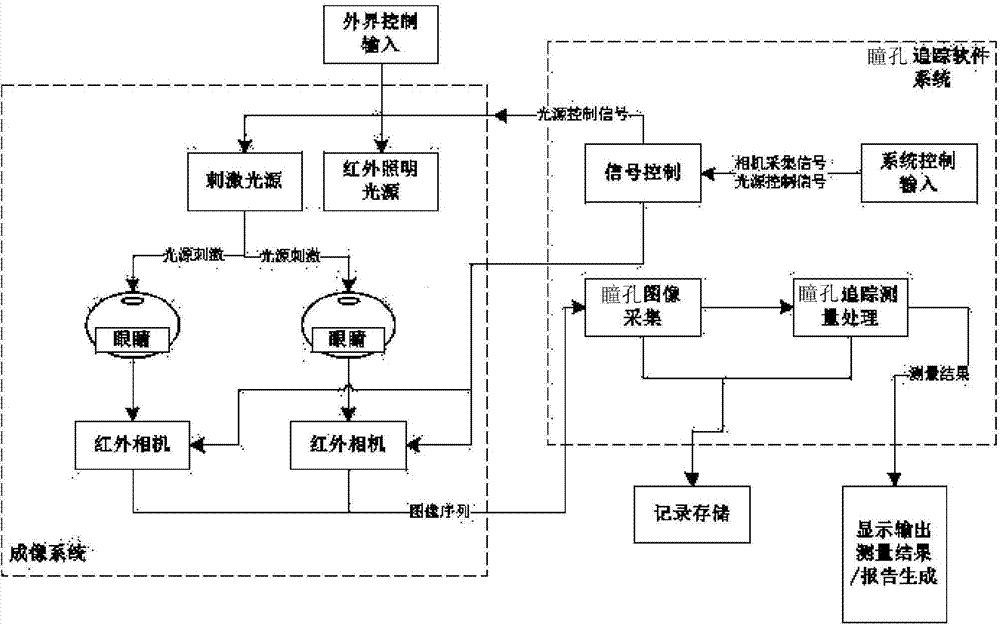

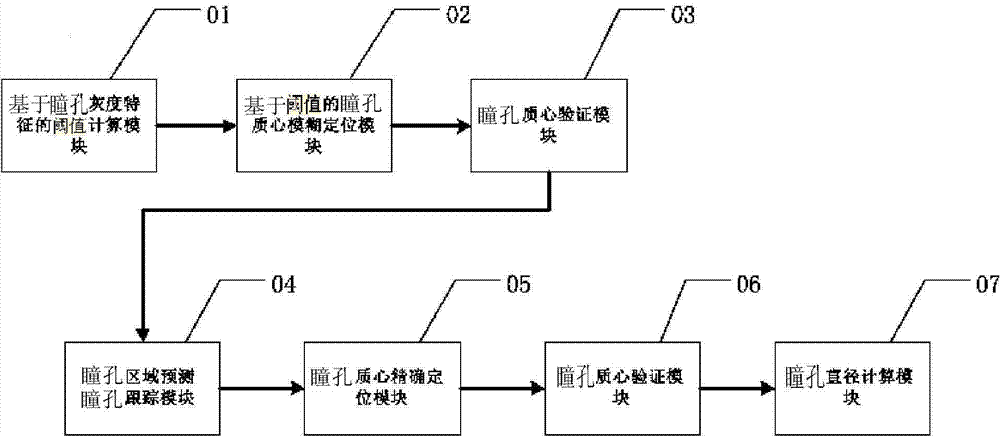

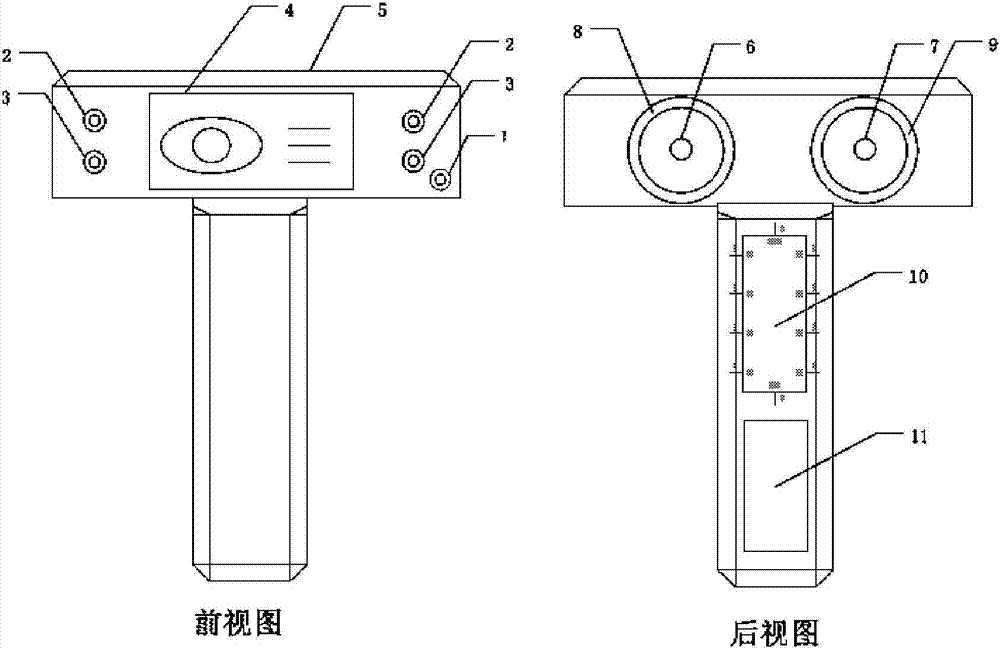

Binocular pupil light reflex tracking system

ActiveCN104739364AImprove portabilityAccurate measurementEye diagnosticsMicrocomputerMicrocontroller

The invention discloses a binocular pupil light reflex tracking system. The binocular pupil light reflex tracking system comprises a grabbing type binocular pupil detection device imaging system and a pupil tracking and measuring module. The imaging system comprises two infrared cameras, two infrared lighting light sources, two stimulation light sources, a grabbing type device and a single-chip microcomputer. The infrared cameras, the lighting light sources, the stimulation light sources and the single-chip microcomputer are integrated in the grabbing type device, the cameras and the light sources are connected with the single-chip microcomputer, and the single-chip microcomputer is in charge of signal control and data input and output. The pupil tracking and measuring module is integrated in the single-chip microcomputer, images collected by the single-chip microcomputer are tracked and measured, and the measuring result is analyzed. The system further comprises a movable seat matched with a handle, and a suspension assembly. The system is high in adaptability, capable of being applied to first-aid and field occasions and the like, and wide in application prospect.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

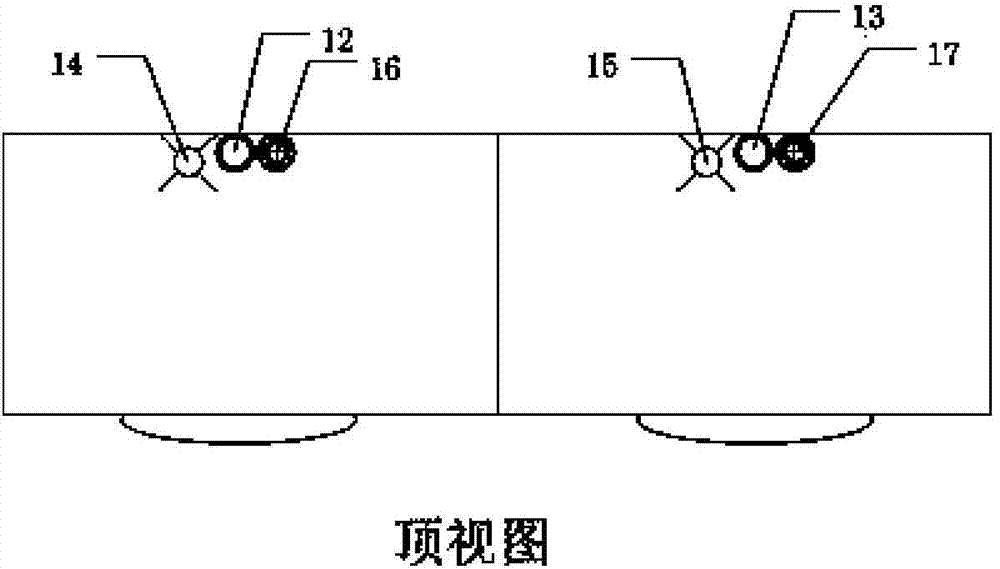

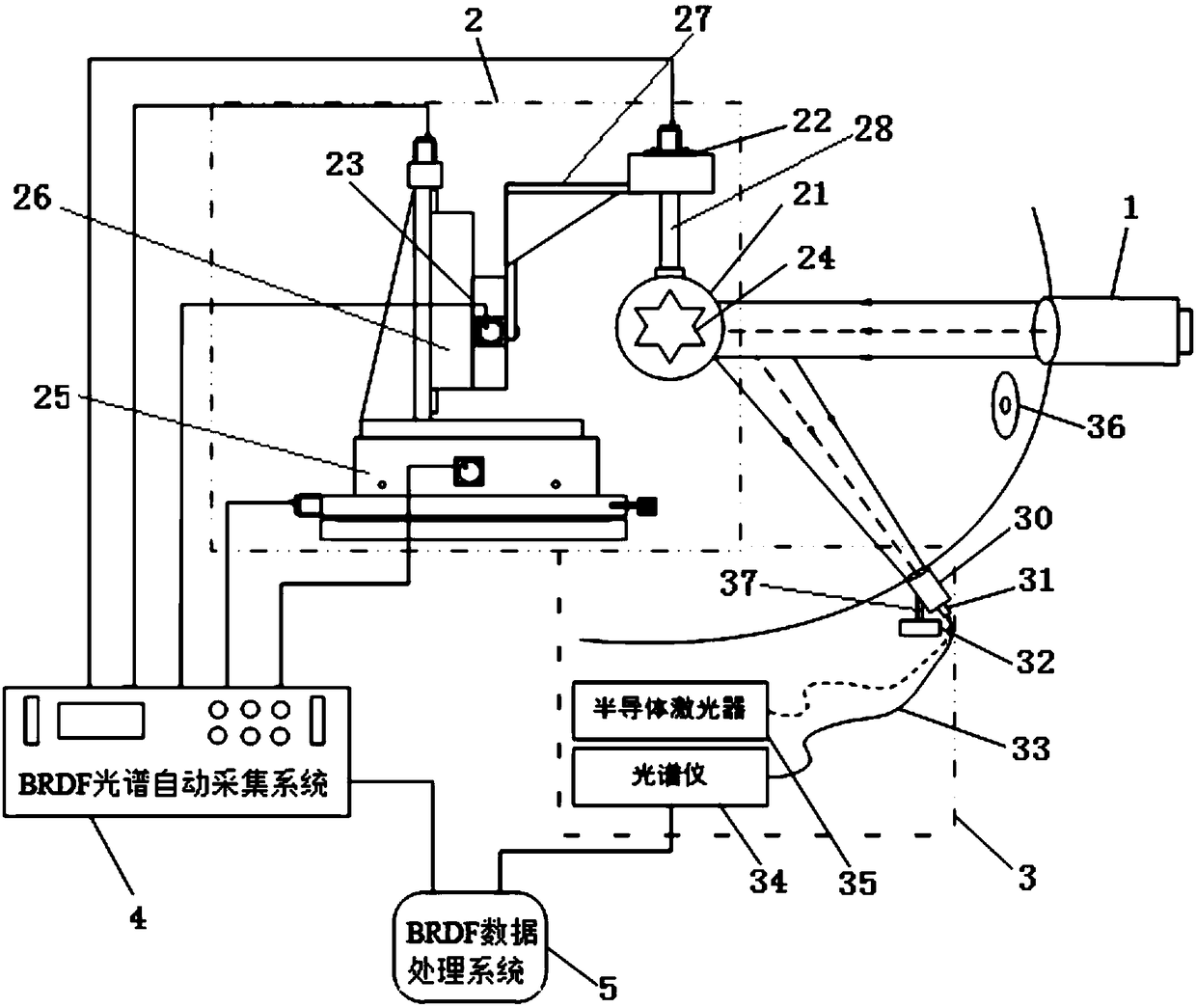

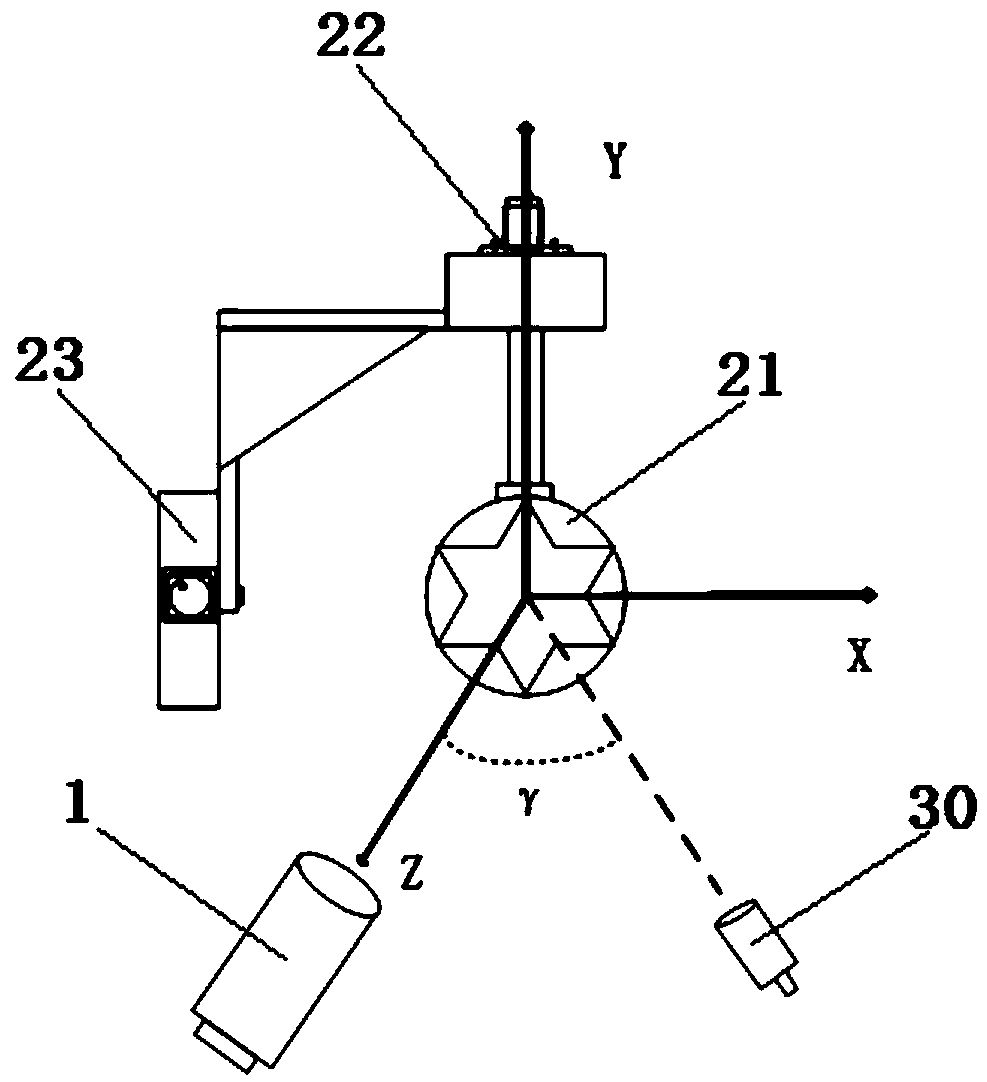

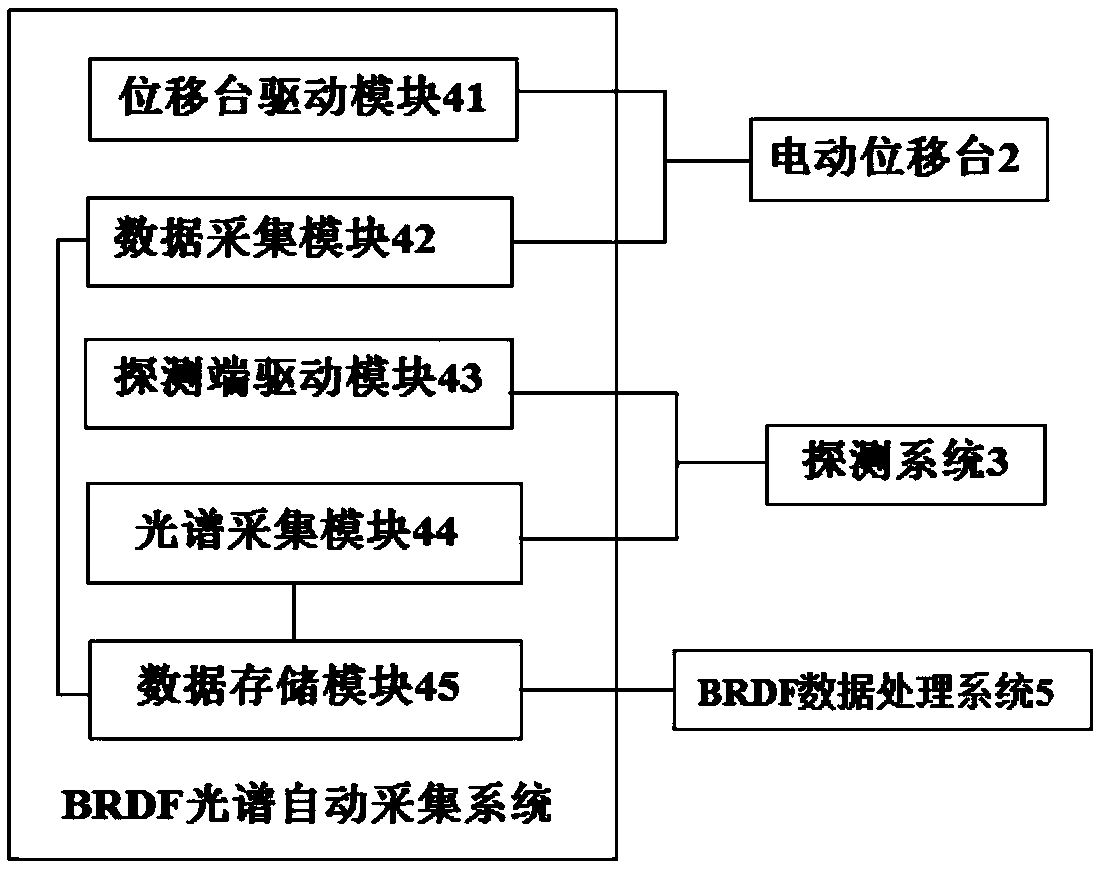

BRDF automatic test system and test method

InactiveCN109342329AImprove continuityHigh light source stabilityColor/spectral properties measurementsData processing systemThree-dimensional space

Disclosed are a BRDF (Bidirectional Reflectance Distribution Function) automatic test system and a test method. The test system comprises a solar simulator, an electric displacement table, a detectionsystem, a BRDF spectrum automatic acquisition system, and a BRDF data processing system. The solar simulator emits a visible light beam to irradiate a sample on the electric displacement table. The electric displacement table is used for realizing movement and rotation of the sample in a three-dimensional space. The detection system comprises a movable platform, a two-dimensional rotary platformmounted on the movable platform, a telescope, a fiber probe, and a spectrometer connected with the optical fiber probe through detection optical fibers. The BRDF spectrum automatic acquisition systemis used for controlling motions of the electric displacement table, so that the electric displacement table drives the sample to rotate at any angle in the space. The spectrometer controlling the detection system collects scattering spectrums at any angle of the sample. The BRDF data processing system is used for processing collected spectrum data to obtain BRDF data at any angle. The BRDF automatic test system is adjustable in detection distance, can achieve detection of long-distance and large-volume objects, and is high in detection precision.

Owner:CHANGCHUN UNIV OF SCI & TECH

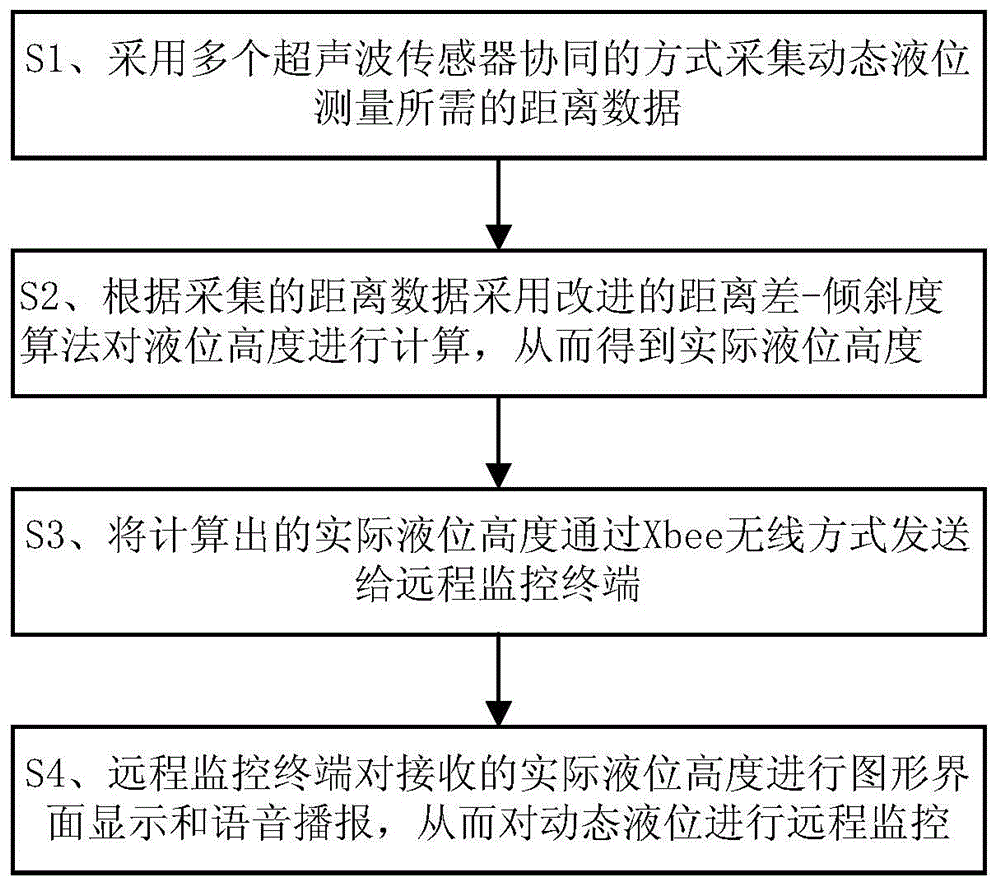

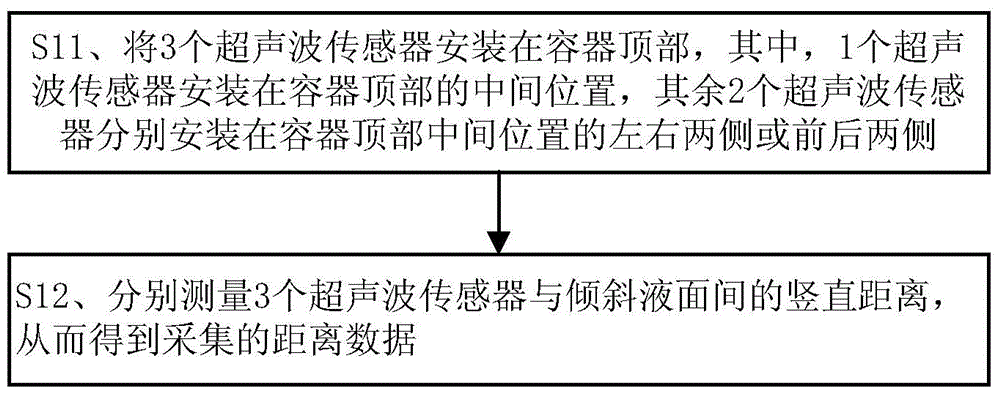

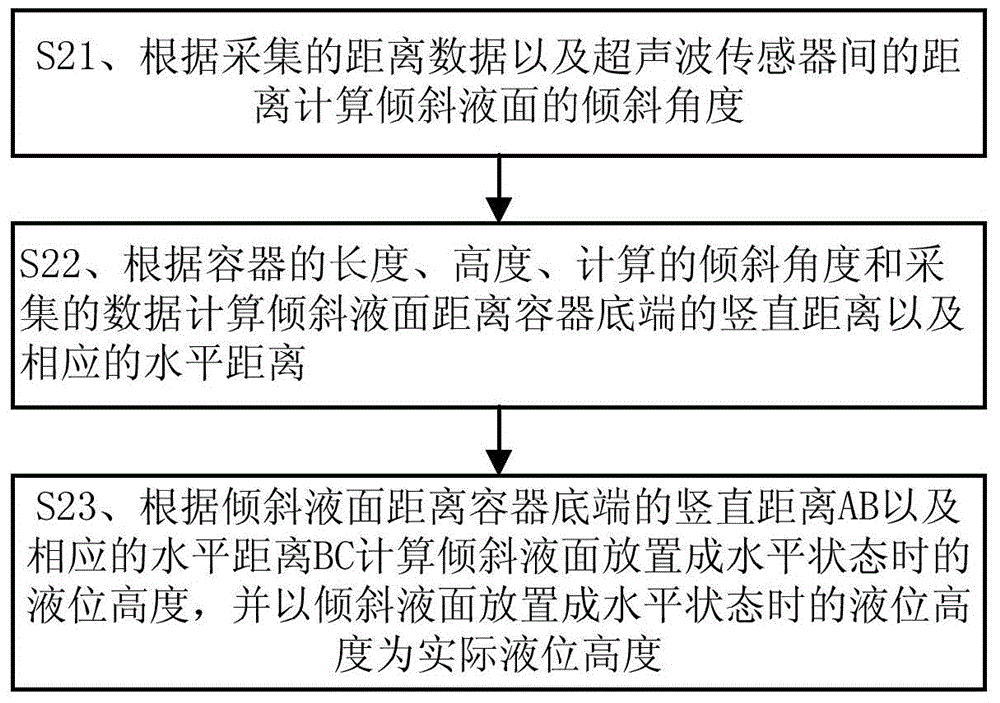

Dynamic liquid level wireless monitoring method and system

ActiveCN105004402AImprove scalabilityIntuitive measurement resultsMachines/enginesLevel indicatorsUltrasonic sensorLiquid level measurement

The invention discloses a dynamic liquid level wireless monitoring method and system. The method comprises following steps: acquiring distance data needed for dynamic liquid level measurement through the cooperation of multiple ultrasonic sensors; calculating the liquid level height through an improved distance difference-gradient algorithm according to the acquired distance data, so that the actual liquid level height can be obtained; sending the calculated actual liquid level height to a remote monitoring terminal through an Xbee wireless manner; and the remote monitoring terminal displays the received actual liquid level height on the graphical interface and broadcasts the actual liquid level height through voice, so that the dynamic liquid level is remotely monitored. According to the invention, the actual liquid level height under a liquid level inclination condition can be accurately measured, and the method and system can be more widely used; the method and the system utilizes ad-hoc network characteristics of an Xbee module, so that the expansion of a sensor network system is facilitated; measuring results can be visually provided for users, and the results are more visual; and the method and the system can be widely applied to the liquid level measurement field.

Owner:SOUTH CHINA NORMAL UNIVERSITY

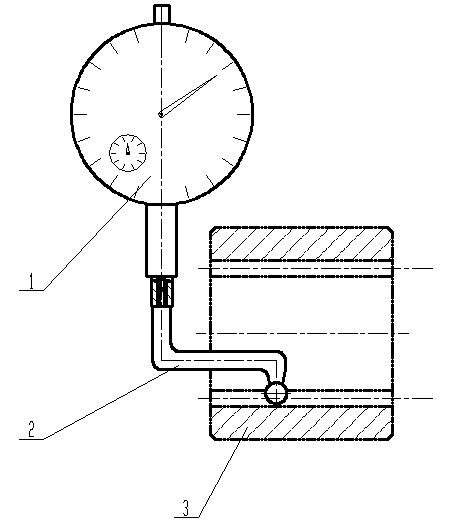

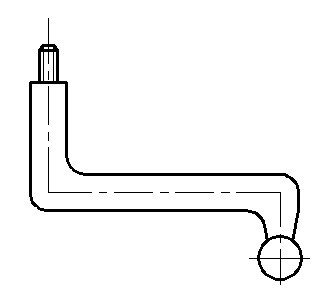

Inner contour measuring meter

InactiveCN102419149AIntuitive measurement resultsAccurate measurementMechanical counters/curvatures measurementsMeasurement deviceMechanical components

The invention discloses an inner contour measuring meter which consists of two parts, namely a commodity dial gauge and a self-control gauge head, wherein an original gauge head is detached from a purchased dial gauge, and axial internal thread holes are reserved at the end face of a measuring rod of the dial gauge; the configured gauge head is in the shape of a two-way right-angled bent rod; and external threads at an upward end are connected with the axial internal thread holes at the end face of the measuring rod of the dial gauge, and a downward end is a measuring end which can extend into an inner cavity of a workpiece to perform measurement. The structure is especially suitable for measuring the inner contour in a machine element with small inner cavity volume, and the measurement result is indicated by external dial gauge magnitude values. On the other hand, the inner contour measuring meter disclosed by the invention is a mechanical measuring device, has no special restrictions on detection conditions, can be used in a production field, and is high in detection efficiency and low in use cost; and in a product line, the inner contour measuring meter used as the measuring device of an operator can be used for avoiding the occurrence of batched outoftolerance accidents.

Owner:JIANGSU AIRSHIP GEAR

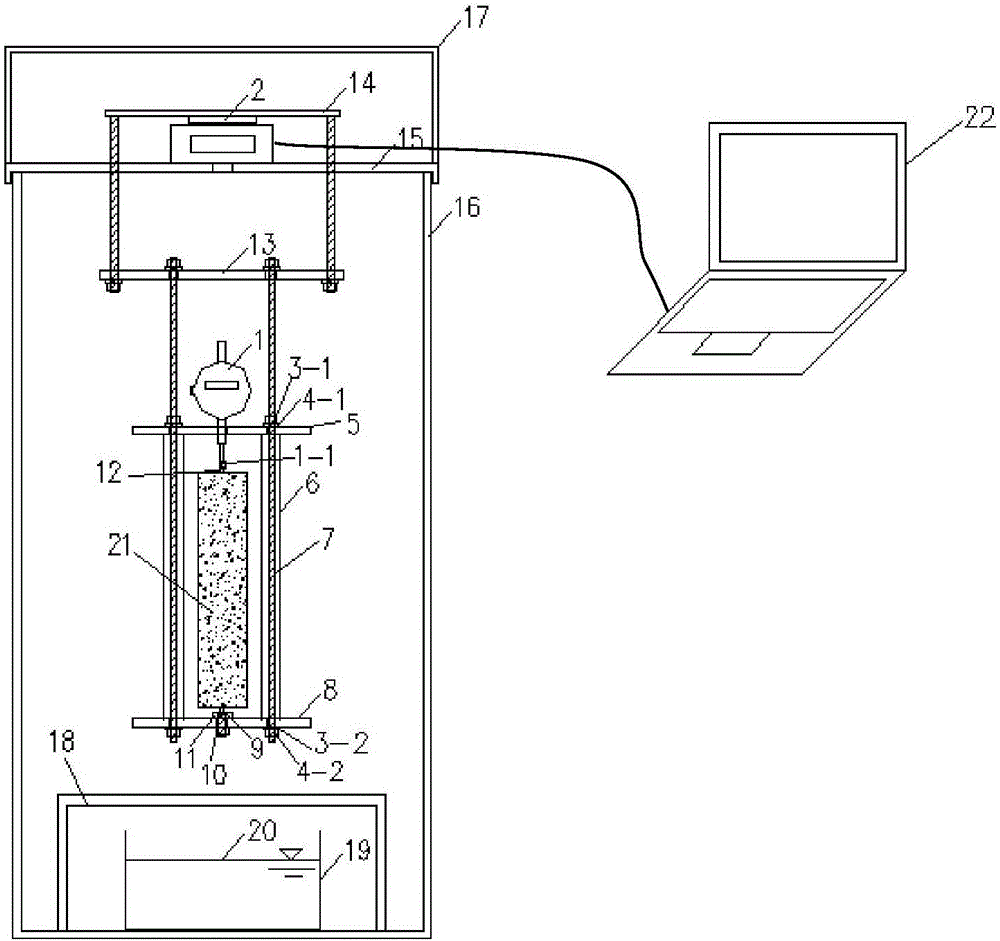

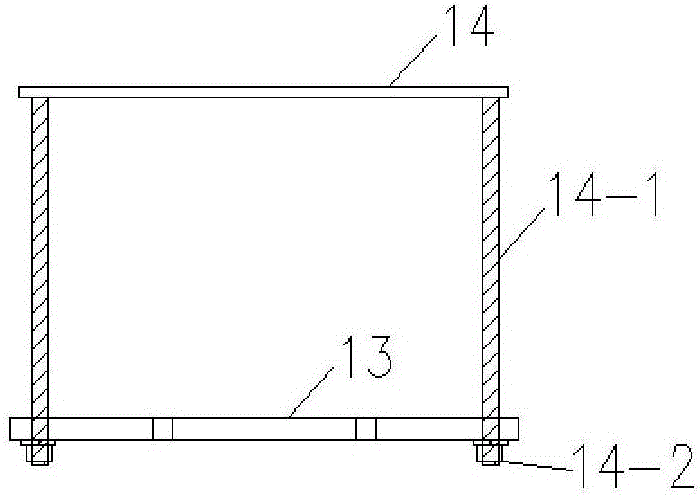

Wall brick hygroscopic-expansion-deformation dynamic testing instrument and testing method

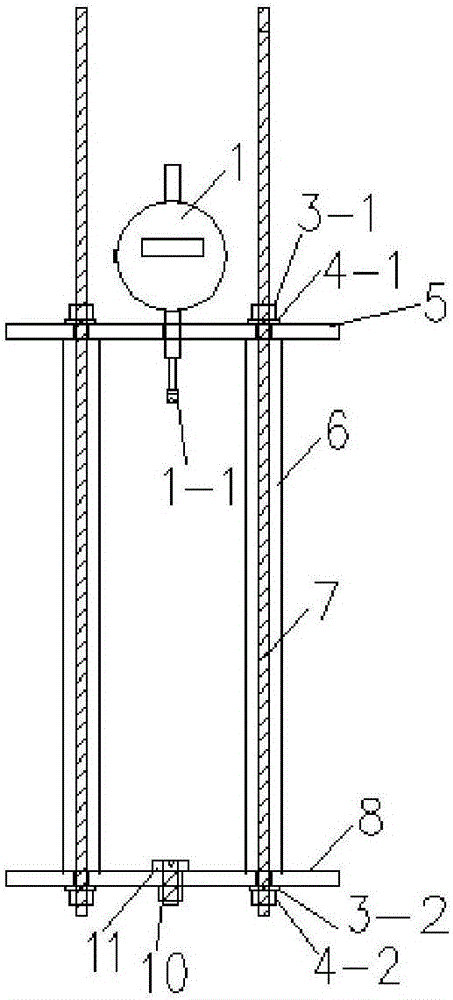

PendingCN106680139ASolving the Key Problems of Gauge Length PositioningRealize dynamic measurementWeighing by removing componentMechanical solid deformation measurementsBrickTester device

The invention discloses a wall brick hygroscopic-expansion-deformation dynamic testing instrument and testing method. The testing instrument comprises a dial indicator, a measuring frame, an electronic balance, a humidistat, a balance hood and a computer, wherein a glass dial indicator pedestal and a glass specimen pedestal are respectively provided with holes, and two quartz tube end sockets are respectively arranged in the holes on both sides; a first threaded rod is respectively arranged in each quartz tube, and is fixedly connected with a first nut and a second nut, and a first spring washer, a second spring washer, the quartz tube, the glass dial indicator pedestal and the glass specimen pedestal are respectively connected flexibly; the balance hood is used for ensuring the humidity in the humidistat from interference of the external environment; and a crystallizing dish containing a saturated solution is arranged in the humidistat and used for controlling and maintaining the humidity in the box body. The dynamic testing instrument can dynamically measure the air hygroscopic expansion deformation amount and hygroscopic capacity of the wall brick to obtain the expansion value-humidity content characteristic curve under isothermal conditions, thereby enhancing the measurement accuracy.

Owner:SOUTH CHINA UNIV OF TECH

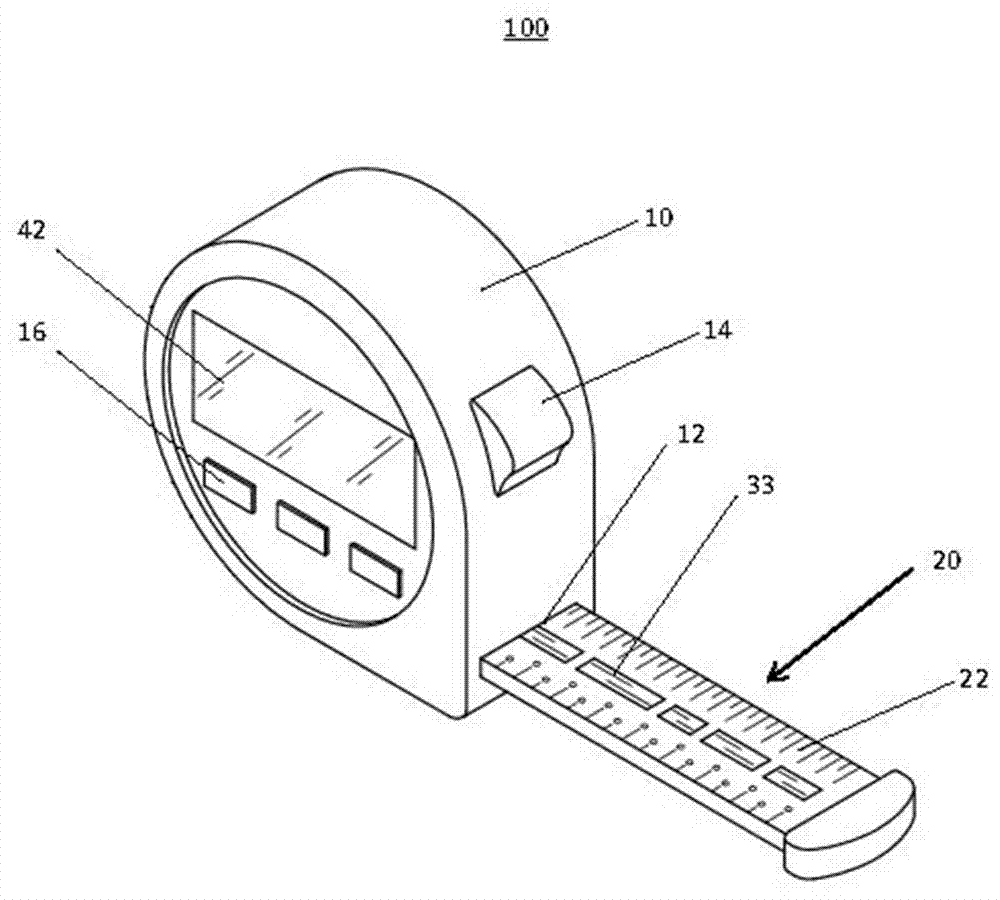

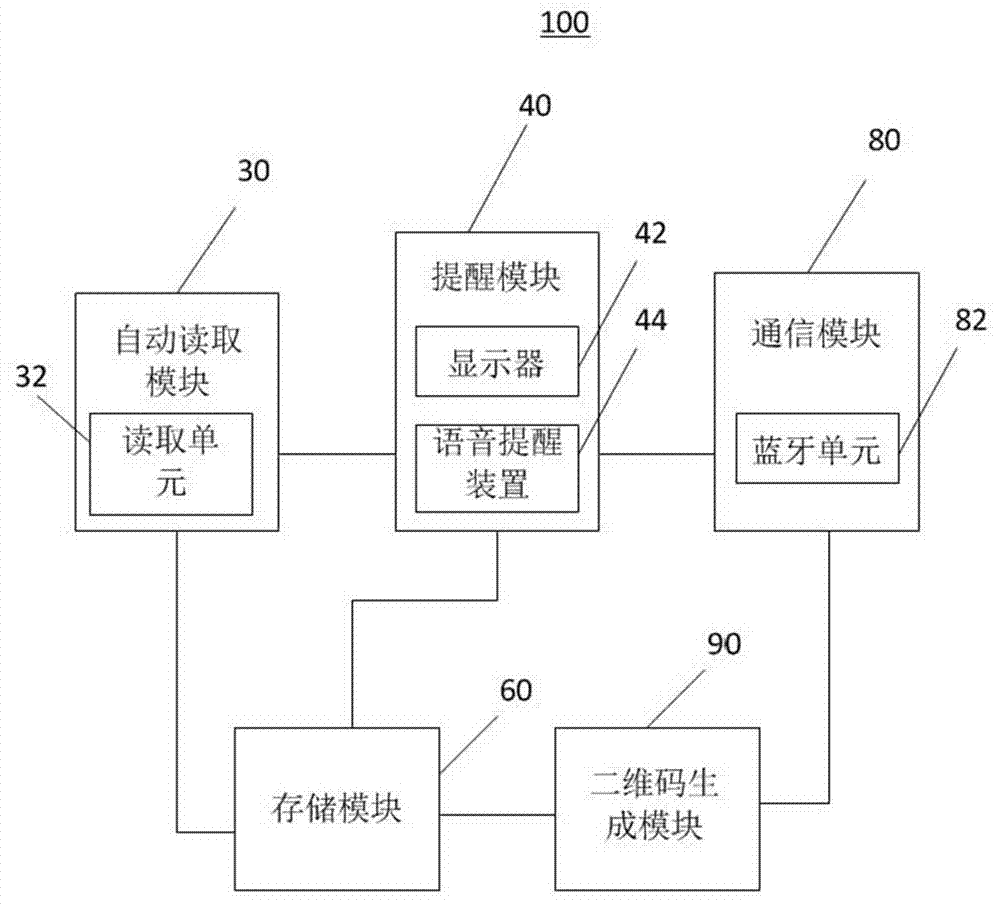

Electronic measuring device

PendingCN107305115AImprove measurement efficiencyEasy to carryMeasuring tapesEngineeringLinear object

The invention provides an electronic measuring device comprising a housing and a stretchable measuring tape installed in the housing. A measuring tape inlet-outlet unit is formed in the housing. In addition, the electronic measuring device also includes an automatic reading module and a prompting module. The automatic reading module consists of a reading unit arranged in the housing and a marking scale arranged at the measuring tape. When the device is used for measurement, the automatic reading unit is used for automatically reading the marking scale of the measuring tape and outputting a corresponding measurement result to the prompting module. The prompting module is used for prompting the user of the measurement result. The electronic measuring device is used for measurement of a human body or some non-linear objects. The automatic reading module reads measurement data automatically, so that the measurement efficiency is improved and the measurement data are standardized; the device can be carried conveniently; and errors are reduced.

Owner:曾庆程

Portable binocular pupil detection device

The invention discloses a portable binocular pupil detection device. The portable binocular pupil detection device comprises a grabbing type binocular pupil detection equipment imaging system and a pupil tracking and measuring module. The imaging system comprises two infrared cameras, two infrared illumination light sources, two stimulation light sources, grabbing equipment and a single-chip microcomputer, wherein the infrared cameras, the illumination light sources, the stimulation light sources and the single-chip microcomputer are integrated in the grabbing equipment, the cameras are connected with the light sources and the single-chip microcomputer, and the single-chip microcomputer takes charge of control of signals and input and output of data; the pupil tracking and measuring module is integrated on the single-chip microcomputer, images collected by the single-chip microcomputer are tracked and measured, and the measurement result is analyzed and processed. The portable binocular pupil detection device is high in portability and can be applied to the occasions of emergency rescue, fields and the like, the measurement result is accurate and visual, and the portable binocular pupil detection device has broad application prospects.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

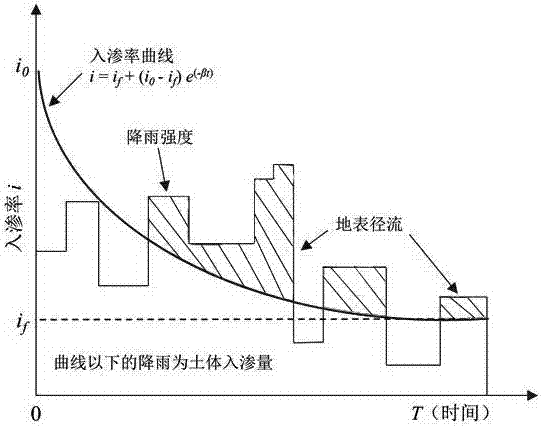

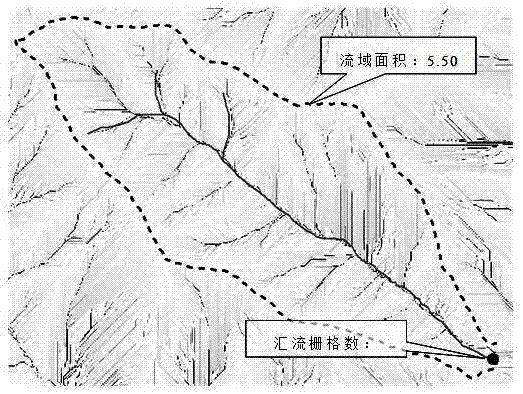

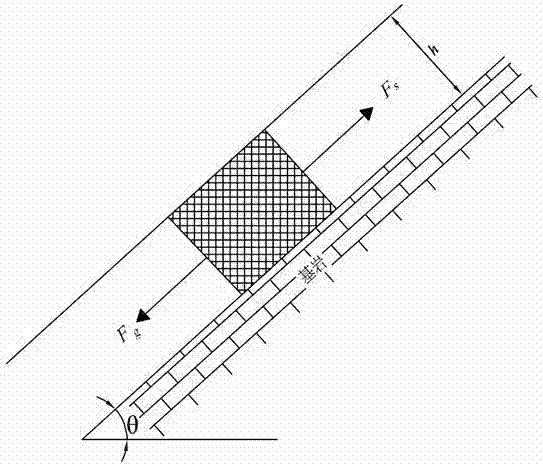

A critical concentration-based debris flow initiation model and application thereof

InactiveCN107169199AAccurate acquisitionEasy accessData processing applicationsDesign optimisation/simulationPorosityCritical micelle concentration

The invention provides a critical concentration-based debris flow initiation model. The method comprises the steps of: a, acquiring the gradient theta of an initiation area, the friction angle phi in a soil body, and the density rho s of the soil body and estimating the volume quantity of solid matter in the initiation area; b, acquiring the water body density rho w of a catchment basin of debris flow and calculating an instability critical volume concentration Cc; c, acquiring the initial solid volume concentration C* and porosity, calculating the volume Vs of solid matter in an unconsolidated formation of an accumulation body, and calculating the water body volume Vw required for initiation of the solid unconsolidated matter; d, calculating the surface area A of a slip mass of the initiation area, calculating the upstream conflux area and acquiring the overland runoff forming time Tp; e, calculating the total water quantity Vw', and comparing the total water quantity with the water body volume Vw required for initiation of the solid unconsolidated matter, wherein the danger of initiation of debris flow exists if Vw' is close to Vw. According to the invention, a rainfall process is not considered and threshold value control can be performed on a rainfall result only by determining cross sectional flow.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com