Test method and test device of confining pressure in steel tube concrete

A technology of concrete filled steel tube and restraint pressure, applied in the direction of measuring device, measuring force, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

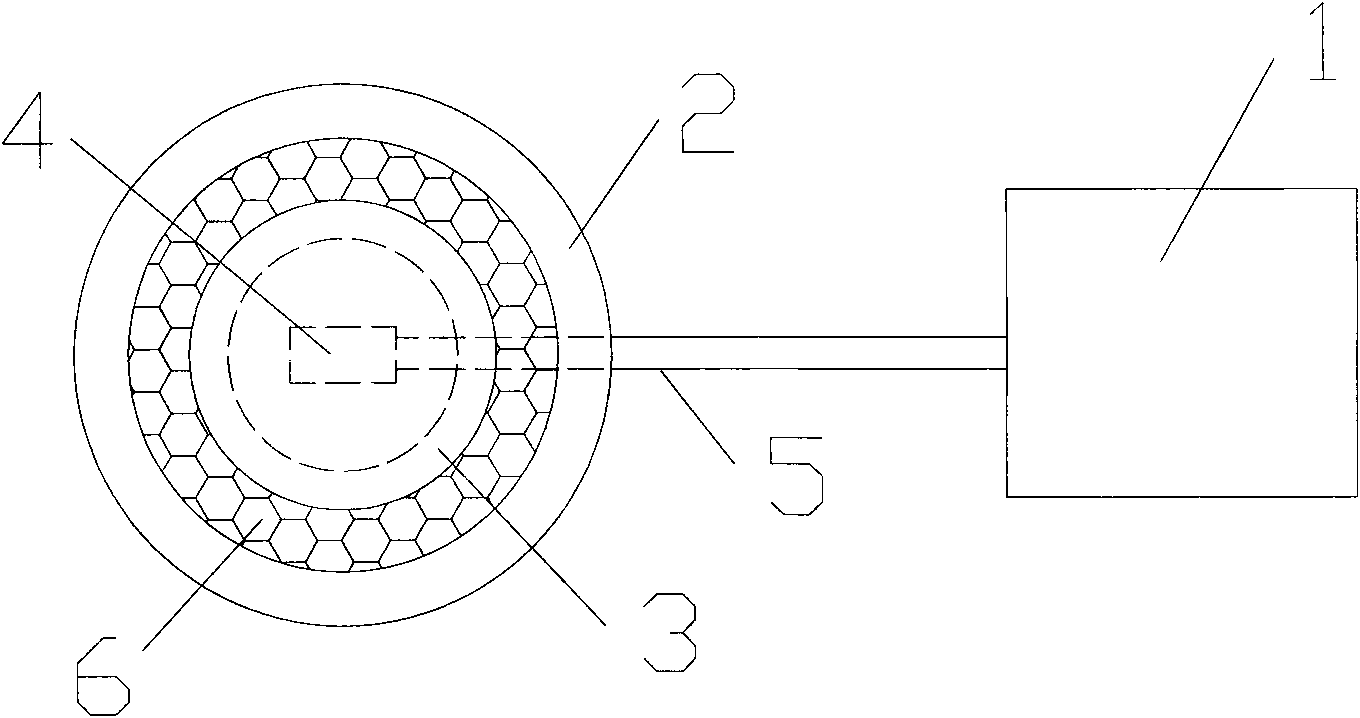

[0011] A test method for the restraint pressure in the concrete-filled steel pipe structure test. Before the concrete is poured, a small waterproof pressure gauge is fixed on the inner wall of the steel pipe with an adhesive, and then the concrete is poured. When the concrete-filled steel pipe structure is under load, the lateral deformation of the core concrete will be The corresponding deformation of the pressure sheet is caused, and the deformation strain is collected by the data acquisition system, and the pressure calibration is applied to convert it into a corresponding pressure value, which is the restraining pressure of the steel pipe on the core concrete.

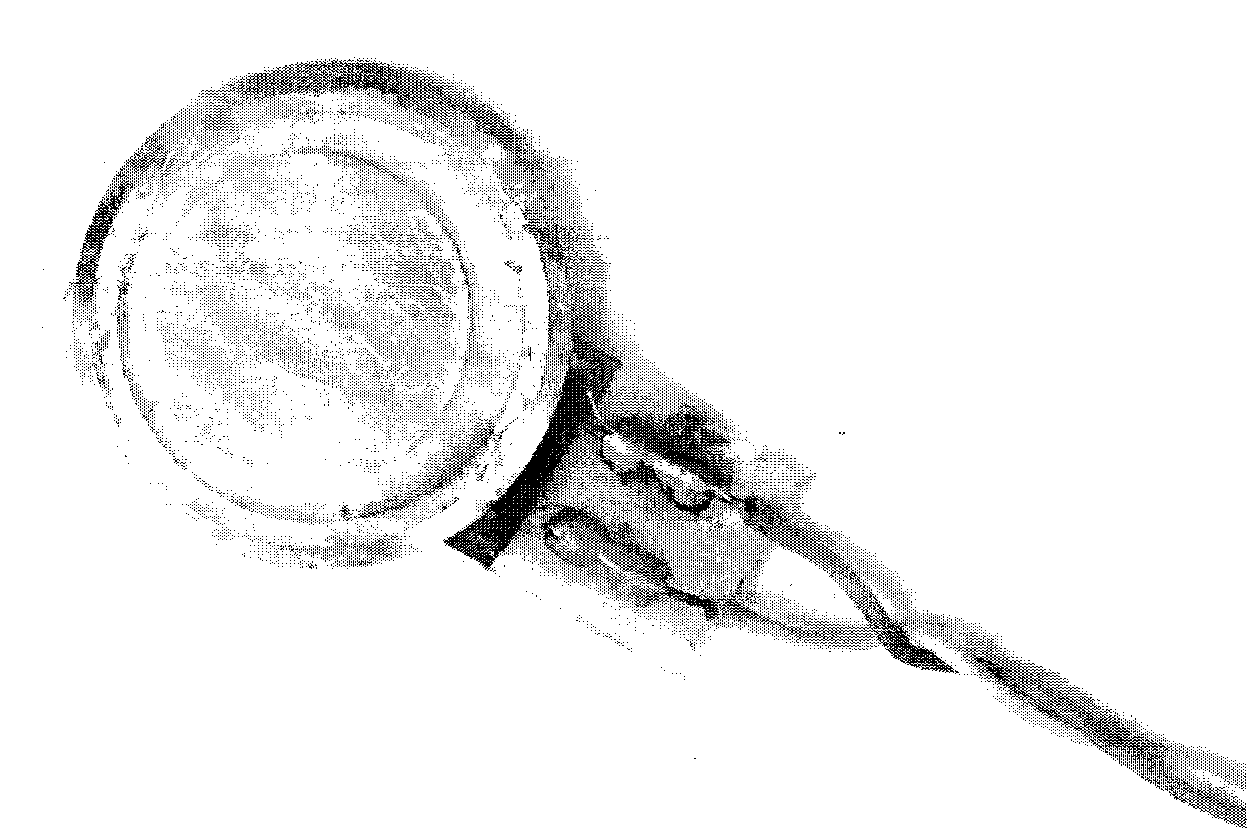

[0012] A test device for realizing the above method, which is composed of a small waterproof pressure gauge and a data acquisition system 1. Among them, the data acquisition system 1 may adopt a general strain acquisition system for structural tests.

[0013] The embodiment of the small waterproof pressure gauge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com