Patents

Literature

553 results about "Critical micelle concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

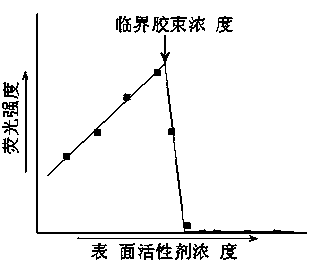

In colloidal and surface chemistry, the critical micelle concentration (CMC) is defined as the concentration of surfactants above which micelles form and all additional surfactants added to the system go to micelles.

Amphiphilic biodegradable block copolymers and self-assembled polymer aggregates formed from the same in aqueous milieu

InactiveUS6569528B2Glass/slag layered productsWood layered productsPolyesterCritical micelle concentration

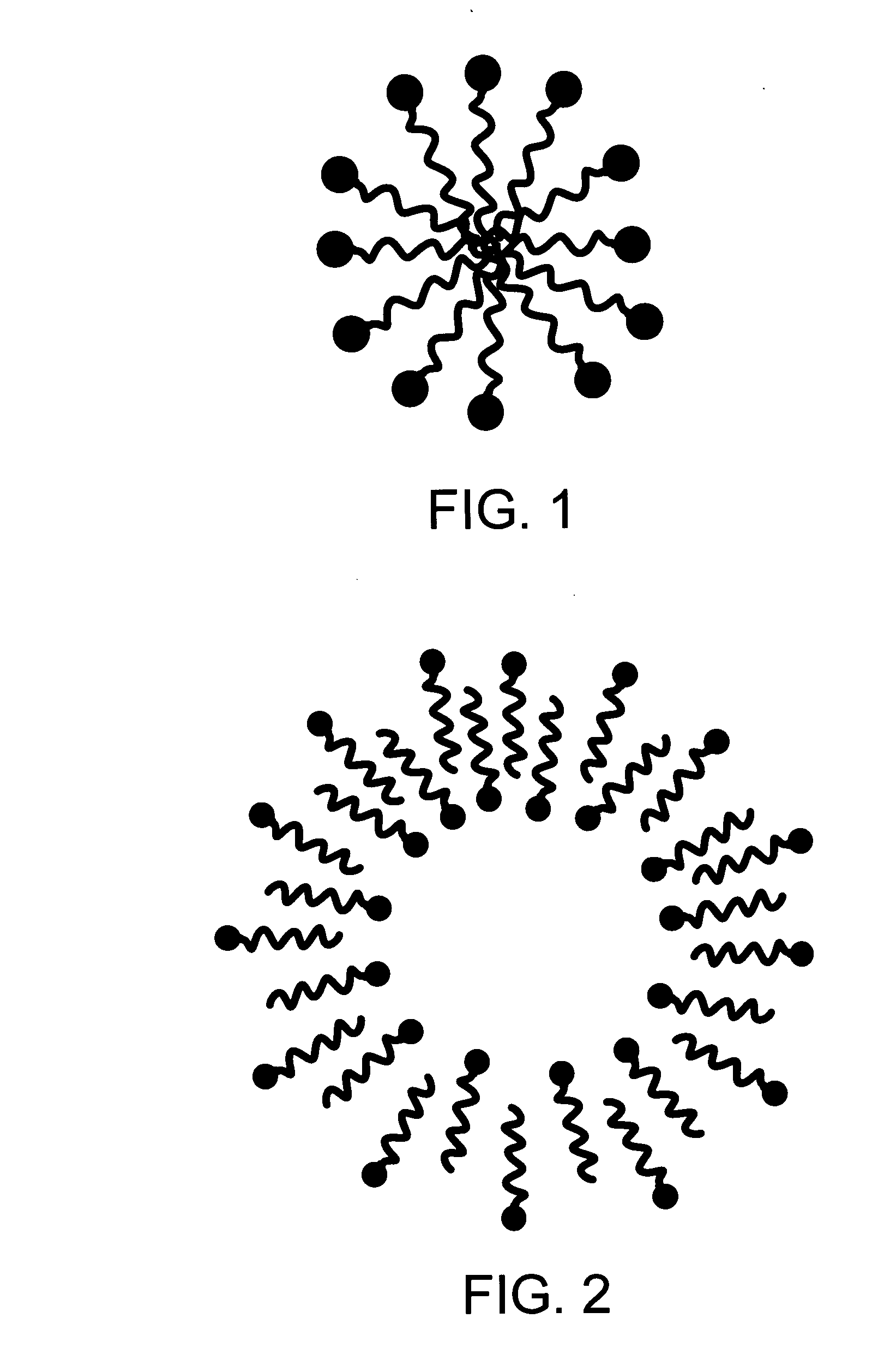

There are provided amphiphilic biodegradable block copolymers comprising polyethylenimine (PEI) as a hydrophilic block and aliphatic polyesters as a hydrophobic block, which can form various size of polymer aggregates and have very low critical micelle concentration, approximately 10-3 g / l in comparison with low-molecular-weight micelle, and self-assembled polymer aggregates formed from the block copolymers in aqueous milieu, which can be applied to solubilization of insoluble drug and a delivery system of proteins, genes or drugs.

Owner:AMOREPACIFIC CORP

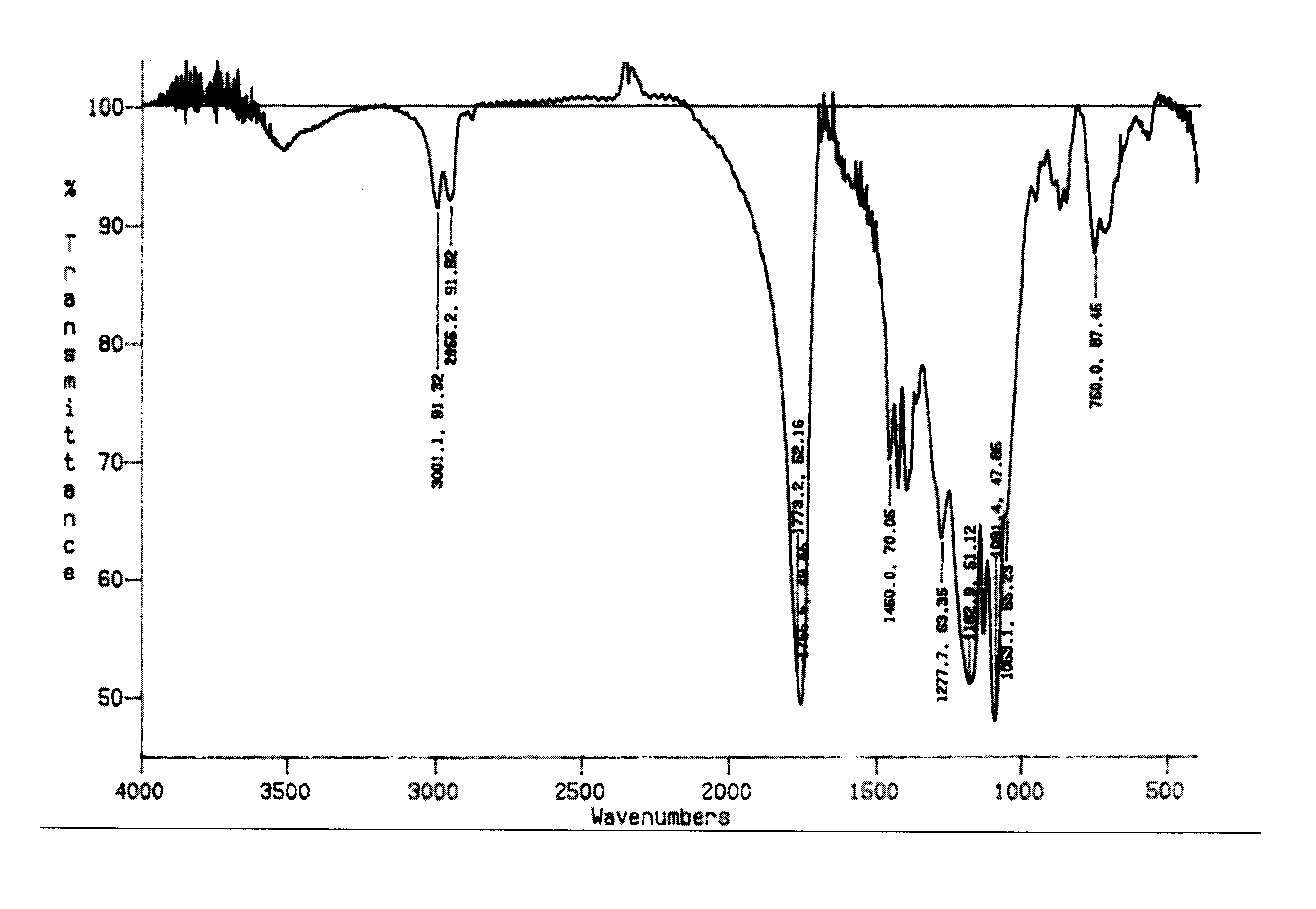

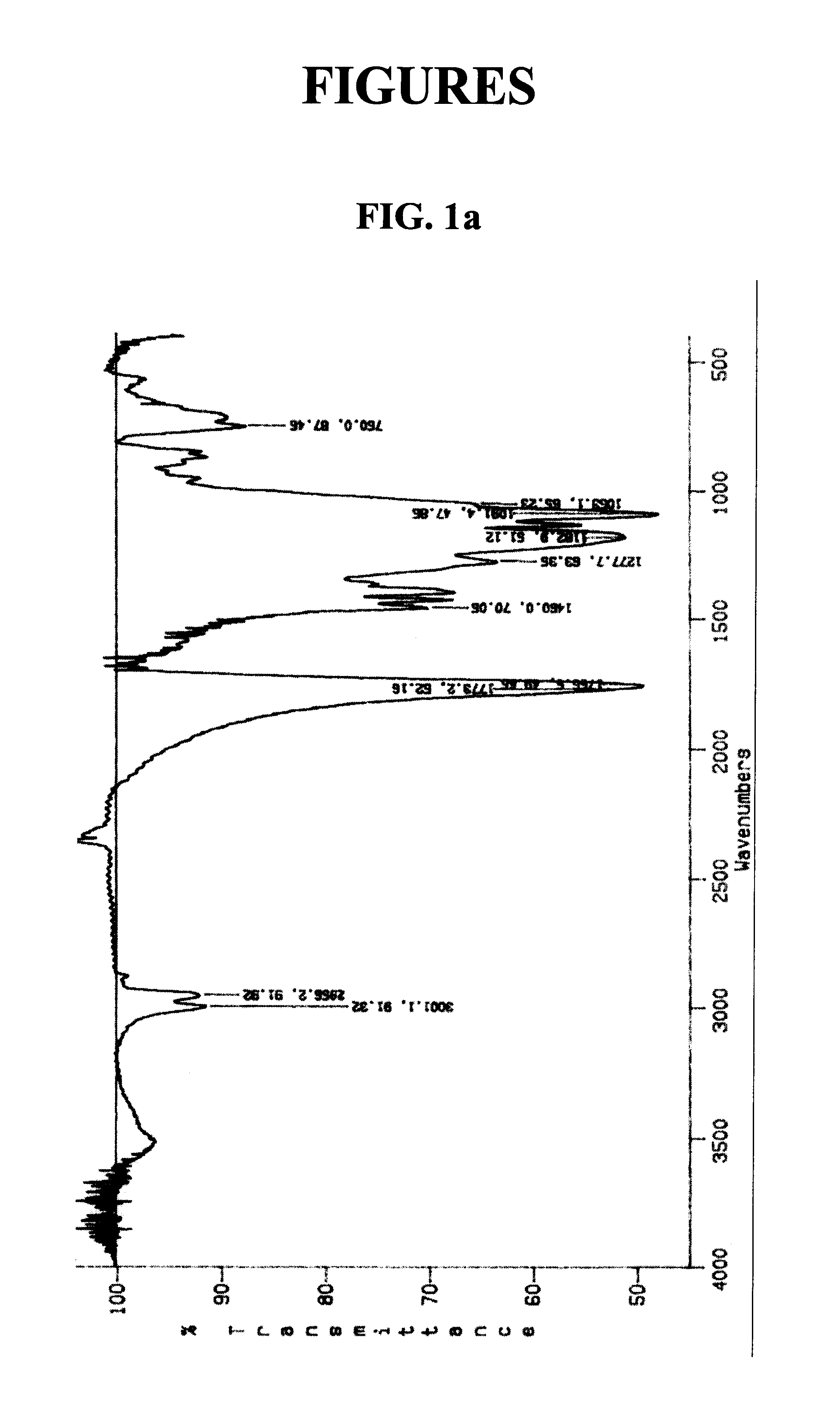

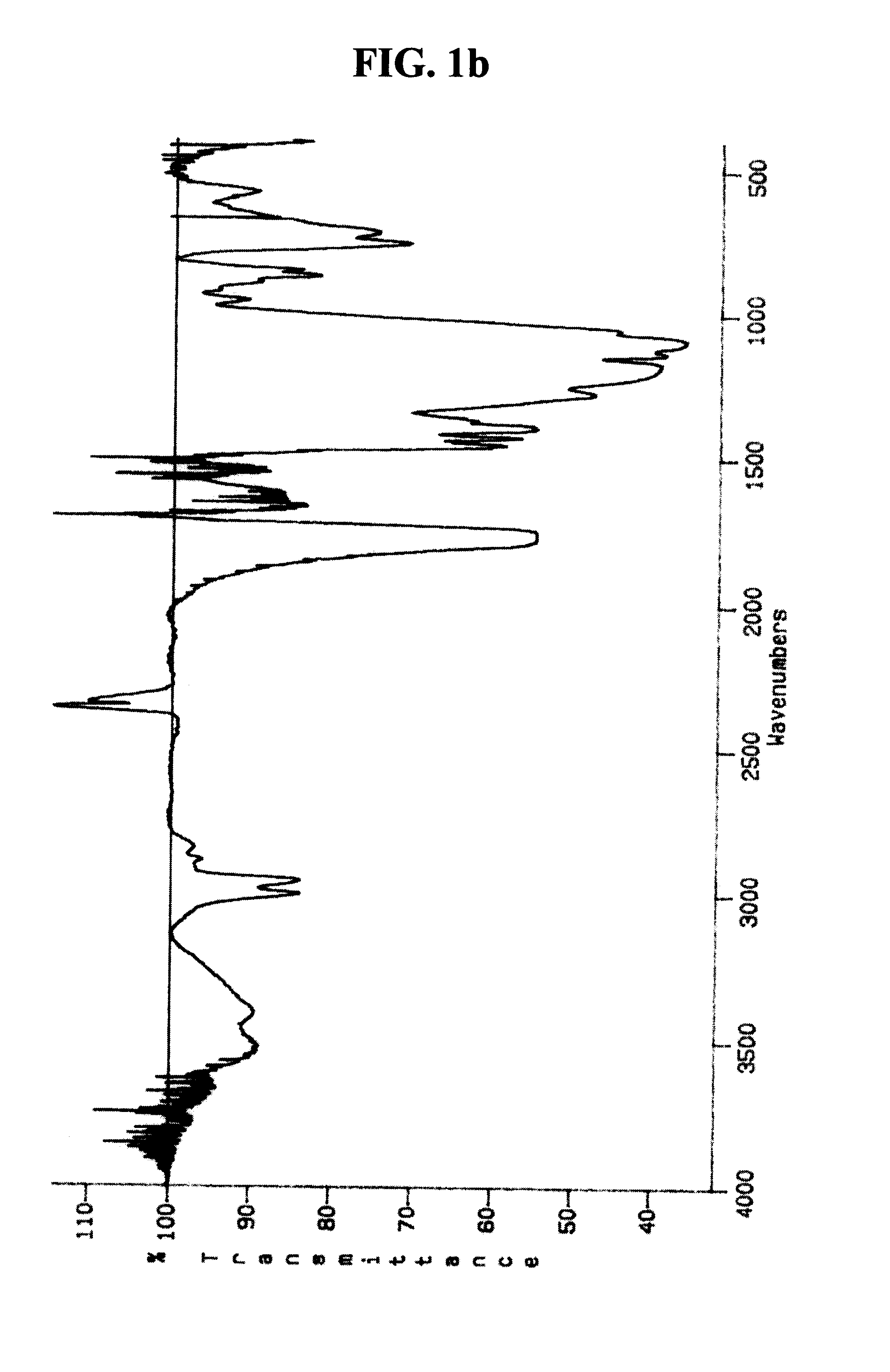

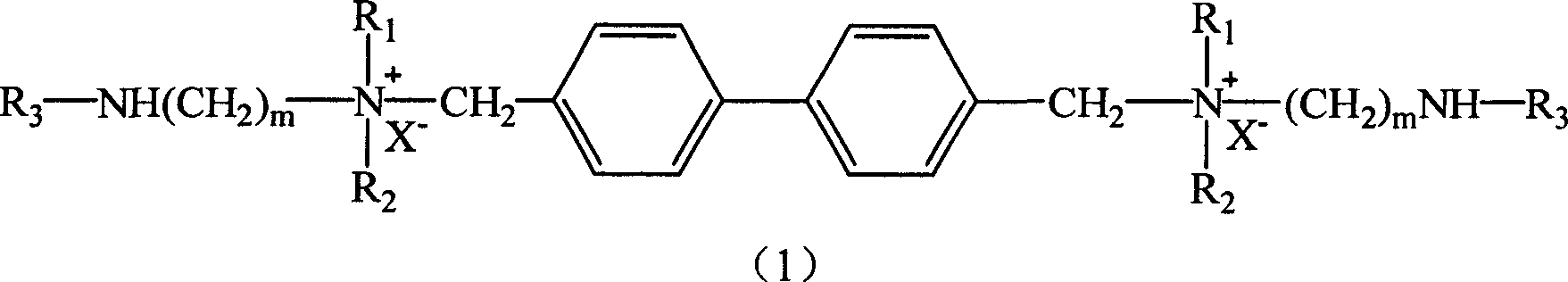

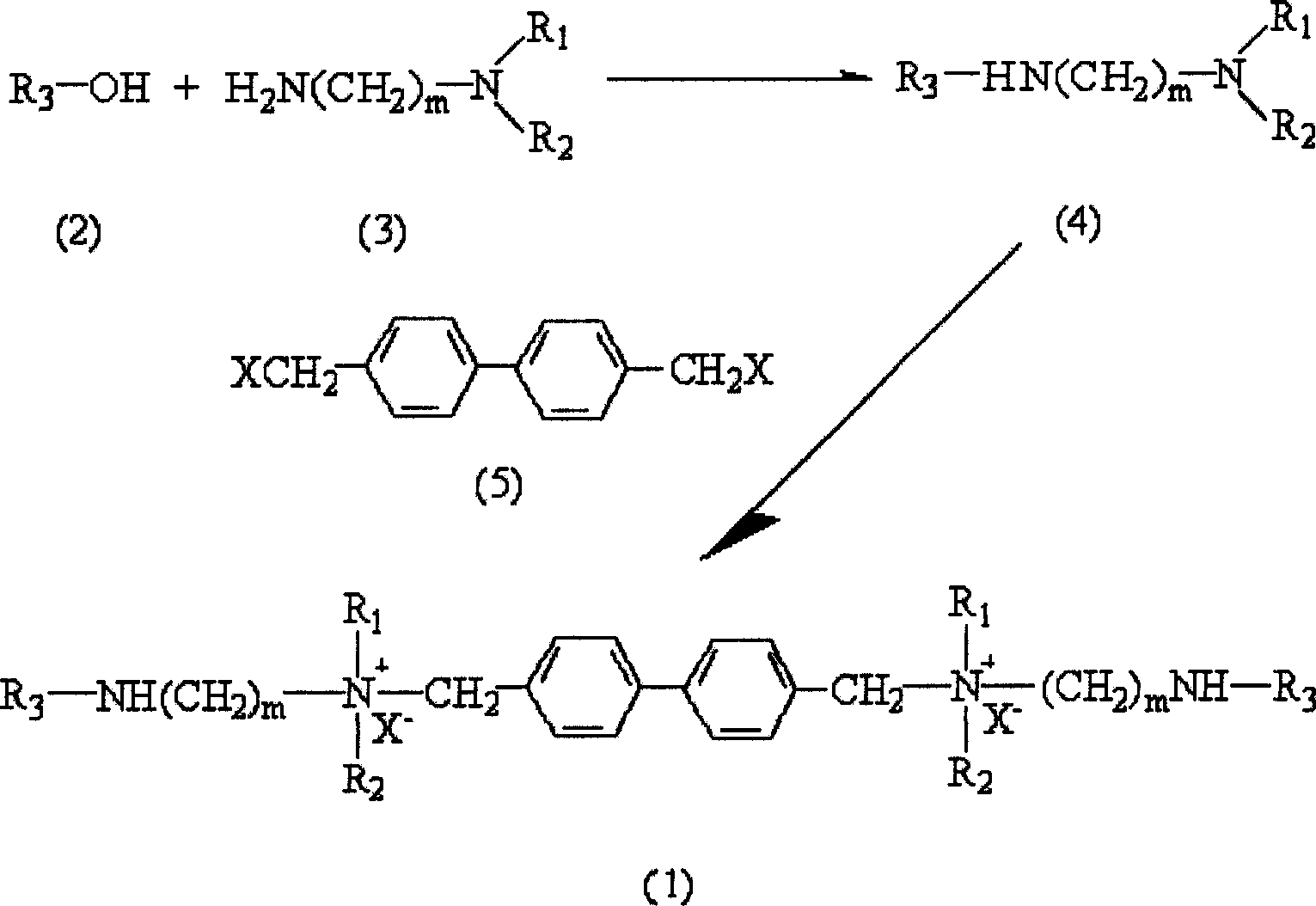

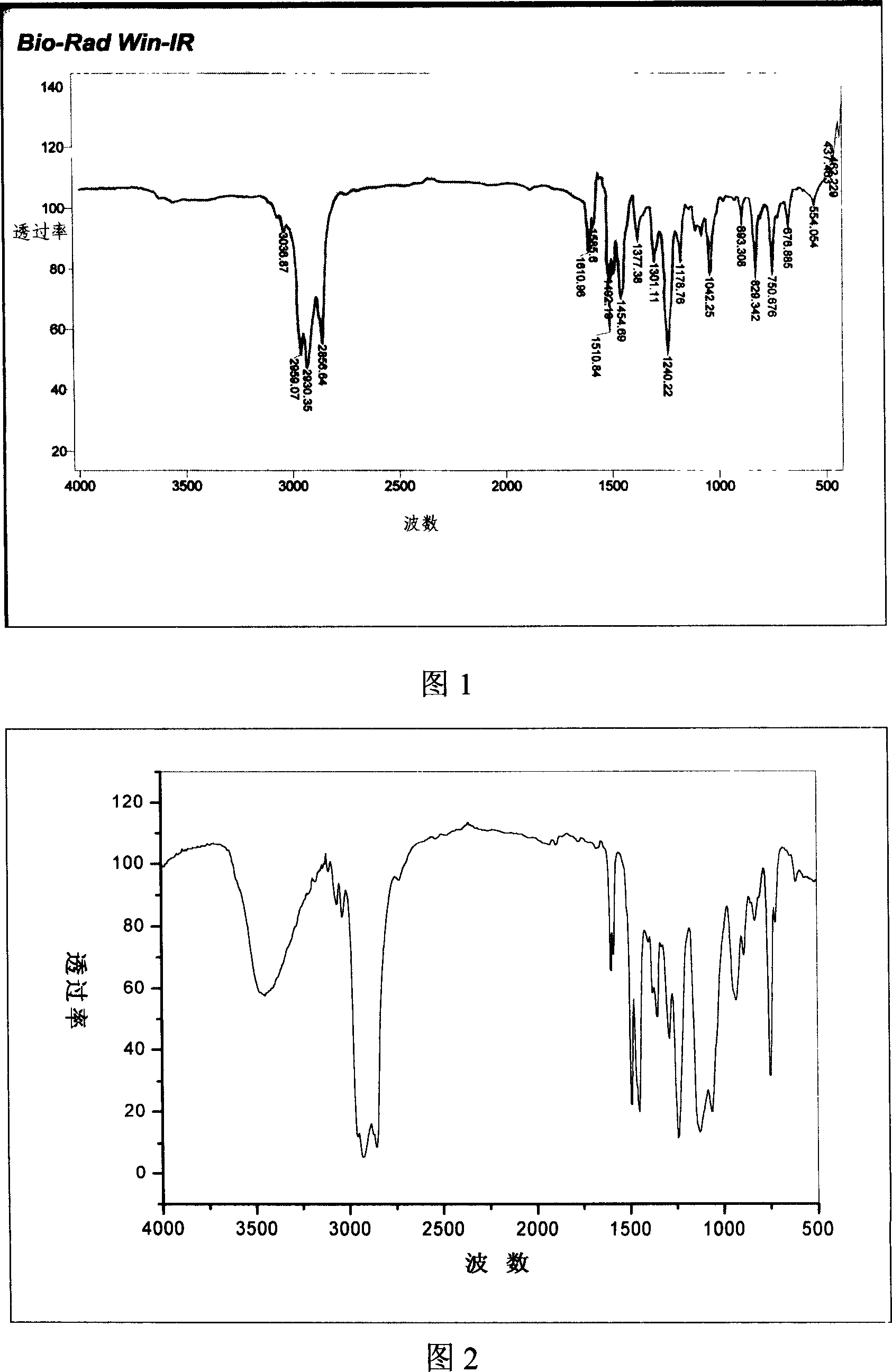

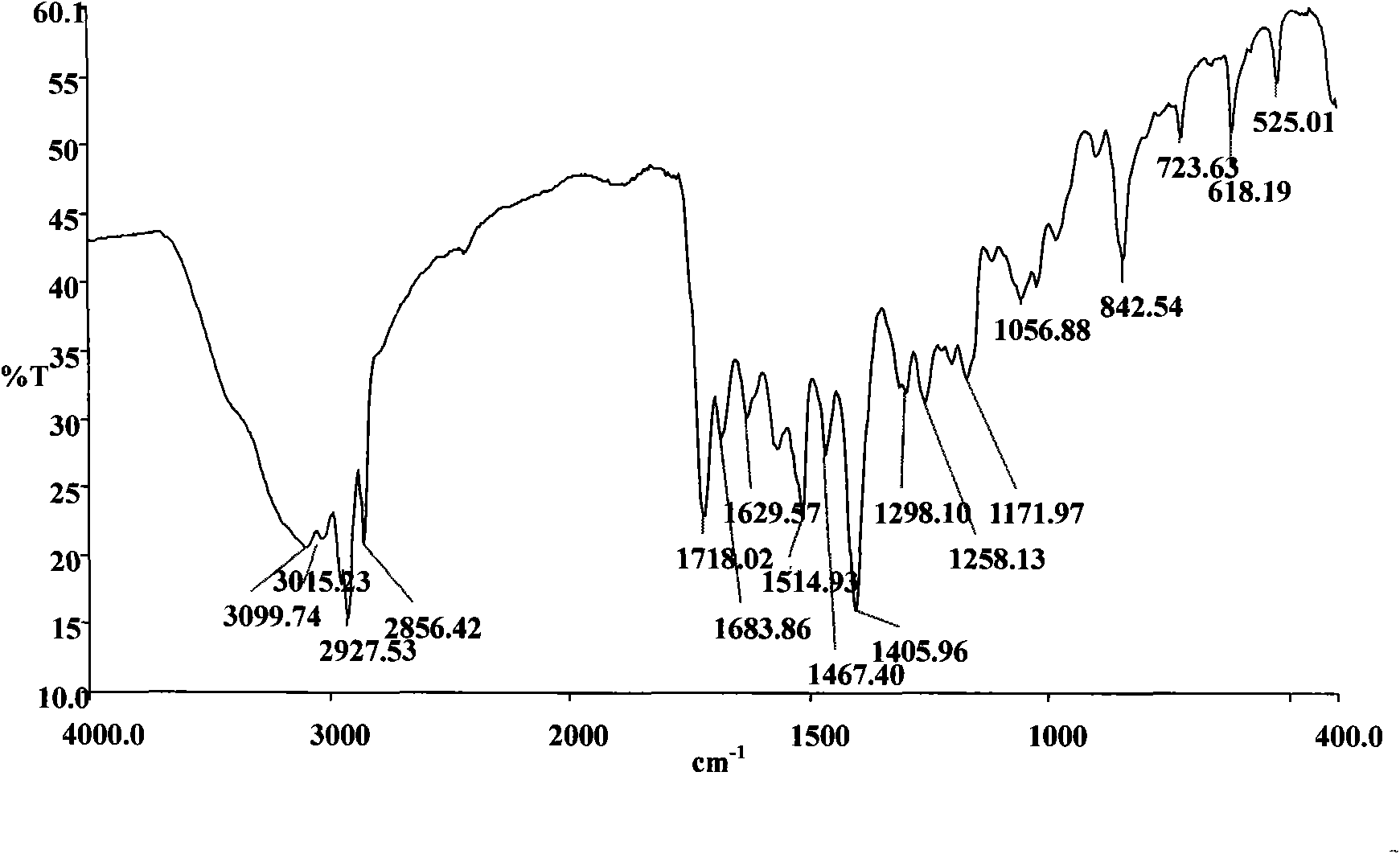

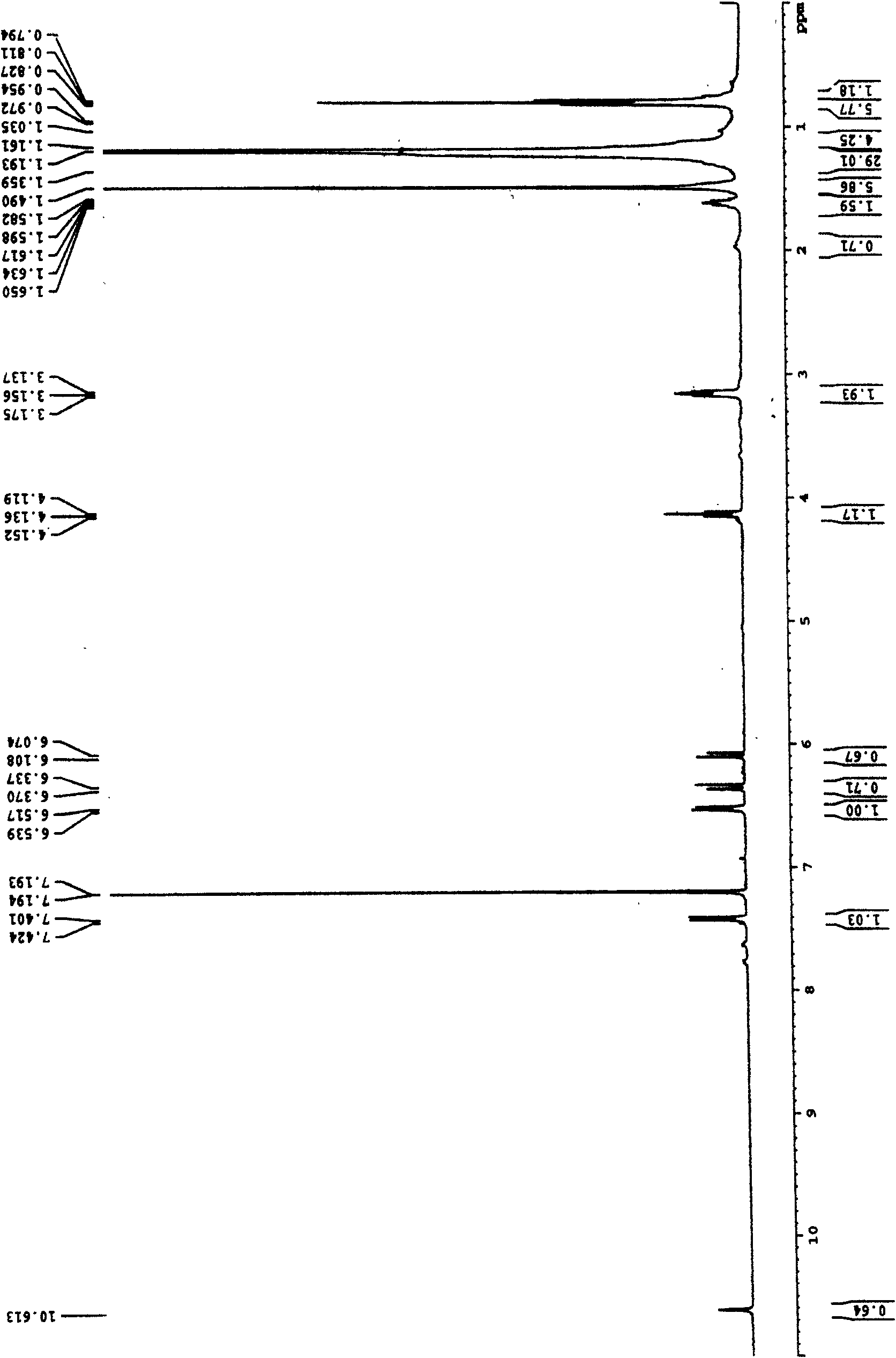

Cation fluoride Gemini surface activator

InactiveCN1817431ALess quantityImprove stabilityTransportation and packagingMixingChemical structureCritical micelle concentration

A cationic fluoric surfactant Gemini and its chemical structure are disclosed. Its advantages are lower critical micell concentration, less consumption, and high dispersity, foam stability, penetrability and wettability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

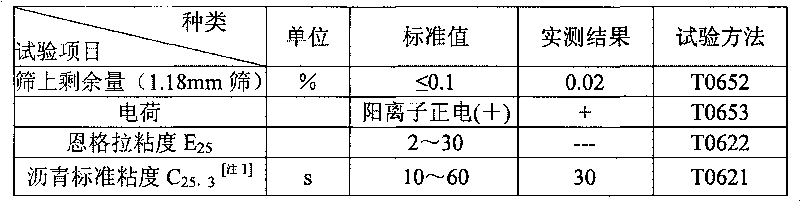

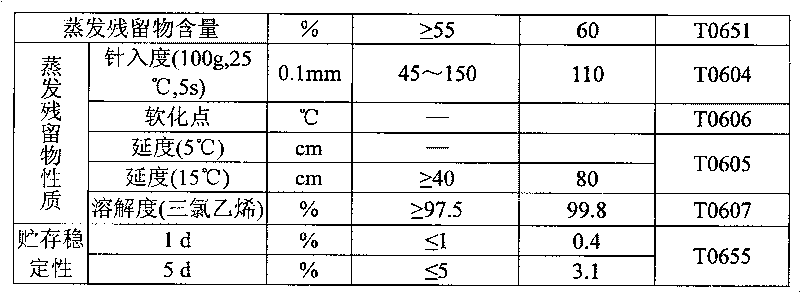

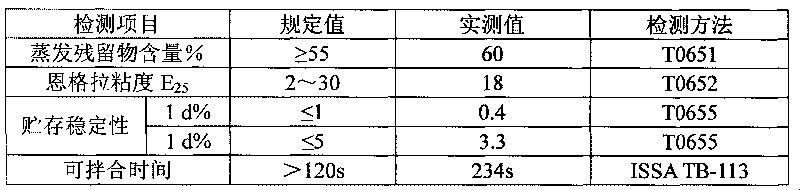

Method for synthesizing amphoteric slow-breaking quick-setting asphalt emulsifier

InactiveCN101712625AWide selectionWide adaptabilityOrganic compound preparationTransportation and packagingChemical synthesisSolubility

The invention discloses a method for synthesizing a novel amphoteric slow-breaking quick-setting asphalt emulsifier, belonging to the technical field of organic chemical synthesis. The method comprises the following steps of: reacting oleic acid with polyamine to generate acid amide polyamine, and then adding chloroactic acid to generate halogenating reaction to prepare the asphalt emulsifier, wherein the polyamine is the mixture of diethylenetriamine and triethylene tetramine. The water solubility of the hydrophilic radical of the emulsifier synthesized by the process is stronger than those of like emulsifiers, thereby obviously lowering the critical micelle concentration (CMC) value, and the particles of the produced asphalt emulsion are finer, smoother and evener. The emulsifier can effectively prevent asphalt from settling, increases the storage stability of the asphalt emulsion, reasonably regulates the charge ratio, widens the selectivity on stone materials in the application of slurry seal construction, enables the mixing time to be sufficient, and has obvious quick-setting effect and improved project quality.

Owner:河南新友公路技术有限公司 +1

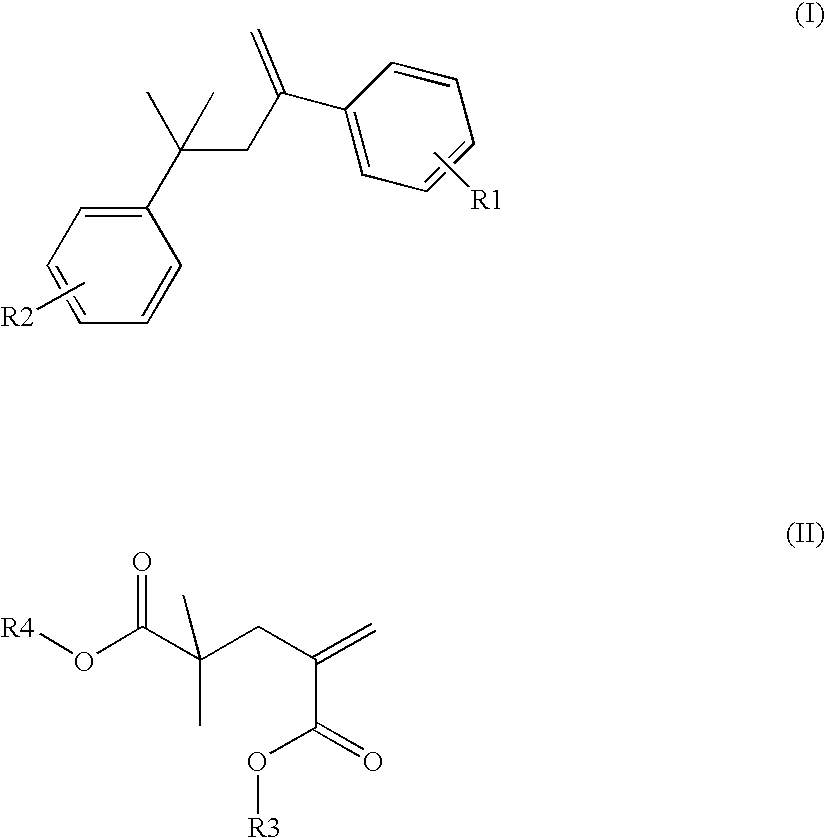

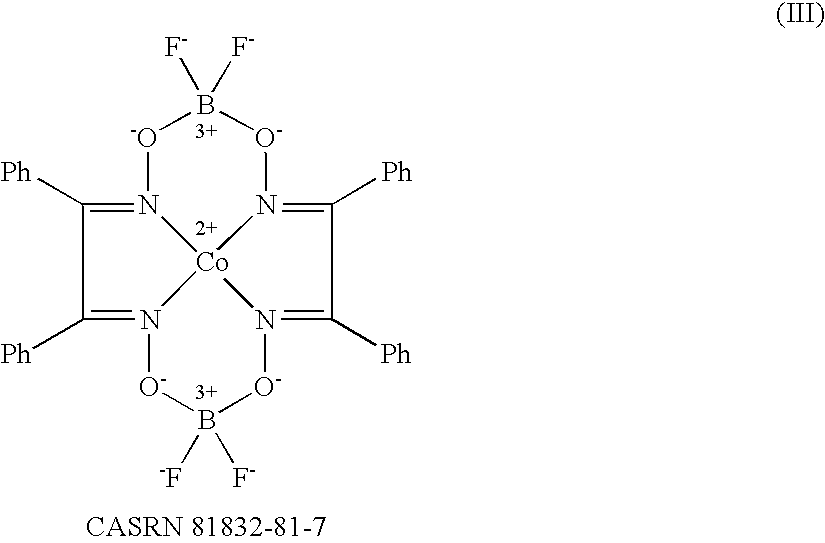

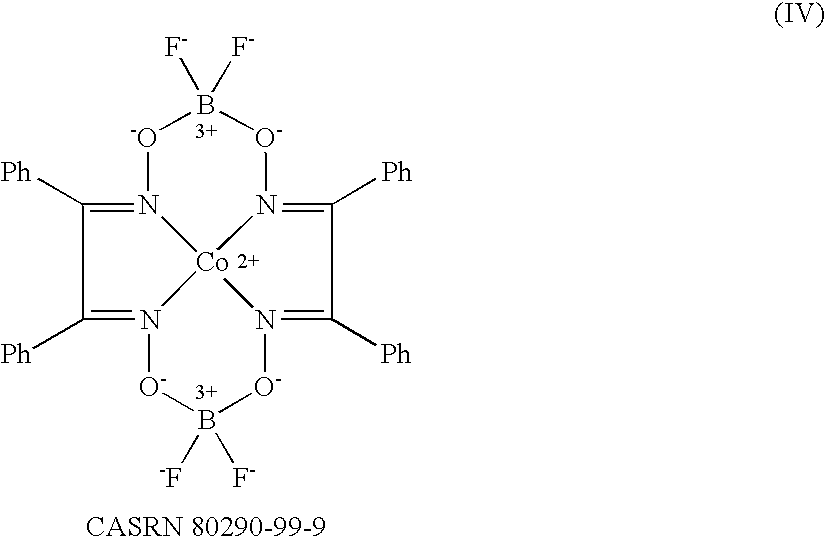

Method of emulsion polymerization

InactiveUS20060009574A1Decreased degree of polydispersityLow indexInksWater basedCritical micelle concentration

A method has been disclosed of preparing ultrafine hydrophobic latex particles of polymers and copolymers by free radical emulsion polymerization in a water-based system, making use therefor, in order to polymerize or copolymerize monomers or monomer mixtures respectively, of at least one compound selected from the group consisting of dimers and cobalt complexes, acting as a chain transfer agent (CTA), wherein said latex particles have an average particle size of less than 100 nm, being more than 10% lower than if prepared in the absence of said CTA, characterized in that said polymerization is conducted in a water-based reaction in the presence of a chain transfer agent and of a surfactant, wherein said surfactant is present in a concentration versus said monomer or monomer mixture of from 5 up to 25% by weight for a non-ionic surfactant or from 0.05 up to 10% by weight for an ionic surfactant, more particularly a surfactant in a concentration below twice its critical micelle concentration.

Owner:AERT HUUB VAN +3

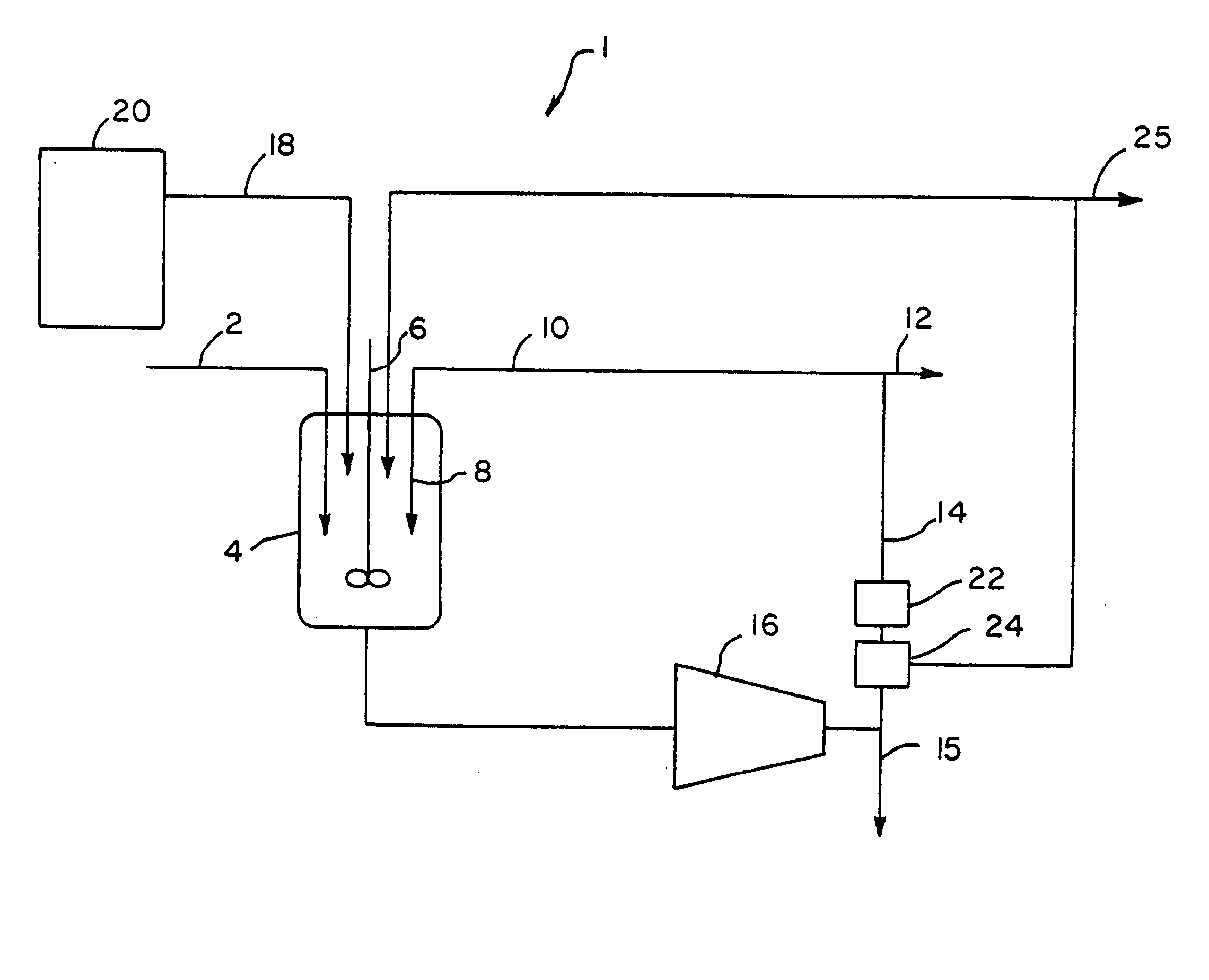

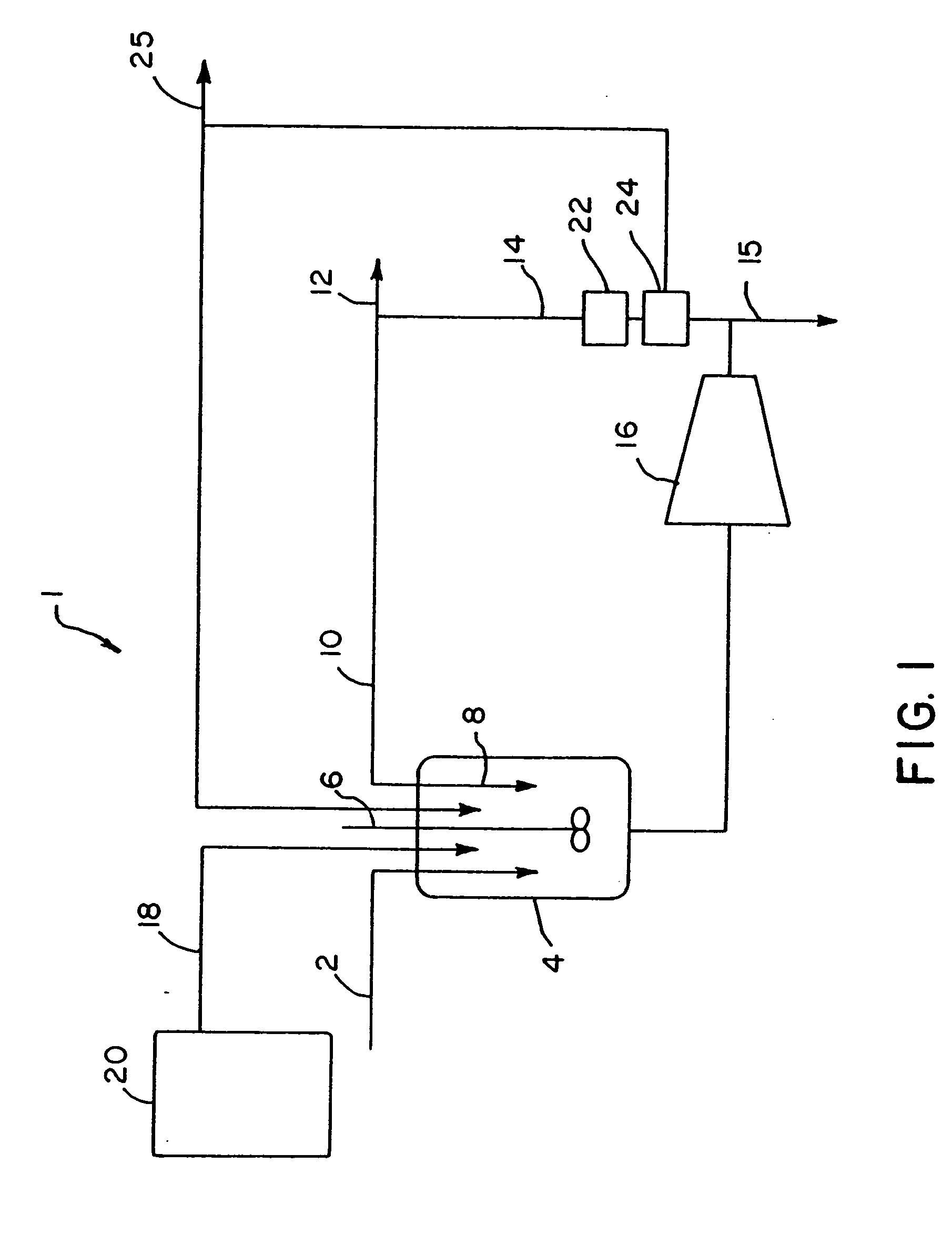

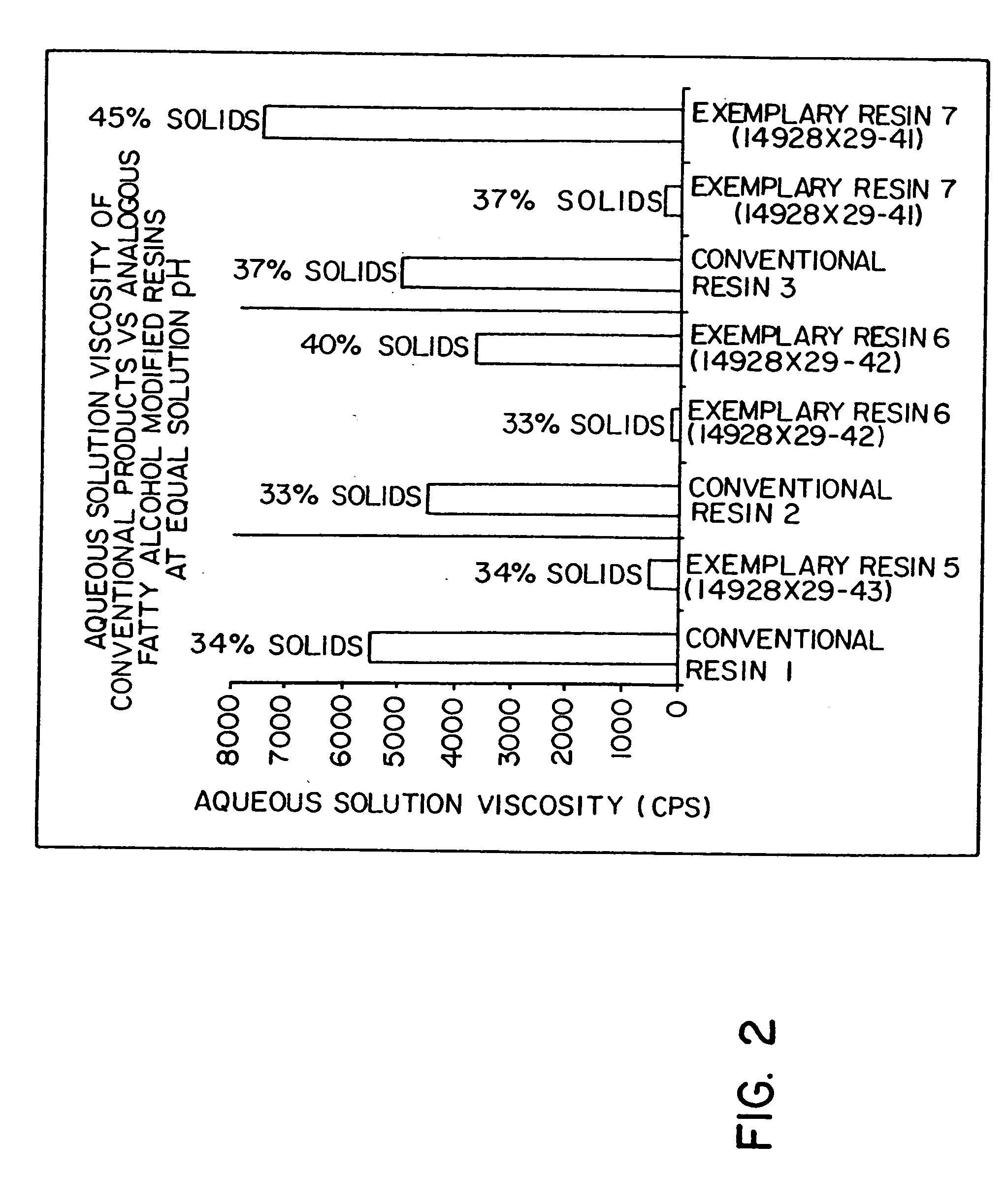

Continuous bulk polymerization and esterification process and compositions

InactiveUS20050059782A1High viscosityWater-repelling agents additionTransportation and packagingPolymeric surfacePolymer science

A continuous bulk polymerization and esterification process includes continuously charging into a reaction zone at least one ethylenically unsaturated acid-functional monomer and at least one linear or branched chain alkanol having greater than 11 carbon atoms. The process includes maintaining a flow rate through the reaction zone sufficient to provide an average residence time of less than 60 minutes and maintaining a temperature in the reaction zone sufficient to produce a polymeric product incorporating at least some of the alkanol as an ester of the polymerized ethylenically unsaturated acid-functional monomer. The polymeric product is used in various processes to produce water-based compositions including emulsions and dispersions such as oil emulsions, wax dispersions, pigment dispersions, surfactants and coatings which contain the polymeric product. A polymeric surfactant includes at least one ethylenically unsaturated acid-functional monomer which has been radically incorporated into the polymeric surfactant and at least one ester of the incorporated ethylenically unsaturated acid-functional monomer which has a linear or branched chain alkyl group with greater than 11 carbon atoms. The molar critical micelle concentration of the polymeric surfactant is less than 1.0×10−2 moles / liter. Aqueous 2 percent solutions of certain polymeric surfactants have a surface tension of less than 45 mN / m at 30° C. and exhibit a decrease in surface tension of at least 5 mN / m as the temperature warms from 30° C. to 50° C.

Owner:BASF CORP

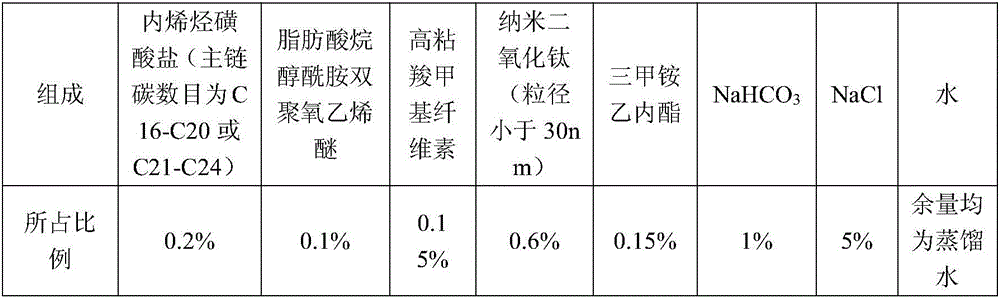

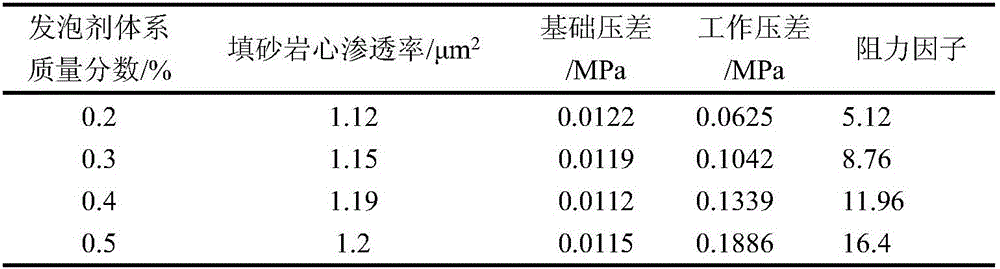

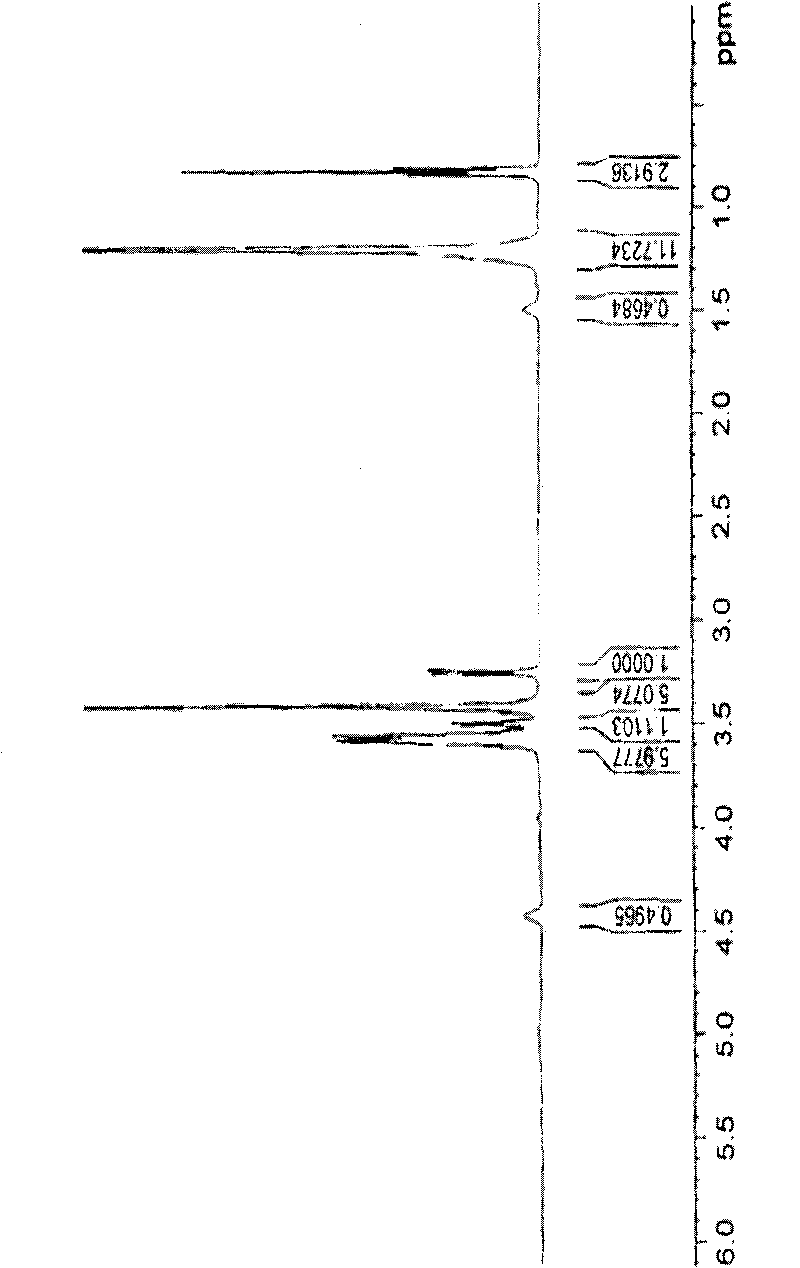

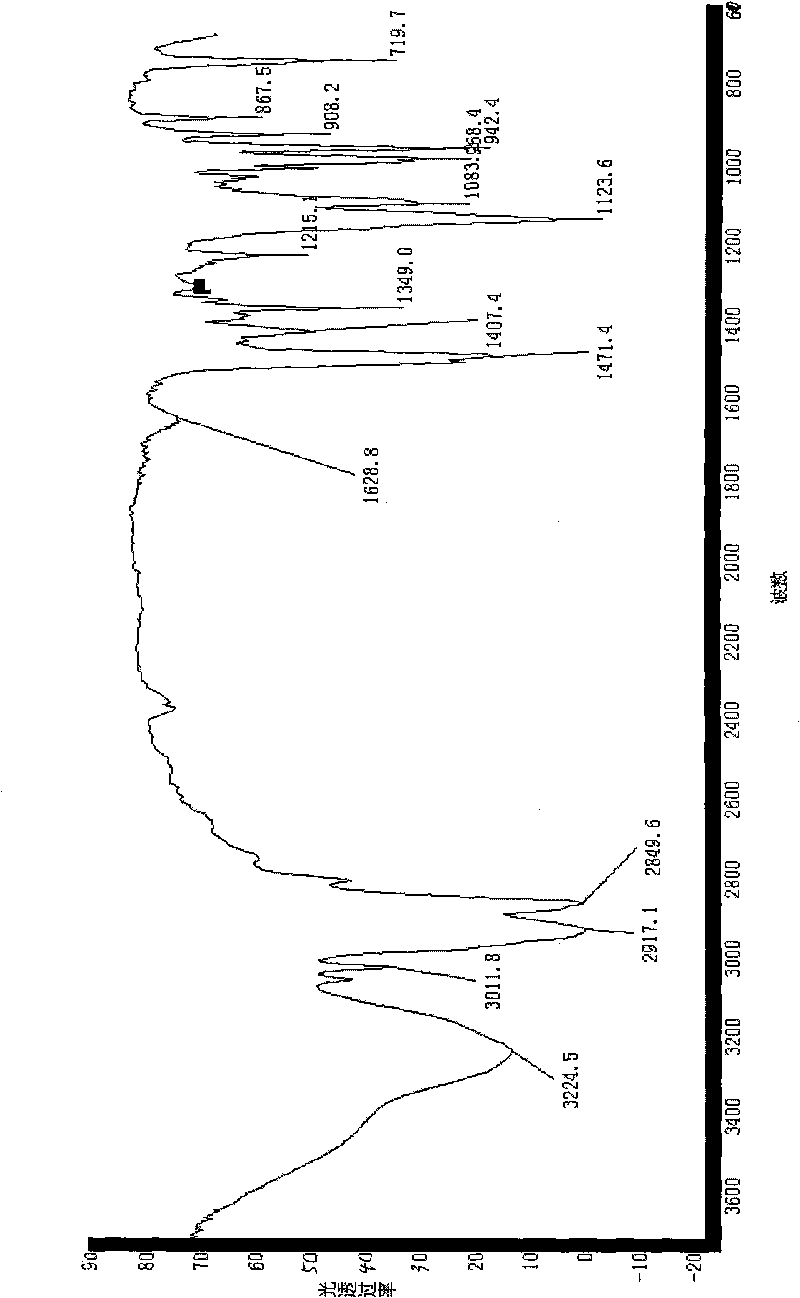

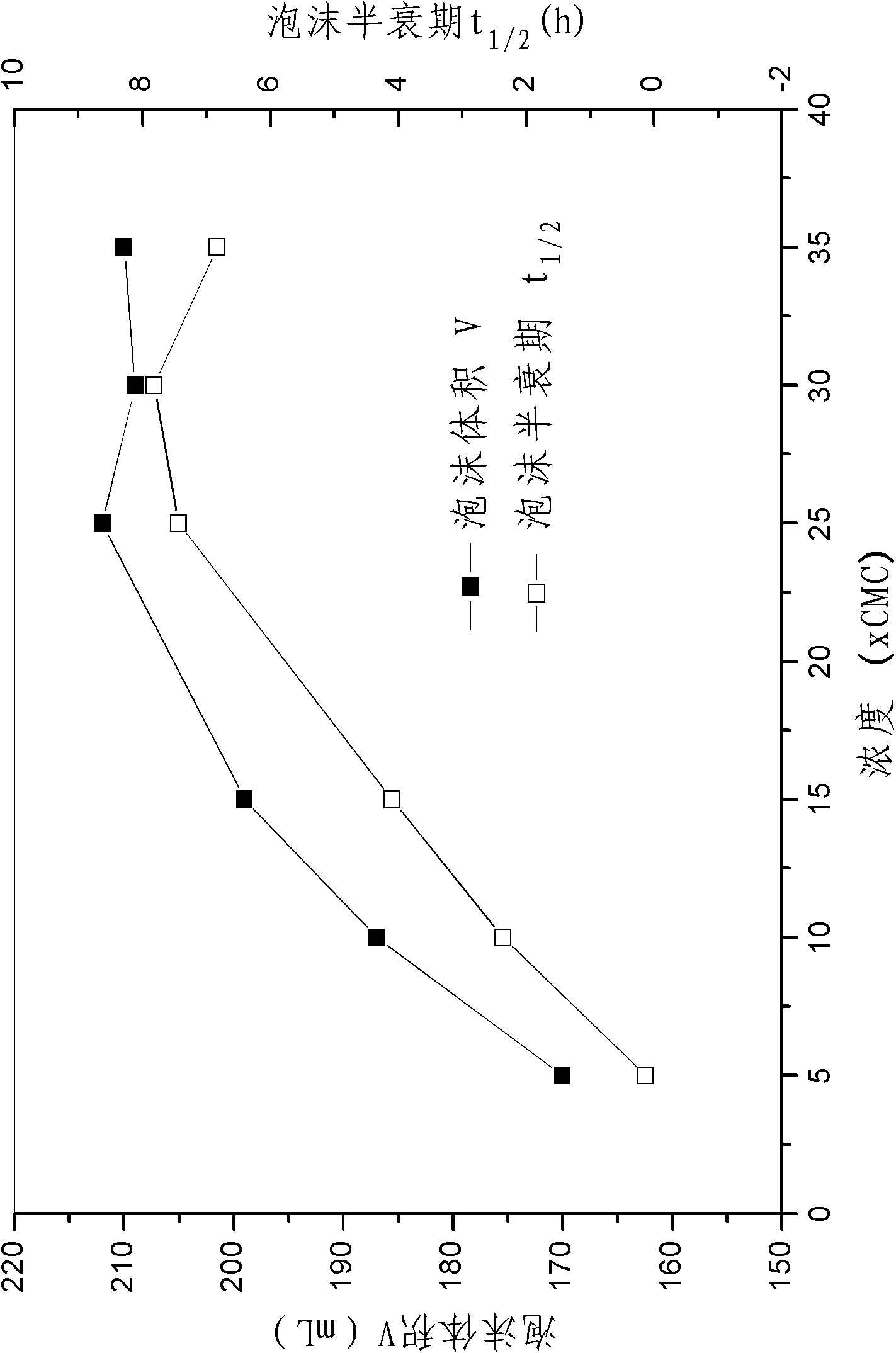

Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

InactiveCN106753307AImprove solubilityImprove performanceDrilling compositionInorganic saltsSolubility

The invention relates to the technical field of heavy oil recovery, in particular to a foam agent system used for switching water drive into steam drive of a heavy oil reservoir or steam huff and puff to improve the oil recovery efficiency. According to the technical scheme, the temperature-resistant and salt-tolerant foaming agent system for thermal recovery of the heavy oil reservoir is characterized by comprising a foaming agent base, a foam stabilizer, a foam fixing agent, a foam promoter, an alkali substance, inorganic salt and a solvent. The foaming agent system can resist the temperature of 350 DEG C and has good thermal stability and better foamability; the foaming agent base in the system is lower than the critical micelle concentration and can produce more foam, the apparent viscosity is substantially increased, and the cost is saved; the foaming agent system has better solubility, causes little damage to formation and is environment-friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

Alkyl group polyoxyethylene ether surface active agent with Guerbet structure and preparation method and application thereof

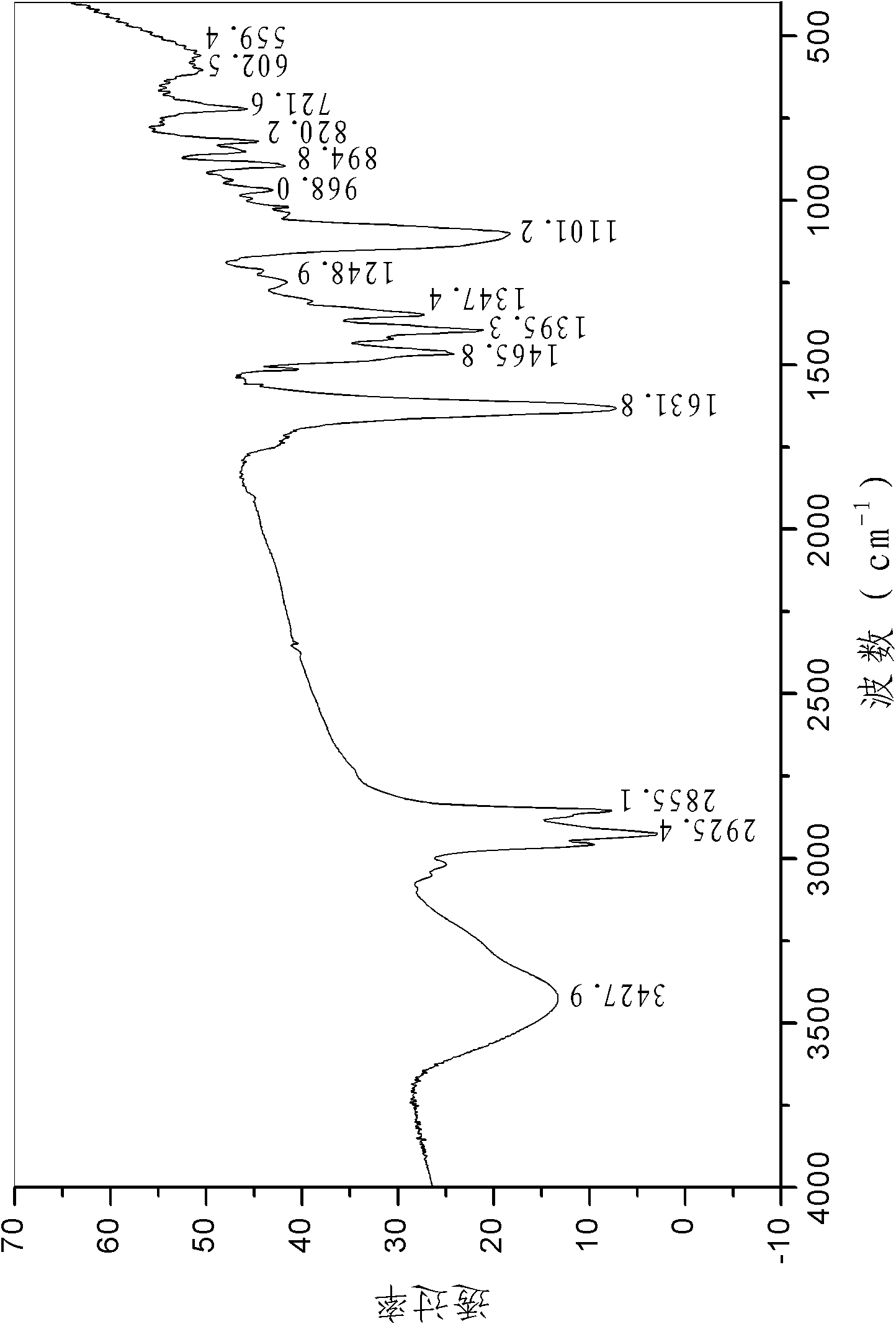

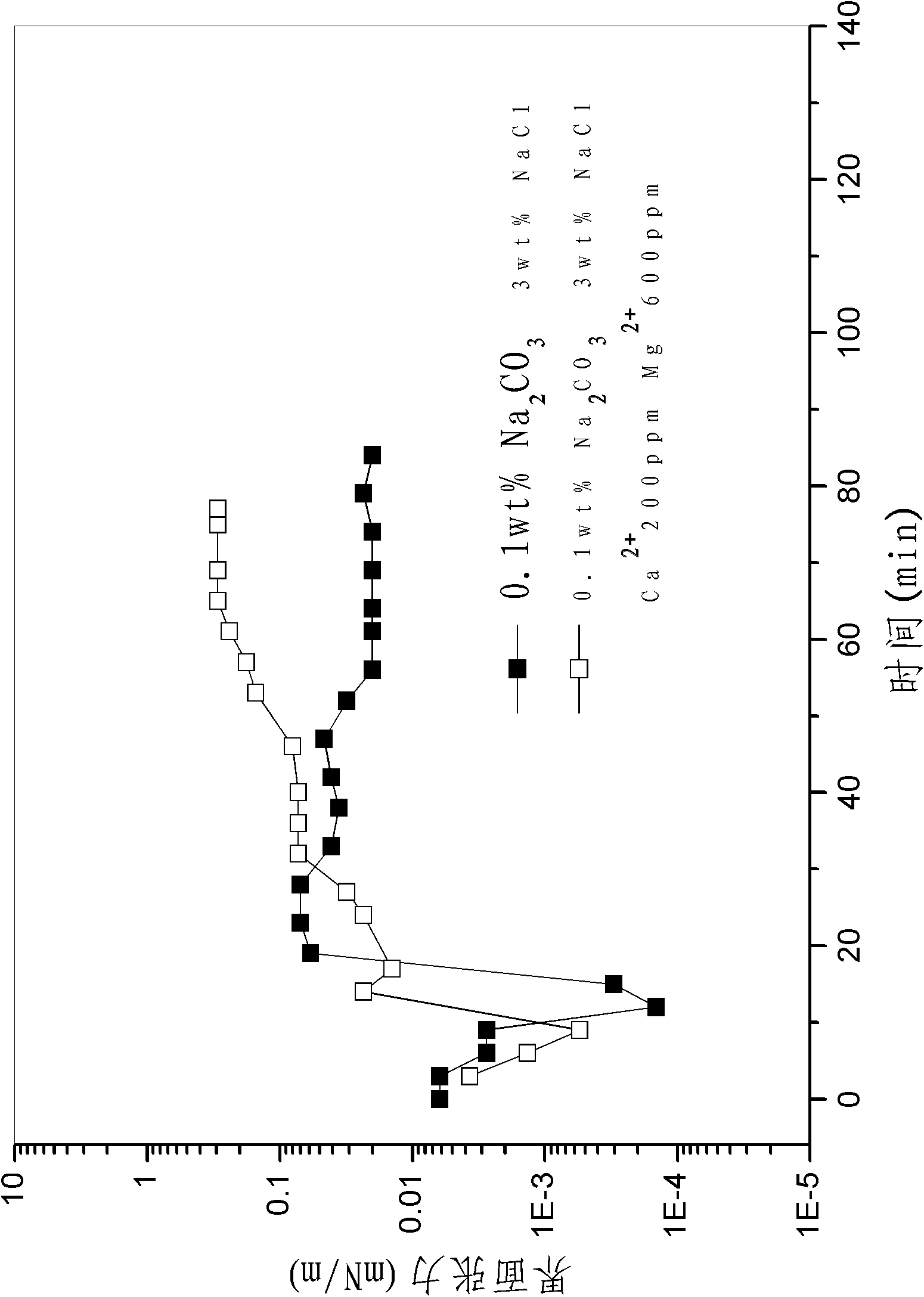

ActiveCN101745343AGood water solubilityLow critical micelle concentrationTransportation and packagingMixingChemical structureSolubility

The invention relates to an alkyl group polyoxyethylene ether surface active agent with a Guerbet structure and a preparation method and the application thereof, which is applied to the tertiary oil recovery technology; alpha-olefin with dialkyl, which is obtained by catalyzing dimerization by the alpha-olefin with short carbon chain, is used as starting material, and after a series of the chemical reaction, the corresponding alkyl group polyoxyethylene ether surface active agent with the Guerbet structure is prepared; the surface active agent comprises a quaternary ammonium cationic surfactant of alkyl polyoxyethylene ether hydroxypropyl and a carboxylic acid oxyneurines amphoteric surfactant of alkyl group polyoxyethylene ether hydroxypropyl, a special molecular structure determines the alkyl group polyoxyethylene ether surface active agent to have good water solubility, low critical micelle concentration, good surface or interface tensile force reduction capacity and high-efficiency foaming capacity, ultra-low oil-water interface tensile force (10-3mN / m) is formed between the brine solution energy and crude oil, therefore, the alkyl group polyoxyethylene ether surface active agent which is used as an effective oil displacement agent has application potential in the tertiary oil recovery; the surface active agent has the following chemical structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Irritation Mitigating Polymers and Uses Therefor

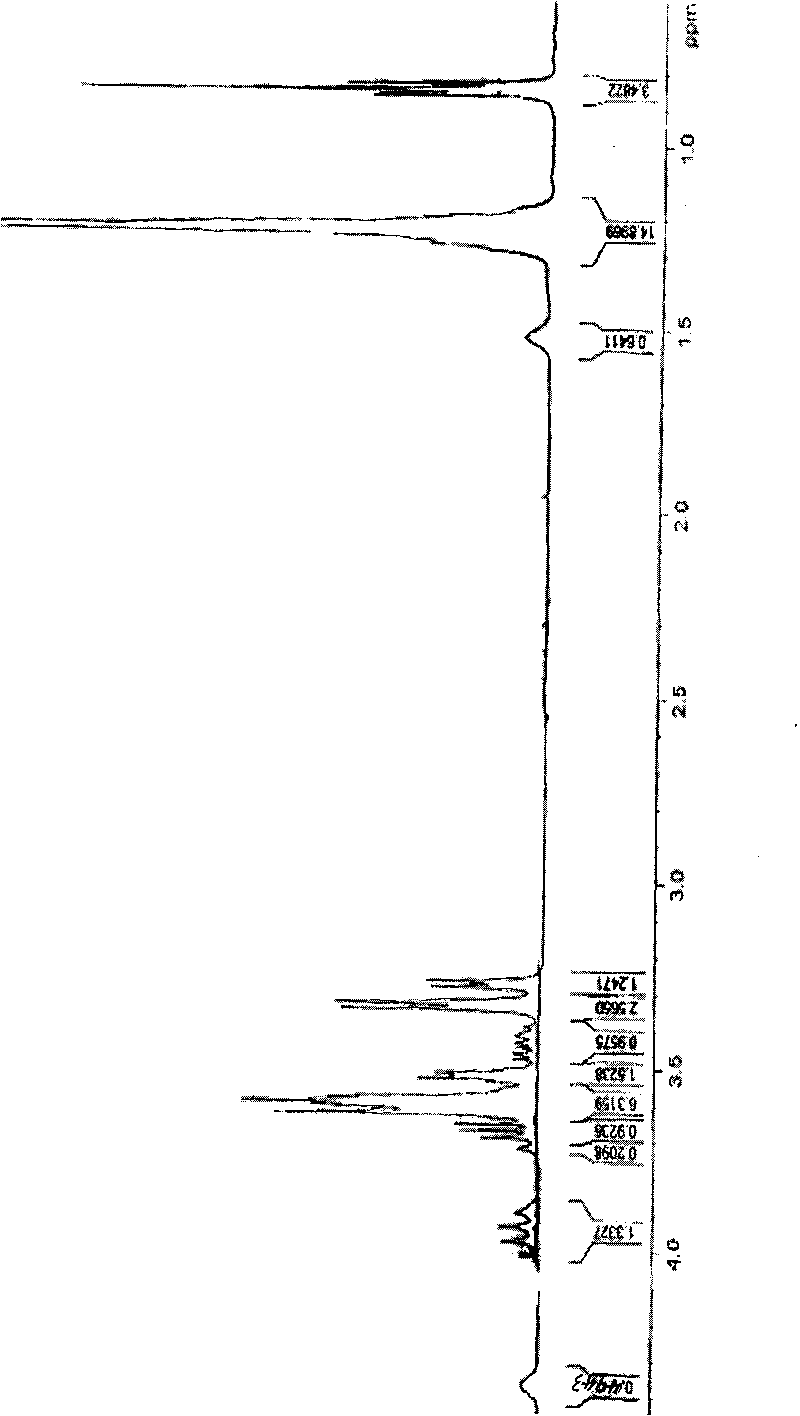

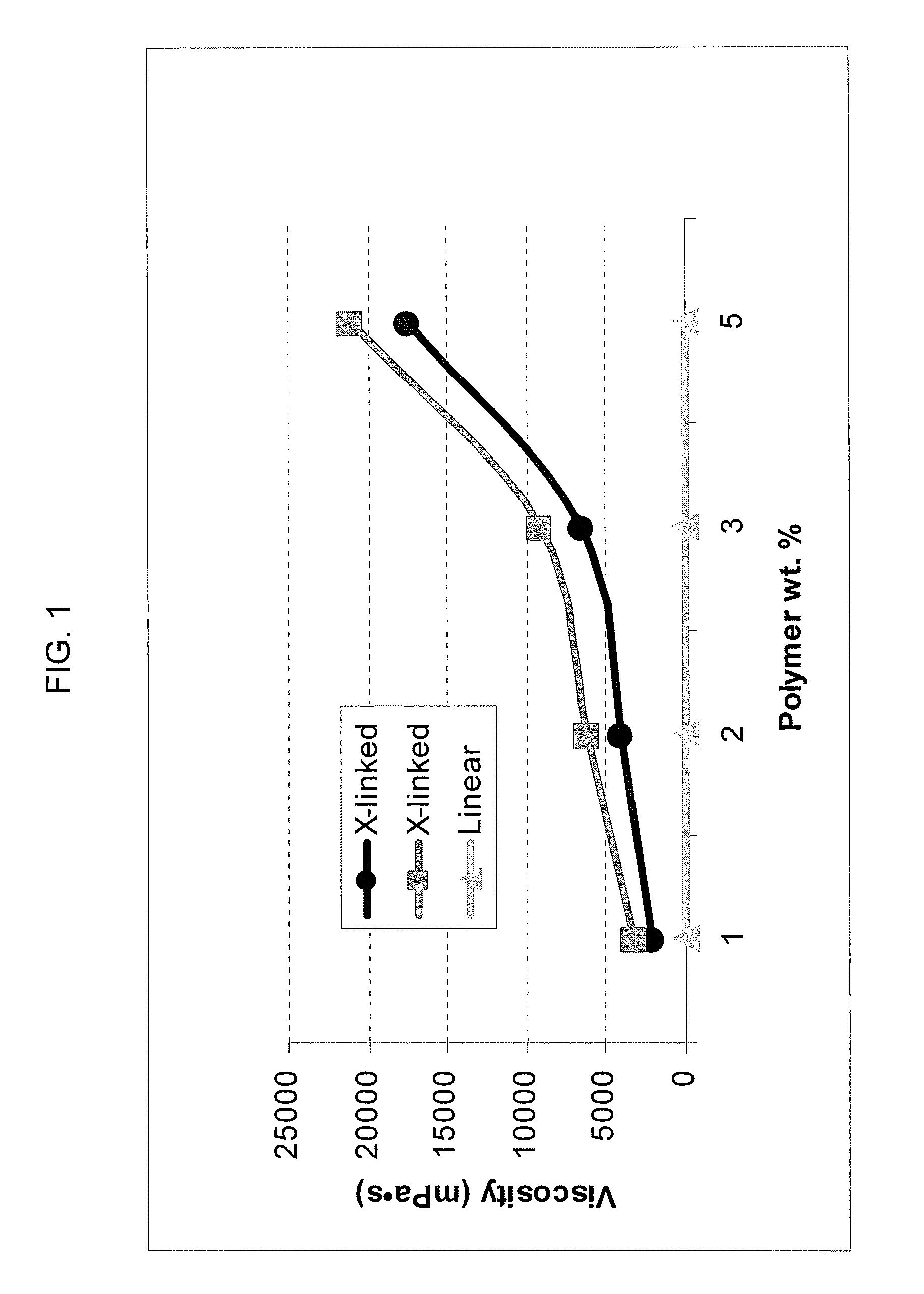

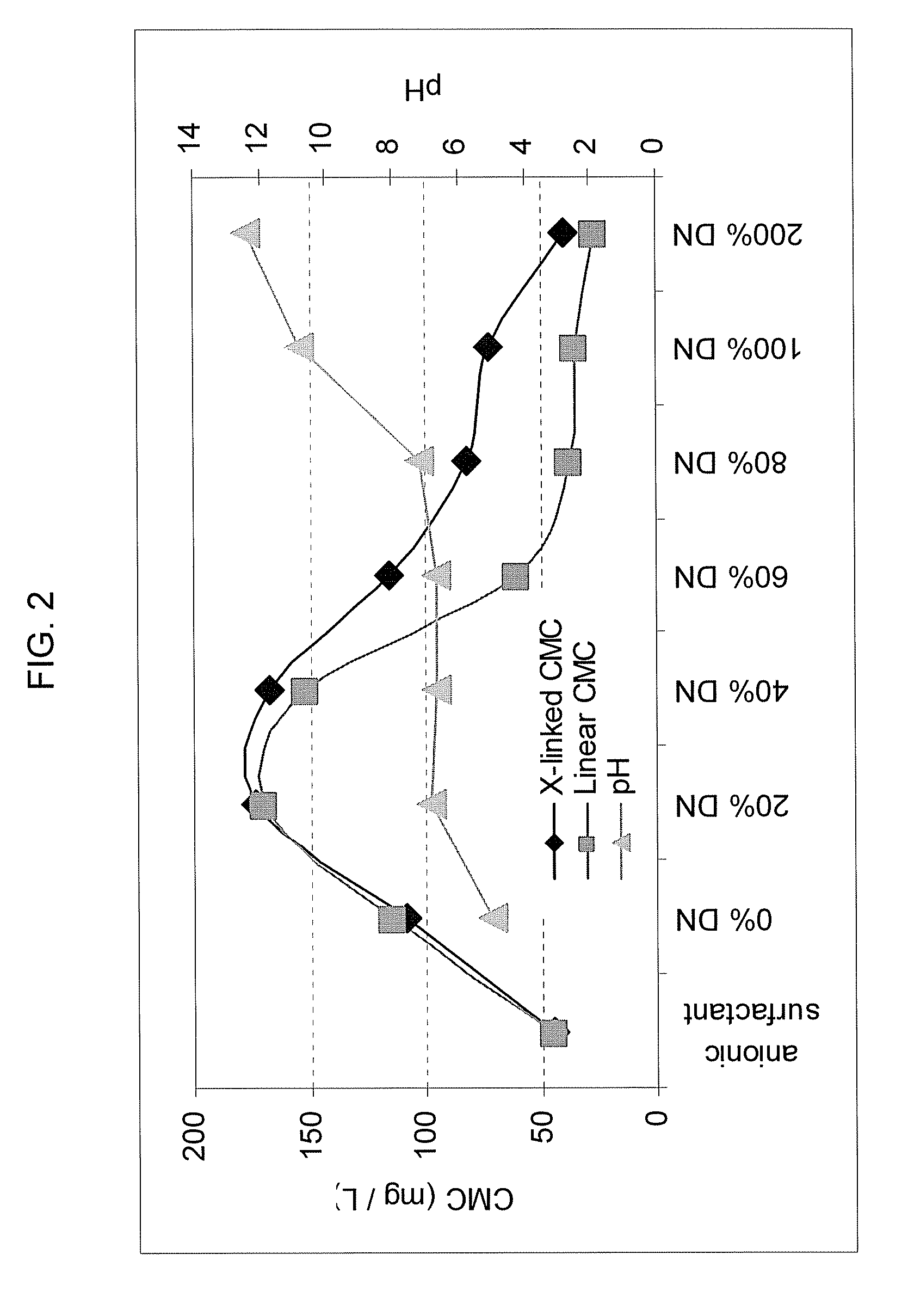

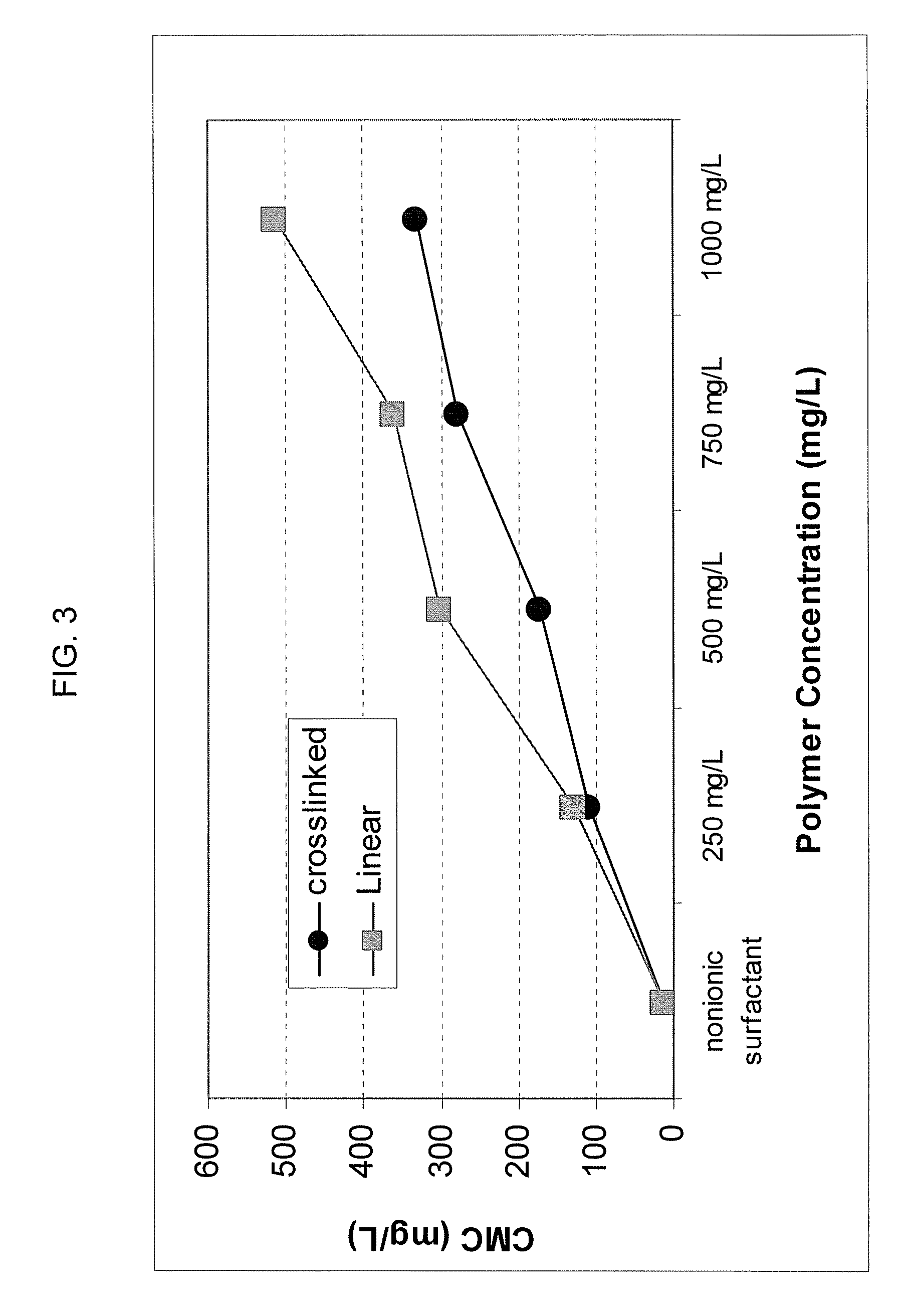

A method for increasing the efficacy of hydrophobically modified (meth)acrylic based polymers to increase the critical micelle concentration of a surfactant composition by attenuating the degree of neutralization (DN) of the polymer is disclosed.

Owner:LUBRIZOL ADVANCED MATERIALS INC

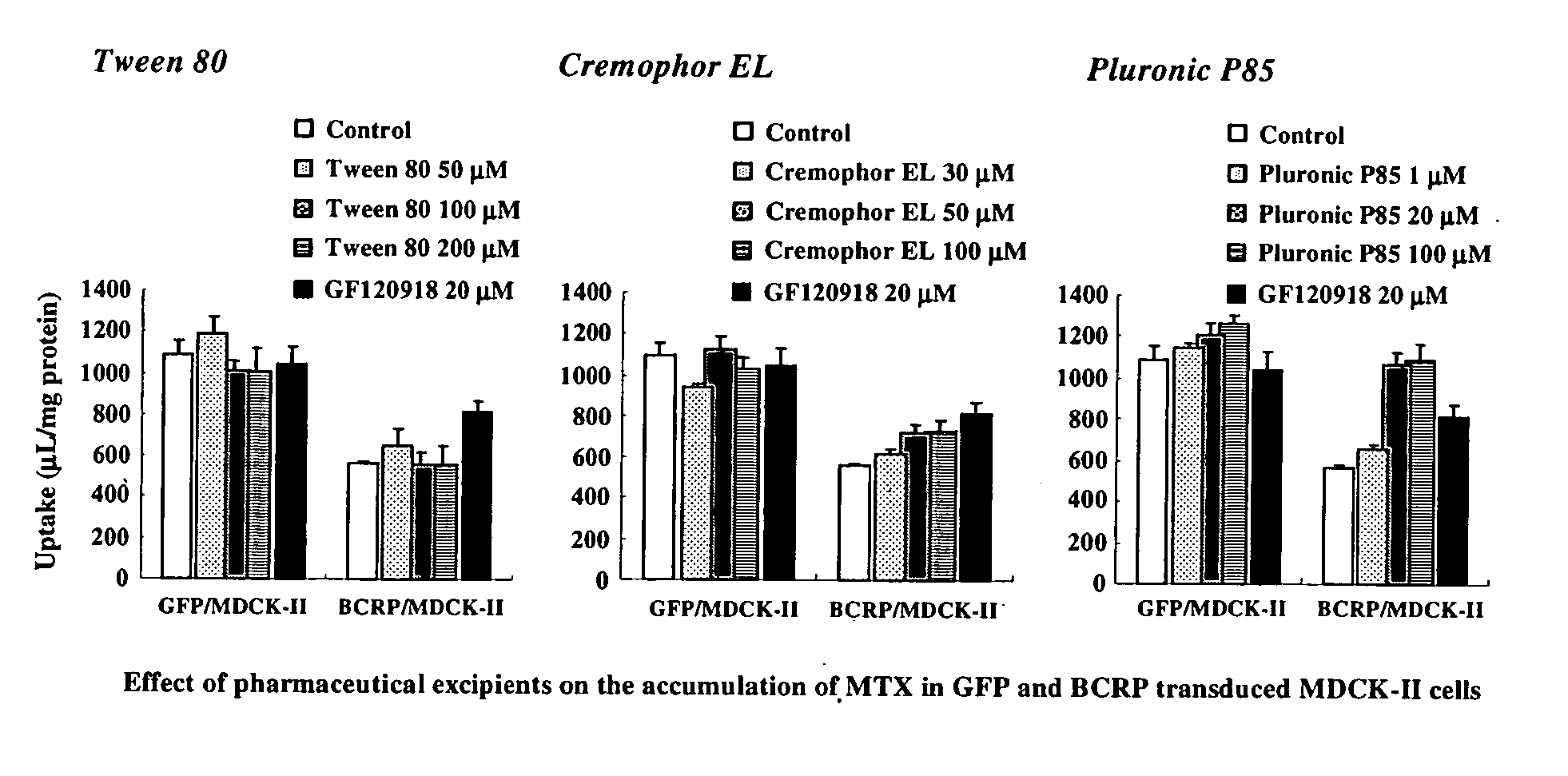

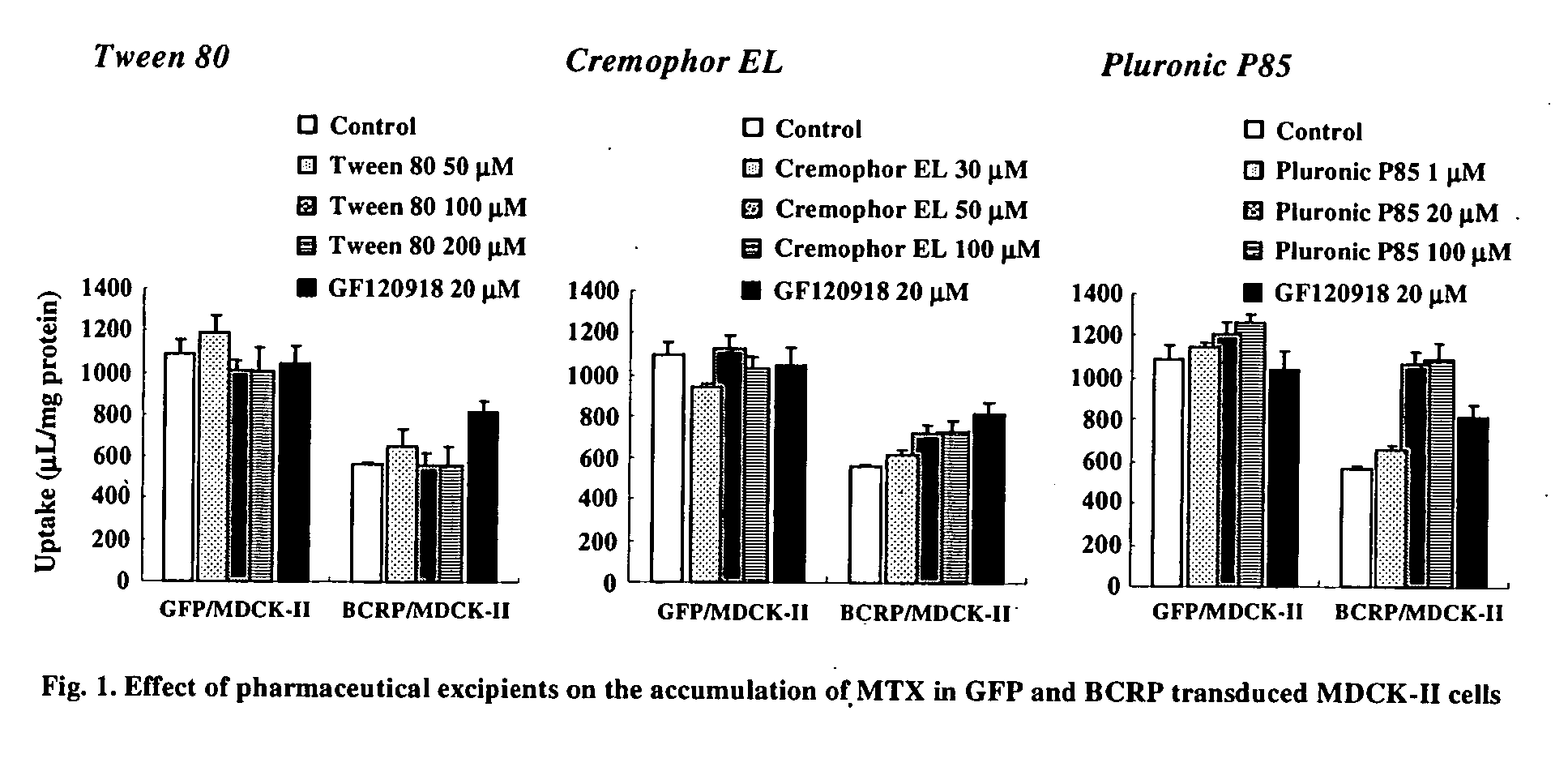

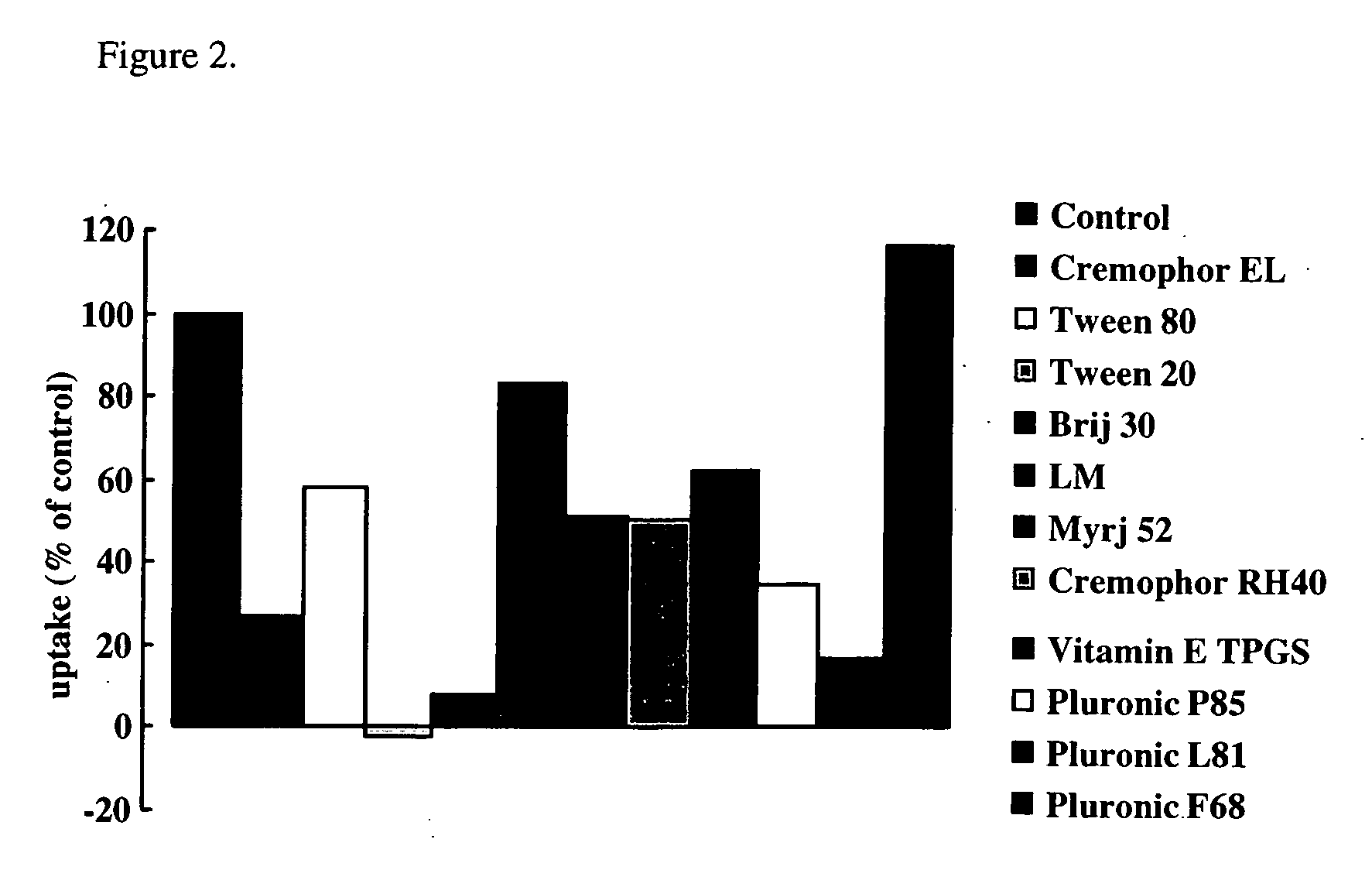

Formulation and method for enhancement of gastrointestinal absorption of pharmaceutical agents

InactiveUS20070053869A1BiocideMetabolism disorderCritical micelle concentrationGastrointestinal absorption

The present invention relates to a method of enhancing absorption of a pharmaceutical agent by administering the agent in combination with an inhibitor of BCRP / ABCG2 wherein the amount of the inhibitor is about the critical micelle concentration of the inhibitor or less than the critical micelle concentration. The invention also relates to a formulation suitable for use to enhance absorption of a pharmaceutical agent. The pharmaceutical agent can be a chemotherapeutic agent. The invention also relates to capsules containing the formulation.

Owner:WARNER-LAMBERT CO

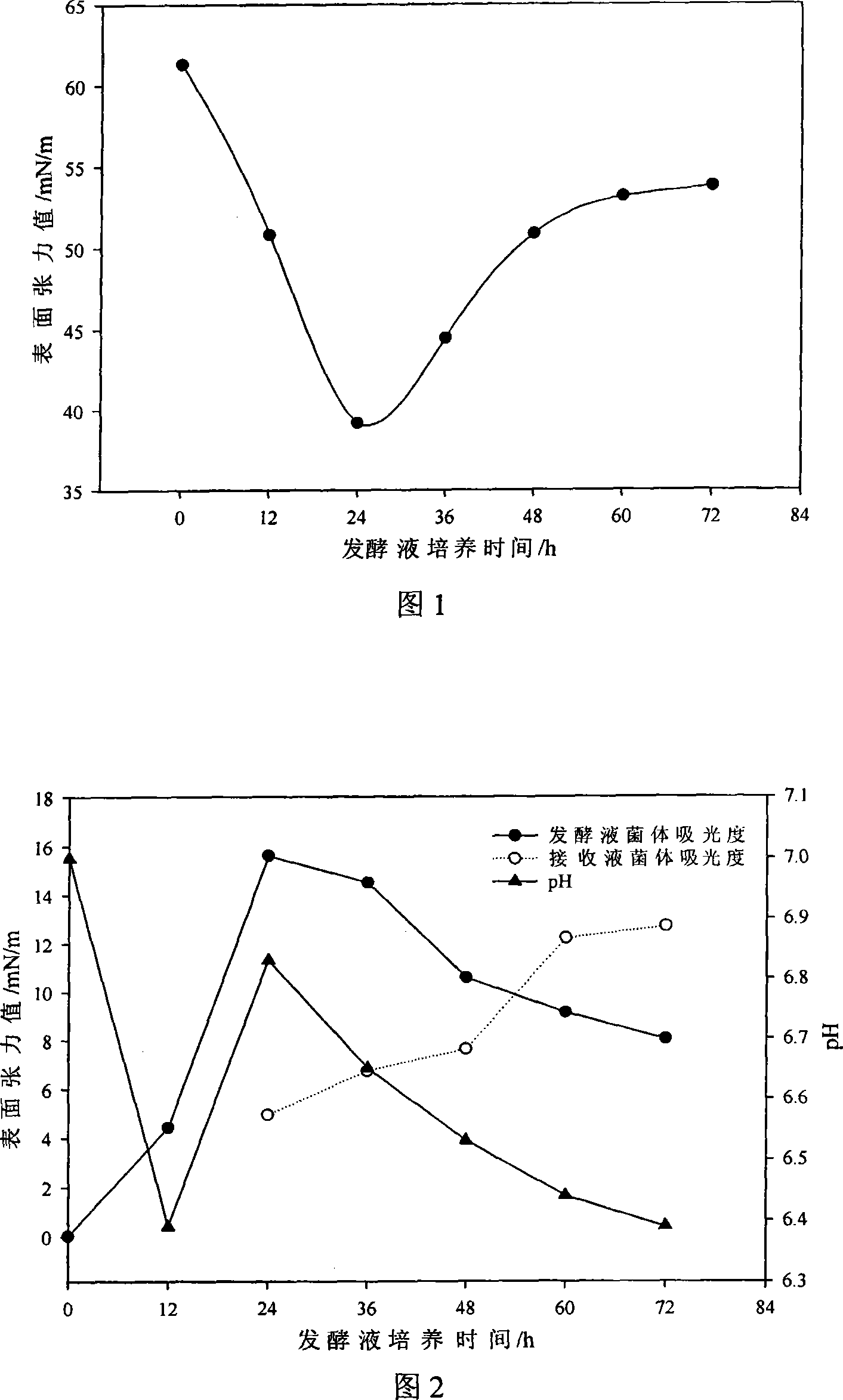

Composite type biological surfactant and its production method

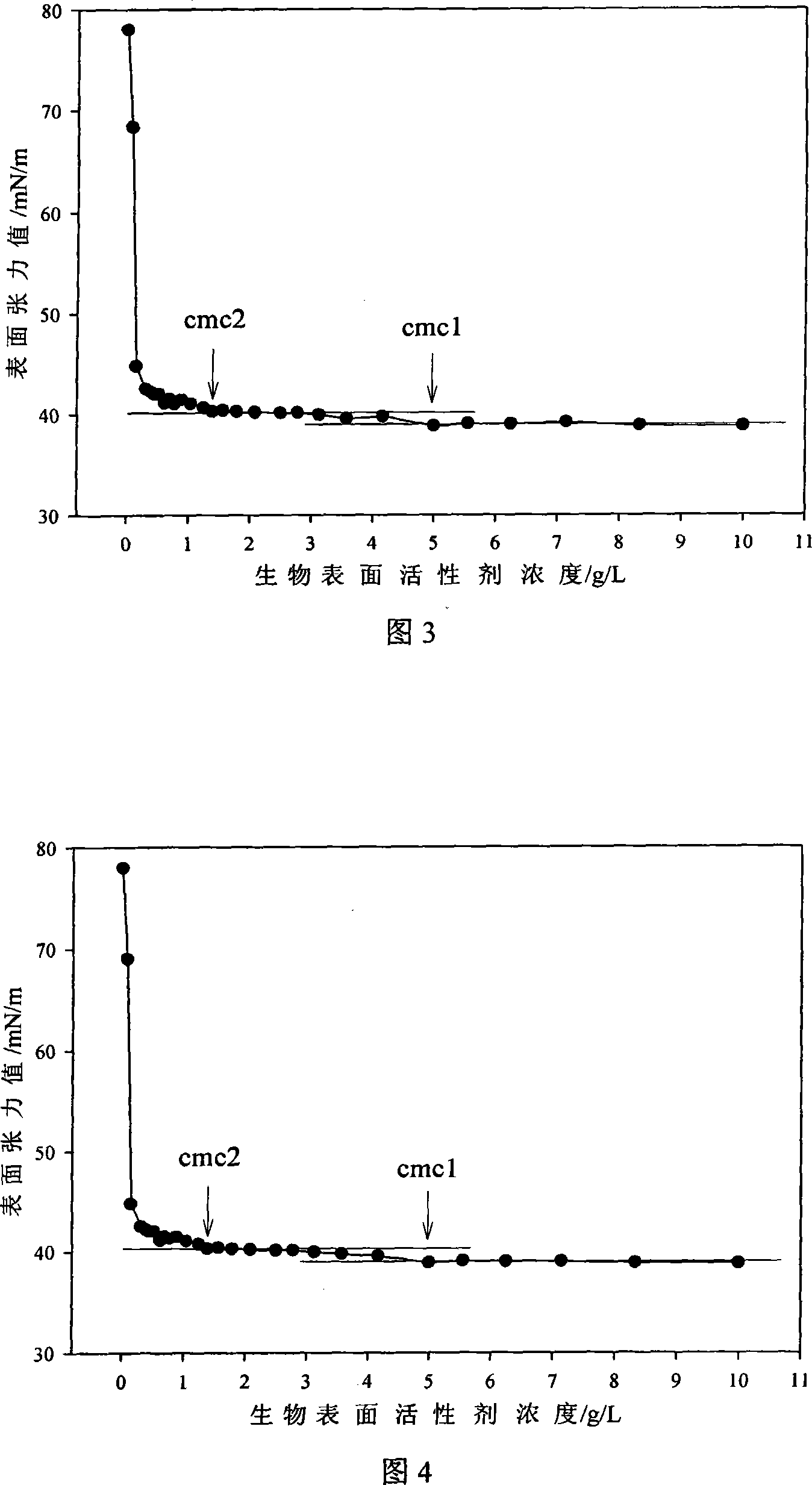

InactiveCN101086006ARich varietyIncrease varietyTransportation and packagingClimate change adaptationCritical micelle concentrationDistilled water

The invention relates to a kind of complex biological surface active agent and the preparation method. It is prepared with bacillus subtilis, and the comprised component and their weight proportion are as follows: fat 98.1+- 0.2%, protein 19.1+- 0.2%, sugar 0.7+-0.1%, the critical micelle concentration of said complex biological surface active agent are 4.2- 5.0 g / l and 1.25- 1.39 g / l respectively, and they reduce interfacial force of distilled water from 78 m / m to 38.4- 39.8 mN / m, and 40.3- 40.8 mN / m. The invention is characterized in that it enriches biological surface active agent species generated by bacillus subtilis, and make it possible for bacillus subtilis wide application in environmental pollution treatment.

Owner:HUNAN UNIV

Method for preparing rosin-based surfactant

InactiveCN101831066AImprove surface activityRaw materials are cheap and easy to getCosmetic preparationsBiocideCritical micelle concentrationPolymer science

The invention discloses a method for preparing a rosin-based surfactant, which comprises the following steps: 1, adding a catalyst in an amount of 0.1 to 1.0 percent based on the mass of the rosin or a rosin derivative and polyethylene glycol or alkylene oxide in an amount of 2 to 3,000 percent based on the mass of the rosin or a rosin derivative into the molten rosin or a rosin derivative to allow the polyethylene glycol or alkylene oxide to react with the rosin or a rosin derivative at the temperature of 230 to 290 DEG C for 2 to 5 hours; 2, perform reduced pressure vacuumization and keeping a vacuum degree of less than or equal to 2kPa for 5 to 60 minutes to remove low-boiling-point substances; and 3, decreasing the temperature to 60 to 120 DEG C, adding antioxygen in an amount of 0.1 to 1 percent based on the mass of the rosin or a rosin derivative and an esterifying agent in an amount of 5 to 12 percent based on the mass of the rosin or a rosin derivative in batch into the product obtained by the step, performing a reaction at the temperature of 65 to 110 DEG C for 2 to 6 hours, and discharging the resulting material to obtain the rosin-based surfactant. The product has low surface tension, low critical micelle concentration, high emulsifying performance and low Krafft point and can be used as an emulsifier, a dispersant and an oil field assistant.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Polymer micelle medicine-carrying system

InactiveCN1524581AReduce the ratioCMC reductionInanimate material medical ingredientsPharmaceutical non-active ingredientsPolyesterCritical micelle concentration

The invention relates to a method for making medicinal preparation, in particular a polymer micelle drug loading system and preparation, wherein the micelle is methyl polyethylene glycol - polyester segmented copolymer micelle, characterized by that, the ratio of methyl polyethylene glycol and polyester is less than 50 / 50, and the advantages of the segmented copolymer micelle is low critical micelle concentration, high drug loading capacity and stabilized micelle.

Owner:涂家生 +1

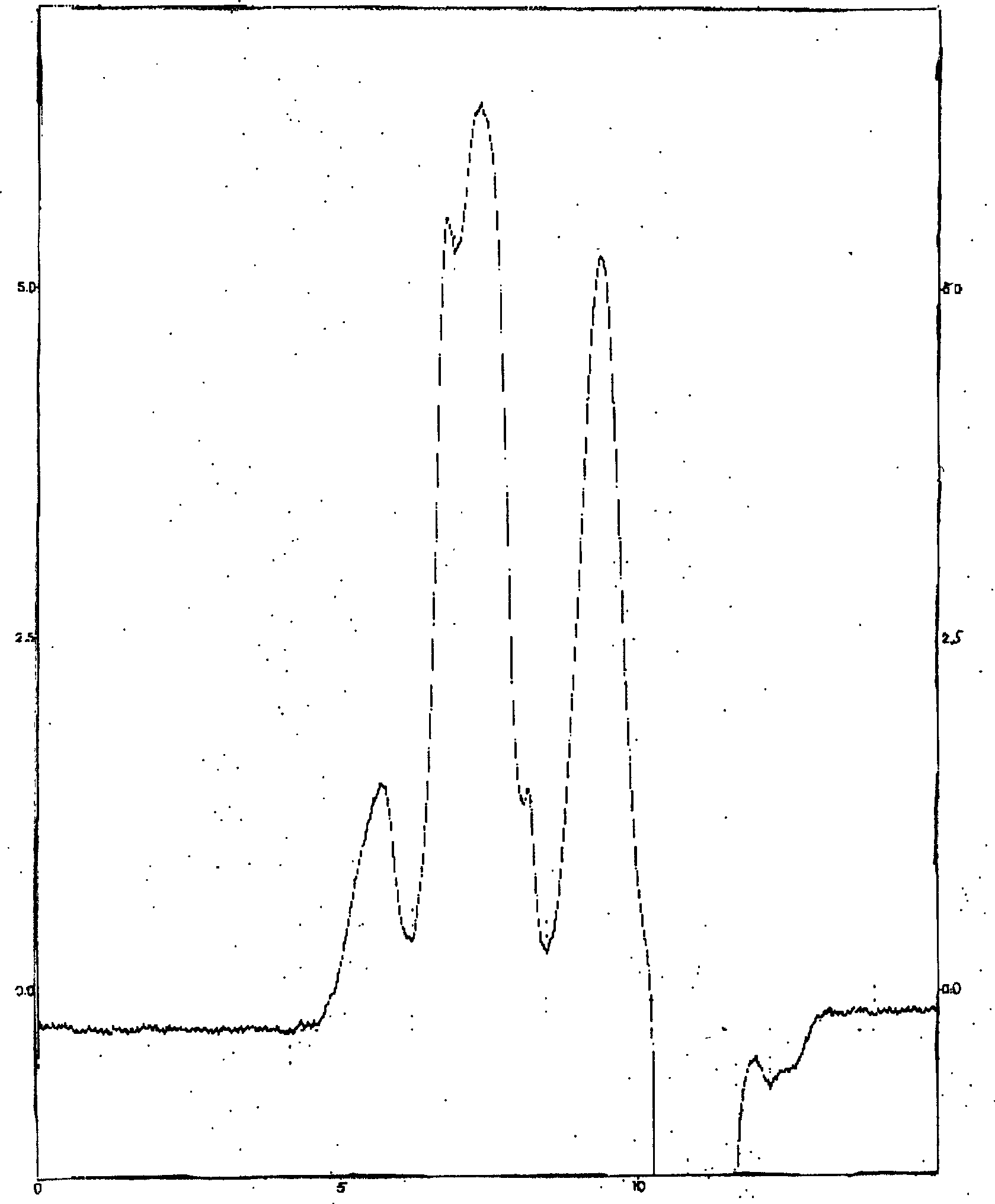

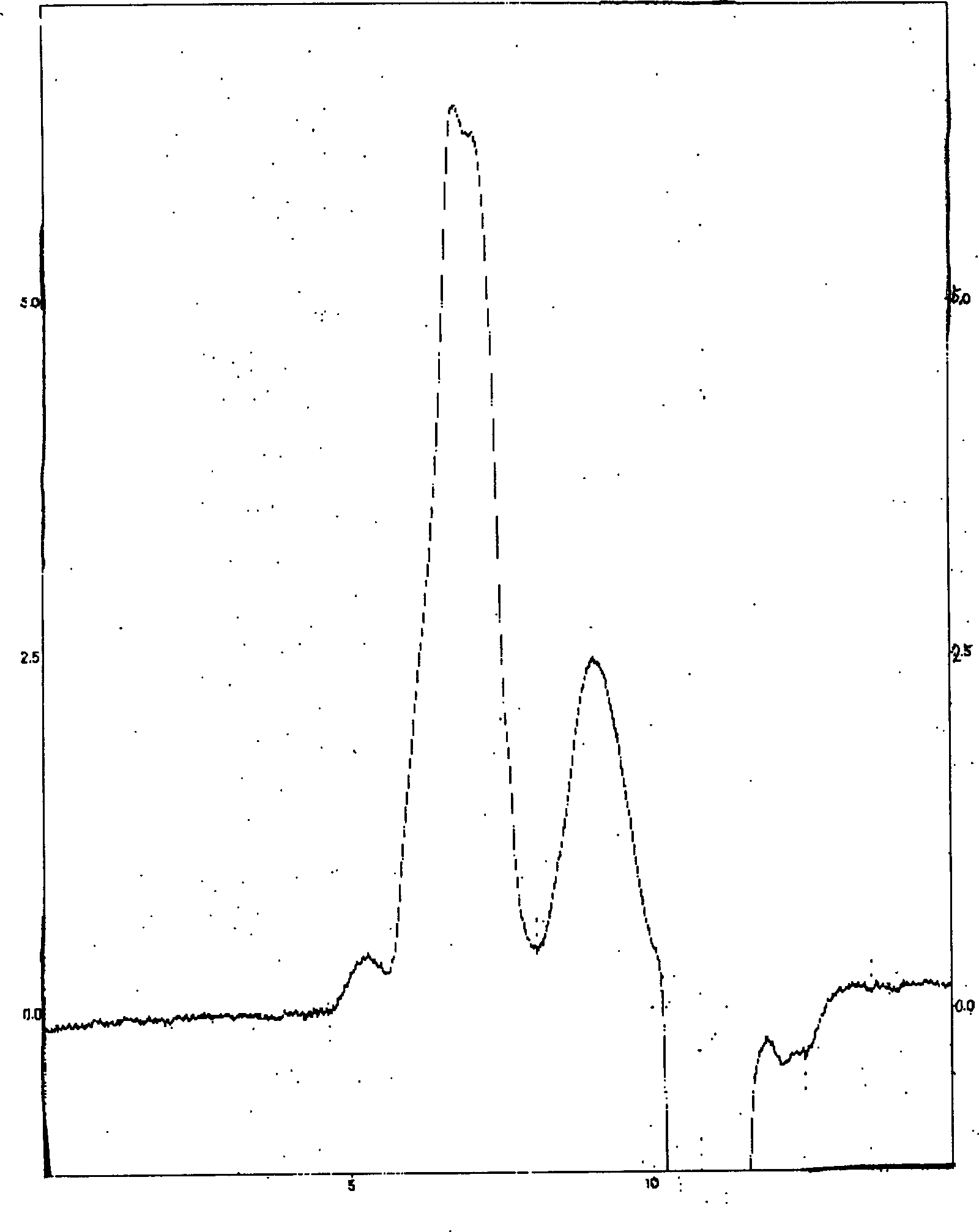

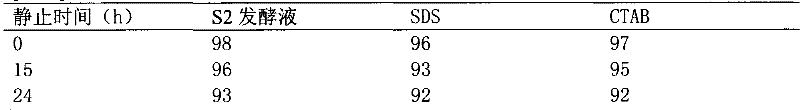

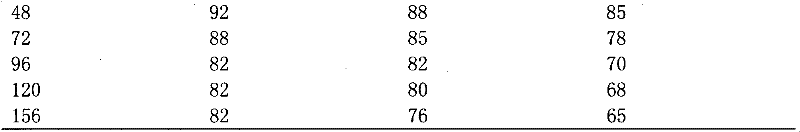

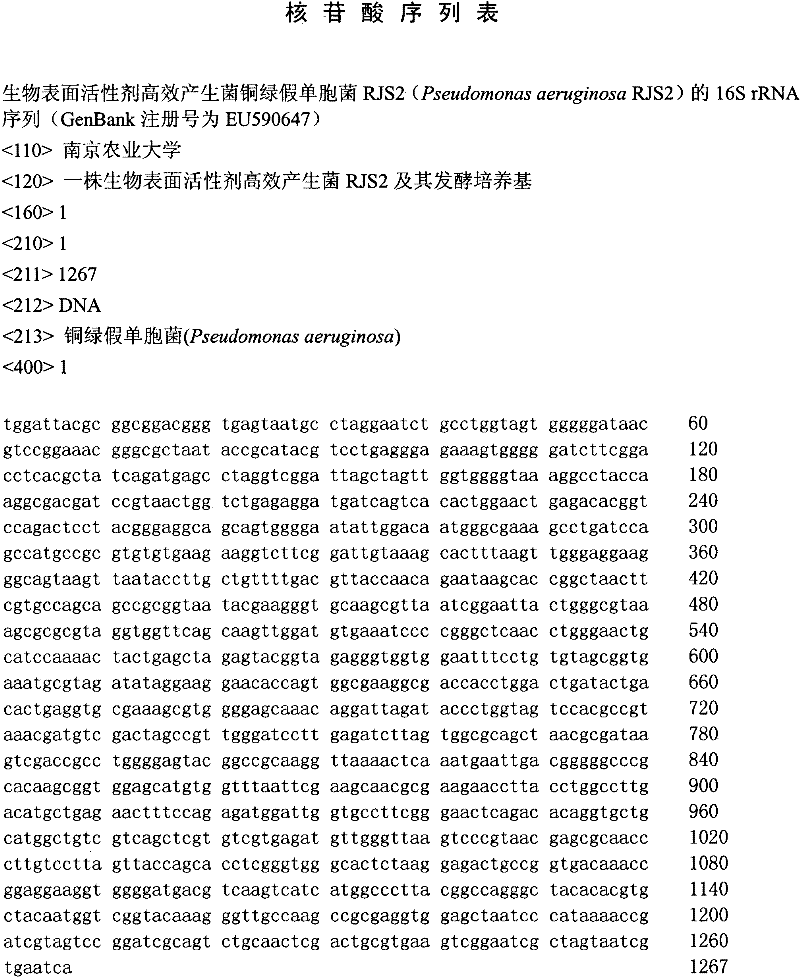

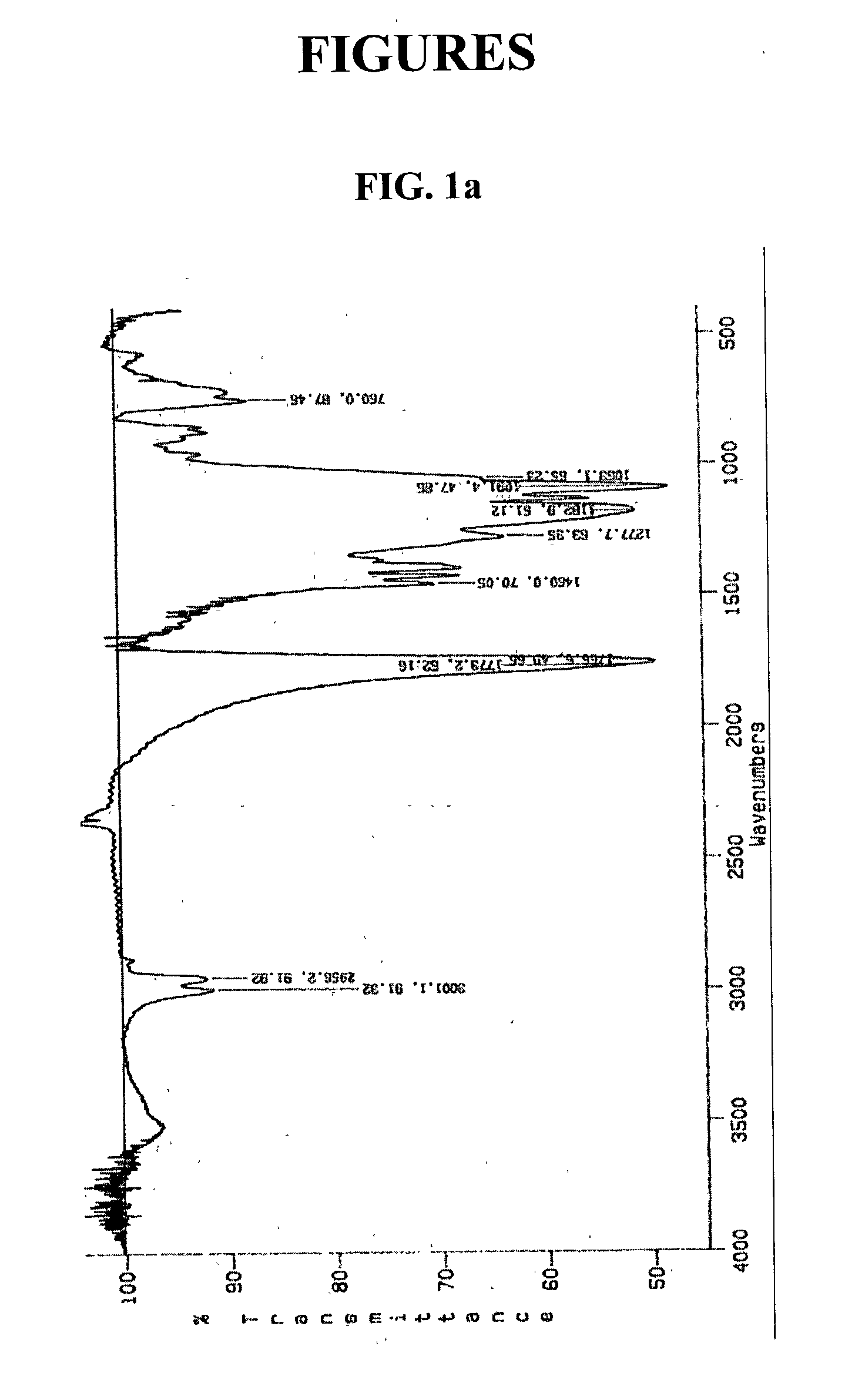

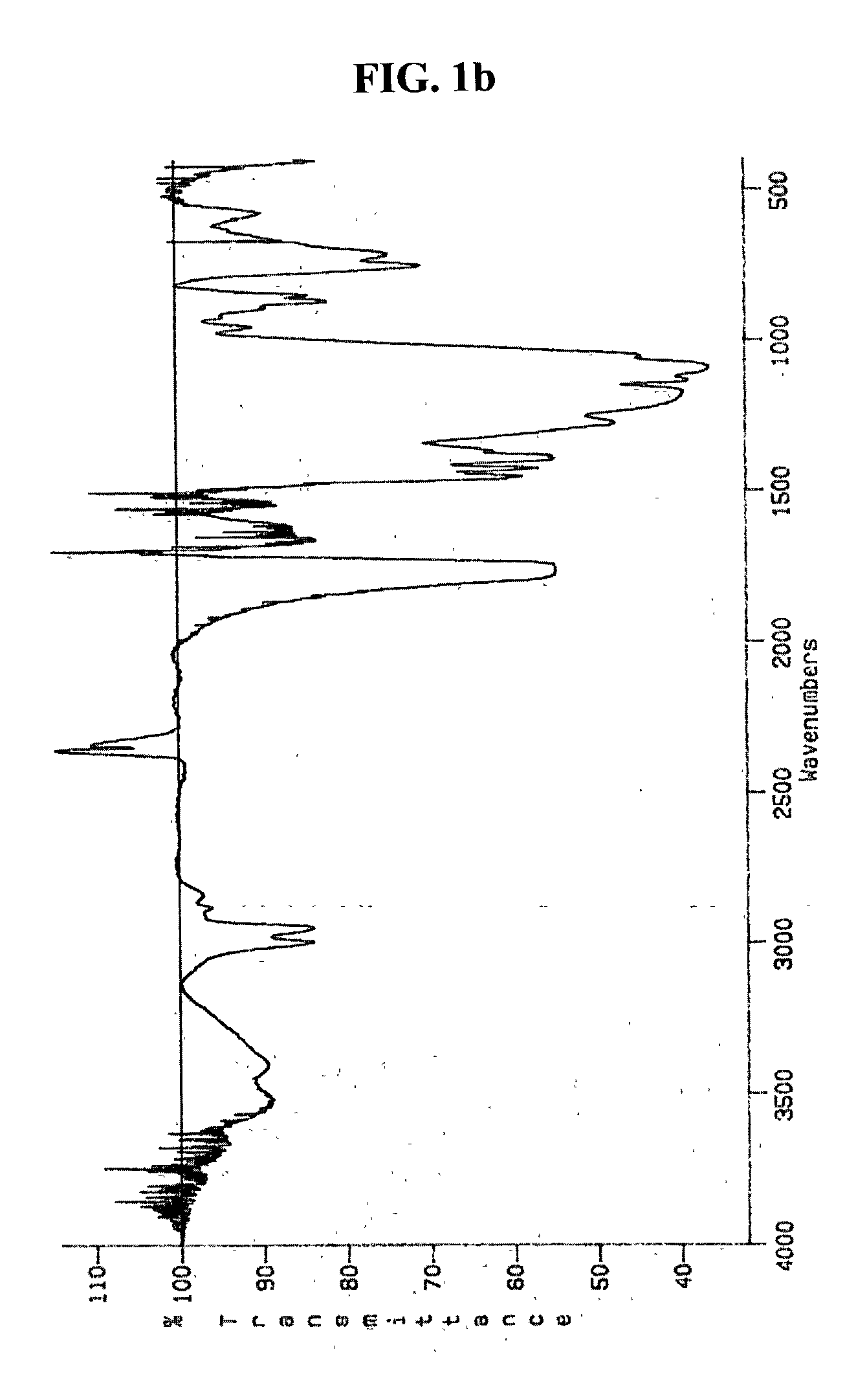

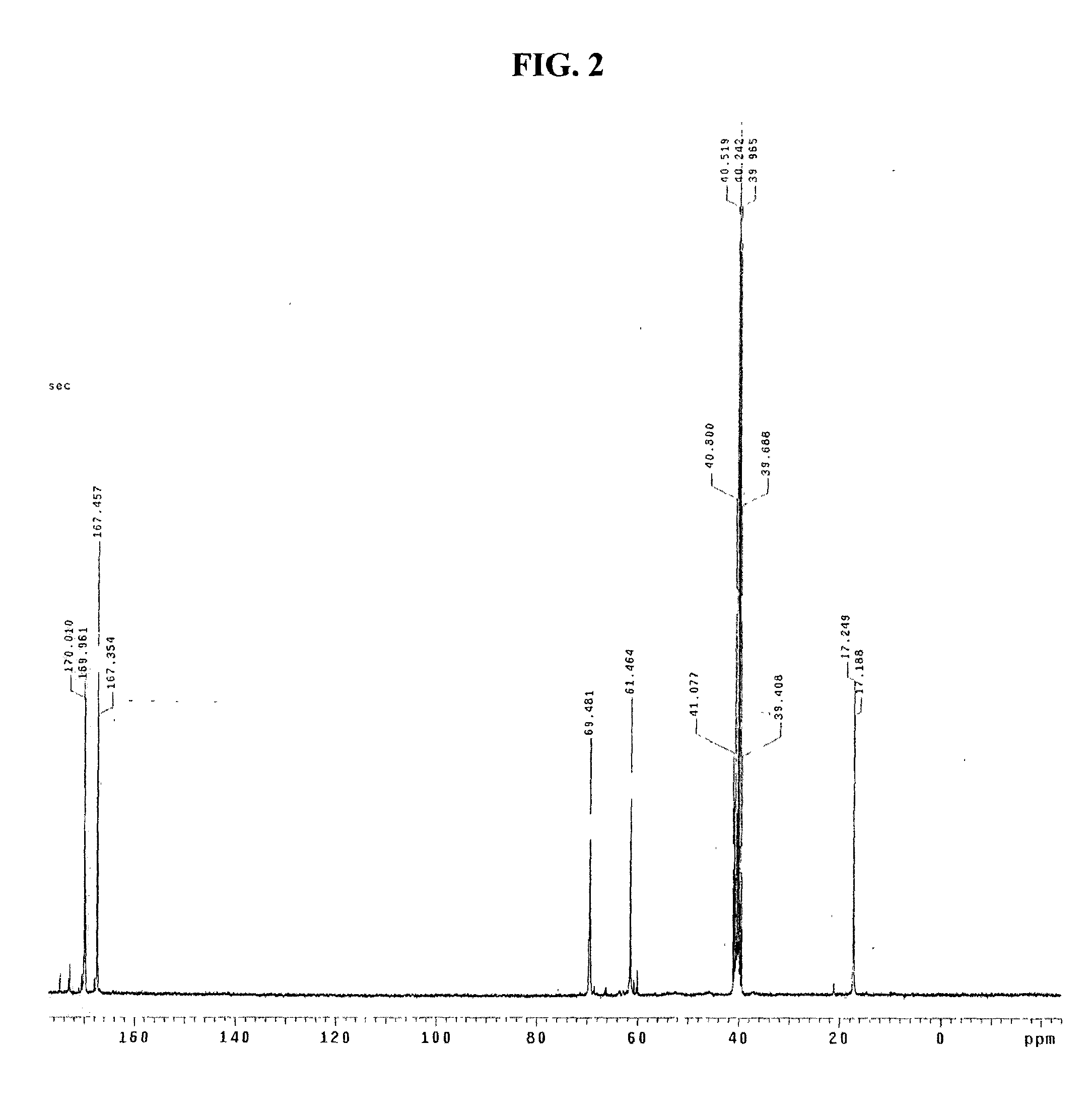

Bacterium S2 for efficiently generating biosurfactant and fermentation culture medium thereof

ActiveCN102250790ALow CMC valueImprove performanceBacteriaMicroorganism based processesRapeseedBacterial strain

The invention relates to a bacterium S2 for efficiently generating biosurfactant and a fermentation culture medium thereof, belonging to the field of biotechnology. The bacterium S2 is gram-negative bacterium which is rod-shaped, is (6-8)*(8-12) micrometers in size and has no spores and capsules. The bacterial strain belongs to the pseudomonas aeruginosa through identifying by morphological and physio-biochemical characteristics and molecular biology, and the collection code is CGMCC No.3034. The best fermentation culture medium is a novel culture medium which takes 50g / L of rapeseed oil as the only carbon source. The rhamnolipid is the only fermentation product of the bacterial strain and has high yield. The CMC (Critical Micelle Concentration) value of the fermentation liquid is 0.25 g / L; compared with the common chemical surfactant, the bacterium has more obvious emulsification and durability on hydrophobic substances, such as oils and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

Amphiphilic biodegradable block copolymers and self-assembled polymer aggregates formed from the same in aqueous milieu

InactiveUS20030009004A1Glass/slag layered productsWood layered productsPolyesterCritical micelle concentration

There are provided amphiphilic biodegradable block copolymers comprising polyethylenimine (PEI) as a hydrophilic block and aliphatic polyesters as a hydrophobic block, which can form various size of polymer aggregates and have very low critical micelle concentration, approximately 10-3 g / l in comparison with low-molecular-weight micelle, and self-assembled polymer aggregates formed from the block copolymers in aqueous milieu, which can be applied to solubilization of insoluble drug and a delivery system of proteins, genes or drugs.

Owner:AMOREPACIFIC CORP

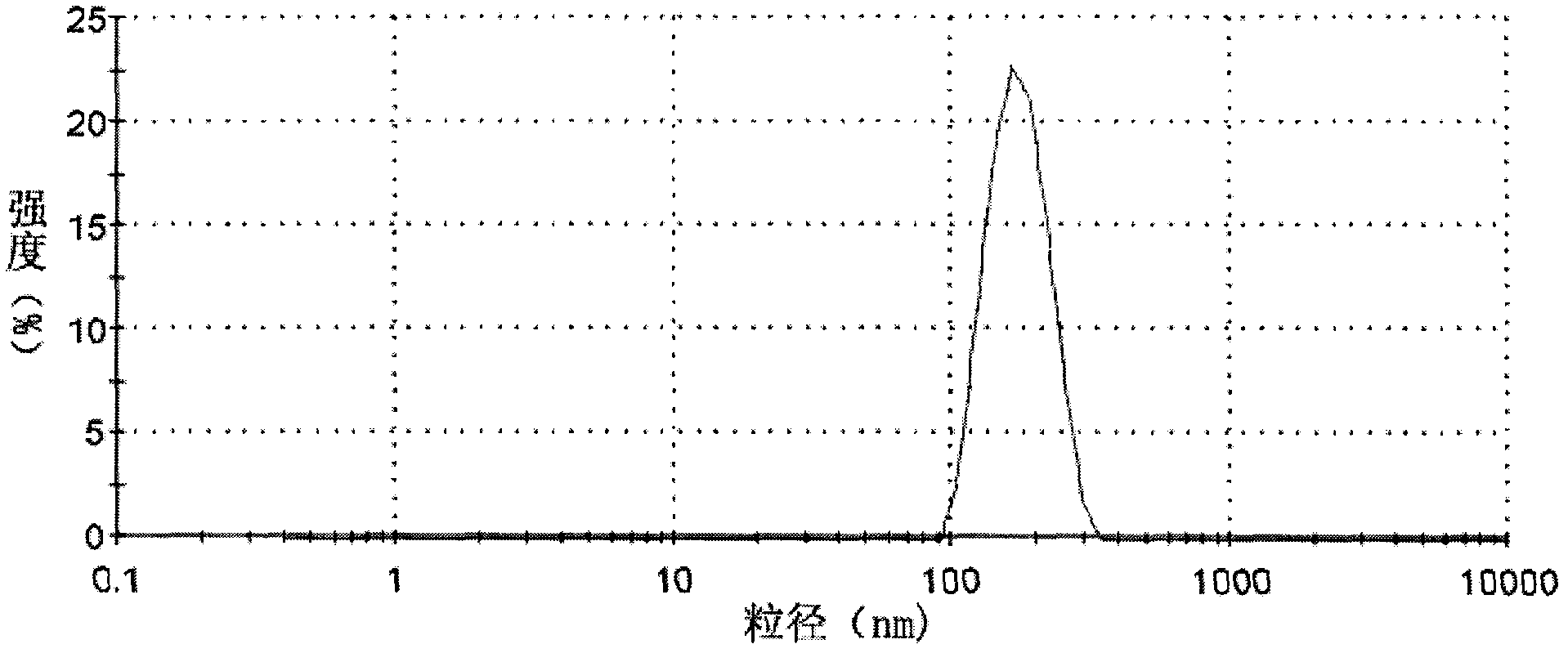

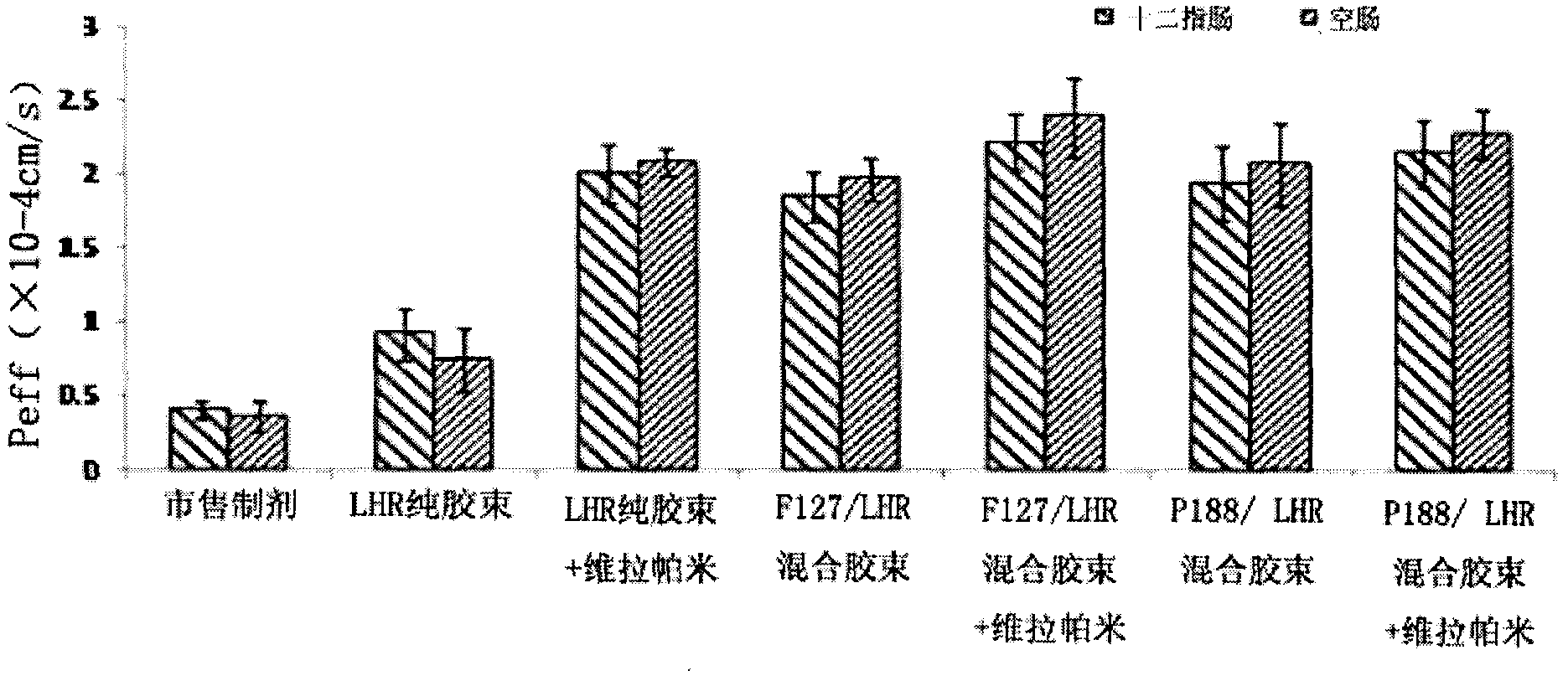

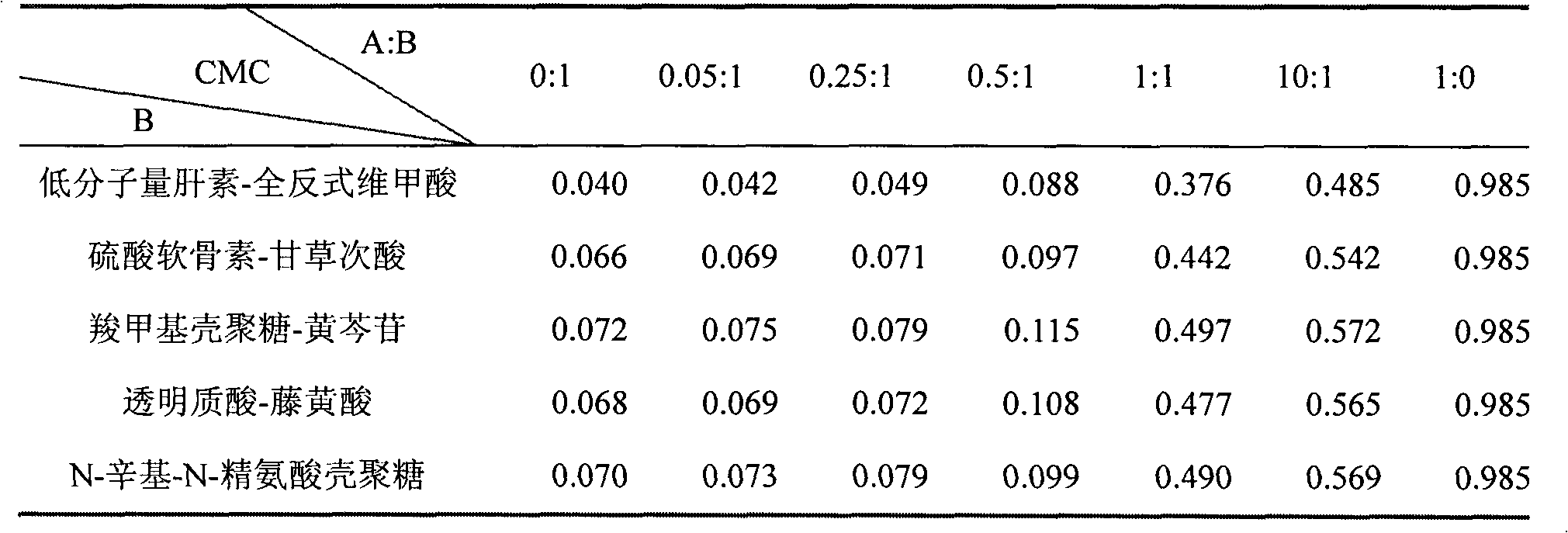

Preparation and application of insoluble drug-entrapped poloxamer/amphiphilic polysaccharide mixed micelle

InactiveCN102626518AOvercome the problems of high critical micelle concentration and low drug loadingImprove oral bioavailabilityPharmaceutical delivery mechanismPharmaceutical non-active ingredientsMixed micelleCytochrome p450 enzyme

The invention discloses preparation and application of an insoluble drug-entrapped poloxamer / amphiphilic polysaccharide mixed micelle. The insoluble drug-entrapped poloxamer / amphiphilic polysaccharide mixed micelle is prepared through a dialysis method or a solvent evaporation method. The mixed micelle is low in critical micelle concentration, is high in drug-loading rate, is capable of obviously prolonging the stabilization time and has the long-circulation function of a nanomicelle and has dual functions of restraining the metabolism of P-glycoprotein and cytochrome P450 enzyme and is capable of increasing the bioavailability of oral administration. The mixed micelle is simple in preparation method, is mature in process and is high in yield and can be prepared into preparations for the oral administration, such as tablets, capsules, pills and syrups.

Owner:CHINA PHARM UNIV

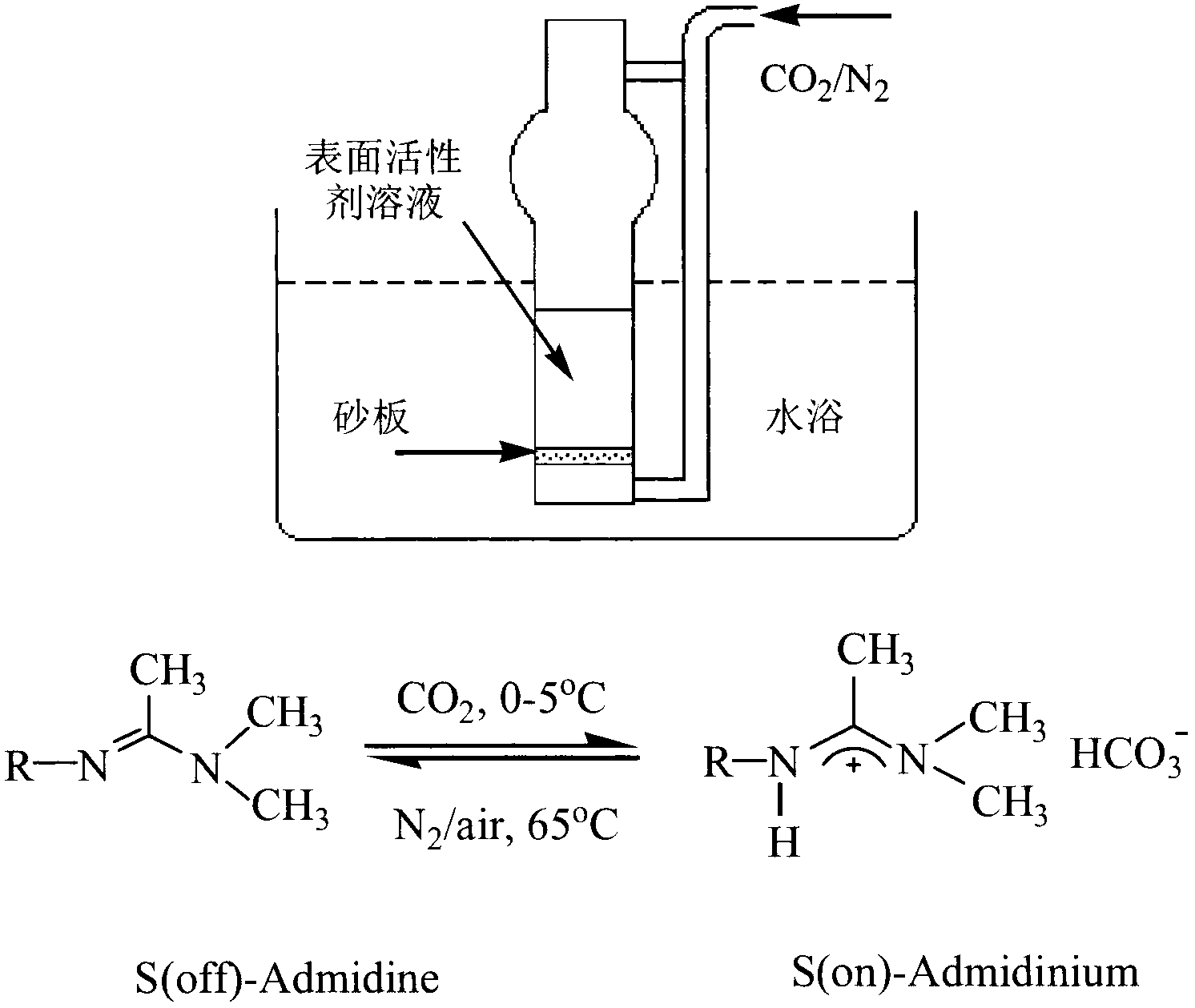

Compound emulsifier with switching property

InactiveCN103301782AImprove switching performanceImprove efficiencyTransportation and packagingMixingVegetable oilWater insoluble

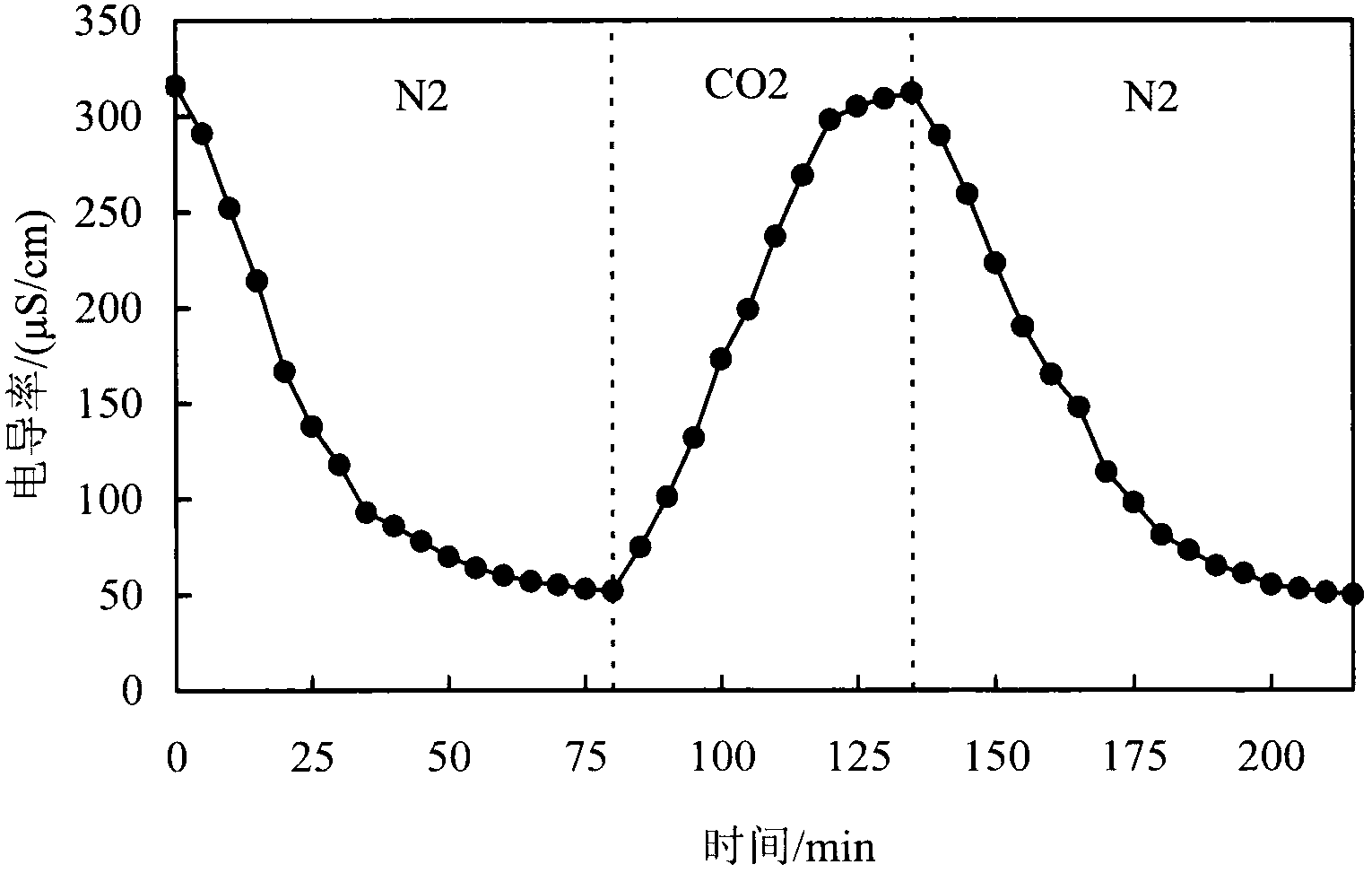

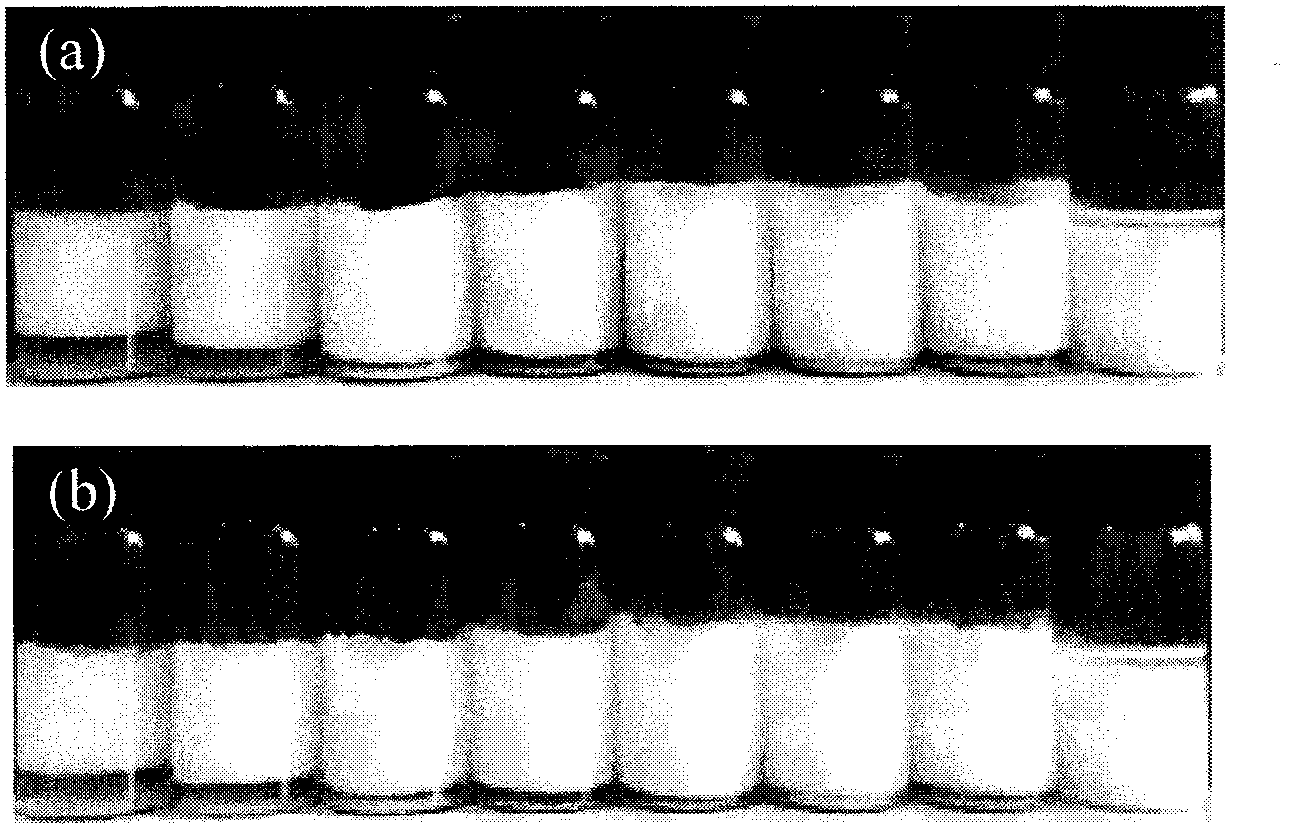

The invention discloses a compound emulsifier with a switching property, belonging to the field of colloid and interface chemistry. The emulsifier consists of nano silicon dioxide particles without any modification and a switching-type amphiphilic compound, wherein the original particle size of the nano silicon dioxide particles is 20-200nm, and the use concentration is 0.1-2.0% (based on an aqueous phase); and the switching-type amphiphilic compound is an N'-long chain alkyl-N,N-dimethylacetamidine substance, wherein the total carbon atom number of the long chain alkyl is 8-18, the long chain can be a straight chain or branch chain, the alkyl is a saturated or unsaturated alkyl containing a benzene ring or not, and the use concentration is less than the critical micelle concentration (based on an aqueous phase). A proper oil phase comprises mineral oil (hydrocarbons), animal / vegetable oil (triglycerides) and water-insoluble polar organic matters such as long-chain fatty acid, fatty alcohol and the like. The emulsion prepared by the compound emulsifier belongs to Pickering emulsion, is generally an O / W type and has hyperstability. By introducing nitrogen (N2) or air, the emulsifier can be deactivated to cause demulsification of the emulsion; by introducing carbon dioxide (CO2), the surface activity of the emulsifier can be recovered; and the system becomes stable Pickering emulsion after homogenizing emulsification, namely that the compound emulsifier has a switching property.

Owner:JIANGNAN UNIV

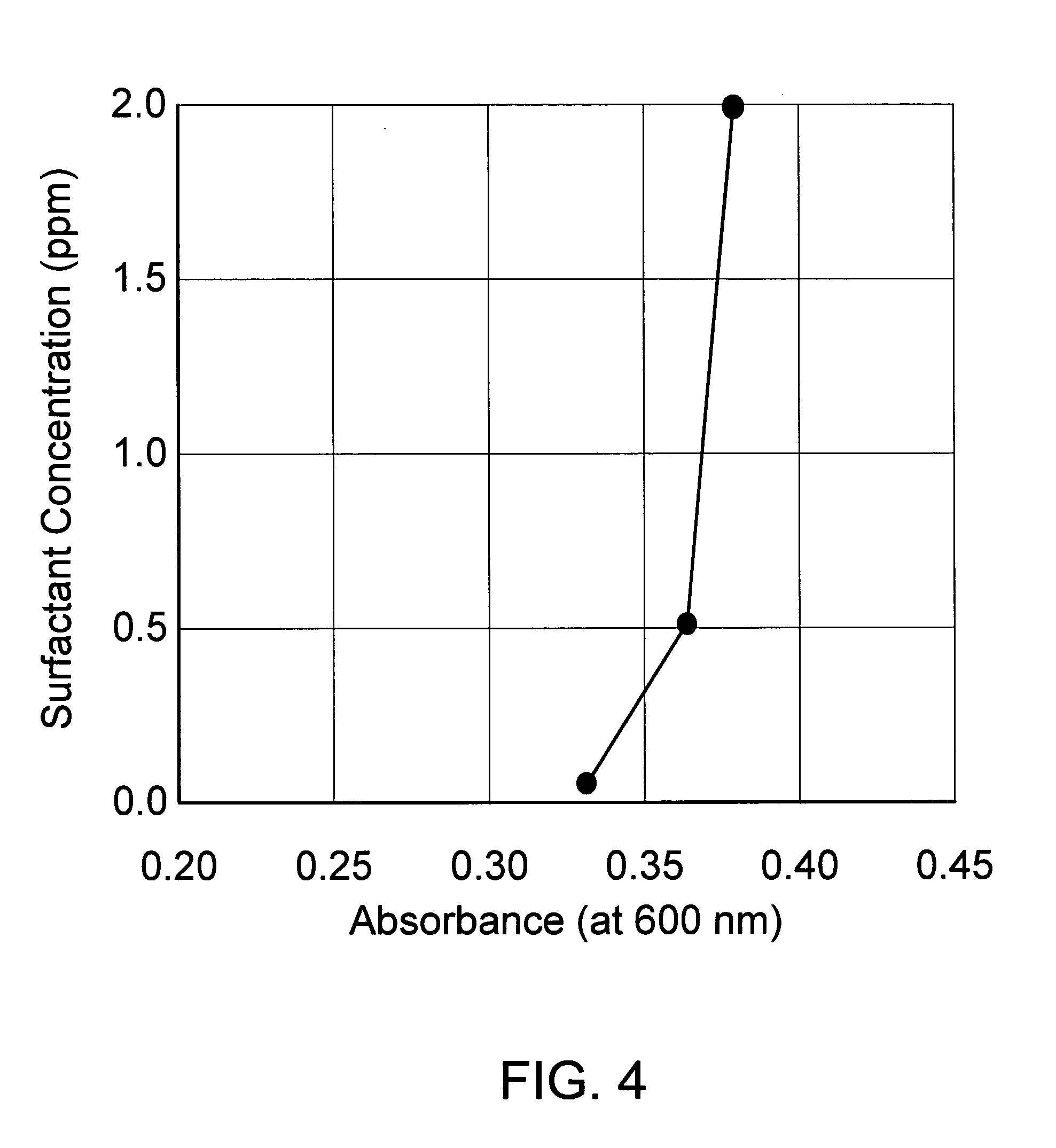

Method for determining surfactant concentration in aqueous solutions

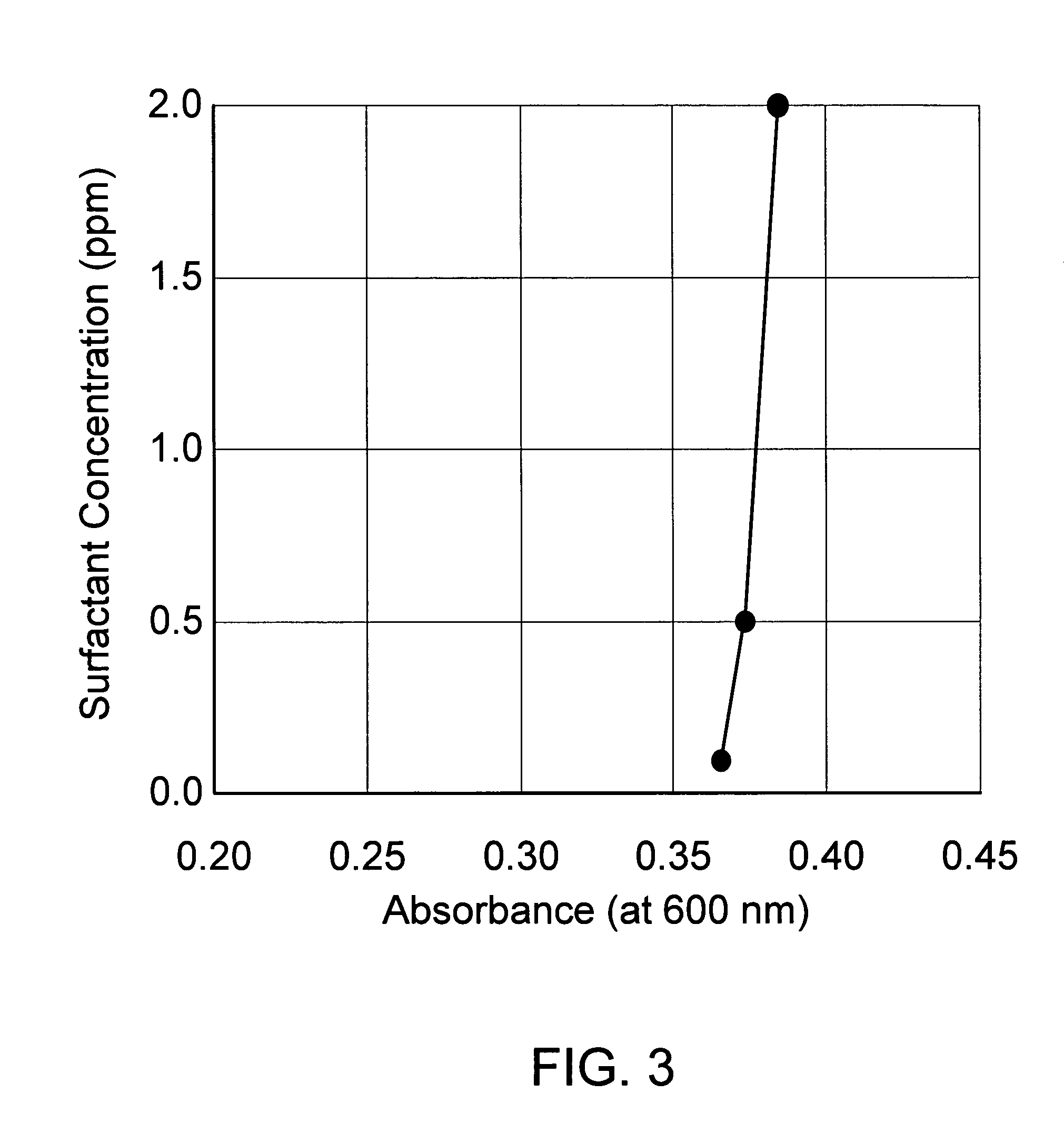

ActiveUS20050037509A1Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorCritical micelle concentrationPresent method

The present method provides a single-phase technique in which an ionic strength adjuster and a water insoluble dye are added to a sample of an aqueous solution containing an unknown quantity of a known surfactant. Even at surfactant concentrations well below the critical micelle concentration (CMC) of the aqueous sample, the addition of an ionic strength adjuster induces the surfactant to form micelles. These micelles absorb the water insoluble dye, thereby imparting a known color to the aqueous sample being tested. The color intensity of the treated aqueous sample is directly related to the concentration of the surfactant in the sample and, through the use of calibration curves prepared from samples of know concentration, can be used to determine the surfactant concentration.

Owner:CHEMTREAT

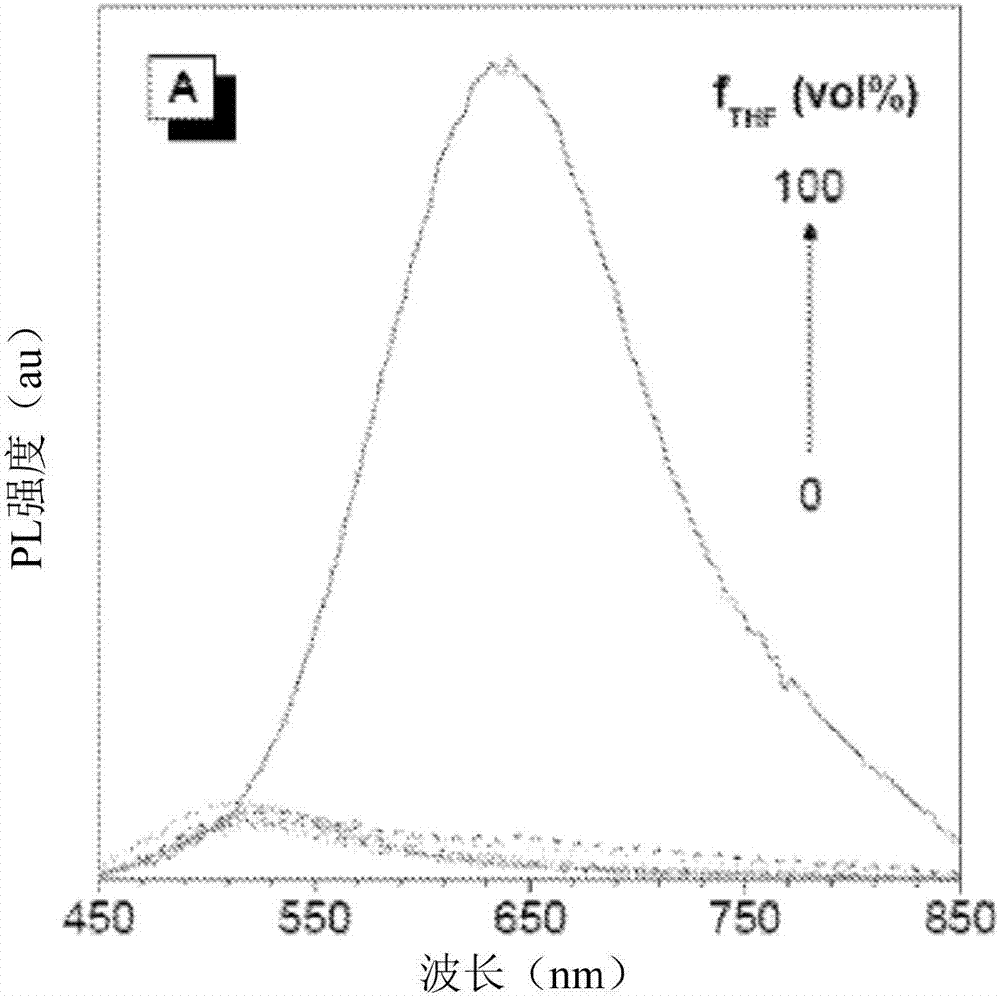

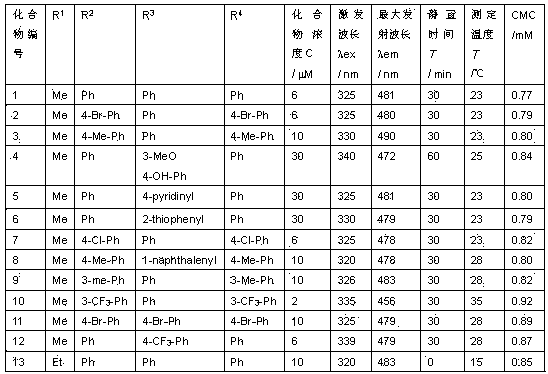

Aie luminogens for bacteria imaging, killing, photodynamic therapy and antibiotics screening, and their methods of manufacturing

ActiveCN107001927ASimplify the imaging processEasy to filterGroup 4/14 element organic compoundsOrganic active ingredientsPhotodynamic therapyCritical micelle concentration

The invention relates to synthesis of fluorescent molecules with aggregation-induced emission (AIE) characteristics and application as fluorescent probes for cellular imaging, killing, and antibiotic screening, wherein the cells are bacteria or mammalian cells. The fluorescent molecules generate reactive oxygen species (ROS) upon light irradiation. The invention also relates to a probe comprising fluorescent molecules exhibiting AIE phenomenon, wherein the probe is used for bacterial and biological study. The invention further relates to a method of imaging and quantifying bacterial, a method of killing cells, a method of high throughput antibiotics screening and determining bacteria resistance, a method of photodynamic therapy, and a method of determining critical micelle concentration.

Owner:THE HONG KONG UNIV OF SCI & TECH

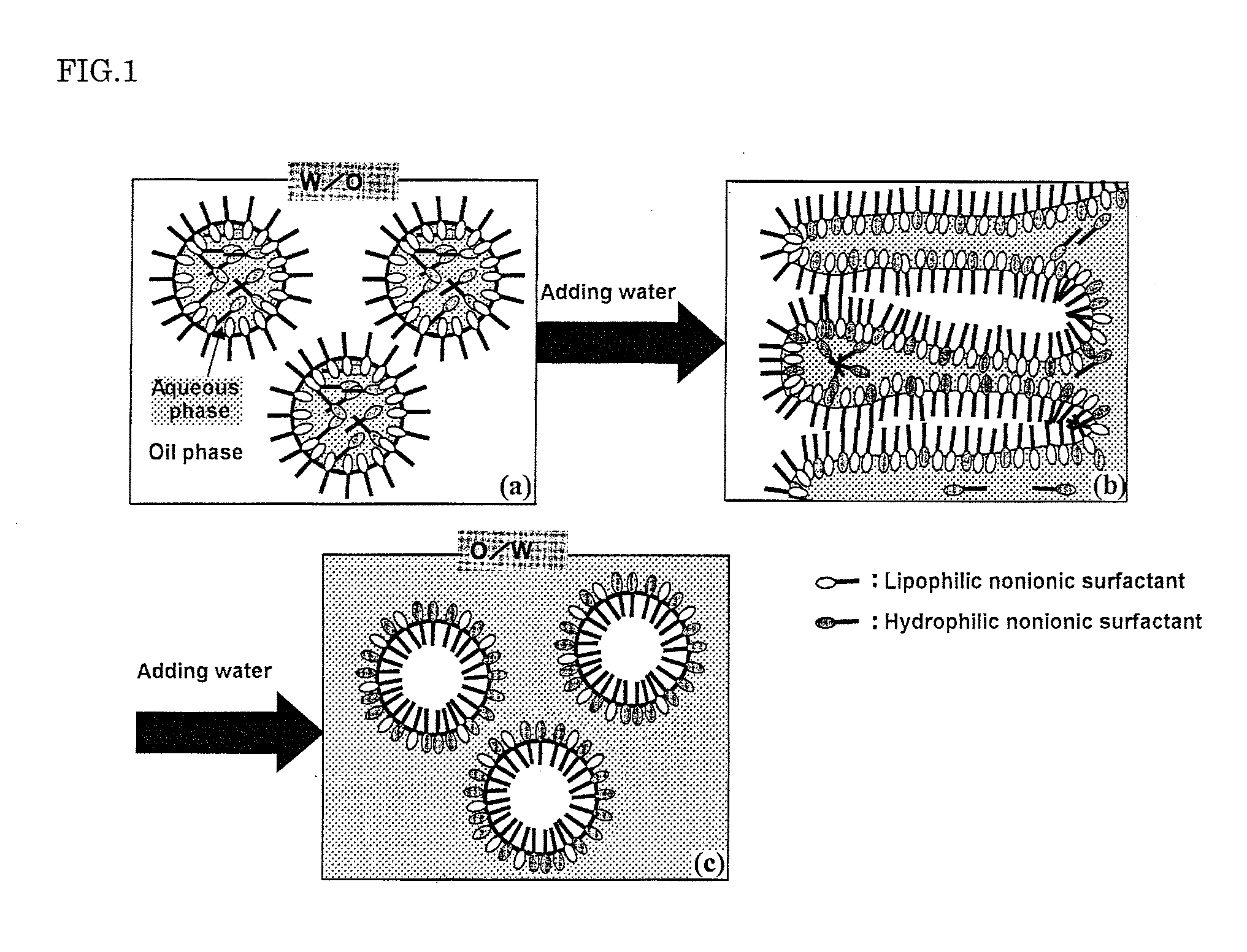

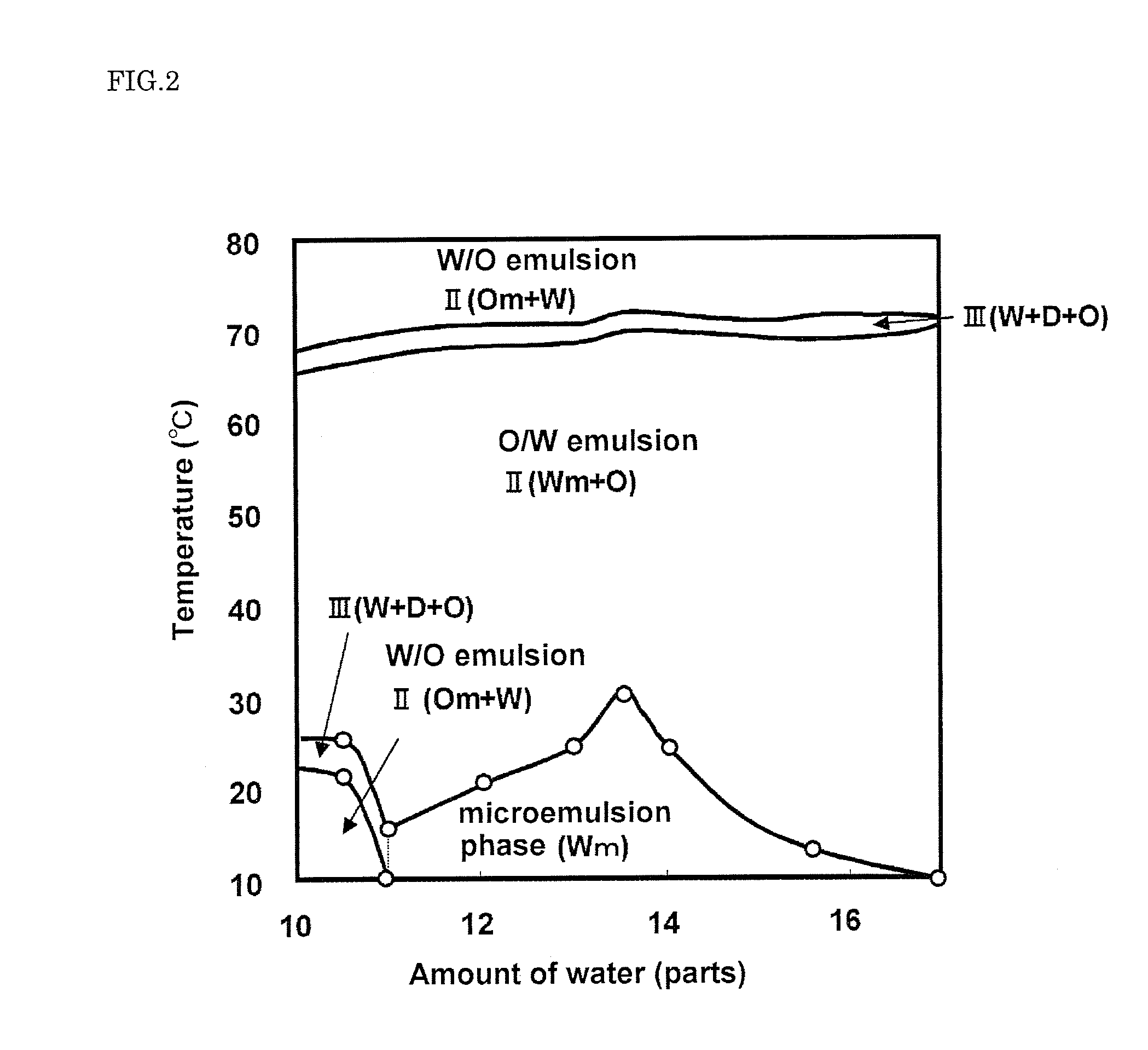

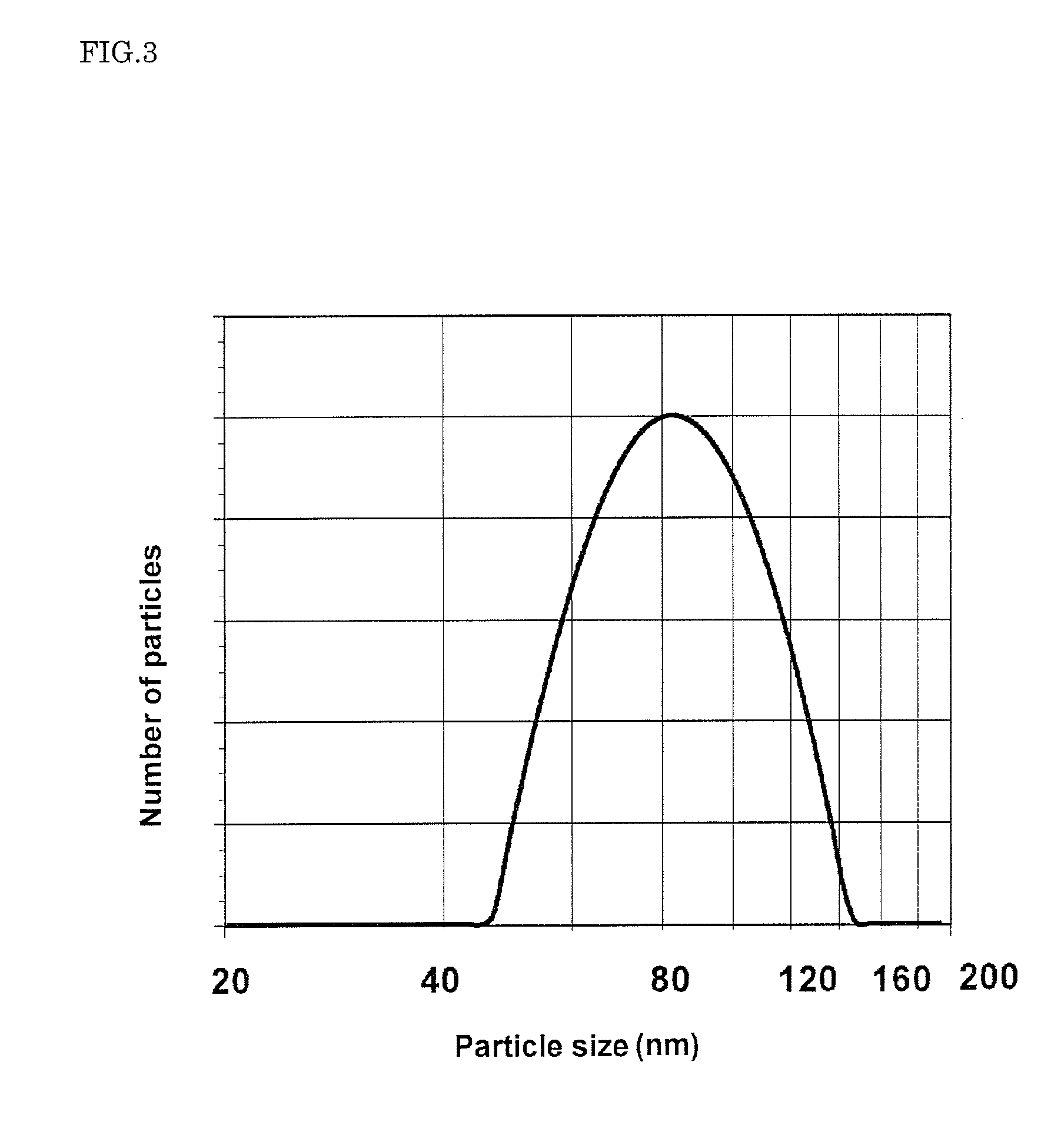

One-Phase Microemulsion Compositions, O/W Ultrafine Emulsion External Formulations And Method For Producing The Same

ActiveUS20080153929A1Safe to human bodyImprove stabilityCosmetic preparationsOther chemical processesCritical micelle concentrationEmulsion

A one-phase microemulsion composition, which can be easily prepared without the use of special equipment, has high safety, and stays stable for a long period in an ultrafine emulsion state when the composition is added to an aqueous formulation, is provided by appropriately adjusting the ratio of (A) a hydrophilic nonionic surfactant, (B) a lipophilic nonionic surfactant, (C) an oil component, (D) a water-miscible solvent that does not interdissolve with the oil component, and the critical micelle concentration (CMC) of the hydrophilic nonionic surfactant in the water-miscible solvent is higher than that of the hydrophilic nonionic surfactant in water, and (E) water.

Owner:SHISEIDO CO LTD

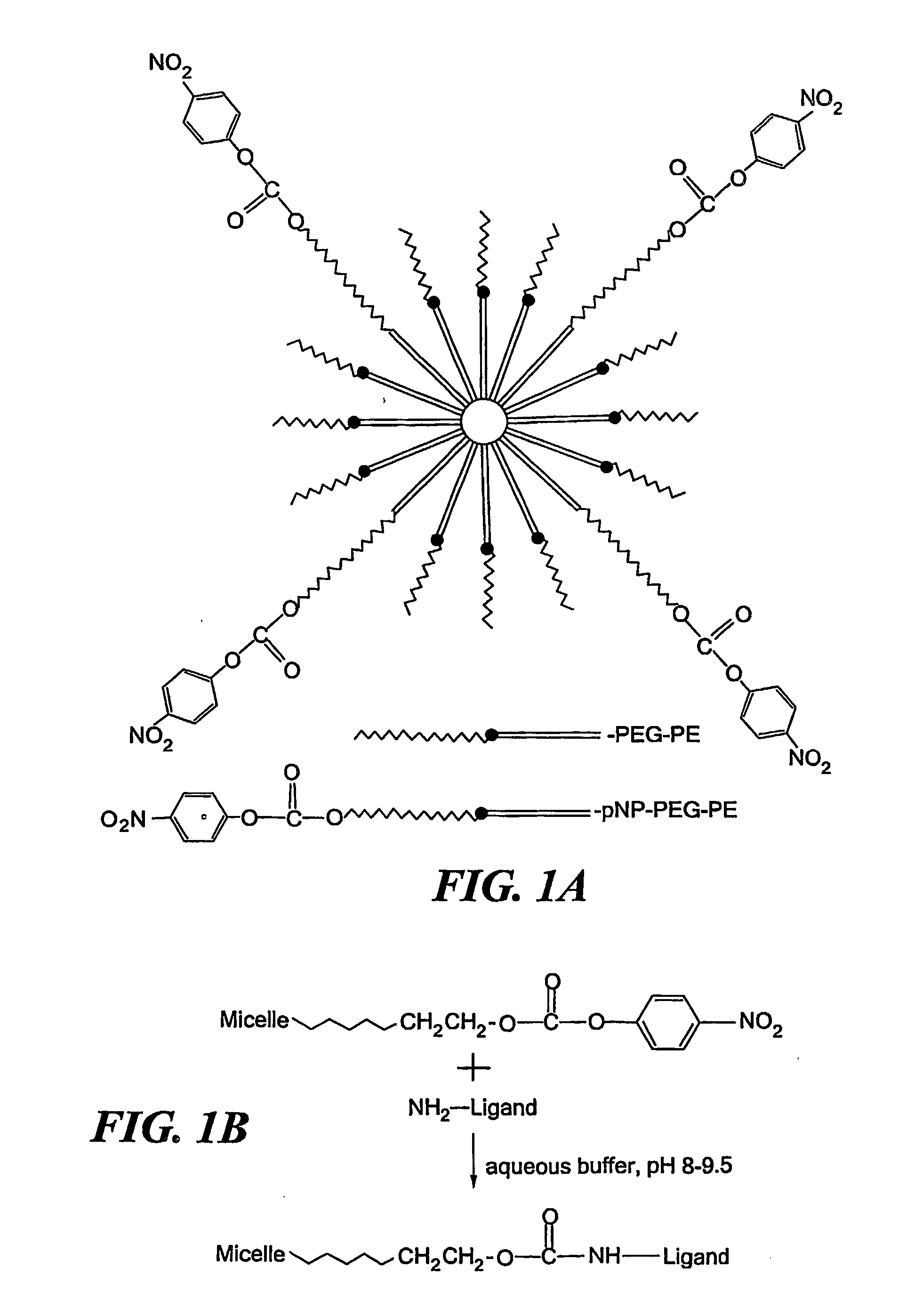

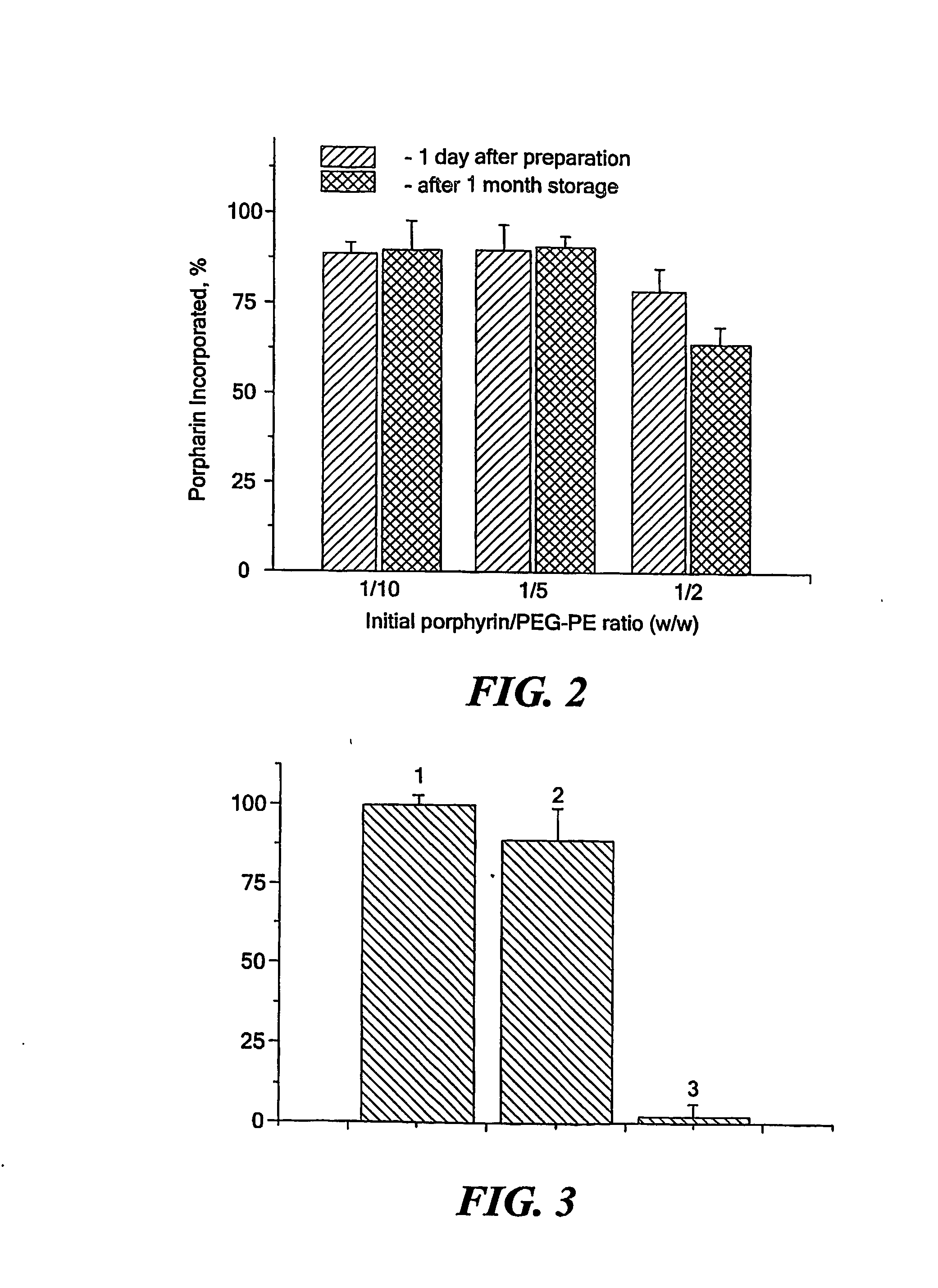

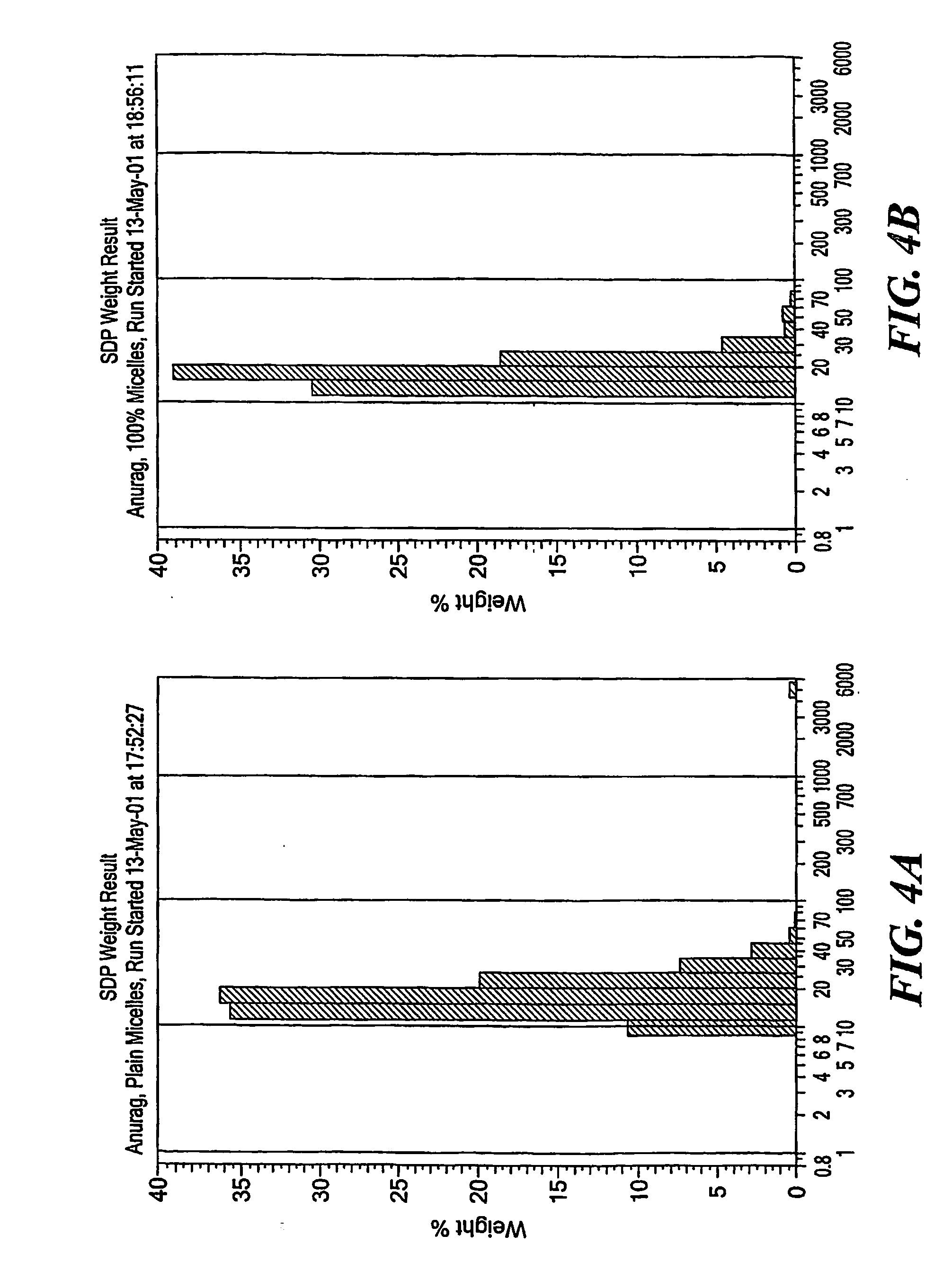

Micelle delivery system loaded with a pharmaceutical agent

InactiveUS20060216342A1Process stabilityGood curative effectBiocidePeptide/protein ingredientsAbnormal tissue growthLipid formation

The invention is directed to an improved drug delivery system that includes a micelle, comprising polyethylene glycol and a lipid component, and a pharmaceutical agent dispersed in the lipid component. The delivery system may also include a targeting ligand. The micelle delivery system of the invention is capable of stabilizing, inter alia, poorly soluble pharmaceutical agents and increasing their delivery efficacy. Appropriate pharmaceutical agents useful in the system of the invention include anti-inflammatory agents, agents for photodynamic therapy, anti-tumor agents, anti-neoplastic agents, anti-metastatic agents, and imaging agents, as well as hydrophobized derivatives thereof. Specifically, the pharmaceutical agent can be porphyrin, chlorine-6-trimethyl ester, tamoxifen, paclitaxel, 1,3-bis(2-chloroethyl)-1-nitrosourea, camptothecin, ellipticine, rhodamine, dequalinium, diphenylhexatriene, vitamin K3, diethylene triamine pentaacetic acid, or a functional derivative thereof. The micelles in the system of the invention have low critical micellar concentration and high kinetic stability, which provides great advantages in biodistribution, for example, accumulation at the site of a tumor.

Owner:NORTHEASTERN UNIV

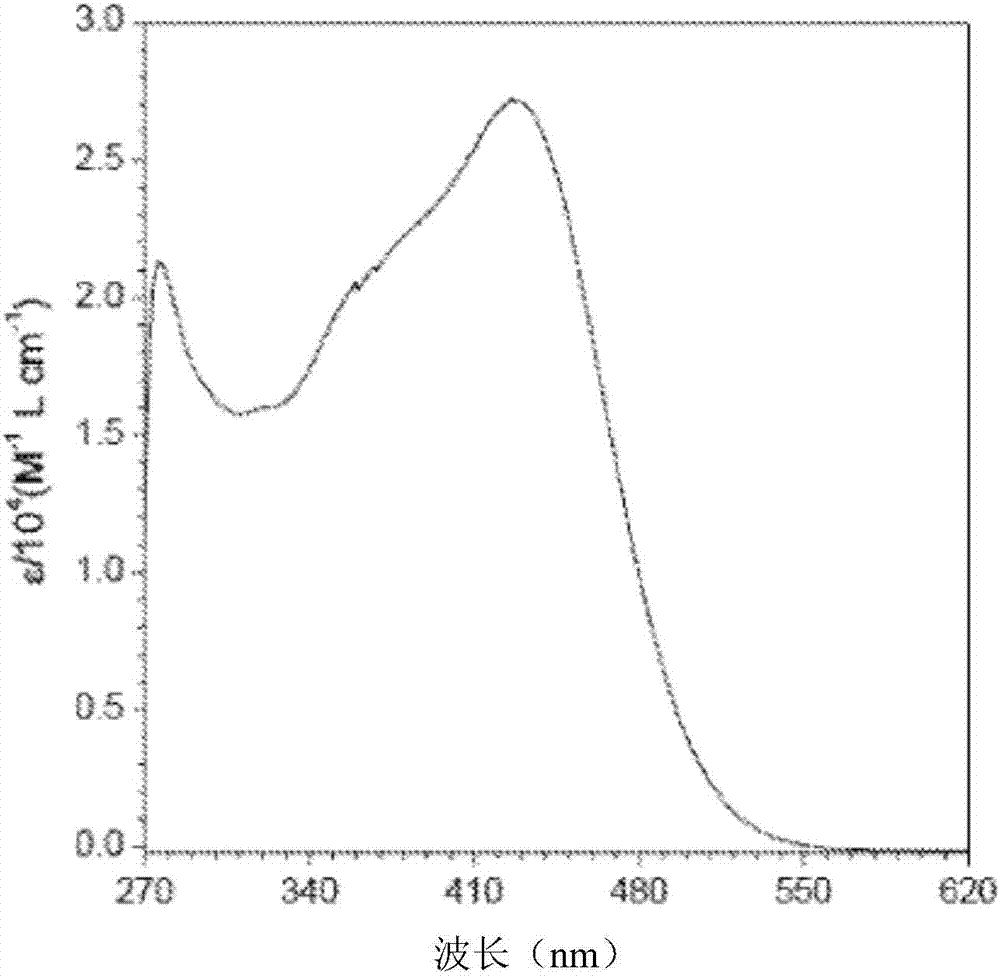

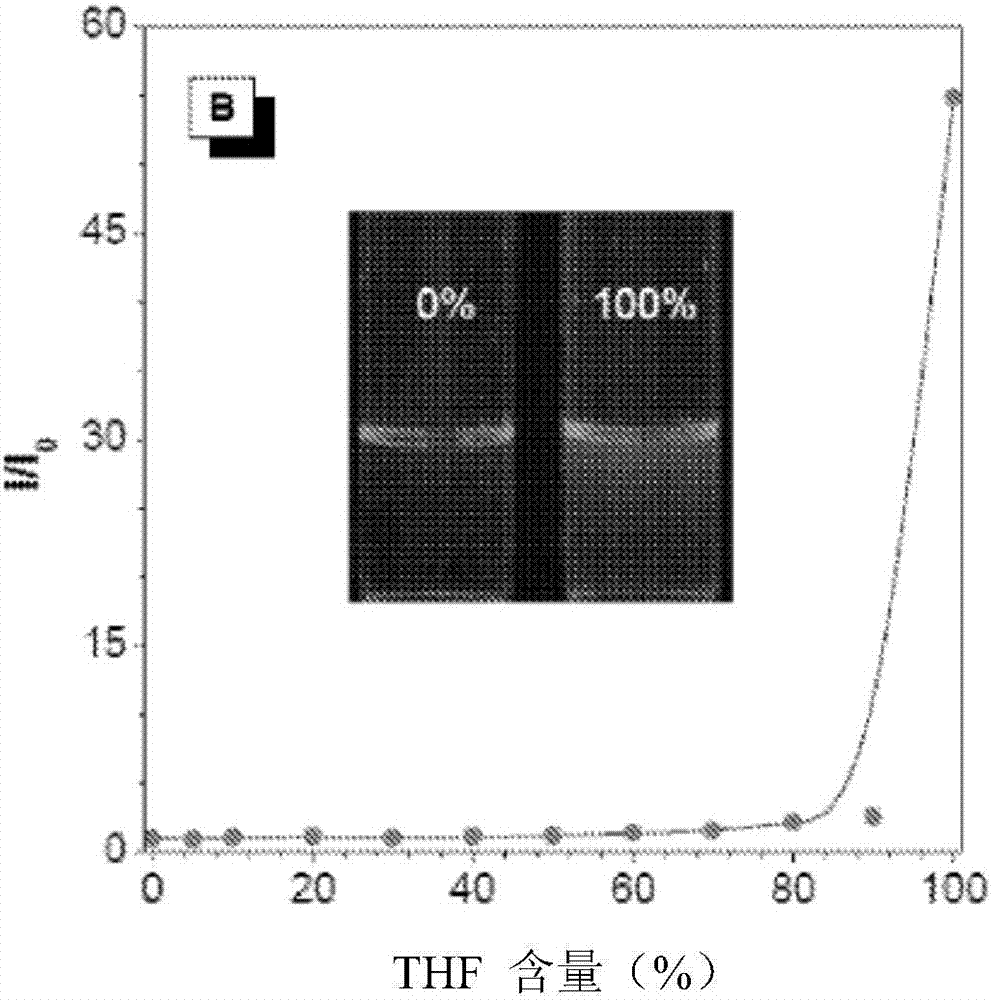

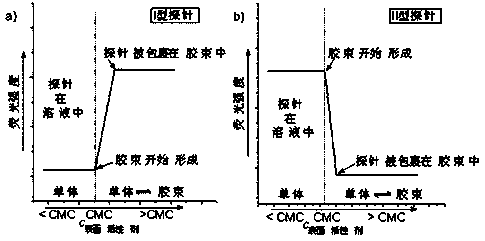

Sensitive fluorescent lighting probe method for determining CMC (critical micelle concentration) of surfactant

ActiveCN103411961AHigh sensitivityEasy to operateChemiluminescene/bioluminescenceLuminescent compositionsCritical micelle concentrationFluoProbes

The invention discloses a method for determining the CMC (critical micelle concentration) of surfactant. The new method for determining the CMC of surfactant is designed by using an aggregation-induced emission organic substance having a structure shown in Formula (I) as a fluorescent probe according to the characteristics of the organic substance. The method is to determine the CMC through the highest fluorescence intensity mutation point of the probe, while the CMC fluorescent determination method reported by others is to determine the CMC through the lowest fluorescence intensity mutation point of the probe. Therefore, the CMC fluorescent determination method disclosed by the invention has higher sensitivity in comparison with the reported CMC fluorescent determination method. According to the CMC fluorescent determination method disclosed by the invention, when surfactant detection solutions of different concentrations are prepared, the concentration of the fluorescent probe does not need to be maintained at the same level, thus greatly simplifying the operation steps and eliminating the error caused by measuring the fluorescent probe repeatedly. The Formula (I) is shown in the specification.

Owner:SOUTHERN MEDICAL UNIVERSITY

Straight chain alkyl phenol homogeneity polyethenoxy ether acetic acid surfactant and method of preparing the same and use thereof

InactiveCN101108326AImprove performanceThere is no problem with the average value of the possion distributionTransportation and packagingMixingChemical structureSolubility

The invention belongs to high efficiency surface activating agent field, in particular relating to nonionic to anion linear chain alkylphenol homogeneous polyoxy divinyl ether etic acid surface activating agent and the preparation method and use. The liner chain alkylpheno is preceded by a series of reactions to form nonionic to anion surface activating agent substance. The unique molecular structure decides the surface activating agent has good water solubility and hardwater resistance, high efficiency foaming capability and excellent temperature tolerance, the surface activating agent has lower critical micelle concentration and surface tension, the critical tension can reach to super low (10 to 3mN / m) with various different oiliness crude oil. The invention has good prospect in industry washing, spinning and three-times oil extraction and other fileds, which can be used as effective oil displacement agent in three-times oil extraction. Comparing with traditional fork chain alkylphenol homogeneous polyoxy divinyl ether etic acid surface activating agent, the invention has stable performance and the biological degradation is easier. The chemical structure formula of the surface activating agent is as drawing.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

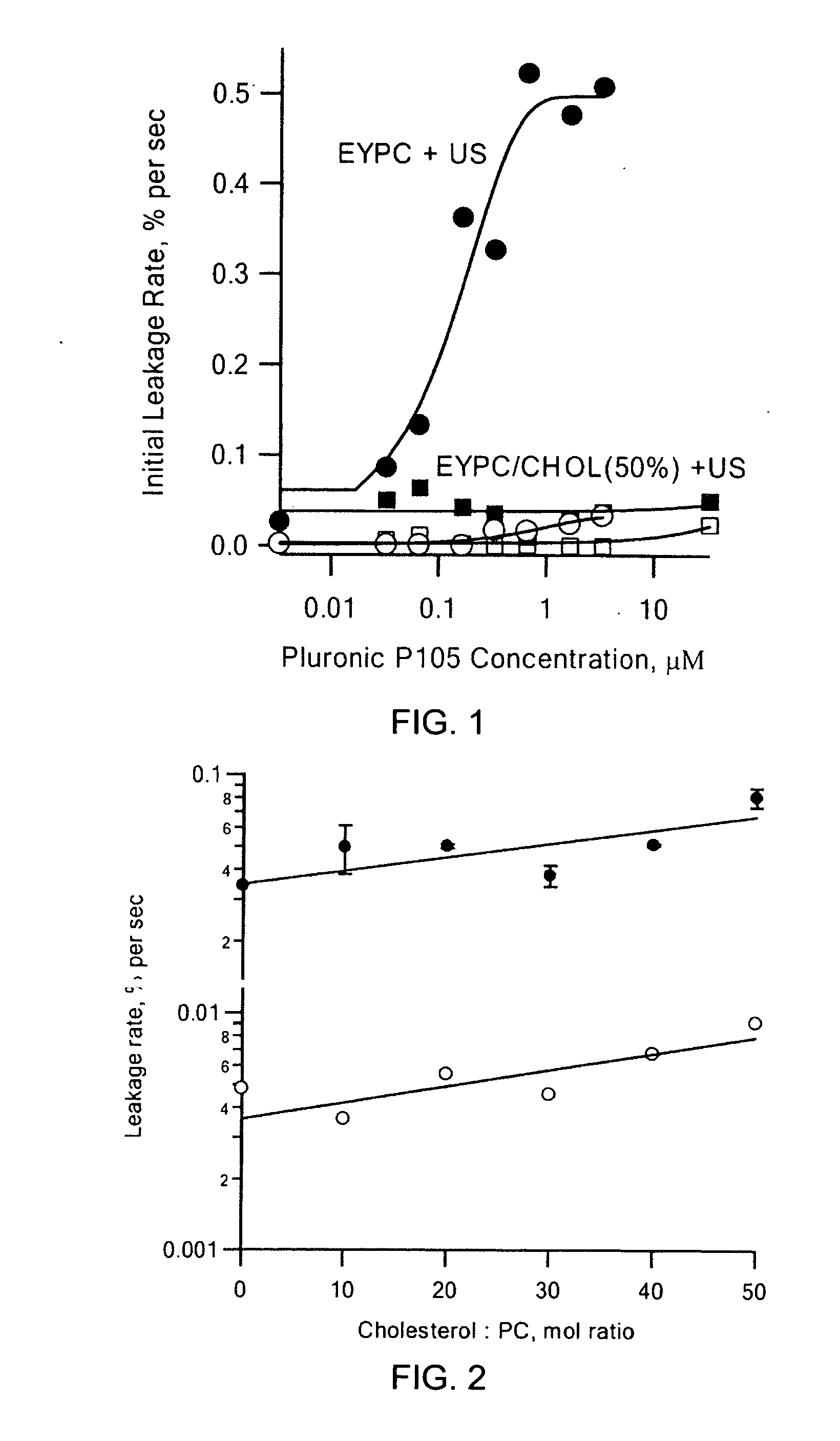

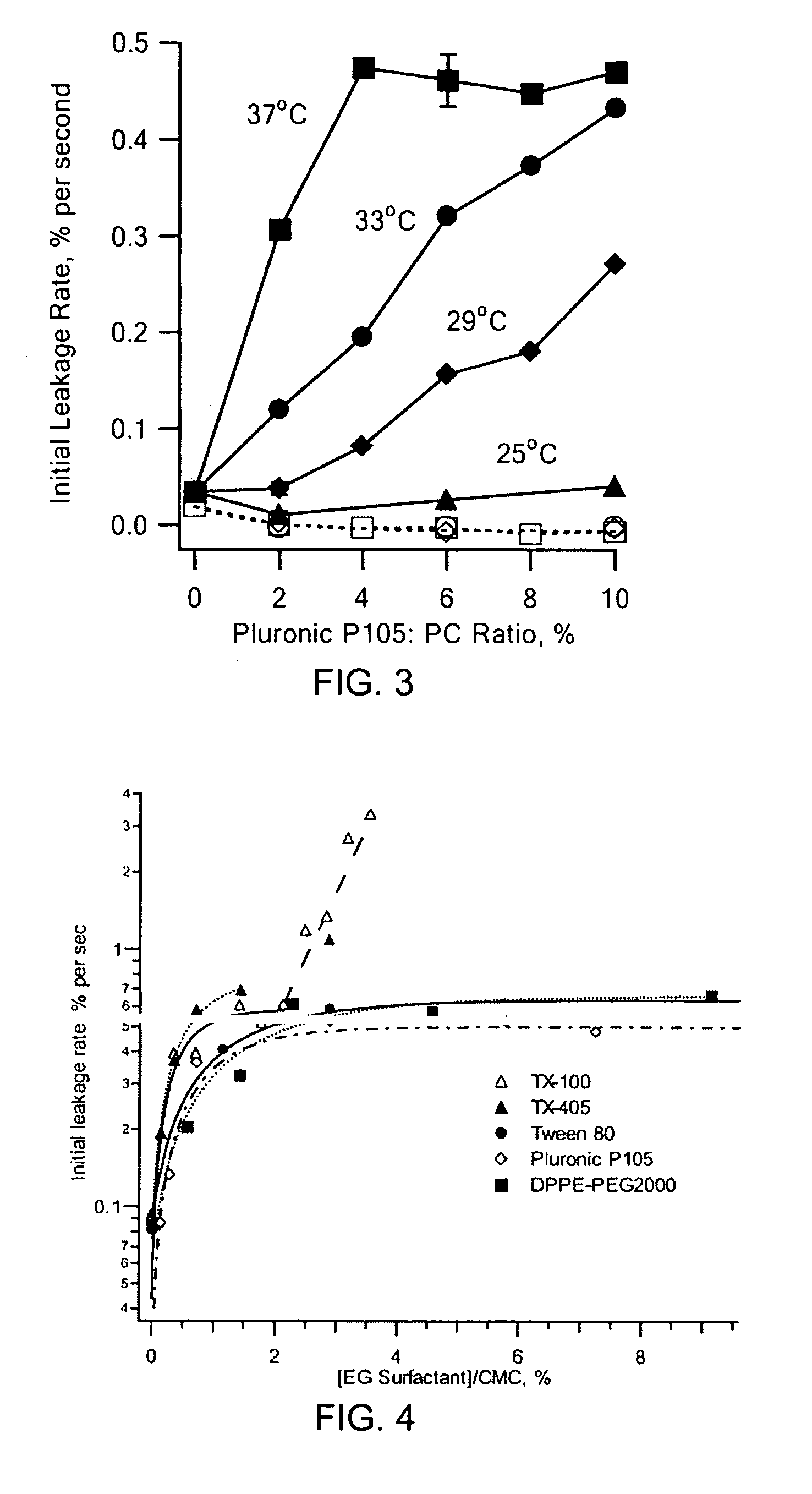

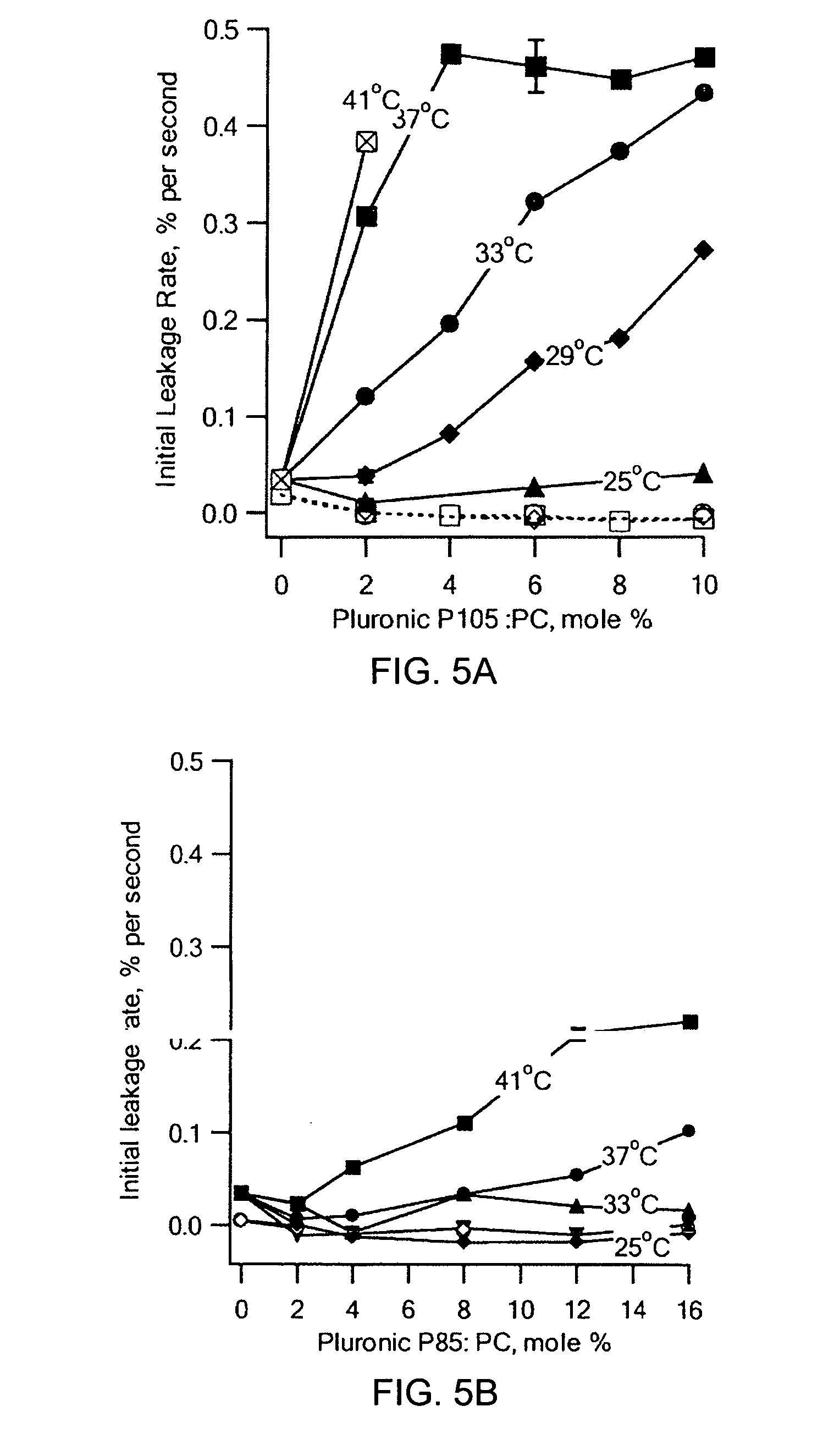

Responsive liposomes for ultrasonic drug delivery

InactiveUS20060002994A1Enhanced response to ultrasoundStably incorporated into liposomeLiposomal deliveryDopantCritical micelle concentration

This invention relates to biotechnology, more particularly, to an improved liposomal drug delivery system. Liposomes treated with or incorporating a surface active dopant, such as those containing polymers or oligomers of ethylene glycol as their hydrophilic “headgroup” component, have strongly increased permeabilizability when exposed to ultrasound. Permeabilizability was measured by the rate of release of self-quenching fluorescent dye at concentrations that caused no increase in permeability in the absence of ultrasound. The surface active dopants reached maximal effectiveness at about 1% of their critical micelle concentration. As disclosed by the present invention, surface active dopants, such as a PEG-lipid and a PLURONIC® triblock copolymer and a PEG-PBLA block copolymer, can be irreversibly incorporated into liposomes to give formulations for use as drug delivery vehicles.

Owner:UNIV OF UTAH RES INST

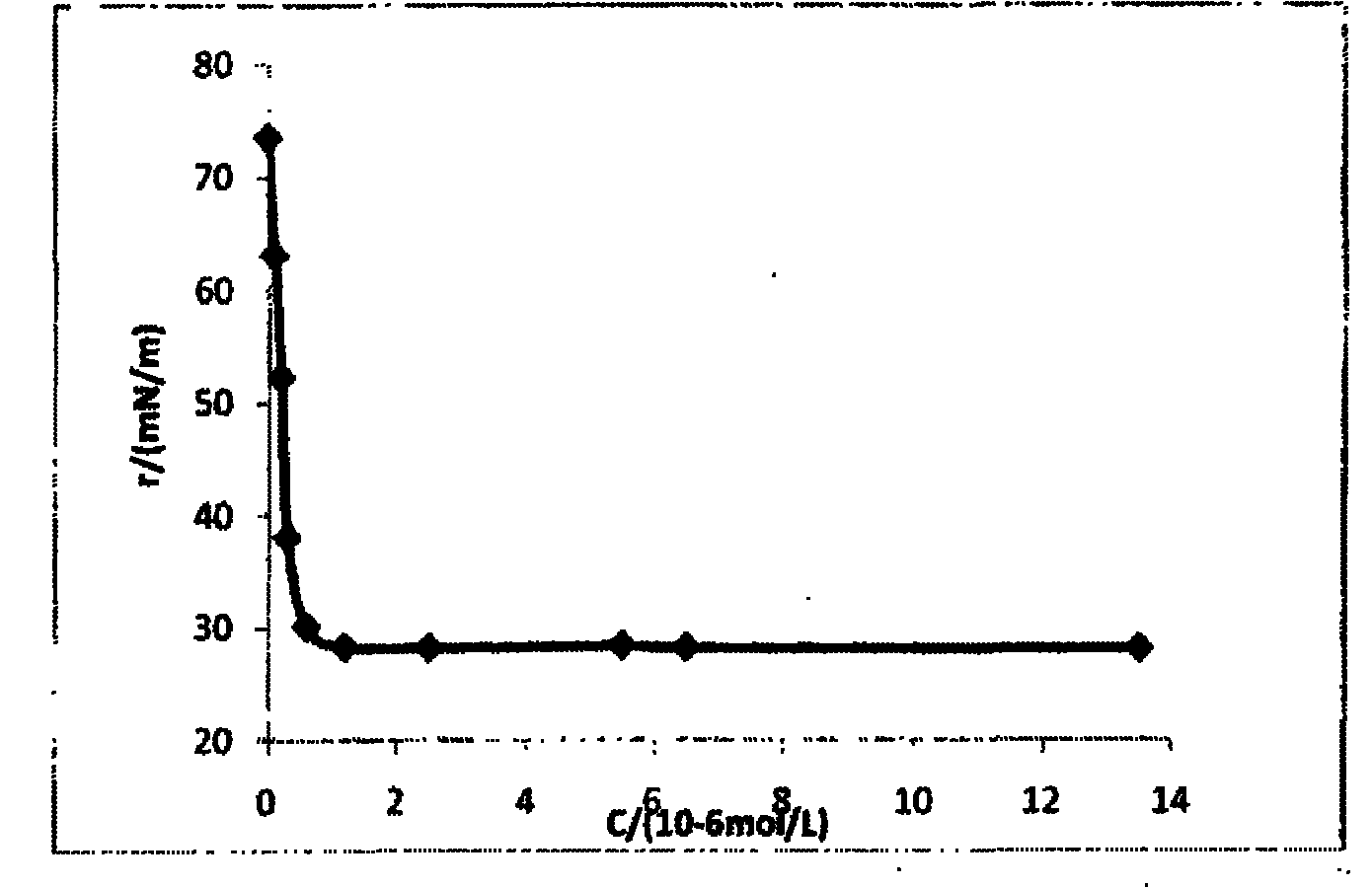

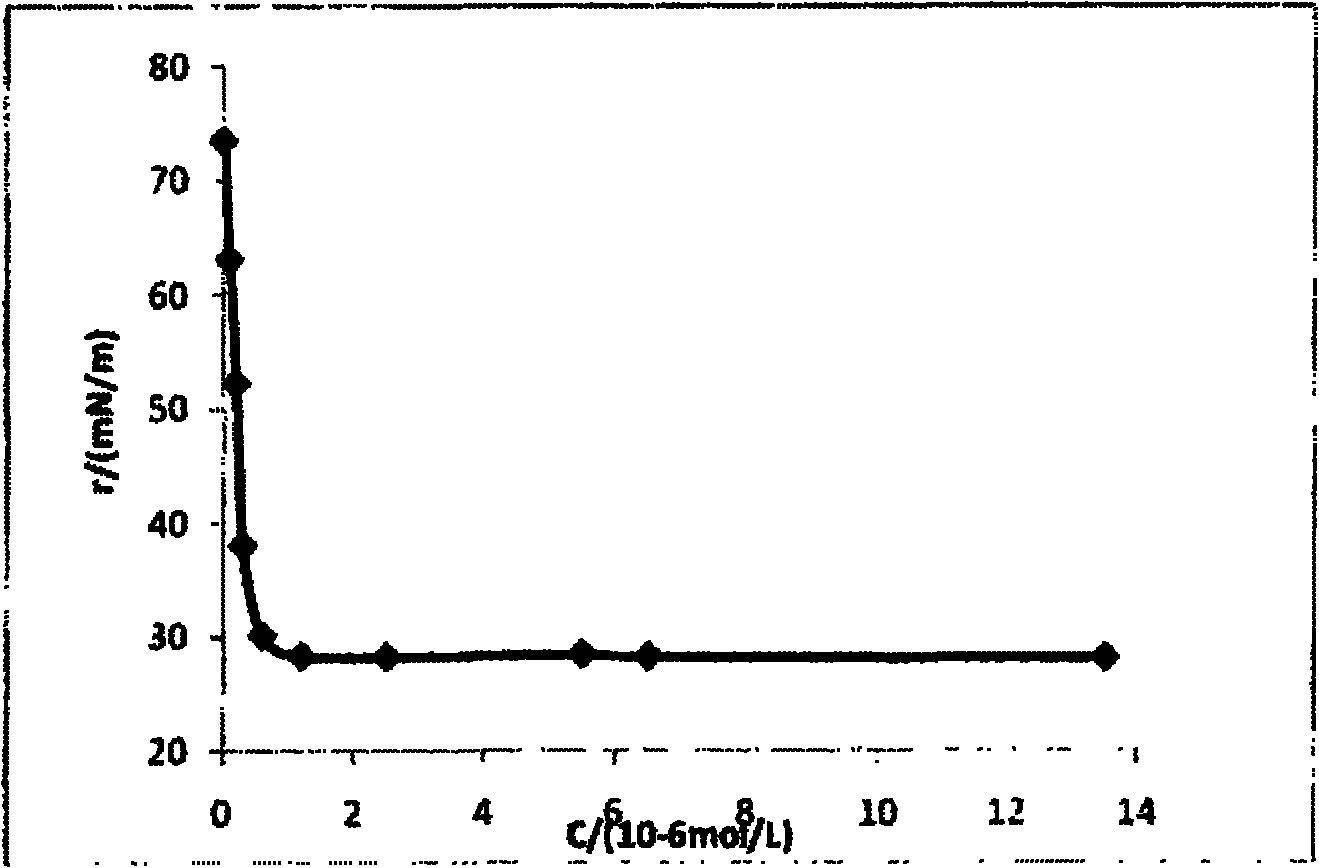

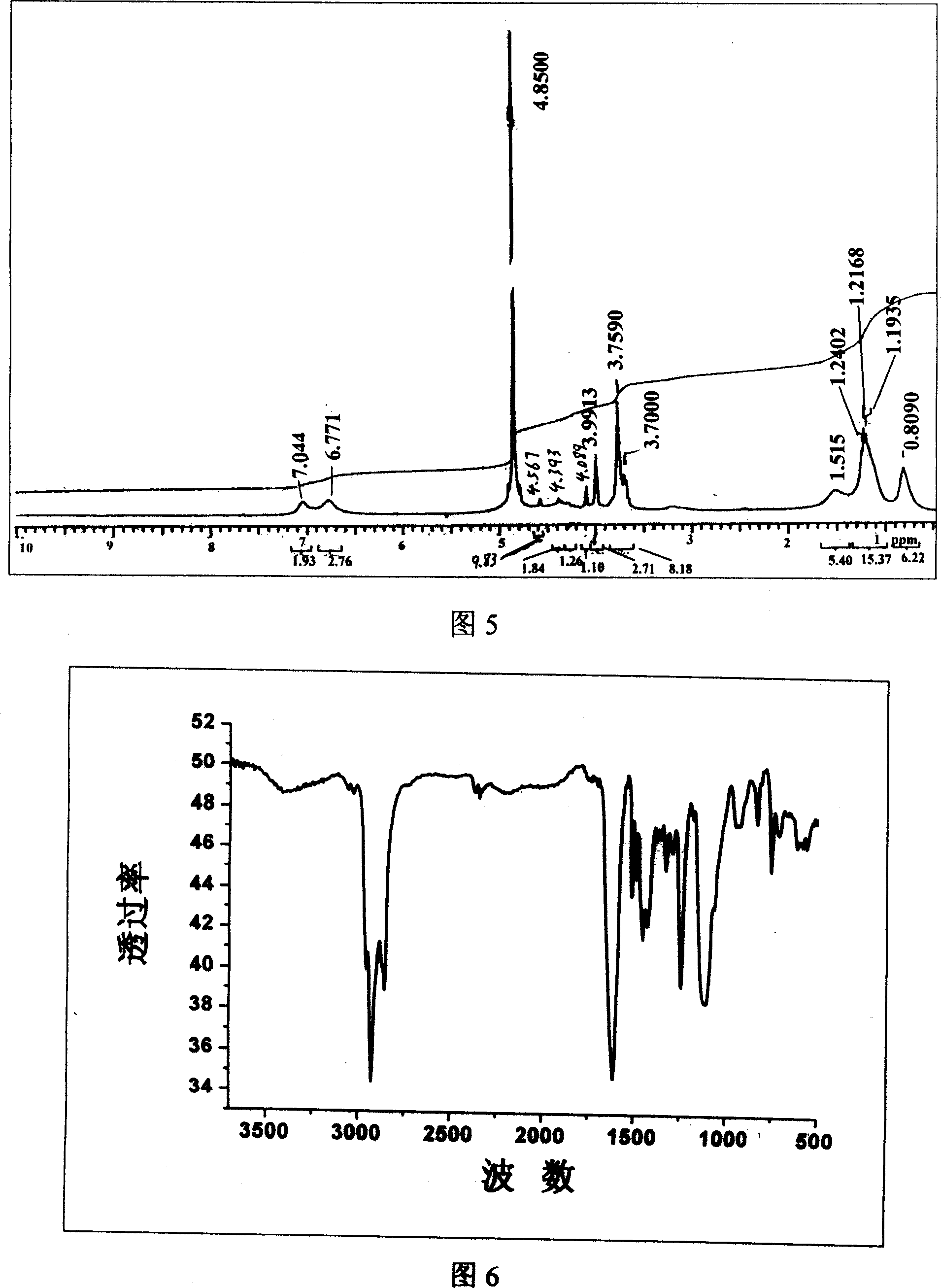

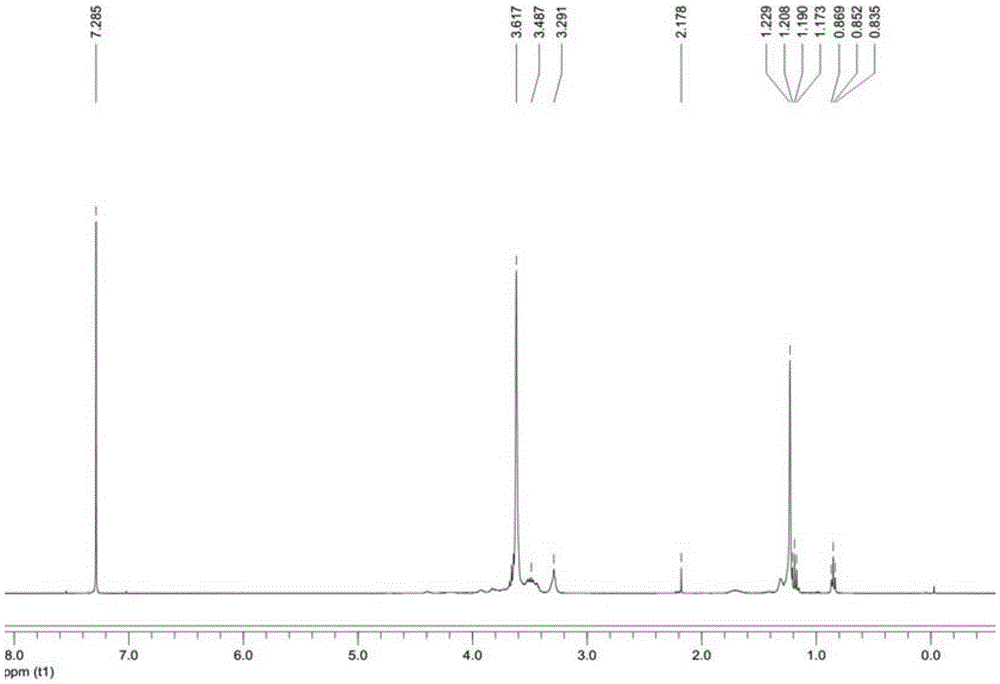

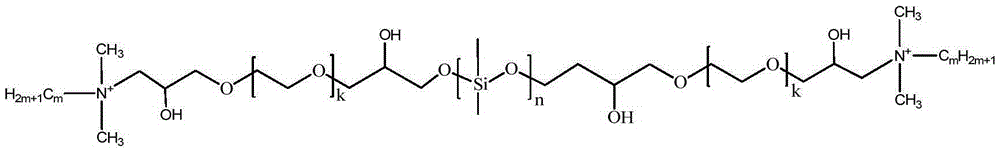

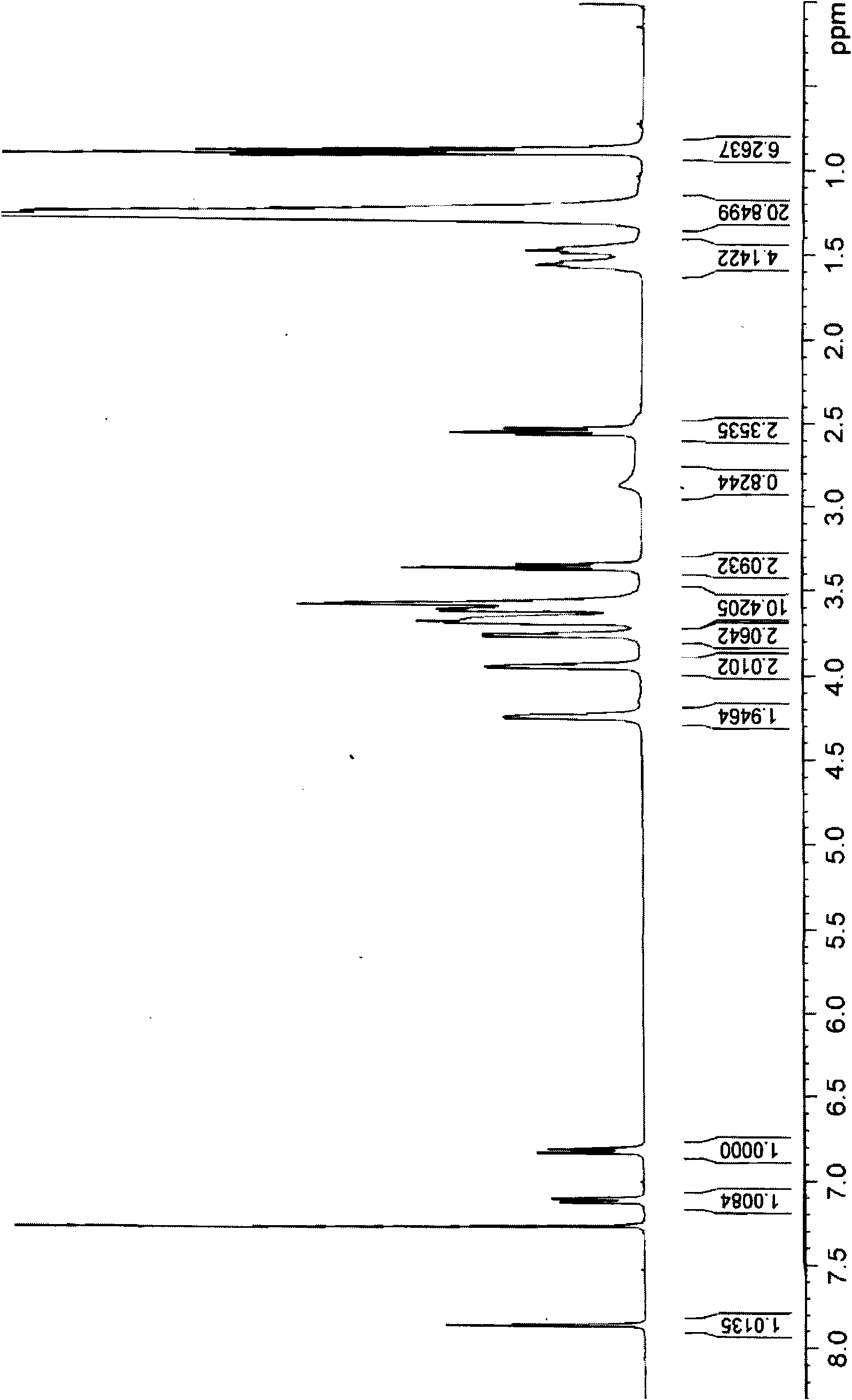

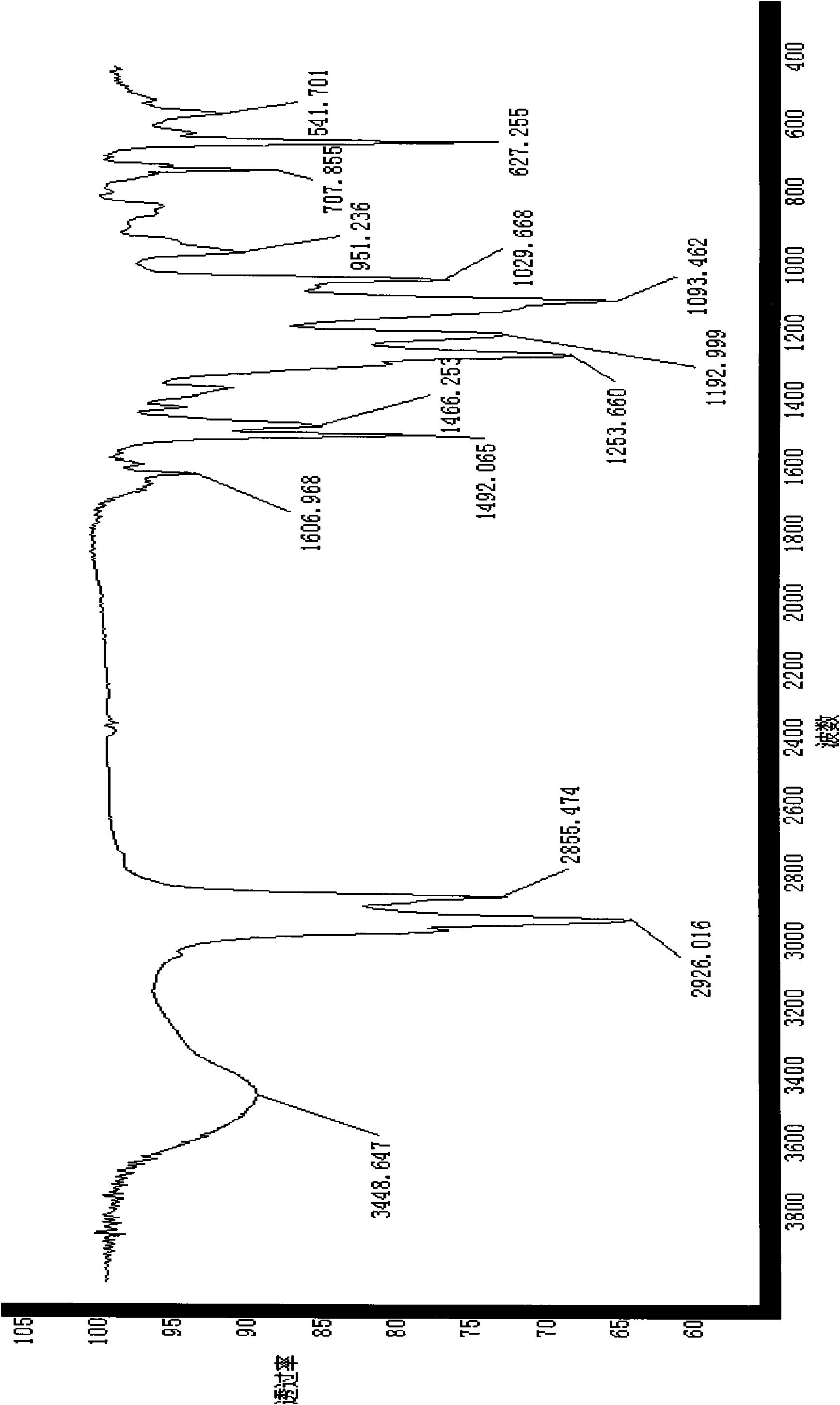

Quaternary ammonium salt organic silicon gemini surfactant and preparation method thereof

ActiveCN105289409AImprove surface activityImprove hydrolysis resistanceGroup 4/14 element organic compoundsTransportation and packagingEpoxyQuaternary ammonium cation

The invention relates to a quaternary ammonium salt organic silicon gemini surfactant and a preparation method thereof. The preparation method is prepared by the following steps of mixing polyethylene glycol diglycidyl ether, alpha-hydrogen-omega-hydroxyl-polydimethylsiloxane and acetone, adding tetrabutylammonium bromide and sodium hydroxide solutions, stirring and refluxing at the temperature of 50 to 70 DEG C, so as to obtain epoxy polyether-modified siloxane; adding a hydrochloric acid solution, long-strand alkyl dimethye third amine and a solvent into a reactor, uniformly stirring, dripping the epoxy polyether-modified siloxane, and reacting until the amine value is not changed, so as to obtain a target product. The quaternary ammonium salt organic silicon gemini surfactant has the advantages that the product has excellent surface activity, the surface tension in the water solution is minimum to 28.24mN / m, and the critical micelle concentration is minimum to 1.5*10-6mol / L, and is far lower than the critical micelle concentration of the traditional hydrocarbon single-strand surfactant DTAB (dodecyl trimethyl ammonium bromide); by using the linking of covalent bonds, the hydrolysis resistance property or organic silicon is improved; the advantages of the quaternary ammonium salt organic silicon gemini surfactant and the organic silicon surfactant are simultaneously realized.

Owner:湖北天喜达生物科技有限公司

Alkyl-blocked alkylphenol polyoxyethylene ether benzene sulfonate surfactant and preparation method and application thereof

The invention belongs to the field of efficient surfactant, in particular relates to an alkyl-blocked alkylphenol polyoxyethylene ether benzene sulfonate surfactant and preparation method and application thereof. The surfactant contains nonionic hydrophilic group polyoxyethylene and negative ion hydrophilic group sulfonate, the special molecular structure determines that the surfactant has good water-solubility, lower critical micelle concentration, excellent capability of reducing surface tension / interfacial tension, efficient foaming and foam stabilizing capability and outstanding temperature endurance and salt endurance, has good application prospect in a plurality of fields of pesticides, mineral flotation, tertiary oil recovery, and the like, and can be used as an effective oil displacement agent in tertiary oil recovery. The surfactant has the structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

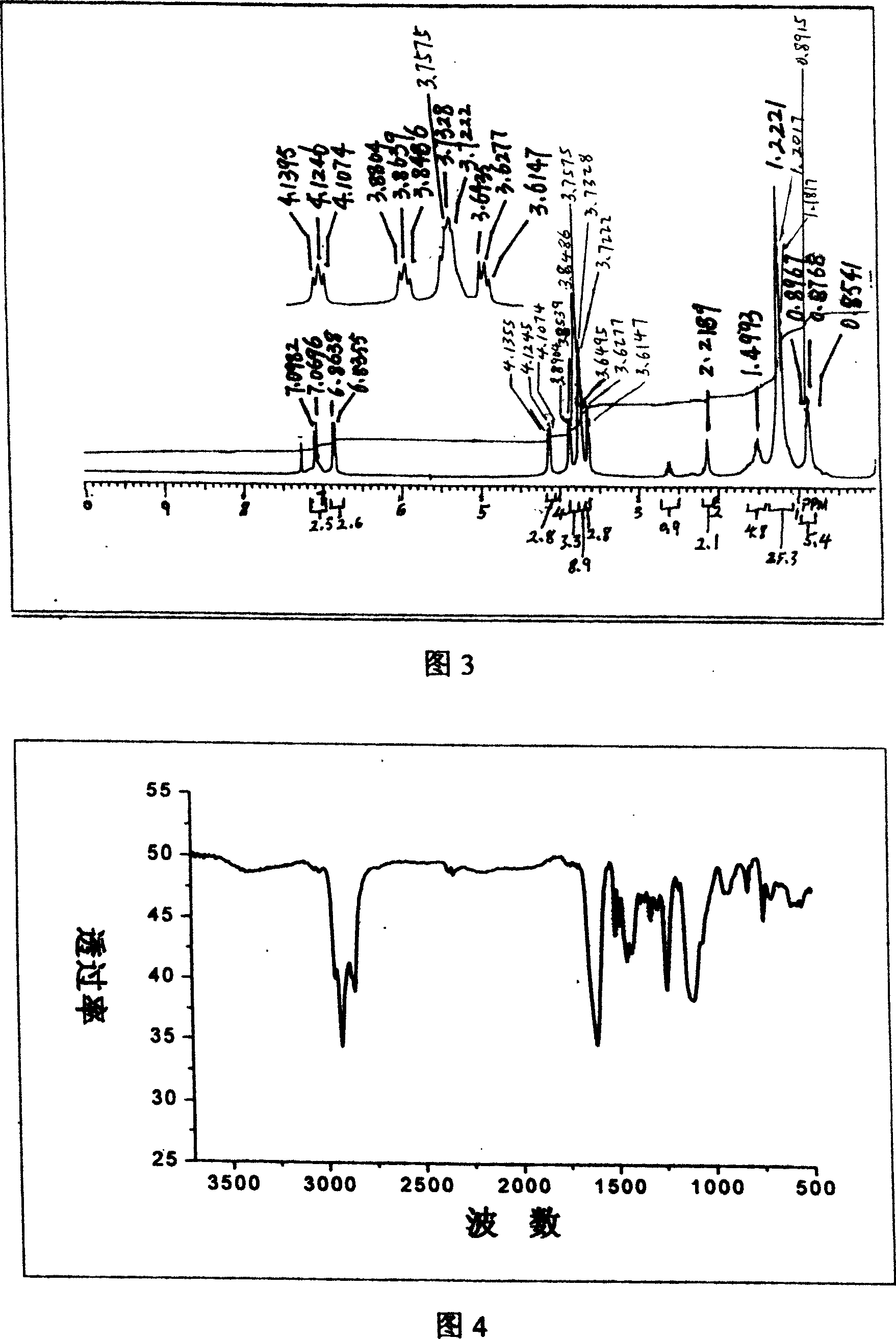

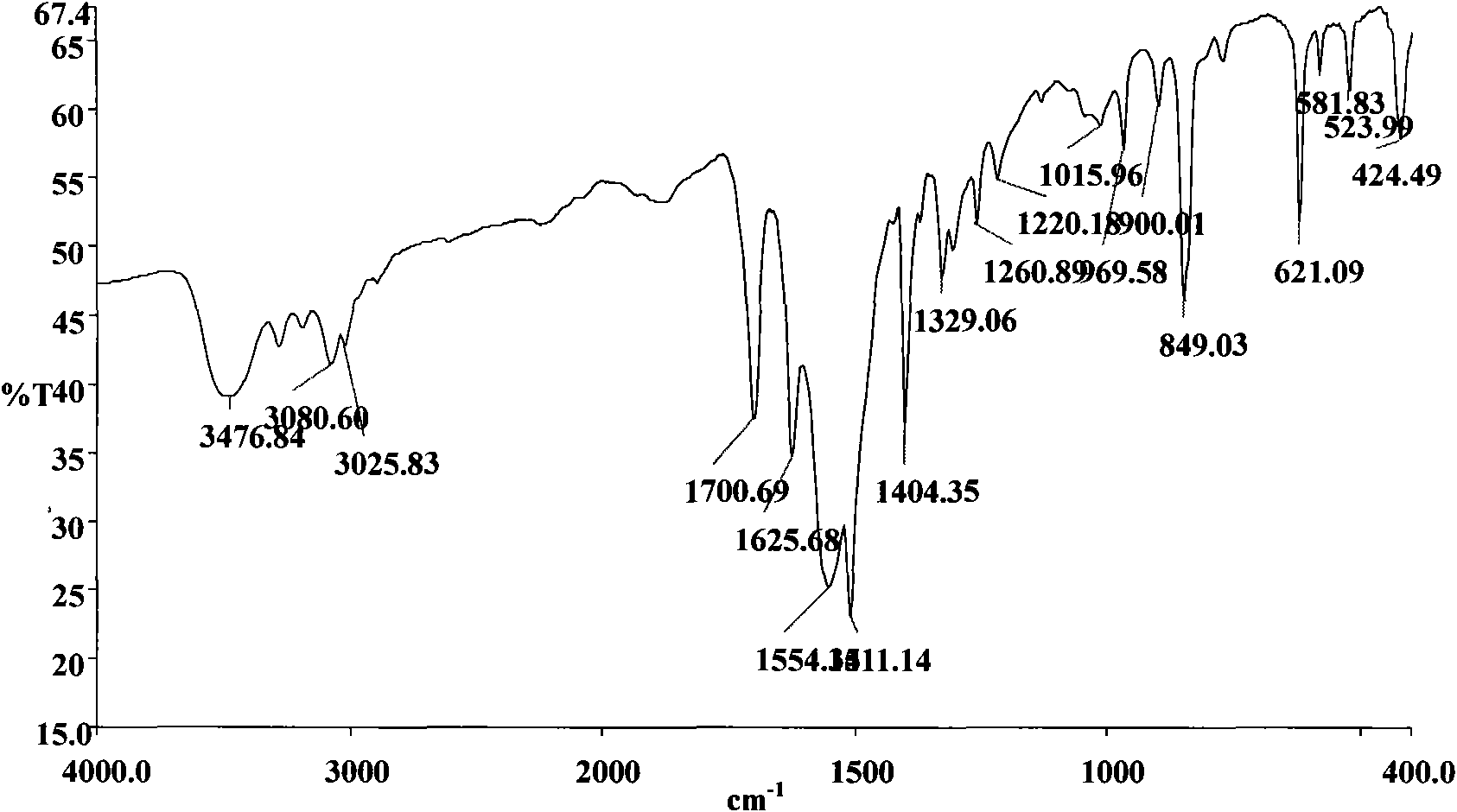

Alkylbenzene sulfonate Gemini surfactant and preparation method thereof

InactiveCN102452966ALow critical micelle concentrationReduce surface tensionTransportation and packagingSulfonic acids salts preparationAlkaneChlorosulfuric acid

The invention relates to an alkylbenzene sulfonate Gemini surfactant and a preparation method thereof. The method comprises the following steps of: undergoing a substitution reaction: undergoing a substitutive etherification reaction at the temperature of 65-70 DEG C for 6 hours on phenol and dihalogenated alkane under the action of a phase transfer catalyst to generate bisether, wherein the molar ratio of the phenol to saturated dihalide is 1:3, the saturated dihalide is head-to-end dibromoalkane, the quantity of atoms C of the dibromoalkane is larger than 2, and the phase transfer catalyst is tetrabutylammonium bromide; performing Fourier alkylation: making the bis-ether react with an alkyl halide at the temperature of 80 DEG C and under the pressure of 0.3 MPa under the action of a Louis acid catalyst to generate dialkyl phenylate, wherein the molar ratio of the bis-ether to the alkyl halide is 1:2; undergoing a sulfonation reaction: undergoing a sulfonation reaction on the dialkyl phenylate and a chlorosulfonic acid in the molar ratio of 1:4 by taking dichloromethane as a solvent at the temperature of 0 DEG C; and undergoing a salt-forming reaction: adding an alkali to generate a target product. The alkylbenzene sulfonate Gemini surfactant has very high interfacial activity and a very low critical micelle concentration.

Owner:PETROCHINA CO LTD

Alkylbenzyl polyoxyethylene ether betaine surfactant and its preparation method and use

ActiveCN102974268AGood water solubilityGood resistance to hard wateOrganic compound preparationTransportation and packagingSolubilityBenzene

The invention relates to an alkylbenzyl polyoxyethylene ether betaine surfactant and its preparation method and use. The alkylbenzyl polyoxyethylene ether betaine surfactant is a zwitterionic surfactant. Alkyl benzene undergoes a series of reactions to produce the alkylbenzyl polyoxyethylene ether betaine surfactant. Through a unique molecular structure, the alkylbenzyl polyoxyethylene ether betaine surfactant has excellent water-solubility, water hardening resistance, a wide pH application scope, low toxicity, good degradability, and good compatibility with other types of surfactants, can be used for fields of washing, weaving and tertiary oil recovery, has high activity, a critical micelle concentration of 10<-5> to 10<-6>mol / L, and surface tension of 23 to 30mN / m at the critical micelle concentration. Through alone use or compounding with other auxiliaries, the alkylbenzyl polyoxyethylene ether betaine surfactant can form ultralow interfacial tension having the magnitude of 10<-3>mN / m with simulated oil alkane or crude oil and can be used in tertiary oil recovery. The alkylbenzyl polyoxyethylene ether betaine surfactant has a structural formula shown in the patent specification.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Carboxylate gemini surfactant and preparation method thereof

InactiveCN101664657AImprove surface activityReduce interfacial tensionTransportation and packagingMixingCritical micelle concentrationSynthesis methods

The invention discloses a carboxylate gemini surfactant and a preparation method thereof. The carboxylate gemini surfactant is benzene-1,4bis(N-beta- sodium acrylate-N- alkylamine). The synthesis method of the carboxylate gemini surfactant comprises three steps which are the ring-opening reaction, bromination and salt-forming reaction of maleic anhydride. The carboxylate gemini surfactant has theadvantages of high activity, a critical micelle concentration of 0.38mmol / L which is one twenty-fifth of that (908mmol / L) of sodium dodecylbenzenesulphonate, a surface tension under the critical micelle concentration of 31.8mN / m which is 7.4mN / m lower than that (39.2mN / m) of the sodium dodecylbenzenesulphonate, and expected application in daily chemical products such as detergent, solubilizer andemulsifier and an oil extraction formula system. The method has the advantages of mild product preparation reaction conditions, simple and convenient operation and easy product separation and purification.

Owner:QIQIHAR UNIVERSITY

Surface-Modified Zeolite and Process for Synthesis Thereof for Sequestration of Anions

Present invention deals with cost-effective surface-modified zeolite materials developed from commercial zeolites and flyash-based zeolites by treating with surface modifiers like hexadecyltrimethyl ammonium bromide (HDTMA-Br). The formation of zeolitic materials with anionic characteristics requires treatment with a surfactant with initial concentrations greater than its critical micelle concentration (CMC). The sorption of oxyanions on the surfactant-modified zeolite (SMZ) is attributed to surface complexation and surface precipitation. Incorporation of metal ions on SMZ showed improved anion uptake for dearsenification of water due to synergistic effects and is able to meet the stringent target of 10 ppb of As on potable water being adopted by most countries. High selectivity, faster kinetics and high adsorption capacity ensures cost effectiveness of this product as compared to other low-cost products for dearsenification. Zeolite analogues with anionic characteristics have been developed for their applications for removal of arsenic from water. The material developed can also be used to remove other anions like chromium and selenium.

Owner:COUNCIL OF SCI & IND RES

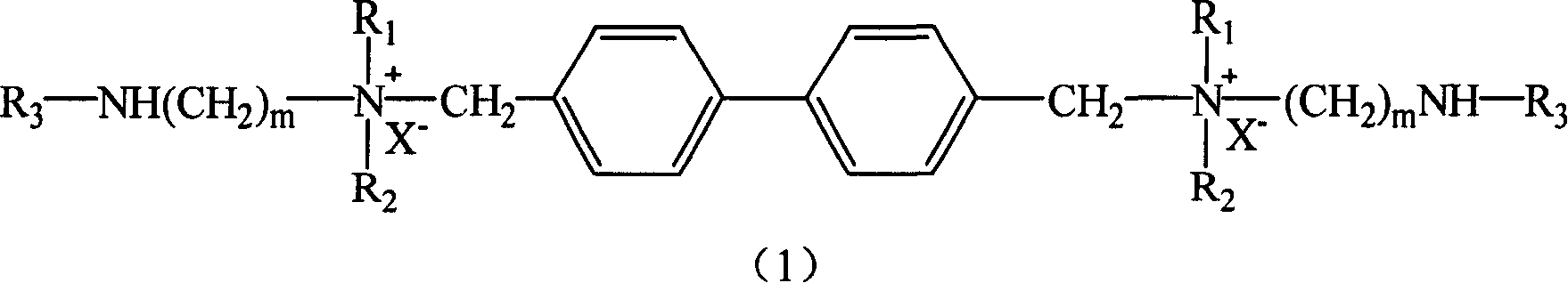

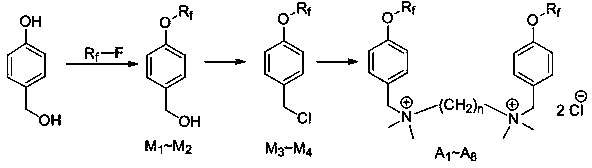

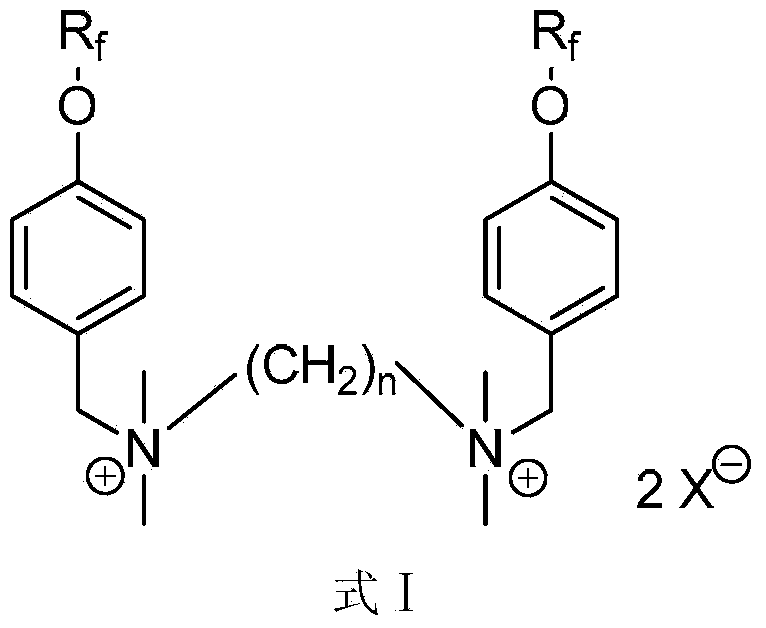

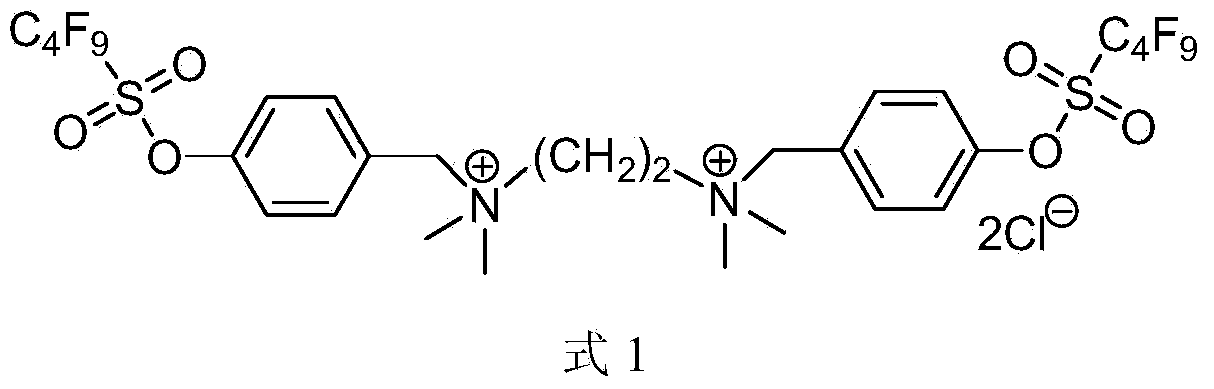

Gemini perfluoroalkylsulfonyloxybenzyl cationic surfactant as well as preparation and application thereof

InactiveCN103446943ASpread fastGood fire extinguishing performanceTransportation and packagingSulfonic acid esters preparationCritical micelle concentrationFluorine containing

The invention discloses a gemini perfluoroalkylsulfonyloxybenzyl cationic surfactant as well as preparation and application thereof. The structural general formula of the surfactant is as shown in a formula I, wherein Rf is perfluorobutylsulfonyl or perfluorohexylsulfonyl; n is 2, 3, 4 or 6; X is a counter anion. The perfluorobutylsulfonyl or the perfluorohexylsulfonyl is a fluorine-containing precursor material; the gemini perfluoroalkylsulfonyloxybenzyl cationic surfactant is obtained through the sulfonation of the fluorine-containing precursor material with p-hydroxybenzylalcohol, chlorination with a halogenating reagent and quaternization with tetramethyl alkyl diamine. The gemini cationic surfactant provided by the invention is free of a perfluorooctyl group with a lasting organic pollutant characteristic, high in surface activity and low in critical micelle concentration; an aqueous film-forming foam fire extinguishing agent obtained by compounding the gemini cationic surfactant with additives is quick in aqueous film-forming spreading speed and excellent in fire extinguishing performance.

Owner:HUAZHONG NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com