Straight chain alkyl phenol homogeneity polyethenoxy ether acetic acid surfactant and method of preparing the same and use thereof

A straight-chain alkylphenol, polyoxyethylene ether technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problem of slow degradation of alkylphenols, unfavorable surfactant applications, product performance differences, etc. problem, to achieve the effect of stable performance and favorable biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

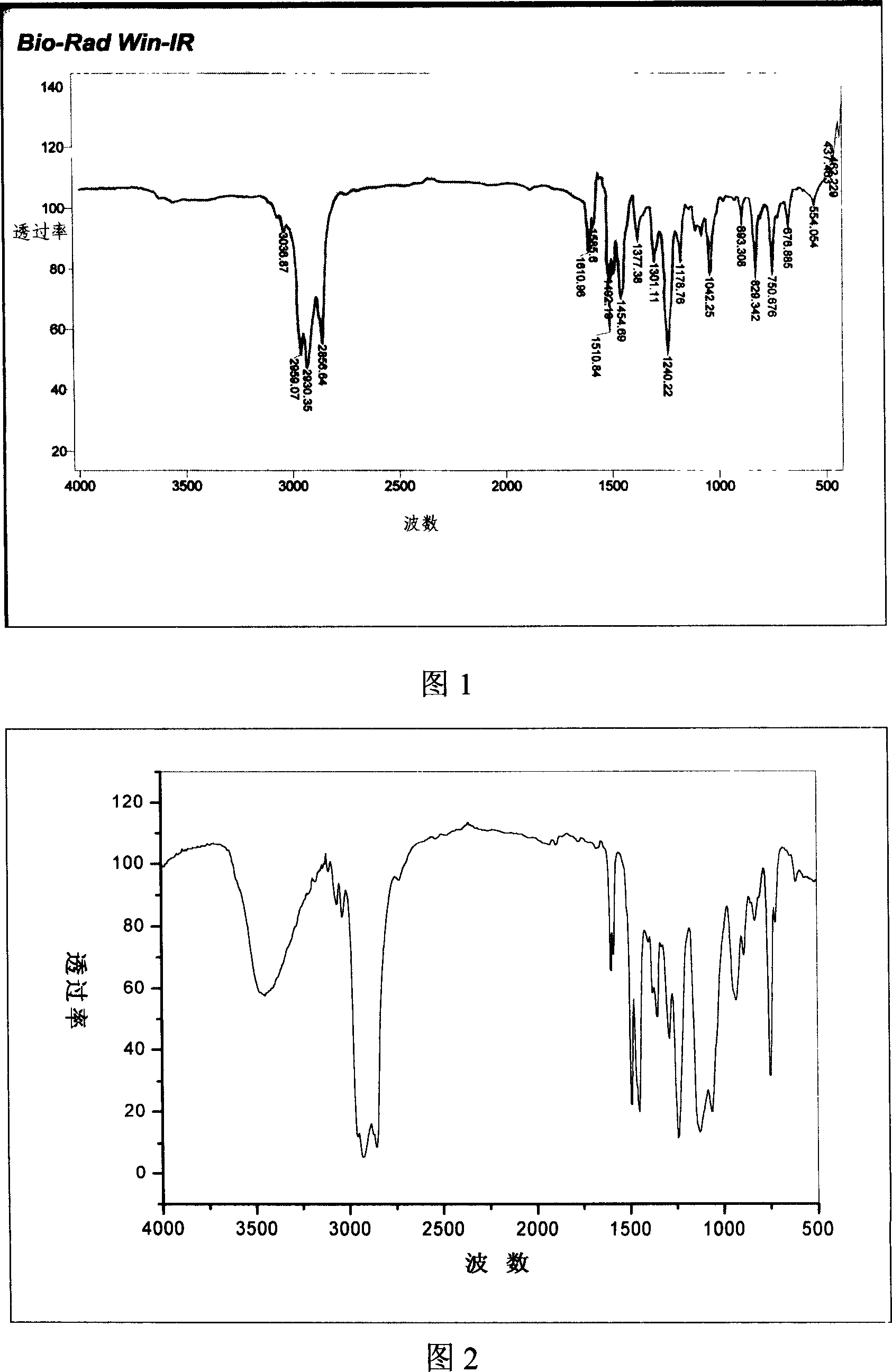

[0073] The synthesis of embodiment 1 laurylphenol trioxyethylene ether sodium acetate

[0074] (a) Synthesis of straight chain lauryl phenol

[0075] method one:

[0076] Add 5 mol of phenol into a three-neck flask equipped with a mechanical stirrer, a thermometer and a constant pressure dropping funnel, add 5 mL of boron trifluoride ether solution at room temperature, and after mixing thoroughly, add 1 mol α-deca Diene, after the dropwise addition, the reaction temperature was controlled to be 50° C. and maintained for 8 hours. After the reaction was completed, excess phenol was distilled off, and then distilled under reduced pressure to collect high boiling range fractions, which were linear laurylphenols, with a yield of 90%.

[0077] Method Two:

[0078]Add 1 mol of phenol into a three-necked flask equipped with magnetic stirring, raise the temperature to 70°C, add 1.05 mol of lauroyl chloride dropwise, continue the reaction until no gas is released after the addition, s...

Embodiment 2

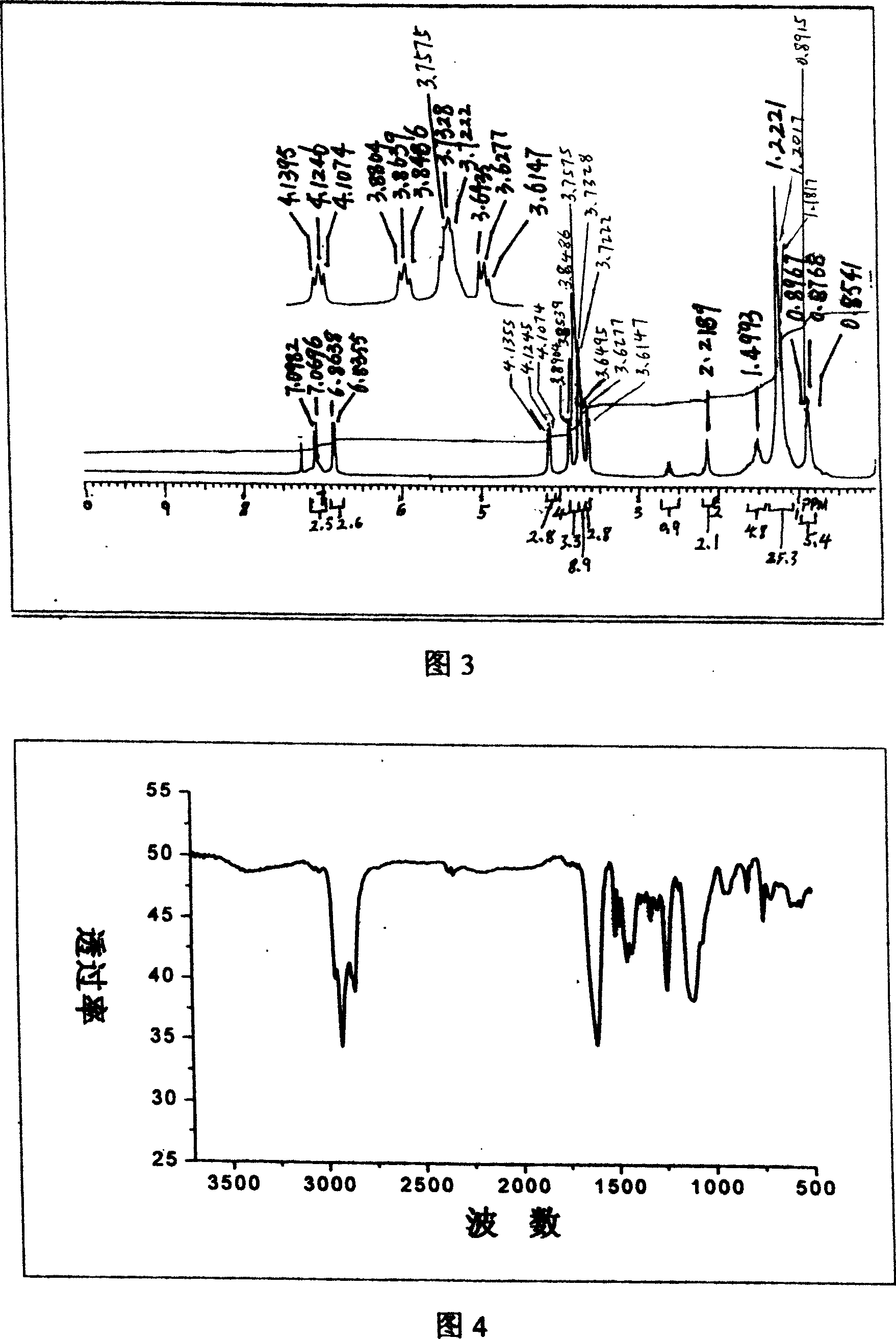

[0087] The synthesis of embodiment 2 laurylphenol trioxyethylene ether ammonium acetate

[0088] (a) Synthesis of straight chain lauryl phenol

[0089] method one:

[0090] Add 5 mol of phenol into a three-neck flask equipped with a mechanical stirrer, a thermometer and a constant pressure dropping funnel, add 5 mL of boron trifluoride ether solution at room temperature, and after mixing thoroughly, add 1 mol α- Dodecene, after the dropwise addition, the reaction temperature was controlled to be 50° C. and kept for 8 hours. After the reaction was completed, excessive phenol was evaporated, and then vacuum distillation was carried out to collect high boiling range fractions, which were linear laurylphenols, with a yield of 90%.

[0091] Method Two:

[0092] Add 1 mol of phenol into a three-necked flask equipped with magnetic stirring, raise the temperature to 70°C, add 1.05 mol of lauroyl chloride dropwise, continue the reaction until no gas is released after the addition, st...

Embodiment 3

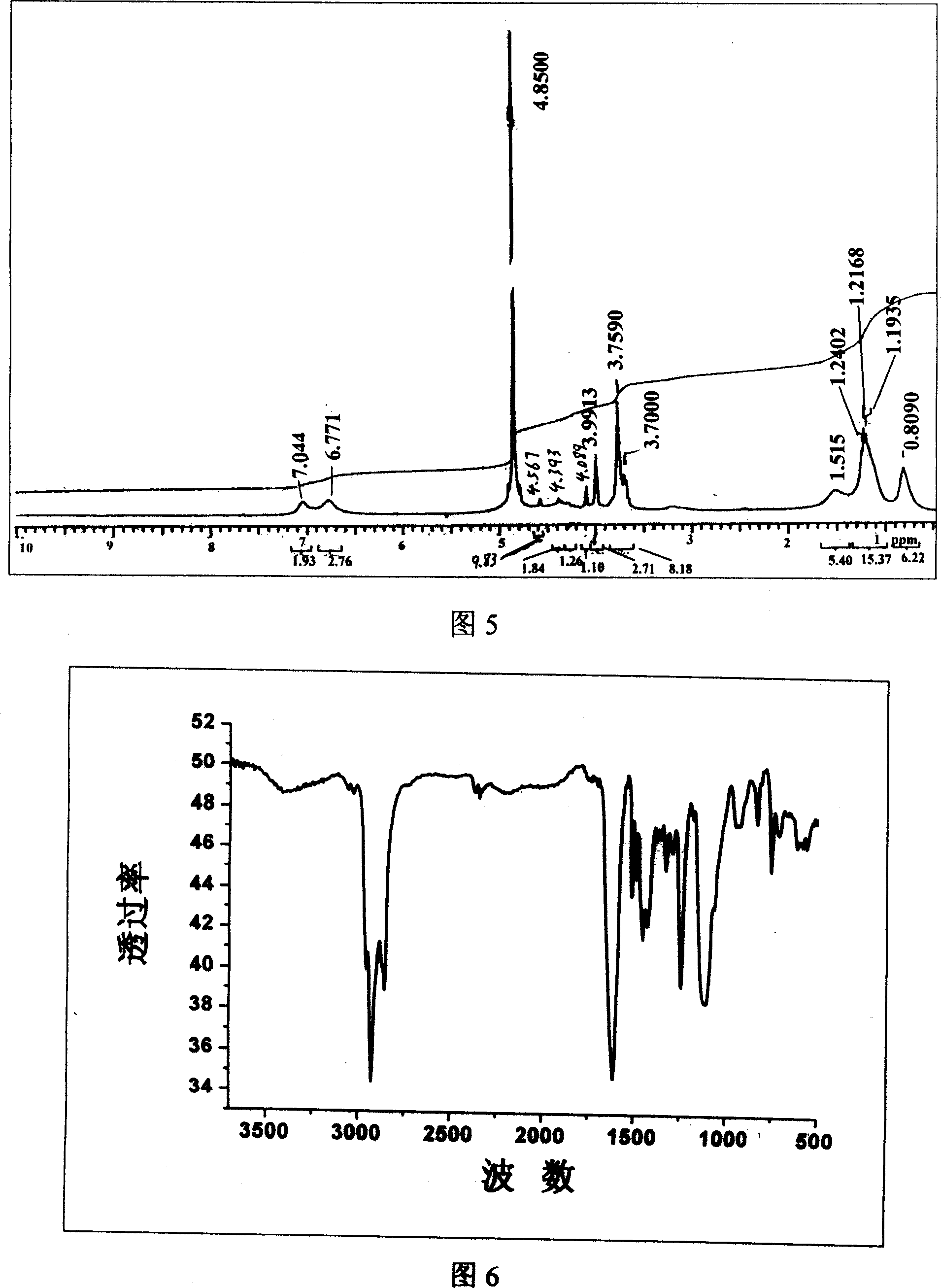

[0101] The synthesis of embodiment 3 octylphenol hexaoxyethylene ether barium acetate

[0102] (a) Synthesis of straight-chain octylphenol

[0103] method one:

[0104] Add 5 mol of phenol into a three-necked flask equipped with a mechanical stirrer, a thermometer and a constant pressure dropping funnel, add 3 mL of boron trifluoride ether solution at room temperature, and after mixing thoroughly, add 1 mol α- Octene, after the dropwise addition, the reaction temperature was controlled to be 45° C. and kept for 4 hours. Excessive phenol was distilled off after the reaction, and then distilled under reduced pressure to collect high-boiling range fractions, which were linear octylphenols, with a yield of 93%.

[0105] Method Two:

[0106] Add 1 mol of phenol into a three-necked flask equipped with magnetic stirring, raise the temperature to 65°C, and drop in 1.05 mol of octanoyl chloride dropwise. Phenyl octanoate.

[0107] Take 0.8mol of the above-mentioned synthesized phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com