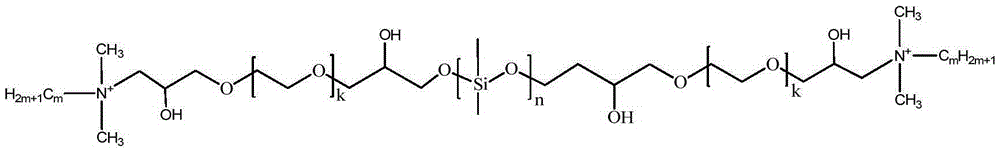

Quaternary ammonium salt organic silicon gemini surfactant and preparation method thereof

A gemini surface and quaternary ammonium salt technology, which is applied in organic chemistry, chemical instruments and methods, compounds of group 4/14 elements of the periodic table, etc., can solve the problems of less reports on organosilicon gemini surfactants, and achieve excellent results Surface activity, easy control, effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

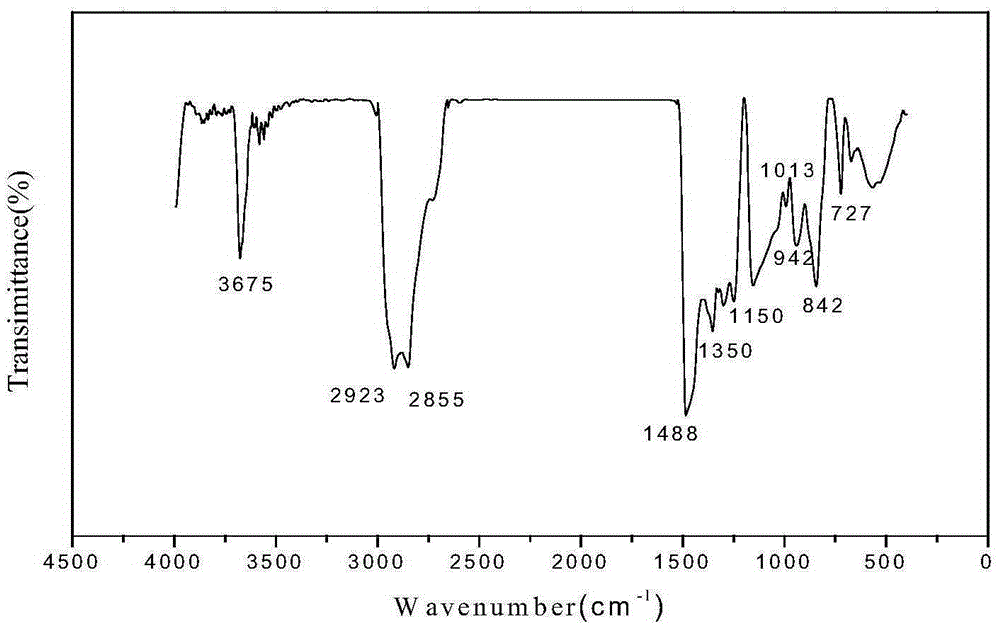

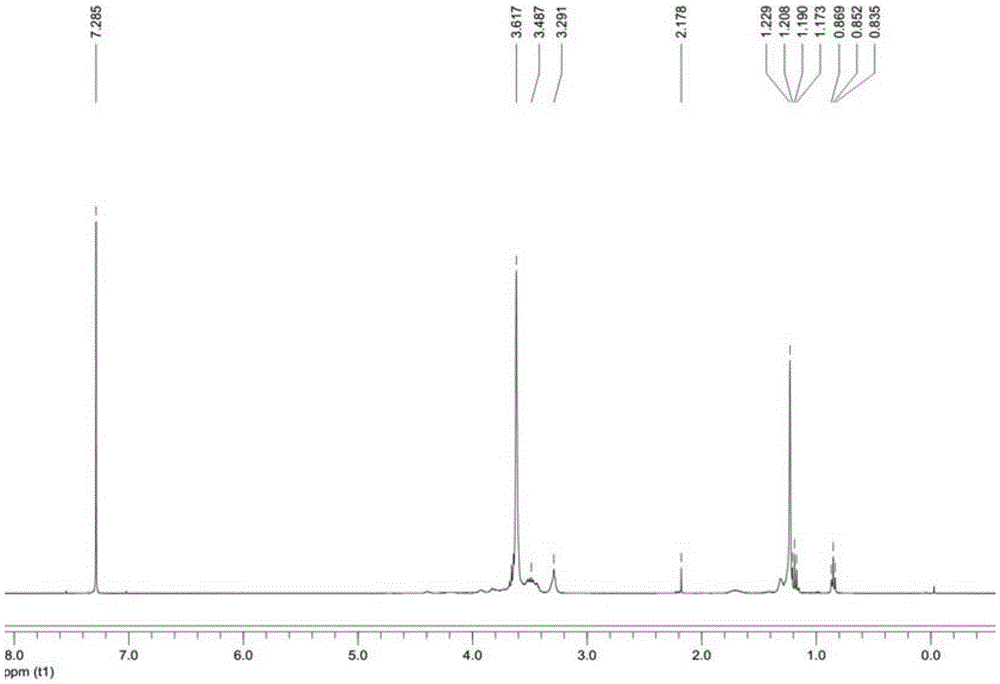

[0032] Step 1. Mix 85g of polyethylene glycol glycidyl ether and 81g of α-hydrogen-ω-hydroxyl-polydimethylsiloxane with 100mL of acetone, then add 0.5g of tetrabutylammonium bromide and 0.5g of mass Fraction 30% sodium hydroxide solution, tetrabutylammonium bromide and sodium hydroxide solution play a catalytic role, then stir and reflux at 70°C for 5h, then wash with a mixed solvent of 30mL acetone and 30mL n-hexane for several times, rotate The solvent was removed by evaporation, and vacuum-dried to obtain a light yellow viscous liquid, which was epoxy-based polyether-modified siloxane.

[0033] Step 2, at 45°C, add 50mL of hydrochloric acid solution (0.202mol / L), 10g of C 12 h 25 NH(CH 3 ) 2 After reacting with 20mL of absolute ethanol for 1h, 21.67g of epoxy polyether modified siloxane prepared in step 1 was added dropwise, and reacted for 10h until the amine value (determined by hydrochloric acid-isopropanol titration) no longer changed. After the reaction, wash with ...

Embodiment 2

[0035] Step 1. Mix 90g of polyethylene glycol glycidyl ether and 83g of α-hydrogen-ω-hydroxyl-polydimethylsiloxane with 100mL of acetone, then add 0.5g of tetrabutylammonium bromide and 0.5g of mass A 30% fraction of sodium hydroxide, tetrabutylammonium bromide and sodium hydroxide solution acted as a catalyst, then stirred and refluxed at 60°C for 8 hours, then washed with a mixed solvent of 40mL acetone and 40mL n-hexane for several times, and evaporated by rotary evaporation Remove the solvent and dry in vacuum to obtain a light yellow viscous liquid, which is epoxy-based polyether-modified siloxane.

[0036] Step 2, at 40°C, add 55mL of hydrochloric acid solution (0.202mol / L), 7.0g of C 12 h 25 NH(CH 3 ) 2 After reacting with 20mL isopropanol for 1h, add 25g of the epoxy polyether modified siloxane prepared in step 1 dropwise, and react for 12h until the amine value (determined by hydrochloric acid-isopropanol titration) no longer changes. After the reaction, wash with...

Embodiment 3

[0038]Step 1. Mix 95g of polyethylene glycol glycidyl ether and 85g of α-hydrogen-ω-hydroxyl-polydimethylsiloxane with 100mL of acetone, then add 0.5g of tetrabutylammonium bromide and 0.5g of mass 30% fraction of sodium hydroxide, tetrabutylammonium bromide and sodium hydroxide solution play a catalytic role, then stirred and refluxed at 55°C for 6h, then washed with a mixed solvent of 35mL acetone and 35mL n-hexane for several times, and rotary evaporated Remove the solvent and dry in vacuum to obtain a light yellow viscous liquid, which is epoxy-based polyether-modified siloxane.

[0039] Step 2, at 50°C, add 60mL of hydrochloric acid solution (0.202mol / L), 8.4g of C 12 h 25 NH(CH 3 ) 2 After reacting with 20mL of distilled water for 1h, 23g of epoxy polyether modified siloxane prepared in step 1 was added dropwise, and reacted for 11h until the amine value (determined by hydrochloric acid-isopropanol titration) no longer changed. After the reaction, wash with cyclohexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com