Method for synthesizing amphoteric slow-breaking quick-setting asphalt emulsifier

An asphalt emulsifier, slow cracking and fast setting technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. problem, to reduce the critical micelle concentration, increase the emulsifying ability, fine and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Take 68.3g of oleic acid, 13.2g of diethylenetriamine and 18.7g of triethylenetetramine, put them into the reactor, raise the temperature to 160°C and react for 5 hours. Cool down to 55°C, add 25g of 95% ethanol, and stir evenly. Dissolve 27.5g of chloroacetic acid into a 50% aqueous solution and add slowly dropwise. After the dropwise addition, keep the temperature not higher than 60°C for 3 hours. Then react with 22.3g of chloroethanol at 72°C for 2 hours to obtain 202.5g of product, which is reserved for emulsified asphalt test.

[0010] Take 1000g of 70# asphalt and heat it to 130°C. 800g of emulsifier aqueous solution, including 27g of emulsifier, adjust the pH value to 2-3, heat to 55°C, and prepare asphalt emulsion through colloid mill. Obtain uniform and fine cationic slow-cracking and fast-setting emulsified asphalt.

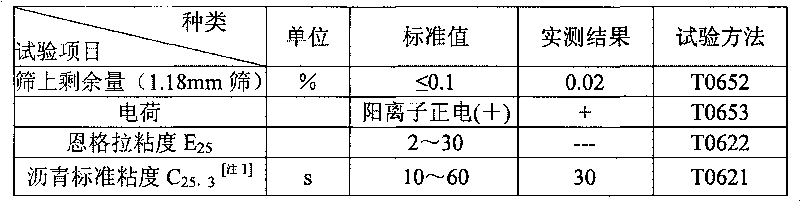

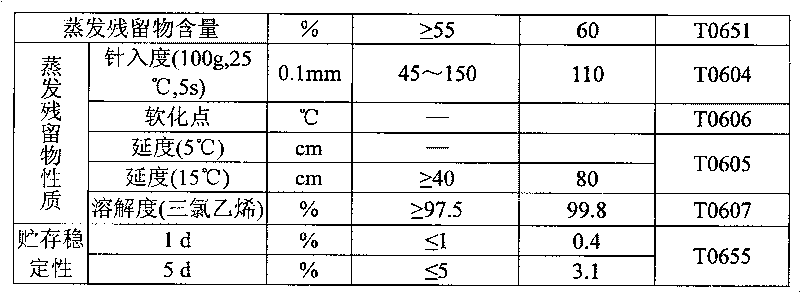

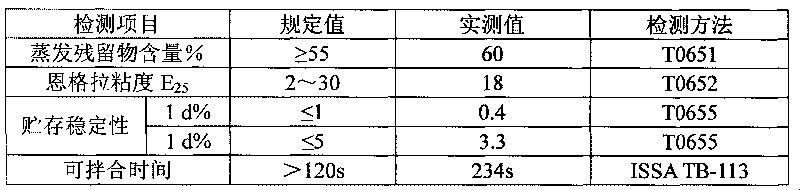

[0011] The performance indicators of emulsified asphalt are as follows:

[0012] Sample serial number

[0013] Through experimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com