Patents

Literature

315 results about "Curdling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In cookery, curdling is the breaking of an emulsion or colloid into large parts of different composition through the physico-chemical processes of flocculation, creaming, and coalescence. Curdling is intentional and desirable in making cheese and tofu; unintentional and undesirable in making sauces and custards. Curdling occurs naturally in cows' milk, if it is left open to air for a few days in a warm environment. Milk is composed of several compounds, primarily fat, protein, and sugar. The protein in milk is normally suspended in a colloidal solution, which means that the small protein molecules float around freely and independently. These floating protein molecules refract light and contribute (with the suspended fat) to the white appearance of milk. Normally these protein molecules repel each other, allowing them to float about without clumping, but when the pH of their solution changes, they can attract one another and form clumps. This is what happens when milk curdles, as the pH drops and becomes more acidic, the protein (casein and others) molecules attract one another and become "curdles" floating in a solution of translucent whey. This clumping reaction happens more swiftly at warmer temperatures than it does at cold temperatures.

Production method of preserved dried beancurd

InactiveCN102405985AReasonable workmanshipImprove resource utilizationCheese manufactureFood scienceFlavorResource utilization

The invention discloses a production method of preserved dried beancurd. The production method comprises the following steps: (1) selecting proper soybean, pretreating the soybean, soaking and washing with water; and (2) pulping the washed soybean, boiling, filtering, curdling, standing to form jellied bean curd, breaking the jellied bean curd, boxing, pressing, removing filter cloth, shaping, quickly boiling in soda, preserving, roasting and mixing with flavor to prepare the preserved dried beancurd. The production method of the preserved dried beancurd disclosed by the invention has reasonable process and high resource utilization rate; and the preserved dried beancurd has delicious taste and rich nutrients, is clean and sanitary, can be stored for longer time, and is convenient for transport and storage.

Owner:王中林

Methods and compositions for consumables

ActiveUS9011949B2Increase aromaAdd flavorMilk preparationAnimal feeding stuffBiotechnologyConsumables

Owner:IMPOSSIBLE FOODS

Methods and compositions for consumables

ActiveUS20150305361A1Increased creamy, milky, buttery, fruityReduced nutty, planty, beanyMilk preparationCheese manufactureBiotechnologyConsumables

Provided herein are methods and compositions for the production of cheese replicas. Generally the cheese replicas are produced by inducing the enzymatic curdling of non-dairy milks.

Owner:IMPOSSIBLE FOODS

Additives for water-resistant gypsum products

ActiveUS20050250858A1Provides water resistanceFireproof paintsAntifouling/underwater paintsWater resistantChemistry

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

Preparation method of Chinese medicinal herbal fermented beancurd

ActiveCN102960466AImprove digestion and absorption rateRich in vitaminsCheese manufactureFood scienceMedicinal herbsIllicium verum

The invention relates to a production technology of Chinese medicinal herbal health fermented beancurd. The preparation method comprises the following steps of: 1) immersing; 2) grinding; 3) filtering; 4) cooking; 5) curdling; 6) culturing uncongealed beancurd; 7) squeezing and slicing; 8) performing early fermentation; 9) preparing the following Chinese medicinal herbal raw materials in 150kg of beancurd raw body by weight: 100g of pepper, 150g of liquorice, 120g of anise, 120g of cinnamon, 100g of medlar, 150g of cumin, 100g of tsaoko amomum fruit, 100g of cardamom, 100g of esmodium, 150g of fructus amomi, 100g of schisandra chinensis, 100g of dried tangerine peel, 150g of mangnolia officinalis, 150g of dogwood, 150g of radix salviae miltiorrhizae, and 100g of galangal, mixing and grinding into fine powder for later use; 10) pickling fermentation materials in later stage of preparation; and 11) stirring and filling into a pot for later fermentation. The beancurd is naturally fermented and brewed, prepared form Chinese medicinal herbs, can be darker and mellower when the preservation period is longer, and has the advantages of unique flavor, rich nutrition, strong color and smell, stomach-invigoration and long-lasting aftertastes, and has more local characteristics of Hunan flavor.

Owner:邹聪终

Preparation process of fried bean curd

ActiveCN103109938AUniform foaming and porosityGood expansion performanceCheese manufactureFood scienceFlavorDeep frying

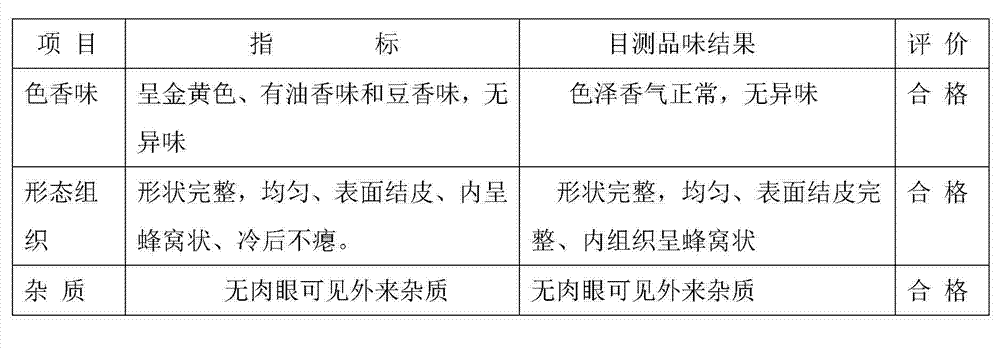

The invention discloses a preparation process of fried bean curd and aims at solving the insufficiencies of poor foaming, thick and hard skin, rough taste and the like of the fried bean curd prepared by the existing method. The preparation process disclosed by the invention comprises the following steps: screening soybeans, soaking, washing, jordaning, centrifugating, siruping, proportioning, curdling, pressing, cutting, deep-frying, foaming, cooling and finally getting the fried bean curd. The fried bean curd prepared by the preparation process has the advantages of good foaming expansion, uniform holes formed in internal structure, honeycomb-like holes, thin, soft, sticky, tough and elastic skin, yellow and bright color and luster of appearance, soft and sticky taste and thick bean flavor and oil flavor.

Owner:ZUMING BEAN PROD

Emulsions for lignocellulosic products, methods of their manufacture, improved lignocellulosic products and methods for their manufacuture

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic products. In one embodiment, the emulsions contain a nonsaponifiable wax, a saponified wax, an alkyl phenol component, a dispersant / surfactant such as a salt of polynaphthalenesulfonic acid, and a carboxymethylcellulose. Such emulsions may be added to hot, even boiling, water without the emulsion separating or curdling. Various embodiments are stable for extended periods of time when stored at room temperature, do not require the addition of a preservative biocide to avoid contributing to biodegradation in a lignocellulosic product. The emulsions are pourable liquids at room temperature. Optionally, the emulsions may be added to lignocellulosic products with a preservative to inhibit the preservative from leaching out.

Owner:HEXION INC

Spicy bean curd snack food

InactiveCN104642559AGreat tasteUniform tasteCheese manufactureFood scienceNutritive valuesSnack food

The invention discloses a spicy bean curd snack food, which is prepared from the following raw materials in parts by weight: 30,000 parts of bean curd, and spicy accessories including 500-700 parts of red oil, 80-120 parts of chilli powder, 30 parts of beef essential oil, 80-120 parts of cumin powder, 100 parts of thirteen spices, 30 parts of sesame oil essence and 30,000 parts of brine. The preparation method comprises the following steps: selecting the raw materials; pulping; boiling; curdling; shaping; baking; marinating; stirring; packaging; sterilizing; cleaning; airing; and warehousing. The invention aims at providing the spicy bean curd snack food which is spicy, good in taste, high in nutritive value and long in storage time.

Owner:XINHUANG XIAOFEINIU FOOD

Method for making dried bean curd

The invention discloses a method for making dried bean curd. The method comprises the following steps: respectively selecting a half of soybeans and black beans, grinding, boiling pulp, filtering pulp, curdling, pressing, cut molding, marinating, vacuum packaging and sterilizing. Compared with the prior art, the method disclosed by the invention has the advantages that the soybeans and black beans are used as raw materials, so that the nutrition is comprehensive and rich, special marinade is adopted and no additive is used, so that the made dried bean curd has good taste, the dried bean curd is more chewy after being squeezed and dewatered by a forming machine, and meanwhile, vacuum package and sterilization are adopted to effectively maintain the freshness of the dried bean curd and prevent the dried bean curd from deteriorating.

Owner:唐照保

Cyclocarya paliurus bean curd

The invention discloses cyclocarya paliurus bean curd which is prepared from soybean milk, fresh green ocarya paliurus leave juice and fresh green ocarya paliurus leave powder. The weight ratio of the soybean milk to the fresh green ocarya paliurus leave juice is 1:(0.06-0.12), and the weight ratio of the soybean milk to the fresh green ocarya paliurus leave powder is 1:(0.02-0.05). The process for preparing the cyclocarya paliurus bean curd comprises the following steps: preparing a mixed syrup according to the adding proportion of 100:(6-12):(2-5) of the soybean milk, the fresh green ocarya paliurus leave juice and hefresh green ocarya paliurus leave powder; boiling; and carrying out the subsequent steps of curdling, marinating, pressing and forming according to the conventional methods to obtain the cyclocarya paliurus bean curd. The cyclocarya paliurus bean curd retains the original smooth and tender flavor of the bean curd, has high nutritional value and has the effects of reducing blood sugar, blood fat and blood pressure, dredging collaterals, losing weight, moisturizing skin, detoxifying and improving the immunity of the human body, thereby being the nutritional healthcare diet therapy functional bean curd which is particularly suitable for the patients with diabetes, high blood pressure and high blood fat to eat.

Owner:陆思烨

Production process of novel egg bean curd cake

InactiveCN103392820ASolve the problem of single nutritional valueRefreshing tasteCheese manufactureFood scienceSlurryWhole egg

The invention discloses a making method of a novel egg bean curd cake. The method mainly includes: (1) selecting high quality dry soybeans, conducting cleaning, soaking, and impurity removal, then performing jordaning and slurry boiling; (2) adding a proper amount of a pasteurized whole egg liquid into cooled cooked soybean milk; (3) mixing the two, performing homogenizing, and then conducting curdling; (4) subjecting the mixed slurry to steam heating, then pressing a bean curd cake; (5) putting the well pressed egg bean curd cake into a seasoning cylinder to perform marinating; and (6) performing cooling sterilization, and packaging. The adding of egg solves the problem of single nutritional value in traditional bean curd cakes, and makes the product taste more smooth, delicious, and palatable.

Owner:JIANGNAN UNIV

Additives for water-resistant gypsum products

ActiveUS7473713B2Provides water resistanceFireproof paintsStarch dervative coatingsWater resistantPhenol

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

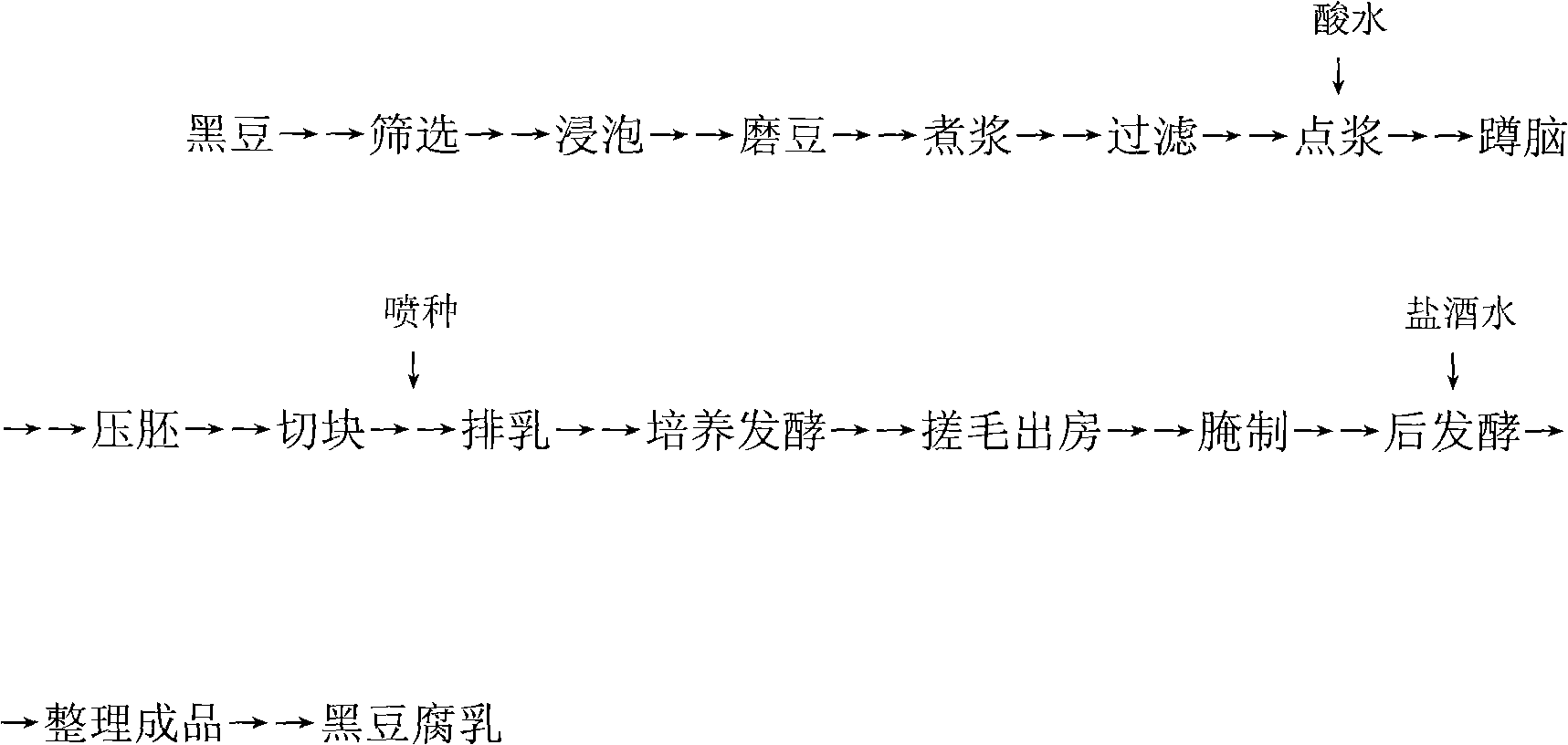

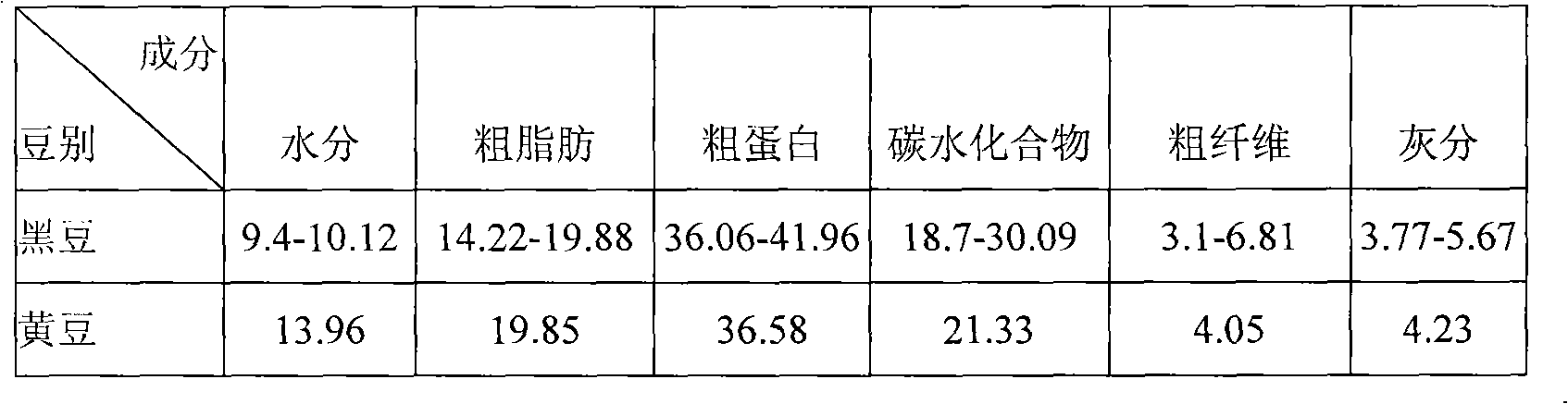

Preparation of preserved beancurd

The invention relates a method for producing preserved beancurd, which is characterized in that black beans are used as main raw materials and the product is produced by using a preserved beancurd process, compared with a common process, the coagulant used for shaping beancurd in the slurry curdling process according to the invention is 1% acid water; in the primary cultivation and fermentation process, the low-temperature bacterium cultivation process is used, the room temperature is controlled at 20-24 DEG C all around the year, the cultivation time is 36-40 hours; in the secondary fermentation process of the post production process, the concentration of the recombined salt wine is lower than the common concentration, so the content of the protein and aminoacid in the produced black preserved beancurd is higher, and the product has salt-fragrant, fresh sweet and soft glutinous mouth feelings.

Owner:开平广合腐乳有限公司

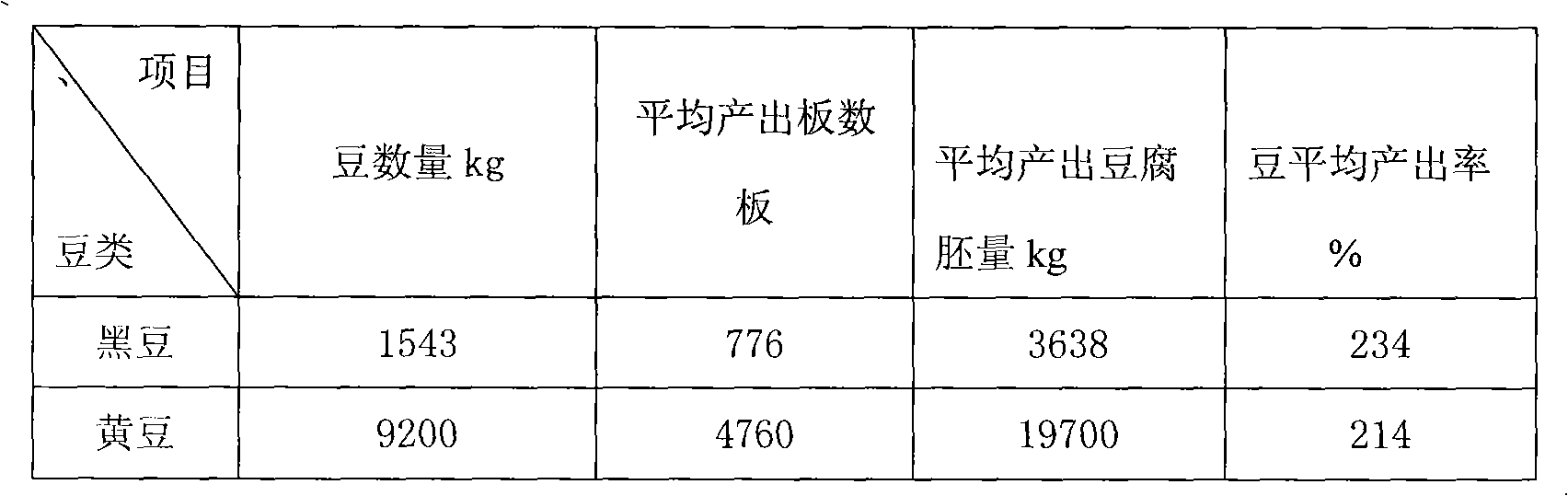

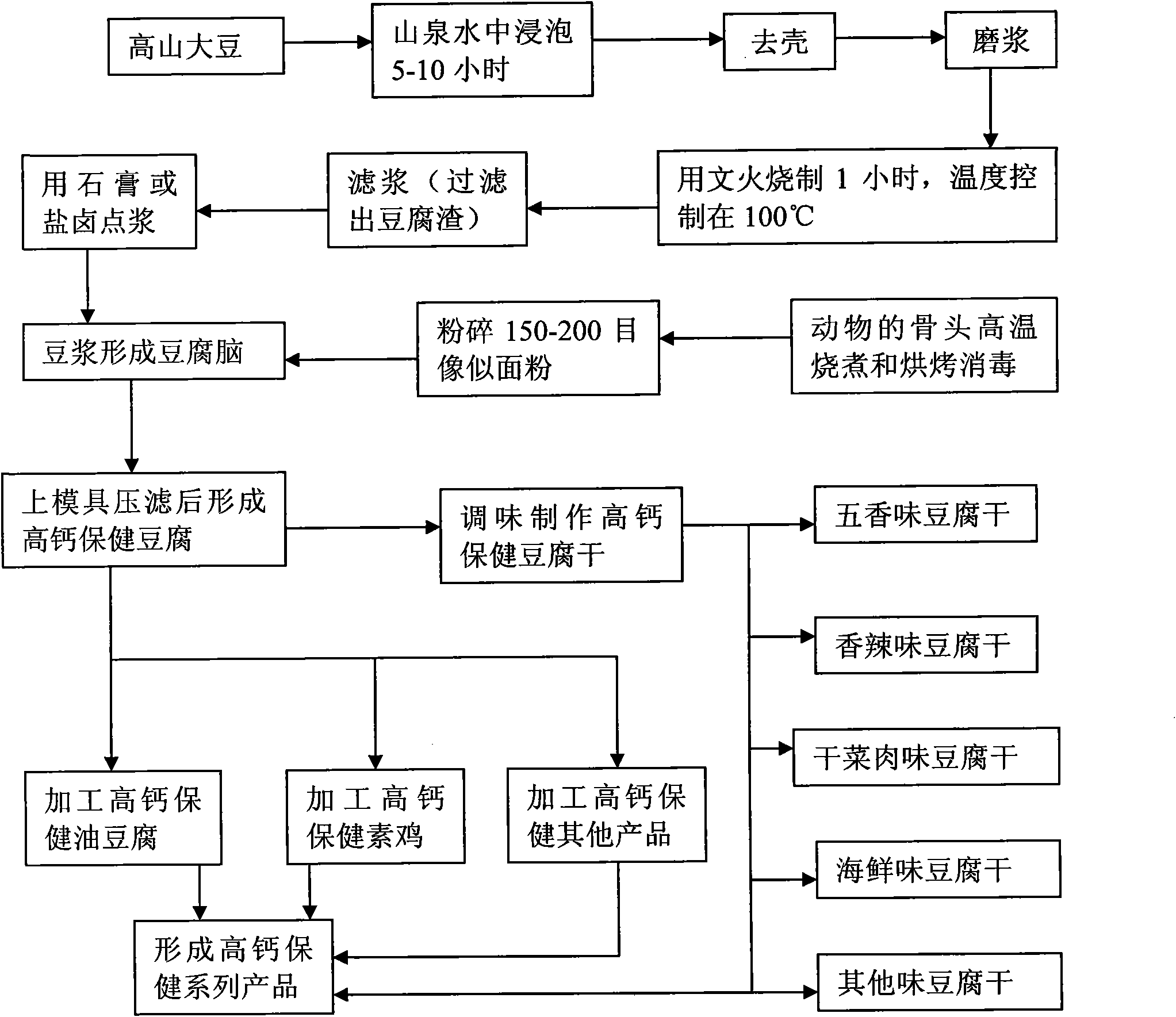

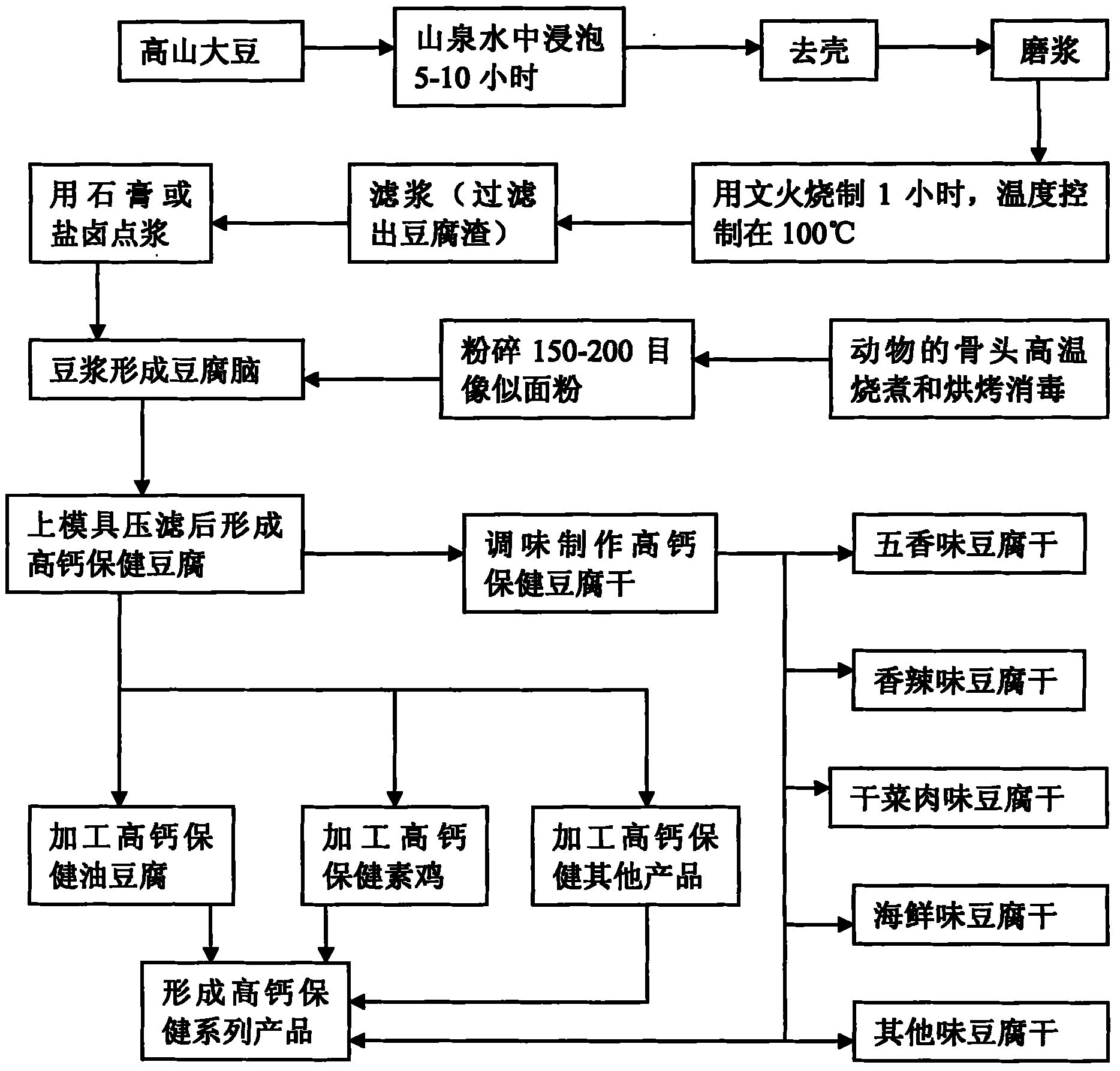

Production method of healthcare bean product

InactiveCN101878818AHigh nutritional valueUnique flavorCheese manufactureFood scienceFlavorCalcium content

The invention relates to a production method of a healthcare bean product. At present, no method for producing the healthcare bean product with simple manufacturing process, good taste of the bean product, unique flavor and rich calcium content exists. The production method is characterized in that: raw materials comprise water, soybean and bone meal, the weight ratio of the soybean and the bone meal is 95: 5; soybean is firstly arranged into water to be soaked for 5 to 10 hours, then the soybean is shelled, the shelled soybean is ground into thick liquid to produce crude soybean milk, then the soybean milk is filtered after being boiled for one hour by slow fire so as to filter the soybean curb residue and to obtain the soybean milk, plaster or bittern is used for curdling, so the soybean milk is solidified to form uncongealed beancurd, then the bone meal is added into the uncongealed beancurd to be uniformly mixed so as to obtain the bean curd bone meal mixture, and the bean curd bone meal mixture is pressed and filtered by a mould to obtain the high-calcium healthcare bean curd. The production method has simple manufacturing process. The produced bean product has comfortable taste, unique flavor, rich calcium content and high nutrition value.

Owner:严雪贤

Method for producing tofu pieces

A process for making bean curd crust from soybean by jordaning, filtering, heating, adding additives, pressuring, etc, is provided. The green harmless bean curd crust is prepared from soybean by cleaning, crushing, immersion, jordaning, filtering, siruping, curdling, pouring, pressing, and collecting peel. The invention aims to substitute additive from grain by fermentation for prior industrial gypsum or bittern based on traditional process, thereby producing a tasty and green bean curd crust for satisfying people's demand.

Owner:张媛

Manufacturing method of compound electromagnetic shield magnet of nanocry stal magnetically soft alloy powder polymer

InactiveCN1658748AImprove uniformityImprove insulation performanceMagnetic/electric field screeningScreening apparatusParticulatesAlloy

This invention is a producing method of the nanometer crystal floppy magnetism alloy powder polymer mulriple electromagnetism shield body. The method adopt the technology of melting body fast curdling to produce the Fe-B-Si-Nb-Cu or the Fe-Si-Al serial of alloy squamas, and stave them to obtain the floppy magnetism alloy particulates, then anneal in vacuum; use the vacuum vaporing and plating technology to deposit a layer of polymeric opposite two methylic benzene membrane on the surface of the magnetic powders; add the magnetic powders into the polymeric monomer solution to produce the suspending system; use the pressed pieces to extrude a pressed and extended technics to produce the mentioned nanometer crystal floppy magnetism alloy powder polymer mulriple electromagnetism shield body. The technics of this invention is simple, its cost is low, the anticorrosive produced magnet has very high chemistry stability, and the magnet shield effect is improved.

Owner:SOUTH CHINA UNIV OF TECH

Pupal protein-viscose filament and manufacturing method thereof

ActiveCN102383219ASolve sheddingImprove fixation effectNew-spun product collectionMonocomponent cellulose artificial filamentFiberLoss rate

The invention relates to a pupal protein-viscose filament and a manufacturing method thereof, which belongs to the field of material in textile industry. The pupal protein-viscose filament is obtained through the following steps: pupal protein essence and cellulose sulphonate solution are processed through static blending, spinning, curdling, solidifying and after-treatment at 1%-60%: 40%-99% by weight percent, the loss rate of protein during the production process of pupal protein-viscose filament is less than 30%, and after finished product is washed with water for 50 times, the expulsion rate of fibrous protein is less than 5%. Formaldehyde is not used during the whole technological process, thereby the influence of formaldehyde on the environment can be eliminated, and the manufactured pupal protein-viscose filament is soft, is golden yellow on color and is good on quality.

Owner:YIBIN SPARK NEW FIBER CO LTD

Methods and compositions for consumables

ActiveUS10986848B2Increased creamy, milky, buttery, fruityReduced nutty, planty, beanyCheese manufactureFood scienceBiotechnologyConsumables

Provided herein are methods and compositions for the production of cheese replicas. Generally the cheese replicas are produced by inducing the enzymatic curdling of non-dairy milks.

Owner:IMPOSSIBLE FOODS

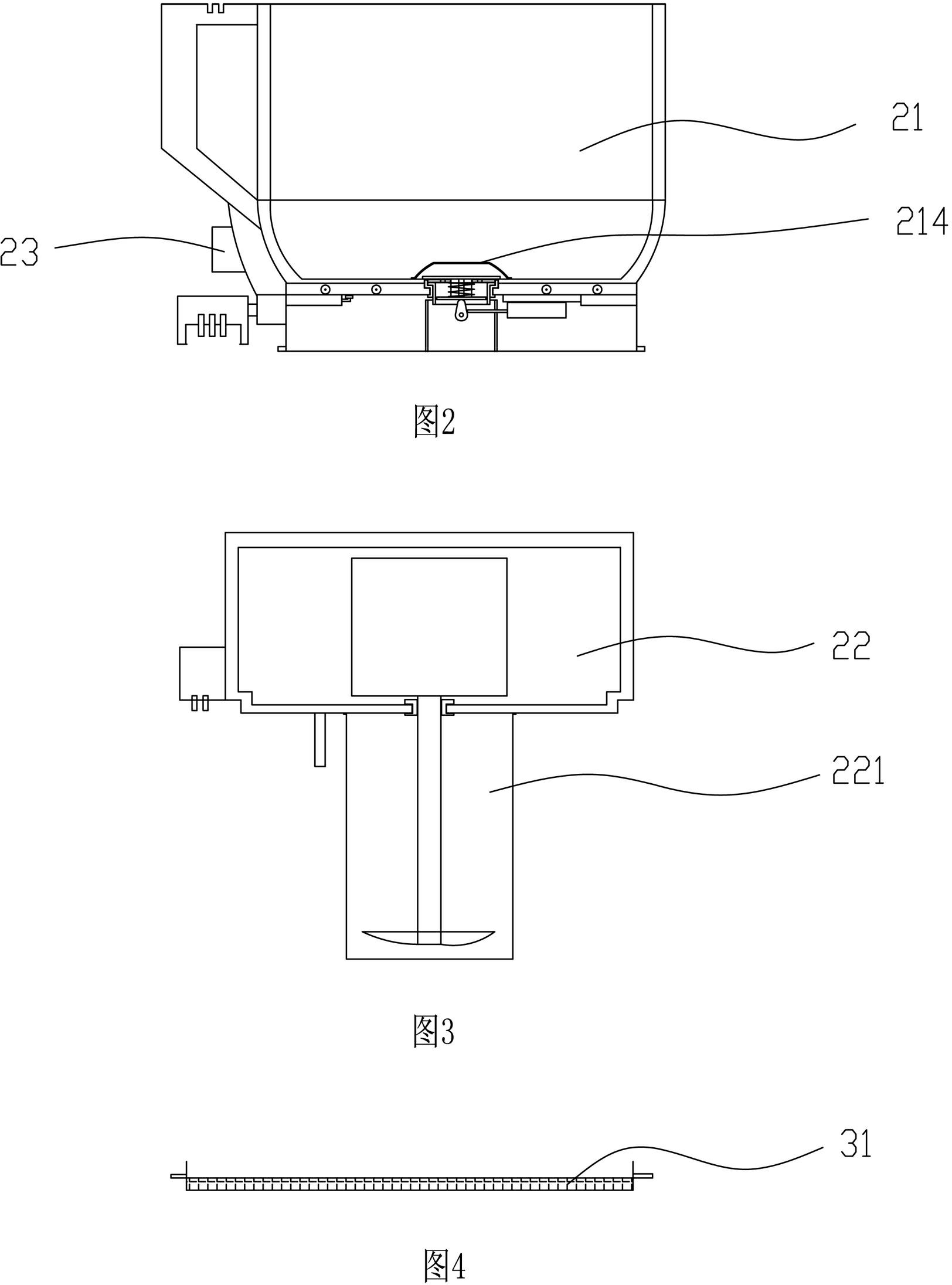

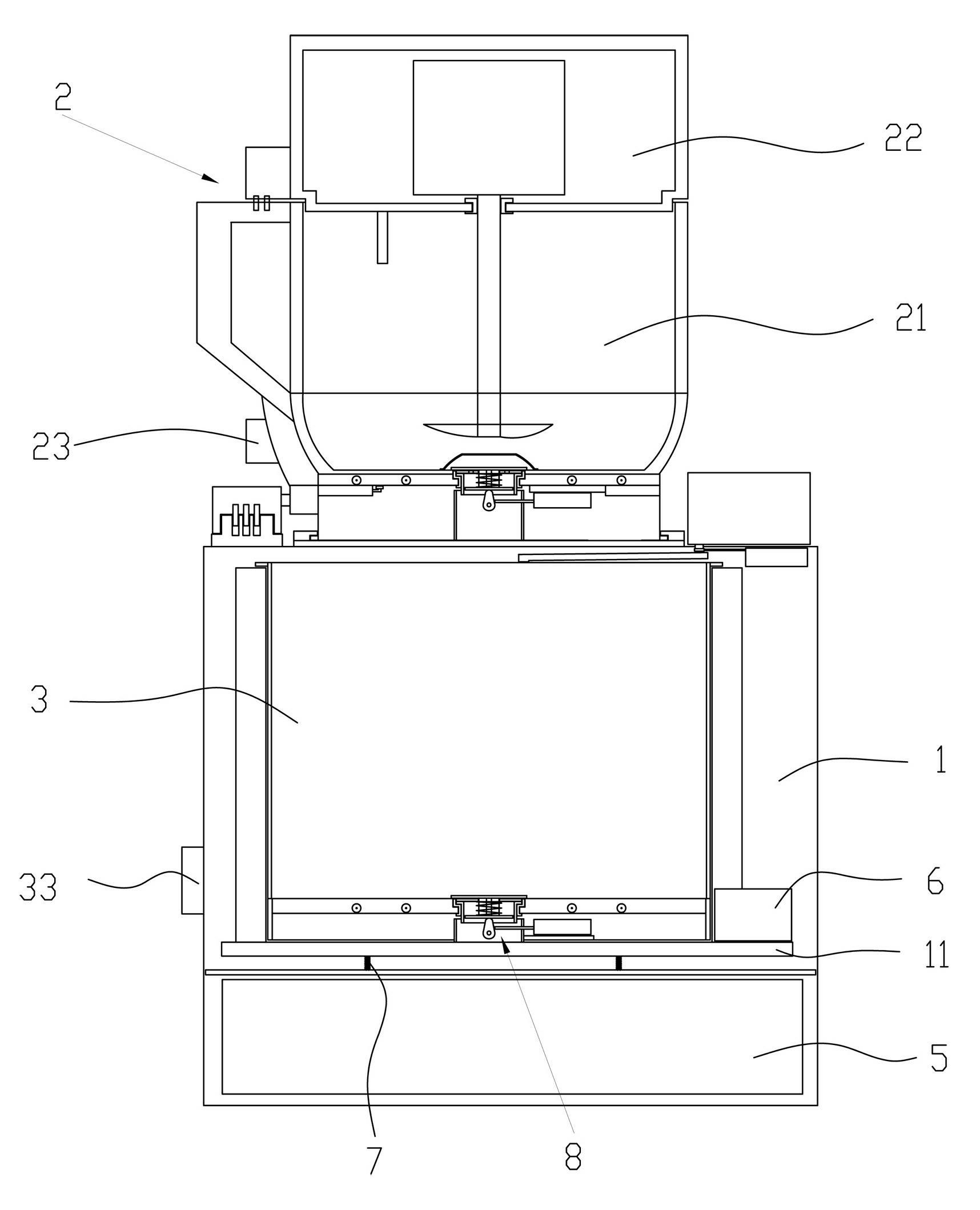

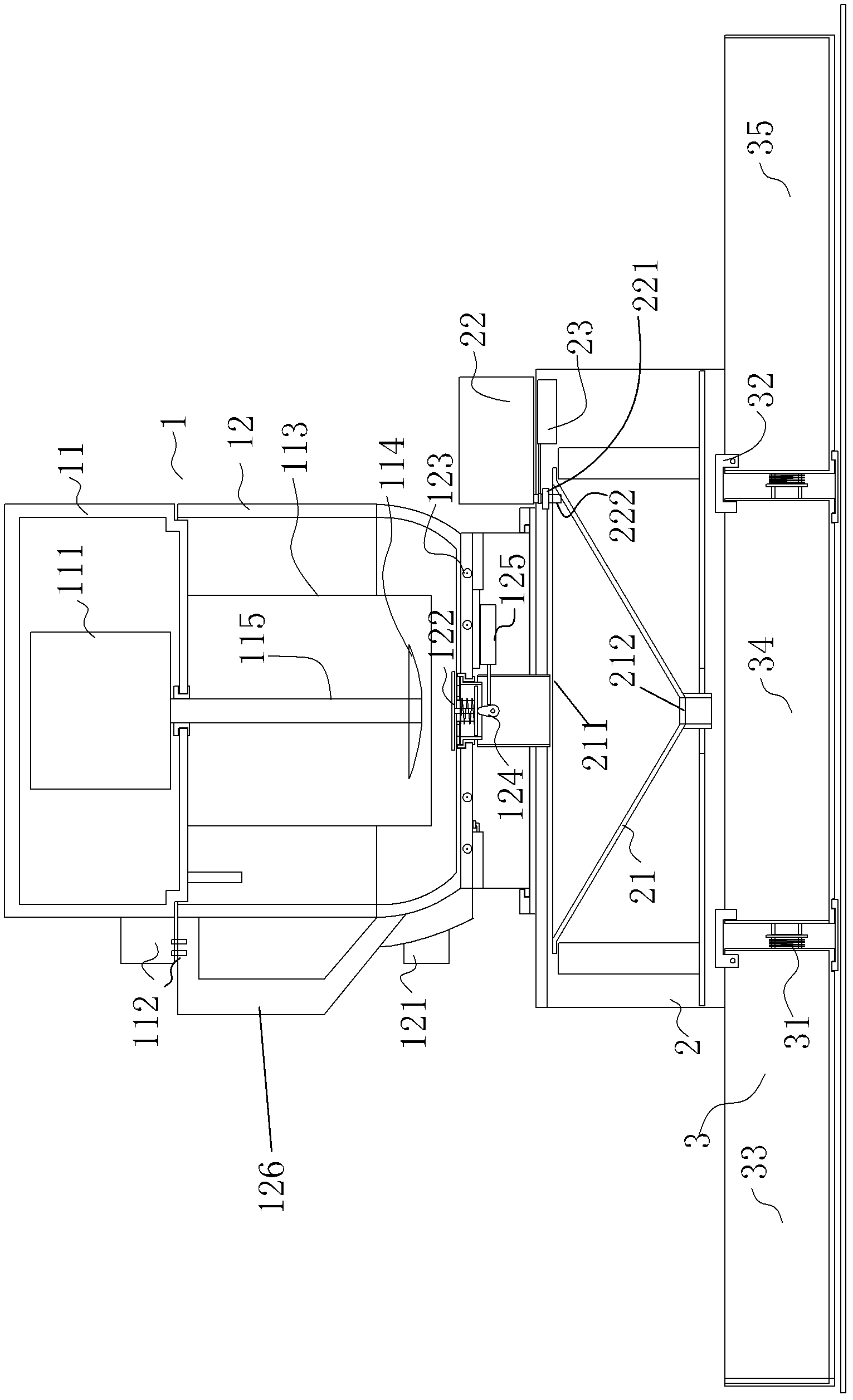

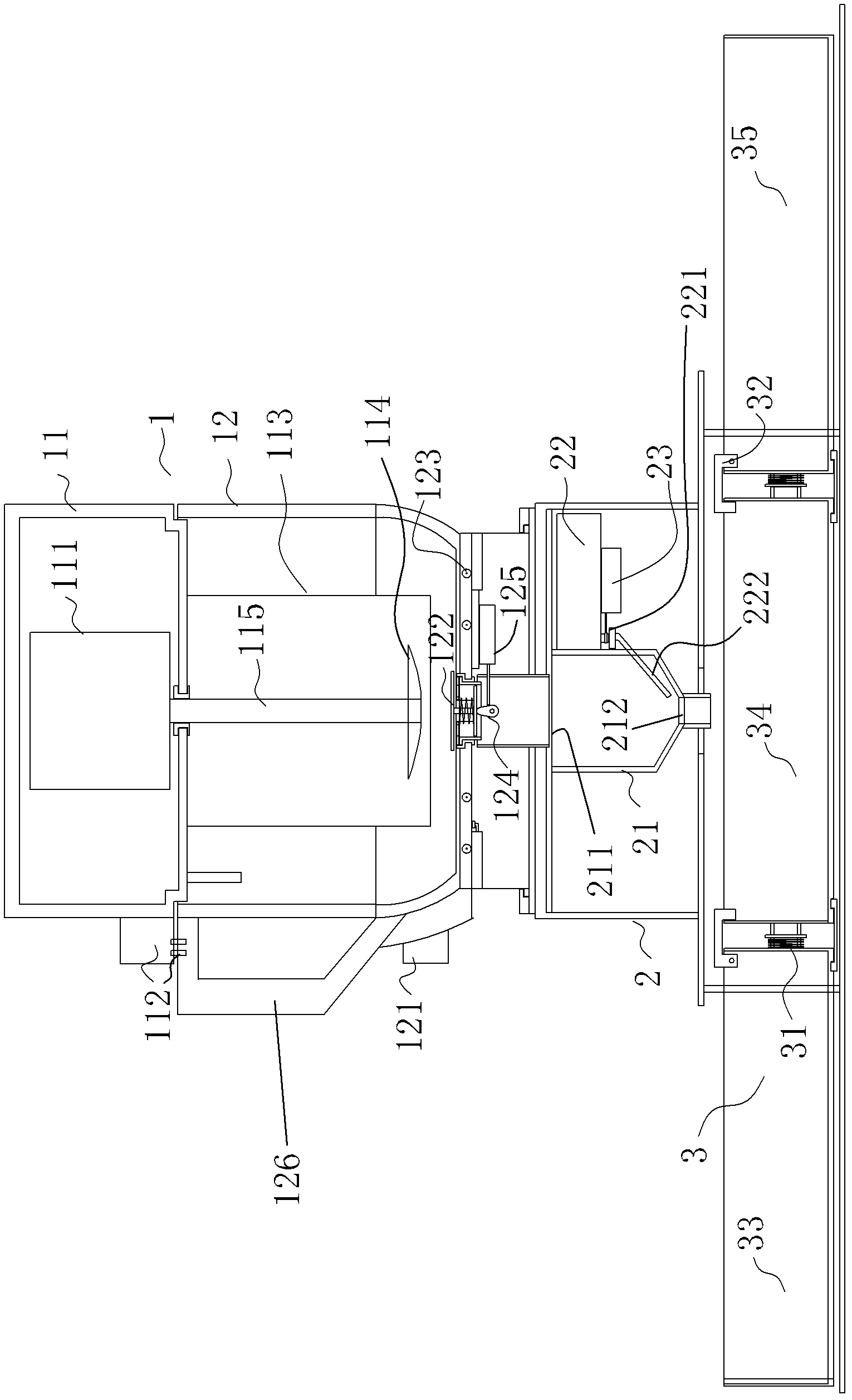

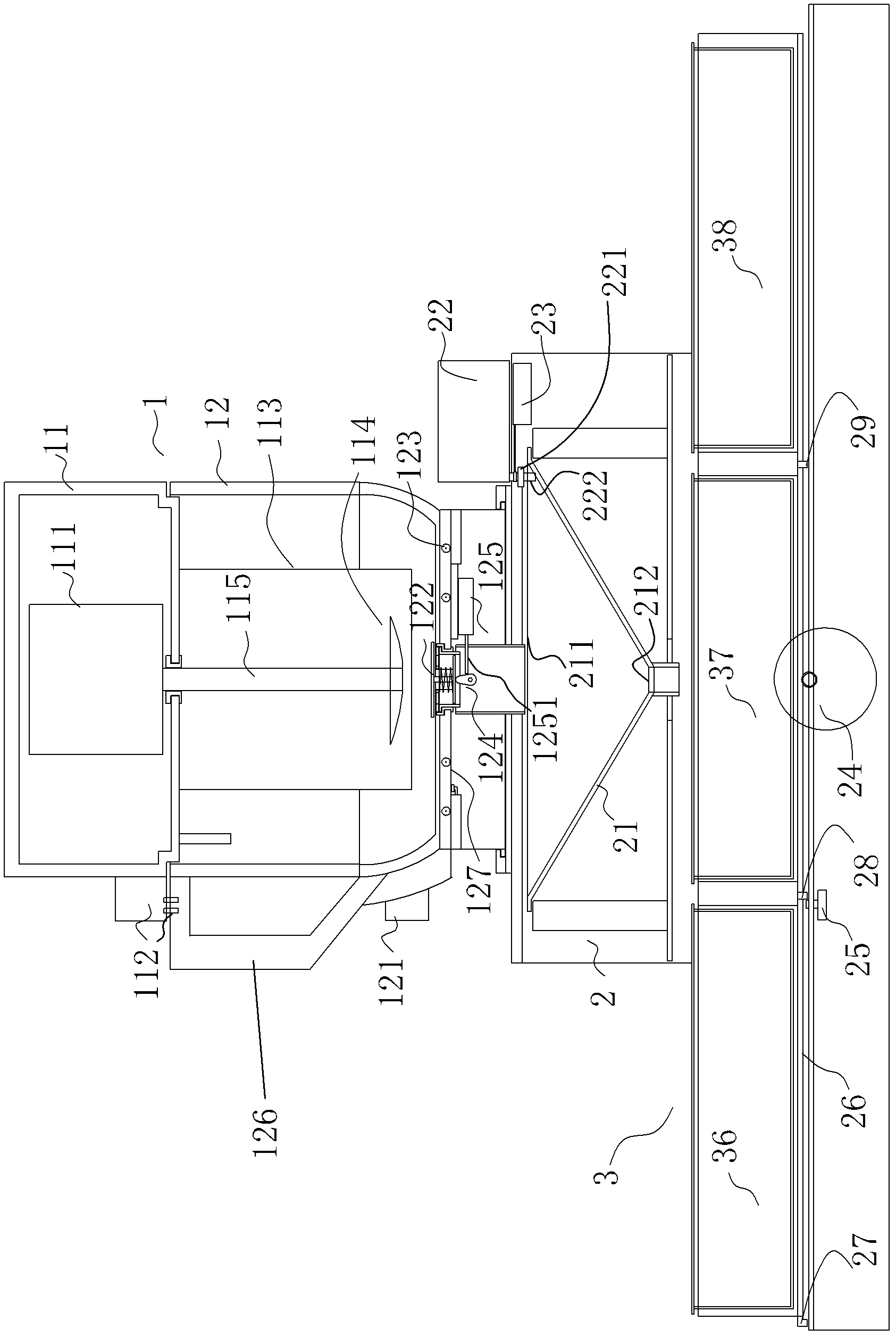

Household bean curd machine

ActiveCN102204593AHigh degree of intelligenceMeet needsCheese manufactureFood scienceElectric machineryPulp and paper industry

The invention discloses a household bean curd machine and particularly provides a highly-intelligent household bean curd machine which is simple in structure, low in cost, safe and hygiene, and can sequentially realize pulping, curdling and draining. According to the implementation scheme disclosed by the invention, the household bean curd machine comprises a base and a control circuit, wherein the base is provided with a bean milk maker, a curdling barrel, a coagulator injection device used for injecting coagulator into the curdling barrel, and a waste water pool arranged below the curdling barrel, the bean milk maker comprises a cup body and a maker head, a pulp outlet communicated with the curdling barrel and a heating element are arranged at the bottom end of the cup body, a valve body is arranged in the pulp outlet, a valve driving device used for driving the valve body to open and close is arranged on the cup body, and a vibrating motor and a filtering mechanism are arranged on the curdling barrel.

Owner:SHENZHEN CRASTAL TECH CO LTD

Production process of dried bean curd with fresh and special taste

InactiveCN103621680AAdapt to various needsGood effectCheese manufactureFood scienceDry beanFood item

The invention relates to a production process of dried bean curd with a fresh and special taste, and relates to the technical field of food processing. The production method comprises the steps: preparing a white blank; enabling lemons to be tasty, soaking soybeans, peeling, cleaning, grinding to obtain soybean milk, curdling, boiling and the like. The production process has the beneficial effects that bean halves in an original state of the soybean milk are tasty through lemon slice, the effect is good, the produced dried bean curd is spiced, is capable of emitting the light lemon aroma when being unsealed, is fresh and special in taste, and adapts to multiple demands of modernists on foods.

Owner:ANHUI MOON FOOD

Domestic bean curd manufacturing machine

ActiveCN102488024AImprove qualityGreat tasteKitchen equipmentCheese manufactureFiltrationSeparation technology

The invention discloses a domestic bean curd manufacturing machine. Only through the domestic bean curd manufacturing machine, bean curd manufacturing processes of beating, filtration, curdling and molding are finished automatically and the mixing uniformity of soya-bean milk raw material liquid and a coagulating agent is fully improved in curdling so that molded bean curd has excellent quality and a good taste. The domestic bean curd manufacturing machine comprises a base, a soya-bean milk machine, a bean curd molding box, and a control circuit. A guiding mixing device for mixing soya-bean milk raw material liquid and a coagulating agent is arranged between the bean curd molding box and a cup body of the soya-bean milk machine. A coagulating agent outlet of a coagulating agent injection device is arranged in the guiding mixing device. The domestic bean curd manufacturing machine adopts a milk-dreg automatic separation technology suitable for a soya-bean milk machine, the guiding mixing device realizing automatic mixing of soya-bean milk and a coagulating agent, and the bean curd molding box capable of realizing automatic bean curd sub-packaging after curdling, so that bean curd obtained by the domestic bean curd manufacturing machine has a fine taste, a good flavor and high quality and uniform mixing of the soya-bean milk raw material liquid and the coagulating agent is realized. Therefore, the domestic bean curd manufacturing machine is suitable for manufacture of home-made bean curd, saves time, a cost and labor, and has safe and healthy characteristics.

Owner:深圳市北鼎晶辉科技有限公司

Preparation method for villi bean curd

InactiveCN102488019AEasy to operate and controlGreat tasteCheese manufactureFood scienceFlavorHigh volume manufacturing

The invention discloses a preparation method for a villi bean curd. The method comprises the following steps: soaking: adding water and sodium carbonate, of which the weight is 0.2%-0.3% of the weight of soybeans, soaking till the soybeans are swelled and two petals of the soybeans are split into flat plates; preparing slurry: grinding while adding a starch solution, grinding till no grain feel exists when the soybeans are touched by fingers, and separating soybean milk from bean dregs; cooking the slurry: quickly boiling the soybean milk to 100 DEG C and sieving cooked bean dregs; curdling: injecting a pouring starch solution, uniformly stirring and solidifying; squeezing and dividing blocks: squeezing the solidified slurry into a bean curd base; sealing for 3-4 hours during a cooling process at 40-30 DEG C and dividing into small blocks; and emulsifying: putting the naturally cooled small blocks of the bean curd base into a mucor strain suspension, standing for 4-5 days at 20-25 DEG C, and then growing uniform, fine and white villi on the surface of the bean curd. The whiteness of the villi of the prepared villi bean curd is approached to the whiteness of cotton; the grey inferior-quality products are few; the villi bean curd smells slight fragrant and is free from other peculiar flavors; during the preparation process, the quality of products is controllable and the taste is stable; and the villi bean curd is suitable for industrialized bath production.

Owner:HUANGSHAN WANAN FOOD

Method for making marinated dried tofu

The invention relates to a method for making marinated dried tofu. The method comprises the following steps: S1, selecting appropriate soybeans, and performing cleaning and soaking on the soybeans; S2, grinding the soaked soybeans, filtering, heating, curdling, forming, pressing, slicing, frying, cooking while adding spices, cooling and packaging. The method for making the marinated dried tofu has the benefits that the making process is simple, the utilization ratio of raw materials is high, the production efficiency is high, and preservation time of the marinated dried tofu is long.

Owner:LIANGPING COUNTY QIWEI FOOD

Marinated dried bean curd manufacturing method

InactiveCN107047796AIncrease profitDeliciousCheese manufactureFood scienceNutritionProcess engineering

The invention discloses a marinated dried bean curd manufacturing method. The method includes steps of material selecting, soaking, pulping, separating, boiling, curdling, standing, pressing moulding and marinating. The manufacturing method is simple in production process, high in material utilization rate and high in production efficiency. A marinated dried bean curd product is delicious, rich in nutrition, clean, long in storage time and convenient to transport and store.

Owner:湖南湘菜源生态食品有限公司

Preparing method of acidophilus milk lump

The invention discloses a preparation method for yogurt lump. The method comprises the steps of fermenting, acidization, curdling, whey discharging, water washing, storing, forming, sealing, after-ripening and packaging by adopting special lactic acid bacteria to inoculate milk or goat milk which is standardized and pasteurized. The invention can not only lead the traditional yogurt lump product to be safer and more sanitary with stable quality, subtle taste and modest hardness. And since the step of the after-ripening is controlled appropriately, the prepared yogurt lump is of fuller flavor with little cream precipitated, high yielding rate and can meet popular taste and be used for producing yogurt lump with different water content, tastes and textural quality, which has more market competitiveness and can greatly enrich the processing technology and flavor of traditional yogurt lump.

Owner:SOUTH CHINA AGRI UNIV +1

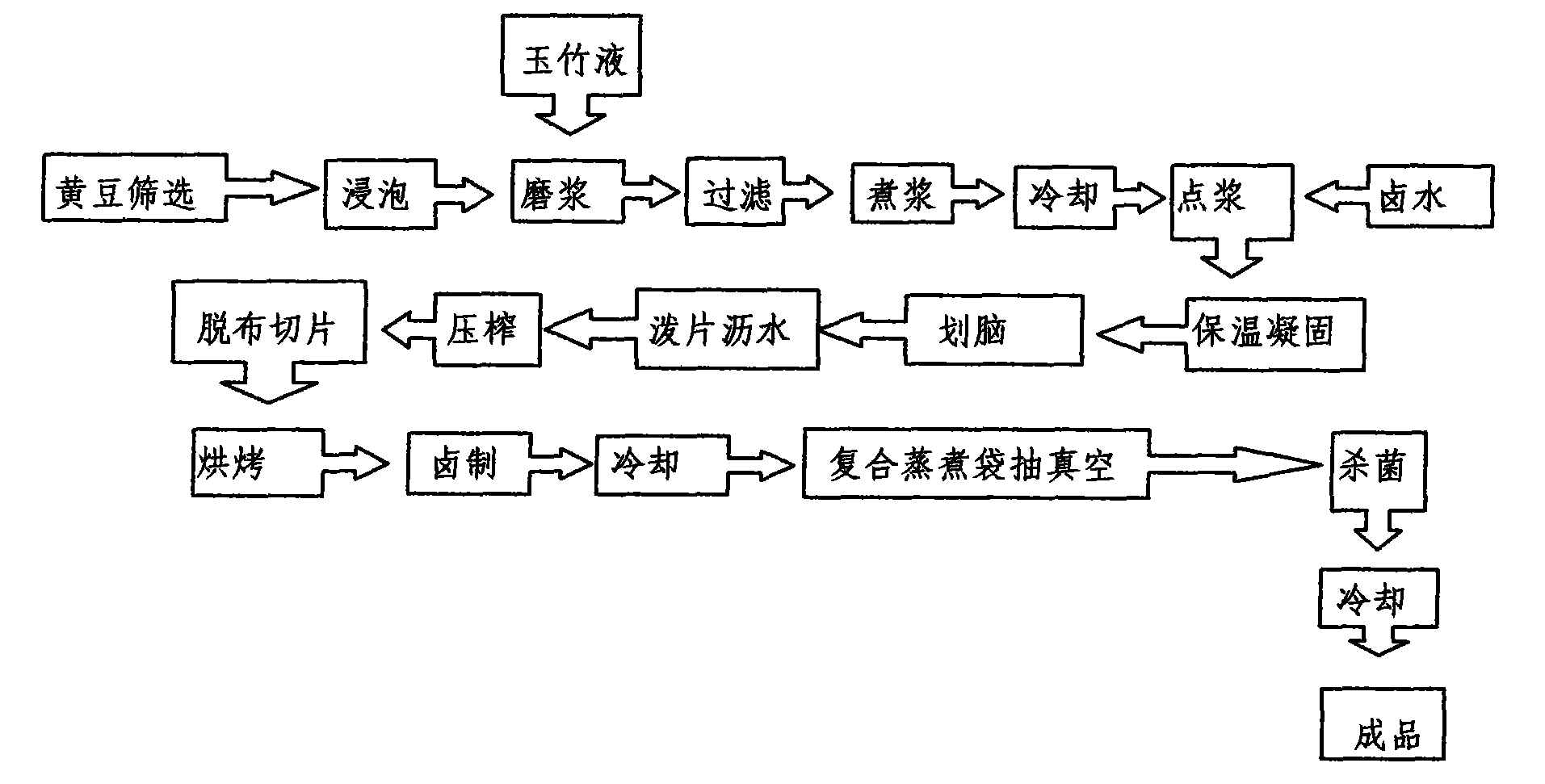

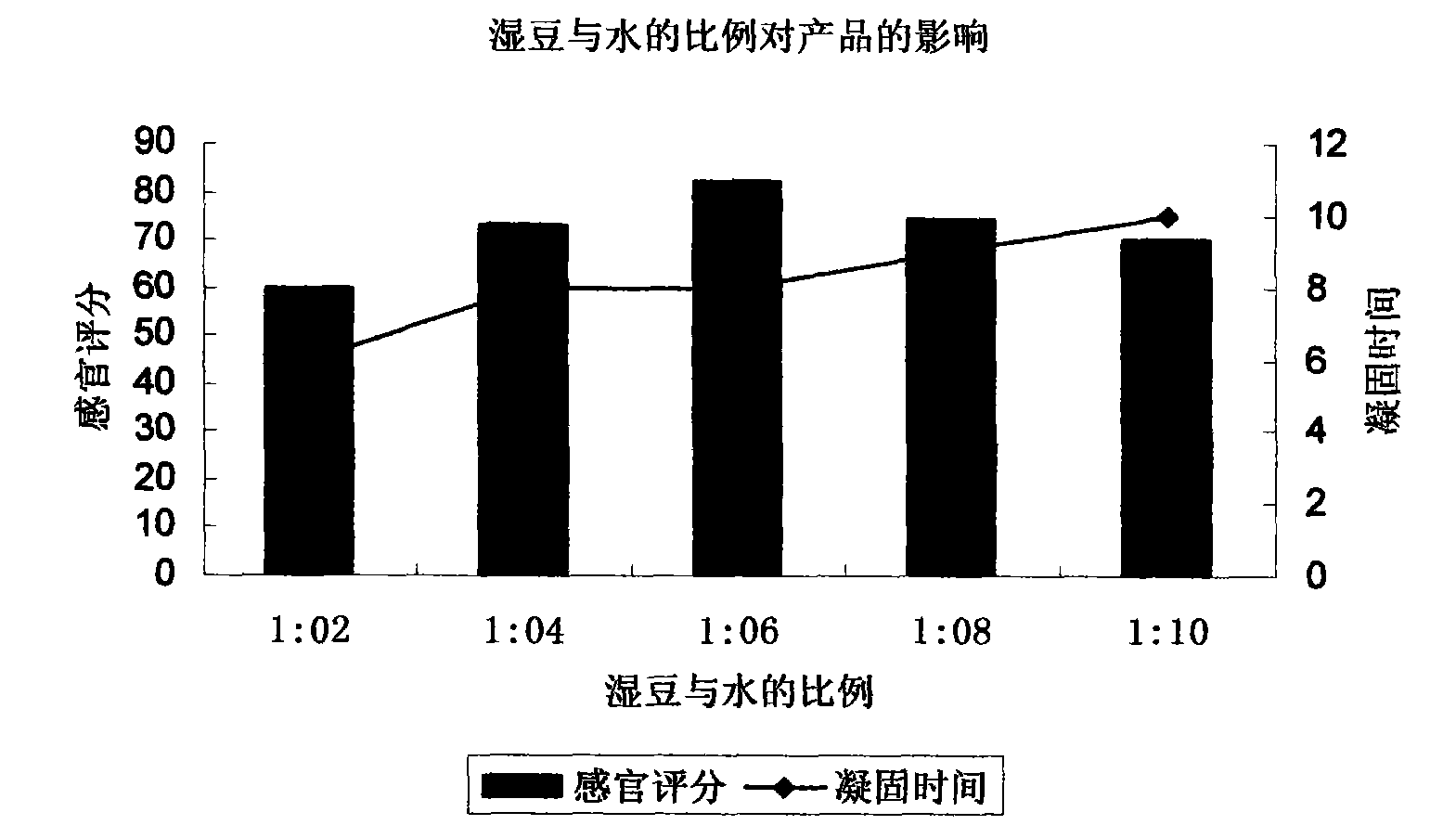

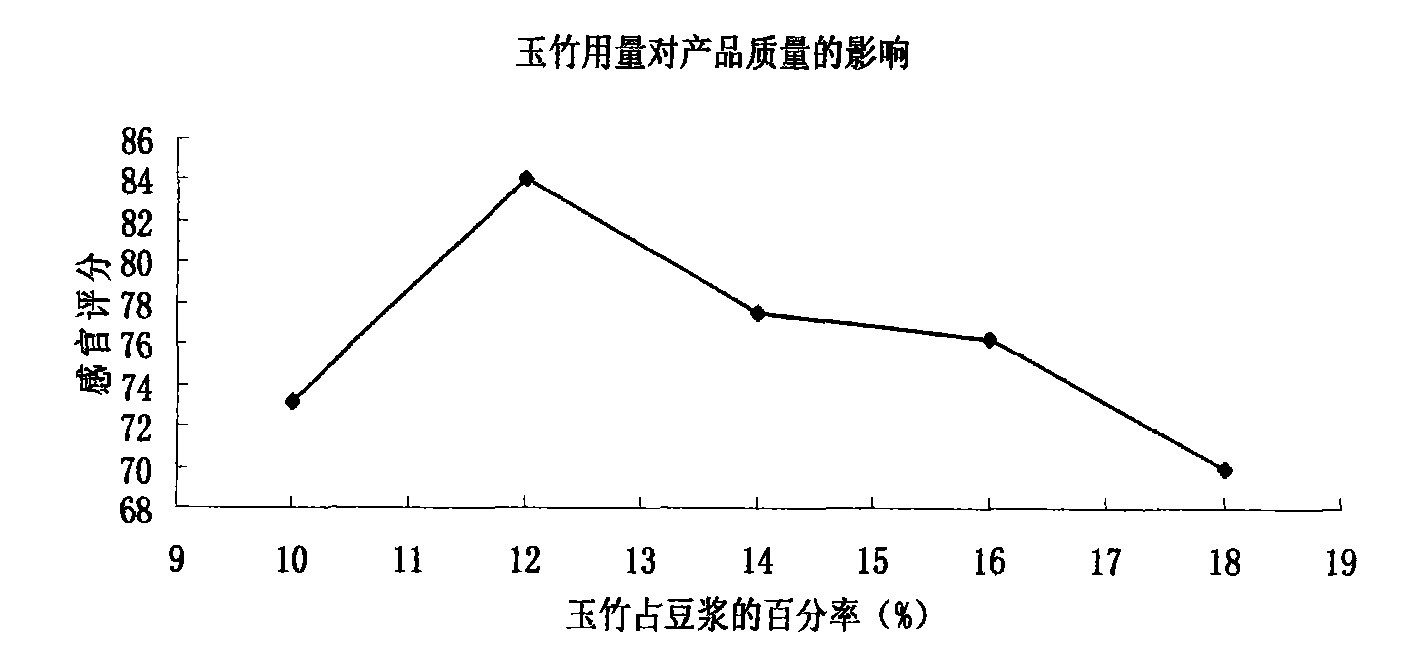

Fragrant solomonseal rhizome dried bean curd and preparation method thereof

The present invention discloses a fragrant solomonseal rhizome dried bean curd and a preparation method thereof. The preparation method comprises the following steps: cleaning and soaking soybean, grinding and decocting fragrant solomonseal rhizome to obtain a fragrant solomonseal rhizome liquid, adding the fragrant solomonseal rhizome liquid to the soaked soybean, and sequentially carrying out pulp grinding, pulp boiling, pulp curdling, breaking, forming, drying, saucing, vacuum packaging and sterilization. The finally-prepared fragrant solomonseal rhizome dried bean curd has characteristics of light yellow, bright color, smooth surface, good elasticity, refreshing taste, and rich fragrant solomonseal rhizome fragrance, and can be adopted a high nutrition health and food therapy food so as to be popular in people, such that the industry prospects are broad with the consumer leisure guiding effect.

Owner:JILIN AGRICULTURAL UNIV

Production process of frozen and dried tofu

The invention discloses a production process of frozen and dried tofu. The production process comprises the steps of selecting materials, soaking, pulping, carrying out centrifugal filtering, continuously heating the pulp, curdling, pressing and forming, steaming and forming, freezing, curing, expanding and softening, and packaging and the like. The frozen and dried tofu prepared by the production process is good in water regaining characteristic, fine in structure and uniform in voids; after water regaining, a product is expanded and softened, is good in toughness and unique in flavor, can be used as an auxiliary material of chaffy dish, also can be used as a main material in fried dish, soup dish and cooked dish, is a convenient non-staple food and is long in quality guarantee period and convenient for transportation and storage.

Owner:安吉祖名豆制食品有限公司

Bean curd containing dragon fruit and preparation method of bean curd

InactiveCN102960471ASmooth tasteSweet and deliciousCheese manufactureFood scienceCarrot juiceFruit juice

The invention discloses bean curd containing dragon fruit and a preparation method of the bean curd. The preparation method comprises the following steps in sequence of: preparing momordica grosvenori leaching liquid, carrot juice and dragon fruit juice; preparing uncooked soybean milk; heating the uncooked soybean milk; sequentially adding the dragon fruit juice, carrot juice and momordica grosvenori leaching liquid; uniformly stirring; adding dissolved edible gypsum for curdling; and then squeezing to remove water, and pressing into the bean curd. By adopting the preparation method, the effective components of the carrot, momordica grosvenori and dragon fruit are integrated into the bean curd, therefore, the bean curd is delicious and sweet and tastes great, and has the healthcare functions such as relaxing bowl, tonifying spleen and beautifying, and reducing blood fat and blood pressure.

Owner:黄丽平

Preparation method of nutritional colored bean curd

InactiveCN102106404ANon-destructive fiberNo loss of nutrientsCheese manufactureFood scienceGypsumSoya bean

The invention aims to provide a preparation method of colored nutritional bean curd. The preparation method mainly comprises the following steps: 1, squeezing fruit and vegetable and taking juice for later use; 2, preparing soybean milk: soaking soybean in 6 Kg of water, pulping the soaked soybean into soybean milk, and adding an antifoaming agent for later use; 3, curdling: adding lactone, edible gypsum, fruit and vegetable juice and rice starch to cold water, pouring the soybean milk into a cylinder, and curdling to form bean curd; 4, packing the soybean milk in form of uncongealed bean curd with cloth and placing in a platform frame; putting a wood plate on the packing cloth, and pressing to obtain the colored bean curd product; and 5, sterilizing and cooling to obtain the colored nutritional bean curd. According to the technical scheme, the raw materials comprise 4,000-5,000 g of soybean milk, 900-1,000 g of fruit and vegetable juice, 24-28 g of lactone, 6-8 g of edible gypsum, 600-700 g of rice starch and 30-35 g of antifoaming agent. The colored nutritional bean curd provided by the invention has diverse colors, meets the requirements of people for various kinds of nutrition and trace elements, and has broad market prospect.

Owner:宋晓东

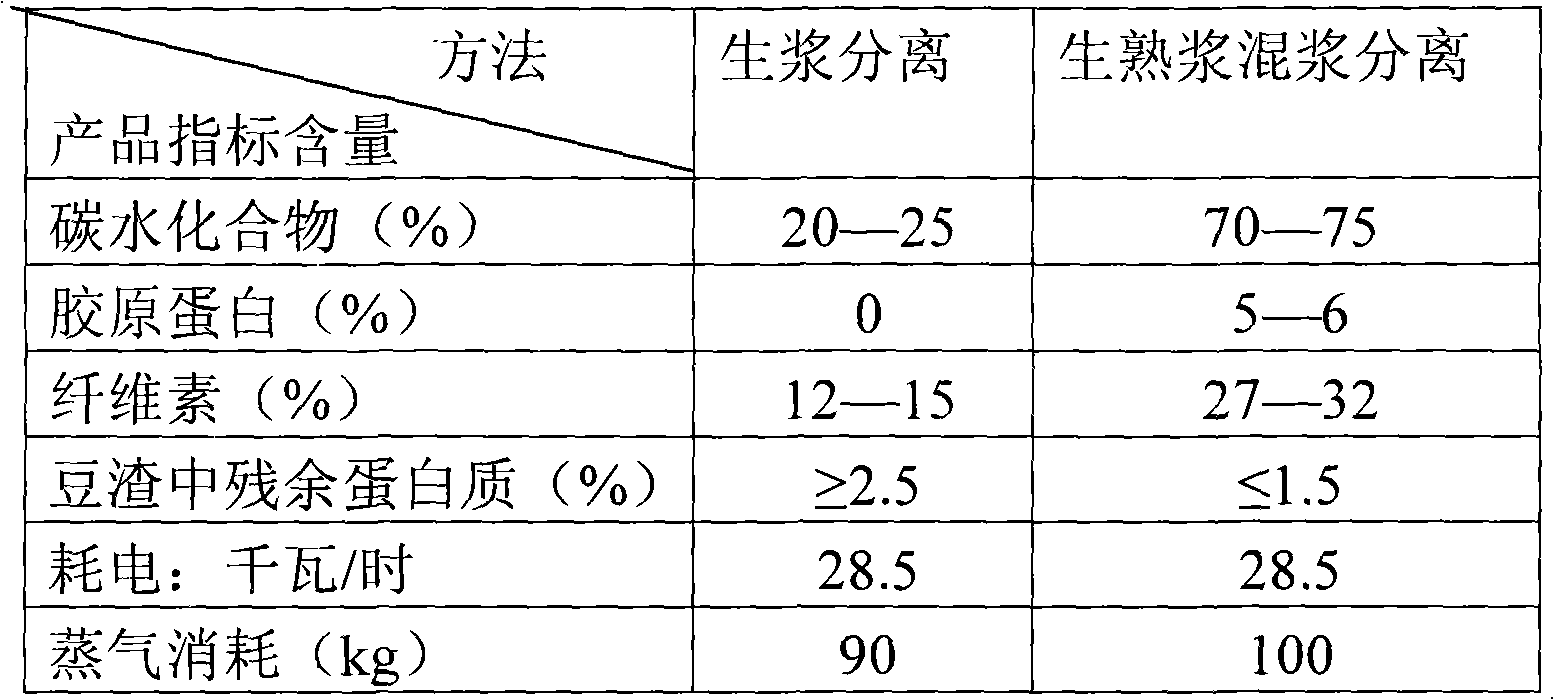

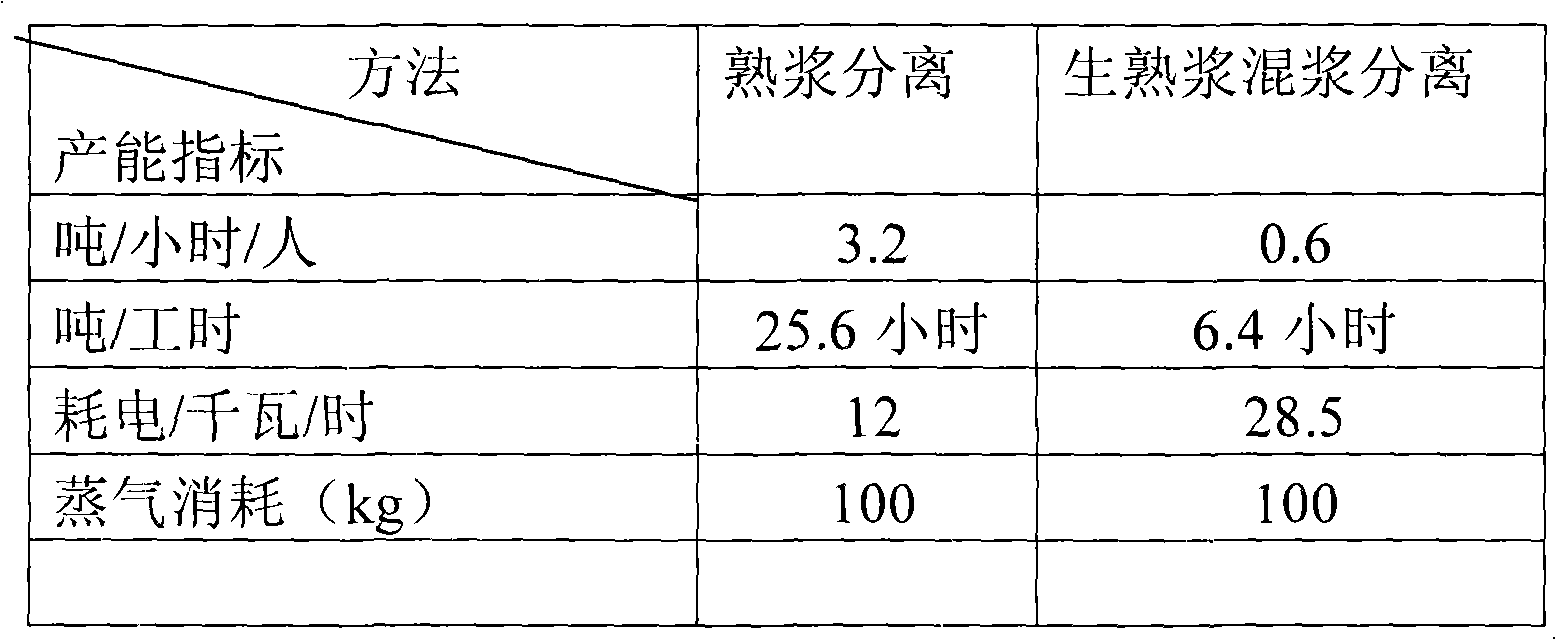

Separation making process of mixed slurry of raw slurry and boiled slurry of dried bean curd

ActiveCN101869148AImprove the mechanization processEfficient separationCheese manufactureFood scienceFiberDry bean

The invention relates to a separation making process of mixed slurry of raw slurry and boiled slurry of dried bean curd, which is characterized in that soaked soybeans are ground to form primary slurry; primary bean dregs and primary raw slurry are obtained by carrying out first separation on the primary slurry; the primary bean dregs are boiled by adding water, and secondary bean dregs and secondary boiled slurry are obtained by carrying out secondary separation; and after the primary raw slurry and the secondary boiled slurry are mixed and boiled, and the dried bean curd is prepared by carrying out the following processes of curdling, pressing forming and blanking drying. Proved by production practice, by adopting the separation process of the mixed slurry of the raw slurry and the boiled slurry, the mechanization degree of industrial production and the labor productivity can be enhanced, proteins in the soybeans are fully extracted, the residual protein in the bean dregs is lowered to be no more than 1.5 percent to enhance the yield and save resources, pectin protein, other proteins, carbohydrate and crude fibers in beancurd skins are efficiently separated, and the advantages of sufficient toughness, tension energy and mastication resistance of the dried bean curd are kept to ensure the product quality.

Owner:四川南溪庶人食品有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com