Household bean curd machine

A tofu machine and home-use technology, applied in applications, cheese substitutes, dairy products, etc., can solve the problems of complex structure, high cost, unhygienic, etc., and achieve the effect of high intelligence, low cost, and ensuring safety and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

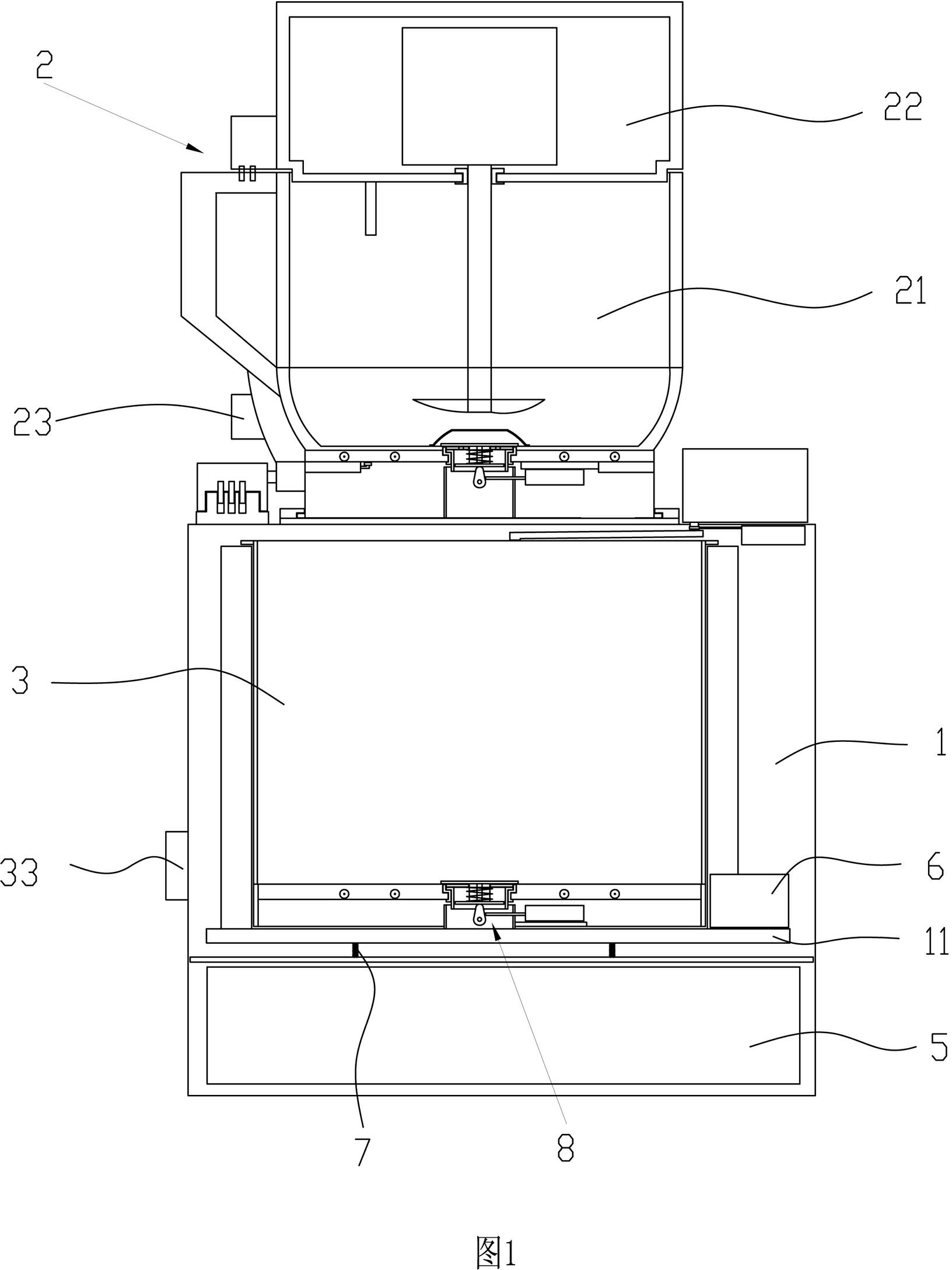

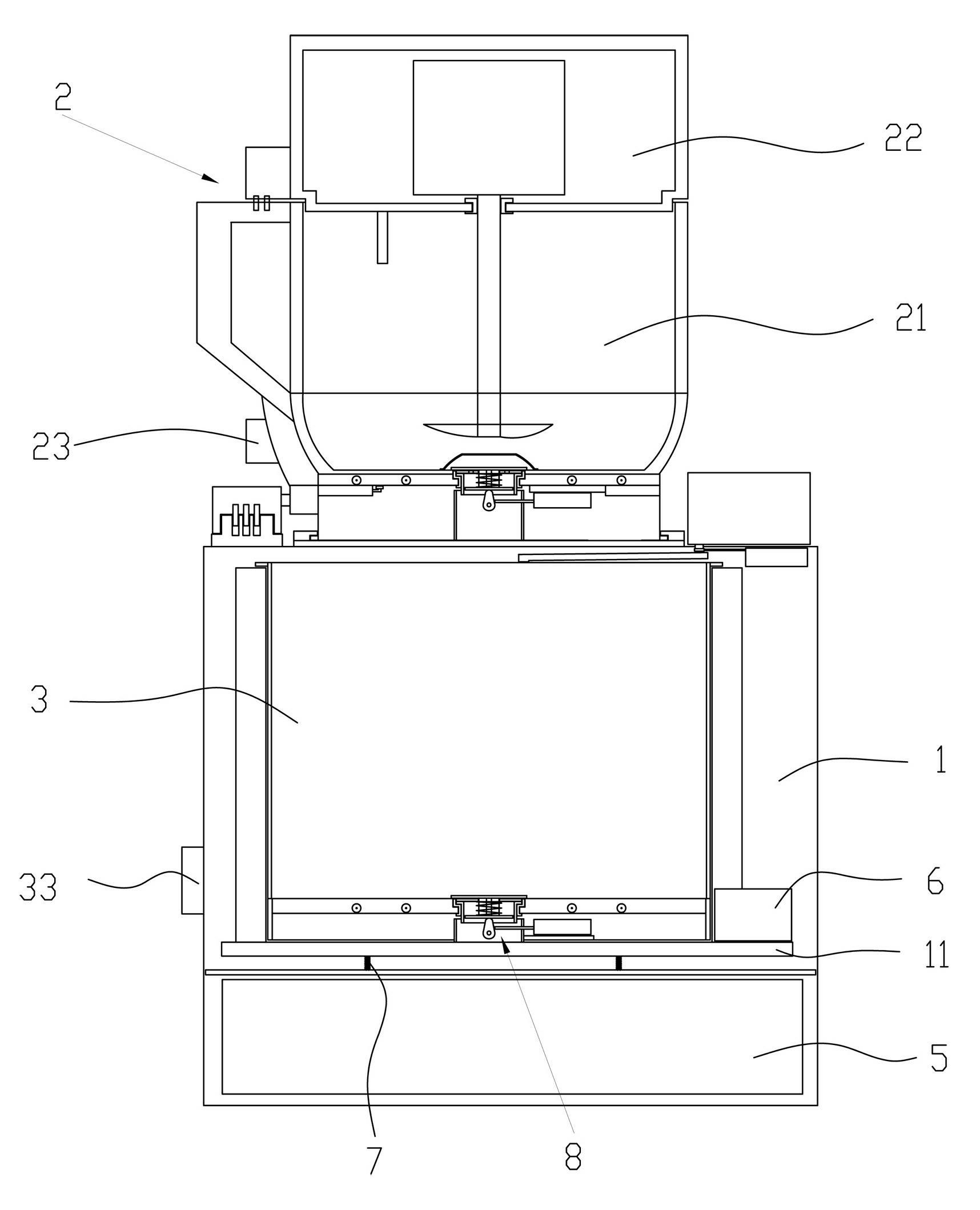

[0026] Such as figure 1 The shown household bean curd machine comprises a base 1 and a control circuit, and the base 1 is provided with a soymilk machine 2, a pointing bucket 3, a coagulant injection device for injecting a coagulant into the pointing bucket 3, and a The waste water pond 5 below the described slurry barrel 3 . The soybean milk machine 2 includes a cup body 21 and a machine head 22, the machine head 22 is covered on the cup body 21, a motor and a blade connected to the output shaft of the motor are arranged in the machine head 22, so The bottom end of the cup body 21 is provided with a slurry outlet hole communicating with the dispensing barrel 3, a valve body is arranged in the slurry outlet hole, and a valve drive for driving the opening and closing of the valve body is provided on the cup body 21. device. The valve driving device can be referred to the applicant's application on January 29, 2011, the application number is: 201120030777.4, and the applicatio...

specific Embodiment 2

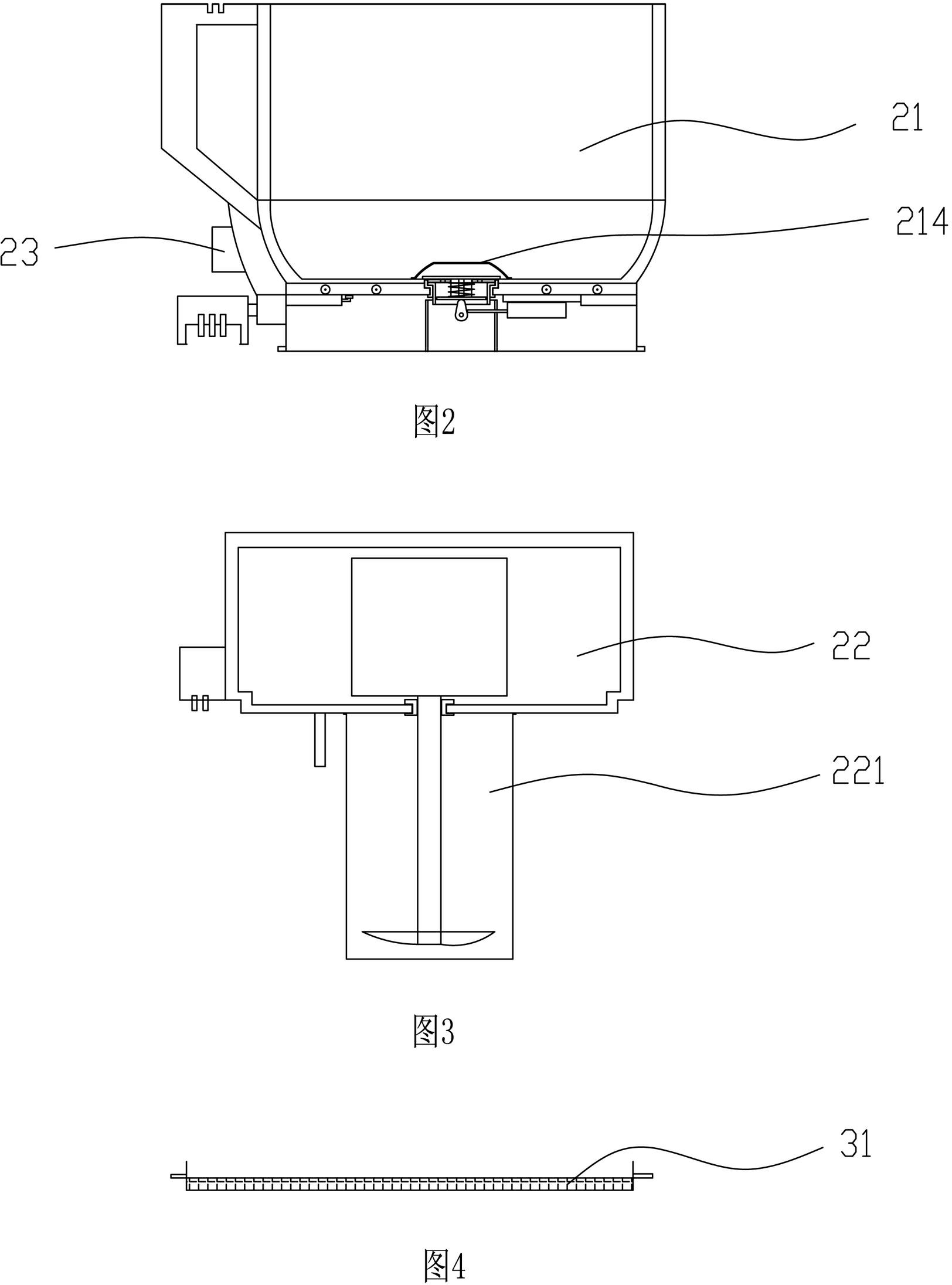

[0032] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that: the bottom end of the cup body 21 is movably provided with a filter cap 214 matching the pulp outlet. The purpose of setting the filter cap 214 is to filter out the bean dregs in the soybean milk through the filter cap 214, so that the made tofu is finer and tastes better.

[0033] The working process of making bean curd in this technical scheme is:

[0034] 1. Preparation before making tofu

[0035] First, prepare the coagulant for soybean milk and point pulp. The coagulant can be materials such as gluconolactone or gypsum (here, gluconolactone is used as an example). The machine head 22 is lifted, and an appropriate amount of beans and water are poured in, and then the machine head 22 is placed over the cup body 21, and the coagulant is poured into the coagulation box. Switch on the power supply of the household tofu machine, select the function key for making tofu,...

specific Embodiment 3

[0043] Such as image 3 As shown, the difference between this embodiment and the specific embodiment 1 is that a filter bucket 221 is movably arranged on the machine head 22 , and the crushing of beans by the blade is completed in the filter bucket 221 . The purpose of setting the filter screen barrel 221 is to filter out the bean dregs in the soybean milk through the filter screen barrel 221, so that the made tofu is finer and tastes better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com