Domestic bean curd manufacturing machine

A tofu machine and household technology, which can be used in home appliances, applications, kitchen utensils, etc., can solve the problems of uneven mixing of soymilk stock solution and coagulant, insufficient reaction, and poor quality of tofu, and achieve simple structure and hygienic quality. Good, economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

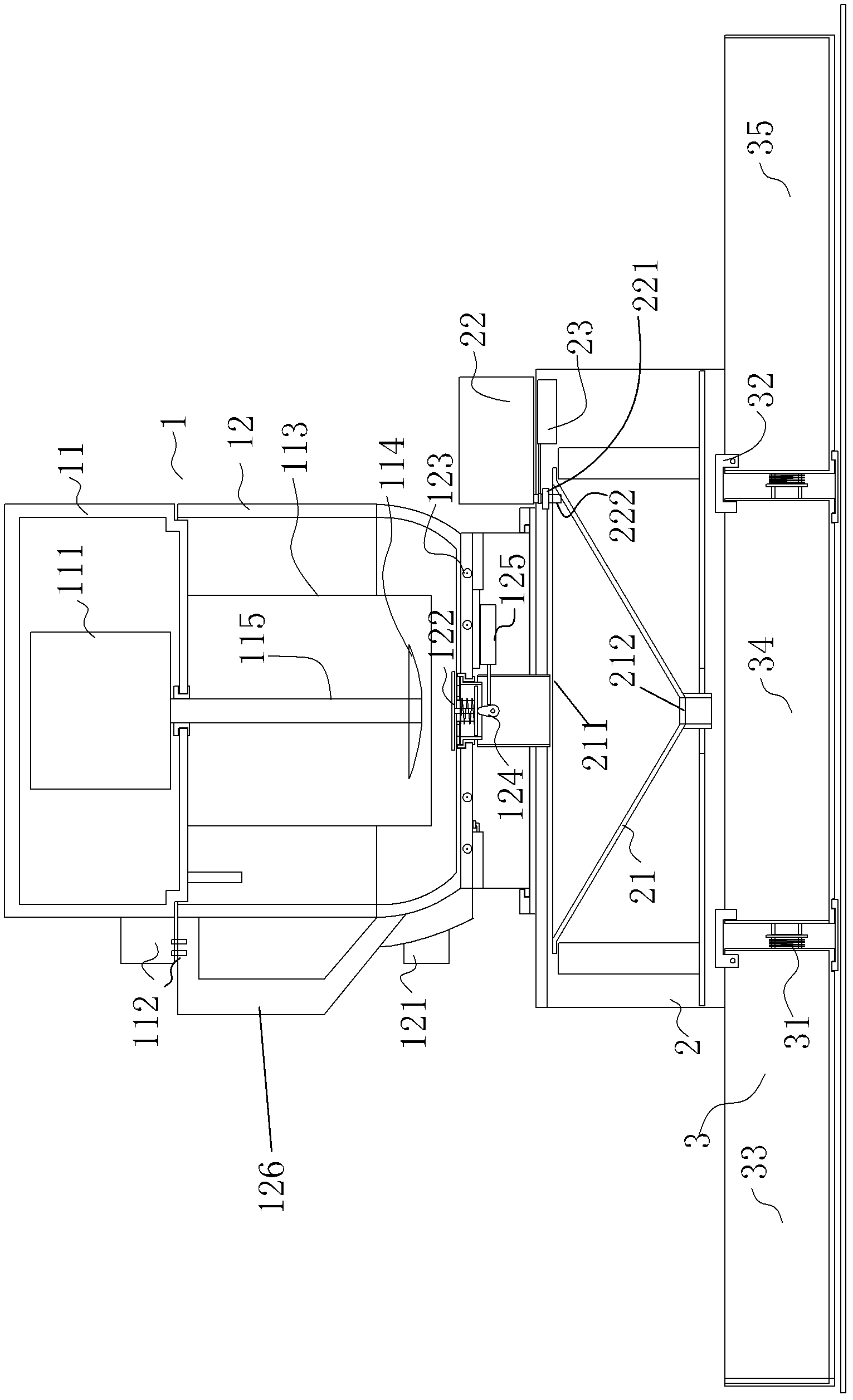

[0035] Such as figure 1 As shown, the diversion mixing device 21 is a conical funnel, the opening area of the slurry inlet 211 is larger than the bottom area of the cup body 12, and the slurry outlet 212 of the conical funnel is far smaller than the size of the slurry inlet 211. Cylindrical outlet, this outlet is facing in the tofu forming box 3, the coagulant injection device is located on the base 2, above the side of the tapered funnel, the liquid outlet 222 of the coagulant solution outflow pipe is placed in this The inner side of a conical funnel.

[0036] The tofu forming box 3 is composed of a first bean curd tank 33, a second bean curd tank 34 and a third bean curd tank 35 arranged side by side; The buckle 32 is provided with an interface 31 connecting it on the adjacent side of the adjacent tofu tank.

[0037] While the prepared soybean milk stock solution flows into the conical funnel through the first one-way valve 122, the control circuit instructs the second...

Embodiment 2

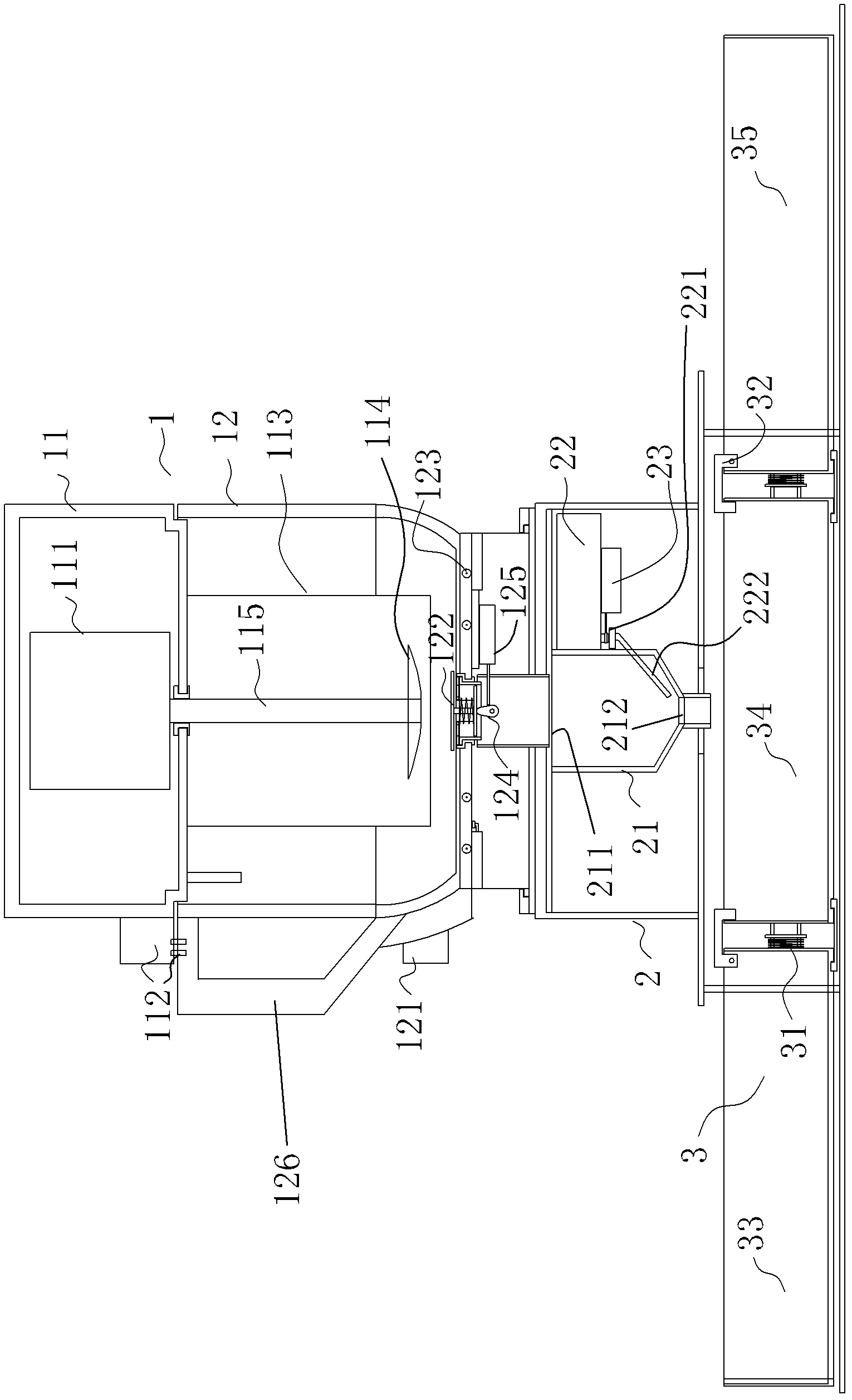

[0040] Such as figure 2 As shown, the diversion mixing device 21 is a cylindrical funnel, the opening area of the slurry inlet 211 is larger than the bottom area of the first one-way valve 122, and the slurry outlet 212 of the cylindrical funnel is smaller than the inlet. The cylindrical outlet of the slurry port 211, which is facing the tofu forming box 3, the coagulant injection device is located below the base 2, on the side of the cylindrical funnel, and the liquid outlet 222 of the coagulant solution outflow pipe Placed at the inner end of the slurry outlet 212 of the cylindrical funnel.

[0041] The tofu forming box 3 is composed of a first bean curd tank 33, a second bean curd tank 34 and a third bean curd tank 35 arranged side by side; The buckle 32 is provided with an interface 31 connecting it on the adjacent side of the adjacent tofu tank.

[0042] While the prepared soybean milk stock solution flows into the cylindrical funnel through the first one-way valve...

Embodiment 3

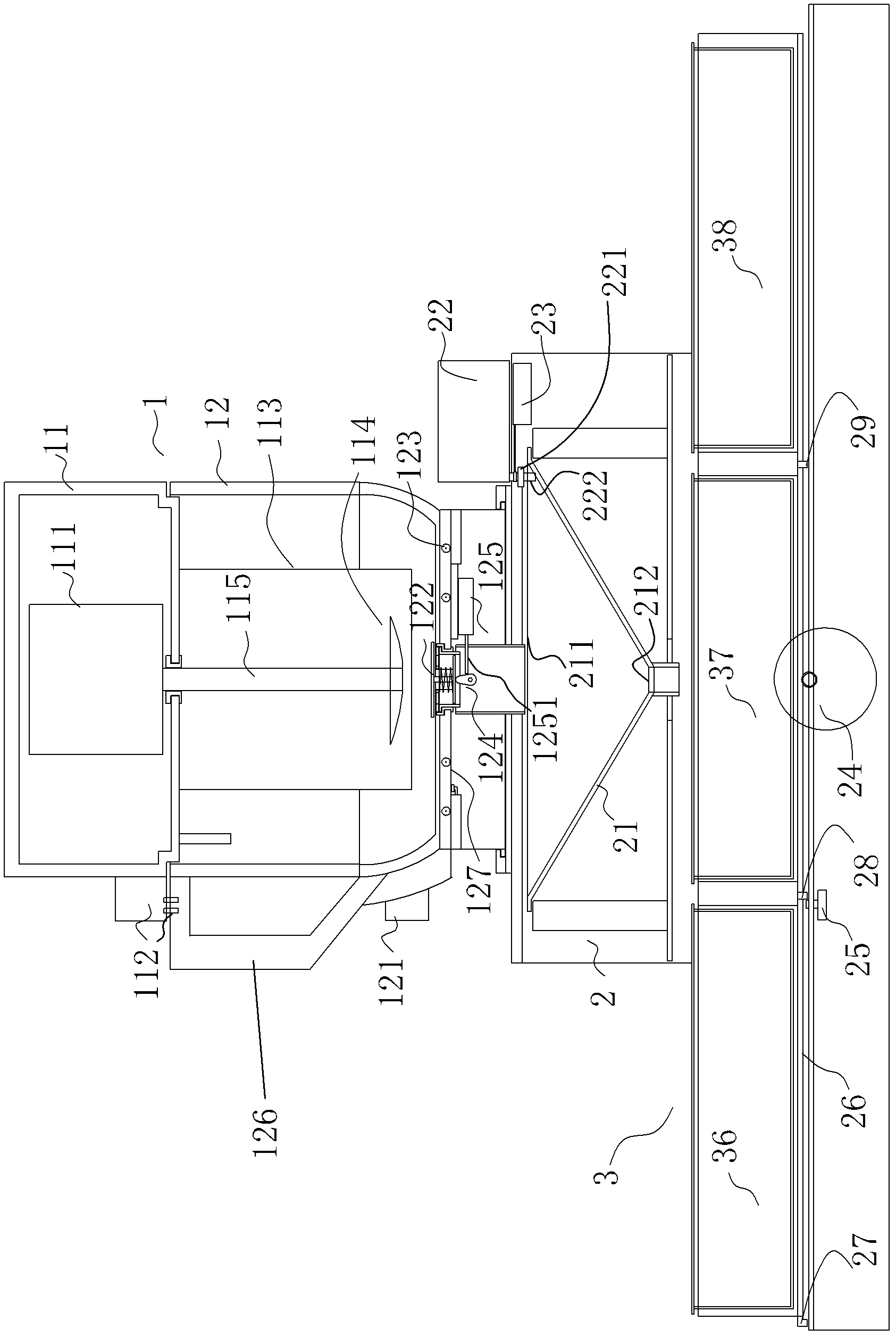

[0045] Such as image 3 As shown, the diversion mixing device 21 is a conical funnel, the opening area of the slurry inlet 211 is larger than the bottom area of the cup body 12, and the slurry outlet 212 of the conical funnel is far smaller than the size of the slurry inlet 211. Cylindrical outlet, this outlet is facing in the tofu forming box 3, the coagulant injection device is located on the base 2, above the side of the tapered funnel, the liquid outlet 222 of the coagulant solution outflow pipe is placed in this The inner side of a conical funnel.

[0046] Such as figure 2 As shown, the diversion mixing device 21 can also be a cylindrical funnel, the opening area of the slurry inlet 211 is larger than the bottom area of the first one-way valve 122, and the slurry outlet 212 of the cylindrical funnel is Smaller than the cylindrical outlet of the slurry inlet 211, this outlet is facing in the tofu forming box 3, and the coagulant injection device is located below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com