Patents

Literature

152results about How to "Improve fixation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of aromatic microcapsule finishing agent with double-layer wall materials

ActiveCN102127864ADense wall membraneFacilitated releaseMicroballoon preparationVegetal fibresFiberMelamine formaldehyde resin

The invention discloses a preparation method and an application of an aromatic microcapsule finishing agent with double-layer wall materials. The method is characterized by preparing the aromatic microcapsule through covering the lavender essence oil capsule core material with the melamine-formaldehyde resin cyst wall and mixing the aromatic microcapsule with an adhesive (VAE) vinyl acetate-ethylene solution as the external wall material, thus generating the aromatic microcapsule finishing agent with double-layer wall materials. Aroma after-finishing on is carried out on the cotton fabrics by adopting the finishing agent and a padding method and the aromatic microcapsule is firmly fixed on the fibers of the cotton fabrics via own external wall with good adhesiveness, so the cotton fabrics have lasting aroma.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Inkjet Recording Ink

InactiveUS20070263054A1Improve discharge stabilityGood storage stabilityMeasurement apparatus componentsInksPolymer scienceMeth-

The present invention aims to provide an ink for ink jet recording that is excellent in storage stability and discharge stability and attains high coloration on regular paper or gloss paper and high glossiness on gloss paper. The ink for ink jet recording of the invention includes: water; and a pigment dispersed by using a polymer which is obtained by polymerizing at least 50% by weight or more of benzylacrylate and 15% by weight or less of (meth)acrylic acid as components of the polymer and has an acid value of no less than 50 mgKOH / g and no more than 120 mgKOH / g and a weight average molecular weight of no less than 10000 and no more than 120000.

Owner:SEIKO EPSON CORP

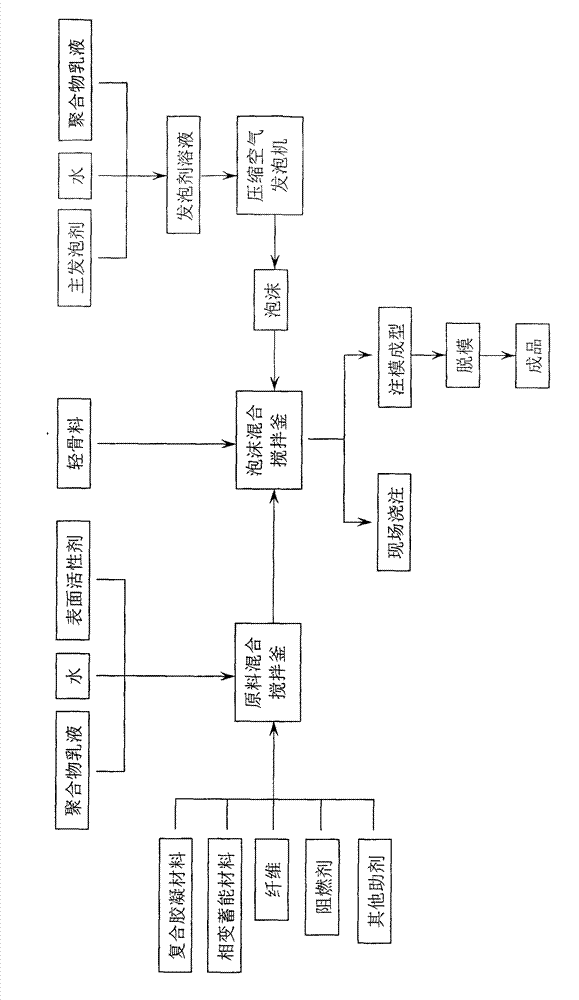

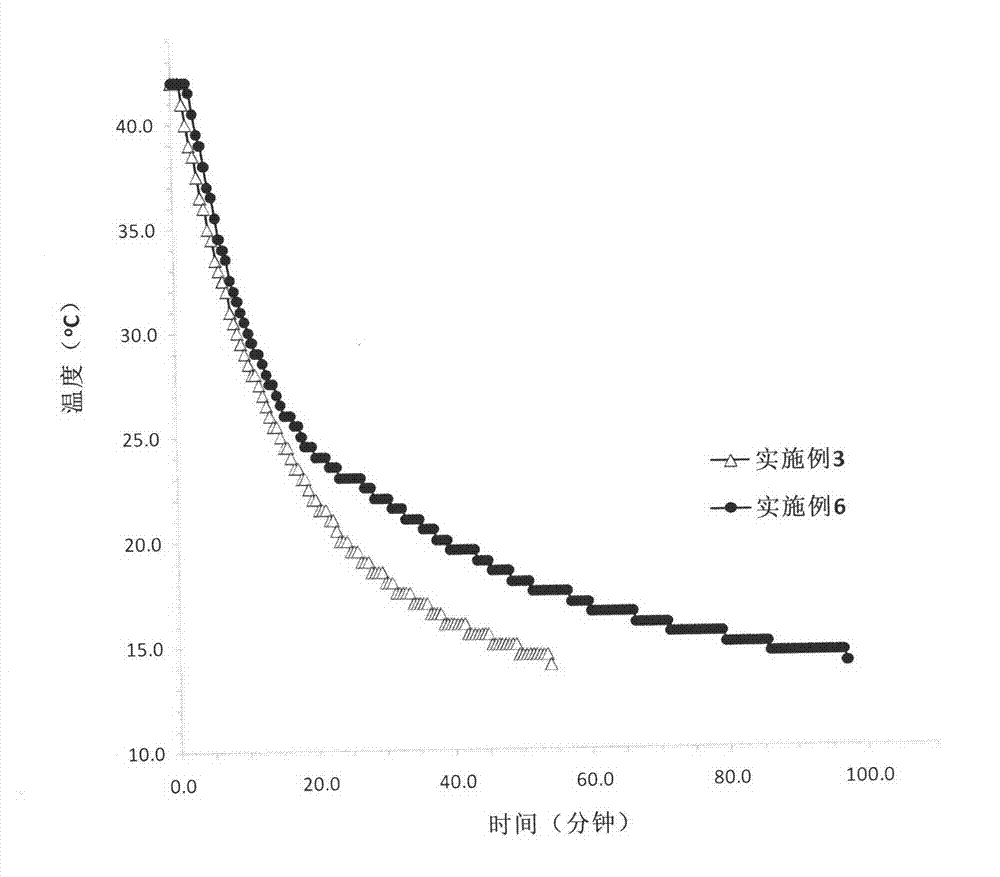

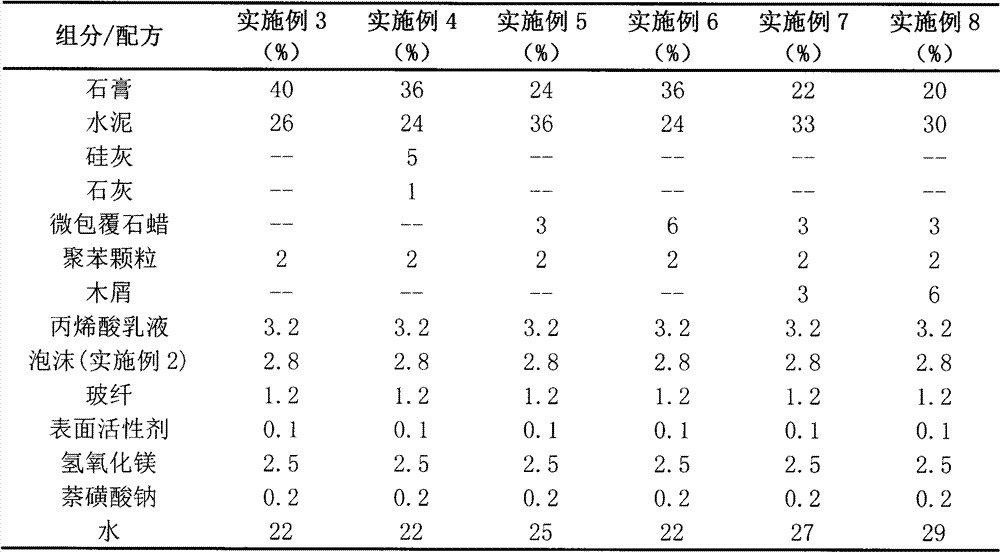

Energy storage energy-efficient foam gypsum cement composite material and preparation method thereof

ActiveCN102765959AImprove fire performancePrevent high temperature penetrationCeramicwareInsulation layerThermal insulation

The invention relates to an energy storage energy-efficient foam gypsum cement composite material and a preparation method thereof. The formula thereof is composed of a composite cementing material, lightweight aggregate, a phase change energy storage material, polymer latex, foam and a foaming agent. The composite cementing material is mainly composed of semi-hydrated gypsum and cement. The preparation method thereof comprises the steps of: preparing a foaming agent solution to prepare stable foam; thoroughly mixing water, polymer emulsion and other liquid state components with the composite cementing material, the phase change energy storage material and other additives such as solid-state components; and sending the solid-liquid mixed slurry to a foam-mixing kettle filled with the lightweight aggregate, while introducing the foam, to prepare the foam gypsum cement composite slurry. The inorganic composite foam material of the present invention has an energy storage function absorbing heat during the day and radiating heat at night, so as to effectively maintain a comfortable indoor temperature, is fire-proof, heat preservative, humidity-adjustable, good in water-resistance, and high in strength, and can be used for manufacturing fireproof insulation layers or fireproof insulation zones for interior and exterior walls of buildings, heat insulation, fire proof and heat preservation wallboards, door panels and core materials, steel structure fireproof cladding materials and the like.

Owner:南京依科国特新材料科技有限公司

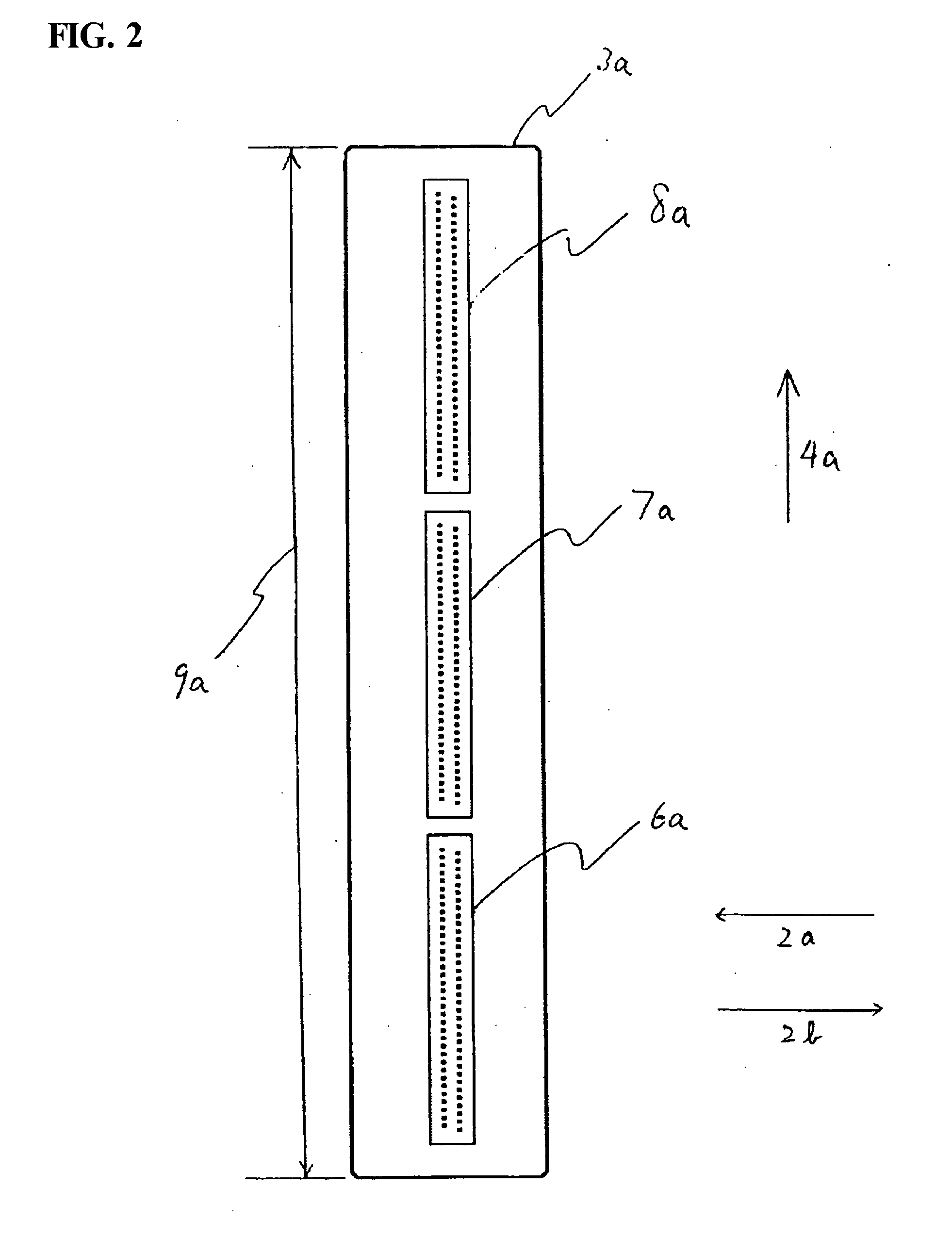

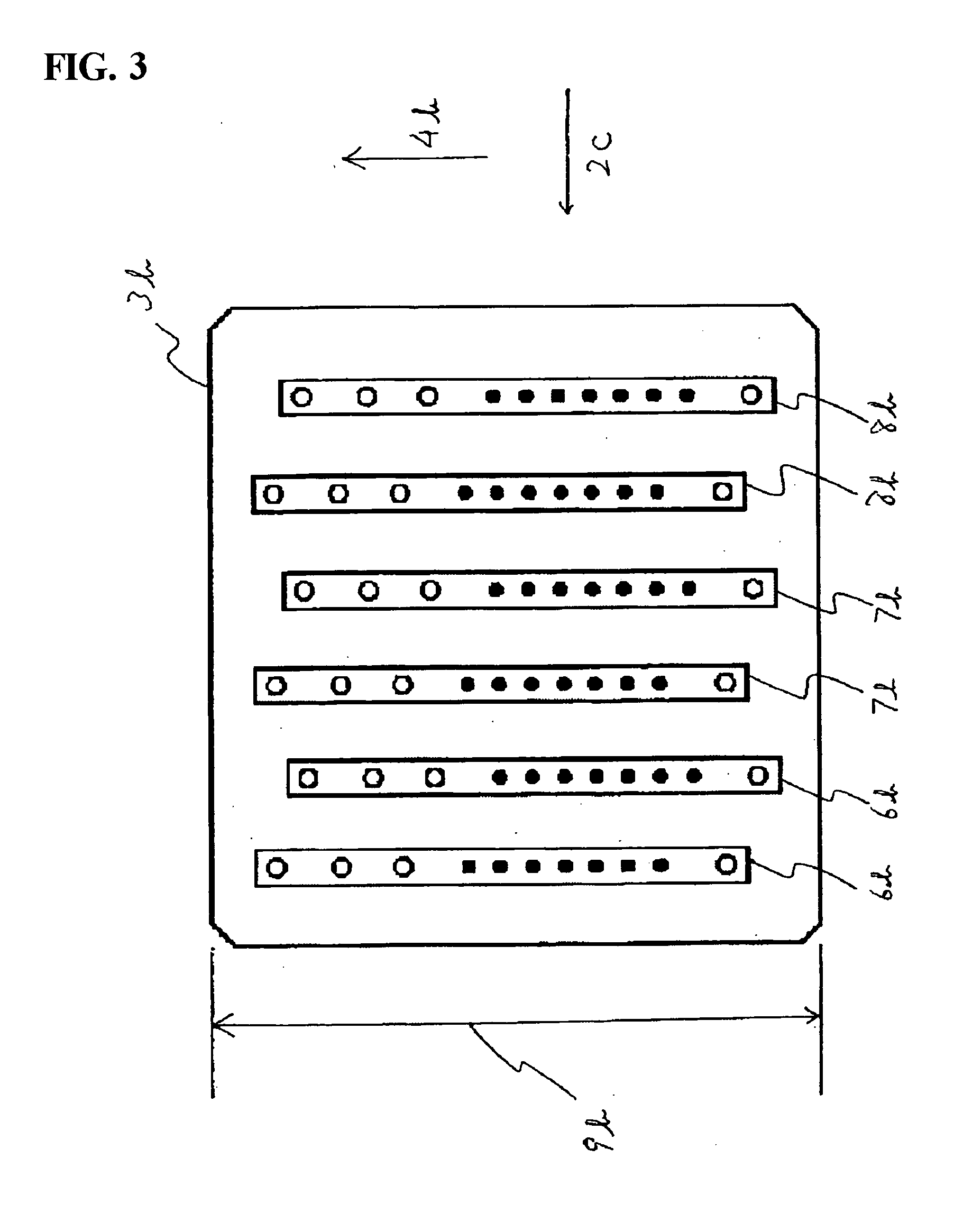

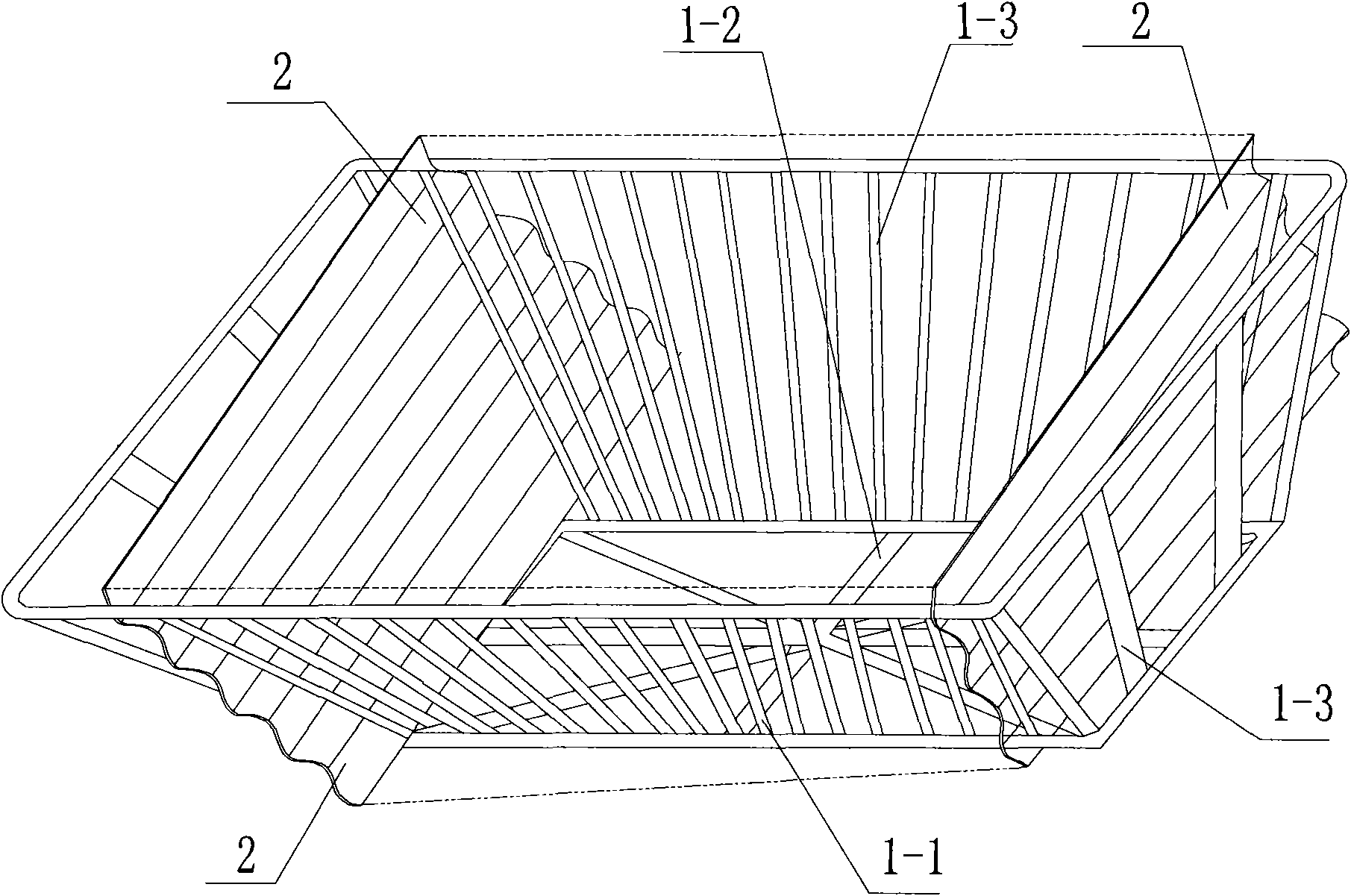

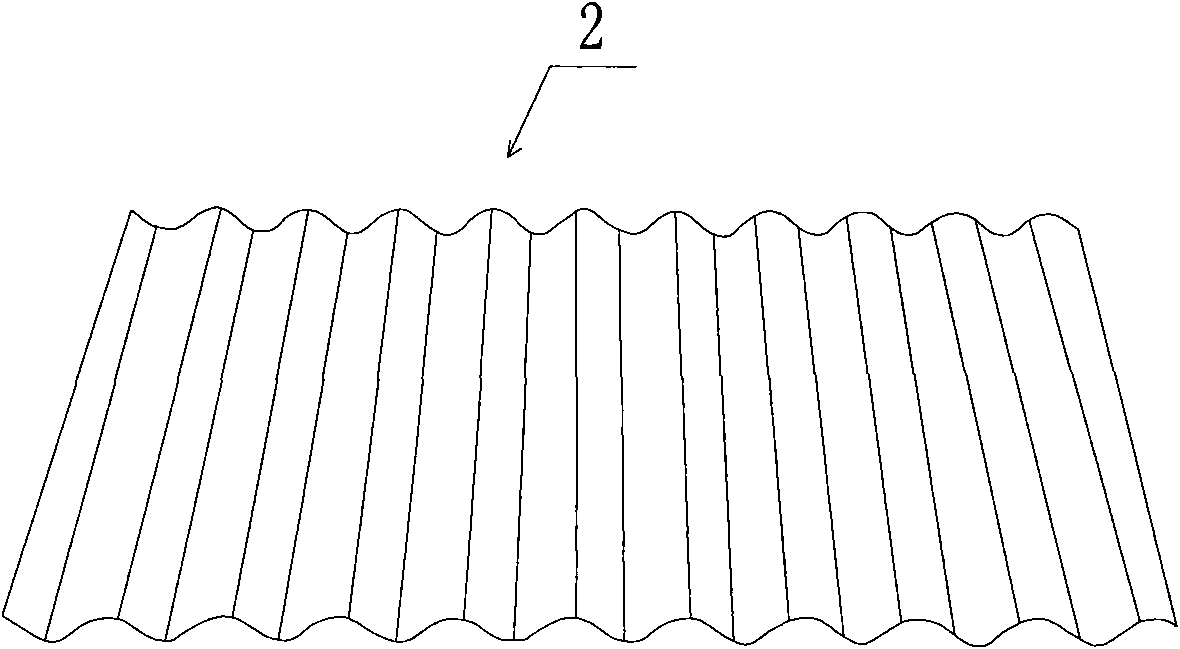

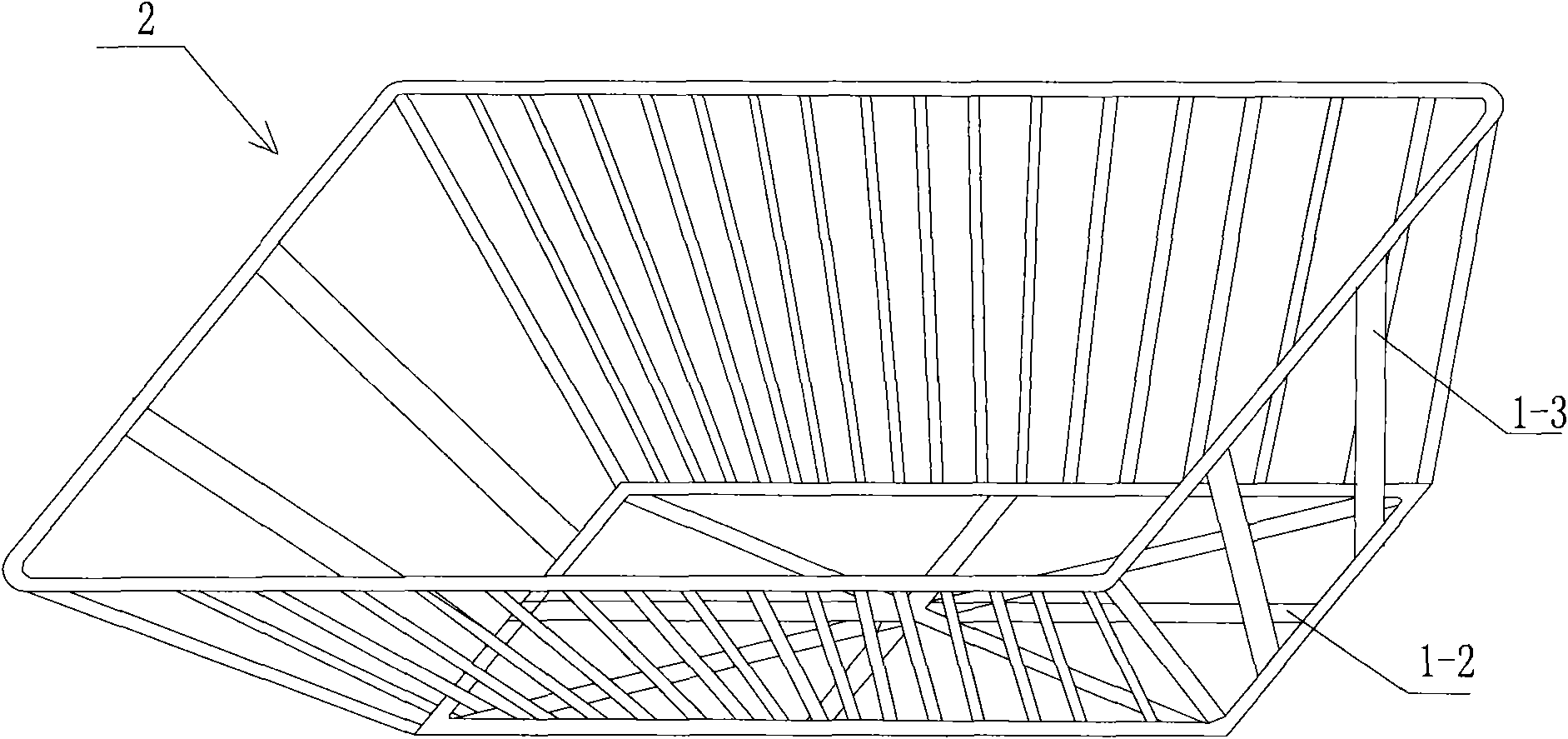

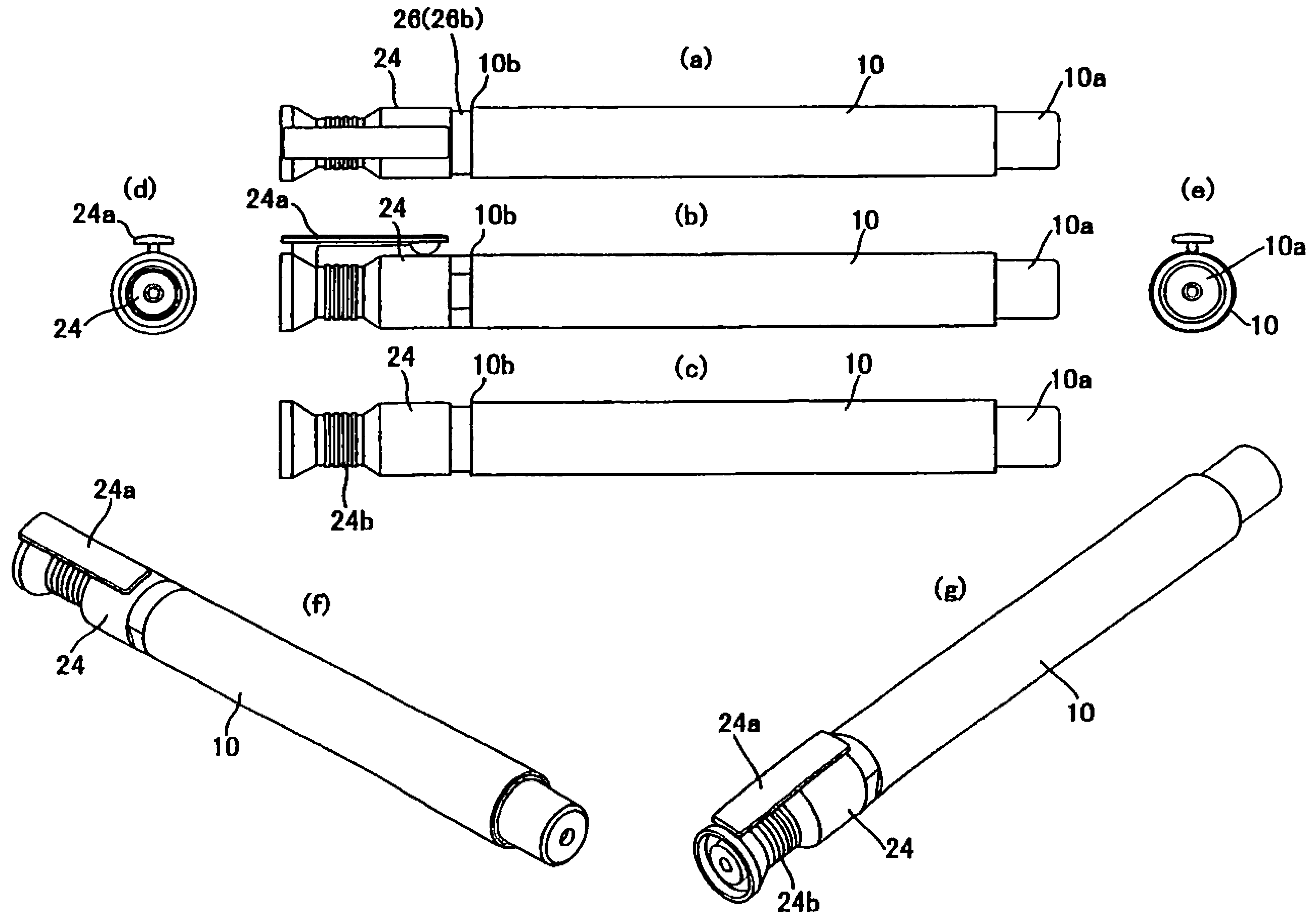

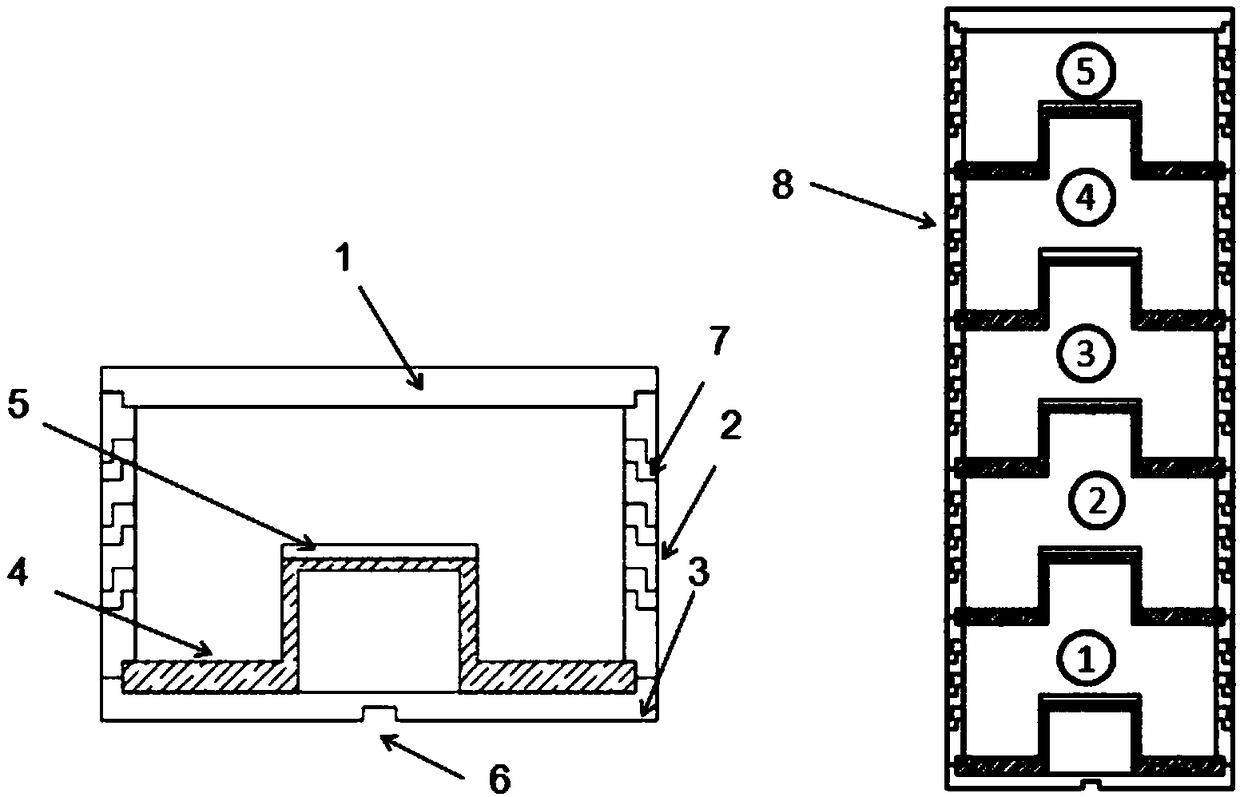

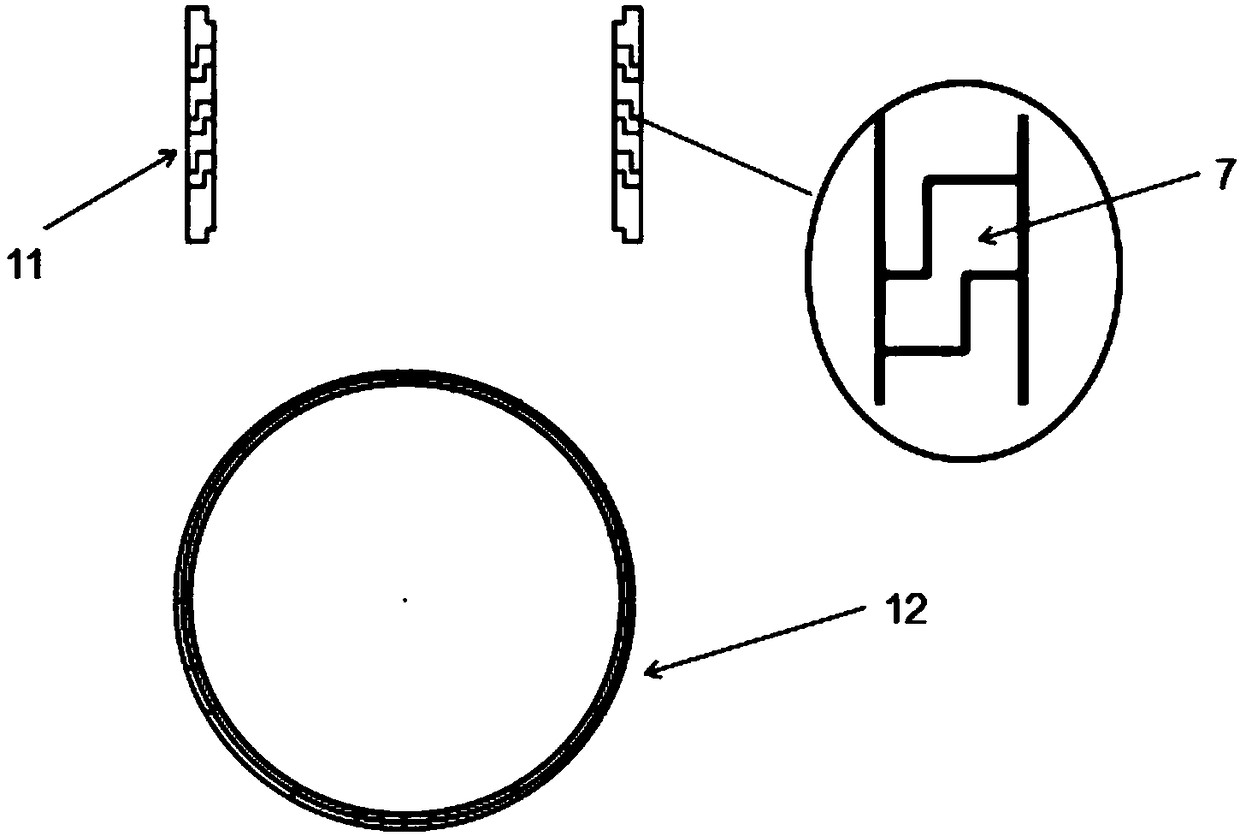

Method for culturing monomeric oyster seeds and seed collector

InactiveCN101773079AEasy to useExcellent adhesionClimate change adaptationPisciculture and aquariaOysterMonomer

The invention provides a method for culturing monomeric oyster seeds and a seed collector. The problems such as poor seed fixation effect, difficult substrate removal and the like in the prior art can be solved. By using a plastic corrugated plate as the fixation substrate of the monomeric oyster seeds in the invention, the problems such as unsatisfactory seed collection effect, difficult substrate removal, easy breakage of the oyster seeds, mutual conglomeration and attachment of oysters and the like in the prior art are solved.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Novel tubular hard surfacing material

ActiveCN101380698ANot easy to fall offImprove wear resistanceWelding/cutting media/materialsSoldering mediaEngineering toolAlloy

The invention provides a novel tubular hard-surface resurfacing welding material which includes a tubular skin and filling powder. The novel tubular hard surface resurfacing welding material includes the components as follows: 20 to 40 percent of steel as well as 60 to 80 percent of filling powder; the components of the filling powder is as follows: 35 to 75 percent of spherical hard alloy grains, 15 to 40 percent of carbonated casting tungsten grains, the surface of which are processed, 5 to 20 percent of spherical carbonated casting tungsten grains, 2 to 6 percent of SiMn alloy powder, 0.2 to 0.6 percent of resin powder as well as 0.1 to 2 percent of metal Nb. The spherical hard alloy grains, the carbonated casting tungsten grains and the spherical carbonated casting tungsten grains with thermal stability are adopted, thus remarkably improving the wear resistance and the impact resistance of a resurfacing welding layer; less Nb element is added to improve the resurfacing welding manufacturability, thereby improving the intensity and the toughness of a substrate metal, enhancing the anti-impact capacity of the resurfacing welding layer and the fixing capacity to the hard grains as well as prolonging the service life of the resurfacing welding layer. The tubular hard surface resurfacing welding material is widely applied to the wear-resistance reinforcement on the working surfaces like the gear surface of a steel gear roller bit, a back cone, a palm tip and the other engineering tools.

Owner:SHAREATE TOOLS

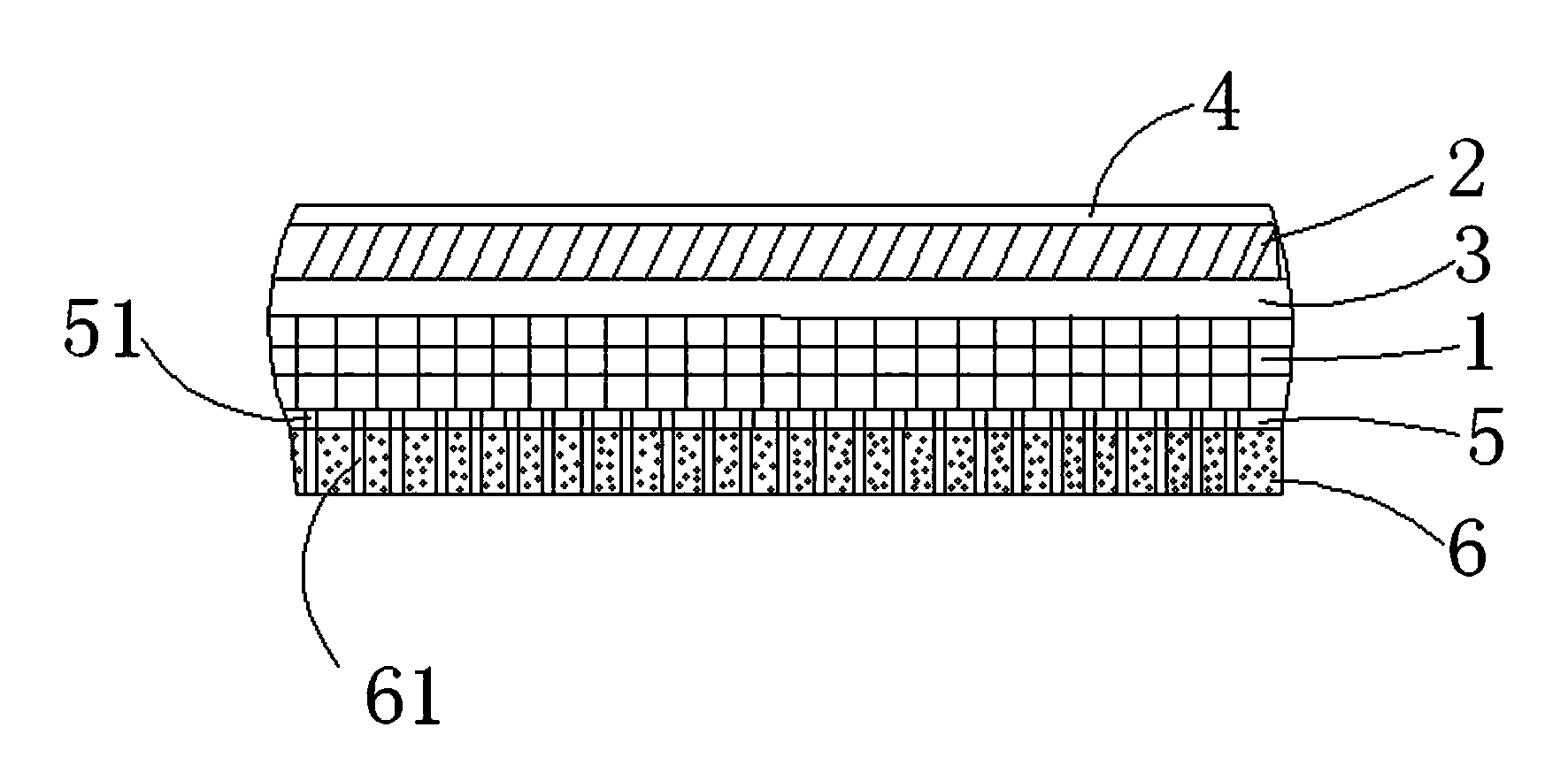

Novel foam composite wound dressing

ActiveCN103637877AStrong ability to lock waterWounds heal fasterNon-adhesive dressingsAdhesive dressingsMoistureBackflow

The invention relates to a medical dressing, in particular to a novel foam composite wound dressing. The novel foam composite wound dressing includes a water absorbing layer and a water locking layer arranged above the water absorbing layer in a covering manner, wherein a transitional layer is arranged between the water absorbing layer and the water locking layer, a waterproof layer is arranged above the water locking layer in a covering manner, and a polyurethane film layer is arranged below the water absorbing layer. The novel foam composite wound dressing is neither toxic nor irritating to human bodies; moisture around a wound can be quickly absorbed through the water absorbing layer, and absorbed and locked through the water locking layer, which prevents the moisture backflow, guarantees a suitable temperature and a suitable humidity of the wound, prevents the soaking reaction of the skin at the application position, and achieves rapid healing of the wound; the application through silica gel achieves good fixation effect and low falling possibility, and avoids the skin injury by pulling.

Owner:吴康平

Plant oil-based offset lithographic printing ink formula and preparation method thereof

The invention provides a plant oil-based offset lithographic printing ink formula and a preparation method thereof. The plant oil-based offset lithographic printing ink formula comprises, by weight, 30-35 parts of soybean oil, 19-29 parts of tung oil, 2-5 parts of soya alkyd resin, 30-35 parts of rosin-modified phenolic resin, 2-6 parts of a dry conditioning agent, 2-5 parts of a gelling agent, 18-28 parts of a pigment, 5-10 parts of a filler, 7-7.5 parts of other auxiliary agents and 2-5 parts of a drier. The preparation method comprises 1, binder preparation, 2, accessory material addition, 3, printing ink rolling and 4, re-rolling. The plant oil-based offset lithographic printing ink formula has the advantages of good rheological performances, fast curing performances, passing performances, good glossiness and good stability and is especially suitable for newspaper and periodical printing.

Owner:TIANJIN ANGEL CHEM GRP

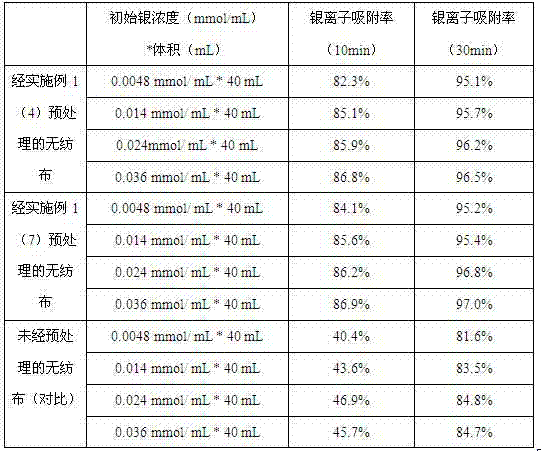

Preparation method of nano silver chloride/chitosan fiber anti-bacterial dressing

ActiveCN104324407AFirm and smooth surfaceHydrophobicAbsorbent padsBandagesPolymer scienceWound dressing

The invention discloses a preparation method of a nano silver chloride / chitosan fiber anti-bacterial dressing. The method includes following steps: (1) pretreatment of a surface of a chitosan fiber nonwoven cloth: spraying an acid solution onto the surface of the chitosan fiber to enable the acid solution to infiltrate into the surface of the nonwoven cloth, treating the nonwoven cloth for 1-5 min and then washing the nonwoven cloth with deionized water; (2) soaking the pre-treated nonwoven cloth in a silver nitrate solution with a concentration of 0.0048-0.036 mmol / mL with a normal-temperature shaking operation for 30 min; (3) draining the nonwoven cloth and air-drying the nonwoven cloth until the water content is 30-40%; (4) uniformly spraying a 0.036-0.27 mmol / mL sodium chloride solution having an equal saturate water absorption amount onto the surface of the nonwoven cloth, wherein molar number of the sodium chloride is 1.2-1.5 times than that of adsorbed silver, and carrying out a reaction for 5-10 min; and (5) spraying deionized water and quickly washing the nonwoven cloth, draining the nonwoven cloth and vacuum-drying the nonwoven cloth at 50-60 DEG C. The preparation method is high in silver recycle ratio. A nano silver chloride anti-bacterial material is stable in physical and chemical performances, is excellent in anti-bacterial performance or bacteria-inhibiting peroformance, is good in fixation performance of silver chloride particles to the chitosan fiber, and can be used as a medical wound dressing.

Owner:FUZHOU UNIV

Ink composition for ink jet recording

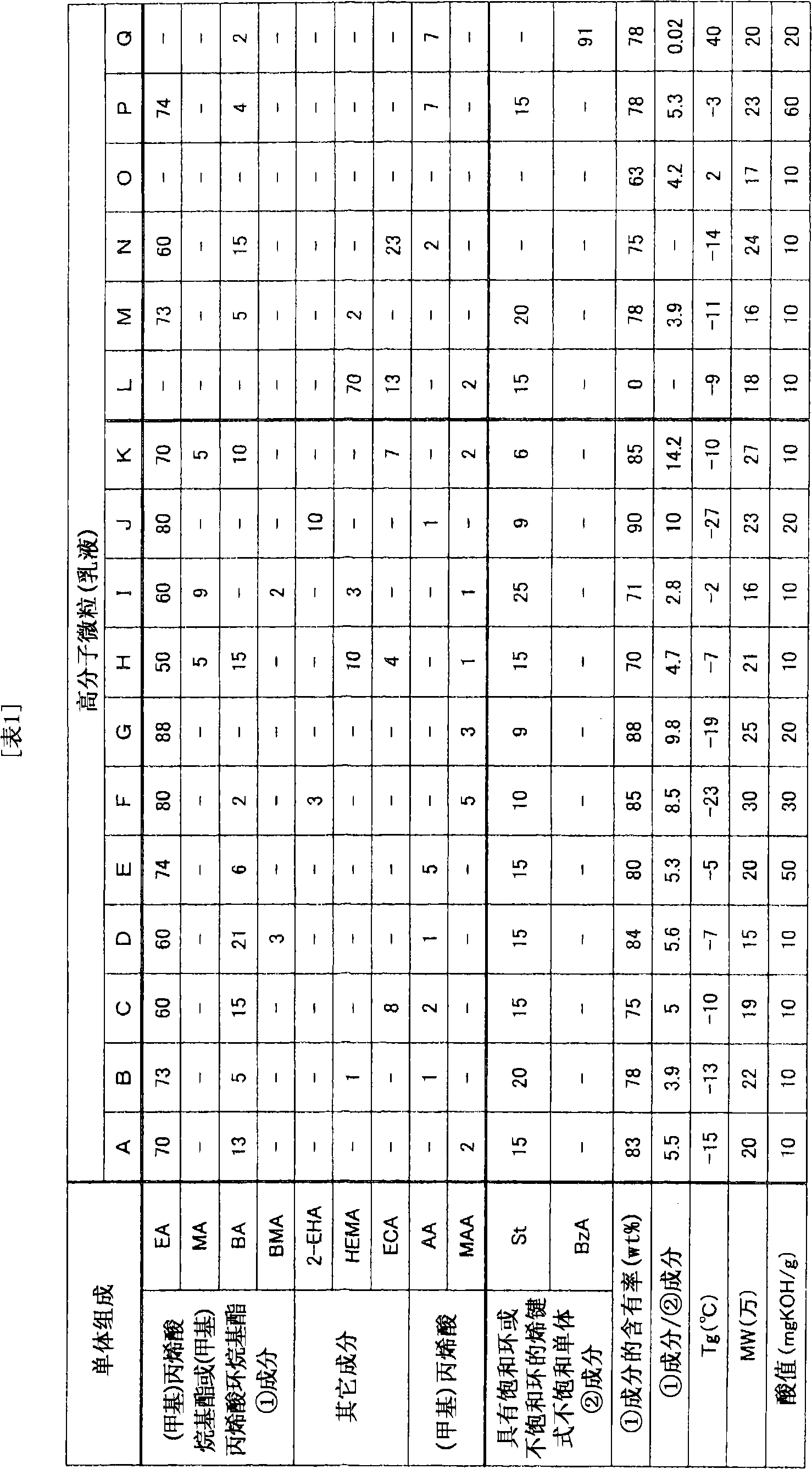

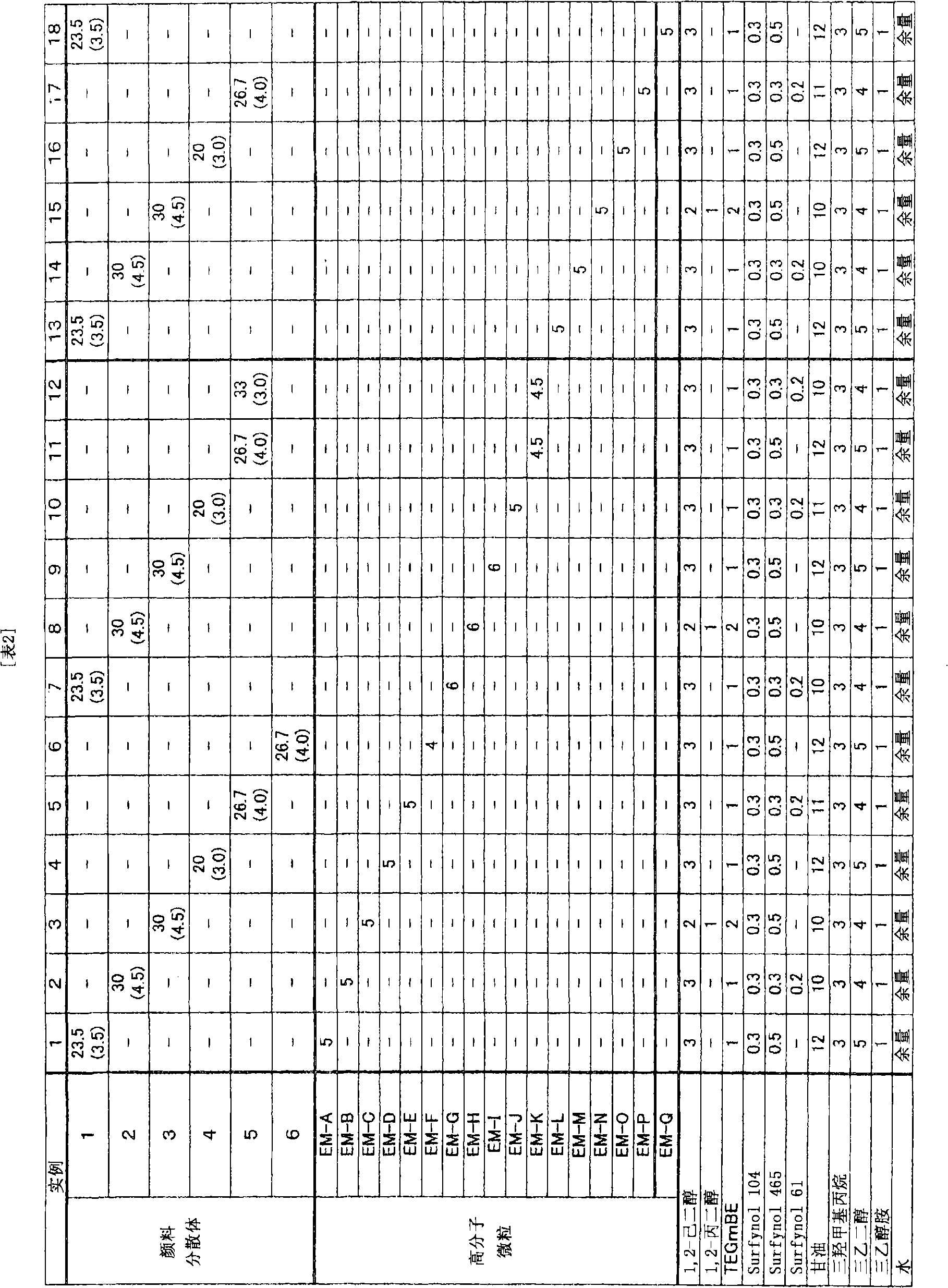

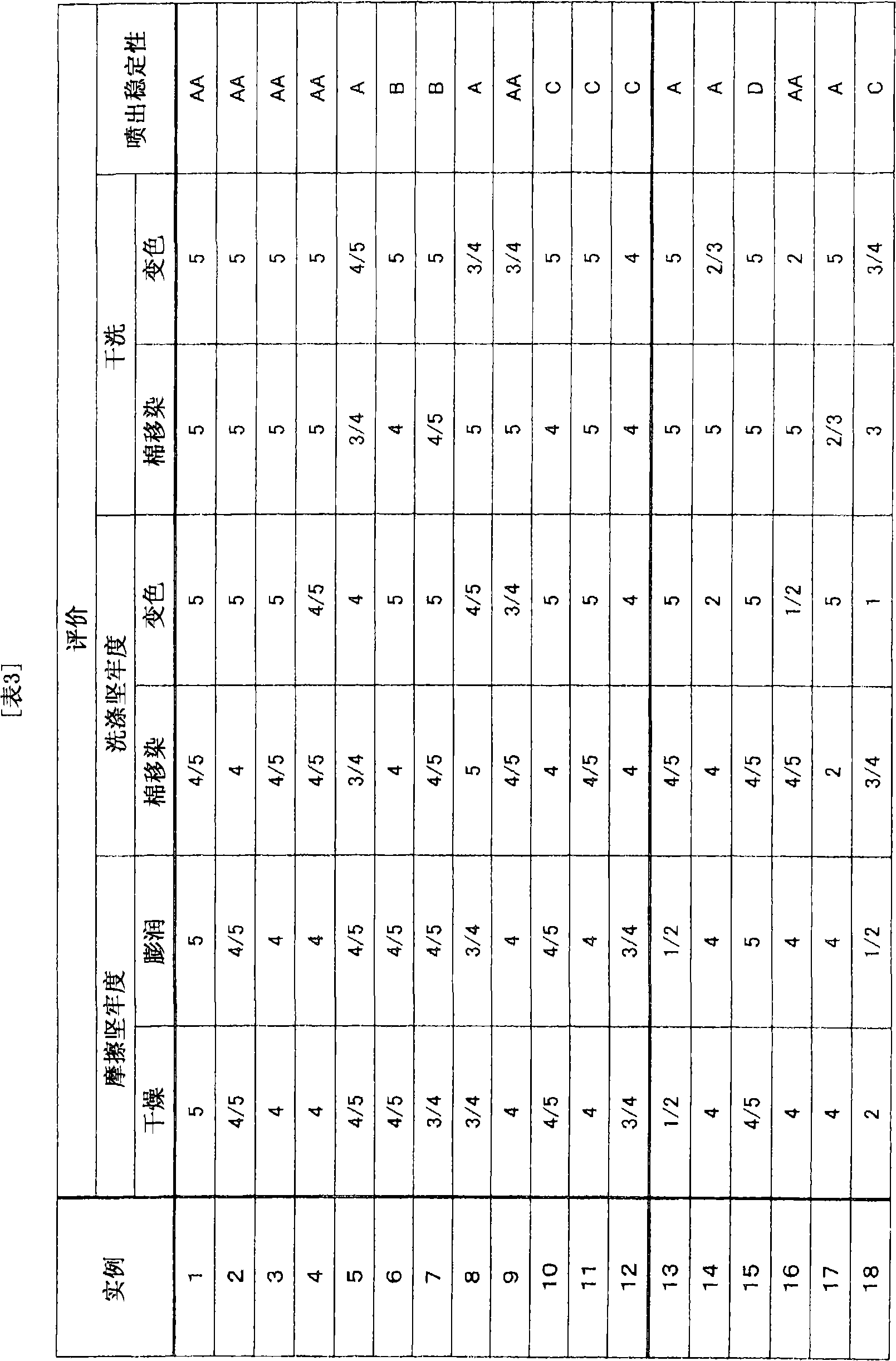

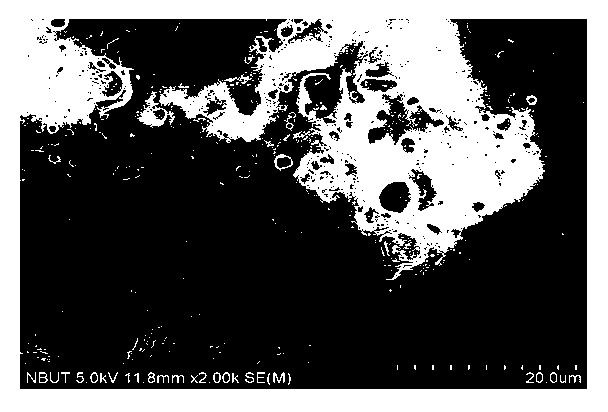

ActiveCN101880494AGood colorImprove fixation effectDuplicating/marking methodsInksWater dispersibleAcid value

The present invention provides an ink composition for ink jet recording, having excellient color rendering property and coating property, excellient jet stability and jam recovering property. The ink composition comprises a dispersoid comprising a water-dispersible a pigment and polymer microparticles, wherein the average particle diameter of the dispersoid is 20 to 300 nm, wherein the polymer microparticles comprise a copolymer comprising (i) at least 70% by weight of alkyl (meth) acrylate repeating units including (ia) ethyl acrylate repeating units and / or cyclic alkyl (meth) acrylate repeating units, and (ib) (meth) acrylic acid repeating units, and (ii) repeating units of an ethylene based unsaturated monomer having a saturated or an unsaturated ring, and wherein the glass transition temperature of the polymer microparticles is 0 DEG C or less and the acid value thereof is 50 mgKOH / g or less.

Owner:SEIKO EPSON CORP

Seedling culture method by using interaction of two plant seedlings

ActiveCN102138447AImprove fixation effectStrong crack resistanceCultivating equipmentsHorticulture methodsPlant rootsVernalization

The invention relates to a seedling culture method by using interaction of two plant seedlings, which comprises the following concrete steps: seeding the seeds of one kind or two or more kinds of plants (interaction plants) and the seeds of a plant (target plant) which is planted in a seedling transplanting way together in the same hole of a seedling tray; after the seeding, covering the hole with a matrix; putting the hole in an agricultural film tunnel or greenhouse; after the seedling of the plant emerges, uncovering the film or opening the tunnel to train the seedling until the plant root system combines the matrix into a tight bowl body; removing the interaction plants by use of a selective herbicide or preventing jointing of the interaction plants by use of vernalization; and then lifting and transplanting the seedling. The invention enhances the strength of the bowl body by use of the root system of the interaction plants so as to prevent easy loosening of the bowl body, shortens the rejuvenation period after planting and realizes low production cost.

Owner:HENAN ACAD OF AGRI SCI

Viscose filament yarn of feather keratin and bamboo fiber and method for producing same

ActiveCN102877158ANo pollution in the processGood environmental protection functionArtificial filament physical treatmentConjugated cellulose/protein artificial filamentsEngineeringViscosity

The invention relates to a viscose filament yarn of feather keratin and bamboo fiber and a method for producing the viscose filament yarn and belongs to the field of materials in textile industry. The invention aims to solve the problem that the conventional technology is not suitable for producing viscose filament yarns of feather keratin and bamboo fiber and provide viscose filament yarn of feather keratin and bamboo fiber and a process method for producing the same. The viscose filament yarn is produced by mixing 1 to 30 weight percent of feather keratin fluid and 70 to 99 weight percent of a bamboo fiber solution, and performing static co-mixing, spinning, solidification and post-treatment; and an aid is added for initiation, so the viscosity of bamboo is lowered, and the viscosity requirement on spinning is met by uniformly mixing the keratin fluid and the viscose.

Owner:YIBIN SPARK NEW FIBER CO LTD

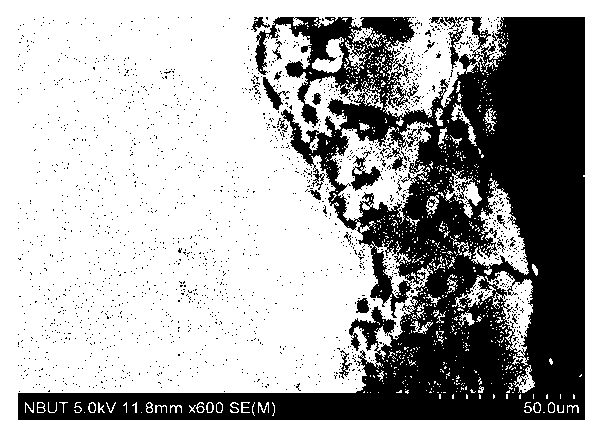

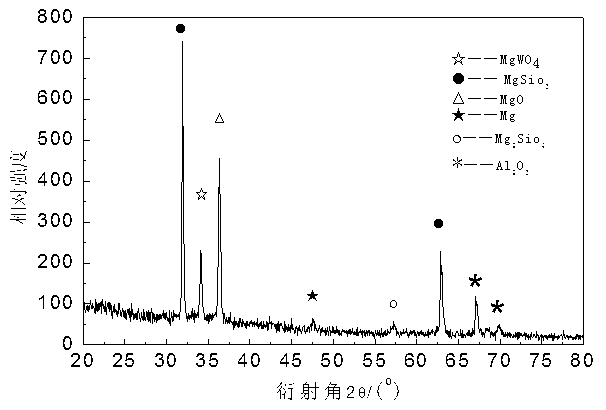

Method for coating film on magnesium alloy plate by microarc oxidation

The invention relates to a method for coating a film on a magnesium alloy plate by microarc oxidation. According to the method, the film is coated on the magnesium alloy plate in electrolyte of sodium silicate, sodium tungstate, glycerol, sodium hydroxide and alumina hydrocolloid; during film coating, the film is coated in the electrolyte of sodium silicate, sodium tungstate, glycerol and sodium hydroxide under the action of pulse direct -current electric field; then alumina hydrocolloid is added to the electrolyte, and a composite film layer is formed on the surface of the magnesium alloy plate; the thickness of the film layer reaches 75 mu m; the composite film layer can be adhered firmly and is high in compactness and corrosion resistance, and few holes are formed on the surface of the composite film layer; the method for coating the film is advanced in process, data is detailed and accurate, the film layer is high in thickness, fixation performance and compactness and does not fall easily; and the invention provides an effective method for coating the film on the surface of the magnesium alloy plate.

Owner:TAIYUAN UNIV OF TECH

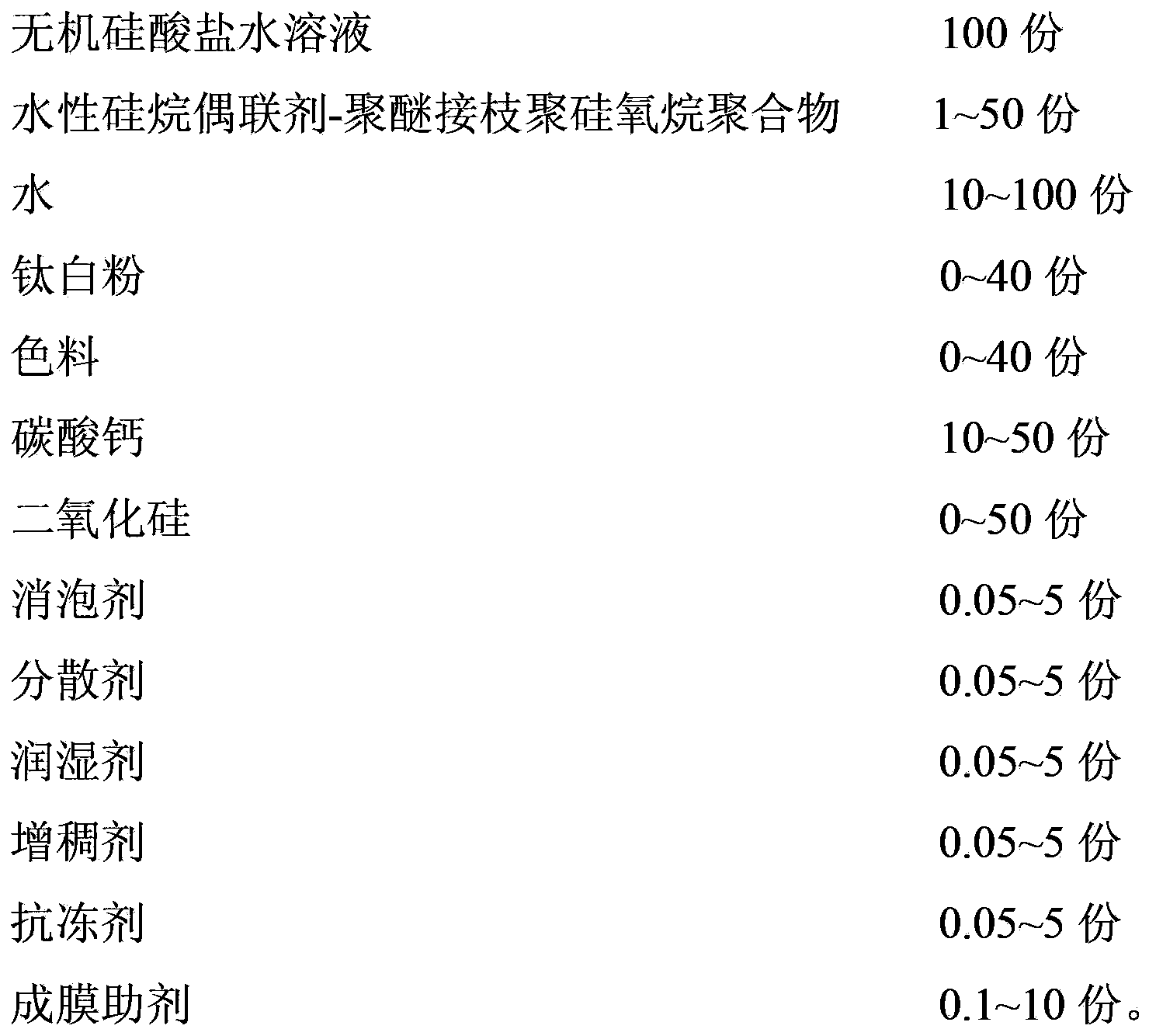

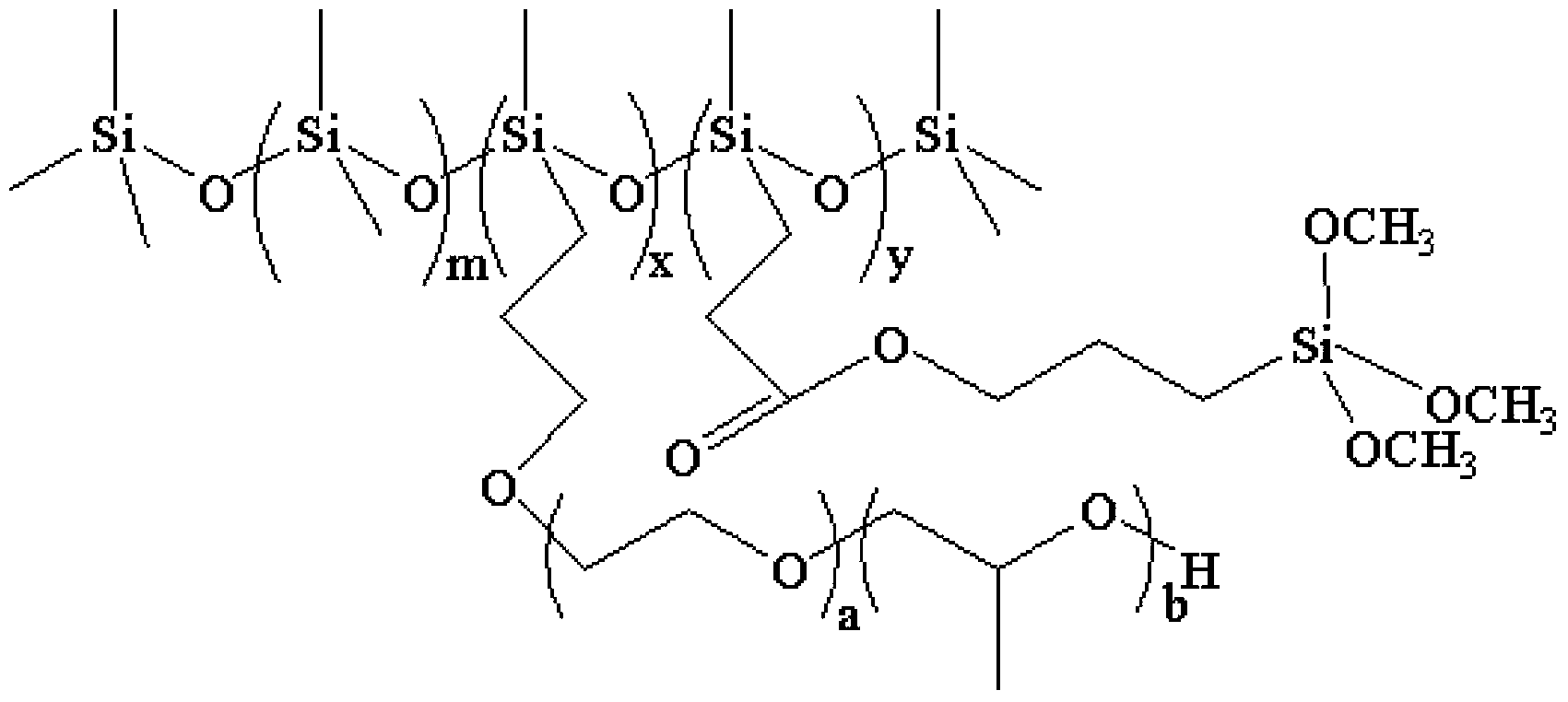

Hydrous silane coupling agent-polyether grafted polysiloxane polymer coating

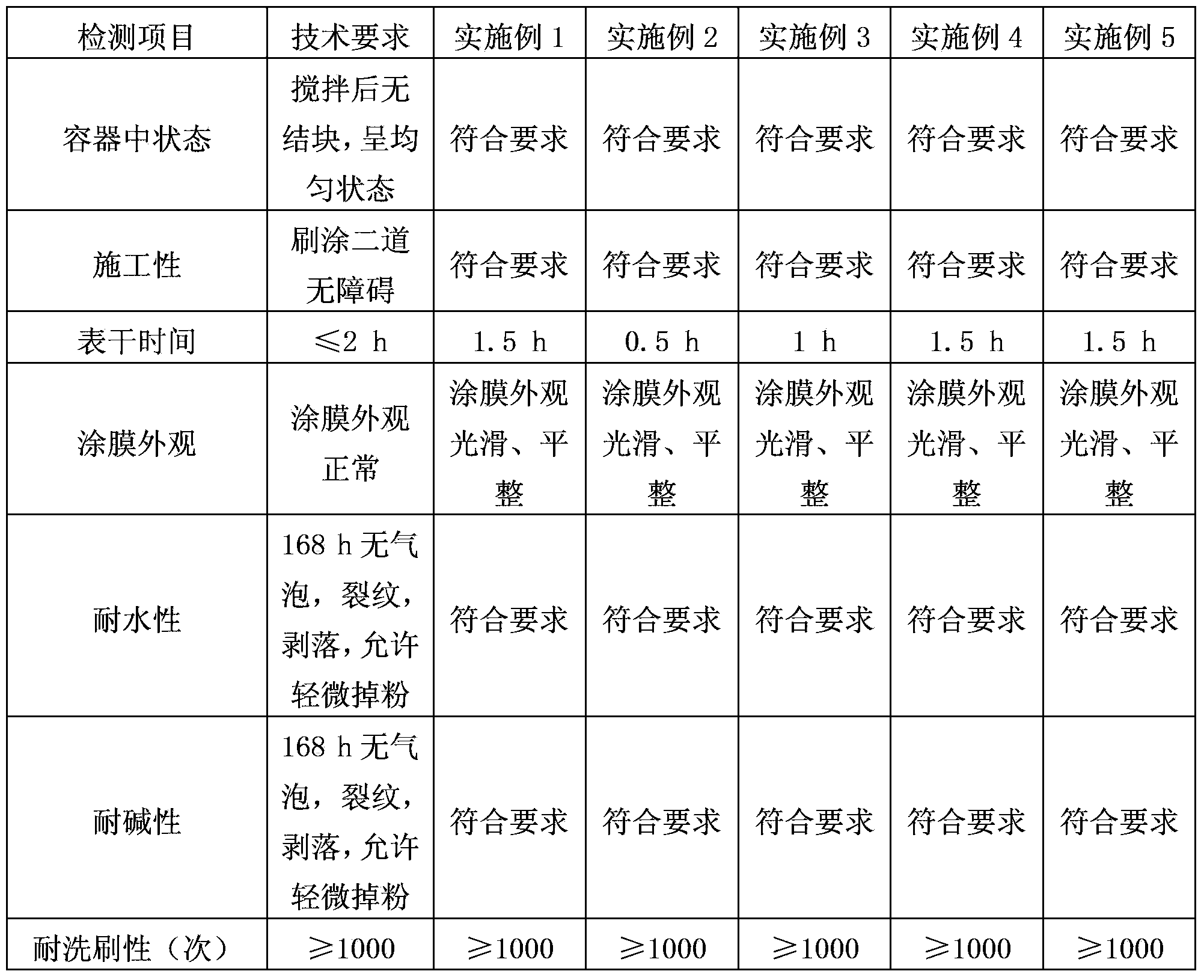

The invention belongs to the field of coatings, and discloses a hydrous silane coupling agent-polyether grafted polysiloxane polymer coating. The hydrous silane coupling agent-polyether grafted polysiloxane polymer coating comprises the following components in parts by weight: 100 parts of inorganic silicate water solutions, 1-50 parts of hydrous silane coupling agent-polyether grafted polysiloxane polymers, 10-100 parts of water, 0-40 parts of titanium dioxide, 0-40 parts of pigments, 10-50 parts of calcium carbonate, 0-50 parts of silicon dioxide, 0.05-5 parts of defoaming agents, 0.05-5 parts of dispersing agents, 0.05-5 parts of wetting agents, 0.05-5 parts of thickening agents, 0.05-5 parts of anti-freeze agents and 0.1-10 parts of film-forming auxiliary agents. The hydrous silane coupling agent-polyether grafted polysiloxane polymer coating disclosed by the invention has the advantages of abrasion resistance, acid resistance, alkali resistance (without bubbles for 168 hours), easiness for construction, good fixation effect, film-forming stability, excellent film-forming appearance, and the like and is suitable for inner and outer walls.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Smectite turbid liquor for treating non-infectious diarrhea and method for preparing the same

ActiveCN101112387AImprove fixation effectIncreasing the thicknessDigestive systemSolution deliveryPrillExcipient

The present invention discloses a montmorillonite suspension to treat non-infectious diarrhea, which is made by montmorillonite, glucose, sodium saccharin, vanillin, sodium benzoate and purified water with certain mix ratio by weight. The preparation method is that the montmorillonite is placed in a preparation tank, the water is added for soaking; then the excipients which are glucose, sodium saccharin, vanillin, sodium benzoate are added and the purified water is supplemented to the prescription dose, fully agitated, the liquid is placed in a colloid mill for milling and refining, after that the liquid can pass through a 325 mesh screen, the screened liquid is cooled down to room temperature after the agitating under the heating condition, the purified water is supplemented to the prescription dose, then the invention is made by fully agitating. Montmorillonite is made into the suspension, thus having finer particles, greater absorption force, stronger effects of gastrointestinal mucosal protection and elimination of pathogens, and faster application of the pharmacological role.

Owner:NANJING BAIJINGYU PHARMA

Preparation method of waterproof and moisture permeable cotton fabric

InactiveCN110983801AImprove water resistanceGood waterproof and moisture permeabilityLiquid/gas/vapor textile treatmentTextile technologyPolymer science

The invention discloses a preparation method of waterproof and moisture permeable cotton fabric, and belongs to the field of fabric coating textile technologies. The preparation method mainly comprises the following steps: firstly padding the cotton fabric that is washed with water and aired into a water repellent finishing agent, and predrying and baking to acquire the water and oil repellent cotton fabric; then performing hydrophobic modification on gaseous nanosilicon dioxide by using a silane coupling agent; adding the improved hydrophobic gaseous nanosilicon dioxide, polyethylene piroxanone, a metallic soap defoamer, an anionic cross-linking agent, an associated thickener into waterborne polyurethane, and thus acquiring a modified waterborne polyurethane coating agent under the condition of stirring at certain temperature; finishing coating of the cotton fabric that is subjected to water and oil repellent treatment with the coating agent, and thus acquiring the cotton fabric withthe coating having waterproof and moisture permeable functions. The prepared fabric can prevent liquid water molecules from entering under certain pressure, meanwhile can enable vapor water moleculesto penetrate through, and thus has good waterproof and moisture permeable effect.

Owner:NANTONG SAIHUI TECH DEV

Light substrate for forcing peony flowers and preparation method thereof

InactiveCN102964183AHigh particle strengthImprove performanceFertilizer mixturesFixation - actionPlant roots

The invention discloses a light substrate for forcing peony flowers and a preparation method thereof. The light substrate contains main body materials (including Pine Needle Mulch, haydite, vermiculite and perlite), fertilizers (including ammonium monoacid phosphate, urea, zinc sulfate, potassium sulfate, copper sulfate, manganese sulfate, ferrous sulfate and boric acid), a plant water-retaining agent and a microbial insecticide. The preparation method comprises the following steps: taking out a certain amount of the fermented Pine Needle Mulch, proportionally adding the haydite, vermiculite and perlite, evenly mixing, proportionally adding the fertilizers, water-retaining agent and microbial insecticide, and evenly mixing. The substrate has the characteristics of light weight, high particle strength, stable performance, high cleanness, favorable draining permeability, fertilizer and moisture retention, wide application range and the like. The specific pellet porous structure is more suitable for plant root system development, has favorable fixation action, can be matched with greenhouses, sheds and electronic automatic spray devices, and has high application and popularization value.

Owner:菏泽市牡丹区牡丹研究所

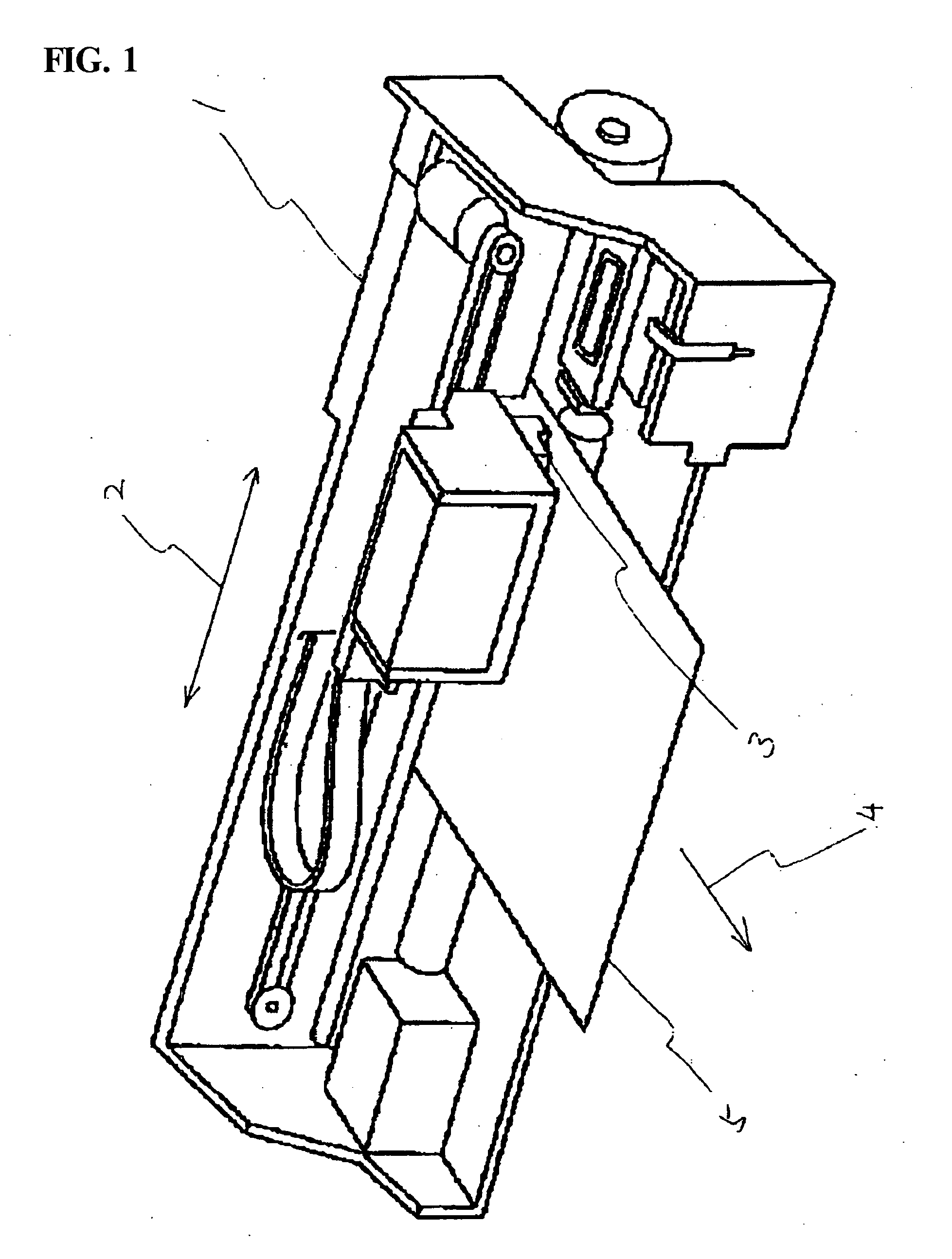

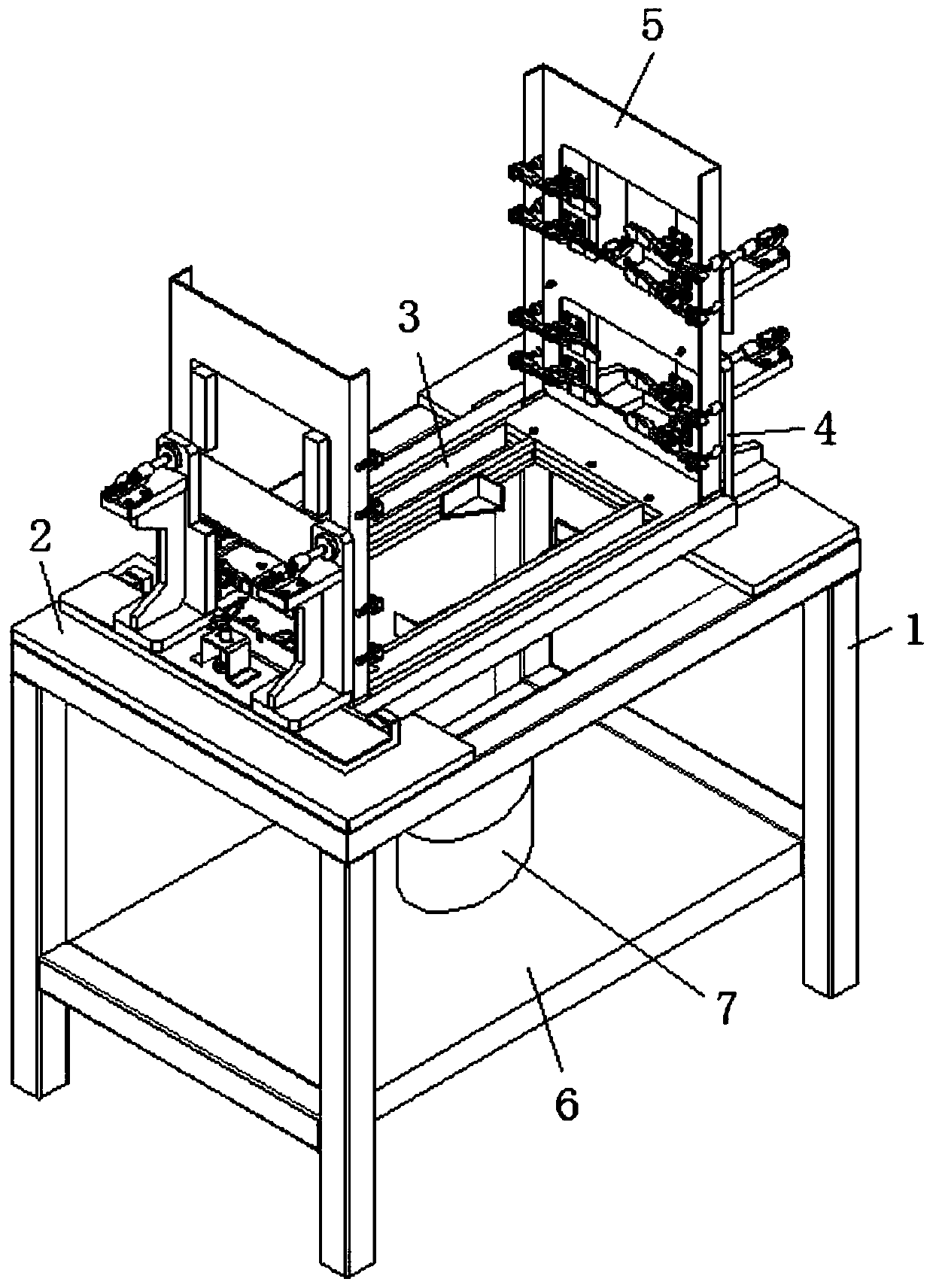

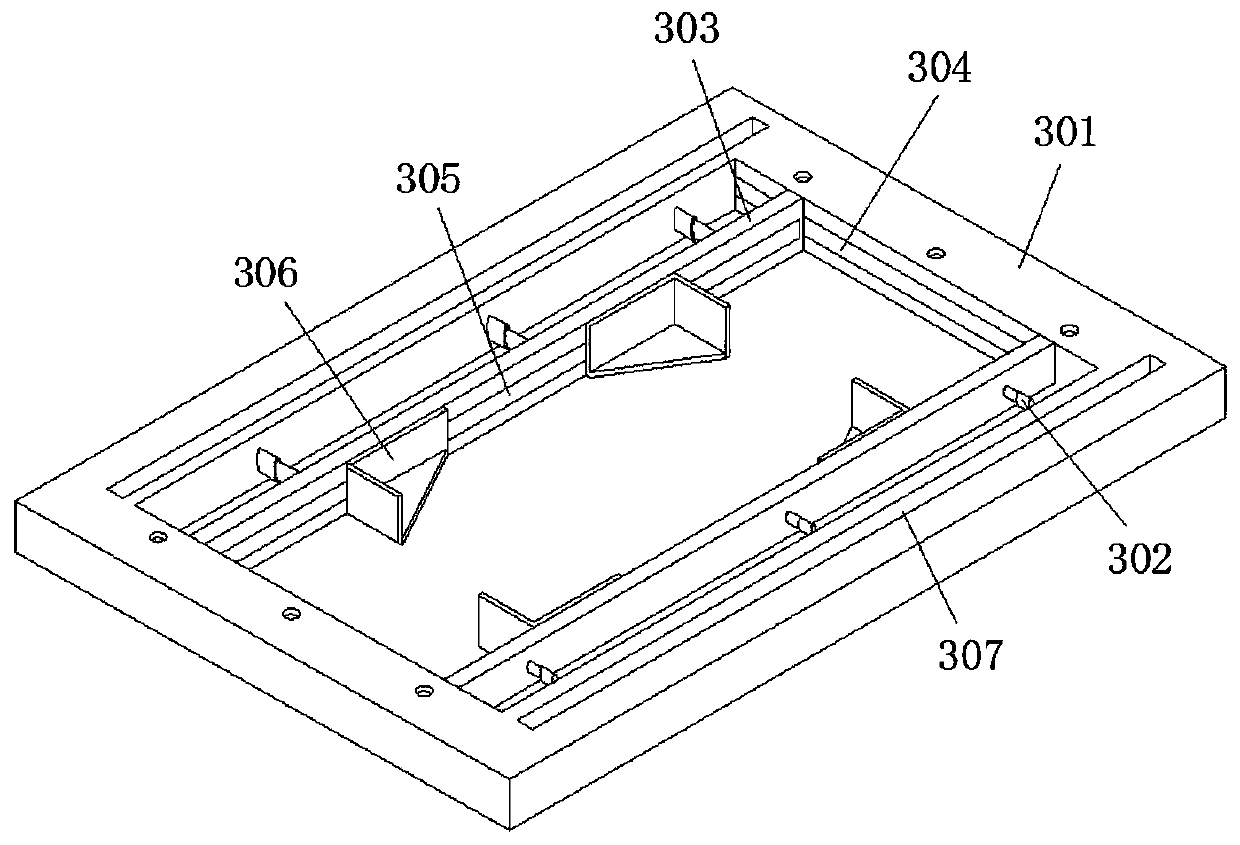

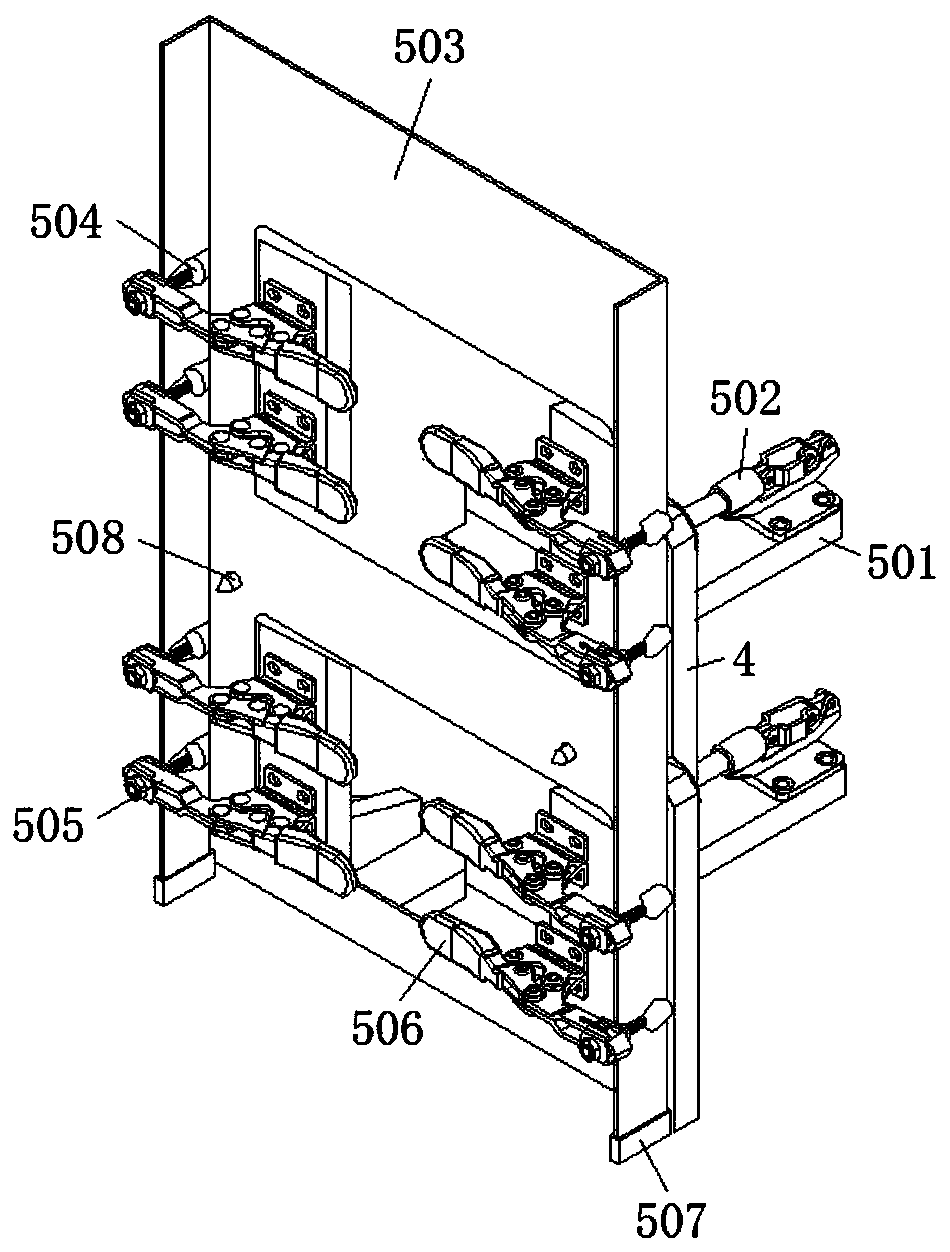

Welding fixture for high-low voltage power distribution cabinet production

ActiveCN111408885AQuick fixImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesLow voltageStructural engineering

The invention discloses a welding fixture for high-low voltage power distribution cabinet production. The welding fixture comprises a fixing frame, mounting plates are fixedly connected to two sides of the top face of the fixing frame respectively, a containing mechanism is fixedly connected to the top faces of the two mounting plates, the containing mechanism comprises a rectangular frame, and electric telescopic rods are fixedly connected to the inner walls of the front end and the rear end of the rectangular frame respectively; supporting strips are fixedly connected to the telescopic endsof the electric telescopic rods at same ends through screws, two sides of each supporting strip are in sliding contact connection with the inner wall of the rectangular frame, adjusting grooves are formed in the ends, close to each other, of the two supporting strips, two right-angle fixing blocks are slidably connected into each adjusting groove, sliding grooves are further formed in the front side and the rear side of the top face of the rectangular frame, and vertical plates are arranged on two sides of the rectangular frame. The welding fixture is reasonable in design, capable of achievingrapid fixing of electric control cabinet plates of different specifications, wide in application range and high in fixing speed of the electric control cabinet plates, and the electric control cabinet welding work efficiency is greatly improved.

Owner:ANHUI HETIAN ELECTRIC

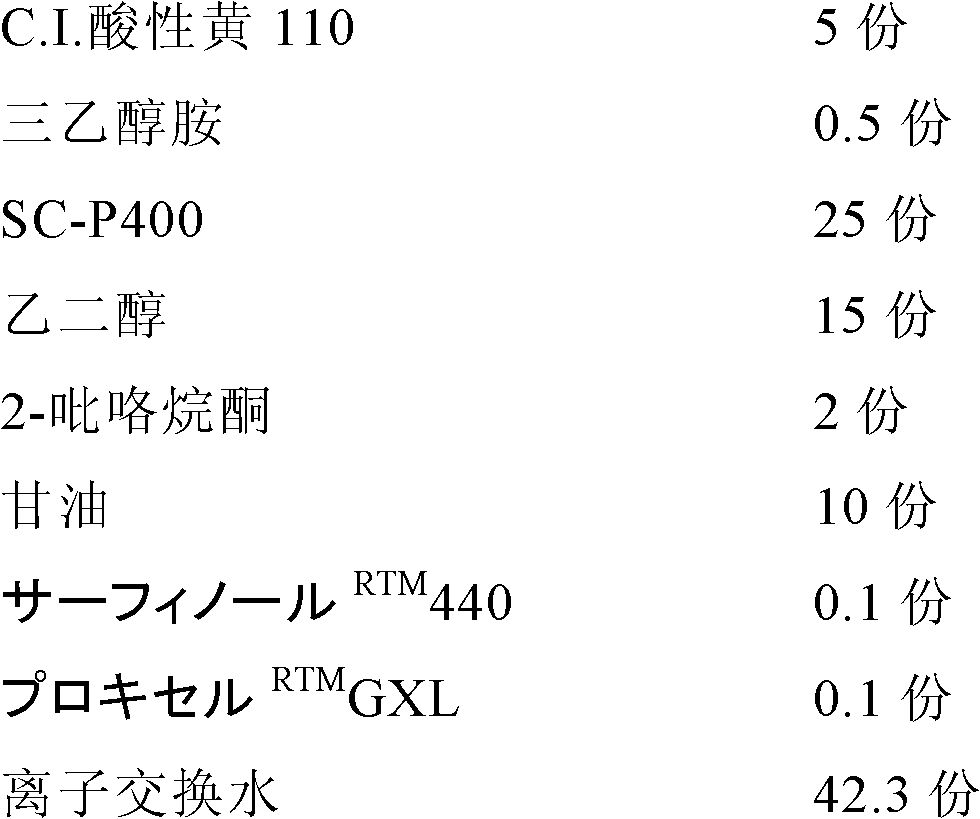

Aqueous marking ink composition

ActiveCN102762675AHigh shieldingImprove fixation effectInksOriginals for photomechanical treatmentAcetylenic alcoholSolvent

Provided is an aqueous marking ink composition with which it is possible to write smoothly with low viscosity on non-absorbent surfaces, such as metals and resins, that are greased with oil, such as cutting oil and lubricating oil, while having suitable and favorable wettability and without being repelled; with which it is possible to draw lines having excellent masking characteristics and excellent adherence; in which the masking agent can be re-dispersed easily by a simple stirring operation even if the masking agent settles out over time; which has excellent masking characteristics and stability; and especially which can be stirred easily even with a stirring element having a low specific gravity. The disclosed aqueous marking ink composition contains at least: 1-20% by mass of a water-soluble resin having a hydrophobic moiety in a molecule thereof; a coloring agent containing at least 5-30% by mass of titanium oxide; 0.05-2% by mass of at least one compound selected from acetylenic glycols, acetylenic alcohols, and derivatives thereof; 1-20% by mass of a water-soluble solvent having a vapor pressure of at most 5 mmHg at 25 DEG C; and water.

Owner:MITSUBISHI PENCIL CO LTD

Composite herbicide for eliminating barnyard grass

InactiveCN105052982AGrowth inhibitionIncrease concentrationBiocideAnimal repellantsBenzoic acidPyrazosulfuron-ethyl

The invention discloses a composite herbicide for eliminating barnyard grass. The composite herbicide comprises the following components in parts by weight: 3 to 6 parts of mesotrione, 0.5 to 1 part of penoxsulam, 1 to 3 parts of pyribenzoxim, 0.8 to 3 parts of flucetosulfuron, 10 to 15 parts of quinclorac, 2 to 5 parts of cyhalofop-butyl, 0.2 to 0.6 part of metribuzin, 15 to 18 parts of fentrazamide, 4 to 8 parts of pyrazosulfuron-ethyl, 0.004 to 0.008 part of ferulic acid, 0.004 to 0.008 part of p-hydroxy benzoic acid, 1 to 4 parts of penetration enhancer, 7 to 10 parts of surfactant, and 10 to 12 parts of safener. The provided composite herbicide has high herbicidal efficiency.

Owner:安徽省圣丹生物化工有限公司

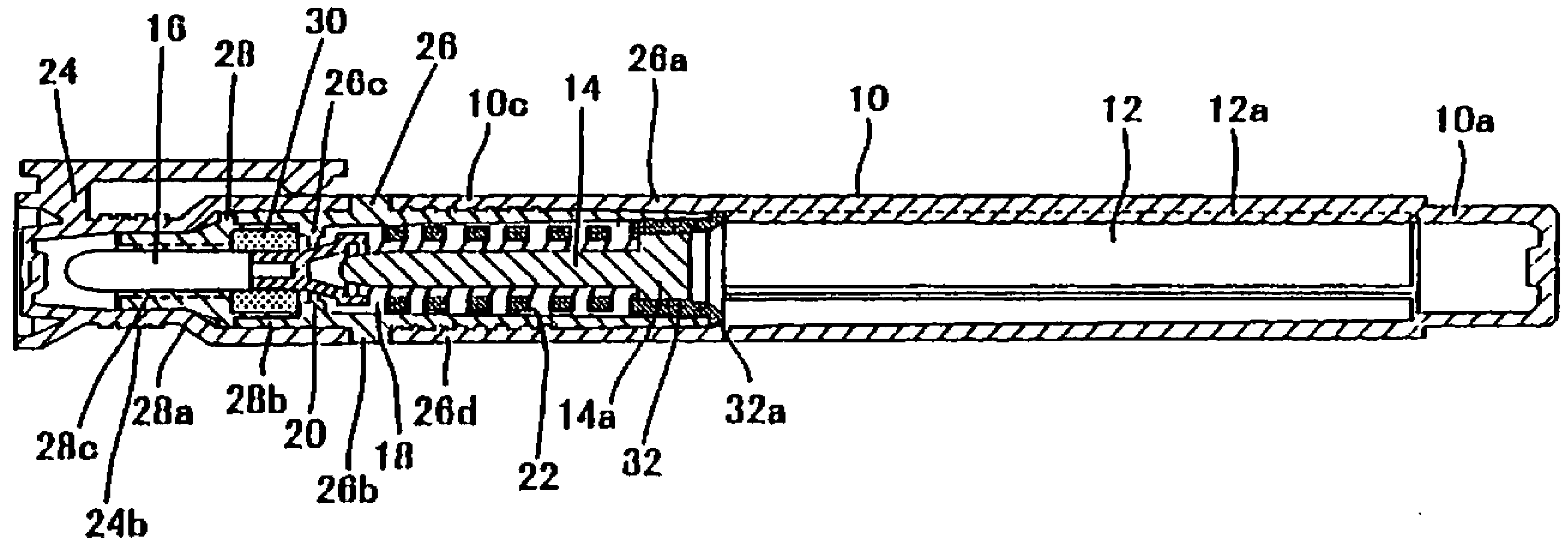

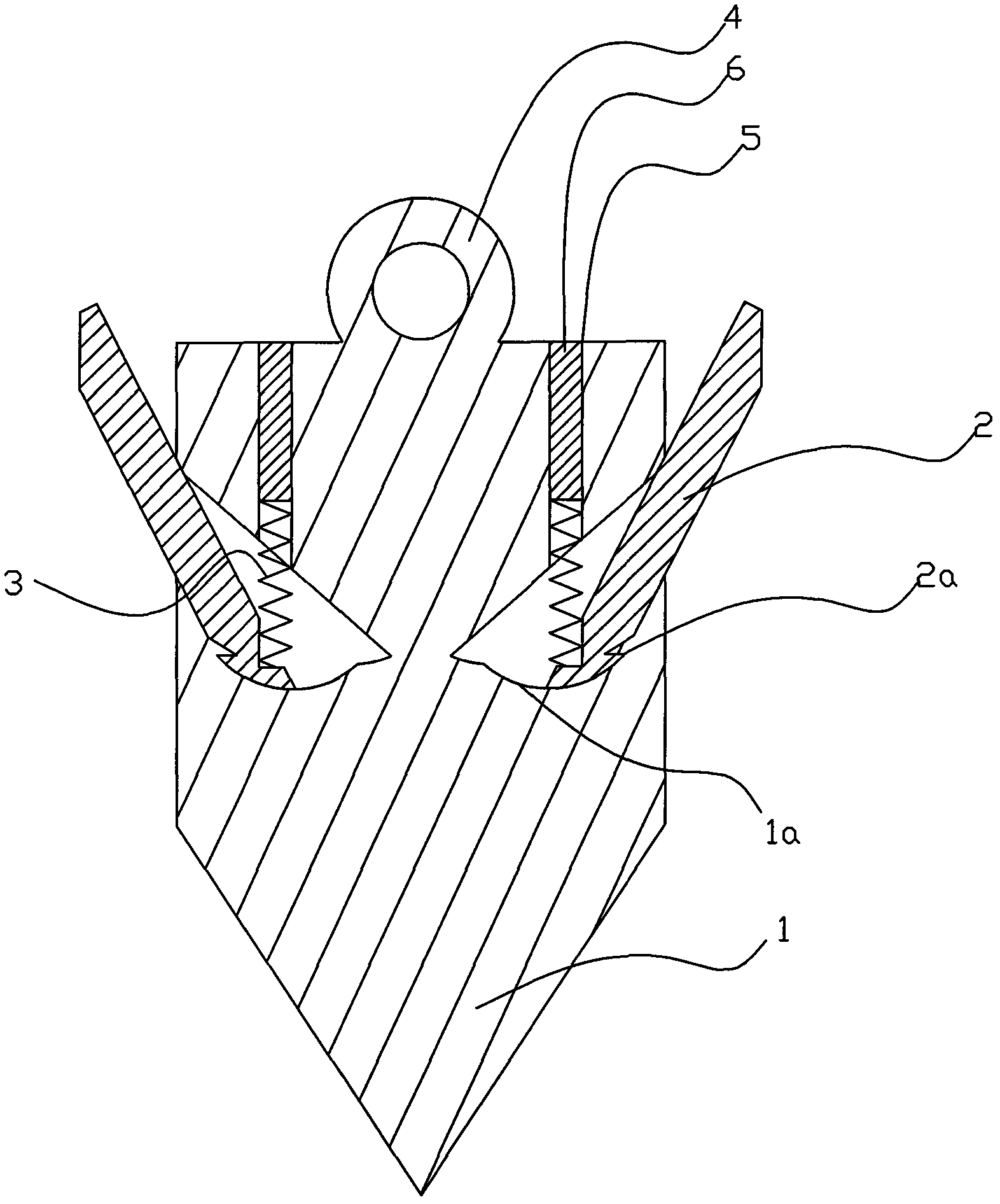

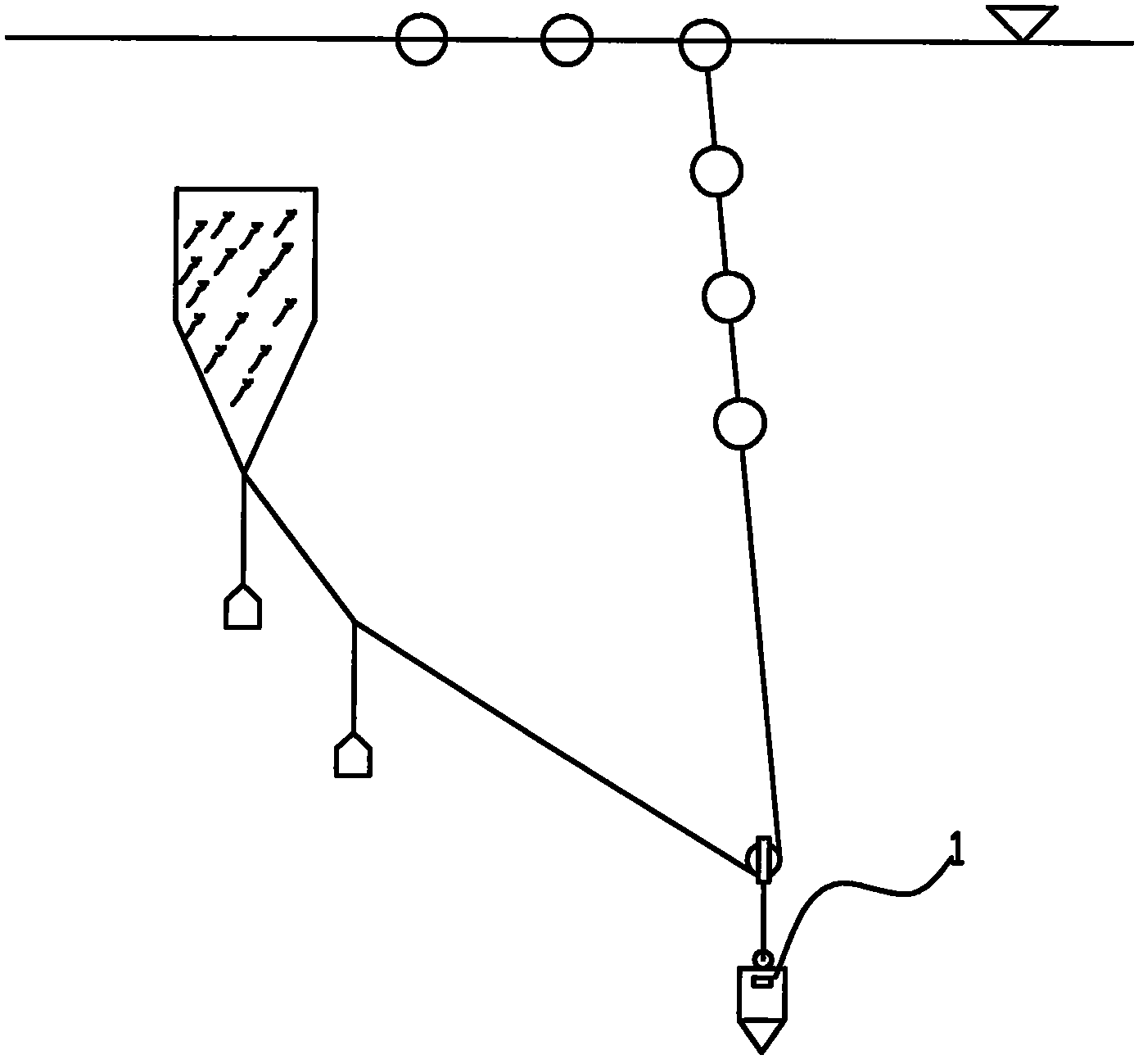

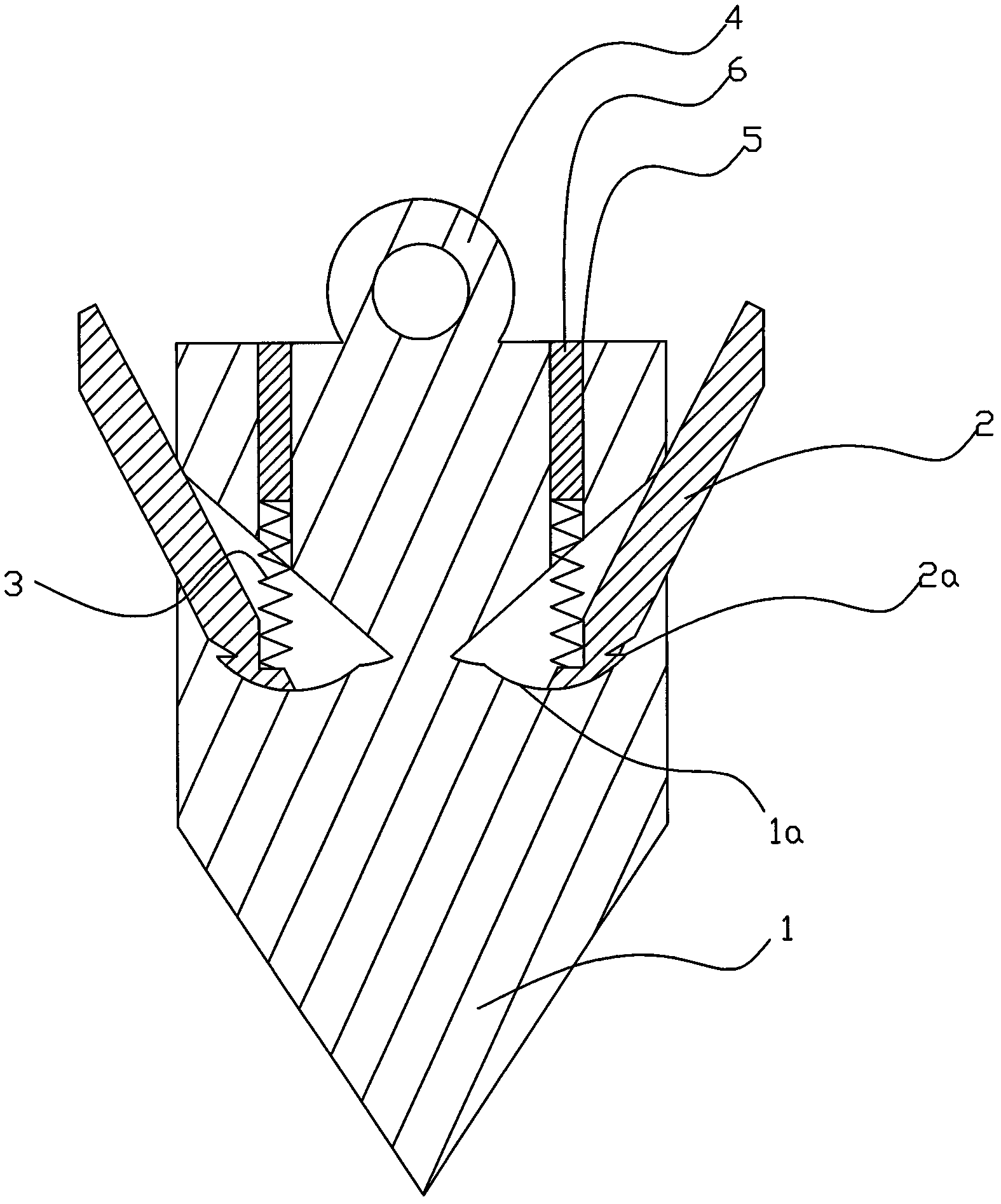

Self-sinking suction anchor

InactiveCN102204518AVariable resistanceImprove fixation effectClimate change adaptationPisciculture and aquariaConvex structurePull force

The invention discloses a self-sinking suction anchor, which comprises an anchor body, wherein radially arranged telescopic hooks are arranged on the anchor; a symmetrically arranged inward concave movable cavity which can accommodate part of telescopic hooks is formed on the anchor body; a convex structure is formed near the bottom of the movable cavity, and stopping hooks are formed near the end parts of the telescopic hooks in the movable cavity; the top end of the anchor body has a through hole which runs through to the movable cavity; a spring is arranged on the part, which is close to the movable cavity, of the through hole; one end of the spring is connected with the end part of the telescopic hooks in the movable cavity, and the other end of the spring extends into the through hole and is sealed and fixed by a sealing and fixing screw in the through; and the top end of the anchor body is provided with a connecting ring. When the anchor body sinks, the telescopic hooks enter a seabed by a small acute angle to facilitate sinking. When under a pull force in an opposite direction, the telescopic hooks open transversely and are finally pressed to contract to deep positions in the movable cavity, so that a large stress area which is benefit for fixation is formed. The anchor has the advantages of variable resistance and desirable fixing effect.

Owner:ZHEJIANG OCEAN UNIV

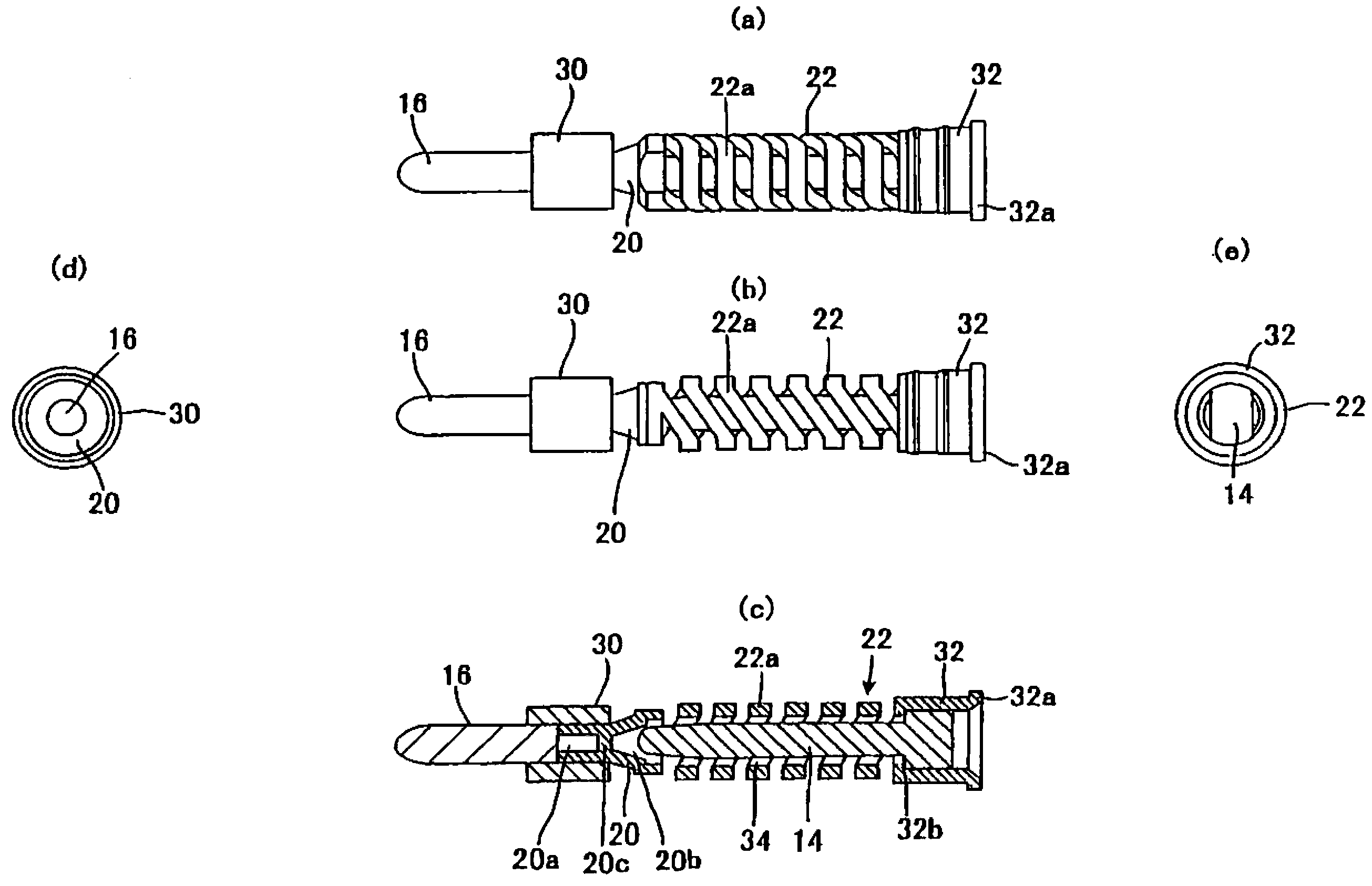

Efficient high-temperature curing technology of silicon carbide seed crystals

ActiveCN108468089AImprove efficiencyConducive to subsequent growthPolycrystalline material growthFrom condensed vaporsElectrical resistance and conductanceCrucible

The invention discloses an efficient high-temperature curing technology of silicon carbide seed crystals. The technology is characterized in that the silicon carbide seed crystals are cured under hightemperature through a crucible jig which is provided with a cover, a crucible cover, a crucible, a chassis, a chassis temperature measuring hole and an air hole; every two adjacent air holes of the air holes form an inverted Z shape; intermediate axes of the two holes are correspondingly inclined by 5-15 degrees relative to a horizontal line and are intersected and connected in the center of thecrucible wall. The method comprises the following steps: adhering the silicon carbide seed crystals to the crucible cover through a carbon-rich adhering agent; sequentially overlapping the crucible and the crucible cover adhered with the seed crystals from the chassis; closing the cover; transferring the crucible jig into a high-temperature furnace; vacuumizing the crucible jig; charging argon into the crucible jig; heating the crucible jig through a water cooling type induction coil or a resistor; and graphitizing carbon paste to realize efficient high temperature curing of the silicon carbide seed crystals. With the adoption of the technology, the seed crystals can be greatly adhered and completely cured; the defects are small; and the subsequent crystal growing quality is high.

Owner:FUJIAN NORSTEL MATERIAL TECH CO LTD

Ink composition and method for producing dyed polyamide-based fiber

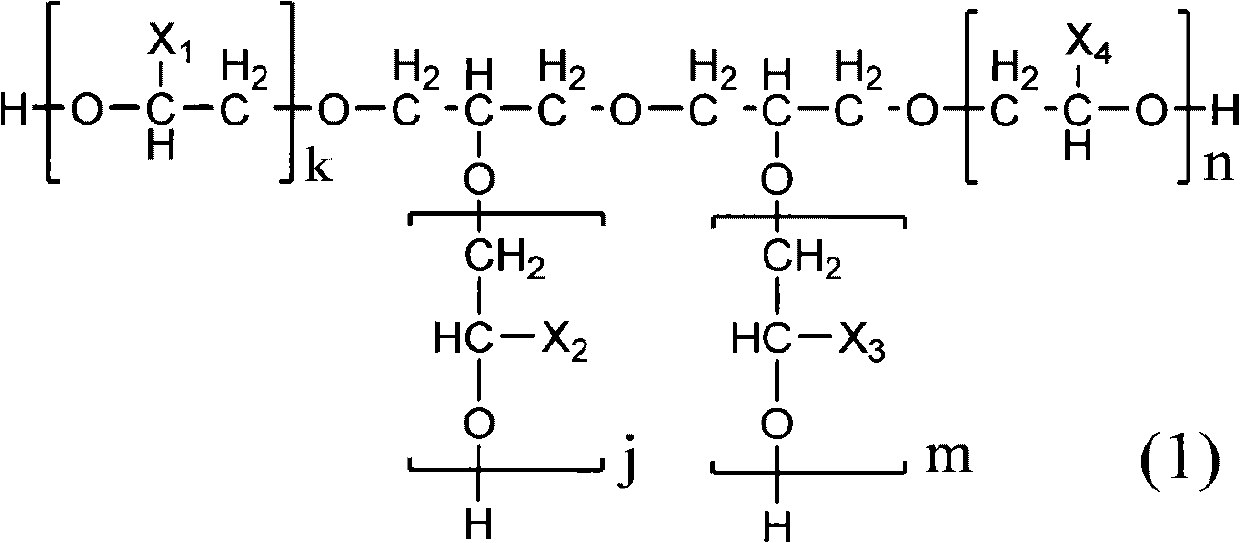

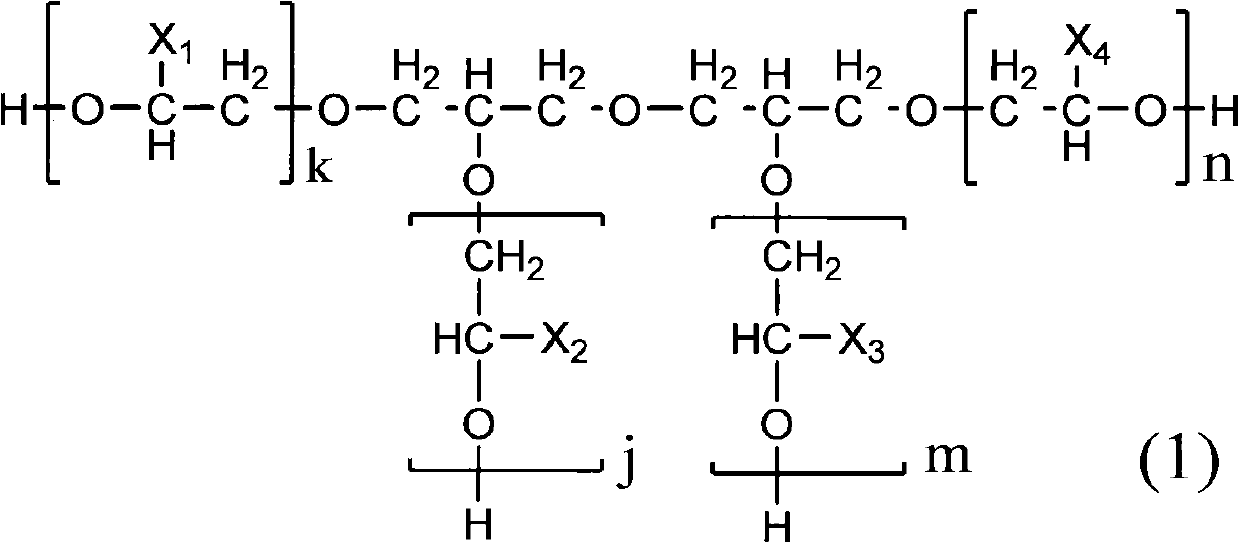

InactiveCN102365336AExcellent storage stabilityImprove fixation effectDuplicating/marking methodsInksFiberHydrogen atom

Disclosed is an aqueous ink composition for dyeing polyamide-based fibers which comprises: at least one kind of dye arbitrarily selected from dyes of three categories including acid dyes, direct dyes and reactive dyes; a compound which is represented by formula (1) [wherein X1, X2, X3 and X4 independently represent each a hydrogen atom or a methyl group; and j, k, m and n represent numbers, provided that the sum thereof is 4 to 40 inclusive] and has an average molecular weight of 340 to 2200; and ethylene glycol. Also disclosed is a method for producing a dyed polyamide-based fiber which comprises a step for applying said aqueous ink composition to a polyamide-based fiber by using an inkjet printer. Thus, it is possible to provide a dye ink for dyeing polyamide-based fibers, which has a high ejection stability in a printer equipped with an industrial inkjet head requiring a high-viscosity ink, has a high storage stability of the ink and shows a good fixability to fibers.

Owner:NIPPON KAYAKU CO LTD

Feather protein viscose filament yarn and manufacturing method thereof

InactiveCN102851786AImprove fixation effectExcellent fiber performanceConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseLoss rateCellulose

The invention relates to feather protein viscose filament yarn and a manufacturing method thereof. The invention belongs to the material field of textile industry. According to the invention, feather protein liquid and a cellulose sulfonate solution with a weight ratio of 1-40%:60-99% are adopted; the materials are subjected to static blending, spinning, solidifying, and post-processing, such that the feather protein viscose filament yarn is obtained. During the production process, a protein loss of the feather protein viscose filament yarn is lower than 30%. After 50 times of washing upon a finished product, a fiber protein loss rate is no higher than 5%. According to the invention, the feather protein viscose filament yarn is manufactured by using waste feathers. The fiber performance is good, the cost is low, and the raw material sources are wide. The filament yarn and the manufacturing method are beneficial for environment protection.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +2

Mould-proof and moth-proof treatment agent for bamboo plaited furniture and preparing method thereof

InactiveCN105751339AImprove dyeing effectImprove fixation effectWood treatment detailsReed/straw treatmentEmulsionPericarpium citri reticulatae

The invention discloses a mould-proof and moth-proof treatment agent for bamboo plaited furniture.The mould-proof and moth-proof treatment agent is prepared from, by weight, 10-15 parts of corn starch, 4-6 parts of nano zeolite powder, 2-4 parts of radix sophorae flavescentis, 2-4 parts of pericarpium citri reticulatae, 2-4 parts of herba asari cum radice, 1-2 parts of folium artemisiae argyi, 1-2 parts of radix isatidis, 1-2 parts of herba schizonepetae, 0.5-1 part of platycodon grandiflorum, 10-15 parts of waterborne polyurethane emulsion, 1-2 parts of maleic anhydride, 3-5 parts of 30% hydrogen peroxide, 0.3-0.5 part of tea saponin, 10-15 parts of a silica sol modifying agent and 40-50 parts of water.The treatment agent for bamboo plaited furniture is capable of effectively improving the dyeing performance of bamboo plaited furniture and preventing color crossing and color cast, high in color fixation capacity, capable of well protecting the surface of bamboo plaited furniture and reducing color fading and losing, large in adhesive force, good in mould-proof and moth-proof performance, environmentally friendly and high in practicability.

Owner:ANHUI SHUCHENG HUAZHU IND

Silk weighting method for fixing sericin by sol-gel process

InactiveCN101333769AOvercoming the problem of high water solubilityImprove fixation effectAnimal fibresWeight gainingEngineering

The invention discloses a silk weight gaining method adopting a sol-gel method to fix sericin, which includes the following steps of: 1) impurity removal and clearing treatment of silk; 2) preparation of finishing liquid of sol; and 3) fixation and finishing of sericin: silk made by the step 2 is fixed and finished by finishing liquid of sol according to a secondary leaching and rolling method so that liquid carrying rate of silk can reach sixty percent to one hundred percent; then finished silk is aged for zero to twenty four hours at normal temperature; finally the silk is baked for ten to sixty minutes at a temperature between 120 and 180DEG C. The silk weight gaining method has the advantages of safety, environmental protection and effective fixation of silk.

Owner:ZHEJIANG SCI-TECH UNIV

Aqueous ink for ball-point pen using oil-in-water type resin emulsion and ball-point pen using the aqueous ink

InactiveCN1690141AKeep dryPrevent drynessOperating means/releasing devices for valvesInksAlcoholPlastic materials

The problem is to provide ink for a ballpoint pen which enables to write well on a flat and smooth, and impermeable surface such as metal, glass, plastic material and the like and a ballpoint pen using this ink. Ink for an aqueous ballpoint pen, of viscosity in the range of 5 through 30 mPa.s at 20 DEG C. and using an oil-in-water type resin emulsion, including a solvent of water and alcohol-based solvent of 0.5 kPa to 10 kPa vapor pressure at 20 DEG C., pigment and water-soluble resin, with an aggregate concentration of solid contents of said water-soluble resin and oil-in-water type resin emulsion being 5.0 to 30.0 mass % against total composition of the ink, and a ballpoint pen using the ink.

Owner:PILOT PEN CO LTD

Silk-screen printing ink

The invention discloses silk-screen printing ink. The silk-screen printing ink is prepared from, by weight, 15-25 parts of pigments, 25-40 parts of a binder, 45-70 parts of solvent, 1-3 parts of calcium carbonate, 1-3 parts of a defoaming agent, 1-3 parts of a leveling agent, 2-7 parts of a 5A molecular sieve, 1-3 parts of fumed silica, 2-7 parts of a dispersing agent, 0.5-1.5 parts of an adhesion promoter, 2-5 parts of gummy oil, 1-3 parts of a slipping agent, 1-4 parts of barium sulfate, 1-3 parts of hydrotalcite and 1-3 parts of a light stabilizer. According to the silk-screen printing ink, adhesion of ink can be enhanced, the ink penetration and ink fusion phenomena of the ink are prevented, the chemical stability is high, the storage time is long, the printing property is stable, the uvioresistant capacity and the antioxidant capacity are high, and wear resistance is achieved.

Owner:SUZHOU ANJIE TECH

Ink composition for ink-jet recording, recording method using same, and record

InactiveCN1592775AImprove reliabilityImprove printing qualityDuplicating/marking methodsInksZeta potentialGlass transition point

It is an object of the present invention to provide an ink jet recording ink composition with good reliability and print quality, a high OD value, and good fixability that affords excellent smear resistance. This object is achieved with the present invention by providing ink jet recording ink composition comprising at least a self-dispersing pigment and two types of resin particles with mutually different properties. The above-mentioned two types of resin particles are two types of resin particles whose glass transition points, average sizes, minimum film-formation temperatures, zeta potentials, and other such properties are mutually different. The present invention also provides a recording method, wherein the above-mentioned ink composition is used to form an image on a recording medium, and provides recorded matter comprising an image formed on a recording medium using the above-mentioned ink composition.

Owner:SEIKO EPSON CORP +1

Microwave dip dyeing method for willow twigs

ActiveCN106956336AReduce rigidityImprove fixation effectRadiation/waves wood treatmentWood treatment detailsFiberMicrowave

The invention discloses a microwave dip dyeing method for willow twigs. The microwave dip dyeing method comprises the following steps: firstly, stewing the willow twigs; secondly enabling the stewed willow twigs to be subjected to alkali-H2O2 one-bath boiling; finally, enabling the materials obtained in the second step to be subjected to pretreatment by a chitosan acid solution; components like xylogen in the willow twigs are degraded, so that the rigidity of the willow twig structures is reduced, and the willow twigs are prevented from cracking under the mechanical force action and a thermal action; chitosan is added to play a certain modifying effect on willow twig fibers, the dye fixation is higher; besides, an anti-cracking dyeing auxiliary is added into the dye, the dyeing power of the dye on the surfaces of the willow twigs is improved, a protective film is formed on the surfaces of the willow twigs, a continuous, flatted and smooth coloring film is formed, the dye can quickly immerse into the willow twig fibers by microwave treatment, and an everlasting and stable dyeing effect is achieved.

Owner:霍邱县淮美奇工艺品有限公司

Treating agent with air purification function for bamboo-plaited articles and preparation method of treating agent

InactiveCN105922414AImprove dyeing performance and fixation performanceImprove dyeing performanceWood treatment detailsWood impregnation detailsMaleic anhydrideChemistry

The invention discloses a treating agent with an air purification function for bamboo-plaited articles. The treating agent is prepared from the following raw materials in parts by weight: 10-15 parts of corn starch, 2-4 parts of nanometer magnesia, 1-2 parts of nanometer titania, 0.1-0.2 part of catechin, 10-15 parts of a water borne polyurethane emulsion, 0.3-0.5 part of polyethylene glycol monolaurate, 1-2 parts of maleic anhydride, 3-5 parts of 25-30% hydrogen peroxide, 0.3-0.5 part of pectin, 10-15 parts of a silica sol modifier and 40-50 parts of water. The treating agent for the bamboo-plaited articles, provided by the invention, not only can effectively improve the dyeing property of the bamboo-plaited articles, can prevent cross color and color loss, and has a strong color fixation performance, but also can play a favorable protection role on the surfaces of the bamboo-plaited articles, can reduce color fading and losing, has a strong adhesion force, and has the auxiliary functions of decomposing harmful substances in air and purifying air, thereby being environment-friendly and strong in practicability.

Owner:安徽华安达集团工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com