Patents

Literature

141results about How to "Stable film formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic engine cooling liquid

InactiveCN1336410AReduce corrosionImprove corrosion inhibitionHeat-exchange elementsSuccinic acidSebacic acid

The present invention relates to organic cooling liquid for engine, it is composed of ethylene glycol 1000 parts, sebacic acid 2-8 parts, terephthalic acid 2-5 parts, octytic acid 1-12 parts, methylbenezenetriazole 1-4 parts, p-tert-butylbenzoic acid 5-25 parts, succinic acid 1-4 parts, antifoaming agent 0.1-0.2 parts, the invented cooling liquid possesses the advantages of good metal corrosion resistance, good transportation stability, strong hard water resistance, small environmental pollution, no harmful component, small use level etc.

Owner:CHINA PETROLEUM & CHEM CORP

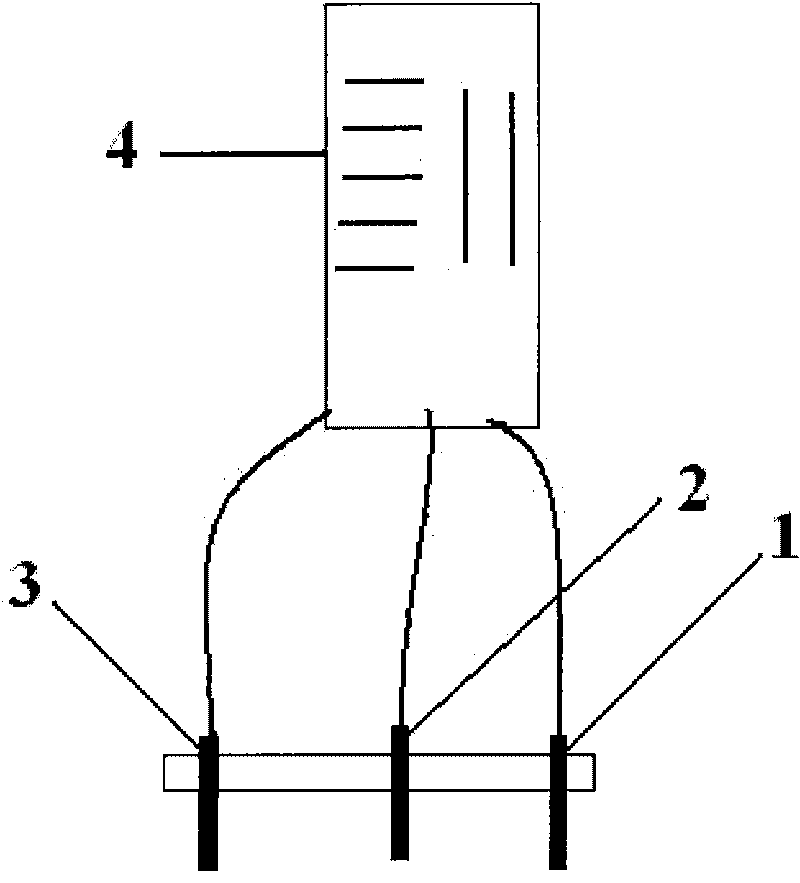

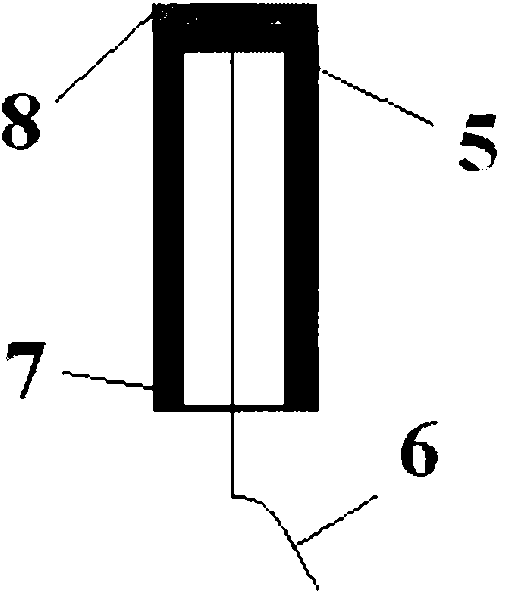

Electrochemical sensor for determining concentration of heavy metal ions in water sample

ActiveCN101706471AGood choiceHigh sensitivityMaterial analysis by electric/magnetic meansIon exchangeAuxiliary electrode

The invention relates to a sensor, in particular to an electrochemical sensor for determining the concentration of heavy metal ions in a water sample. The electrochemical sensor specifically comprises a working electrode, a reference electrode and an auxiliary electrode, and the working electrode, the reference electrode and the auxiliary electrode are respectively connected to a control potential meter through conducting wires; the working electrode consists of a polytetrafluoroethylene pipe and a carbon electrode clamped therein, the bottom end of the carbon electrode is connected with a lead wire for leading out, and a sensitive membrane is arranged at the top end of the carbon electrode; and the sensitive membrane consists of a nano-functional absorbing material, a heavy metal ion carrier and an ion exchange agent, 1-20mmol of nano-functional absorbing material, 0.5%-5% by weight of the ion exchange agent and the 0.5-10mmol of the ion carrier are added in each liter of dispersant and evenly mixed, and then 1mu L-30mu L of the mixture is taken and evenly coated on the surface of the carbon electrode. The electrochemical sensor has low cost, simple technology, high selectivity and sensitivity and good stability, and can be extensively applied in the detection of the heavy metal ions in waste water, fresh water, sea water, daily necessities and body fluid.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

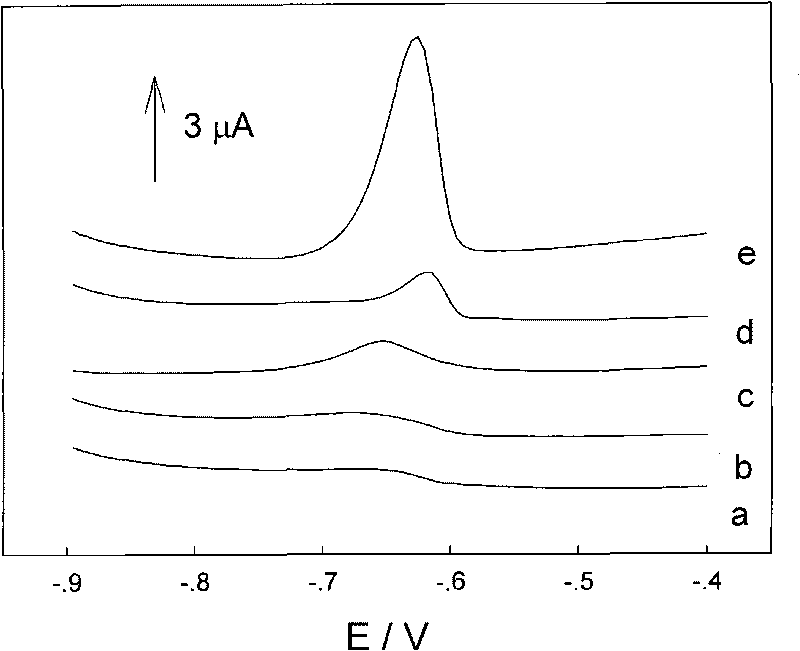

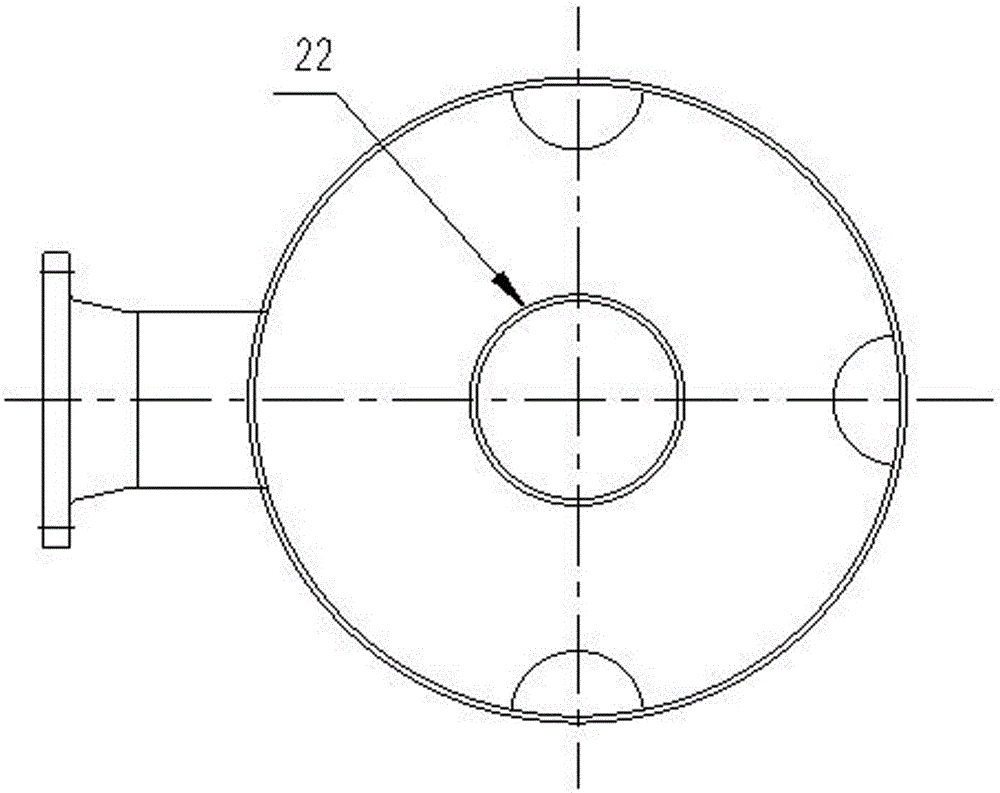

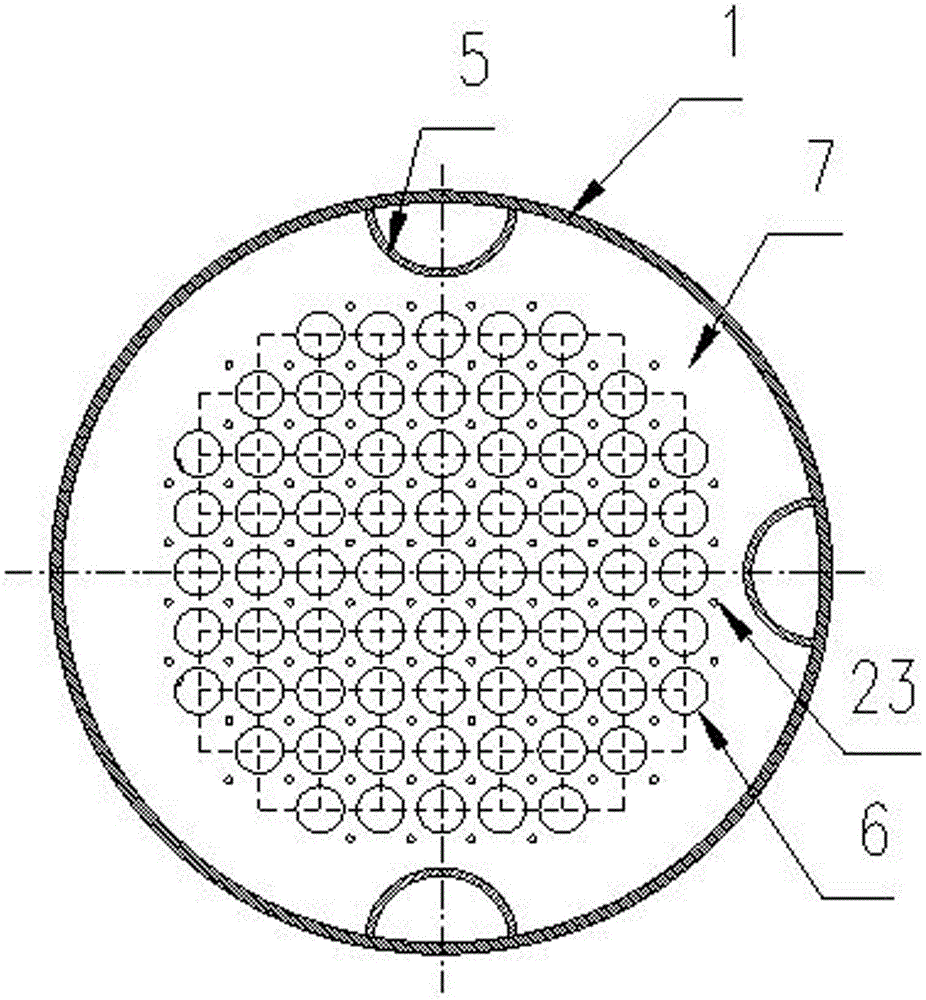

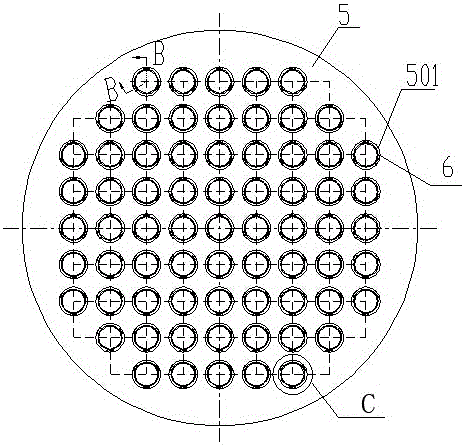

Vertical tube type falling-film evaporator

ActiveCN106178557AGuaranteed centralityHigh recovery rateGeneral water supply conservationEvaporators with vertical tubesVertical tubeEngineering

The invention relates to a vertical tube type falling-film evaporator. The vertical tube type falling-film evaporator comprises an upper tube box, a lower tube box, a casing, multiple heat exchange tubes, an upper tube plate and a lower tube plate, wherein a solution inlet and a secondary steam outlet I are arranged at the upper tube box, a concentrated liquid outlet and a secondary steam outlet II are arranged at the lower tube box, a steam inlet is arranged at the upper part of the casing, and a condensed water outlet is arranged at the lower part of the casing; a film distributing device used for distributing a solution on the inner walls of the heat exchange tubes is arranged in the upper tube box; the film distributing device comprises a liquid bearing plate, a liquid feeding plate, a liquid distributing plate and liquid guiding tubes. By means of a steam stripping effect generated by secondary steam and liquid films, the heat transferring push force and the evaporation efficiency are increased. The liquid films can be uniformly distributed by the film distributing device, the film forming is stable, the wall drying phenomenon is avoided, the recovery rate of secondary steam produced in an evaporator is high, the recovery is convenient, and the heat transferring efficiency is improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

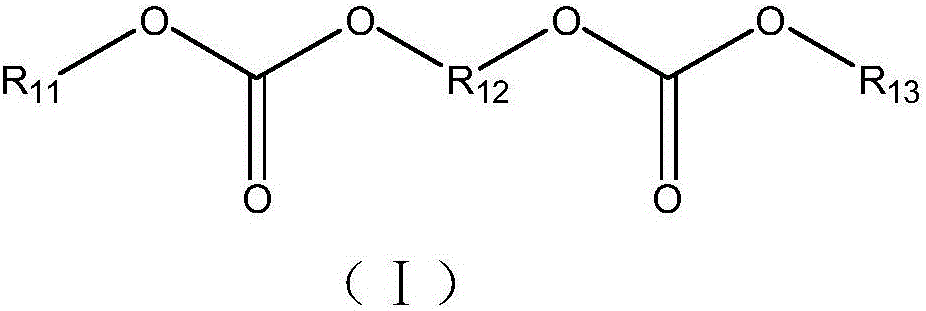

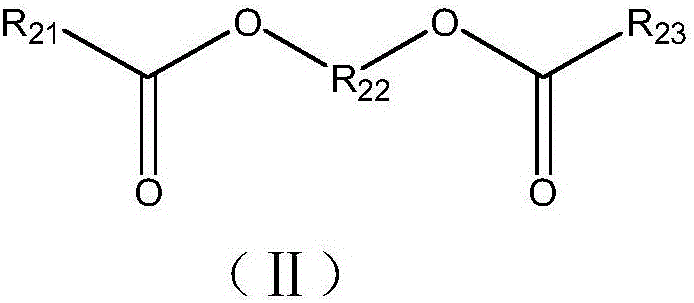

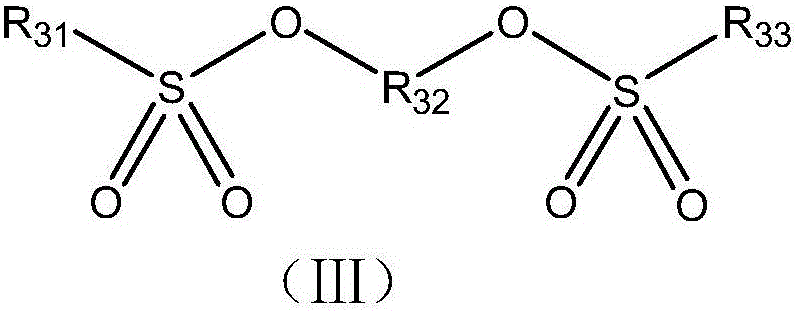

Electrolyte and lithium ion battery containing electrolyte

ActiveCN105826607AHigh molecular weightHigh viscosityLi-accumulatorsOrganic electrolytesOrganic solventEther

The invention relates to the technical field of lithium ion batteries, in particular to an electrolyte and a lithium ion battery containing the electrolyte .The electrolyte comprises lithium salt, organic solvent and additives, wherein the additives include fluoro-ether and a dimerization ester compound, and the dimerization ester compound includes carbonic acid ester dimer, carboxylic acid ester dimer and sulfonated lactone dimer .The lithium ion battery containing the electrolyte can achieve the high-voltage purpose, the highest normal working voltage can be increased to 4.4-5.0 V, the cycle performance of the lithium ion battery is good, a higher capacity retention ratio is achieved during charging and discharging, and the service life of the lithium ion battery is prolonged.

Owner:NINGDE AMPEREX TECH

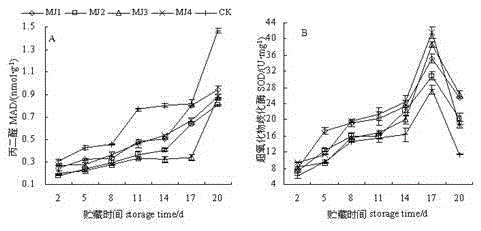

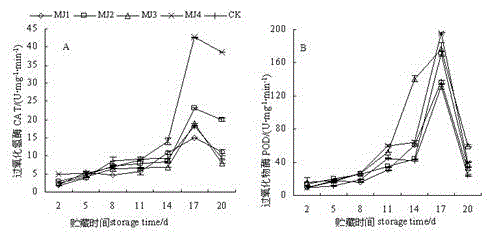

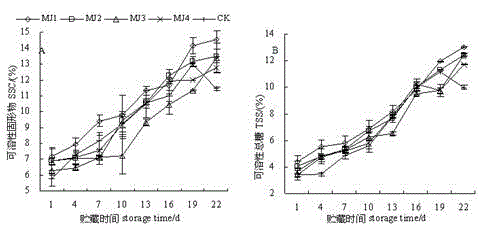

Novel method and protective film agent for preventing and controlling soft rot of actinidia and preparation method for protective film agent

InactiveCN105660267AImprove disease resistanceImprove storage effectBiocideFungicidesTectorial membraneNatural barrier

The invention discloses a novel method and a protective film agent for preventing and controlling soft rot of actinidia and a preparation method for the protective film agent. The chitosan composite protective film agent is adopted in the method. The protective film agent comprises the following components in percentage by mass: 2.5-7.5% of chitosan, 0.5-2.5% of calcium salt, 1.5-3.5% of a film former, 0.5-1.5% of an antibacterial substance and the balance of water. The fruit surface is sprayed with a 25-100-fold solution of the protective film agent in the field during the early stage of pathogen infection of the soft rot of the actinidia or the germination stage, young fruit stage and strong fruit terminal stage of the actinidia, so that a layer of natural barrier is formed on the fruit surface for protecting the actinidia from being infected with pathogenic microorganisms. The protective film agent for the actinidia is high in stability and can effectively improve the nutritional quality and the eating quality of the actinidia.

Owner:GUIZHOU UNIV

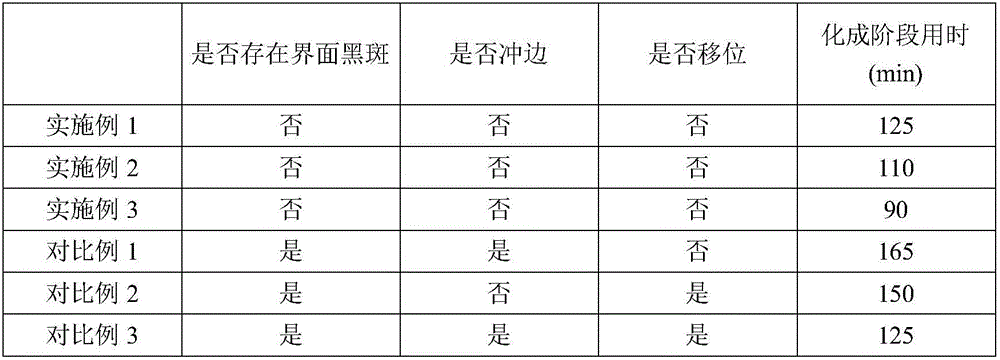

Formation process for lithium ion cell with high energy density

ActiveCN106299461AEase edgeAlleviate displacement problemsFinal product manufactureSecondary cells charging/dischargingProduction rateBlack spot

The invention belongs to the technical field of lithium ion batteries, in particular to a formation process for a lithium ion cell with high energy density. During the formation process of the cell, a form of segmental pressurization is adopted, the cell is charged under the conditions of small pressure and low current, on the one hand, through low-current charging in the first charging process, the reaction of Li+ and electrolyte is not too violent, so that the gas production rate is reduced and the problems of cell trimming and displacement are alleviated; on the other hand, through the form of segmental pressurization, the gas generated by reaction is gradually discharged, so that a problem of a black spot interface caused by poor exhaust is effectively improved. In addition, the generated gas is gradually increased along with the deepening of formation; through increasing the surface pressure and current, the contact is closer, so that formation is more stable while the formation efficiency and the capacity are improved.

Owner:DONGGUAN LIWINON ENERGY TECH

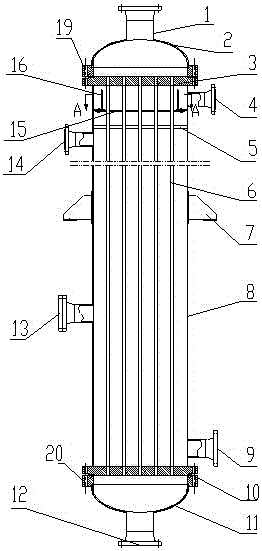

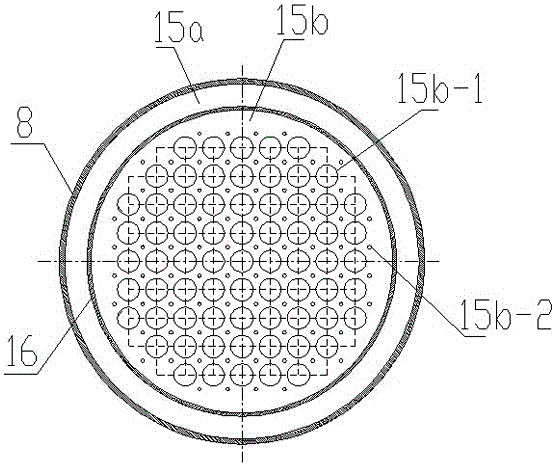

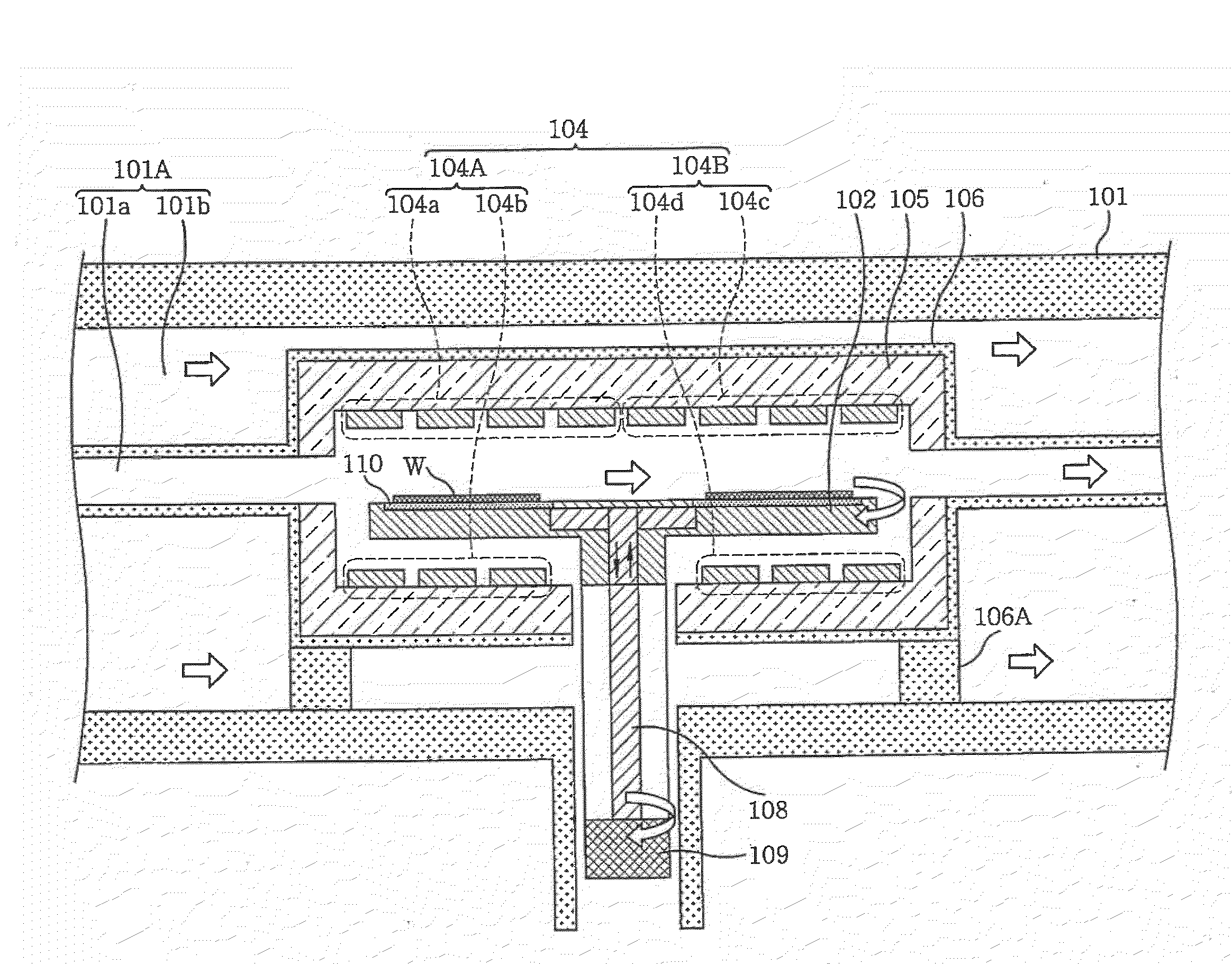

Vertical-tube falling film absorption reactor

ActiveCN106268595AUniform film distributionUniform supplyLiquid-gas reaction of thin-film typeChemical/physical/physico-chemical stationary reactorsVertical tubeBarrel Shaped

A vertical-tube falling film absorption reactor comprises an upper tube box, a lower tube box and a shell, wherein the shell is arranged between the upper tube box and the lower tube box and is connected with the upper tube box and the lower tube box in a sealed manner respectively; a tube plate is arranged at each of the upper end and the lower end of the shell; a vertical tube bundle is arranged between the two tube plates; a film distributing device is arranged inside the shell; the film distributing device comprises an upper liquid distributing plate, a lower liquid distributing plate, and a barrel-shaped overflowing plate arranged on the upper liquid distributing plate; film distributing annular spaces are formed between lower liquid distributing plate tube holes in the lower liquid distributing plate and heat exchange tubes running through the lower liquid distributing plate tube holes; centering bulges for centering the heat exchange tubes are arranged inside the lower liquid distributing plate tube holes; spiral grooves are formed in the outer walls of the heat exchange tubes. The vertical-tube falling film absorption reactor uses the more reasonable film distributing device, so that purposes of uniformly distributing a liquid film and stably forming the film can be achieved, a dry wall phenomenon can be avoided, and the heat transfer efficiency and the mass transfer efficiency are greatly improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

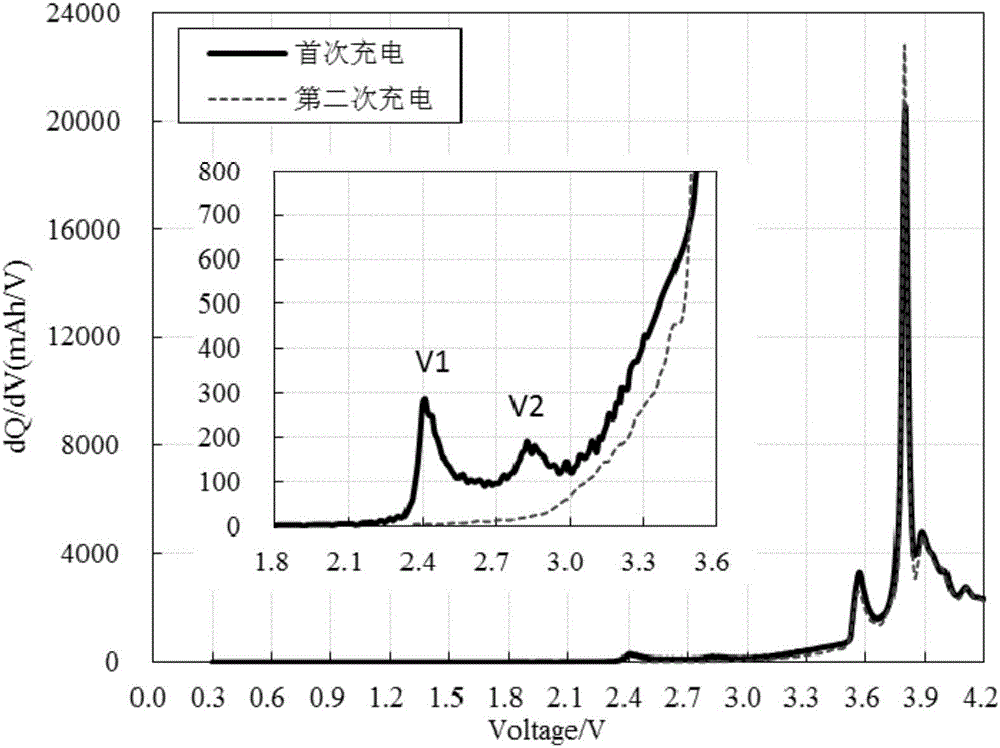

Lithium ion battery formation method for optimizing performances of SEI membrane

ActiveCN106058326AGood film formingMake the most of synergiesFinal product manufactureElectrical testingPower flowElectrical battery

The invention relates to a lithium ion battery formation method for optimizing the performances of an SEI membrane. The method comprises the following steps: taking a sample battery, determining the film forming potential of the sample battery, setting sine alternating current at all film forming potentials carrying out periodic charging and discharging multiple times, and carrying out charging with large current in a potential interval for realizing no film formation. The pertinent formation method of a lithium ion battery is designed, and large current charging is adopted in the potential interval for realizing no film formation, so the integral performances of the battery are improved, the formation time is saved, and the making period of the battery is shortened.

Owner:TIANJIN LISHEN BATTERY +1

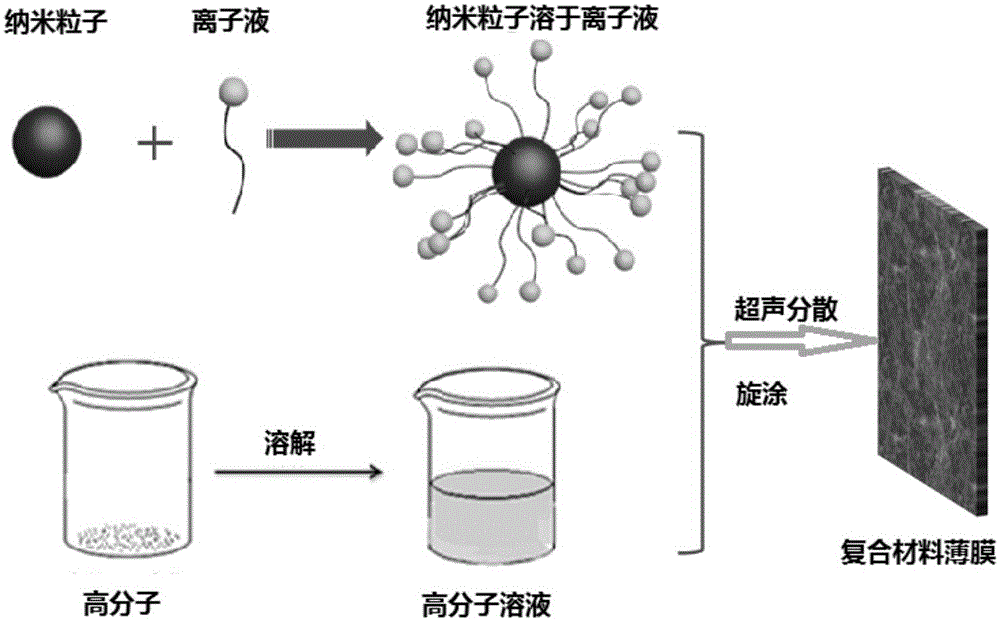

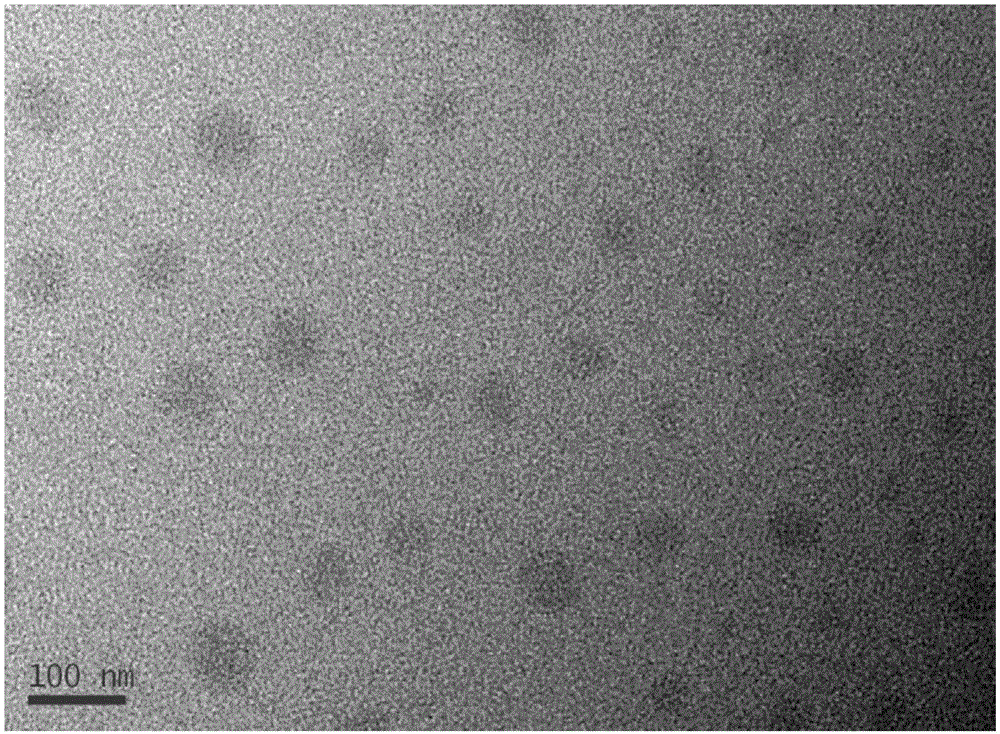

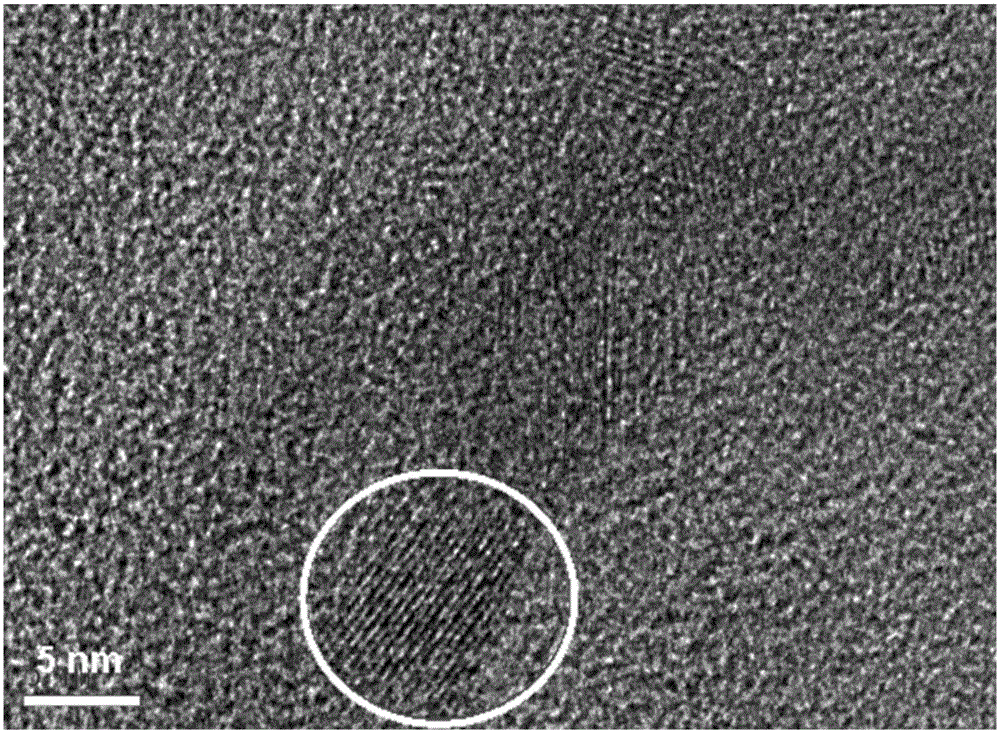

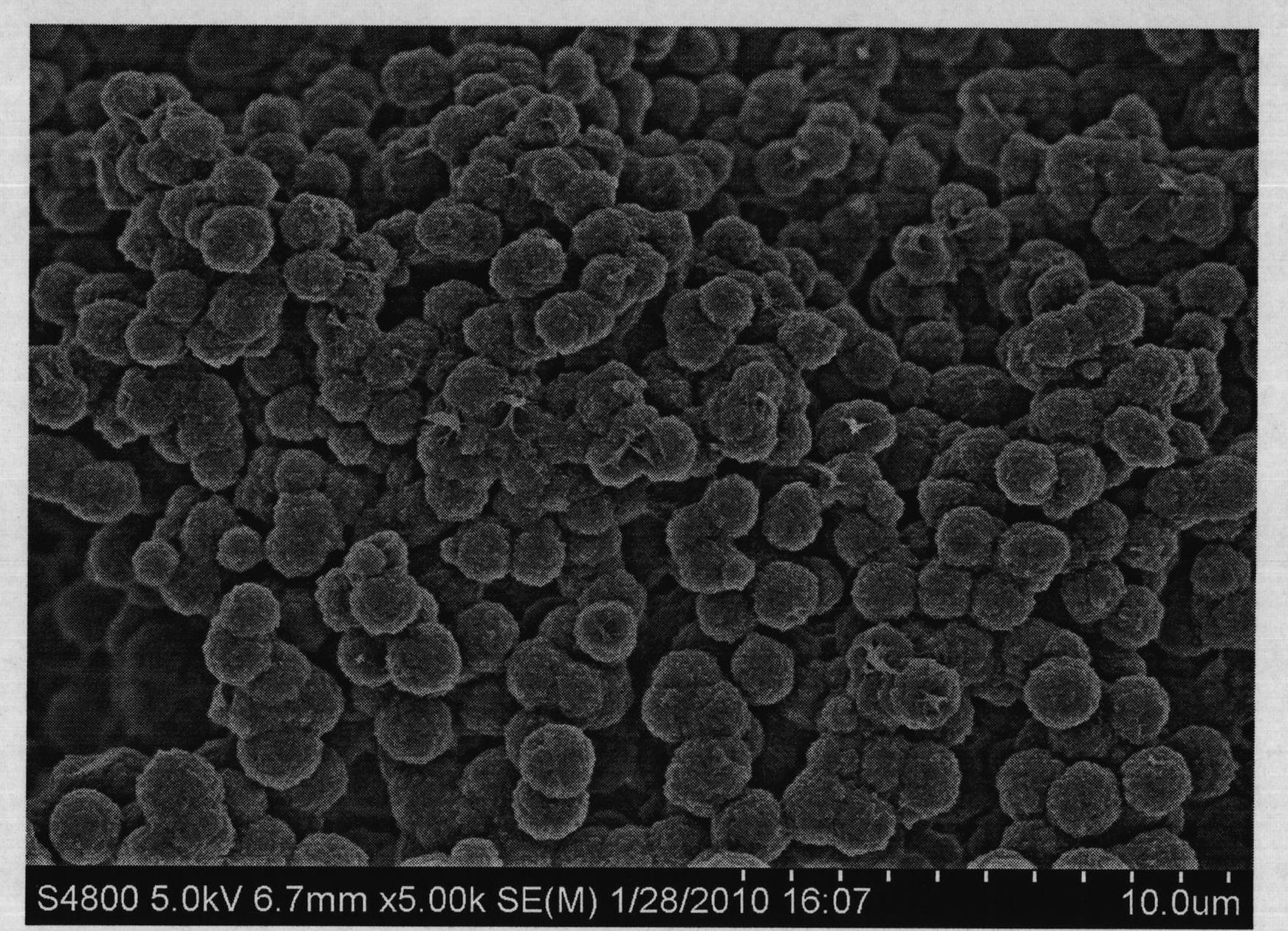

High molecular nano composite film and preparing method thereof

The invention discloses a high molecular nano composite thin film and a preparing method thereof. The high molecular nano composite thin film comprises a high molecular substrate and a nano metal material and ionic liquid which are dispersed in the high molecular substrate. The preparing method comprises the steps: (1) supersonically dispersing the nano metal material in the ionic liquid to obtain first dispersion liquid; (2) supersonically dispersing the high molecular material in an organic solvent to obtain second dispersion liquid; (3) mixing the first dispersion liquid with the second dispersion liquid; (4) spinning-coating the mixed solution onto a substrate to obtain the high molecular nano composite thin film. In the high molecular nano composite thin film, nano particles are uniformly dispersed, no second agglomeration phenomenon exists, and the preparing method is simple, short in production period and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

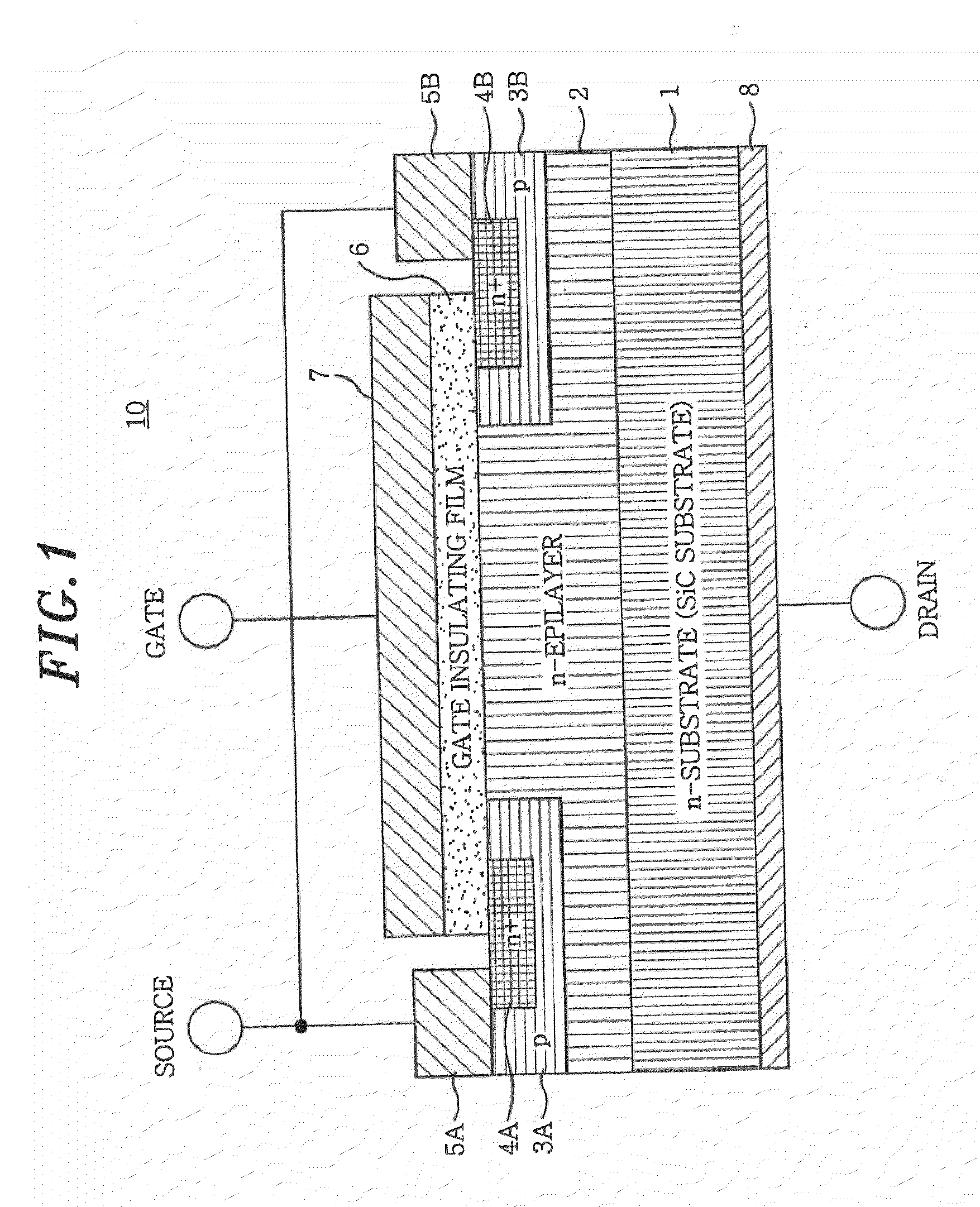

Sputtering target, dielectric film formed from the sputtering target and method for producing the dielectric film

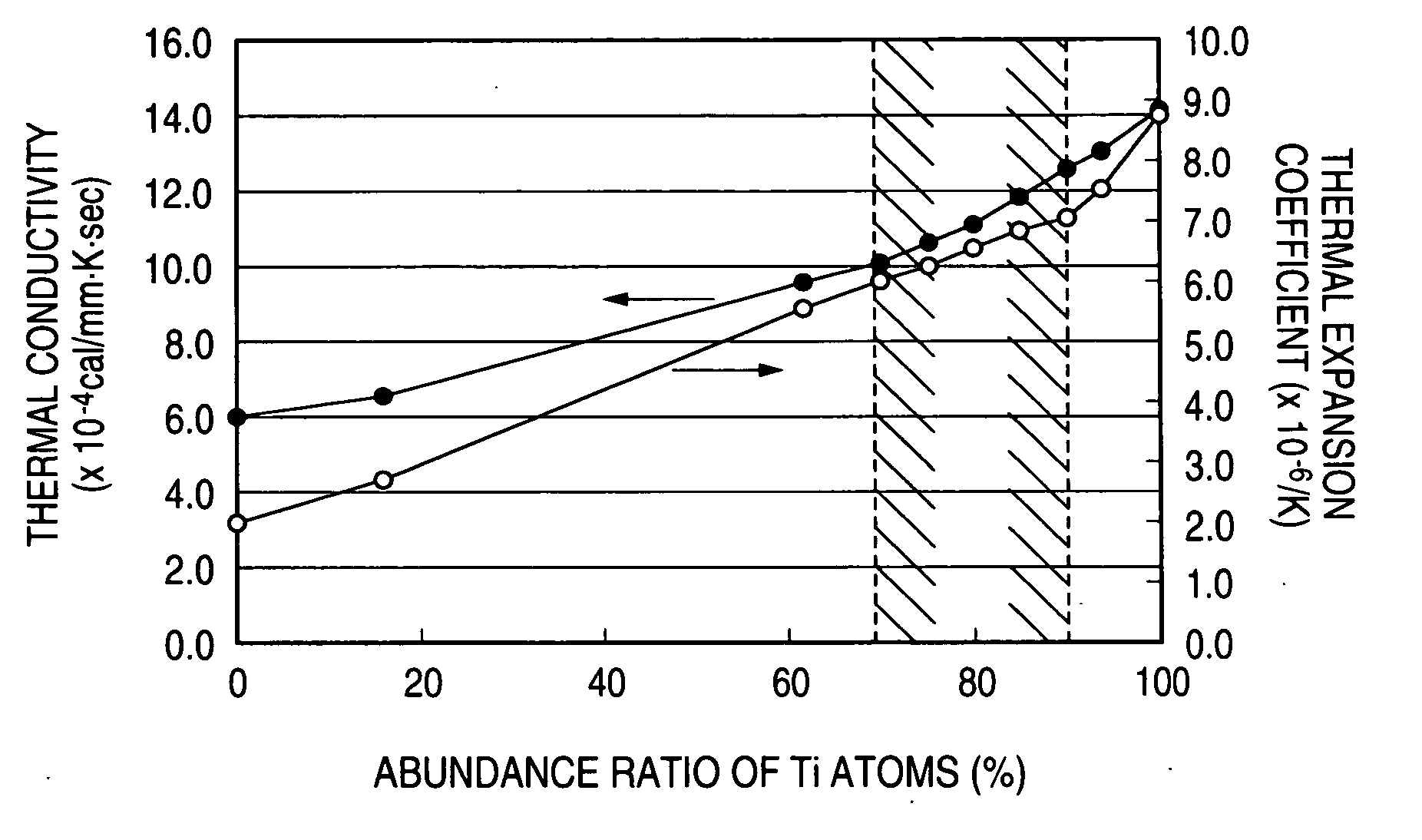

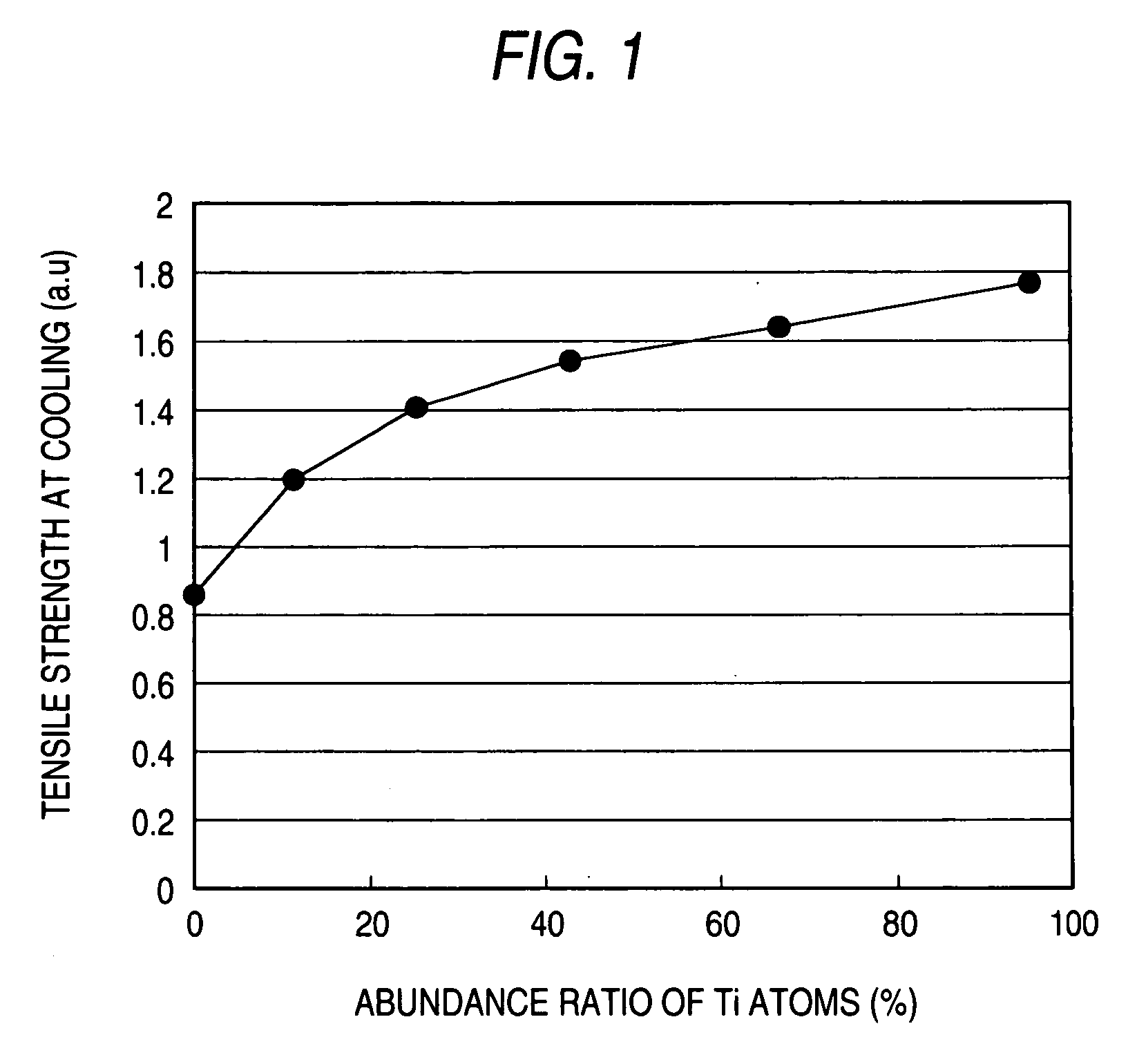

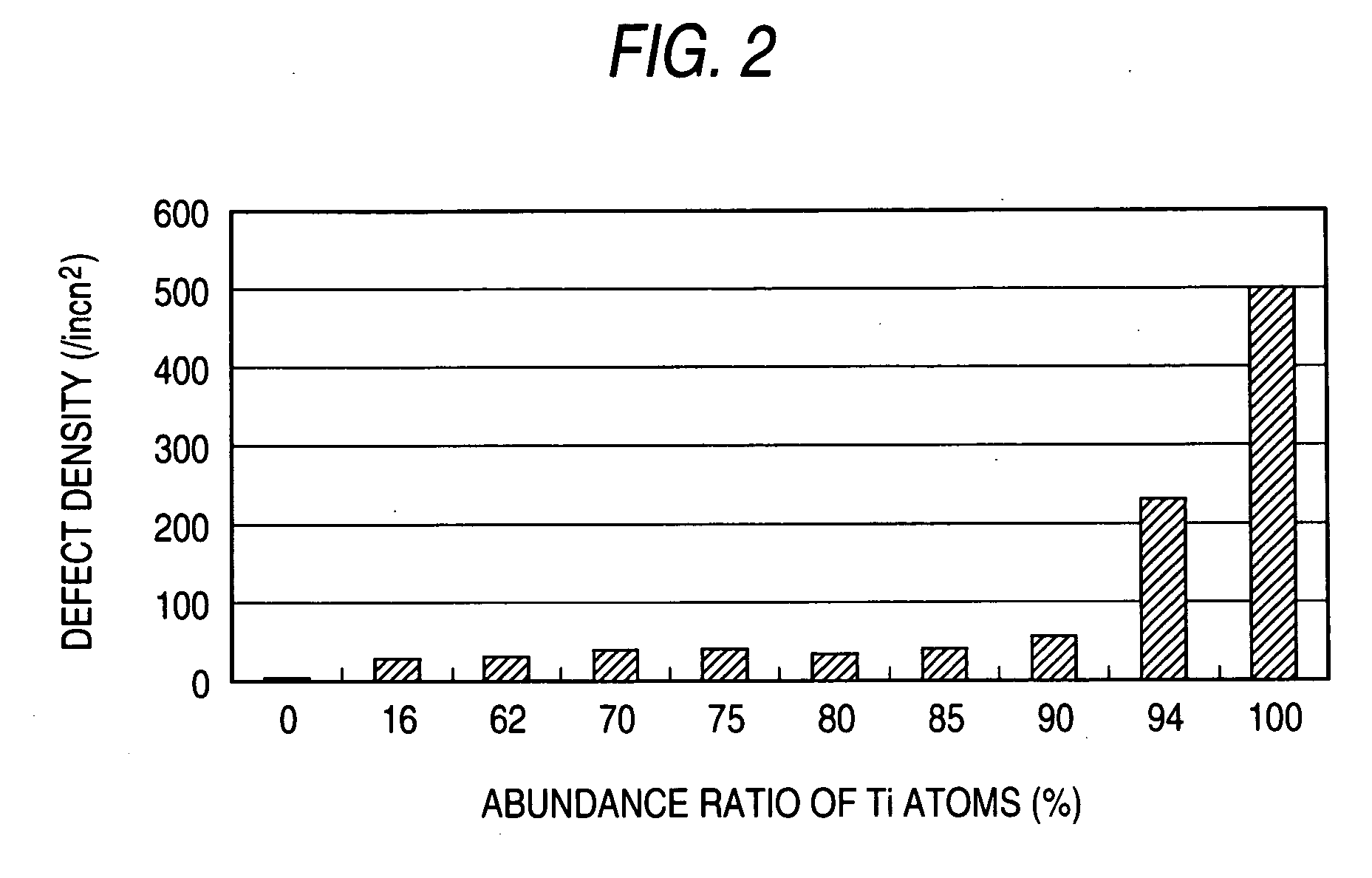

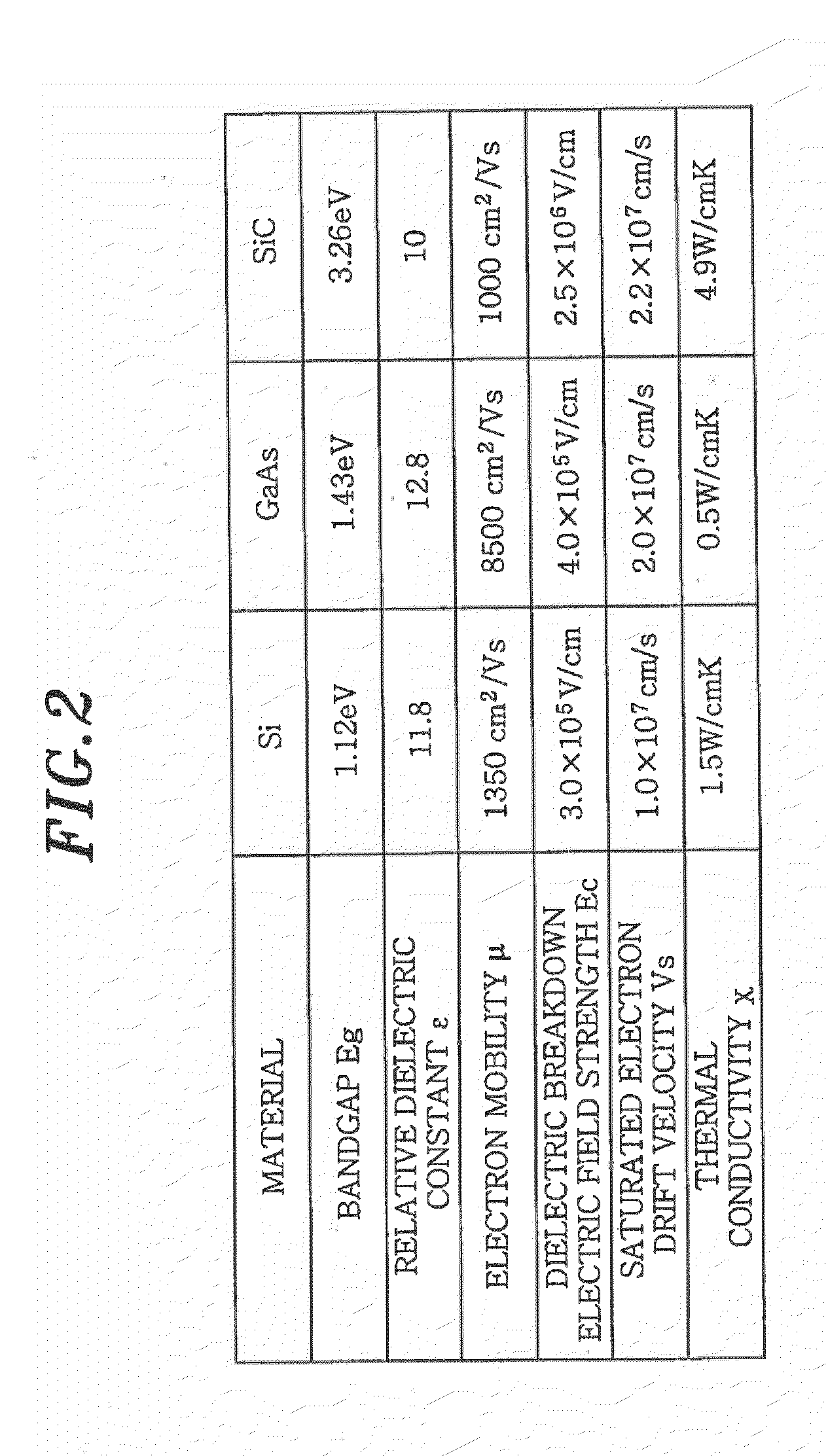

InactiveUS20060159950A1Stable film formationFew defectCellsVacuum evaporation coatingThermal conductivityTitanium dioxide

A sputtering target according to the invention including an oxide sintered body containing NbOx and TiOx in which the abundance ratio of Ti atoms in the target is from 70% to 90% both inclusively. Preferably, the oxide sintered body has a specific resistance value not higher than 10Ω·cm. Preferably, theoxidesinteredbody has a thermal expansion coefficient not larger than 7 ×10−6 / K and a thermal conductivity not lower than 10 ×10−4 cal / mm-K-sec.

Owner:NIPPON SHEET GLASS CO LTD

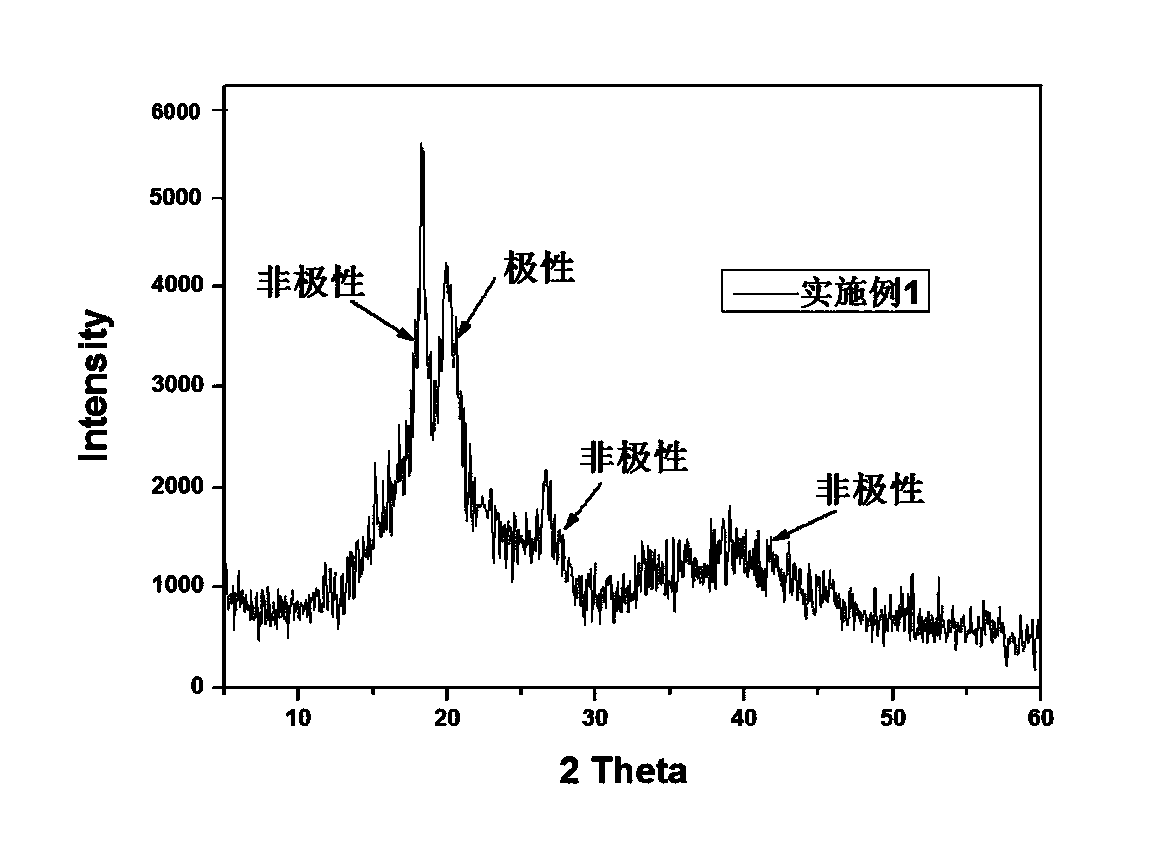

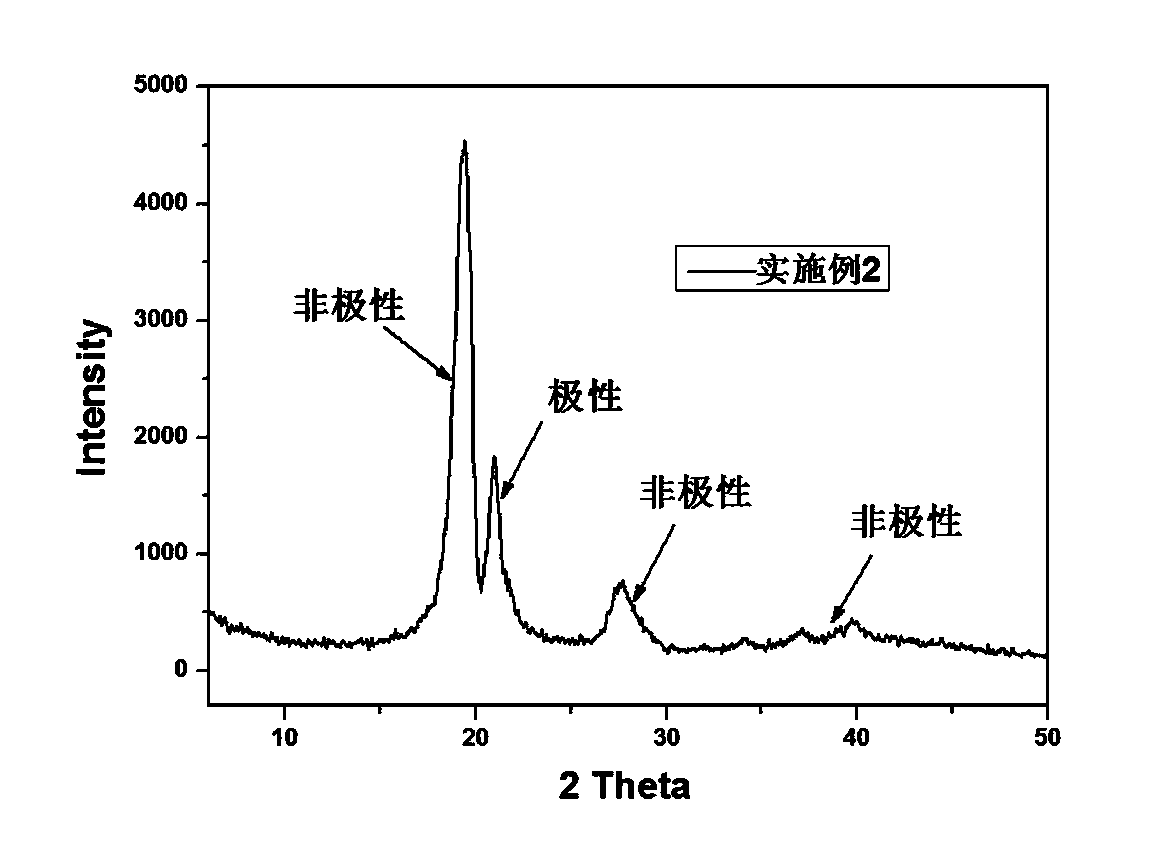

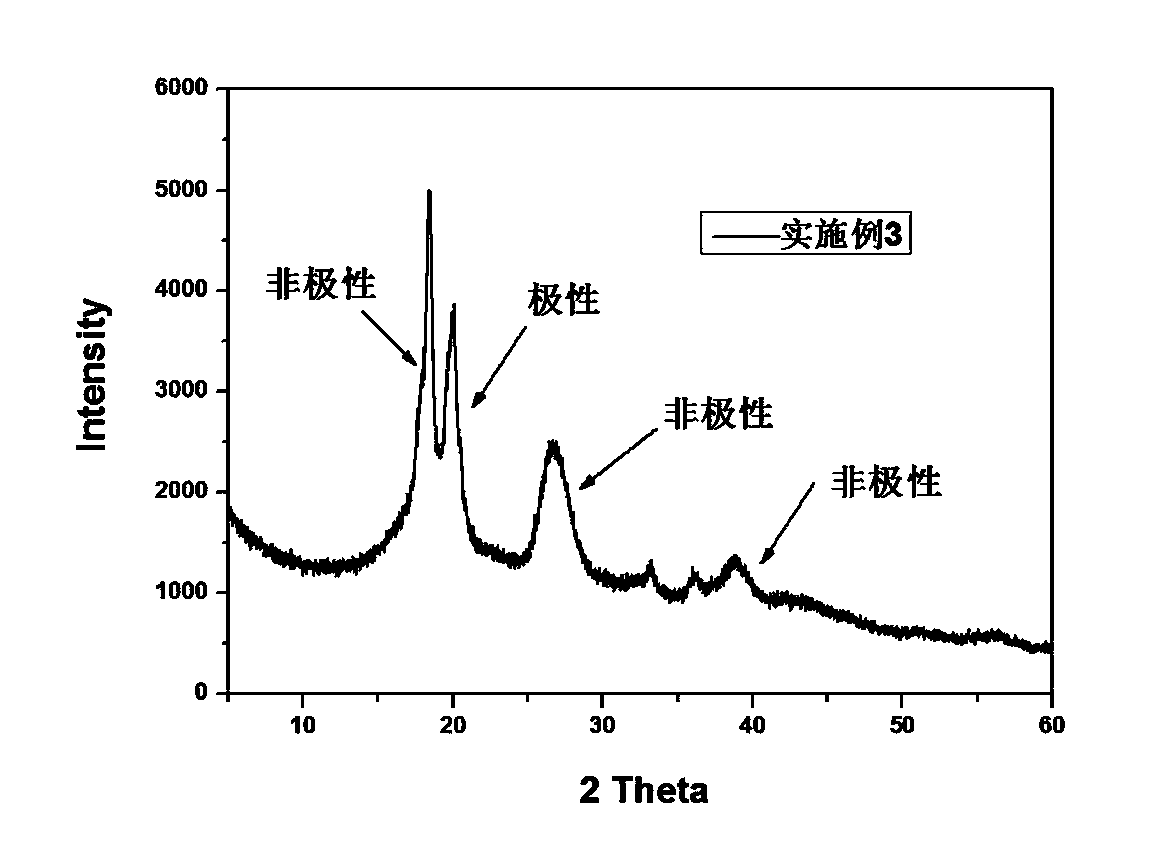

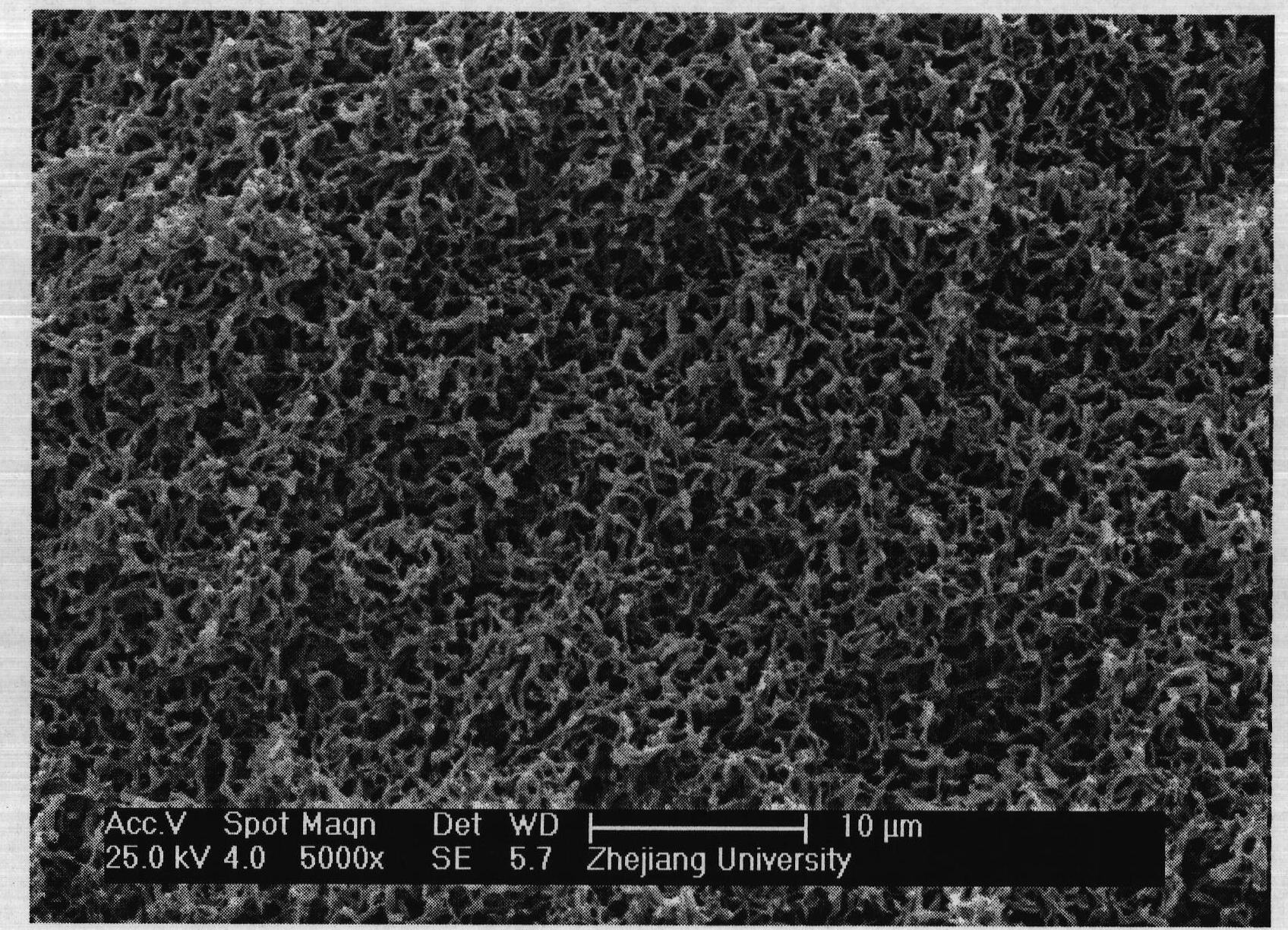

Method for preparing nonpolar polyvinylidene fluoride ultrafiltration membrane

ActiveCN103623714ANot easy to interfereSimple preparation processSemi-permeable membranesPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a method for preparing a nonpolar polyvinylidene fluoride ultrafiltration membrane. The method comprises the following steps: (1) mixing raw materials, evenly agitating at 40-80 DEG C, standing and defoaming to obtain polyvinylidene fluoride membrane liquid, and standing for later use; (2) scraping the membrane liquid on a clean and smooth glass plate, exposing in air to volatize solvent for 0.5-24 hours, wherein the thickness of the membrane liquid is 120-600 microns; (3) immersing the scraped membrane liquid into a first coagulation bath alcohol-water solution, and soaking for 0.02-72 hours under the condition at 40-80 DEG C, so as to prepare a coarse ecological membrane; (4) immersing the coarse ecological membrane into a second coagulation bath, and soaking for 24-72 hours under the condition at 0-80 DEG C; (5) immersing the membrane into a third coagulation bath alcohol-water solution for 2-24 hours, and airing under the condition at 20-50 DEG C, so as to obtain the nonpolar polyvinylidene fluoride ultrafiltration membrane with stable performance. The preparation method disclosed by the invention is simple in technology, and low in production cost; the prepared polyvinylidene fluoride ultrafiltration membrane is non-polar, strong in mechanical strength, good in hydrophilicity, and strong in anti-pollution capacity.

Owner:XIAMEN UNIV OF TECH

Film forming apparatus and method

InactiveUS20100047448A1Stable film formationIncrease heightSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasEngineering

A film forming apparatus includes a processing chamber inside which a vacuum space is maintained and to which a film forming gas is supplied, a substrate supporting unit which is disposed inside the processing chamber and supports a substrate, and a heater which is made of a compound material comprising a high-melting point metal and carbon, is disposed inside the processing chamber, and heats the substrate.

Owner:TOKYO ELECTRON LTD

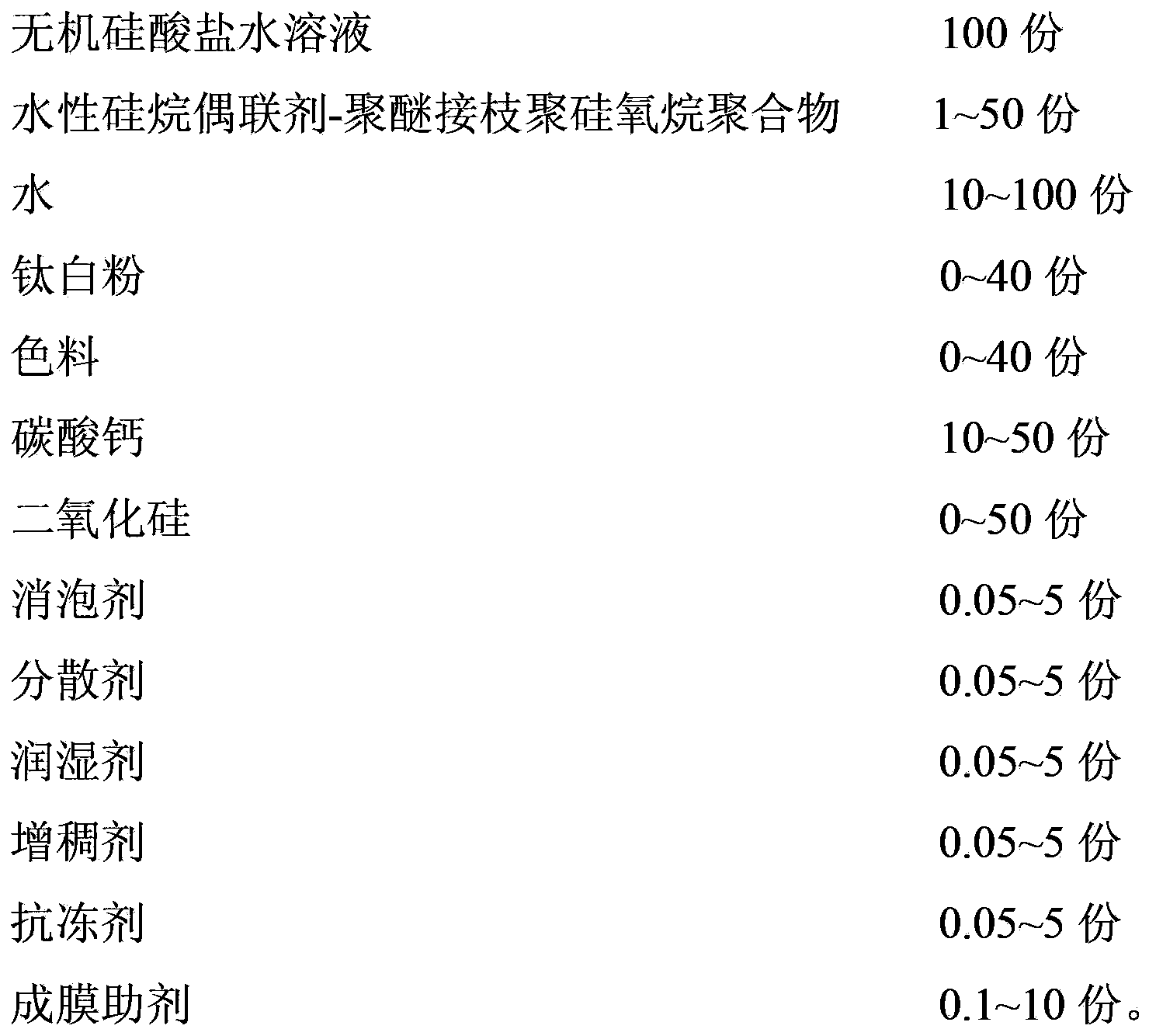

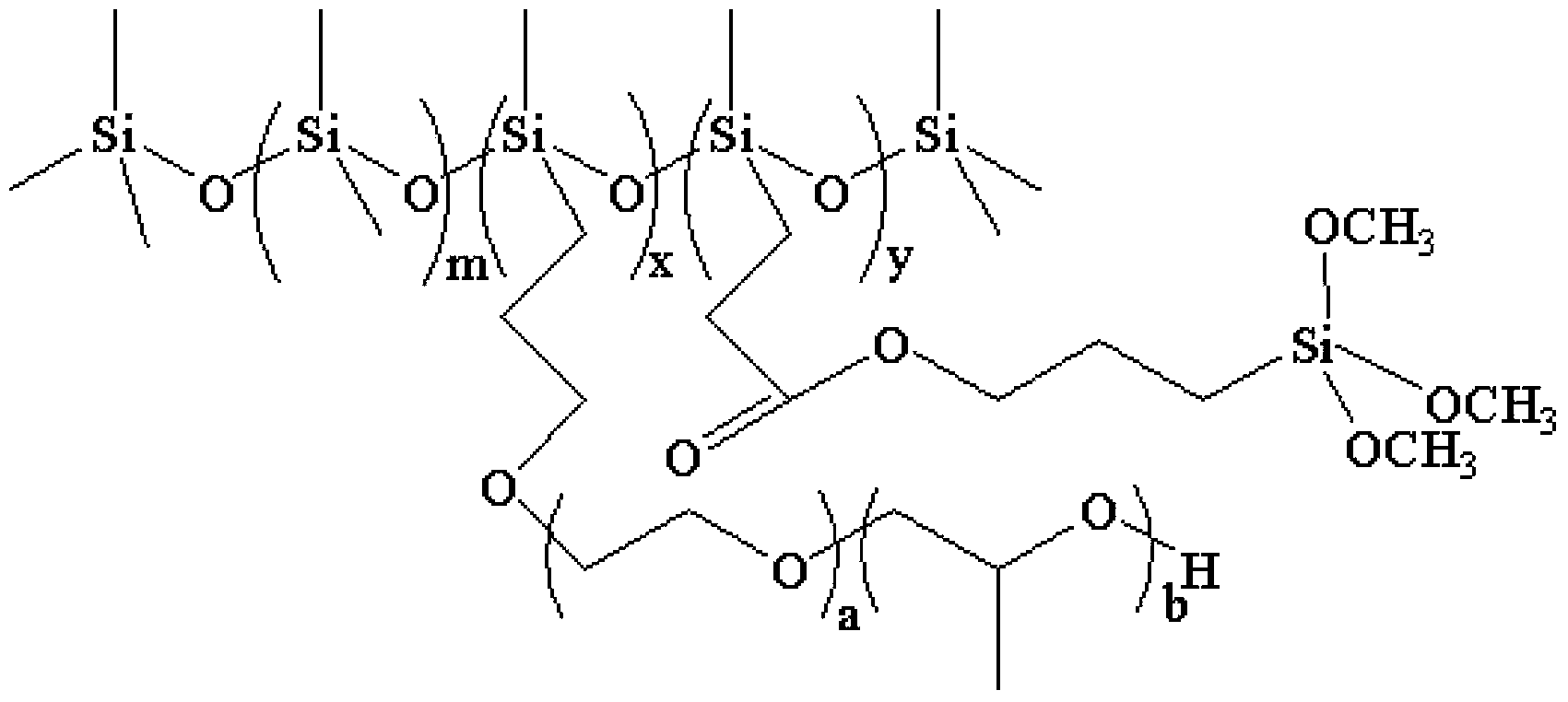

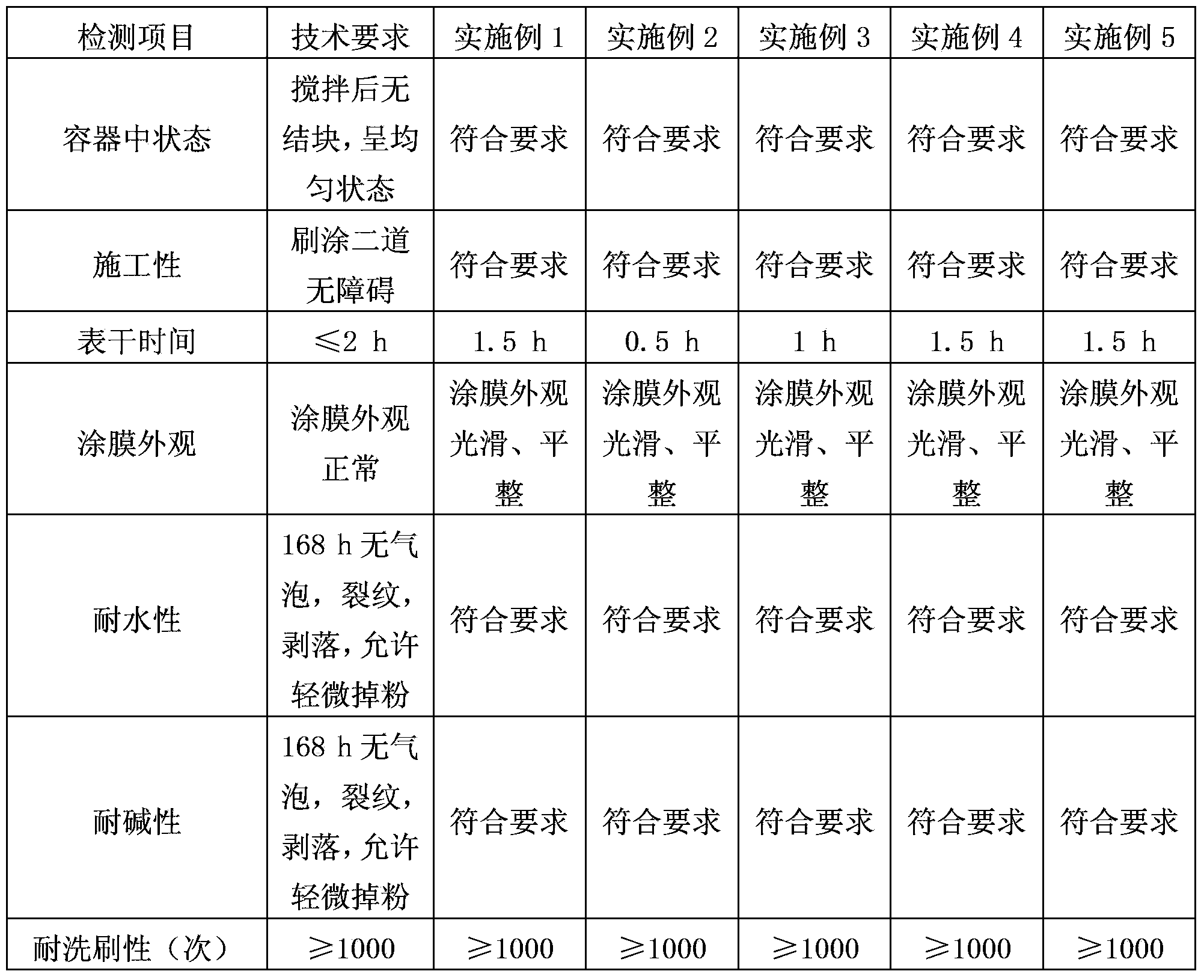

Hydrous silane coupling agent-polyether grafted polysiloxane polymer coating

The invention belongs to the field of coatings, and discloses a hydrous silane coupling agent-polyether grafted polysiloxane polymer coating. The hydrous silane coupling agent-polyether grafted polysiloxane polymer coating comprises the following components in parts by weight: 100 parts of inorganic silicate water solutions, 1-50 parts of hydrous silane coupling agent-polyether grafted polysiloxane polymers, 10-100 parts of water, 0-40 parts of titanium dioxide, 0-40 parts of pigments, 10-50 parts of calcium carbonate, 0-50 parts of silicon dioxide, 0.05-5 parts of defoaming agents, 0.05-5 parts of dispersing agents, 0.05-5 parts of wetting agents, 0.05-5 parts of thickening agents, 0.05-5 parts of anti-freeze agents and 0.1-10 parts of film-forming auxiliary agents. The hydrous silane coupling agent-polyether grafted polysiloxane polymer coating disclosed by the invention has the advantages of abrasion resistance, acid resistance, alkali resistance (without bubbles for 168 hours), easiness for construction, good fixation effect, film-forming stability, excellent film-forming appearance, and the like and is suitable for inner and outer walls.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

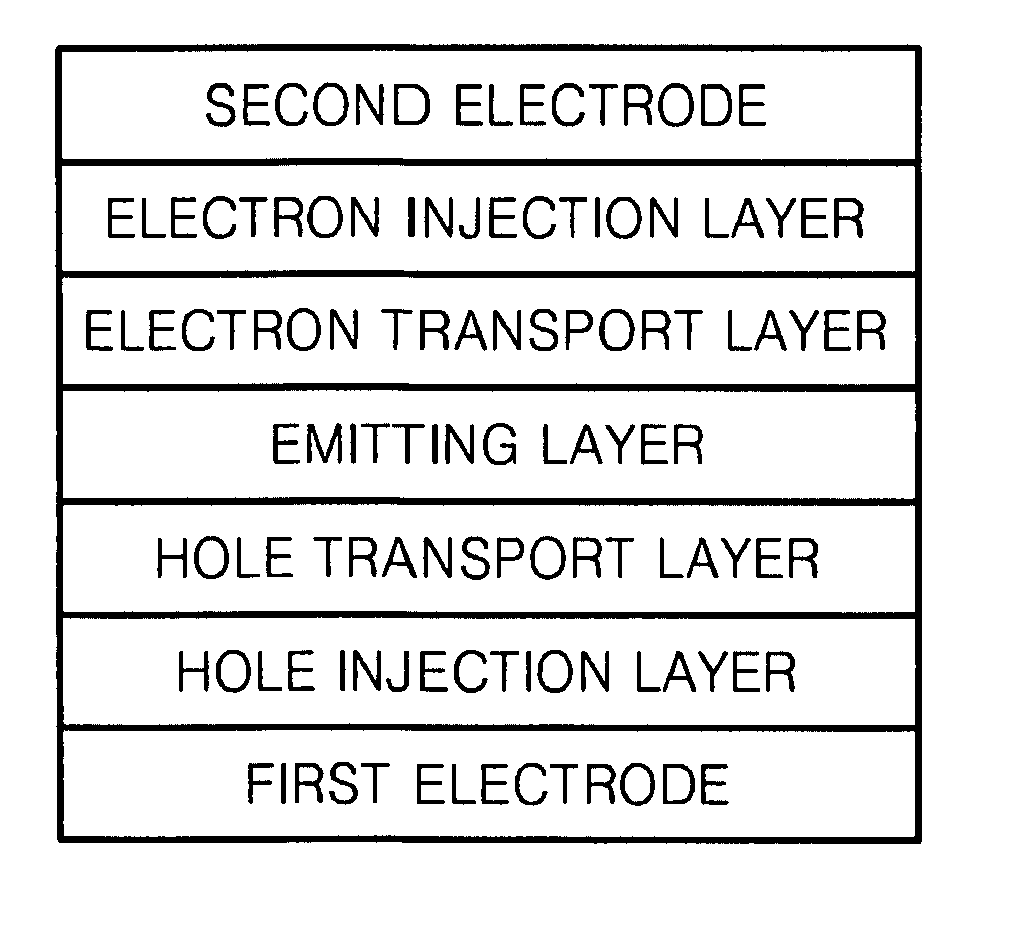

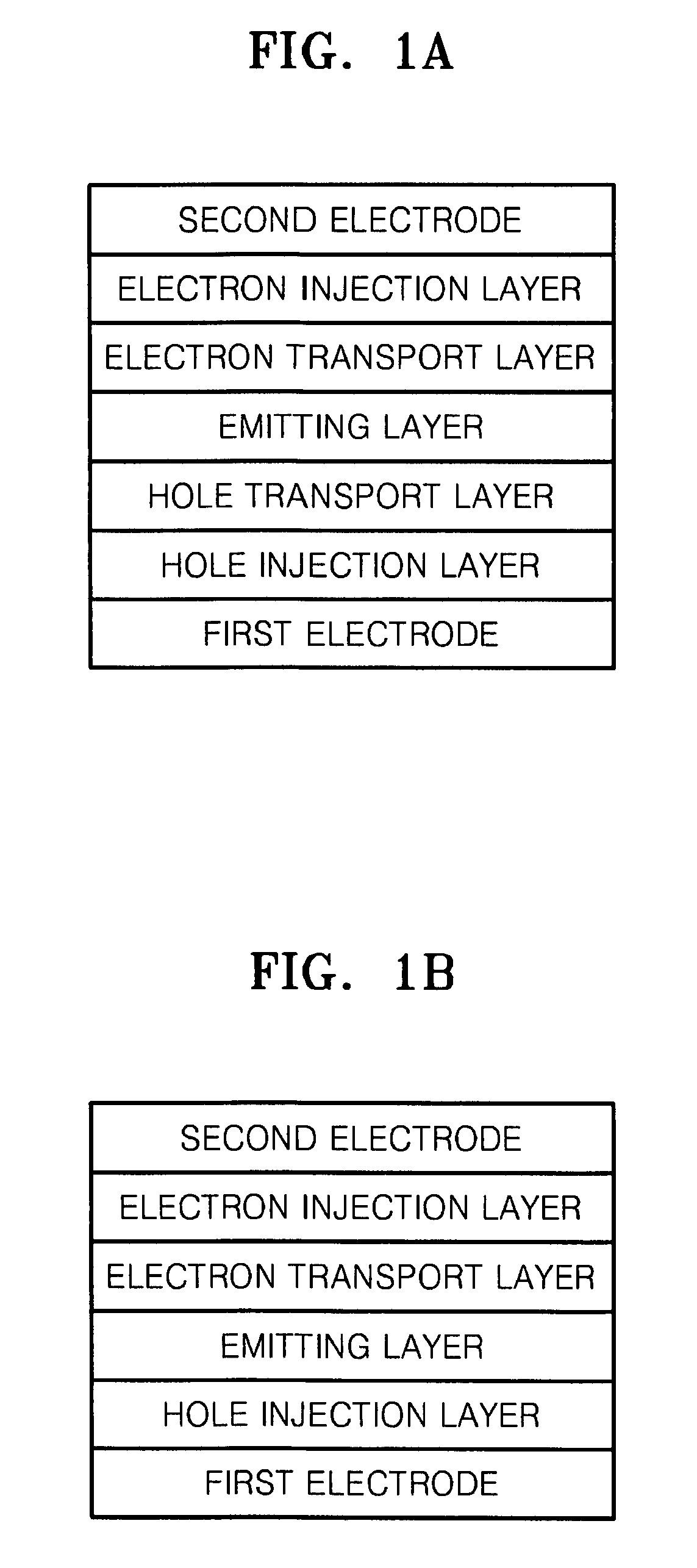

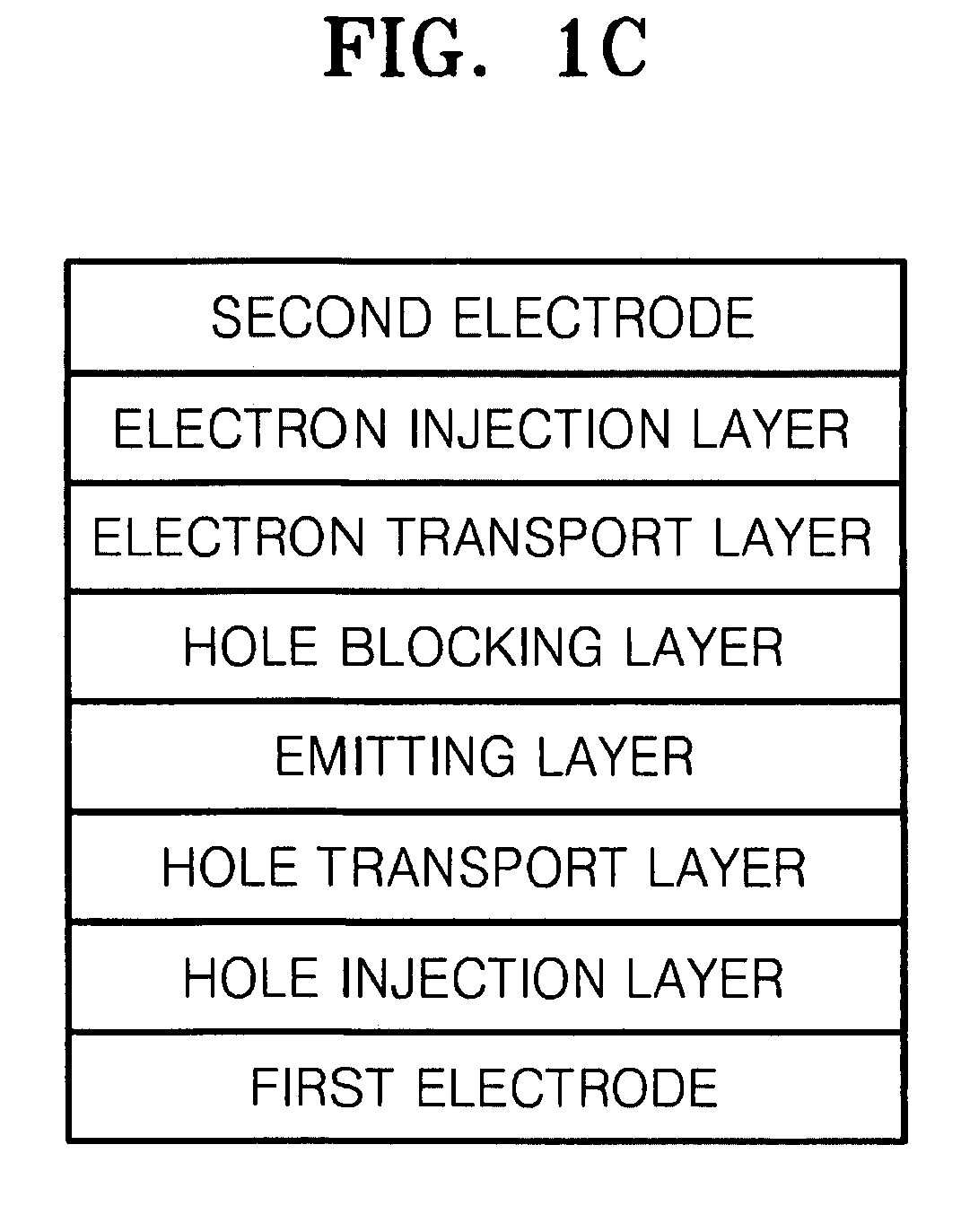

Organoelectroluminescent compound and organoelectroluminescent device employing the same

ActiveUS7854999B2Improve thermal stabilityAccelerate emissionsDischarge tube luminescnet screensOrganic compound preparationSolubilityOrganic light emitting device

Provided are a cyclopentaphenanthrene-based compound and an organoelectroluminescent device employing the same. The cyclopentaphenanthrene-based compound is easy to prepare and excellent in solubility, color purity, color stability, and thermal stability. The cyclopentaphenanthrene-based compound is useful as a material for forming an organic layer, in particular, an emitting layer, in an organoelectroluminescent device, and as an organic dye or an electronic material such as a nonlinear optical material.

Owner:SAMSUNG DISPLAY CO LTD

Trivalent chromium concentrated blue and white zinc passivant and passivation method by means of blue and white zinc passivant

InactiveCN103132068AWide process toleranceProcess tolerance is simpleMetallic material coating processesRare-earth elementNitrate

The invention belongs to the field of passivation treatment and discloses a trivalent chromium concentrated blue and white zinc passivant. The trivalent chromium concentrated blue and white zinc passivant is prepared from 8-50g / L of chromic chloride, 10-60g / L of aluminium potassium sulfate, 3-10g / L of aluminium potassium sulfate, 3-20g / L of cobalt nitrate, 8-15ml / L of coupling agent, and 0.5-5g / L of rare earth element. The invention further discloses a passivation method by means of the trivalent chromium concentrated blue and white zinc passivant. The passivation method includes a first step of galvanizing the surface of a product, washing the product with water, activating the product with concentrated hydrochloric acid, and washing the product with water, a second step of processing the product by means of the blue and white zinc passivant, washing the product with water, and sealing the product with hot water, and a third step of drying the product. The trivalent chromium concentrated blue and white zinc passivant and the passivation method by means of the trivalent chromium concentrated blue and white zinc passivant are environment-friendly, wide in technology tolerance, easy to operate, good in stability, firm in film formation, little in consumption, and low in cost.

Owner:CHONGQING DIANSHI METAL SURFACE TREATMENT

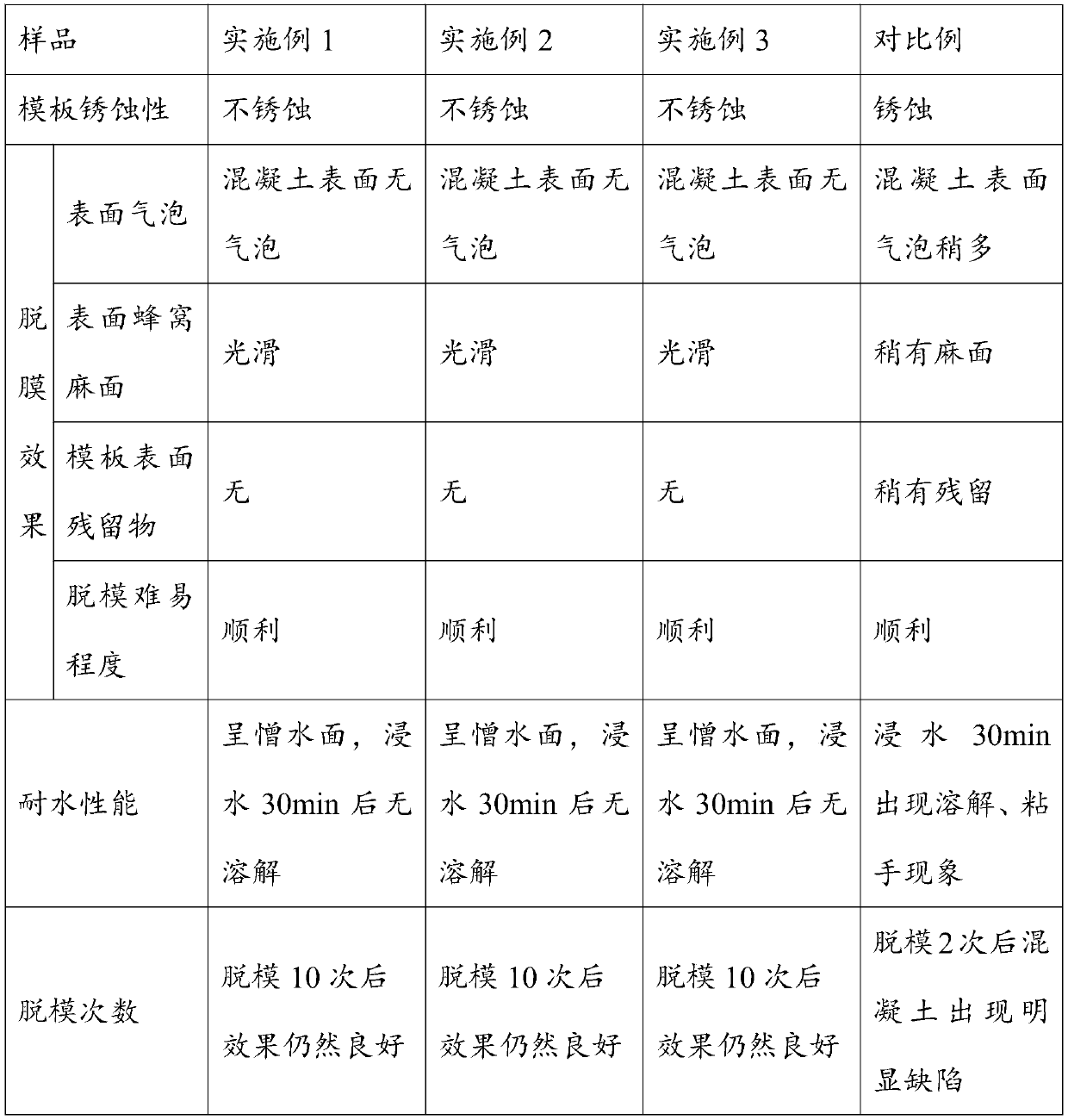

Long-acting concrete water-based mold release agent suitable for steel mold and preparation method of mold release agent

InactiveCN110804483AEnhanced coatability and barrier lubricationEasy to operateLubricant compositionChemistryComposite material

The invention belongs to the technical field of chemical building materials, and particularly relates to a long-acting concrete water-based mold release agent suitable for a steel mold and a preparation method of the mold release agent. Aiming at the problems, the invention mainly overcomes the defects in the prior art, and provides the long-acting concrete water-based mold release agent suitablefor the steel mold and the preparation method of the mold release agent; the long-acting concrete water-based mold release agent comprises the following components: vegetable oil, a coalescing agent,a compound emulsifier, a stabilizer, a corrosion inhibitor and water, wherein the coalescing agent comprises a long-chain alkyl silane coupling agent and aminopropyltriethoxysilane. The prepared concrete water-based mold release agent is stable in performance, good in water scouring resistance and good in reusability, and the apparent mass of hardened concrete can be effectively improved.

Owner:CHINA WEST CONSTR GRP +1

Plant empty capsule and manufacturing method thereof

InactiveCN104274424AReduce moisture contentWide applicabilityPharmaceutical non-active ingredientsCapsule deliveryCelluloseCarrageenan

The invention provides a plant empty capsule with a good moulding effect, high surface smoothness and good elasticity and a manufacturing method thereof. The plant empty capsule comprises 88-90wt% of complex gum, 1-3wt% of potassium chloride, 0.3-0.5wt% of humectant, 0-0.2wt% of polysaccharide, 3-5wt% of medical glycerinum, 1-3wt% of titanium dioxide and 0.2-0.3wt% of food colourant, wherein the complex gum comprises carrageenan, plant cellulose and sodium carboxymethylcellulose. The plant empty capsule is low in water content, is especially applicable to being filled with medicines which have strong hygroscopicity and are sensitive to moisture, has the advantages of wide applicability, no crosslinking reaction and high stability and is preservative-free, and microorganisms can hardly grow on the empty capsule; and meanwhile, the plant empty capsule is hardly crisp or broken at a low temperature and is still stable in capsule shell character at a high temperature.

Owner:韩字光

Preparation method of fluorosilicone modified carbamido compound

ActiveCN109851738AEasy to operateSimple stepsAntifouling/underwater paintsPaints with biocidesSolventProper weights

The invention discloses a preparation method of a fluorosilicone modified carbamido compound. The preparation method comprises following steps: (1) synthesizing fluorosilicone; (2) preparing a fluorosilicone modified carbamido compound; (3) refining the finished product; and (4) diluting and cooling: adding a proper weight of a DMF solvent into the finished product obtained in the step (3) under astirring speed of 500-900 r / min, cooling to the room temperature, measuring, and obtaining the high purity fluorosilicone modified carbamido compound. The provided preparation method has the characteristics of simple technology, good solubility, stable performance, and wide application range.

Owner:广东坚派新材料有限公司

Laminate film

ActiveCN101218098AReflectiveStable film formationMirrorsDiffusing elementsLiquid-crystal displayCarboxylic acid

A white laminated film which has practically sufficient reflectivity at a visible range, can be formed stably, is free from deterioration (yellowing) by ultraviolet radiation, rarely deforms by heat and can be advantageously used as a reflector substrate for liquid crystal displays and internal illumination type electrically spectacular signs, is provided. The laminated film comprises a first layer of a composition which comprises 31 to 60 wt% of inert particles having an average particle diameter of 0.3 to 3.0 µm and 40 to 69 wt% of a polyester consisting of 1 to 100 mol% of naphthalenedicarboxylic acid and 0 to 99 mol% of terephthalic acid as a dicarboxylic acid component and ethylene glycol as a diol component, and a layer B of a composition which comprises 0 to 30 wt% of inert particles having an average particle diameter of 0.3 to 3.0 µm and 70 to 100 wt% of a polyester consisting of 3 to 20 mol% of naphthalenedicarboxylic acid and 80 to 97 mol% of terephthalic acid as a dicarboxylic acid component and ethylene glycol as a diol component and which is in direct contact with the first layer.

Owner:TEIJIN DUPONT FILMS JAPAN

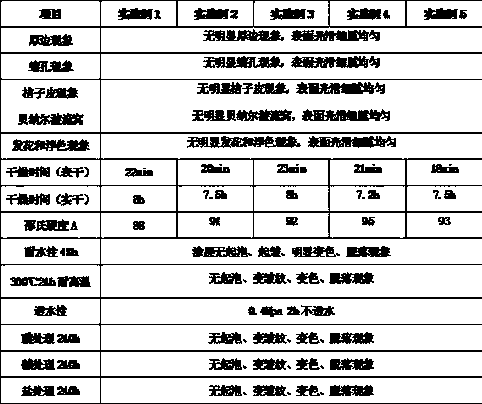

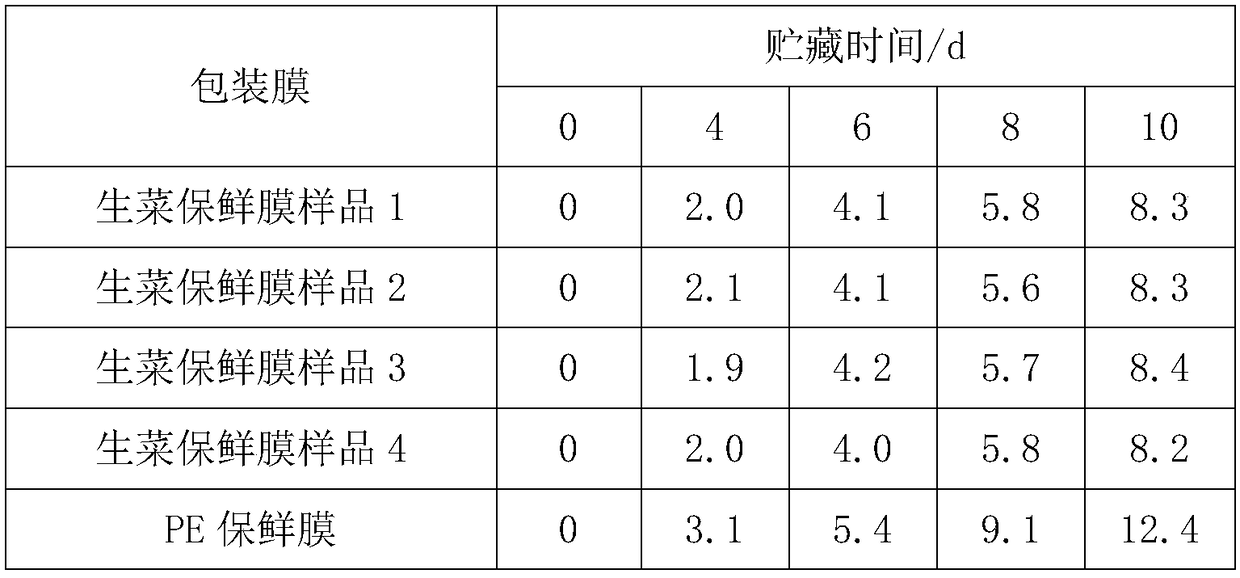

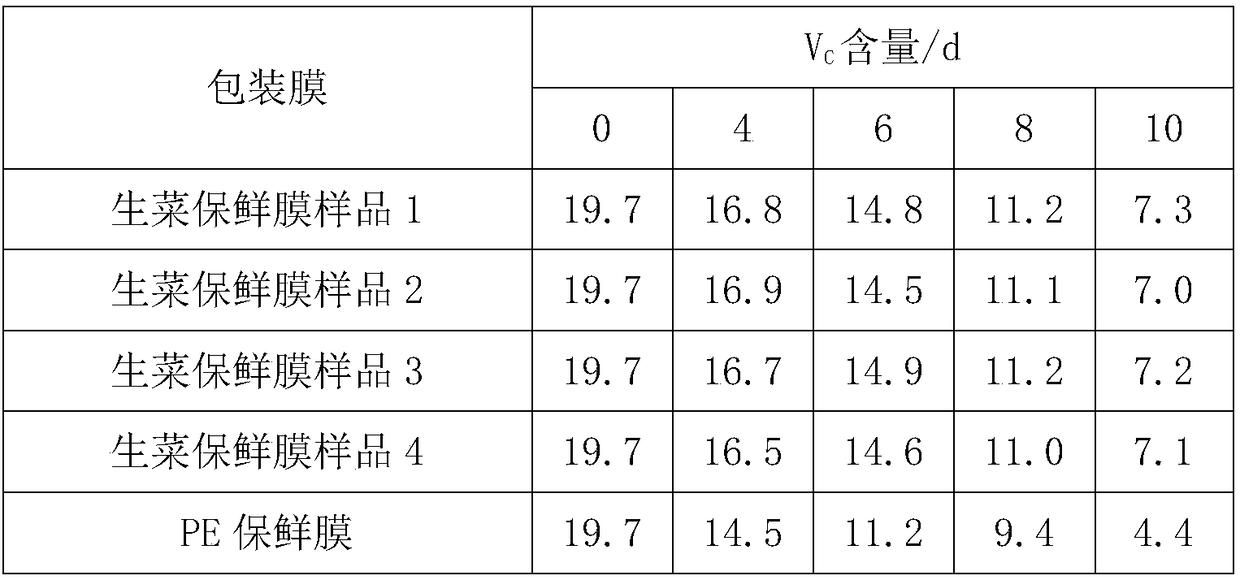

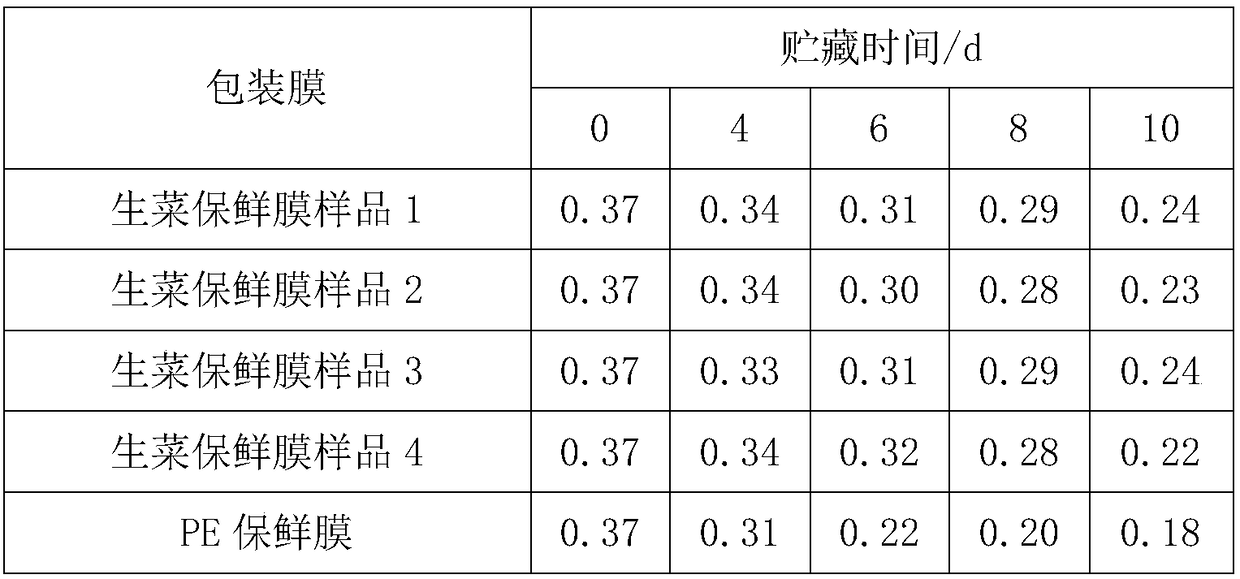

Antibacterial emulsion for fresh keeping of var. ramosa Hort. and method for preparing var. ramosa Hort. fresh keeping film

InactiveCN109479953AGood dispersionImprove stabilityFruits/vegetable preservation by coatingPropolisPolyphenol oxidase

The invention discloses an antibacterial emulsion for fresh keeping of var. ramosa Hort. and a method for preparing a var. ramosa Hort. fresh keeping film. Plant essential oil, carbon quantum dots, aco-emulsifier, an emulsifying agent and distilled water are mixed in a specific sequence and a technology so that a microemulsion is prepared. According to the antibacterial emulsion disclosed by theinvention, a carbon quantum dot technique is introduced into the field of fresh keeping of vegetables for the first time, the characteristics of the carbon quantum dots and the characteristics of antibacterial plant essential oil are sufficiently utilized, and the antibacterial emulsion good in dispersibility, stable in film formation and high in bacteriostasis capacity is obtained. The antibacterial emulsion and propolis liquid are compounded to obtain a mixture, then the mixture is coated onto packaging films to be used for fresh keeping of the var. ramosa Hort. in the warehouse storing course, respiratory intensity of the fresh-cut var. ramosa Hort., microorganism growth and activity of polyphenol oxidase can be well restrained, VC losses in the storage period can be reduced, and favorable organoleptic quality of the var. ramosa Hort. can be maintained. After the fresh-cut var. ramosa Hort. coated with the fresh keeping film is in low-temperature preservation under the condition of4 DEG C, the shelf life can be prolonged to 10-15 days.

Owner:AGRO PROD PROCESSING RES INST YAAS

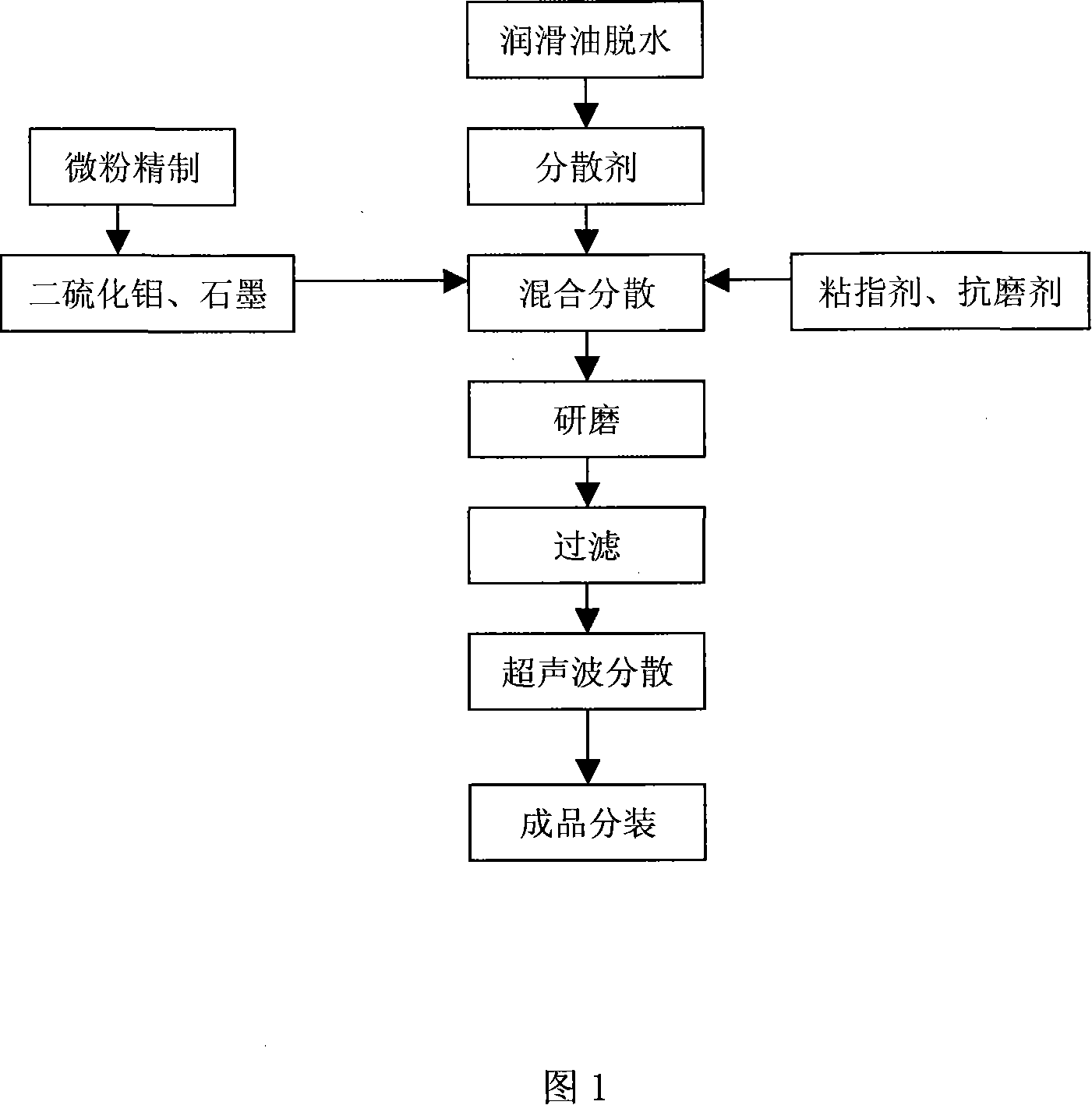

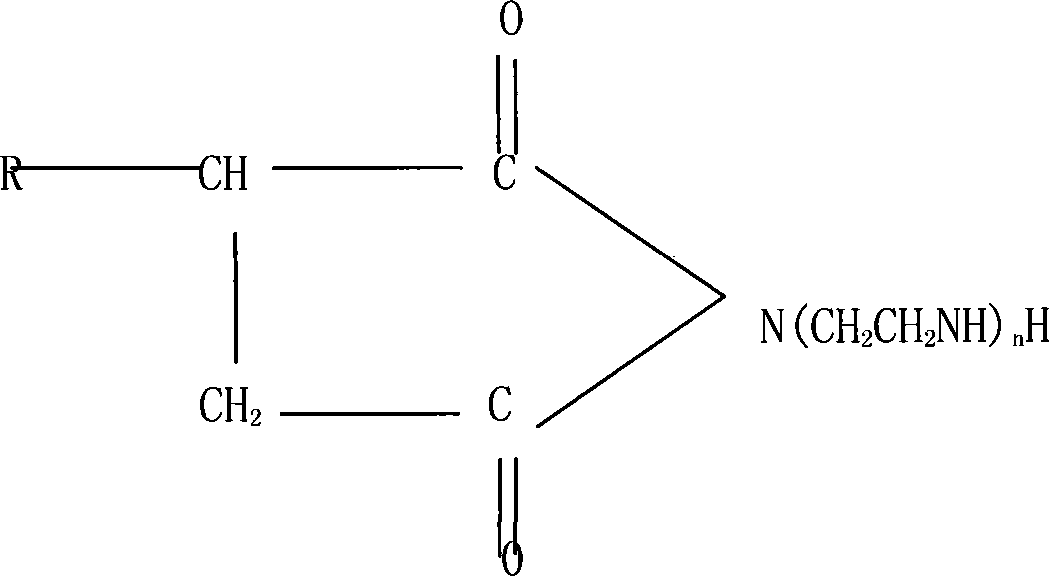

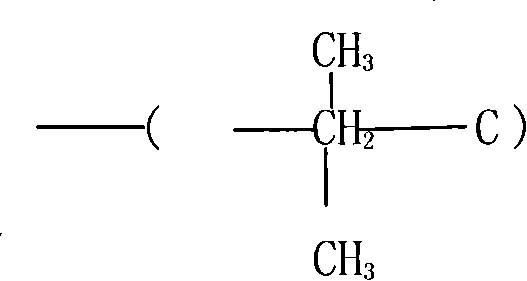

Energy-saving environment protecting function type lubricant agent

The invention discloses an energy-saving environment-protective lubricant with lubricating reinforcing and abrasion proof and squeezing proof effect for the lubricating part of kinds of mechanic equipment, which comprises the following parts: 5%-8% molybdenum disulphite with grain size at 30-5000nm, 5%-8% graphite powder with grain size at 30-5000nm, 5%-8% molybdenum oxide dialkyl dithiophosphate as antiwear agent, 10%-15% succinyl imines as dispersant, 10%-15% polymethacrylate ester as adhesive and residual liquid lubricating material. The invention can repair and fill the side-surface abrade by metal automatically to film rapidly and stably, which lengthens the lift of lubricating part of the mechanic equipment by one time and improves the effective efficiency by 4-10%, therefore saving the fuel by 10-15%, reducing the discharge of harmful gas and smoke obviously and the mechanic noise by 1-8 decibel.

Owner:SHANDONG SUN RISES & THE EAST GASOLINEEUM & CHEM CORP

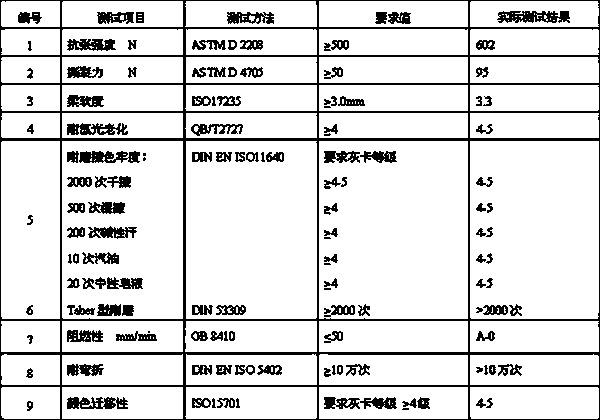

Production technology of contrast-effect automobile seat cushion leather

ActiveCN103667542AFlexibleImprove viewabilityTanning treatmentPre-tanning chemical treatmentFolding enduranceRoom temperature

The invention relates to a production technology of contrast-effect automobile seat cushion leather. The protection technology comprises the steps of liming: dissolving Na2S, NaHS and lime into water in a mass ratio of 1:1:2 to form a liming alkali liquor, reacting fur with the liming alkali liquor in a liquor ratio of 100:100 for 6 h, adding the liming alkali liquor step by step to enable the liquor ratio to increase to 100:200, and continuously reacting for 12 h; retanning: for every 100 parts of fur, adding 100 parts of water, 1 part of a pre-fatting agent and 3 parts of a chrome tanning agent or a chrome-free tanning agent, reacting at the normal temperature for 1 h, adding 2 parts of sodium formate, reacting at the temperature of 40 DEG C for 1 h, and controlling the pH in a range of 3.6-4.0; and finishing: the finishing comprises the steps of roller coating of a bottom layer, embossing, spraying of a color layer, roller coating of an effect layer and spraying of a top layer. The leather produced through the technology is soft, fine in grain side, full in hand feeling, elastic, safe and environment-friendly and has characteristics of wear resistance, folding endurance, light resistance, color migration resistance and the like; and ornamental and pleasant characteristics of the leather are added due to roller coating of the effect layer, and the rigid and non-flexible appearance of ordinary automobile seat cushion leather is changed.

Owner:HAINING SENDE LEATHER

Special medicinal fertilizer for overwintering pisum sativum and production method thereof

InactiveCN104692929ANutritional balanceLong and significant fertilizer effectSuperphosphatesAmmonium salt fertilisersFruit setImidacloprid

The invention discloses a special medicinal fertilizer for overwintering pisum sativum and a production method thereof. The production method of the special medicinal fertilizer is characterized by mixing and granulating urea, calcium superphosphate, Sugumi potassium, ammonium molybdate, borax and DMPP to obtain inner cores, pelletizing for two times, and coating with a coating agent, wherein the components pelletized for the first time comprise urea, monoammonium phosphate, Sugumi potassium, compound potassium nitrophenolate, the solution of tea saponin and nicotine, matrine, DMPP and a colloidal suspension, the components pelletized for the second time comprise urea, a calcium, magnesium and phosphate fertilizer, Sugumi potassium, a chelated salt of amino acid and trace elements, borax, DMPP and a colloidal suspension, and the components of the coating agent comprise imidacloprid, Dual metolachlor, a film forming agent, pearl powder, titanium dioxide and a dye. Through one-time coating, two-time granulating and three-time controlled-release material using, the effective period of urea can be prolonged to 170 days from 15 days or so. The special medicinal fertilizer disclosed by the invention has the effects of weeding, killing insects, promoting the growth of plants and increasing the fruit setting rate of plants.

Owner:SHANDONG COTTON RES CENT

Preparation method and using method of anti-stripping exterior wall putty powder

The invention discloses a preparation method and a using method of anti-stripping exterior wall putty powder. The preparation method comprises the following steps of: step one, adding 6-8 parts of talcum powder, 2-4 parts of white bentonite and 12-14 parts of white portland cement to a pulverizer so as to be pulverized to obtain powder less than 150 meshes; step two, mixing the obtained powder, 40-44 parts of diatomite, 7-9 parts of high-strength gypsum powder and 6-8 parts of titanium dioxide, placing the mixture in a pulverizer so as to be pulverized for 10-15 minutes, then adding 2-3 parts of hydroxypropyl methyl cellulose, and pulverizing for 5-10 minutes again; step three, sieving the powder obtained in the step two by using a screen mesh with 320 meshes, wherein sieve residue is the anti-stripping exterior wall putty powder. The using method comprises the following steps of: placing the anti-stripping exterior wall putty powder in a container, adding water to the putty powder in the proportion of the exterior wall putty powder to the water being 10: (2-3), adding a right amount of pigment according to the color of an exterior wall, soaking for 40-60 minutes, and then stirring the mixture for 5-10 minutes by adopting a stirrer for blade coating.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Nano glass antifogging agent and preparation method thereof

InactiveCN106497518AEasy to useGood anti-fog effectOther chemical processesCoatingsSolventActive agent

The invention provides a nano glass antifogging agent and a preparation method thereof. The nano glass antifogging agent comprises effective components and water. The effective components comprise an anionic surfactant, a non-ionic surfactant, a nano photocatalytic active substance, an active agent stabilization additive, an organic acid solvent and a volatilization dispersant. In the preparation process, the organic acid solvent and the volatilization dispersant are mixed with partial water so as to obtain solution A; the anionic surfactant is mixed with the non-ionic surfactant so as to obtain solution B; the active agent stabilization additive is added to the solution B, the solution is uniformly mixed, then the solution A is added, and the rest water is added after uniformly mixing, the nano glass antifogging agent is obtained after uniformly mixing. The preparation method is capable of stably dispersing the nano photocatalytic active substance into a carrier solvent, using the super-hydrophilic property and nano adhesiveness thereof, and using own specific ultraviolet shielding and the decomposing and removing of harmful gases in the air as the function extension of the nano glass antifogging agent, and obtaining the nano glass antifogging agent with the long-term stable antifogging effect and the possible functional recovery after long-term use.

Owner:重庆返璞科技有限公司

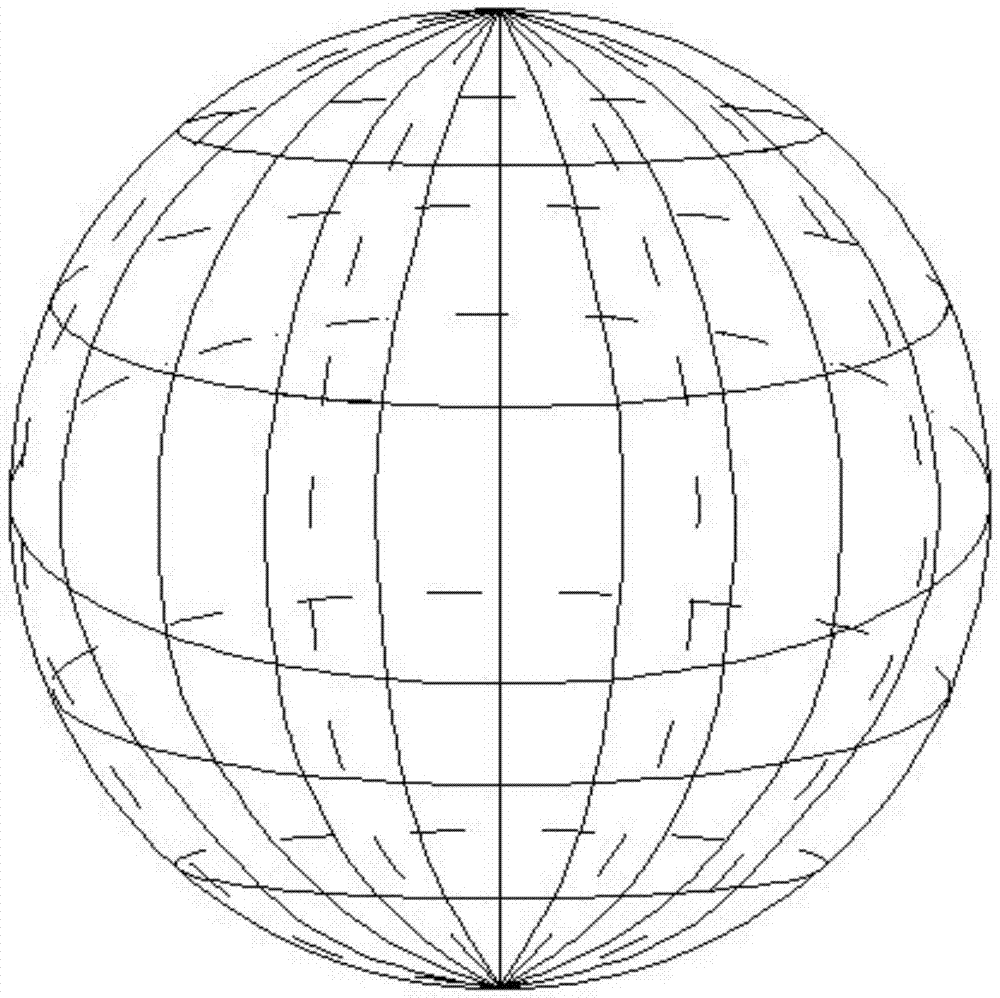

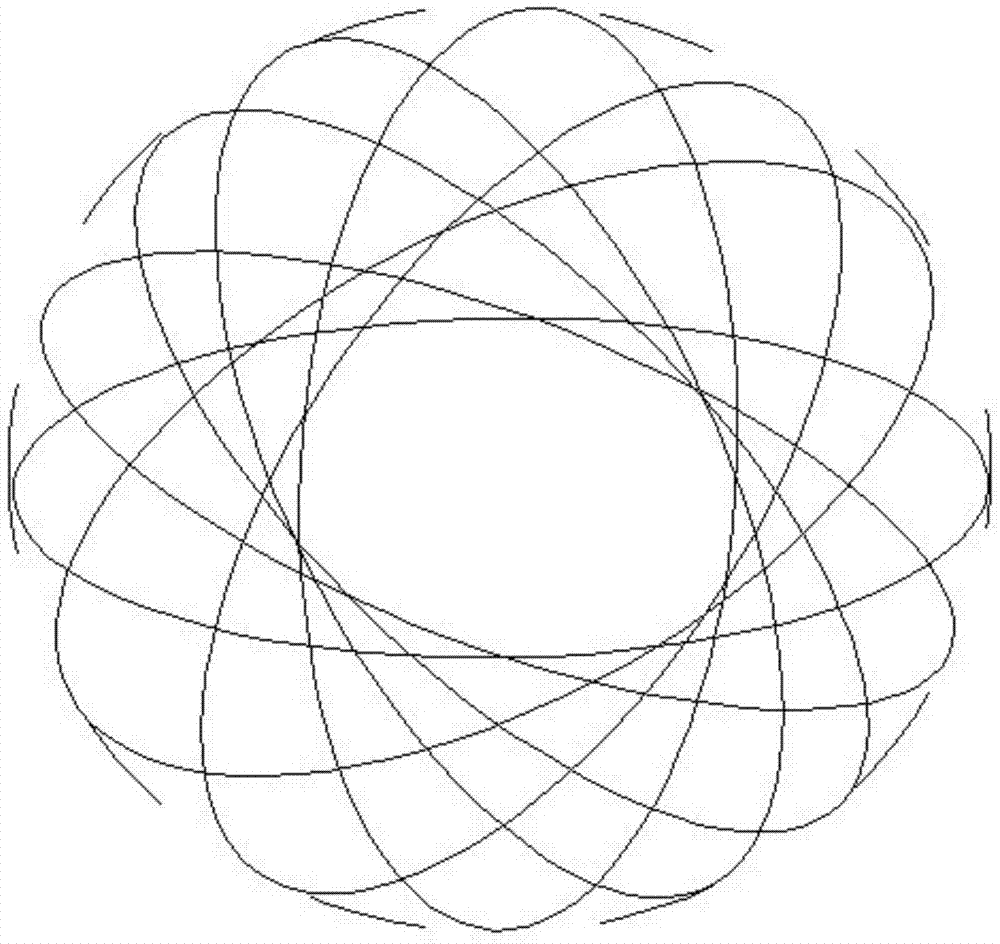

Efficient denitrification biological carrier filler and applications of efficient denitrification biological carrier filler in sewage treatment

InactiveCN106966510AIncrease surface areaLarge attachment spaceWater treatment compoundsWater contaminantsHigh concentrationSludge

The invention discloses an efficient denitrification biological carrier filler and applications of the efficient denitrification biological carrier filler in sewage treatment. The efficient denitrification biological carrier filler comprises a shell and hollow bamboo balls, and specially comprises a hollow plastic spherical shell and a plurality of built-in hollow bamboo ball knitted from phyllostachys pubescens strips, wherein the surface of the phyllostachys pubescens contains a large amount of hydroxyl groups and carboxyl free radicals, and has good hydrophilicity and good bio-affinity so as to rapidly form the active sludge film and provide the firm active sludge film, and when the carbon source is insufficient, the hollow bamboo balls can be decomposed into denitrifying bacteria so as to provide the carbon source. According to the present invention, the efficient denitrification biological carrier filler has the characteristics of rapid film forming and firm formed film of the bamboo filler, the characteristic of high mechanical strength of the plastic filler, further has characteristics of greatly-increased filler surface area, unit volume biomass increasing, greatly-increased active sludge concentration in the reactor, nitrification effect improving, denitrification effect improving, and substantially-increased denitrogenation efficiency of the high concentration nitrogen-containing wastewater.

Owner:CENT SOUTH UNIV +1

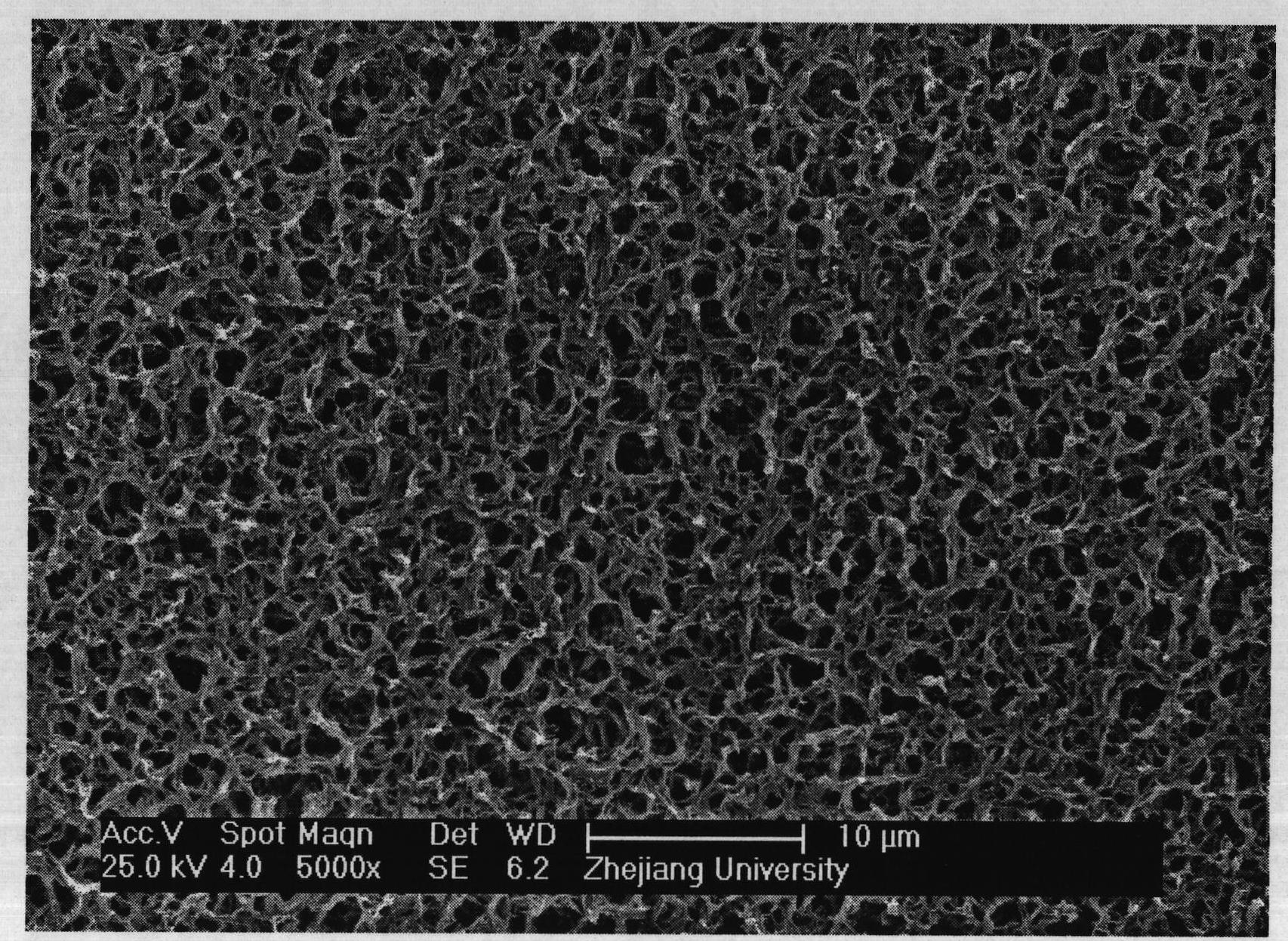

Method for preparing skin-free homogeneous structural polyvinylidene fluoride transfer film

InactiveCN101850217AStable performanceUniform pore sizeSemi-permeable membranesPolyvinylidene fluorideChemistry

The invention discloses a method for preparing a skin-free homogeneous structural polyvinylidene fluoride transfer film, which comprises the following steps of: (1) mixing raw materials, stirring the raw materials uniformly at the temperature of between 60 and 140 DEG C, standing and de-foaming the mixture to obtain polyvinylidene fluoride film-making solution, and standing the film-making solution for later use; (2) scraping the film-making solution on a clean and flat glass plate, wherein the thickness of the film solution is 300 to 700 microns; (3) dipping the scraped film solution into a first gel bath, and soaking the film solution for 0.05 to 48 hours at the temperature of between 0 and 30 DEG C to obtain a coarse ecological film; (4) dipping the coarse ecological film into a second gel bath, and soaking the coarse ecological film for 0.1 to 2 hours at the temperature of between 5 and 70 DEG C; and (5) soaking the film into purified water for at least 24 hours, fully displacing the residual organic solvent and additive, then taking the film out, and naturally airing the film to obtain the homogeneous network structural polyvinylidene fluoride transfer film. The preparation method has simple process and low production cost, and the prepared polyvinylidene fluoride transfer film has high strength and high protein adsorption quantity.

Owner:ZHEJIANG UNIV

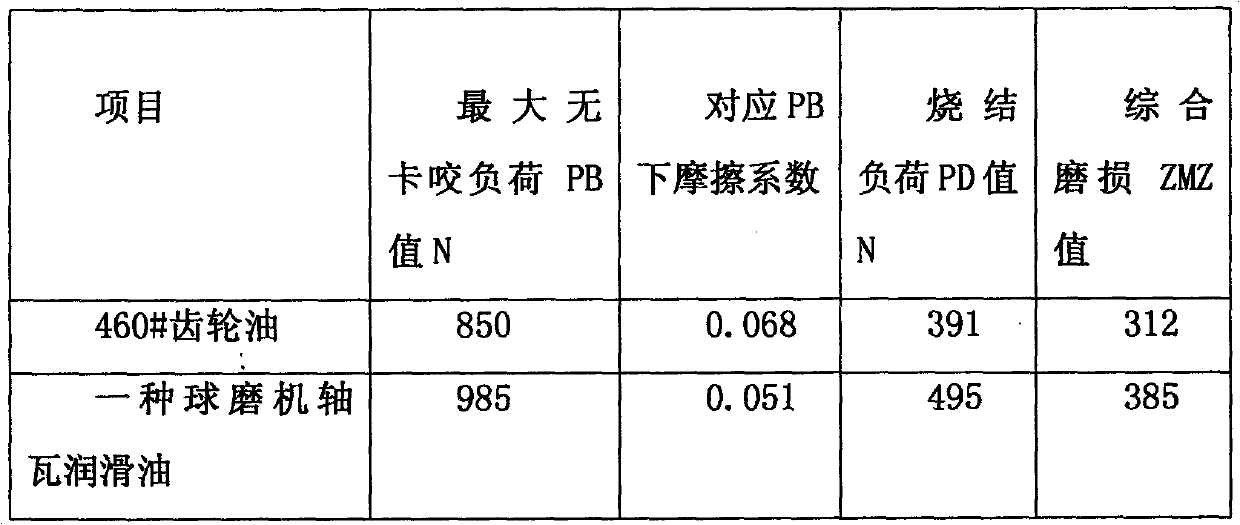

Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

ActiveCN102559347AImprove the lubrication effectReduce the temperatureBase-materialsPolyesterEngineering

Ball grinding mill bearing bush lubricating oil and a manufacturing method thereof solve the problem that a ball grinding mill bearing bush is poor in lubrication in the severe environment. The ball grinding mill bearing bush lubricating oil is formed by using synthetic oil as base oil and refining multiple added efficient composite additives, has the advantages of being abrasion-resisting, high-temperature-resisting, oxidation-resisting, firm in formed film and the like, and can repair wire drawing and reduce abrasion and bearing bush temperature at fastest speed. The work efficiency and the product quality are improved obviously, the repair and maintenance costs are reduced, the service life of a device is prolonged, and energy consumption is reduced greatly. The ball grinding mill bearing bush lubricating oil is composed of, by mass, mineral lubricating oil 49%-69%, polyester synthetic oil 20%-40%, thickening agent 0.05%-0.15%, organic molybdenum composite additive 2.5%-4.5%, T306 additive 1%-3%, T202 antioxygen 0.4%-0.6%, T551 metal deactivator 0.7%-0.9% and T704 antirust additive 0.6%-0.8%, wherein the summation of the components is a hundred percent.

Owner:洛阳正本润滑材料有限公司

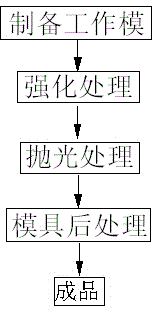

Preparation method of gypsum plastic suction mold

InactiveCN104960119AReasonable structure and cost allocationReasonable cost allocationPolymer scienceGypsum

The invention discloses a preparation method of a gypsum plastic suction mold. The preparation method comprises a, work mold preparation, b, reinforcement treatment, c, polishing treatment, and d, mold aftertreatment. The preparation method has reasonable processes, can be implemented simply, and has a moderate preparation cost. The gypsum plastic suction mold has a reinforced layer structure on the surface. The reinforced layer structure has the advantages of reasonable cost and stable and excellent film forming ability and can effectively improve strength, surface quality and a service life of the gypsum mold and improve practicality of the gypsum plastic suction mold.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Anti-stripping exterior wall putty powder

InactiveCN103351687AStrong covering powerLiquidityFilling pastesMethyl celluloseWhite Portland cement

The invention discloses anti-stripping exterior wall putty powder. The anti-stripping exterior wall putty powder is prepared from the following raw materials in parts by weight: 40-44 parts of diatomite, 6-8 parts of talcum powder, 2-4 parts of white bentonite, 12-14 parts of white portland cement, 7-9 parts of high-strength gypsum powder, 2-3 parts of hydroxypropyl methyl cellulose and 6-8 parts of titanium dioxide. The anti-stripping exterior wall putty powder disclosed by the invention does not contain harmful substances. As the components of the anti-stripping exterior wall putty powder are adjusted, the bonding strength of the putty is enhanced, and the anti-stripping property of the putty is improved.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com