Long-acting concrete water-based mold release agent suitable for steel mold and preparation method of mold release agent

A concrete and release agent technology, applied in the field of chemical building materials, can solve the water resistance and long-term evaluation of water-based release agents, general evaluation, reusability and erosion resistance evaluation, long-term and reusable performance evaluation, etc. problems, achieve the effect of improving appearance quality, enhancing coating performance and isolating lubrication performance, and overcoming construction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a long-acting concrete water-based release agent suitable for steel molds, the detailed steps are as follows:

[0030] (1) Weigh 100.0g of vegetable oil (rapeseed oil), 5.0g of octadecyltrimethoxysilane, and 1.0g of aminopropyltriethoxysilane and mix them uniformly, and stir at a constant temperature for 20min to obtain a modified film-forming aid. vegetable oil;

[0031] (2) Add 12.5g sodium dodecylbenzenesulfonate, 12.5g Span-80, 18.75g Tween-80 and 1.0g stabilizer to the modified vegetable oil obtained in step (1) and mix with each other, constant temperature shear dispersion 40min, shear rate 3500 / min, then add 1000g water and stir to obtain vegetable oil emulsion;

[0032] (3) Add 0.5 g of triethanolamine and 0.5 g of sodium benzoate to the vegetable oil emulsion obtained in step (2), stir evenly and adjust the pH to about 9.0 to obtain a concrete water-based release agent.

Embodiment 2

[0034] A preparation method of a long-acting concrete water-based release agent suitable for steel molds, the detailed steps are as follows:

[0035] (1) Weigh 50.0g of vegetable oil (rapeseed oil), 2.0g of hexadecyltrimethoxysilane, and 0.5g of aminopropyltriethoxysilane and mix them uniformly, and stir at a constant temperature for 20min to obtain a modified film-forming aid. vegetable oil;

[0036] (2) Add 7.5g sodium dodecylbenzenesulfonate, 7.5g Span-80, 15g Tween-80 and 1.0g stabilizer to the modified vegetable oil obtained in step (1) and mix with each other, and then shear and disperse at a constant temperature for 40min , shear rate 3000 / min, then add 480g water and stir to obtain vegetable oil emulsion;

[0037] (3) Add 0.3 g of triethanolamine and 0.1 g of sodium benzoate to the vegetable oil emulsion obtained in step (2), stir evenly and adjust the pH to about 9.0 to obtain a concrete water-based release agent.

Embodiment 3

[0039] A preparation method of a concrete water-based release agent suitable for steel molds, the detailed steps are as follows:

[0040] (1) Weigh 40.0g soybean oil and 40.0g rapeseed oil, 2.0g dodecyltrimethoxysilane, 2.0g octadecyltrimethoxysilane, 0.8g aminopropyltriethoxysilane and mix with each other Evenly, stir at a constant temperature for 20 minutes to obtain a film-forming aid modified vegetable oil;

[0041] (2) Add 10.0 g of sodium dodecylbenzene sulfonate, 10.0 g of Span-80, 15.0 g of Tween-80 and 0.8 g of stabilizer to the modified vegetable oil obtained in step (1) and mix with each other, and shear and disperse at a constant temperature for 40 min , shear rate 3000 / min, then add 1000g water and stir to obtain vegetable oil emulsion;

[0042] (3) Add 0.2 g of triethanolamine and 0.2 g of sodium benzoate to the vegetable oil emulsion obtained in step (2), stir evenly and adjust the pH to about 9.0 to obtain a concrete water-based release agent.

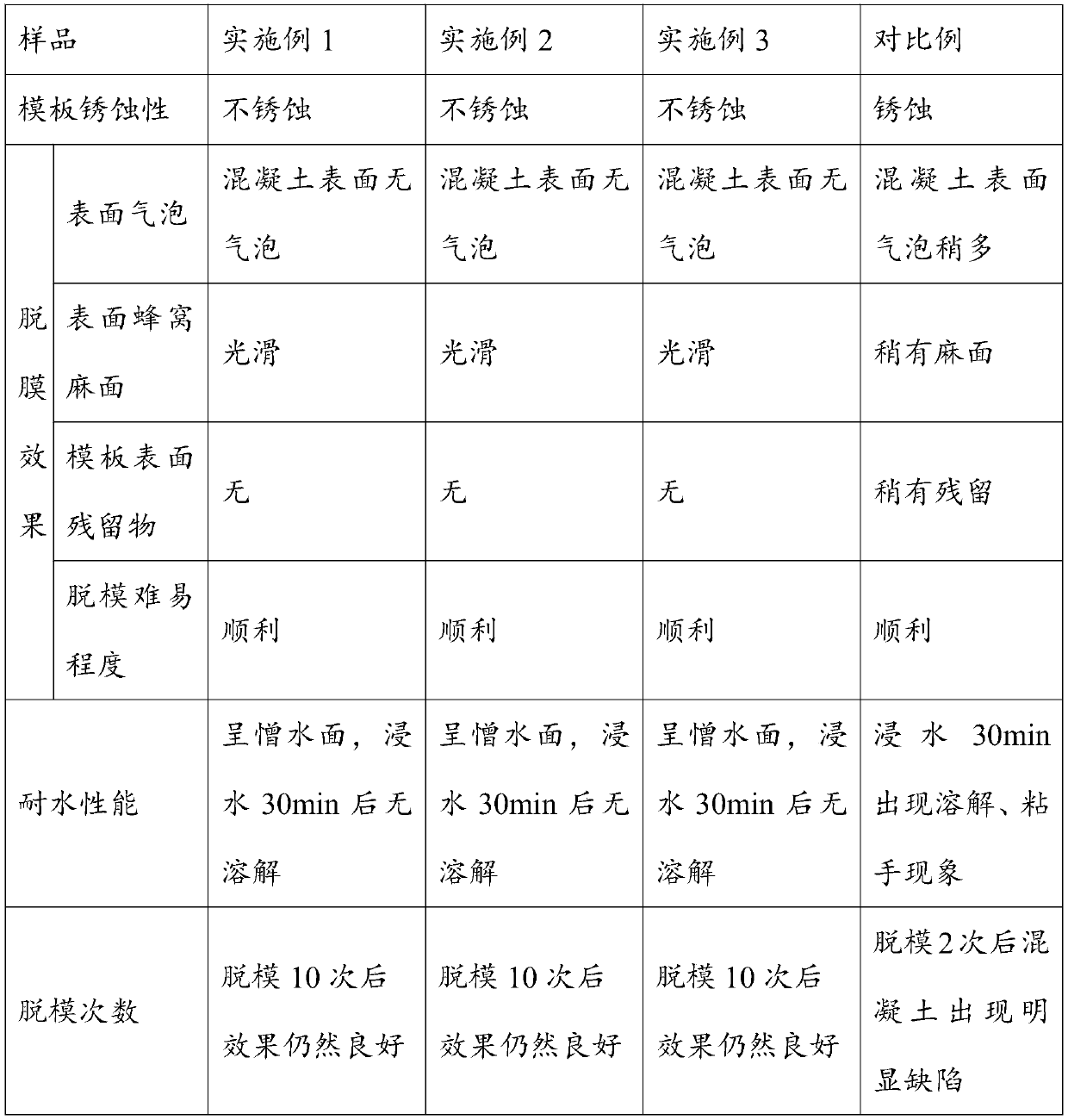

[0043] 2. Rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com