Patents

Literature

561 results about "Polyphenol oxidase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyphenol oxidase (PPO; also monophenol monooxygenase or polyphenol oxidase i, chloroplastic) is a tetramer that contains four atoms of copper per molecule, and binding sites for two aromatic compounds and oxygen. The enzyme catalyses the o-hydroxylation of monophenol molecules in which the benzene ring contains a single hydroxyl substituent to o-diphenols (phenol molecules containing two hydroxyl substituents at the 1, 2 positions, with no carbon between). It can also further catalyse the oxidation of o-diphenols to produce o-quinones.

Compound enzyme preparation for fermentation of pu'er tea and application

InactiveCN102492665APromote decompositionImprove the unique quality of connotationHydrolasesPre-extraction tea treatmentBiotechnologyPhytase

The invention relates to a compound enzyme preparation for fermentation of pu'er tea, which is formed by compounding 10% to 20% of cellulase, 10% to 20% of pectinase, 5% to 15% of polyphenol oxidase, 5% to 10% of glucose oxidase, 5% to 10% glucoamylase, 5% to 10% xylanase, 5% to 10% of beta-glucanase, 5% to 10% of beta-mannase, 5% to 10% of tannase, 5% to 10% of acidic protease, 5% to 10% of lipase, 1% to 5% of alpha-amylase and 1% to 5% of phytase. By the aid of coordination of the enzyme system, polysaccharide and other substances in tea including cellulose and hemicellulose can be effectively decomposed, so that various physiochemical substances in cells can be dissolved. Meanwhile, oxidation and condensation of tea polyphenol, decomposition of protein, amino acid and carbonhydrate, a series of reactions of various products including polymerization and condensation and the like are accelerated and promoted.

Owner:YUNNAN NORMAL UNIV

Use of mixed duplex oligonucleotides to effect localized genetic changes in plants

InactiveUS7094606B2Other foreign material introduction processesFermentationACC oxidaseGenetic Change

Owner:CIBUS

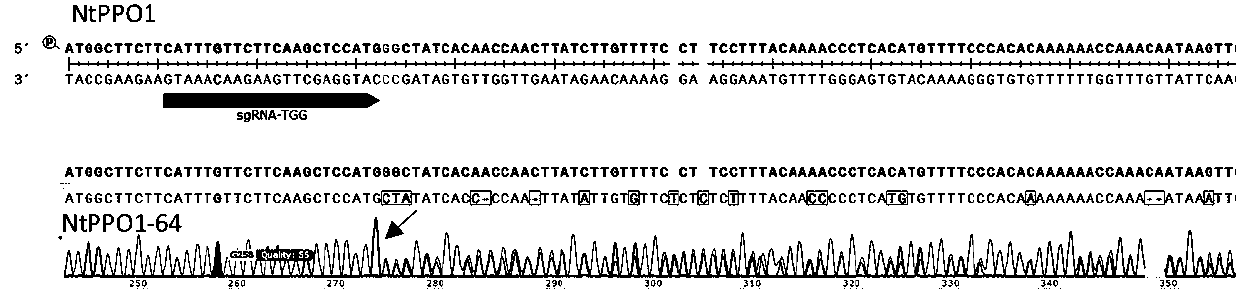

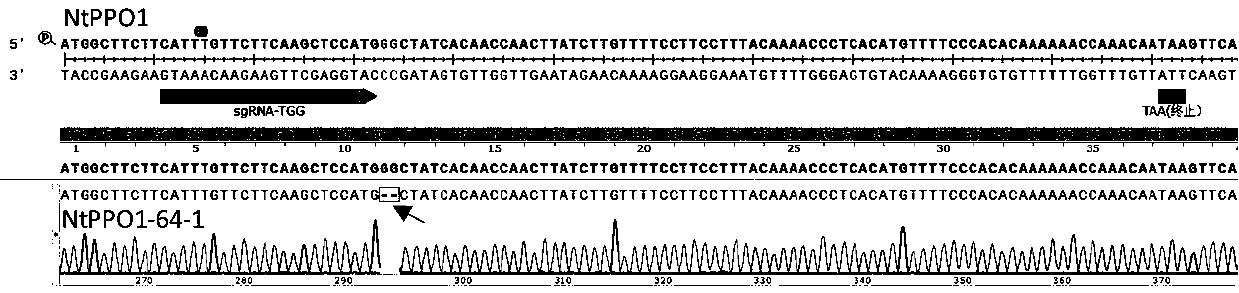

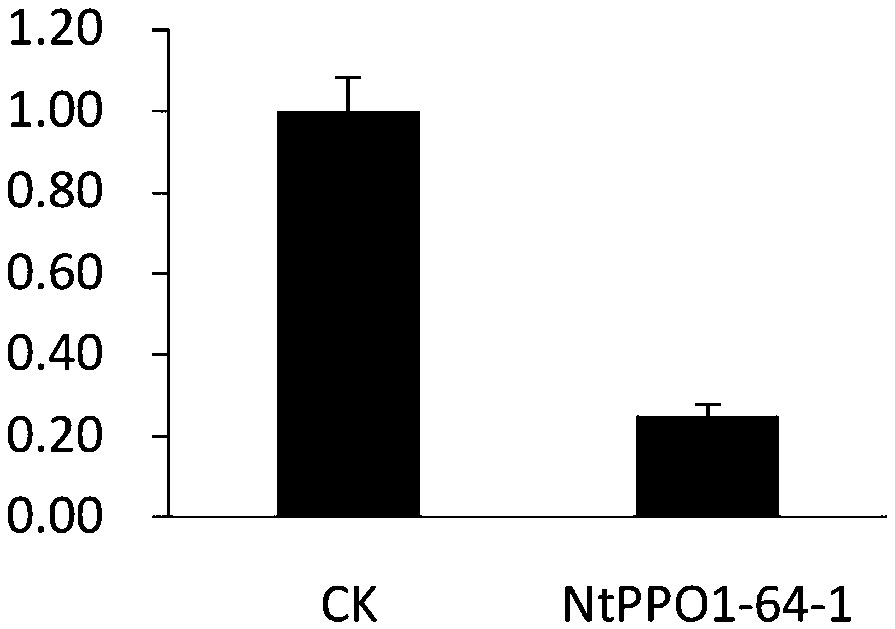

Tobacco polyphenol oxidase gene NtPPO1 and site-directed mutagenesis method and application thereof

InactiveCN107653256AReduce expressionReduce PPO enzyme activityHydrolasesOxidoreductasesNicotiana tabacumPolyphenol oxidase

The invention discloses a tobacco polyphenol oxidase gene NtPPO1 and a site-directed mutagenesis method and application thereof. The nucleotide sequence of the tobacco polyphenol oxidase gene NtPPO1 is shown in SEQ ID:No.1, the coded amino acid sequence is shown in SEQ ID:No.2. The invention further discloses a clone method of the tobacco polyphenol oxidase gene NtPPO1. The clone method comprisesthe specific steps that firstly, cDNAs of tobacco leaves are synthesized; secondly, PCR amplification of the NtPPO1 gene is conducted; thirdly, a CRISPR / Cas9 carrier of the NtPPO1 gene is constructed;fourthly, sequencing detection of the NtPPO1 gene mutation is conducted. The NtPPO1 gene has a wide application prospect in preventing tobacco browning. The tobacco polyphenol oxidase gene and the encoded protein thereof provide the gene and technology support for crops especially for anti-browning breeding of tobaccos.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

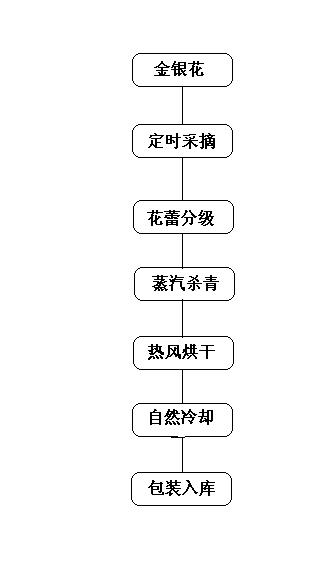

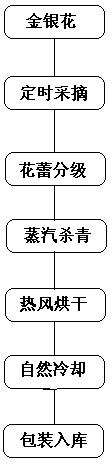

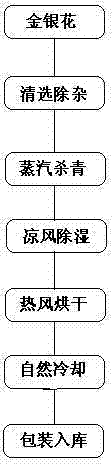

Processing method of honeysuckle tea

InactiveCN102356794ARapid inhibitory activityAvoid decompositionTea substituesCold airChlorogenic acid

A processing method of honeysuckle tea has a technical scheme that the method comprises the following steps of picking at regular time, bud grading, enzyme deactivation by steam, hot air drying, natural cooling, packaging and warehousing; the beneficial effect is that: honeysuckle buds are picked at 8:30-11:00 in the morning everyday, which can ensure that fresh flowers contain the most beneficial components and dew is prevented; grading of the buds can ensure uniform processing; enzyme deactivation by steam can rapidly inhibit the activity of polyphenol oxidase, and effectively prevent the decomposition of honeysuckle chlorogenic acid; direct hot air drying is performed after enzyme deactivation without cooling or cold air dehumidification, which can rapidly remove residual water contained in fresh flowers, destroys the activity of polyphenol oxidase, and allows the honeysuckle tea to be maintained to be undeteriorated for a long time; the honeysuckle tea processed by the method has a jade green color, and a lifelike shape; nutrient components can be maintained to be less lost; the infused tea has a bright and clear soup color, and a complete flower shape; the invention can greatly increase the drinking value and appearance quality of honeysuckle tea.

Owner:重庆市秀山红星中药材开发有限公司

Method for preparing blueberry fruit wine

ActiveCN103114020AAvoid influenceImprove product qualityAlcoholic beverage preparationMicroorganism based processesPectinaseFiltration

The invention discloses a method for preparing blueberry fruit wine and belongs to the technical field of deep-processing of agricultural products. The method comprises the following steps: juicing blueberries, performing instantaneous high-power pulse microwave treatment and composite pectinase enzymolysis, inoculating brewer's yeast, fermenting at controlled temperature, performing vacuum drum datomite filtration, composite flocculation clarification treatment, diatomite filtering, microfiltration and pulse microwave treatment and filling. According to the method, instantaneous high-power pulse microwave treatment is performed before fermentation, infectious microbes in the blueberry juice are killed under normal temperature conditions, polyphenol oxidase in the blueberry juice is passivated, sulfur dioxide is not required to be added, and pure fermentation is performed through inoculation of a good fermentation agent, so that high-quality blueberry fruit wine is produced, and the economic value of blueberries is obviously improved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Dried persimmon processing method

The invention discloses a dried persimmon processing method. The processing is executed by combining microwave sterilization and baking in a baking room of a heat pump. The method comprises the specific steps of: selecting persimmon fruits, sterilizing the persimmon fruits, baking the persimmon fruits, softening the persimmon fruits, removing bitterness, stacking and covering, shaping, packaging and scattering flour. In the method, the microwave sterilization is used, microorganisms on the surfaces of the persimmon fruits can be quickly killed, so that the persimmon fruits can be prevented from going bad during the processing; furthermore, polyphenol oxidase (PPO) in the persimmon fruits can be killed; the brown stain of the persimmon fruits can be prevented; during the processing of dried persimmon, most working procedures can be executed in the baking room; the continuity is high; the pollution of the dried persimmon is avoided; the dried persimmon production efficiency is improved; the production cost is reduced; the dried persimmon processing method is easy to operate and low in investment; the quality of the dried persimmon is controllable; and the dried persimmon processing method is suitable for large-scale industrial production.

Owner:桂林普兰德生物科技有限公司 +1

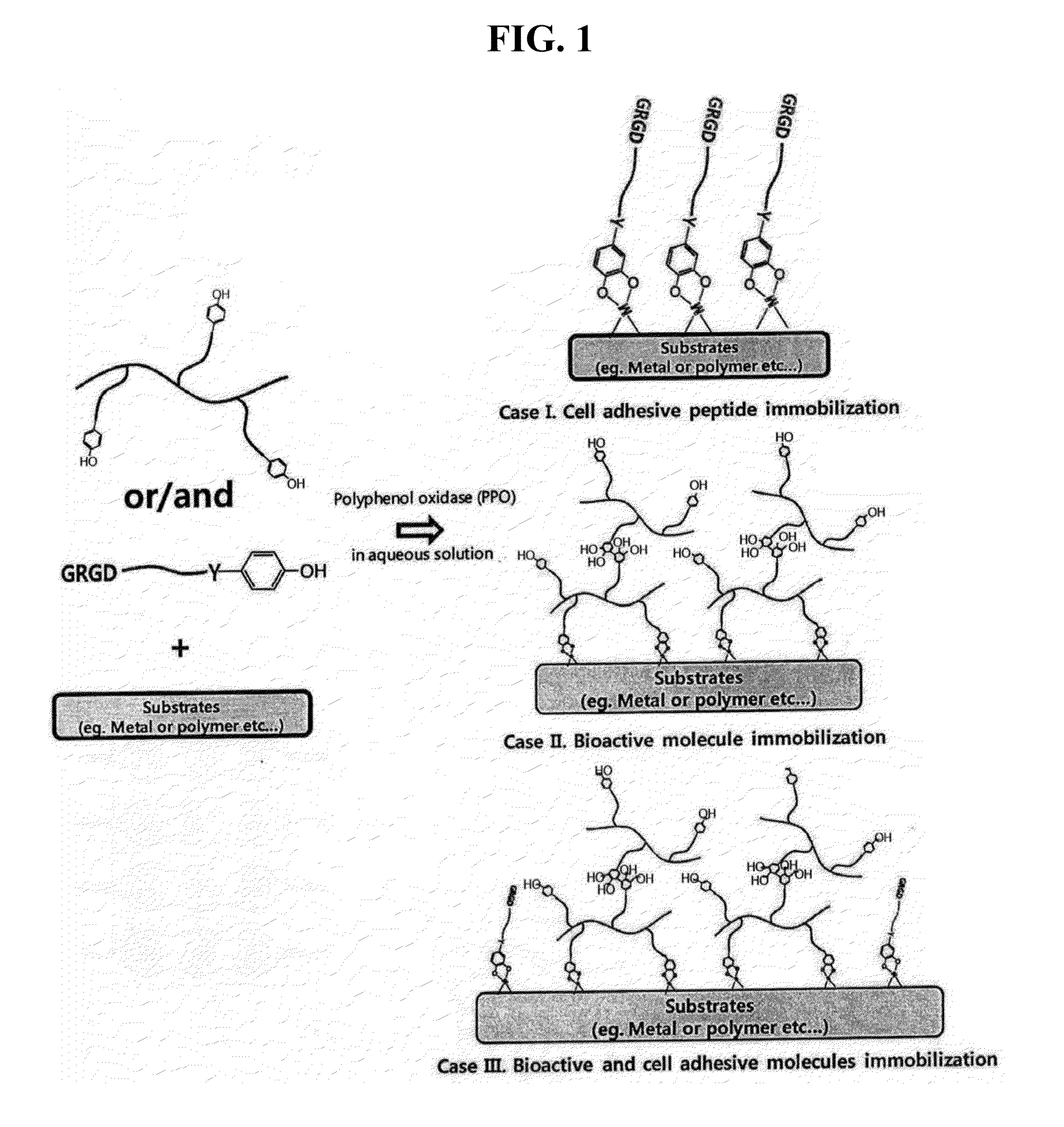

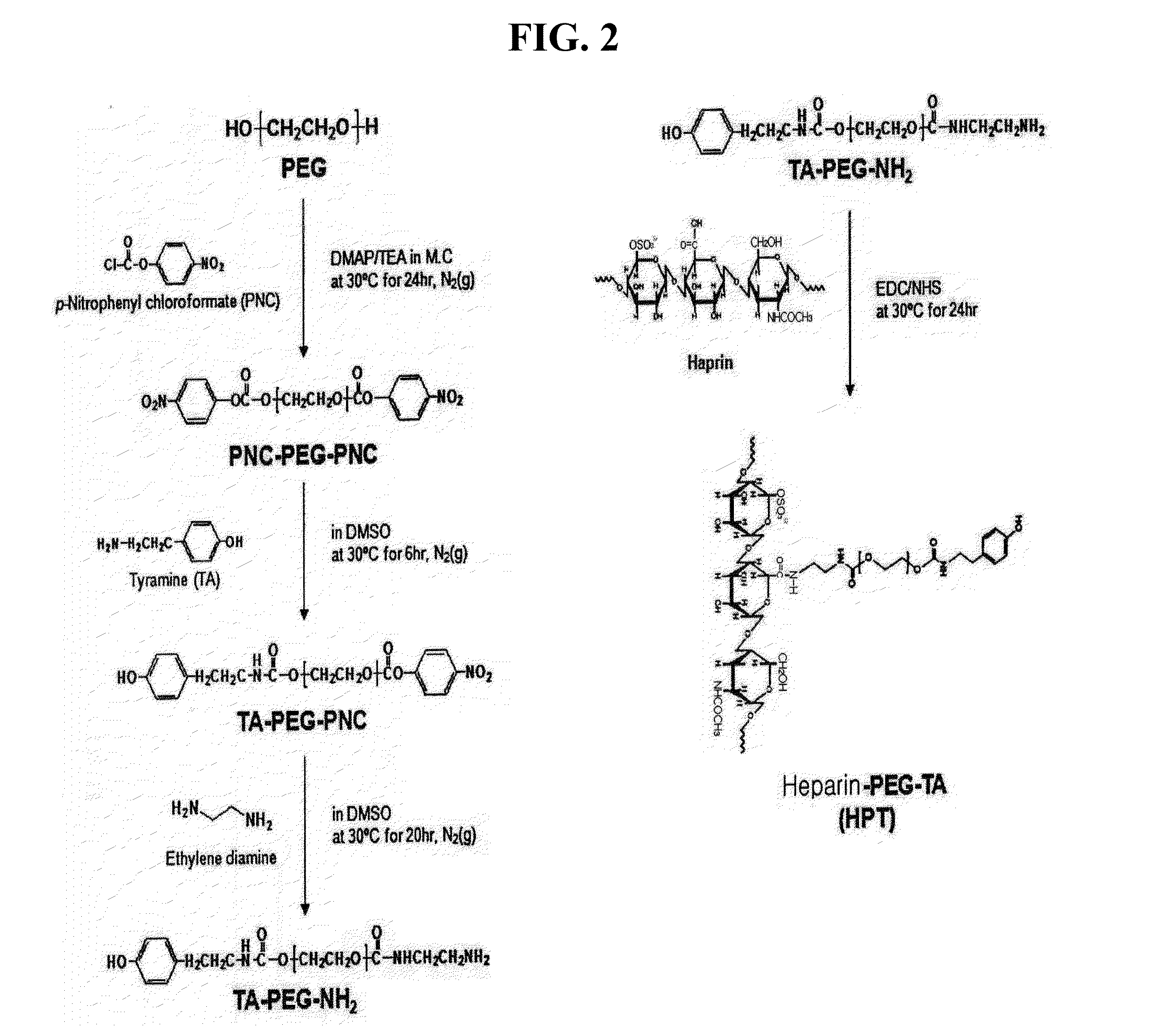

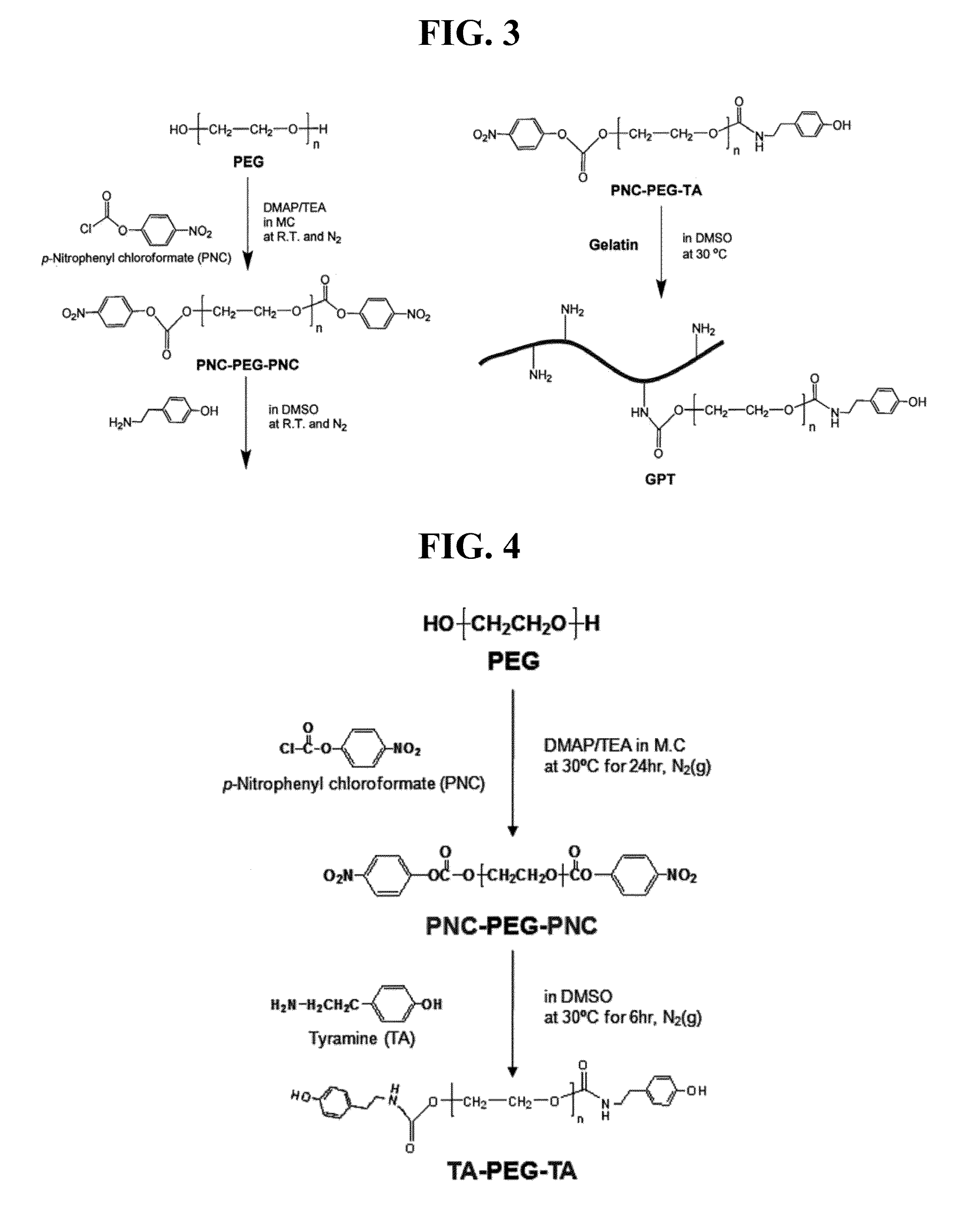

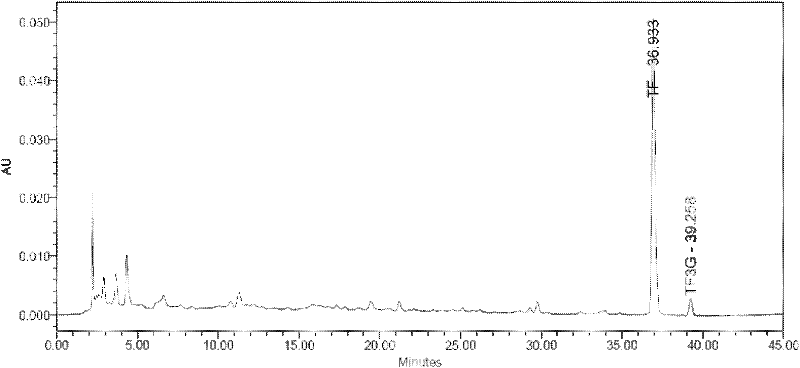

Immobilization method of bioactive molecules using polyphenol oxidase

InactiveUS20130224795A1Guarantee hemocompatibilityEasy to fixSurgeryAntithrombogenic treatmentPolyphenol oxidaseDental implant

A method is provided for immobilizing a bioactive molecule onto a surface using polyphenol oxidase. In the presence of polyphenol oxidase, a bioactive molecule containing a phenol or catechol group can be simply in situ oxidized within a short time to dopa or dopaquinone which forms a coordinate bond with a metal or polymer substrate, thus immobilizing the bioactive molecule onto the surface with stability. Based on the surface immobilization of bioactive molecules using polyphenol oxidase, various bioactive molecules such as osteogenetic peptides and growth factors can be simply immobilized to medical metal or polymer substrate surfaces such as orthopedic or dental implants which can be then effectively used to induce rapid osteogenesis after being transplanted. Also, antithrombotic agents and / or entothelialization inducing agents may be immobilized to medical substrates for vascular systems, such as stents and artificial blood vessels, thus guaranteeing hemocompatibility to the medical substrates.

Owner:AJOU UNIV IND ACADEMIC COOP FOUND

Safe and efficient antioxidant for compound food

The invention discloses a safe and efficient antioxidant for a compound food. The safe and efficient antioxidant consists of an antioxidant 1, an antioxidant 2, an antioxidant 3, an antioxidant 4, an antioxidant 5, an acidity regulator, a stabilizer and an antitackiness agent. According to the safe and efficient antioxidant for the compound food provided by the invention, brown stain of products such as vegetables, fruits and preserved fruits is alleviated by effects of inhibiting an activity of polyphenol oxidase in food, slowing down degradation of vitamins and preventing oxidation and the like, so that a shelf life of the products is effectively prolonged. Compared with conventional preservatives, preservative time for the safe and efficient antioxidant for the compound food can be effectively prolonged more than double.

Owner:唐洪权

Additive for flue-cured tobacco, prepn. method and application thereof

ActiveCN1723811AAccelerate the speed of alcoholizationReduce contentTobacco treatmentLiquid productVitamin C

An additive of flue-cured tobacco is prepared from the protein degradation enzyme, starch degradation enzyme, pectin degradation enzyme, poly-phenol oxidase, cellulose, VC and potassium tartrate through adding them to water, stirring for dissolving and filtering to obtain the liquid product. It can be sprayed onto the leaves of tobacco to decreasing the content of organic high-molecular substances in tobacco leaf and improving its quality.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Composite biological enzyme preparation for deweighting treatment of domestic sludge, and production and application method thereof

InactiveCN102351321AStable structurePrevents oxidative deactivationBiological sludge treatmentBiological water/sewage treatmentManganese peroxidaseNitrogen gas

The invention relates to a composite biological enzyme preparation for the deweighting treatment of domestic sludge, and a production and application method thereof. The invention is characterized in that 100-500 kilograms of composite biological enzyme for the deweighting treatment of domestic sludge are used for 100 thousand tons of municipal domestic sewage, wherein the composite biological enzyme for the deweighting treatment of domestic sludge comprises 25-30 parts of protease, 20-25 parts of one or more of laccase, polyphenol oxidase and manganese peroxidase, 17-21 parts of one or more of xylanase, pentosanase and mannase, 20-25 parts of one or more of cellulase, pectinase and hemicellulase, 10-15 parts of lipase and 12-16 parts of amylase. Compared with the prior art, the invention removes hydrogen sulfide gas and undesirable odor thereof, simultaneously eliminates the inhibiting effect of H2S on the nitrification process, effectively reduces nitrate and ammonia, decomposes proteins, starch, fat, food oil, xylan, cellulose and other organic substances, converts suspended substances, accumulated waste and soluble organic substances in the sludge into carbon dioxide, nitrogengas, oxygen gas, water and sulphate, reduces the TSS (Total Suspended Solids), COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand), greatly decreases the yield of the sludge, and has the advantages of no poison, no corrosiveness and no secondary pollution production.

Anti-browning method of milky lotus root juice

InactiveCN101703301AImprove securityEliminate enzymatic browning reactionsFood scienceFiltrationUltrafiltration

The invention discloses an anti-browning method of milky lotus root juice and belongs to the technical field of fruit and vegetable food processing. The method comprises: cleaning lotus roots, peeling the lotus roots, removing the stem nodes of the lotus roots and slicing; adding a compound color fixative, blanching the sliced lotus roots for inactivating enzymes and adding water into the sliced lotus roots for pulping, wherein the compound color fixative added in the processing process can inhibit the complex browning reactions of the lotus roots in a high-temperature blanching process, the blanching can inactivate endogenous polyphenol oxidase in the lotus roots and inhibit enzymatic browning (the major cause of the browning of lotus root juice) of the lotus root juice in post-processing, storage and transport processes, and blanching can gelatinize the starch in the lotus roots to facilitate a follow-up enzymolysis process, destruct cell tissues and promote the dissolution of flavor substances; and adding fungalamylase for decomposing starch in the lotus root juice, obtaining mother lotus root juice for use in subsequent processing by rough filtration and ultrafiltration, and subjecting the lotus root mother juice to sugar and acid adjustment, sterilization and vacuum filling to obtain a lotus root juice drink. The lotus root juice drink keeps a desirable white index.

Owner:杭州天堂食品有限公司 +1

Processing method for low-caffeine and high-GABA (Gamma Aminobutyric Acid) black tea compounded with folium mori

InactiveCN103478332APicking time limitSoup color bright red and yellowPre-extraction tea treatmentGamma-Aminobutyric acidBlack tea

The invention discloses a processing method for low-caffeine and high-GABA (Gamma Aminobutyric Acid) black tea compounded with folium mori. The processing method comprises the following steps: dipping fresh tea leaves by hot water to remove caffeine in the tea leaves, spreading out and cooling the tea leaves, adding a defined amount of folium mori subjected to anaerobic and withering processing into the tea leaves, rolling the mixture, and performing fermentation by using polyphenol oxidase and peroxidase which are contained in the folium mori. For the prepared black tea, the content of the caffeine is smaller than or equal to 0.5%, and the content of the GABA is larger than or equal to 1.5 mg / g; during drinking, the black tea has fruity fragrance and tastes sweet, the liquor color is reddish yellow and bright, and the tea tastes mellow, not only has mellow fragrance of tea, but also has unique sweetness of the folium mori; the processing method is free from limitation of the picking time of the tea leaves.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

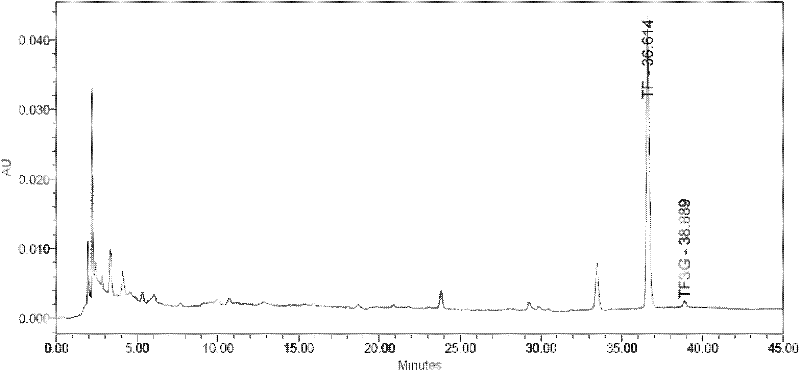

Method for preparing theaflavin by dynamic continuous oxidation on immobilized polyphenol oxidase

InactiveCN102226211AEasy to operateStable contentOn/in organic carrierFermentationTheaflavinBlack tea

The invention discloses a method for preparing theaflavin through carrying out dynamic continuous oxidation on immobilized polyphenol oxidase. in the method, tea polyphenols is taken as a raw material. At present, the content of theaflavin only accounts for 0.3-1.5% of dry matter of black tea, and the yield is low because the black tea is directly used for extracting. The synthesis and preparation technology of the existing theaflavin can not be dynamically and continuously prepared and is only confined in the laboratory to be prepared, thereby causing higher theaflavin cost and confining the application of theaflavin in medical heath care. In the method, tea polyphenol serves as a substrate, and immobilized polyphenol oxidase serves as a catalyst medium. Reaction temperature is controlled. The substrate and oxygen continuously enter on a packed bed reactor to oxidize tea polyphenol and polymerize to form theaflavin substance, and the theaflavin substance is continuously pumped out by a constant flow pump. In the method, the immobilized polyphenol oxidase is repeatedly utilized on a bioreactor to continuously and dynamically prepare the theaflavin to obtain the theaflavin mixed liquor. The method provides a basis for industrial preparation of theaflavin.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Instant nutrient purple potato chips and preparation method thereof

ActiveCN102125243ANo pollution in the processLow costFood preparationAdditive ingredientPolyphenol oxidase

The invention discloses instant nutrient purple potato chips and a preparation method thereof. The purple potato chips are prepared from raw materials, namely purple potato whole syrup, white granulated sugar, starch, soybean protein isolate, a thickener, a compound mineral enhancer, a compound vitamin enhancer and water according to a certain mass part ratio. The preparation method comprises thefollowing steps of: A, selecting fresh and full purple potato as raw materials; B, washing and trimming, namely washing by using a washer; C, slicing and conserving color; D, heating and cooking, namely softening a tissue structure of the purple potato, treating, inactivating polyphenol oxidase and amylase which are inherent in the purple potato to protect purple potato pigments and purple potatostarch; E, beating, mixing and inflating, namely crushing heated and cooked purple potato pieces in a beater into the purple potato whole syrup; F, refining and homogenizing by using a colloid mill; G, drying and scraping slices by using a roller; H, performing secondary drying; and I, packing. The instant nutrient purple potato chips has a rational formula, wide sources of the raw materials, lowcost, excellent flavor, beautiful color, high content of the purple potato pigments and high content of nutritional ingredients, and is rapidly rehydrated and instant, and the product has a porous structure.

Owner:WUHAN PUZETIAN FOOD

Wool dyeing method using enzymic method

ActiveCN104264490AHigh color depthHigh fastnessBiochemical fibre treatmentDyeing processCelluloseProcess conditions

The invention discloses a wool dyeing method using an enzymic method. The wool dyeing method comprises the following steps of (1) enzyme treatment, namely, after wool washing, dipping a wool fiber product into a composite enzyme solution, wherein the technological conditions for enzyme treatment are as follows: papain is 10-12U / mL, polyphenol oxidase is 3-6U / mL, cellulose is 12-15U / mL, pH is 7, the temperature is 30-50 DEG C, the time is 0.5-1 hour, and the bath ratio is 1 to 10; (2) acid dyeing, namely, dyeing the wool fiber product after enzyme treatment in step (1) by acid dyes; and (3) washing aftertreatment, namely, washing dyed fabrics in the step (2) at 30-100 DEG C for 5-20 minutes in the bath ratio of 1 to (5-30).

Owner:CHANGXING GUOYUAN PRINTING & DYEING

Method for improving color fastness of protein fiber product through enzymic method

ActiveCN103911867AHigh color depthHigh fastnessBiochemical fibre treatmentDyeing processAfter treatmentTyrosine

The invention discloses a method for improving color fastness of a protein fiber product through an enzymic method. Tyrosine in silk, wool and other protein fibers is subjected to catalytic oxidation to generate quinonyl by means of polyphenol oxidase (tyrosinase, catechol oxidase and laccase), the quinonyl is further subjected to an addition reaction with amino-containing acid dyes, and the dyeing depth and color fastness of the fiber product are improved. The method comprises the following process steps: performing polyphenol oxidase treatment on protein fibers, dyeing through acid dyes and performing washing after-treatment, wherein the steps of enzyme treatment and dyeing can be performed in a two bath process or in a one-bath two-step method. The protein fiber modification conditions are mild, the color depth and color fastness of the dyed fiber products are improved, the chroma of dyeing waste liquor is reduced, the dye utilization rate is improved, and the requirements of the protein fiber products on clean dyeing production are met.

Owner:无锡协新毛纺织股份有限公司

Method for processing purified konjac flour

A method for processing purified konjac flour comprises twelve steps of material selection, swelling, extraction, material placing in a low temperature oxygen-free room, grinding, dehydration, dehumidification drying, dry grinding, winnowing, sieving, checkout and homogeneous warehousing. The method for processing the purified konjac flour has the advantages that the swelling and the extraction can enable impurities in the konjac flour to be soluble in impregnation liquid and accordingly separated out, the activity of polyphenol oxidase can be restrained and brown stain can be prevented through processing in the low temperature oxygen-free room. Starch and the impurities attached to glucomannan particles can be further peeled off through the grinding, and then the impurities are removed through the dehydration. Heating can be avoided and brown stain, gelatinization and adhesion can be prevented through the dehumidification drying. By means of the grinding in the low temperature environment, the ragility of konjac particles can be improved, the impurities can be easily separated, and small particles can be obtained. Various levels of purified konjac flour meeting the national requirements is obtained after the sieving. Therefore, produced purified konjac flour does not contain sulfur, is free of brown stain, gelatinization and adhesion and is pure white, and the product quality is improved.

Owner:重庆天娇农业开发有限公司

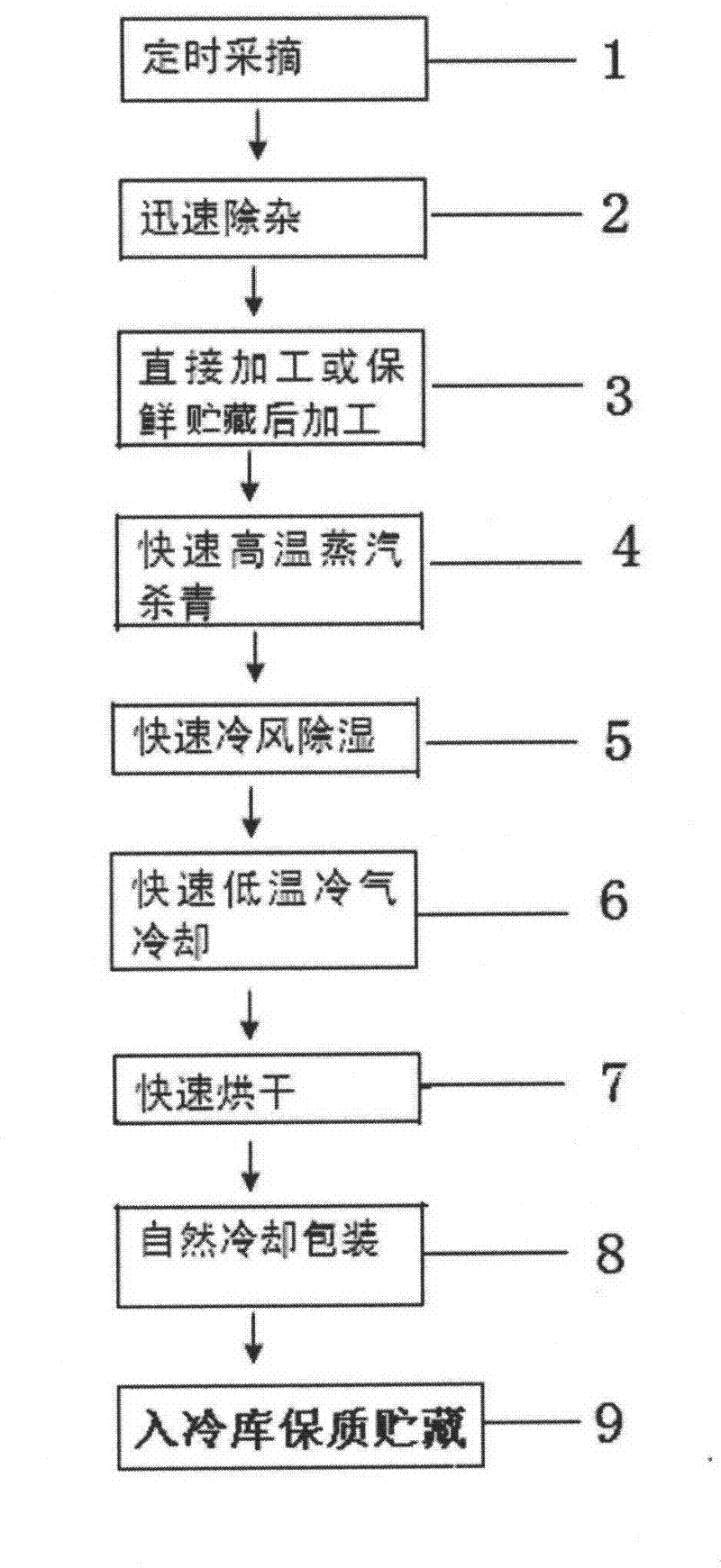

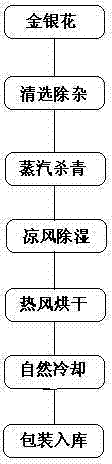

Production method of wild honeysuckle flower tea

InactiveCN102326648AFull flower shapeComplete flower shapeTea substituesChlorogenic acidDecomposition

The invention discloses a production method of wild honeysuckle flower tea. By adopting the production method, the original color and shape of wild honeysuckle flower can be kept unchanged and stable chlorogenic acid content can be ensured. The production method specifically comprises the following steps: picking at regular time; rapidly removing impurities; directly processing; carrying out rapid enzyme deactivation by high-temperature steam; rapidly dehumidifying by cold air; rapidly cooling by low-temperature cold air; rapidly drying by high-temperature hot air; naturally cooling and packaging; and warehousing for storage so as to guarantee quality. The production method has the beneficial effects of rapidly destroying activity of polyphenol oxidase in the wild honeysuckle flower, effectively avoiding decomposition of the beneficial substance namely chlorogenic acid contained in the wild honeysuckle flower, preventing the wild honeysuckle flower from browning, avoiding the procedures of turnover as well as pickup and placement, and ensuring that the appearance of the wild honeysuckle flower is not damaged and the flower shape is complete. The wild honeysuckle flower tea processed by the method has the advantages of green color, new shape and less loss of the chlorogenic acid; and the brewed wild honeysuckle flower tea has the advantages of light green and bright and clean color, delicious taste as well as complete and lifelike flower shape. Therefore, the drinking value and appreciation grade of the wild honeysuckle flower tea are obviously improved by adopting the production method.

Owner:XIUSHAN SHENGDA AGRI DEV

Chinese chestnut or castanea henryi unshelling method

InactiveCN102669796AOvercoming the problem of leaving several scratchesReduce the problem of low whole kernel rateHuskingHullingEngineeringDegradation Problem

The invention belongs to the technical field of nut processing and relates to a Chinese chestnut or castanea henryi unshelling method. The method comprises the following steps of opening cutting, shell blasting, drying, cooling, quick freezing and unshelling. The laser opening cutting technology is adopted, the problem of a plurality of cut marks remained on chestnut kernels caused by the traditional cutter cutting is solved, and meanwhile, the problem of non-enzymatic browning caused by metal cutter cutting is also avoided. The quick freezing treatment method is adopted, so the chestnuts are unshelled under the frozen state, on one hand, the intensity of the chestnut kernels is improved, the problem of low perfect kernel rate caused by kneading and extrusion in the chestnut unshelling process is avoided, and on the other hand, the deterioration problem caused by high temperature in the unshelling process is reduced. Air jet flow impact shell blasting and enzyme inactivation technology is adopted, on one hand, the flesh and inner layer red skin separation of the chestnuts is completed after the laser opening cutting, on the other hand, the polyphenol oxidase is inactivated through high-temperature short-time treatment, and the color degradation problem caused by enzymatic browning is overcome.

Owner:CHINA AGRI UNIV

Antistaling agent of composite phosphate for fruits-vegetables and using method thereof

InactiveCN101317595ASuitable for production and processingSuitable for useFruit and vegetables preservationVitamin CPhosphate

The invention discloses a composite phosphate fruit and vegetable preservative and a usage method thereof. The preservative is compounded by the composite proportion of (0.8-1.2):(1.5-2.5):(0.05-0.15) of sodium pyrophosphate, citric acid and vitamin C. For the fresh-keeping of fruits such as freshly cut green apple, and the like, which contains polyphenoloxidase and chlorophyll, the preservative is compounded into the water solution with the massfraction of 1.0%-1.20% and the PH value of 2.0-3.0; according to the proportion of 100ml:100g of the solution and the freshly cut green apple, the freshly cut green apple is dipped into the solution at the temperature of 15-20 DEG C for keeping fresh; For the fresh-keeping of melons such as freshly cut potato, and the like, which contains polyphenoloxidase, the preservative is compounded into the water solution with the PH value of 5.5-6.0; according to the proportion of 100ml:100g of the solution and the freshly cut potato, the freshly cut potato is dipped into the solution at the temperature of 15-20 DEG C for keeping fresh. The preservative of the invention has dual efficacies such as browning prevention and greening prevention, affects no taste of the fruits and vegetables, has wide application range, simple and convenient operation and low expense and is generally suitable for the fruits and vegetables which are easy to be browned due to the promotion of the enzyme.

Owner:WENGFU (GRP) CO LTD

Extraction process of tea polysaccharide

The invention discloses an extraction process of tea polysaccharide. The process includes: firstly washing fresh tea leaves with clean water, then performing microwave vacuum drying, then crushing the tea leaves, adding water into the obtained tea powder, and adding acid to adjust the pH value of the solution, then adding cellulase and polyphenol oxidase, carrying out hydrolysis under certain temperature, sending the obtained enzymolysis liquid into ultrasonic equipment to conduct ultrasonic treatment, then performing filtering and sending the filtrate into ultrafiltration equipment to conduct ultrafiltration treatment, then putting the ultrafiltrate into a centrifugal machine to conduct centrifugal separation, concentrating the obtained centrifugate, adding ethanol into the concentrated solution, carrying out centrifugal separation, and drying the tea polysaccharide, thus obtaining tea polysaccharide. By adopting the microwave low temperature vacuum drying and ultrasonic wave synergistic treatment technology, the process provided by the invention ensures effective wall breaking, and significantly improves the yield and antioxidant activity of polysaccharide.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

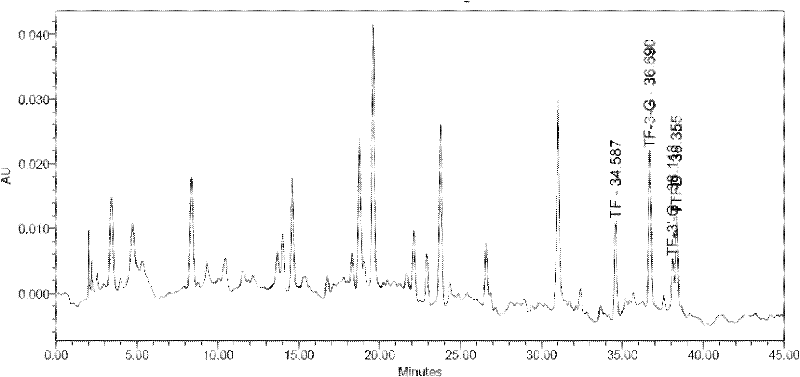

Method for preparing high-purity theaflavin composite

InactiveCN102605016AReduce usageSimple processOrganic chemistryFermentationFreeze-dryingEthyl acetate

The invention provides a method for preparing a high-purity theaflavin composite. The method comprises the following steps of: adding a mixture of green tea and catechinic acid into a crude polyphenol oxidase liquid for carrying out in-vitro oxidation; then, extracting the mixture with ethyl acetate; concentrating the extract in vacuum and drying to obtain a theaflavin crude product; dissolving the theaflavin crude product with ethanol water with volume concentration being 20% and then absorbing by using a chromatographic column with absorbing resin till the chromatographic column with absorbing resin is in a saturated state; eluting by using the ethanol water with volume concentration being 20%, and then eluting by using acetone or ethanol water with volume concentration being 60%; concentrating the eluting liquid, namely the collected acetone or ethanol water solution with volume concentration being 60% in vacuum; and obtaining the high-purity theaflavin composite through freeze drying. The method provided by the invention has the advantages of simple process and low cost and avoids using toxic and harmful organic reagents during a production process, thereby being environment-friendly. Furthermore, the high-purity theaflavin composite with different theaflavin components can be obtained by controlling different reaction conditions, so that the product yield is high and the content is high.

Owner:HUNAN AGRICULTURAL UNIV

Technology for efficiently extracting radix puerariae starch and radix puerariae total isoflavone

The invention discloses a technology for efficiently extracting radix puerariae starch and radix puerariae total isoflavone, comprising the following steps: breaking, draw filing, pH value adjustment and dipping, slag slurry separation, radix puerariae starch extraction, concentration, drying and radix puerariae total isoflavone recovery in process water; applying high pressure to the mixture obtained by draw filing to passivate polyphenol oxidase; adding cellulose enzyme to degrade the cellulose to ensure starch ionization rate; further setting the dipping time after the pH value of the slag slurry mixture is adjusted so as to not only ensure the full extraction of total isoflavone but also avoid character change of the radix puerariae starch due to improper dipping time; and further recovering the radix puerariae total isoflavone by the air flotation of dissolved air in the whole process so as to ensure the extraction rate of the radix puerariae total isoflavone. The whole process flow is simple, has easily controlled condition, protects environment, efficiently extracts radix puerariae starch and radix puerariae total isoflavone and greatly improves economic benefit.

Owner:重庆正里元实业有限公司

Composite biological emzyme/amboceptor system and use for textile scouring process

ActiveCN1986953ABiodegradable solutionRealize comprehensive utilizationHydrolasesBiochemical fibre treatmentCellulosePectinase

Owner:JIANGSU HUAXIN LINEN TEXTILE

Preparation technology for high-purity ultramicro particle brownless konjac powder

InactiveCN104605293AOptimization parametersParticle refinementFood preparationCelluloseProcess engineering

The invention relates to a preparation technology for high-purity ultramicro particle brownless konjac powder. The preparation technology comprises the following steps: raw material preparation, starch and cellulose removing treatment, color-protecting powder preparation, color-protecting treatment on a konjac raw material, drying, smashing, examining, homogeneity warehousing and the like. Compared with the prior art, the preparation technology improves various parameters of the obtained konjac powders, reduces the contents of plant starch and plant cellulose in the konjac powder, avoids generating polyphenol oxidase oxide and pigment in products, improves product quality, refines particles of the konjac powder, develops the potential utilization value of the konjac powder, and increases the application field of the konjac powder.

Owner:四川森态源生物科技有限公司

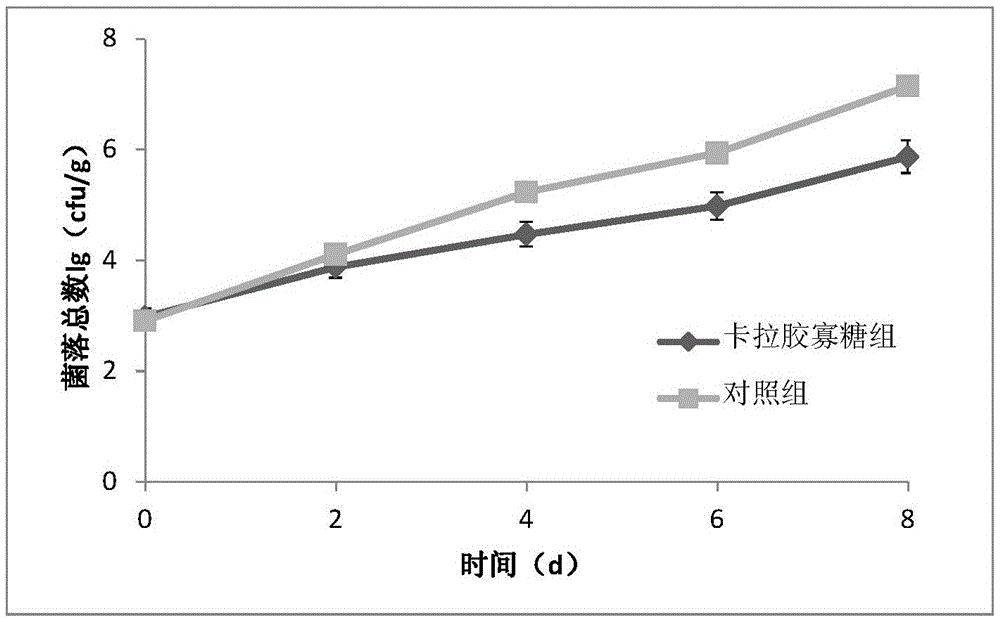

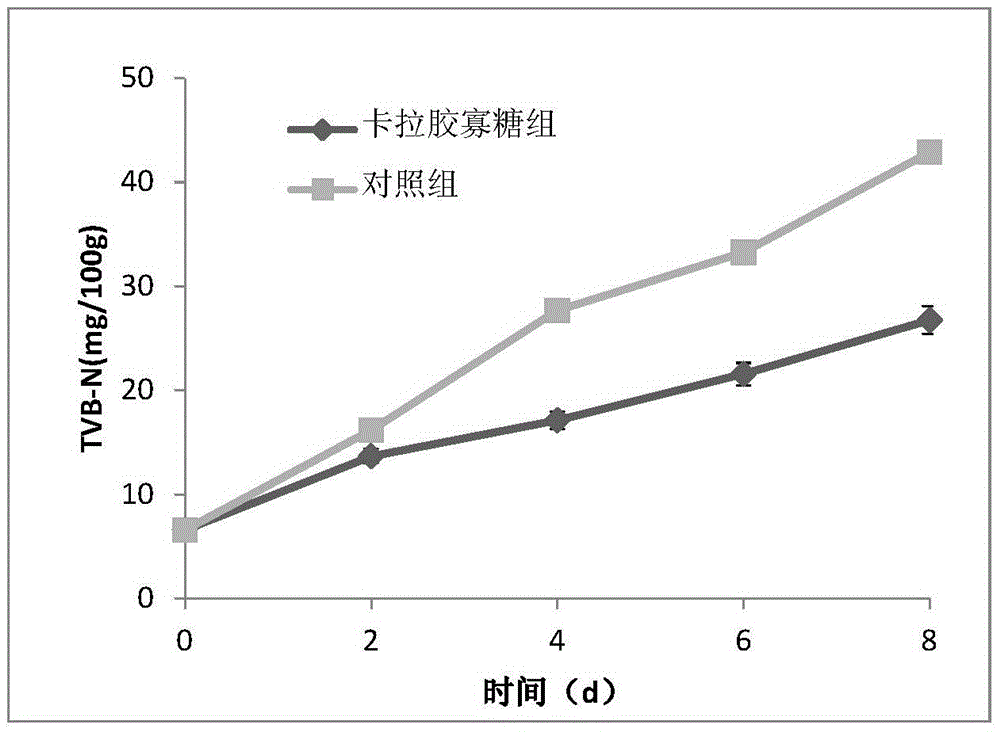

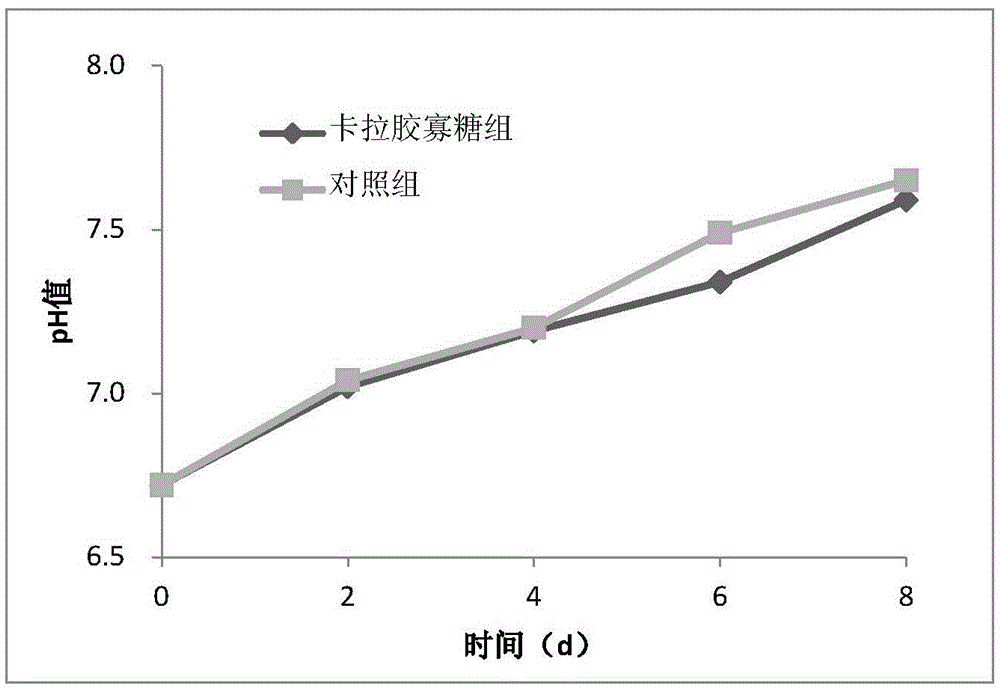

Seafood preservative and preparation and application thereof

InactiveCN105613708APrevent corruptionExtended shelf lifeMeat/fish preservation using chemicalsHydrolysisPolyphenol oxidase

The invention relates to seafood preservative and preparation and application thereof and belongs to the field of food preservation and fresh-keeping. The seafood preservative is prepared from carrageenan oligosaccharides and water, and the concentration of carrageenan oligosaccharides is 10-25 g / L. A preparation method includes the steps that firstly, the carrageenan oligosaccharides are prepared from carrageenan through an enzyme hydrolysis method, then the carrageenan oligosaccharides are used for preparing the preservation, specifically, the carrageenan oligosaccharides are dissolved in water, and the concentration of the carrageenan oligosaccharides in a solution is 10-25 g / L. The seafood preservative has the advantages that seafood can be effectively prevented from decaying, the total number of bacterial colonies of shrimps, the total volatile basic nitrogen (TVB-N), the Ph value, the activity of polyphenol oxidase, sensory indexes and other physiological and biochemical indexes are effectively improved, the shelf life of seafood is prolonged, and the preservative is in the food level and is safe and free of toxin.

Owner:DALIAN UNIV

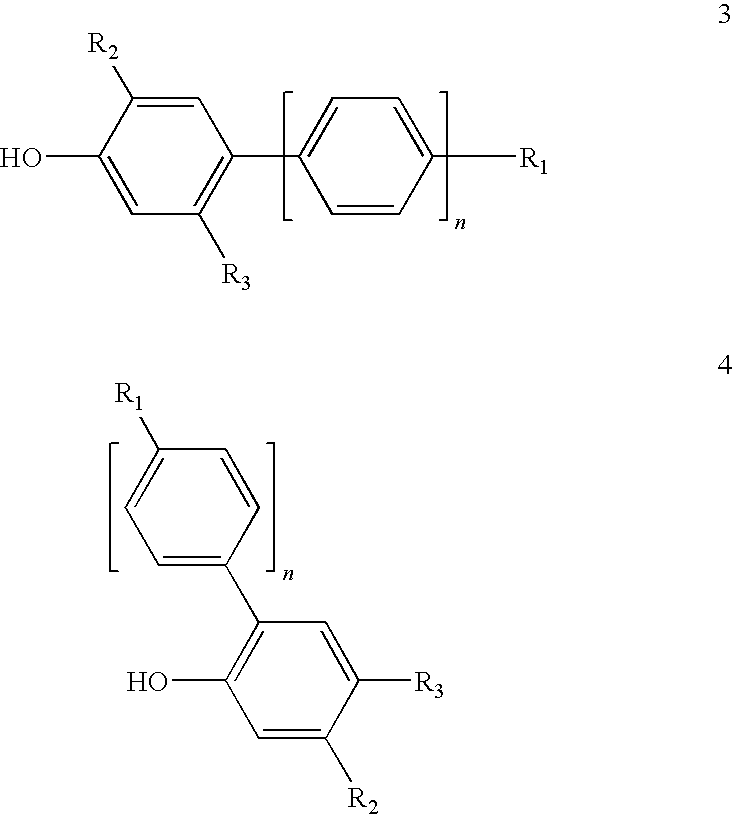

Adhesive for Medical Applications and Means for Haemostasis

ActiveUS20090318584A1Easy to prepareImprove adhesionAntibacterial agentsSurgical adhesivesHydroxydicarboxylic acidPolyphenol oxidase

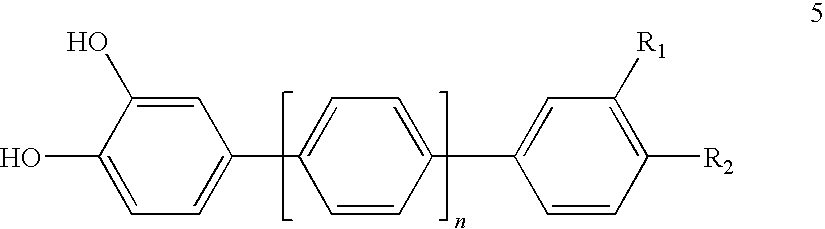

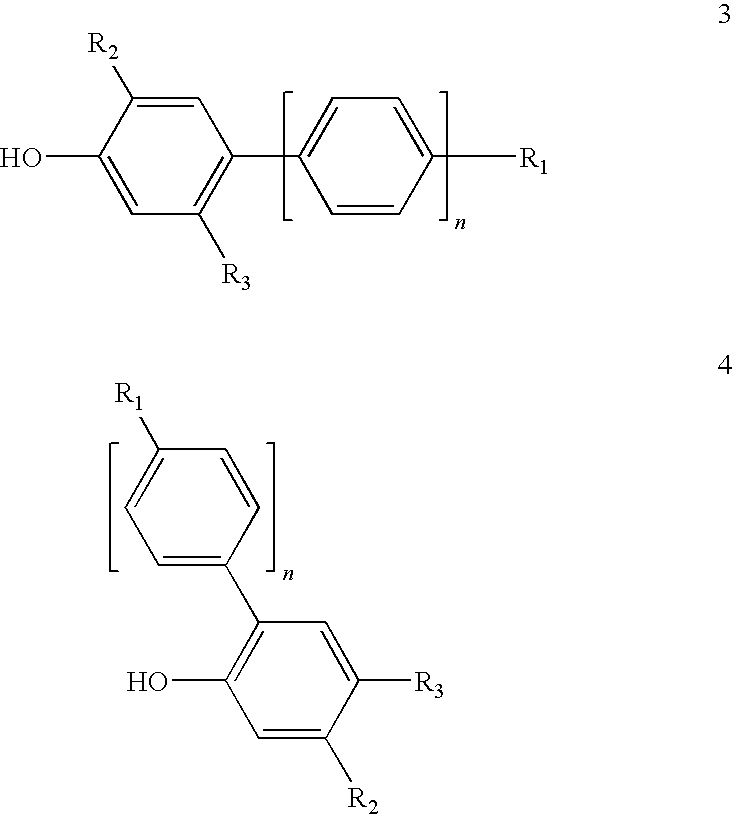

The invention relates to a kit comprising the following individual components: (a) polymers comprising at least one free amino group, (b) bridge molecules selected from the group consisting of monocyclic ortho-dihydroxyaromates, mono-cyclic para-dihydroxyaromates, bicyclic monohydrxyaromates, polycyclic monohydroxyaromates, bicyclic dihydroxyaromates, polycyclic dihydroxyaromates, bicyclic trihydroxyaromates, polycyclic trihydroxyaromates, and mixtures thereof, and (c) polyphenoloxidases, in particular, lignolytic polyphenoloxidases, whereby the individual components b) and c) are not in contact.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Fresh-wet noodle color protecting method

The invention discloses a fresh-wet noodle color protecting method. The method includes the steps: performing microwave treatment for flour for 60-180 seconds before dough kneading, and controlling the discharge temperature at 75-85 DEG C so as to passivate polyphenol oxidase in the flour; adding starch acetate accounting for 5-8% of the mass of the flour, fumaric acid accounting for 0.03-0.06% of the mass of the flour and sterile water accounting for 33-40% of the mass of the flour during dough kneading, and performing vacuum dough kneading for 5-10min; performing composite rolling for kneaded doughs for three times on a noodle maker, and moisturizing and curing for 15-45min; rolling prepared dough strips into pieces on the noodle maker, and slicing so that wet noodles 2.0mm in width and 1.0mm in thickness are formed; and disposing the wet noodles under an ultraviolet lamp for sterilization for 20-40min, performing aseptic packaging and performing cold preservation for the packaged noodles at 4 DEG C. The fresh-wet noodles prepared by the method have the advantages that an L*value reaches 85.7-89.8, an a* value is decreased to 0.6-1.2 and a b* value is decreased to 13.1-14.2, while in a blank group, an L*value is 81, an a* value is 1.6 and a b* value is 17, and accordingly browning of the fresh-wet noodles is effectively inhibited, and the quality guarantee period of the fresh-wet noodles at the 4 DEG C reaches 20-28 days.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Honeysuckle piece processing method

InactiveCN102342972ARapid inhibitory activityDestructive activityAntipyreticDigestive systemChlorogenic acidDecomposition

The invention provides a honeysuckle piece processing method. The technical scheme is that: the honeysuckle piece processing method comprises the following steps of cleaning and picking honeysuckle; deactivating the honeysuckle in steam; dehumidifying the honeysuckle in cool air; drying the honeysuckle in hot air; naturally cooling the honeysuckle; and packaging the honeysuckle for shipment. The honeysuckle piece processing method has the following beneficial effects that: activity of polyphenol oxidase can be quickly inhibited through steam deactivation; chlorogenic acid of the honeysuckle can be effectively prevented from decomposition; water content attached to surfaces of the honeysuckle can be removed through the dehumidification in cool air, so that drying speed can be accelerated; remaining water content contained in fresh flower can be quickly removed through the drying in hot air; activity of the polyphenol oxidase can be broken; and packaged honeysuckle medicine (pieces) can be preserved in a storage room for a long term without going bad.

Owner:重庆市秀山红星中药材开发有限公司

Chinese goosebeery clear juice concentrating process

A Chinese gooseberry clear juice concentrating process comprises the steps of shedding, cleaning, crushing, beating and separating of Chinese gooseberry to obtain Chinese gooseberry primary pulp, and also comprises the following steps: the Chinese gooseberry primary pulp is processed by zymohydrolysis, polyphenol oxidase inactivation, horizontal screw separation, clarification, hyperfiltration, decolorization and concentration to obtain the concentrated Chinese gooseberry clear juice. The invention solves the difficulties on the aspects of fruit pulp separation, clarification and decolorization of the Chinese gooseberry clear juice production, realizes the massive production, also integrally adopts the UHT sterilization technology and the temperature reduction technology so as to better ensure the quality index of the sterilized Chinese gooseberry clear juice and remain the nutrient content rich in Chinese gooseberry to the maximum, including juice color, flavor, nutrient content, and the like.

Owner:SHAANXI TIANREN ORGANIC FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com