Method for preparing high-purity theaflavin composite

A technology of theaflavin and compound, which is applied in the field of preparation of high-purity theaflavin compound, can solve the problems of low product purity, high cost, unstable properties, etc., and achieves high product yield, environmental protection and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

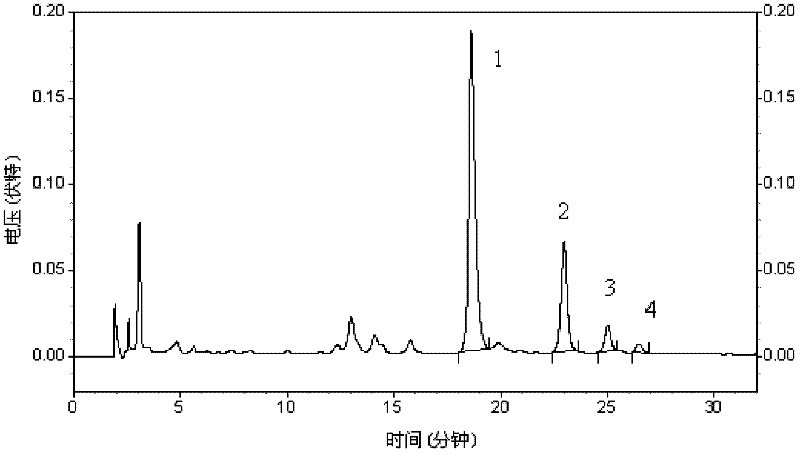

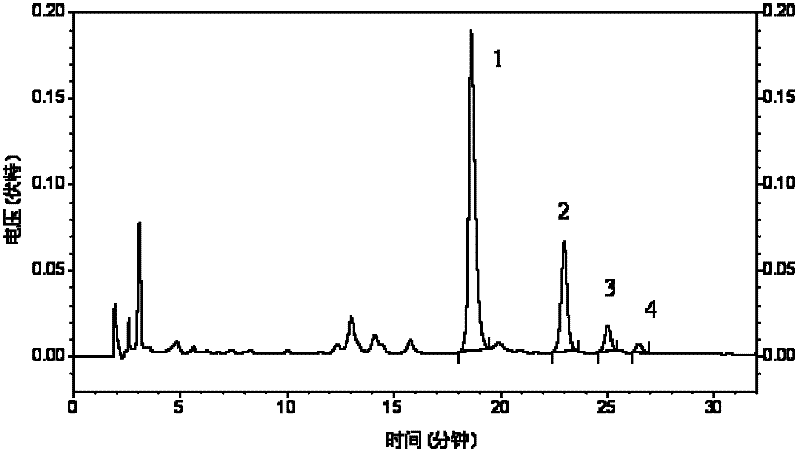

Image

Examples

Embodiment 1

[0023] Dissolve 4.00g of catechin mixture (EGC>20%, EC>9%, EGCG>10%) in 400ml polyphenol oxidase crude enzyme liquid (add 100ml lemon pH 5.5 to the polyphenol oxidase crude enzyme liquid Acid-disodium hydrogen phosphate buffer solution), feed oxygen, it is advisable that the bubbles do not overflow the reaction vessel, stir, and react in a constant temperature water bath at 30°C for 30min, and immediately pre-cool to -18 Ethyl acetate extraction at ~-20°C, the ester layer was concentrated in vacuo at 40°C, the ethyl acetate was recovered, and dried to obtain 1.70 g of crude theaflavin; the crude theaflavin was dissolved in 20 ml of 20% ethanol aqueous solution, The solution is passed through a chromatographic column (φ3cm×60cm, 30-60 mesh, pretreated according to the general method of polyamide treatment for column chromatography) equipped with polyamide powder at a flow rate of 0.6-0.8BV / h until the adsorption is saturated, followed by Use 2.5BV of 20% volume concentration of...

Embodiment 2

[0025] Dissolve 8.00g of small leaf catechin mixture (EGC>10%, ECG>9%, EGCG>40%) in 800ml polyphenol oxidase crude enzyme solution, feed oxygen, it is advisable that bubbles do not overflow the reaction vessel, stir , reacted in a constant temperature water bath at 20°C for 40min, immediately extracted with ethyl acetate pre-cooled to -18~-20°C equal to the volume of catechin mixture solution, concentrated the ester layer in vacuum at 45°C, recovered ethyl acetate, and dried to obtain Crude theaflavin 3.76g. This theaflavin crude product is dissolved with the ethanol aqueous solution of 40ml 20% volume concentration, and dissolving solution is passed through the chromatographic column (φ 3cm * 60cm that NKA macroporous adsorption resin is housed with the flow velocity of 0.6~0.8BV / h, according to column chromatography Use the macroporous adsorption resin treatment general method for pretreatment) to adsorption saturation, and then use 3BV 20% volume concentration of ethanol aq...

Embodiment 3

[0027] Dissolve 8.00g of catechin mixture (EGC>20%, EC>9%, EGCG>10%) in 800ml polyphenol oxidase crude enzyme solution, feed oxygen, it is advisable that bubbles do not overflow the reaction vessel, stir, React in a constant temperature water bath at 40°C for 20 minutes, immediately extract with an equal volume of ethyl acetate pre-cooled to -18~-20°C with the catechin mixture solution, and concentrate the ester layer in vacuum at 42°C, recover ethyl acetate, and dry to obtain Crude theaflavin 3.60g. This theaflavin crude product is dissolved with 50ml of 20% ethanol aqueous solution of volume concentration, and the dissolving liquid is passed through the chromatographic column (φ 3cm * 60cm, 30~60 meshes of polyamide powder with the flow rate of 0.6~0.8BV / h, according to The column chromatography is pretreated by the general method of polyamide treatment) to adsorption saturation, and then eluted with 2BV of ethanol aqueous solution with a volume concentration of 20% and 2.5B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com