Method for preparing theaflavin by dynamic continuous oxidation on immobilized polyphenol oxidase

A polyphenol oxidase, theaflavin technology, applied in the direction of being fixed on/in an organic carrier, fermentation, etc., can solve the problems of toxicity, waste of enzyme source, difficult separation of product and enzyme, etc., and achieve the content of theaflavin. Stable, easy to control reaction conditions, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

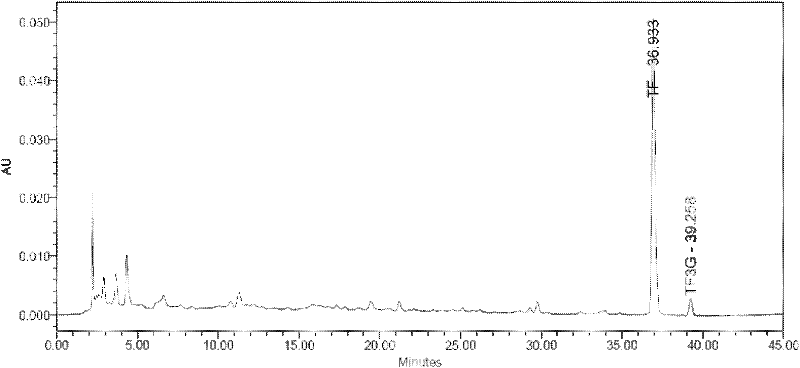

[0024] Weigh an appropriate amount of immobilized polyphenol oxidase and use the pH 3.2 disodium hydrogen phosphate-citric acid wet packing column prepared with the corresponding tea polyphenol substrate, fill the bottom of the column with a little absorbent cotton, and control the column bed at 100mL. Use disodium hydrogen phosphate-citric acid to prepare 10 mg / mL of tea polyphenol base material solution with pH 3.2 and 40% total amount of catechins, control the temperature of circulating water at 30°C, oxygen flow rate of 55 mL / min, and base flow rate of 2.5 mL / min. Oxygen and the substrate enter the packed bed reactor at the same time to react, and the theaflavin mixture is pumped out continuously with a pump, and the mixture is analyzed in liquid phase. Under this reaction condition, TF is the main body. See figure 1 , and theaflavin content is 16.25%. A theaflavin product with a content of 55% can be obtained by freeze-drying the theaflavin mixture, the freeze-drying pr...

Embodiment 2

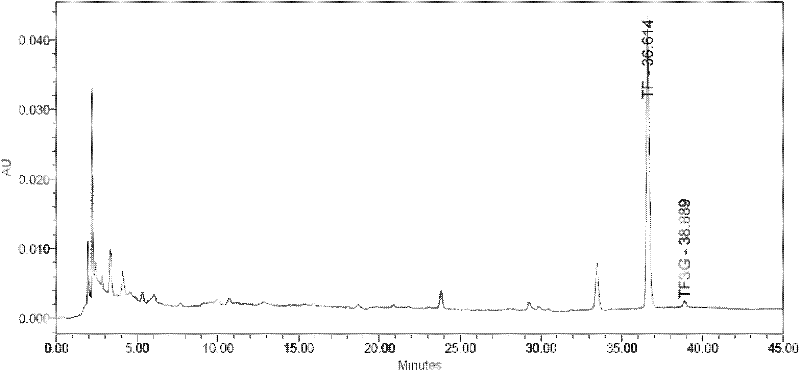

[0026] Mix 10mg / mL of tea polyphenols (pH5.7) substrate material solution with 70% total catechins in water, control the temperature of circulating water at 28°C, oxygen flow rate of 70mL / min, and substrate flow rate of 2.0mL / min. Oxygen and the substrate enter the packed bed reactor at the same time to react, and the theaflavin mixture is pumped out continuously with a pump, and the mixture is analyzed in liquid phase. Under this reaction condition, TF is the main body. See figure 2 , and the theaflavin content is 18.39%. A theaflavin product with a content of 70% can be obtained by freeze-drying the theaflavin mixture, the freeze-drying pre-freezing temperature is minus 40° C., and the thickness of the material is 1.5 cm.

Embodiment 3

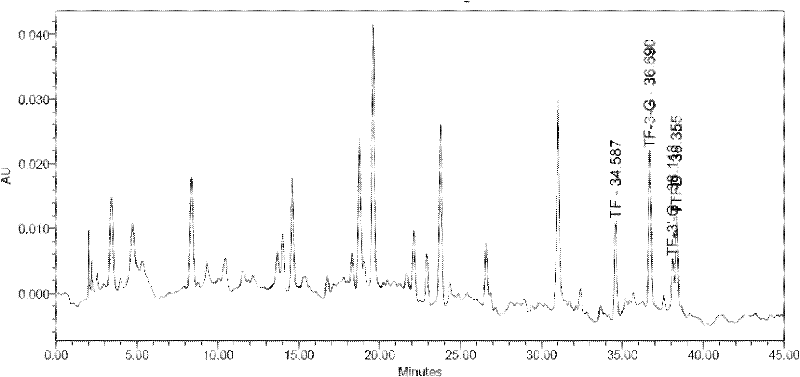

[0028] Use 30% ethanol to prepare 10 mg / mL of tea polyphenols (pH5.0) base material solution with 80% total catechins, the temperature of circulating water is controlled at 32 °C, the oxygen flow rate is 45 mL / min, and the base flow rate is 3.0 mL / min . Oxygen and the substrate enter the packed bed reactor at the same time to react, and the theaflavin mixture is pumped out continuously with a pump, and the mixture is analyzed in liquid phase. Under this reaction condition, all four main theaflavins appear, see image 3 , and the theaflavin content is 24.57%. The theaflavins mixture was separated on a separation column, and different theaflavins collected fractions were concentrated by rotary evaporation to remove the organic eluent, and the temperature was controlled at 45°C. Then freeze-dry to obtain theaflavin products with different theaflavin contents and ester type ratios, the freeze-drying pre-freezing temperature is minus 50°C, and the material thickness is 1.5cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com