Patents

Literature

221results about How to "Particle refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

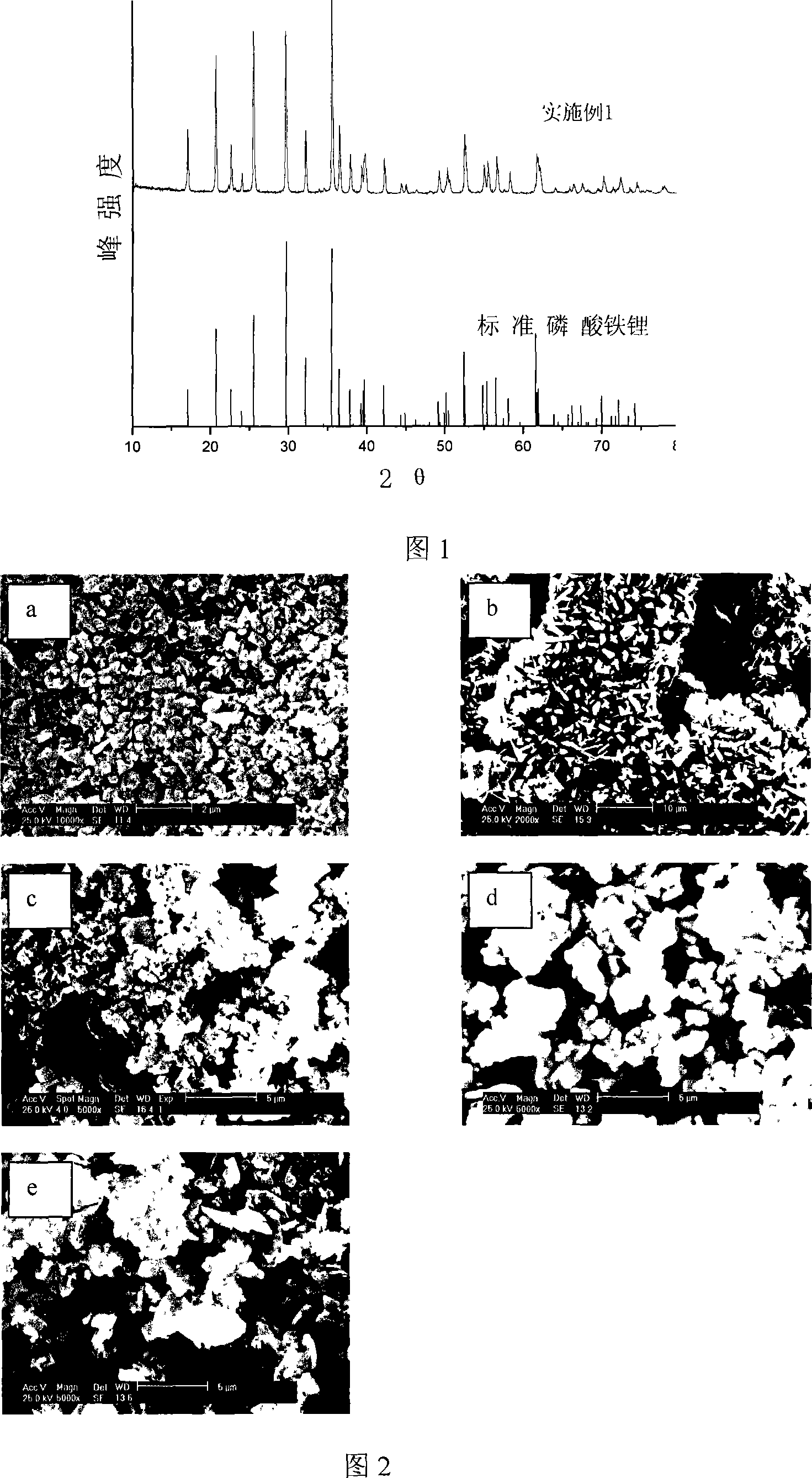

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

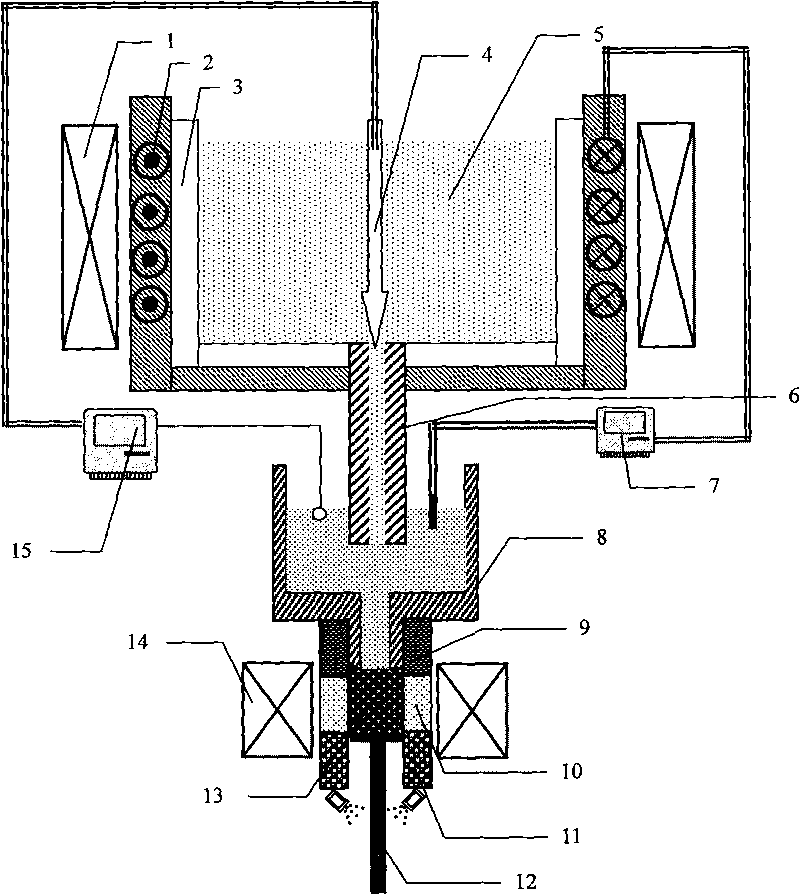

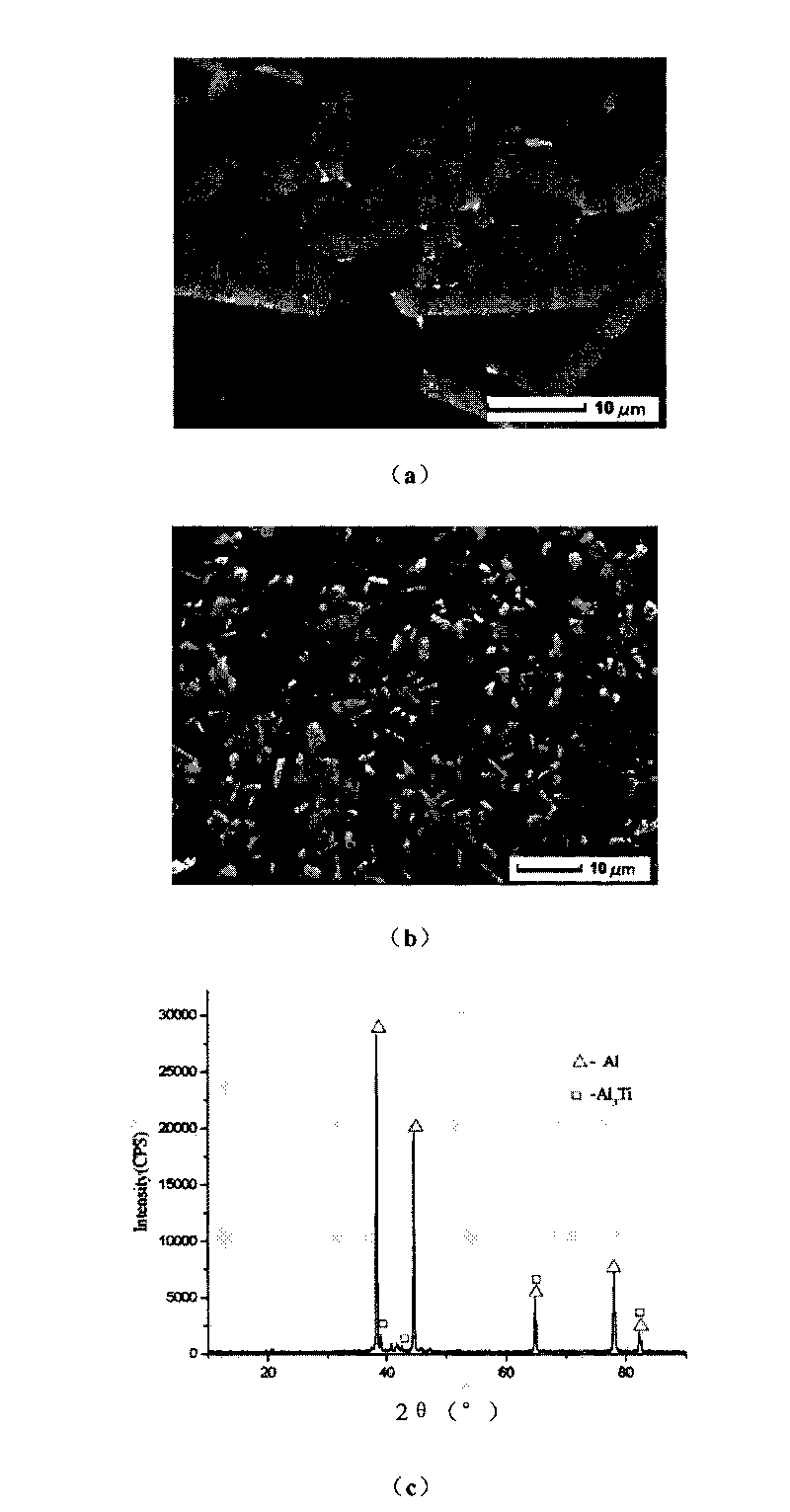

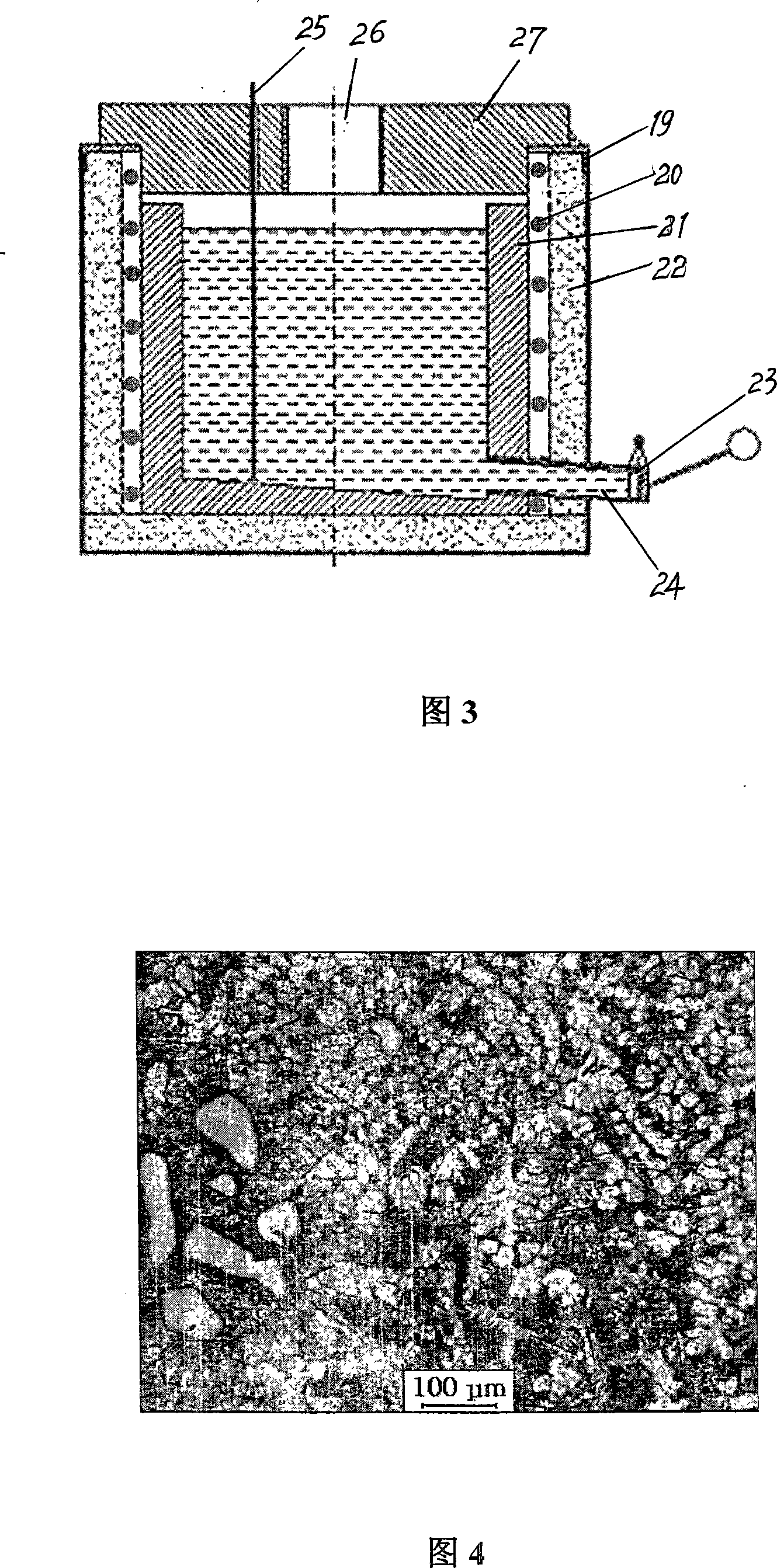

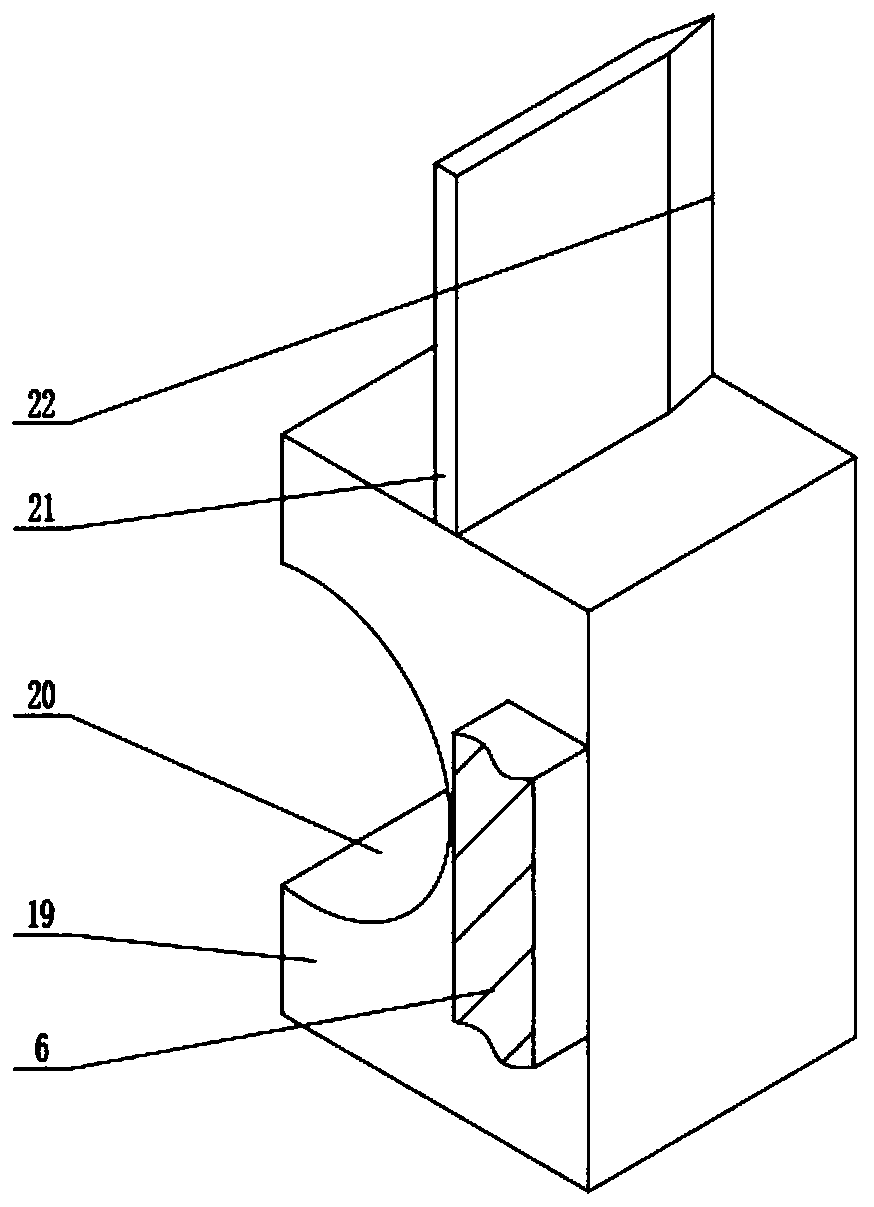

Method and device for preparing high-performance aluminum-base composite material under the action of pulsed magnetic field

The invention provides a method and a device for preparing high-performance aluminum-base composite material under the action of the pulsed magnetic field with the in situ crystallization method, belonging to the technical field of material preparation. The method comprises the following steps: smelting to synthesize compound material melt at the temperature of 10-200 DEG C higher than the compound material melt liquidus temperature and pouring the compound material melt into a specially-designed crystallizer to make the compound material melt solidify under the action of the pulsed magnetic field. The pulsed magnetic field has the key parameters of the pulse width of 1-500 ms and the amplitude strength of 0.1-50T. The pulsed electromagnetic force is applied to the process of solidifying the compound material melt under the action of the pulsed magnetic field so as to refine the matrix structure and the particle reinforced phase of the compound material at the same time, control the growth of the particle reinforced phase in cluster, increase the bonding strength of the interface of the particle reinforced phase and the matrix and obviously improve the performance of the composite material.

Owner:JIANGSU UNIV

High-temperature glaze coating, preparation method thereof, binder and using method of coating

The invention discloses a high-temperature glaze coating, a preparation method thereof, a binder and a using method of the coating, and aims at solving the problems of poor high-temperature resistance, low emissivity and absorptivity in a high-temperature zone, instability, and easiness of attenuation of the existing far-infrared energy-saving coating. The high-temperature glaze coating has the characteristics of good radiation heat transfer effect, high external blackness (the emissivity is greater than 0.95) and the like, and has the advantages of stable emissivity and absorptivity, non-attenuation performance and long service life in a long-term use process. Meanwhile, the coating can be tightly combined with a basal body by matching with the binder disclosed by the invention; the adhesive force is increased; a glazed ceramic polymer can be formed on the basal body after high-temperature sintering; the high-temperature glaze coating has the advantages of hardness, abrasive resistance, and long service life, and does not fall off; and the coating disclosed by the invention can also evenly coat the surface which cannot be covered by general coatings.

Owner:四川科达节能技术有限公司

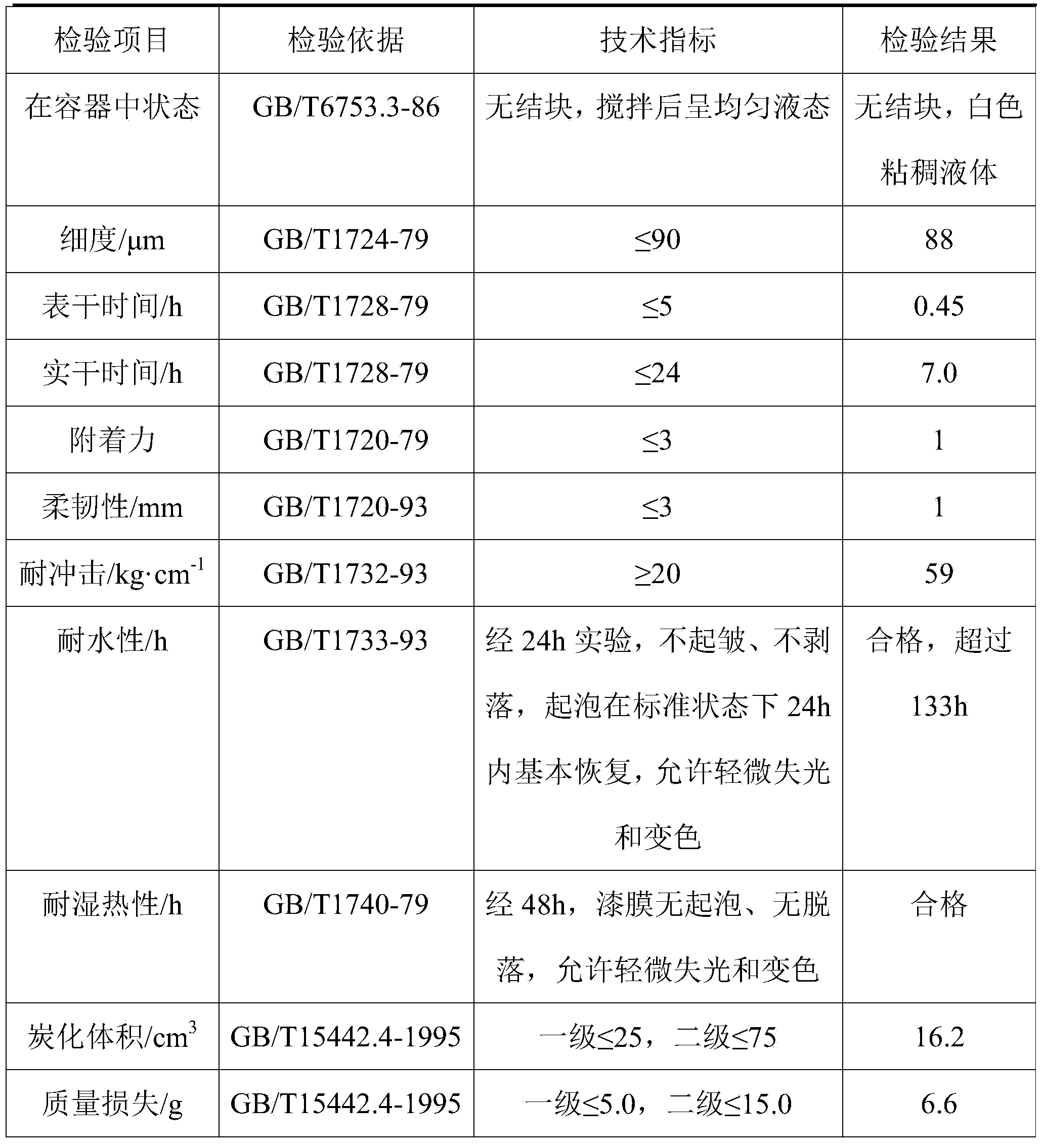

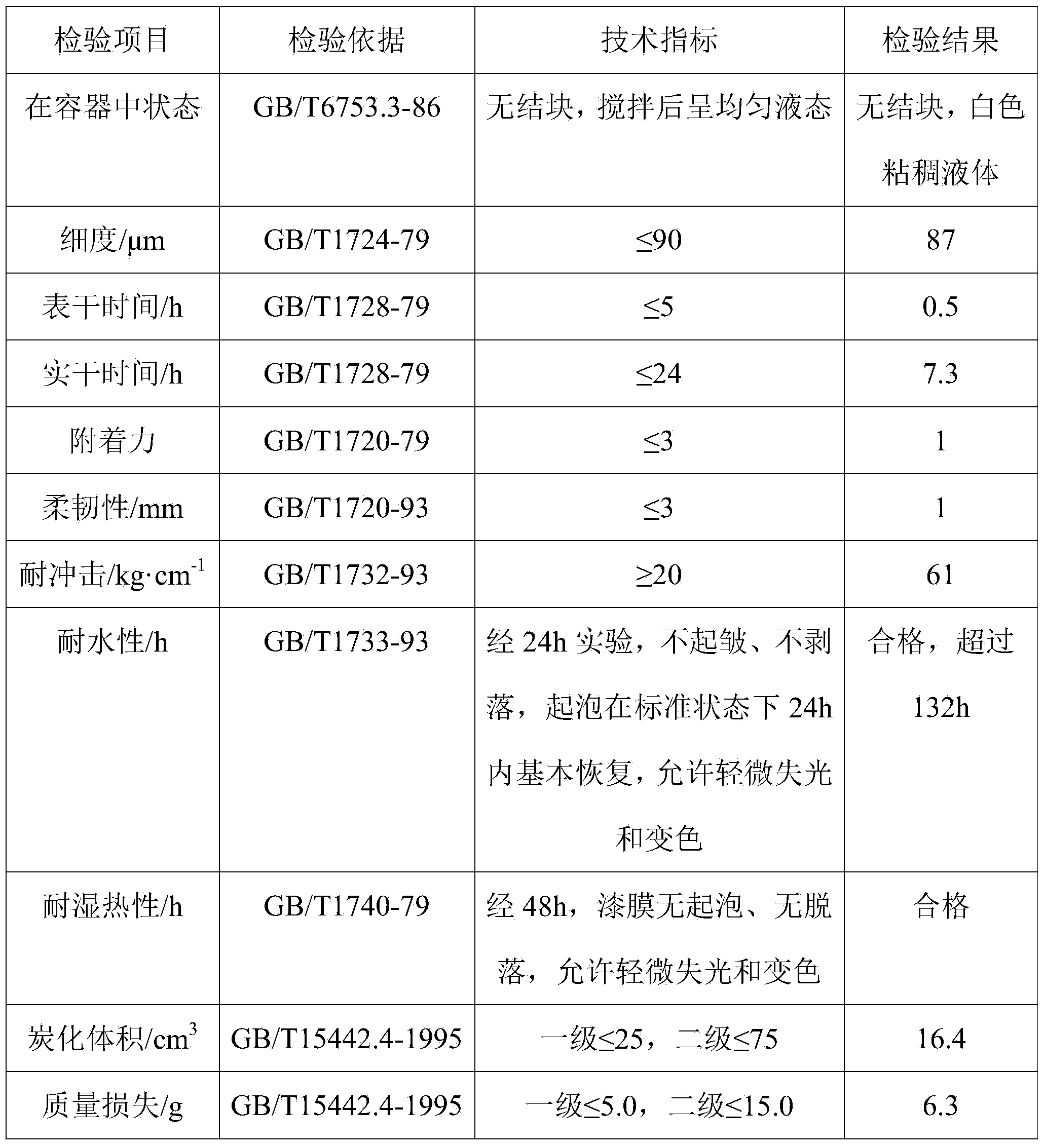

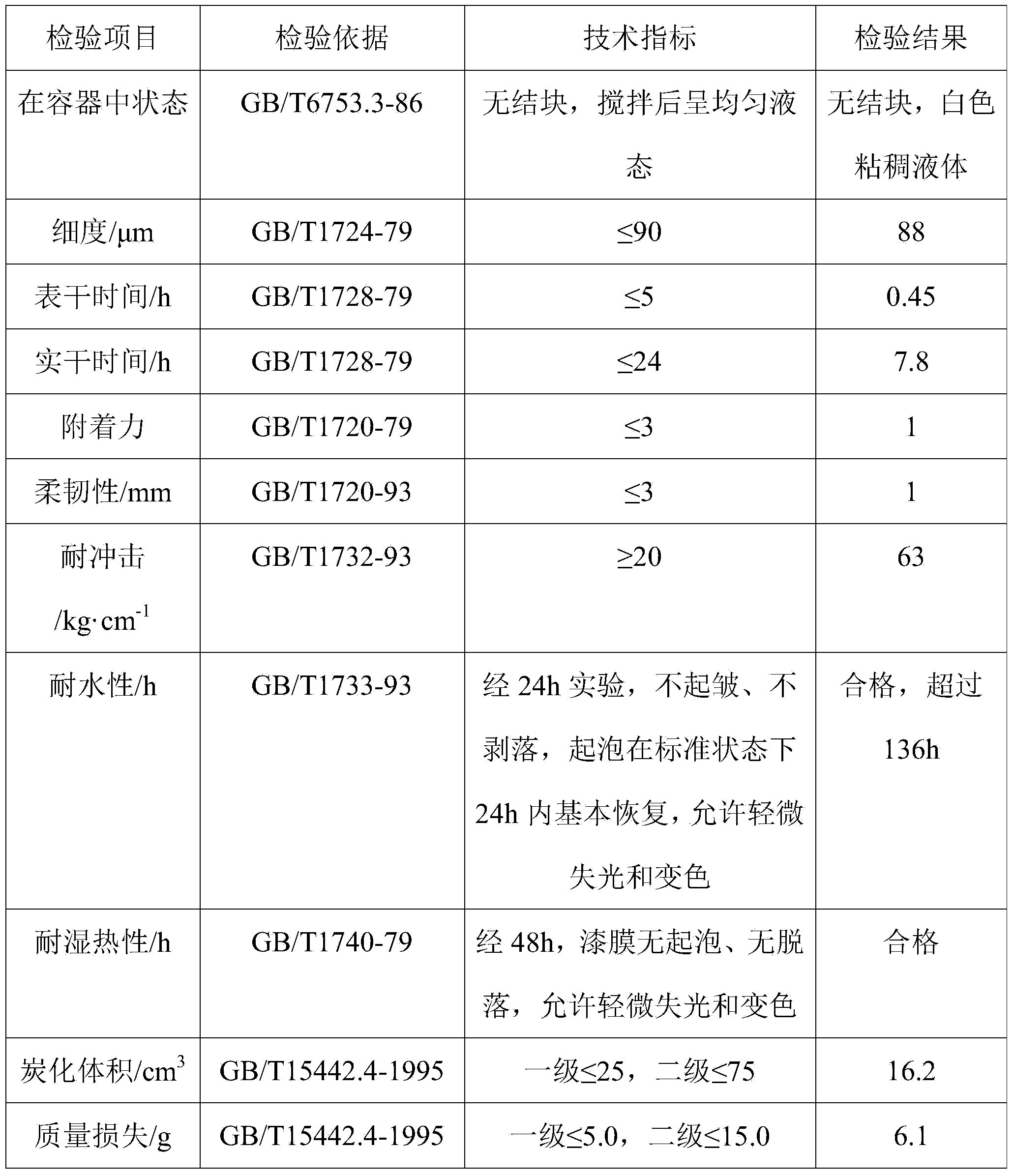

Water-based facing type fireproof paint and preparation method thereof

ActiveCN104277607AImprove fire performanceImprove water resistanceFireproof paintsEpoxy resin coatingsWater basedFoaming agent

The invention discloses water-based facing type fireproof paint. The water-based facing type fireproof paint is prepared from the following raw materials in mass fraction: 18.0-20.0wt% of film forming matter, 23-23.5wt% of a carbon forming catalyst, 10-11wt% of a carbon forming agent, 12-13wt% of a foaming agent, 9-11wt% of pigment filler, 0.49-1.13wt% of auxiliaries, 20-27.5wt% of water, 0-0.8wt% of trisodium phosphate and 0-0.4wt% of a silane defoaming agent. The invention further discloses a preparation method of the water-based facing type fireproof paint. The water-based facing type fireproof paint prepared by the preparation method disclosed by the invention has good fireproof performance, good water resistance, strong adhesive force for a combustible matrix and good decorativeness, and can be used for surface coating of buildings and decorative materials.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

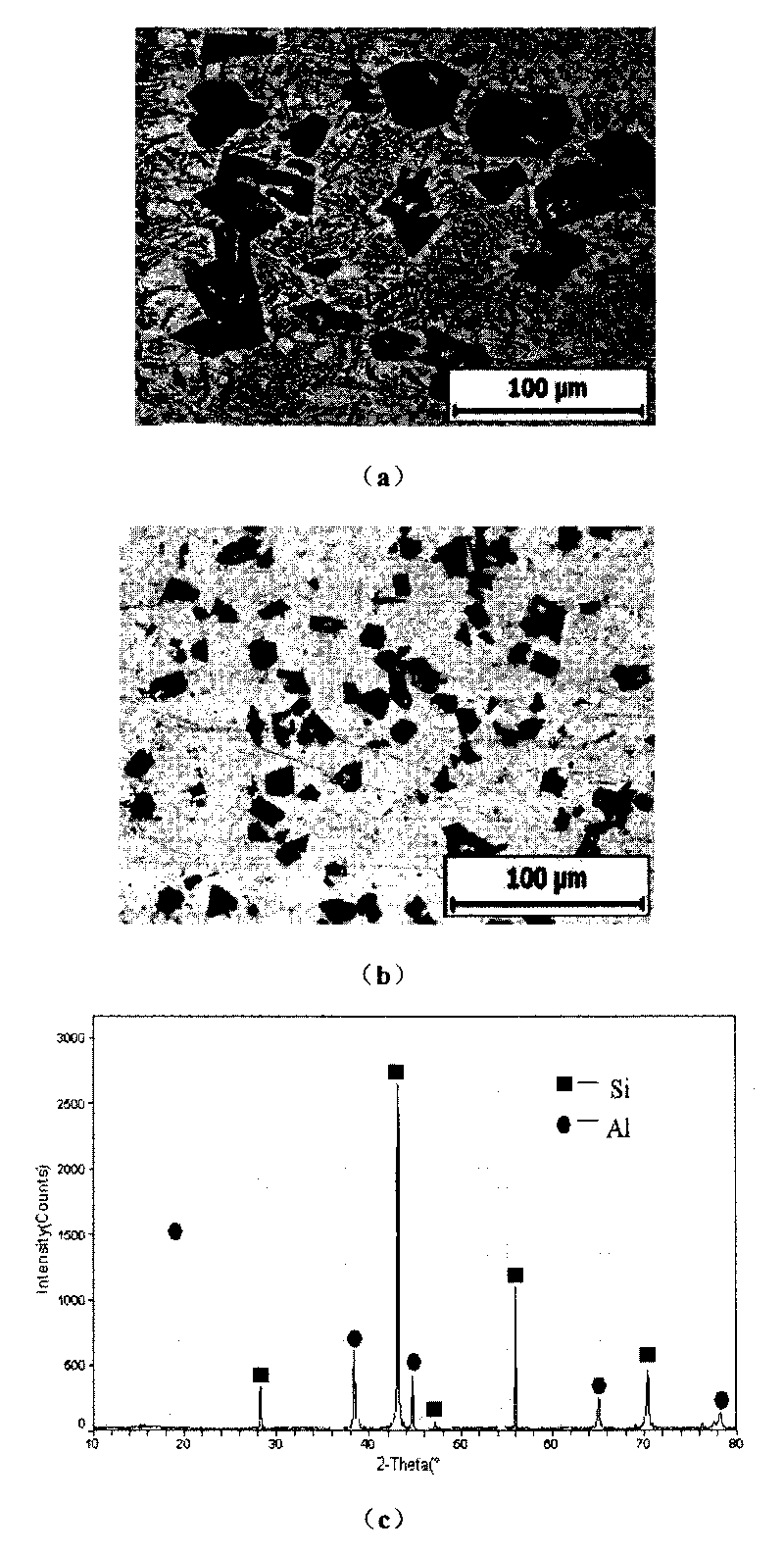

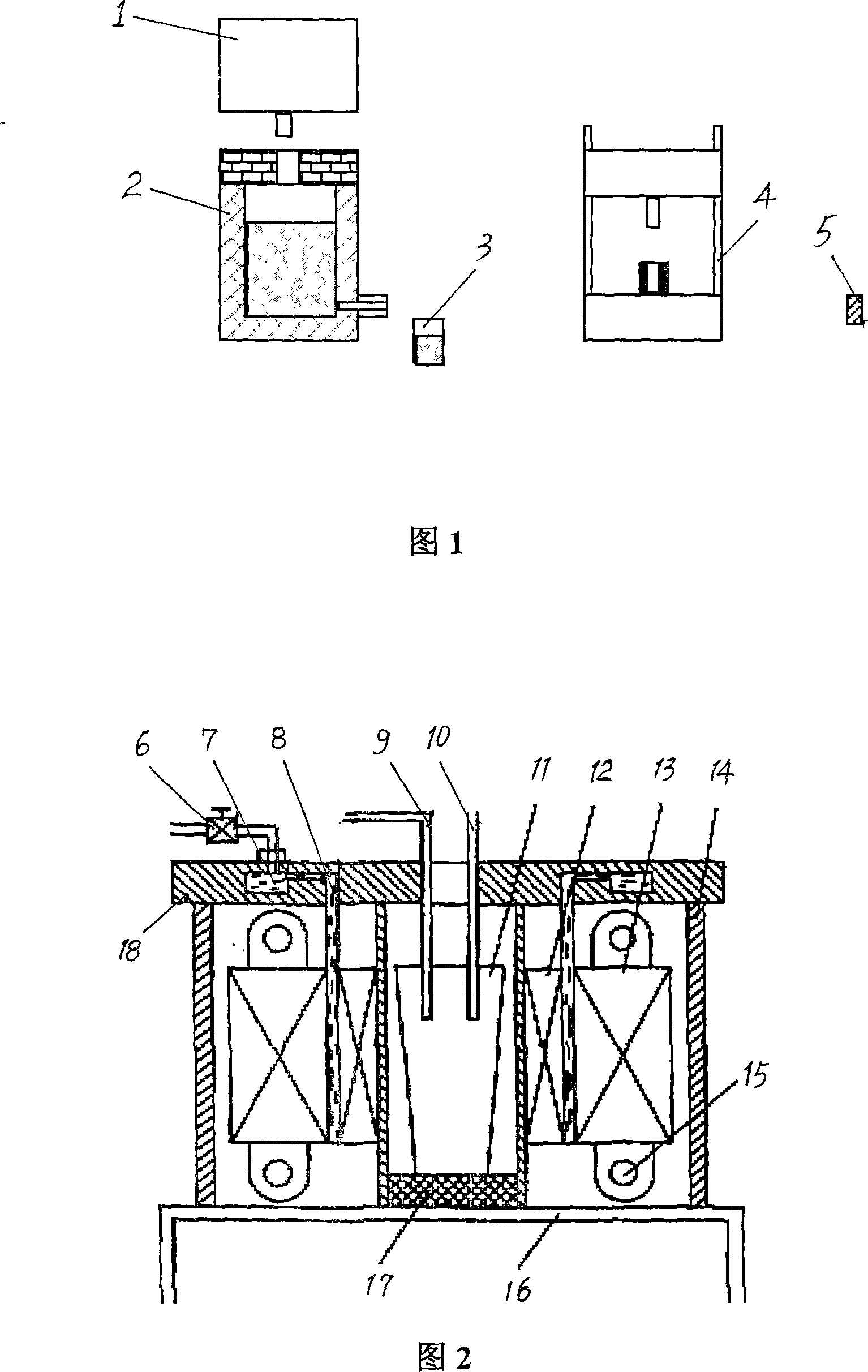

Semi-solid rheo-extrusion casting technology and equipment of hypereutectic Al-Si alloy casting

The invention provides a hypereutectic Al-Si alloy semi-solid rheological squeezing casting technique and a device, which pertains to a technical field of metal material semi-solid forming. The technique comprises the steps: alloy molten metal is smelted; hypereutectic Al-Si alloy semi-solid sizing agent is prepared by an electromagnetic stirring method; the sizing agent is cast into a holding furnace with a temperature of 610 DEG C-630 DEG C for storing; then a quantitative vacuum cup is utilized to cast the sizing agent into a mould which is preheated with a temperature of 150 DEG C-250 DEG C; the sizing agent is squeezing cast with a squeezing speed of 0.1mm / s-0.5mm / s, under moulding pressure of 50MPa-150MPa and with a pressure-keeping time of 10s-80s. The semi-solid continuous rheological squeezing casting of the hypereutectic Al-Si alloy products is realized, which improves the utilization ratio of the materials, reduces finishing allowance and reduces energy consumption but also refines granules of primary Si, refines and spheroidizes eutectic structure. The whole structure of a cast is compact with high-quality surface. The technique is simple and has short process, small investment of equipment, low cost and relatively strong practicability of the technique and the equipment.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing lithium ion battery positive electrode material

ActiveCN106784671AIncrease coverageImprove cycle performanceCell electrodesSecondary cellsSlurryGraphene

The invention discloses a method for preparing a lithium ion battery positive electrode material. The method comprises the following steps: preparing a monodisperse graphene solution with consistent flake diameter size and good dispersion in an ultrasonic oscillation manner; and transferring the graphene solution into a high-shear emulsifying homogenizer for performing shearing dispersion, and filling the sheared graphene solution and a positive active material into a zirconia ball milling tank together for performing ball milling and mixing. The graphene solution is mixed with the positive active material in a mechanical ball milling manner, so that the graphene can be inlaid into or coated with positive active material granules, an excellent bonding interface can be formed, and the positive active material granules are refined; and therefore, the material is uniform, and the rate capability and consistency of the material are improved. Finally, the positive slurry subjected to ball milling is dried, ground and screened so as to obtain the positive electrode material powder.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing titanium diboride dispersion-strengthened Cu-base composites by using mechanical alloying method

The invention discloses a method for preparing titanium diboride dispersion-strengthened Cu-base composites by using a mechanical alloying method, taking Cu powder, TiO2 powder, B2O3 powder and Mg powder with the granularity less than 100 meshes and purity more than 99 percent as raw materials. The method comprises the following steps of: thoroughly mixing the Cu powder, the TiO2 powder, the B2O3 powder and the Mg powder; carrying out high-energy ball-grinding on the mixed powder for 3 to 15 hours at the revolution speed of 1000 to 2000 rpm at room temperature; acid pickling the powder for 2 to 15 hours at the temperature of 20 to 80 DEG C with 1 to 3 mol / L hydrochloric acid to get mixed powder of Cu and TiB2; drying the mixed powder of Cu and TiB2, and carrying out high-energy ball-grinding on mixed powder of Cu and TiB2 for 1 to 3 hours ; cold pressing the mixed powder of Cu and TiB2 for forming; and at last sintering the mixture of Cu and TiB2 for 1 to 3 hours in a resistance furnace with argon protection gas at the temperature of 800 to 1000 DEG C to get the TiB2 dispersion-strengthened Cu-base composites with granularity of 5 to 10 microns. The method for preparing the TiB2 dispersion-strengthened Cu-base composites by using the simple high-energy ball-milling mechanical alloying method has the advantages of simple technology, low production cost, high product yield and high product quality.

Owner:KUNMING UNIV OF SCI & TECH

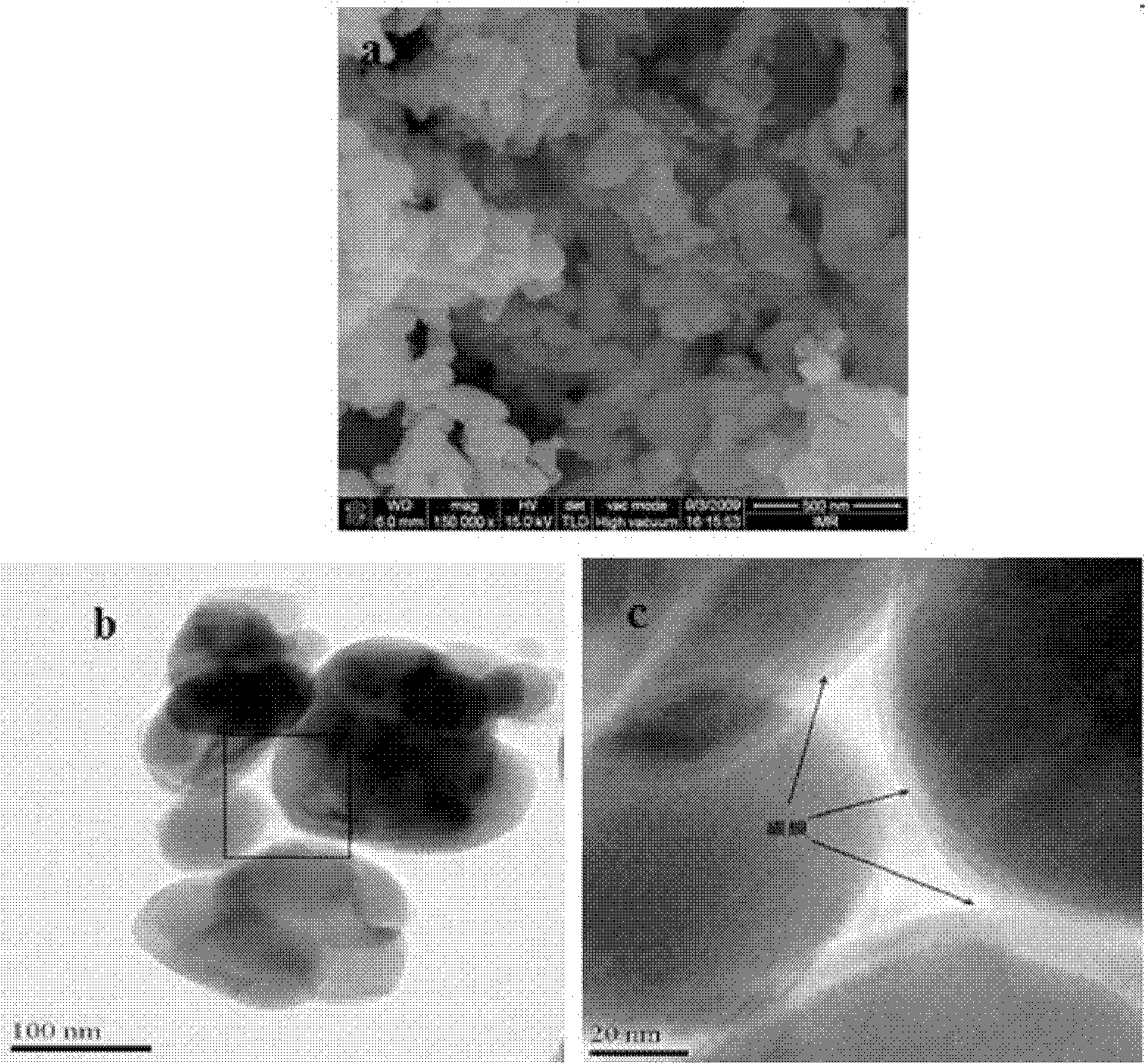

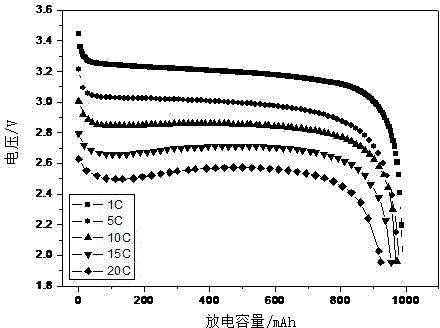

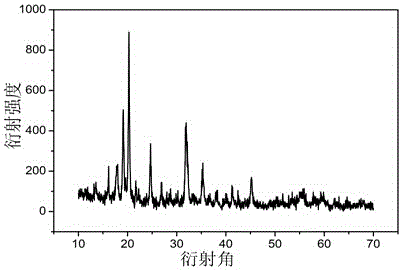

Preparation method of nano LiFel-xMxPO4/C lithium phosphate composite positive pole material

ActiveCN101789504AImprove dynamic conditionsComposition is stableCell electrodesChemical reactionHigh energy

The invention relates to a preparation method of nano LiFel-xMxPO4 / C lithium phosphate composite positive pole material. Lithium dihydrogen phosphate, iron powder, an M element source and an organic carbon source are uniformly mixed in a solvent medium, are treated for 2 to 7h through a high-energy ball mill, have chemical reaction under mechanical activation, and a uniformly dispersed precursor is prepared. The precursor is thermally treated for 2 to 10h at 600 to 800 DEG C under atmosphere protection and cooled to be room temperature, and the nano LiFel-xMxPO4 / C lithium phosphate composite positive pole material is prepared. The preparation method has simple and high-efficiency process and the whole process does not produce ammonia, wastewater and other polluting substances, and is applicable to industrial production. The primary particles of the prepared material are nano particles which are uniformly distributed, and the material is characterized by high specific capacity and good rate cycle performance.

Owner:四川浩普瑞新能源材料股份有限公司

Oat compound side crops beverage and production method thereof

InactiveCN101912142AHigh protein contentComprehensive and balanced nutritionFood preparationAdditive ingredientThirst

The invention discloses a compound side crops milk beverage which is complemented with high dietary fiber, protein and linoleic acid by using oat as the raw material together with side crops containing high protein and high grease such as white sesame seed, soybean, peanut, and the like. The production method utilizes baking incensing technique, emulsifying colloid compound, glue rubbing technique, high-pressure uniform technique and high-pressure sterilizing technique, to completely maintain the nutrition constituents such as dietary fiber in oat, linoleic acid and protein in white sesame seed, soybean, peanut, and the like, efficiently remove the fishy smell of the soybean and the fresh smell of the peanut and increase the compound fragrance of the products. Without adding essence and preservative, the oat compound side crops beverage of the invention contains more nutrition, is more natural and has a function of health protection. The faint scent of oat and the baking fragrance of white sesame seed, soybean and peanut are completely mixed, so the beverage is smooth, fragrant and sweet, is fit for all kinds of customers, can be drunk in four seasons, can be drunk for quenching thirst and can be applied as the breakfast drinking for supplying dietary fiber and protein.

Owner:SICHUAN BLUE RAY MAYSUN DRINK & FOOD

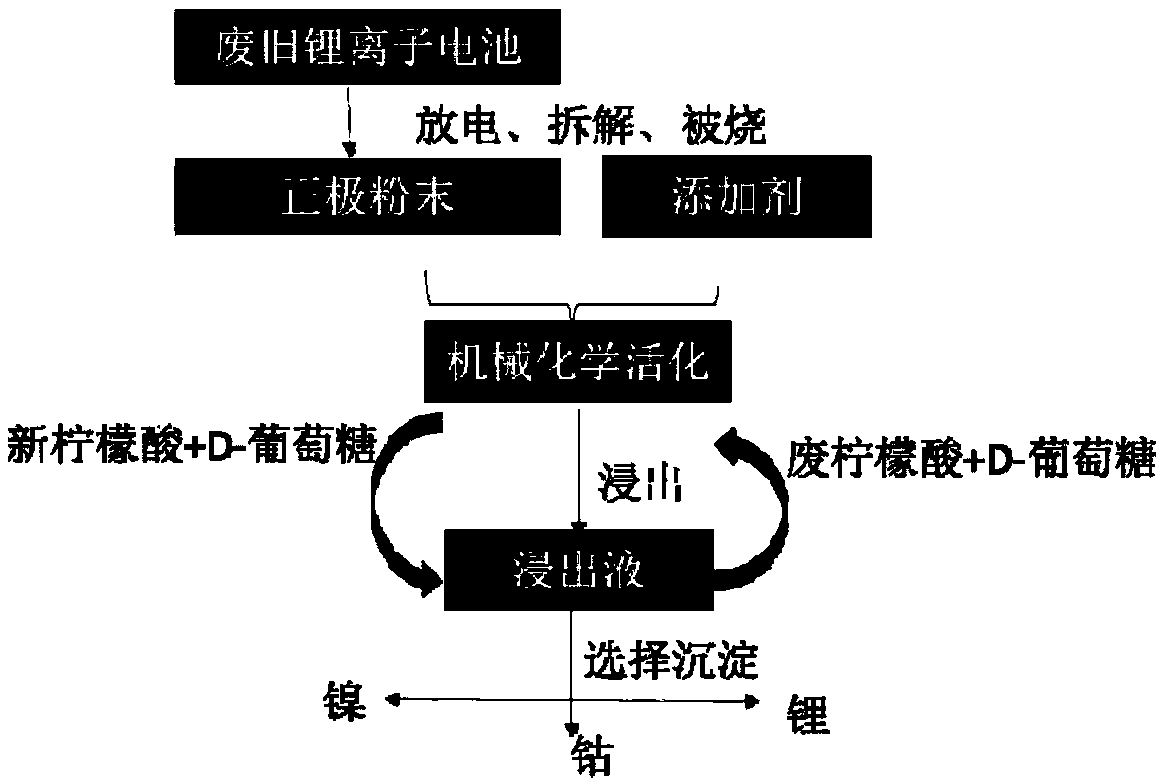

Waste lithium battery wet wire recovery method

InactiveCN109868364AEfficient Simultaneous RecoveryImprove recycling efficiencyGrapheneWaste accumulators reclaimingRecovery methodEnvironmental resistance

The invention discloses a waste lithium battery wet wire recovery method. The waste lithium battery wet wire recovery method includes the following steps that firstly, discharging processing is conducted on a waste lithium battery, a negative electrode copper foil sheet, containing a graphite negative electrode material, and a positive electrode material are obtained after a shell of the lithium battery is broken; secondly, a graphite powder material subjected to heat treatment is taken, a citric acid-D glucose leaching agent is added, lithium ion leaching is conducted in a low-temperature andconstant-temperature reactor with a stirring device, and a solution, containing lithium, and a graphite material are obtained through separation after the leaching process is finished; thirdly, positive electrode powder is activated; and fourthly, leaching reaction is conducted after the activated positive electrode powder and the citric acid-D glucose leaching agent are mixed, nickel, cobalt, manganese and lithium elements dissolved in filtrate are deposited out, and first-stage waste liquid is obtained after deposition. By means of the waste lithium battery wet wire recovery method, the positive electrode material and the negative electrode material of the lithium battery are effectively recovered at the same time, and the recovery efficiency is improved; and due to the adoption of thecitric acid-D glucose leaching agent system, environment friendliness is achieved, and cost is low.

Owner:GANZHOU HIGHPOWER TECH CO LTD

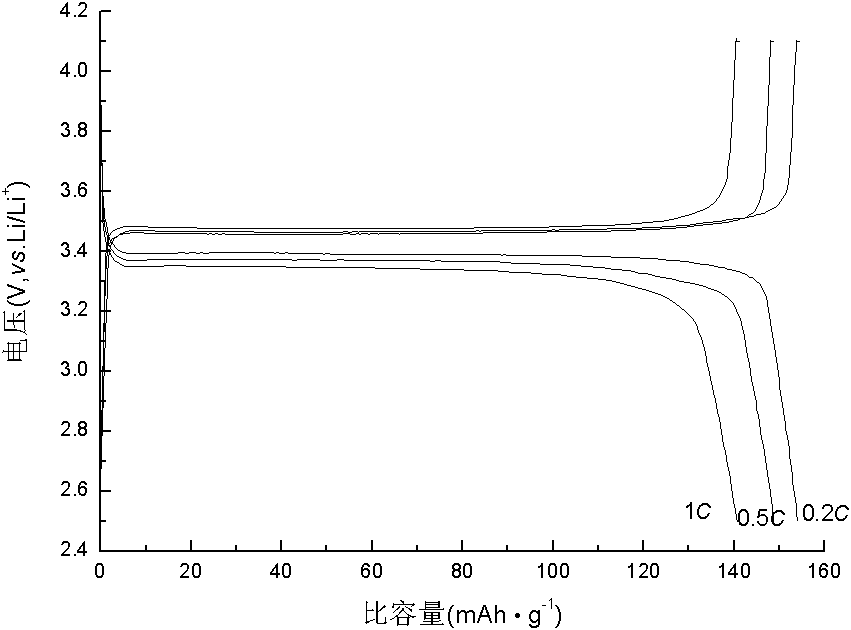

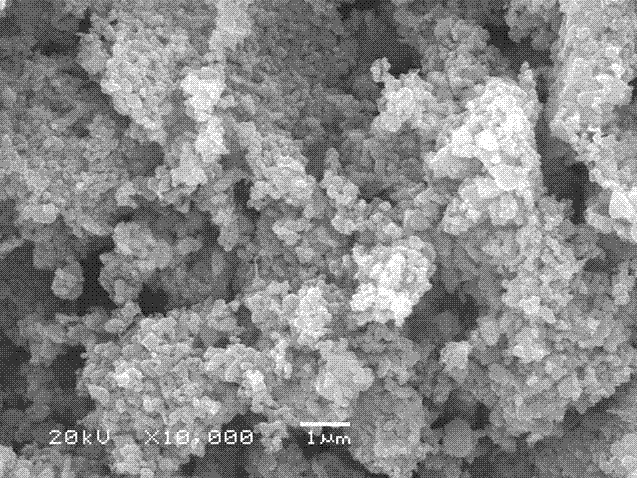

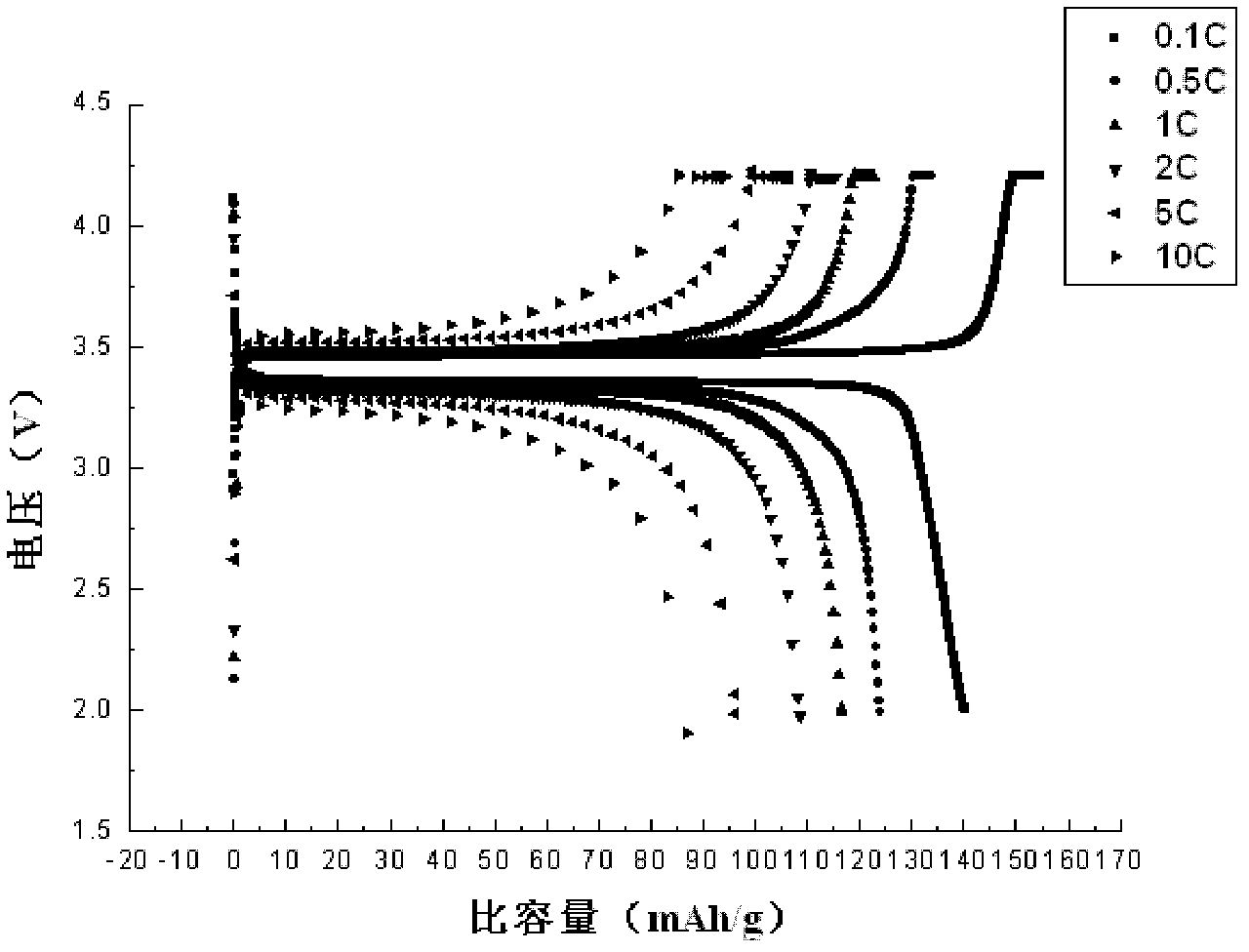

Nanometer lithium zirconate modified lithium iron phosphate composite material and preparation method thereof

InactiveCN103400982AImprove ionic conductivityImprove cycle stabilityCell electrodesPhosphorus compoundsStructural formulaLithium zirconate

The invention discloses a nanometer lithium zirconate modified lithium iron phosphate composite material and a preparation method thereof. The structural formula of the composite material is LixFeyPO4.zLi2ZrO3 / C, and the composite material comprises lithium iron phosphate, nanometer lithium zirconate and organic matter pyrolysis carbon. The composite material is characterized by being prepared by virtue of any one of the following methods: (1) preparing a precursor mixed liquor containing nanometer lithium zirconate through a hydrothermal reaction, drying, adding an organic carbon source, mixing, and calcining at a high temperature in an inert atmosphere; (2) preparing the precursor mixed liquor through the hydrothermal reaction, drying, calcining at a low temperature in the inert atmosphere, then adding the organic carbon source and nanometer lithium zirconate, mixing, and calcining at a high temperature in the inert atmosphere. The preparation method is simple; the prepared lithium iron phosphate composite material has the advantages of high conductivity, excellent multiplying power and low temperature performance, good cycle performance and the like, and can be widely applied to field of power batteries.

Owner:YANTAI ZHUONENG BATTERY MATERIAL

Preparation method of particular-reinforced molybdenum-based composite material

The invention discloses a preparation method of a particular-reinforced molybdenum-based composite material and belongs to the technical field of preparation of composite materials. The method includes following steps: (1) adding enough ammonia water to an ammonium molybdate solution for enabling the ammonia water to be alkaline; (2) dissolving a soluble aluminum salt, a soluble zircon salt or a soluble lanthanum salt in water to obtain a solution and slowly adding the solution to the ammonium molybdate solution with stirring to generate a flocculent precipitation; (3) performing a heating and evaporatively-drying process to obtain an ammonium molybdate / metal hydroxide composite powder; (4) performing low-temperature calcination to obtain a molybdenum trioxide / metal hydroxide composite powder; (5) reducing the molybdenum trioxide into molybdenum powder; and (6) performing a pressing process and a sintering process to obtain the particulate reinforced molybdenum-based composite material. In the invention, a second phase is firstly precipitated out for forming a nano-scale flocculent precipitation, and then an evaporative crystallization process is carried out so that the ammonium molybdate forms a nucleus with the nano-scale second phase being a nucleation core, wherein the second phase is dispersed and distributed on a molybdenum substrate and is completely metallurgically bonded with the molybdenum substrate. Growth of crystal grain during sintering can be effectively stopped and a crystal grain refining effect is achieved.

Owner:HENAN UNIV OF SCI & TECH

Method for extracting rapeseed peptides through wet milling combined with enzymic method

The invention discloses a method for extracting rapeseed peptides through wet milling combined with an enzymic method. The method comprises the following steps of: taking dry degreased and unshelled rapeseed dregs, grinding and filtering the dry degreased and unshelled rapeseed dregs through a 40-mesh sieve, adding water which is 5 times of the materials in weight, adding 5-10 u / g of cellulase, and performing wet grinding on black soybean meal for 1-3 hours under the condition of a rotating speed in the range from 250 to 400 rpm (revolutions per minute) by using a ball mill to obtain an ultrathin powder turbid liquid; (2) supplementing water to the ultrathin powder turbid liquid until the concentration of the dry materials is in the range from 50 to 100 g / l, adjusting the pH to 7.0, adding 40u / g of protease, maintaining the temperature at 55 DEG C and the pH at 7.0, and hydrolyzing for 1-2 hours; (3) centrifuging the enzymatic hydrolysate for 15 minutes under the condition of 10000 rpm, continuously adding water which is 5-10 times of residues in weight to the residues, adding 20u / g of protease, hydrolyzing for 1-2 hours at the temperature of 55 DEG C and the pH of 7.0, centrifuging, and blending the two supernates to obtain a rough peptide solution. According to the invention, cellulose dissolving causes large-molecular materials such as protein to be hydrolyzed more easily, and also the hydrolysis rate of the protein can be increased; in addition, the conversion rate of the peptides is greatly increased.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

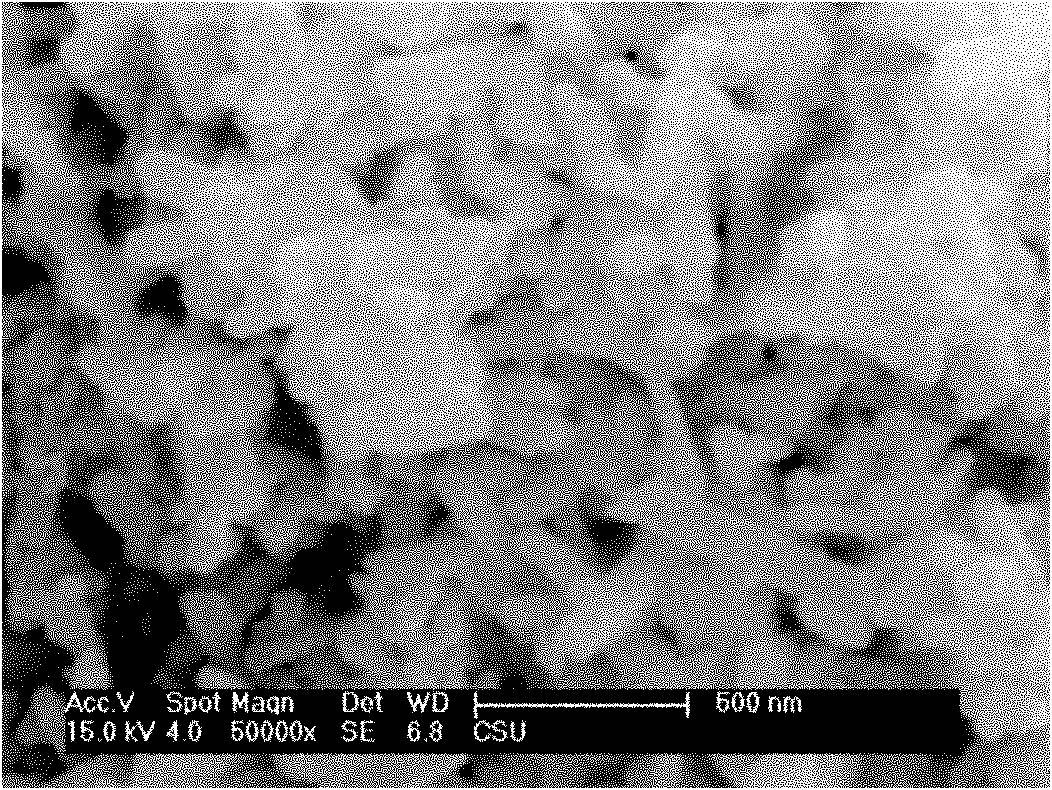

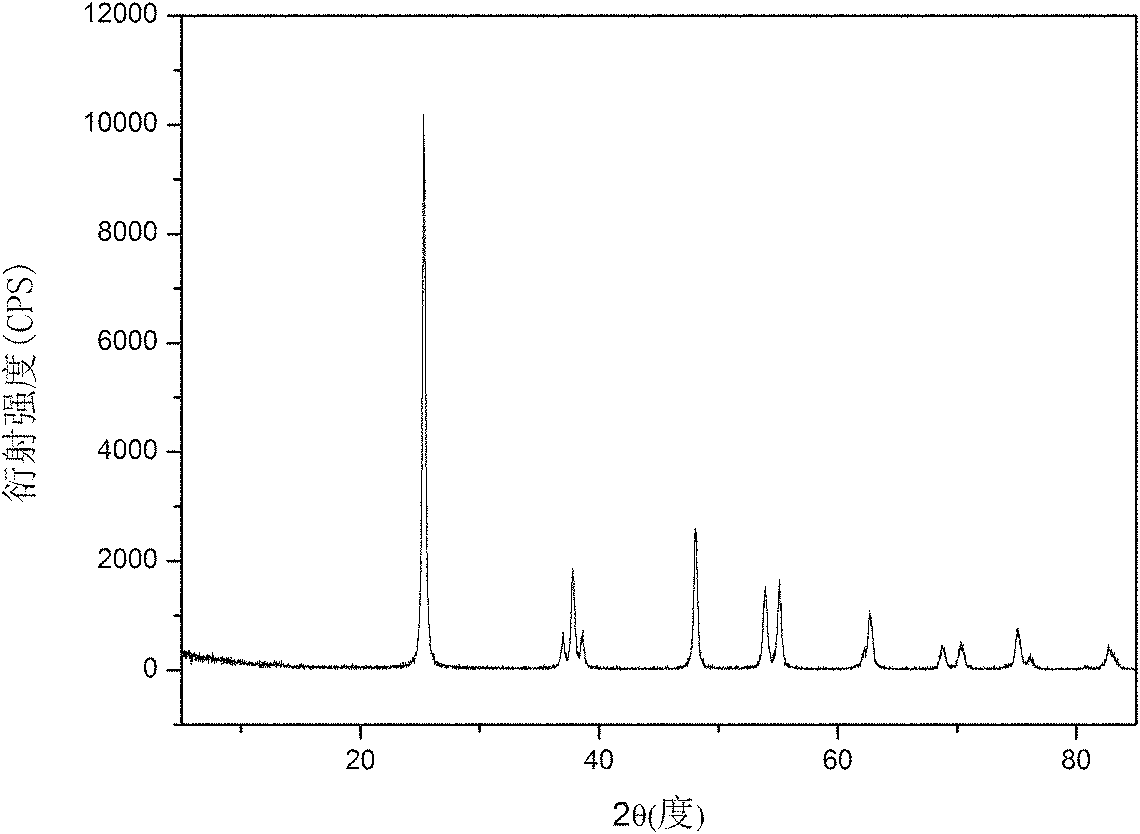

Method for preparing nano-TiO2 serving as cathode material of lithium ion battery

The invention discloses a method for preparing nano-TiO2 serving as a cathode material of a lithium ion battery. The method comprises the following steps of: beating precipitates of titanium prepared from metatitanic acid or various titanium sources by using water, adding a coordinating agent into thick liquid according to a molar ratio of the coordinating agent to the titanium of 1.0:1-10:1, regulating the pH value to be between 7 and 14 by using alkali, reacting in a stirring reactor at the temperature of between 20 and 80 DEG C for 10 to 720 minutes, and filtering to obtain solution of the titanium; and adding the alkali into the solution according to a molar ratio of the alkali to the titanium of 1.0:1-50:1, heating the solution to between 80 and 200 DEG C for 10 to 600 minutes, filtering and washing to obtain a precursor of nano-TiO2, and calcining the precursor at the temperature of 120 and 850 DEG C for 0.5 to 20 hours to obtain the nano-TiO2 serving as the cathode material of the lithium ion battery. The method has the characteristics of wide range of raw materials, simple process flow, low energy consumption, low cost, good appearance of product granularity and excellent electrochemical properties.

Owner:CENT SOUTH UNIV

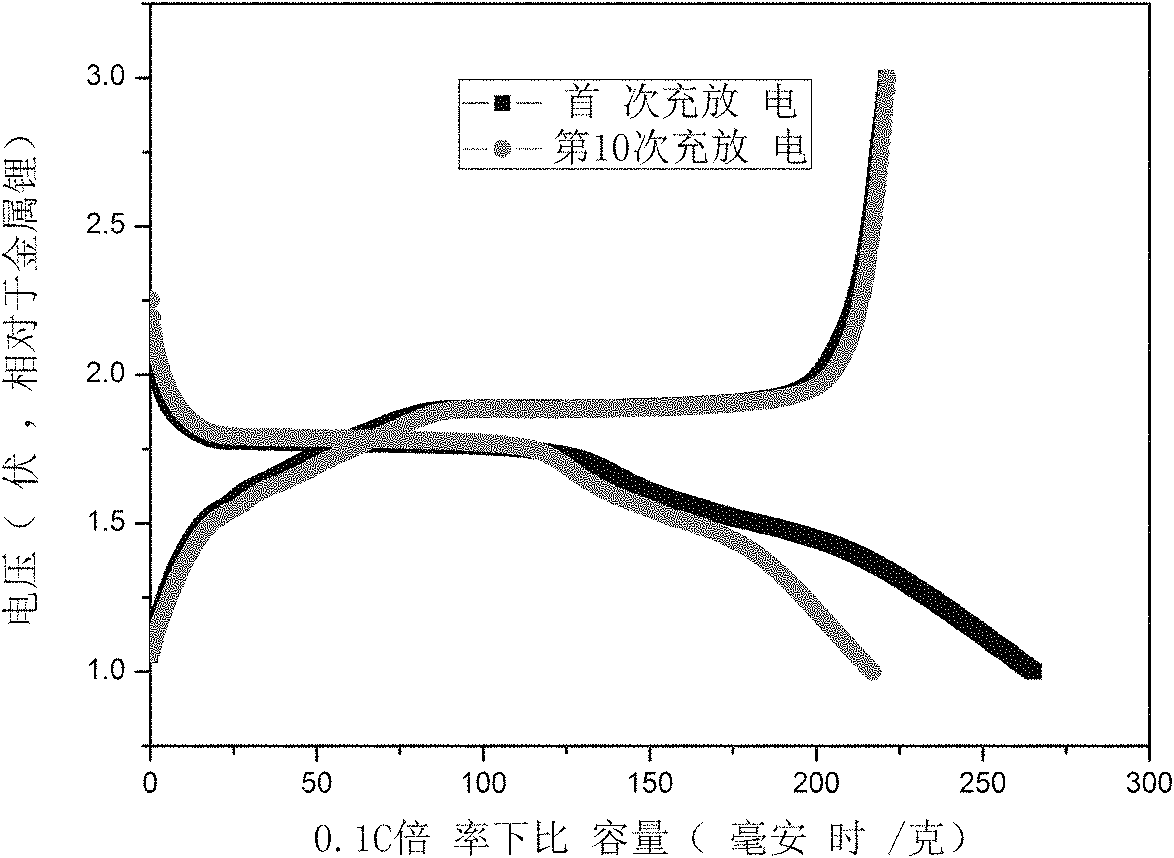

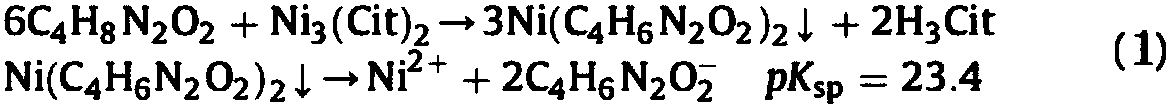

Method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries

InactiveCN108913873AConducive to enhanced leachingParticle refinementWaste accumulators reclaimingProcess efficiency improvementAdhesiveManganese

The invention relates to a method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries and belongs to the technical field of recovery of lithium batteries. The method comprises the following steps: (1) thoroughly discharging waste nickel-cobalt-manganese batteries, disassembling and sorting out positive powder, and carrying out heat treatment on the positive powder to remove impurity components such as conductive agents and adhesives in the positive powder; (2) mixing the positive powder subjected to heat treatment with active additive according to a ratio, then mechanically and finely grinding so as to carry out machine-chemical synergistic activation of the positive powder; and (3) mixing the activated positive powder with citric acid-D glucose leachate leaching agent, then carrying out leaching reaction and precipitating nickel, cobalt, manganese and lithium in the filtrate to obtain the high-value-added metals. According to the method, citric acid in the citric acid-D glucose leachate can be recycled after extracting the metal elements; high consumption of the leachate is avoided; the leaching efficiency is improved; the recycling costis reduced.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Preparation technology for high-purity ultramicro particle brownless konjac powder

InactiveCN104605293AOptimization parametersParticle refinementFood preparationCelluloseProcess engineering

The invention relates to a preparation technology for high-purity ultramicro particle brownless konjac powder. The preparation technology comprises the following steps: raw material preparation, starch and cellulose removing treatment, color-protecting powder preparation, color-protecting treatment on a konjac raw material, drying, smashing, examining, homogeneity warehousing and the like. Compared with the prior art, the preparation technology improves various parameters of the obtained konjac powders, reduces the contents of plant starch and plant cellulose in the konjac powder, avoids generating polyphenol oxidase oxide and pigment in products, improves product quality, refines particles of the konjac powder, develops the potential utilization value of the konjac powder, and increases the application field of the konjac powder.

Owner:四川森态源生物科技有限公司

Preparation method and application of MAX-phase enhanced nickel-based high-temperature lubricating composite material

ActiveCN109666815AHigh bonding strengthGood self-lubricating performanceCylinder headsGas turbine plantsAlloyGraphite

The invention discloses a preparation method and application of a MAX-phase enhanced nickel-based high-temperature lubricating composite material. The preparation method comprises the following steps:carrying out mechanical mixing on Ti powder, Si powder and TiC powder; preparing loose block-shaped Ti3SiC2 ceramic through a powder metallurgy method; then carrying out crushing and ball-milling treatment on the prepared loose block-shaped Ti3SiC2 ceramic, so as to obtain Ti3SiC2 ceramic powder; then carrying out mechanical mixing on the sieved Ti3SiC2 powder and NiAl powder; compacting and molding; and finally, preparing a block-shaped NiAl-Ti3SiC2 composite material through hot-pressing sintering, wherein the phase content of NiAl and Ti3SiC2 in the block-shaped NiAl-Ti3SiC2 composite material is 60 to 90 percent and 10 to 40 percent respectively. The NiAl composite high-temperature lubricating material is prepared by adopting the powder metallurgy method and the self-lubricating performance of hot-pressing sintering and synthesis in the composite material is better than that of Ti3SiC2-phase ceramic of graphite and MoS2; and meanwhile, an NiAl alloy has excellent corrosion resistance and abrasion resistance, and has good sintering performance, so that NiAl alloy powder is selected as a matrix of the composite material.

Owner:咸阳瞪羚谷新材料科技有限公司

Frictional heat self-sintering antifriction material

InactiveCN101205457AStable coefficient of frictionSmall fluctuationOther chemical processesFiberTO-18

The invention belongs to the friction material field of friction stopping devices used in transport machinery and various engineering operation machineries, and relates to a friction heat self-sintering friction-resistant material. The material comprises the following raw materials by weight percent: 10 to 16 percent of adhesive, 8 to 20 percent of modified framework material, 10 to 20 percent of friction stabilizer, 10 to 25 percent of plasticizing fiber, 5 to 15 percent of various auxiliary agents, 3 to 13 percent of sintering material, 8 to 18 percent of friction-increasing agent, 2 to 8 percent of chopped glass fiber, 3 to 16 percent of petroleum coke and 4 to 16 percent of coke dust. The invention is characterized in that: ceramic-like material is converted into compound with low melting point by utilization of the heat on a friction surface; moreover, the conversion ensures that grains are refined and compact and distributed more evenly. Test result shows that the friction material has stable friction coefficient, small fluctuation, not more than +-0.035 deviation, less abrasion loss, long service life, no braking noise, no smoke and spark and no dust; moreover, the outstanding characteristic of the friction material lies in that the material does not cause damages on a brake drum (disc).

Owner:信义集团公司

Preparation method of composite MnO2 anode material for chargeable Li-Mn battery

InactiveCN101746829AHigh purityImprove product qualityCell electrodesManganese oxides/hydroxidesElectrolysisElectrical battery

The invention provides a preparation method of composite MnO2 anode material for a chargeable Li-Mn battery and relates to a manufacturing method of electrode material; finished products are manufactured by the steps of purification of raw material, calcining and refining and reactive sintering; the method comprises the following steps: merchant electrolysis MnO2 material is acid-dipped and then is filtered and cleaned, and the washed material is ground finely; and then nonionic surface active agents with 0.3-0.5 percent of weight ratio are added, the mixture is heated to 120-140 DEG C in a sealing agitated reactor, and the temperature is kept for 3-5 hours, after the temperature is reduced, the reaction material is filtered and dried, and the dried material is placed in an electric furnace for calcining; the calcined MnO2 and chemically pure lithium nitrate are mixed with 1:(0.3-0.4) of molar ratio, the mixture is ground in a dry state, and then is sintered for 10-24 hours at 260-400DEG C under atmosphere, and then dry ball-milling and sieving are carried out to obtain the needed composite MnO2 material.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Method for growing polycrystalline diamond piece by using microwave plasma chemical vapor deposition method

InactiveCN109911894AInhibition of growing phenomenaInhibition of growthDiamondSurface finishPolycrystalline diamond

The invention discloses a method for growing a polycrystalline diamond piece by using a microwave plasma chemical vapor deposition method and relates to the field of artificial diamond. The method specifically comprises the following steps: (1) pretreating a substrate in microwave plasma chemical vapor deposition equipment; (2) forming a core for 0.4-0.6 hour on the pretreated substrate accordingto common polycrystalline diamond piece growth process, controlling growth time according to a final growth thickness, and carrying out power-off, grinding and polishing for multiple times for repeated multi-time growth. The self-support thickness of the polycrystalline diamond piece grown by using the method can be a millimeter grade or greater, the phenomenon that diamond granules are continuously increased along with increase of thicknesses can be effectively inhibited, then the purposes that the diamond granules are refined while thickness requirements are met, and the density, the mechanical strength and the surface smoothness after polishing of the diamond piece are improved, are achieved, and effects of a CVD (Chemical Vapor Deposition) polycrystalline diamond material can be sufficiently taken into play.

Owner:河北地质大学

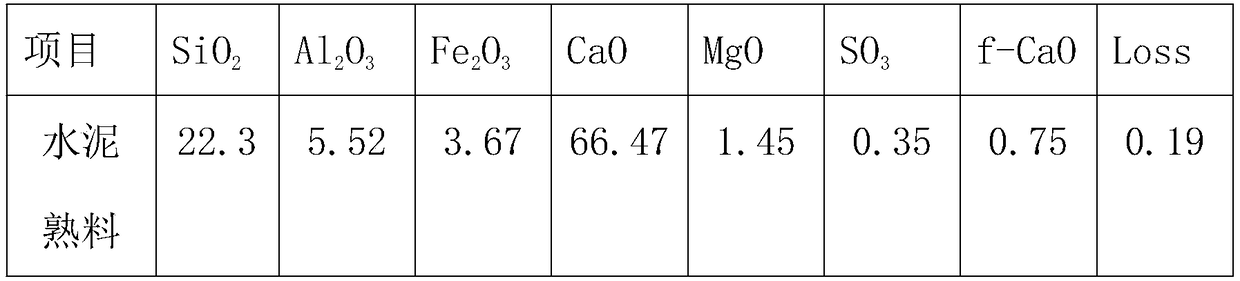

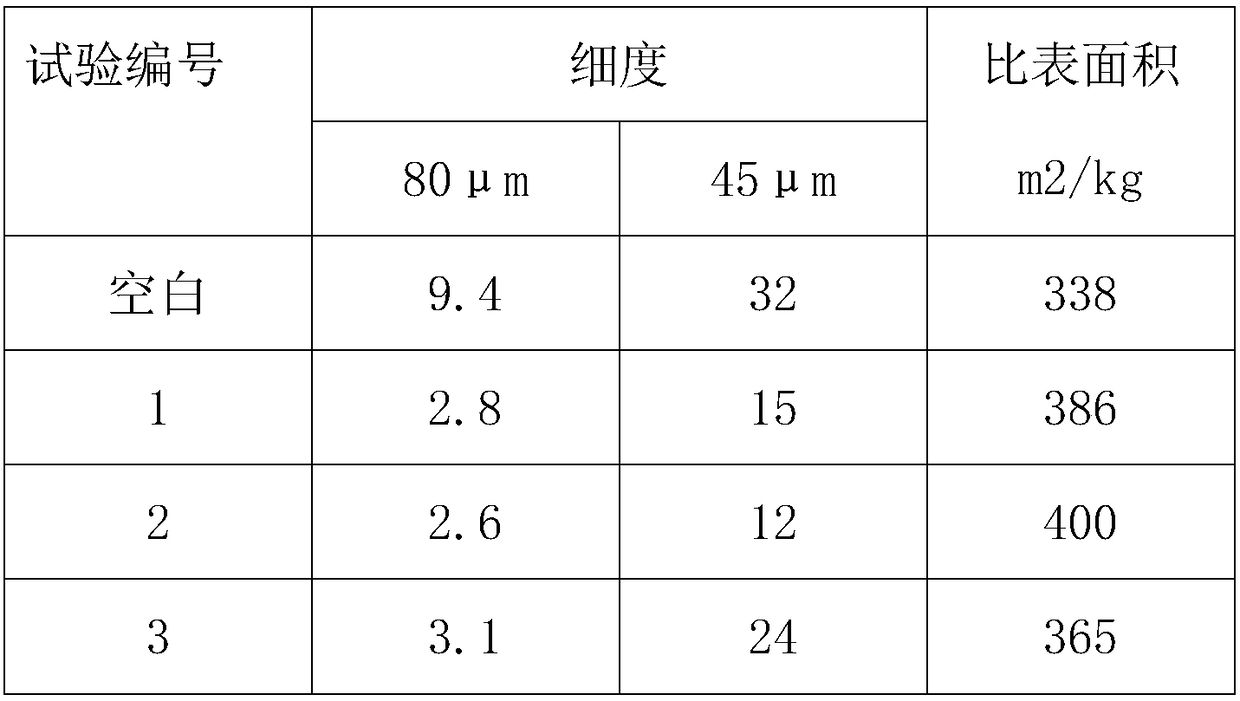

Compound grinding aid for cement

InactiveCN109231875AGood synergyMeet grinding aid requirementsEnvironmental resistanceSodium stearate

The invention discloses a compound grinding aid for cement. The compound grinding aid comprises the following components in parts by weight: 12-28 parts of polyalcohol amine, 12-28 parts of polyalcohol, 6-13 parts of lignosulfonate, 3-7 parts of sodium stearate, 6-12 parts of molasses, 2-6 parts of sodium sulfate and 22-28 parts of water. The compound grinding aid disclosed by the invention has the beneficial effects that environment-friendly, stable and low-toxicity materials are adopted, so that better synergistic effect of all the components is ensured, the grinding-aiding requirements of all the materials at different grinding stages can be met, the optimum grinding-aiding effect is achieved, the particles are refined, the particle aggregation is eliminated and the grinding efficiencyis improved.

Owner:颍上县永军建材有限责任公司

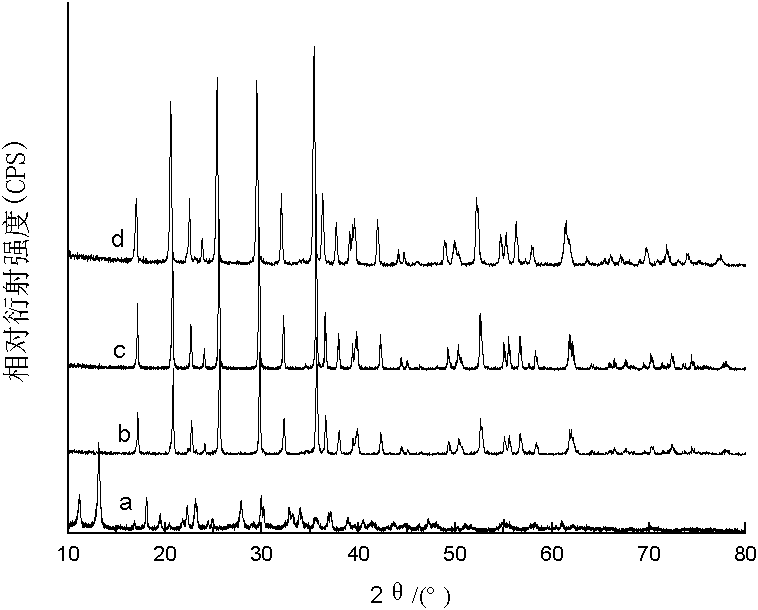

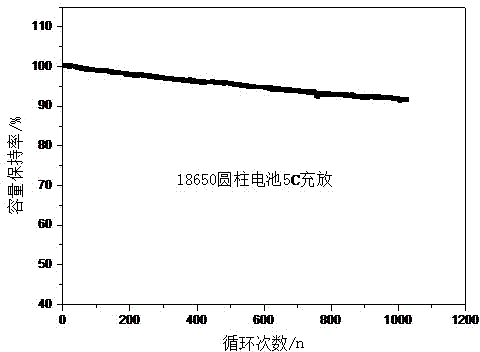

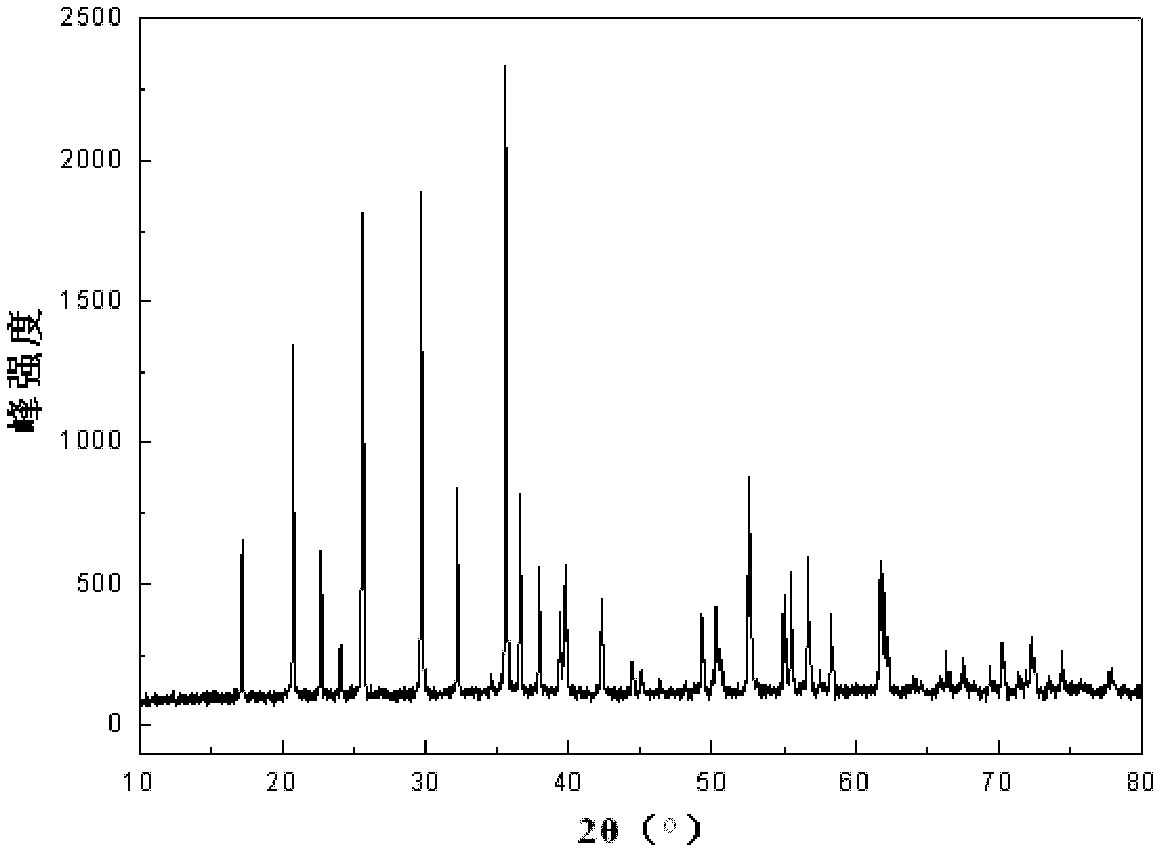

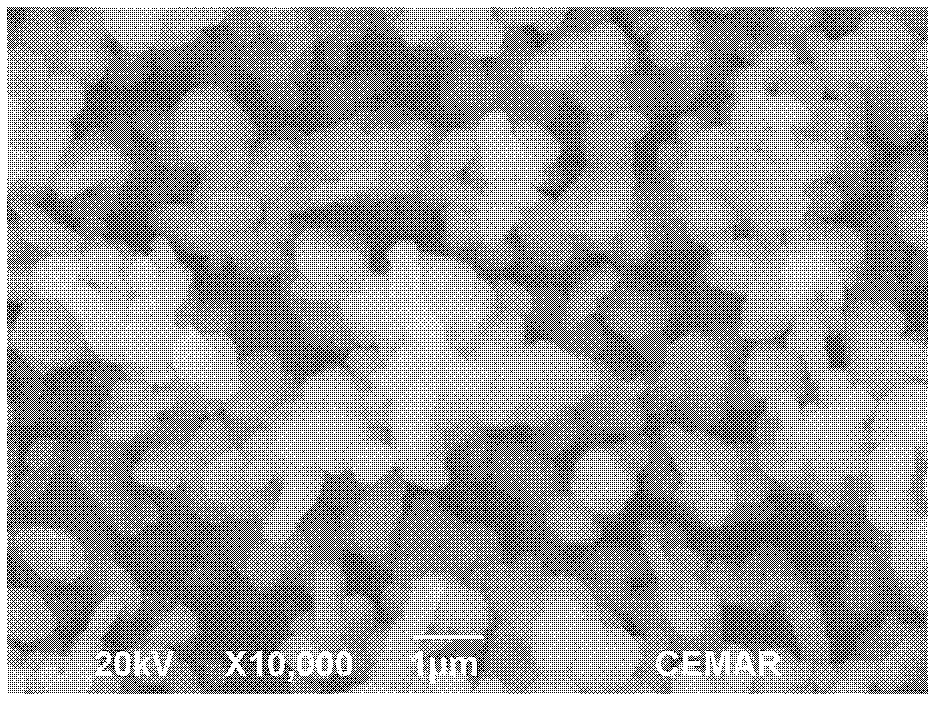

Method for preparing lithium iron phosphate cathode material of lithium ion battery by supercritical hydrothermal process

InactiveCN102569800AImprove discharge capacityImprove cycle lifeCell electrodesCarbon coatingFiltration

The invention relates to a method for preparing a lithium iron phosphate cathode material of a lithium ion battery by a supercritical hydrothermal process and belongs to the technical field of a novel material. The method comprises the following steps: (1) hydrothermal synthesis reaction, i.e. dissolving an iron source, a phosphorus source, a lithium source and a template agent in water, placing mixes solution into a reaction kettle, pumping out the air in the kettle by adopting a vacuum pump, heating the reaction kettle to the temperature of 380 DEG C to 500 DEG C, regulating the pressure in the kettle into 23MPa to 40MPa by a water injection pump, performing a reaction for 10s to 100min, and controlling the proportion of the added materials into a molar ratio of Li to Fe to P of (3.0 to 3.15):1:(1.0 to 1.15); (2) filtration, washing and drying of a product, i.e. after the reaction is completed, carrying out water-cooling temperature reduction on the reaction kettle and finally, filtering, washing and drying the generated product to obtain gray white LiFePO4 powder; (3) calcining and carbon coating treatment, i.e. calcining the obtained product for 1 to 8 hours at the temperature of 500 DEG C to 800 DEG C in the protective atmosphere to obtain carbon-coated lithium iron phosphate. The product obtained by the method of the invention has excellent electrochemical performance and uniform particle size distribution. The sizes of the particles of the product are in the range of 300nm to 800nm. The phase purity of the product can reach over 99%. The electron conductivity of the material and the diffusion performance of lithium ions are improved.

Owner:DALIAN UNIV OF TECH

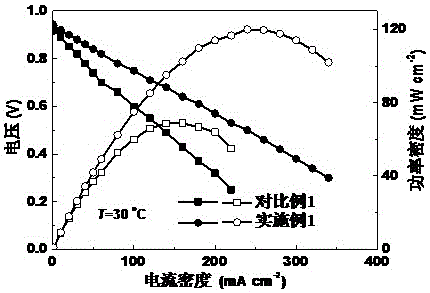

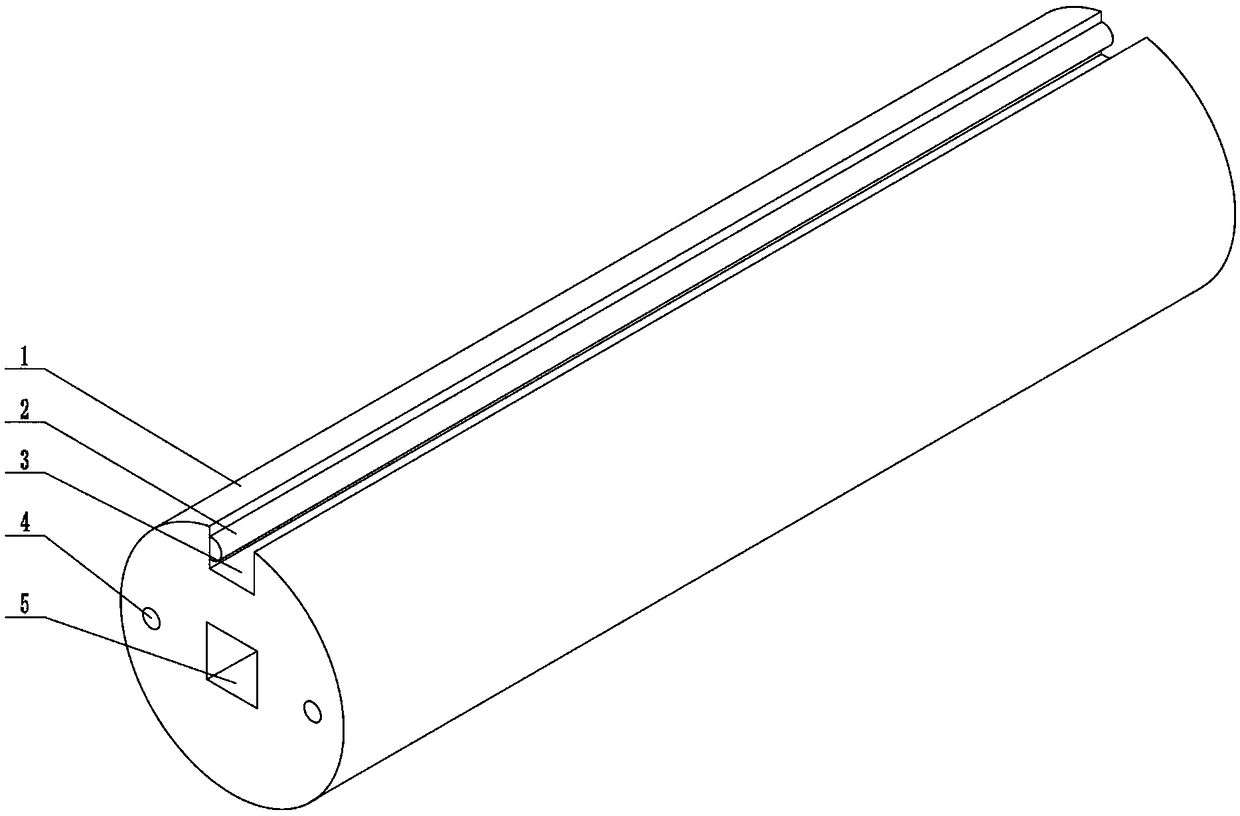

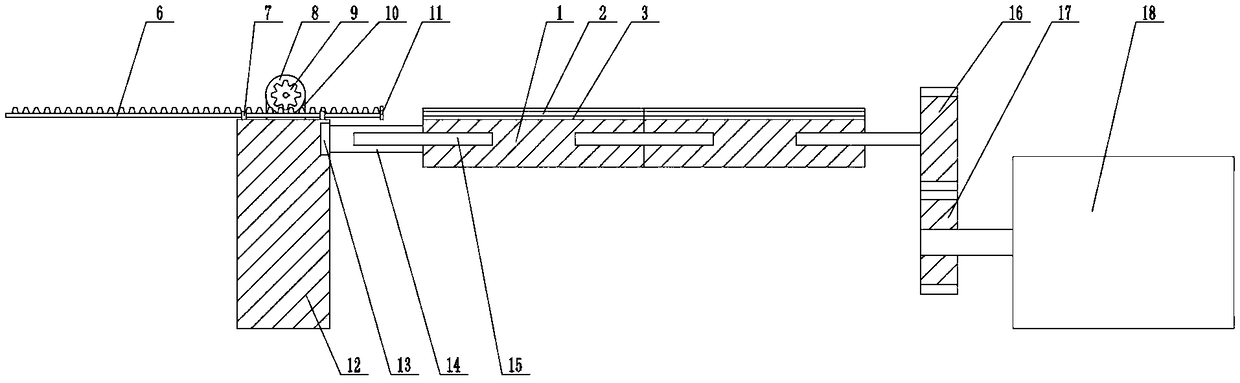

Preparation method of alkaline anion-exchange membrane for fuel cell

ActiveCN106410246AParticle refinementGood technical effectFuel cellsAlkaline anion exchange membraneIon-exchange membranes

The invention discloses a preparation method of an alkaline anion-exchange membrane. The preparation method comprises the treatment process on alkaline resin, and the treatment process comprises the steps that AER alkaline resin is placed in an inorganic salt aqueous solution for soaking, then the AER alkaline resin and the inorganic salt aqueous solution are transferred to a heat-insulated vessel, liquid nitrogen is injected into the vessel for cooling, and AER alkaline resin particles are fully ground and crushed; liquid nitrogen freezing treatment is stopped, when the temperature is naturally recovered to room temperature, materials in the vessel are filtered with a filter screen, and fine alkaline resin powder is obtained. The fine alkaline resin powder serves as anion exchange resin of a chemical active group to prepare the alkaline anion-exchange membrane. By means of the resin treatment process, the AER alkaline resin particles can be uniformly distributed in the prepared anion-exchange membrane, the electrochemical performance of the alkaline anion-exchange membrane is further improved, and a fuel cell assembled through the alkaline anion-exchange membrane prepared through the method shows the excellent electricity generation performance.

Owner:ZHEJIANG UNIV

Antibacterial deodorizing nanometer fiber, and preparation method thereof

ActiveCN109183193ALow priceNo pollution in the processSpinning solutions preparationArtifical filament manufactureFiberManufacturing technology

The invention belongs to the technical field of fiber manufacturing, and more specifically relates to an antibacterial deodorizing nanometer fiber, and a preparation method thereof. The antibacterialdeodorizing nanometer fiber is prepared from, by weight, 22 to 26 parts of nanometer titanium dioxide, 30 to 35 parts of chitosan, 3 to 5 parts of rose flower, 55 to 60 parts of Glacial Acetic Acid, 2to 4 parts of single layer graphene, 2 to 3 parts of bamboo fiber micropowder, 1 to 2 parts of carboxymethylcellulose sodium, and 1 to 2 parts of garlic essential oil. The antibacterial deodorizing nanometer fiber possesses excellent bacteria killing and inhibiting and deodorizing effect; the antibacterial validity and broad spectrum activity of chitosan nanometer fiber are improved; the raw materials are relatively cheap; no high temperature treatment is needed in the preparation process; the preparation process is simple and convenient; cost is low; efficiency is high; no pollution is caused; and energy consumption is low.

Owner:HEYE HEALTH TECH CO LTD

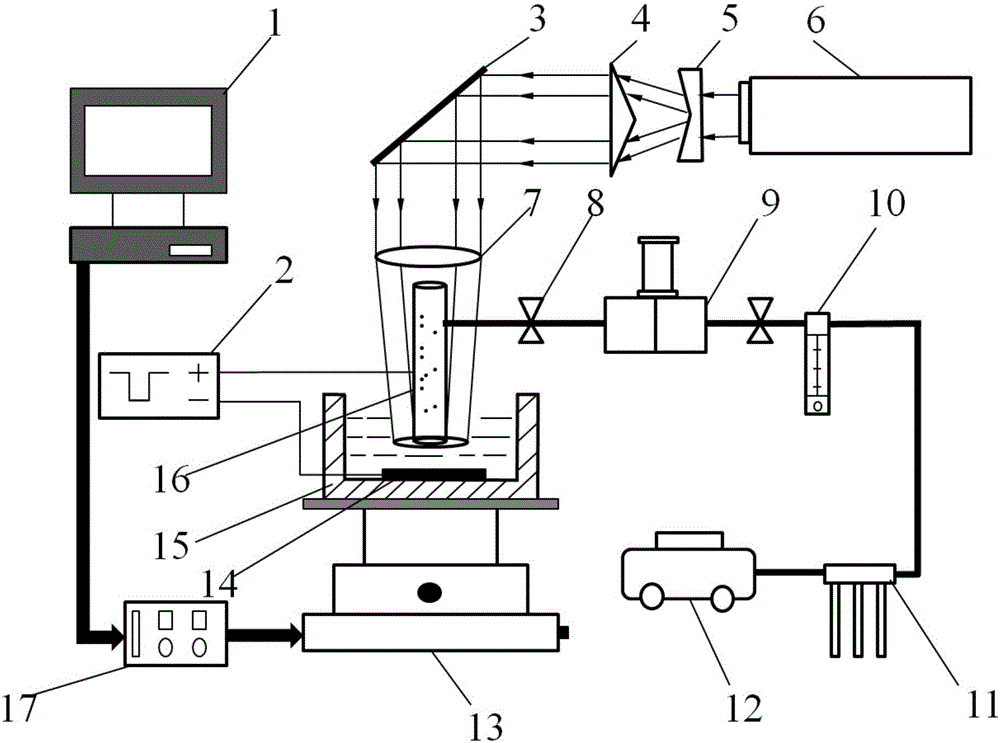

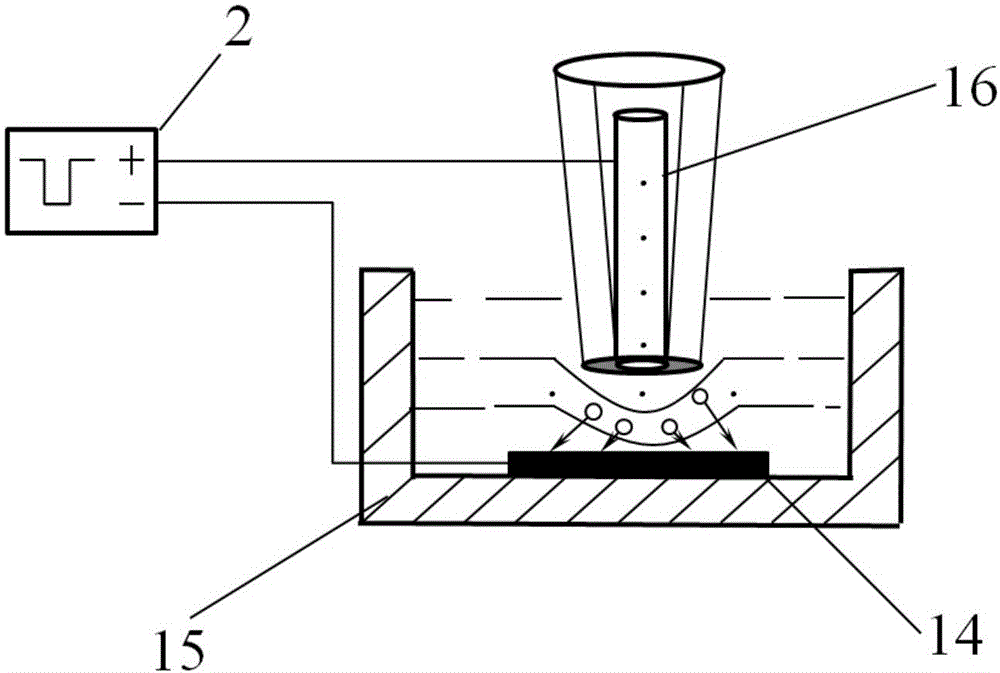

Hollow laser inside-beam powder feeding composite electrodeposition machining method and device

ActiveCN106757285AAvoid reunionEvenly dispersedElectrolysis componentsElectrolytic coatingsElectrochemical responseManufacturing technology

The invention discloses a hollow laser inside-beam powder feeding composite electrodeposition machining method and device, relates to electrochemical deposition machining of composite materials, and belongs to the field of non-traditional machining in a manufacturing technology. According to the device, a hollow anode tube is perpendicularly placed in hollow laser, particles are sprayed out from an anode, are scattered in a laser focal region and then drop in a solution, the laser illuminates the solution to generate high-temperature and high-pressure plasma, in an outward expansion process of the plasma, the particles are dispersed by a generated jet impact force, and the particles can uniformly reach the surface of a cathode and then are captured by the cathode, so that the particles easily enter a coating to form a nano-particle composite coating. By the impact effect of the laser, the agglomeration probability of the particles in the traditional composite electrodeposition process is reduced, the compound quantity of the particles is increased, and the quality of a deposition layer can be improved remarkably. Meanwhile, electrochemical reaction rate can be increased by heat effect of the laser, and therefore, the deposition speed is increased.

Owner:JIANGSU UNIV

Preparation method of iron phosphate dihydrate

InactiveCN105895914AGood environmental protectionLow costCell electrodesSecondary cellsIonIron phosphate

The invention provides a preparation method of iron phosphate dihydrate. The method comprises the following steps: adding 115-126 parts by weight of phosphoric acid to 400 parts by weight of deionized water to prepare a phosphoric acid solution and keeping the temperature of the solution at 50-65 DEG C; adding 56 parts by weight of reduced iron powder in a stirring state, reacting for 1-3 hours, adding the obtained product to a ball mill for ball-milling to obtain a ball-milled material; putting the taken ball-milled material into a container, adding 56-68 parts of hydrogen peroxide, stirring the hydrogen peroxide evenly and then putting the hydrogen peroxide into a reaction kettle for treatment at 60-140 DEG C for 6-12 hours to obtain a reaction product; and stirring and dispersing the reaction product evenly and then carrying out spray drying at 150-180 DEG C to obtain the iron phosphate dihydrate. The iron phosphate dihydrate synthesized by the method has the characteristics of being high in purity, simple in preparation technology, low in cost and free of pollution in treatment, and can be used as a raw material of producing lithium iron phosphate.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

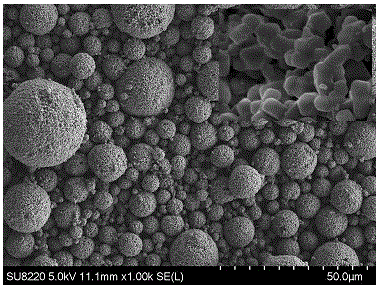

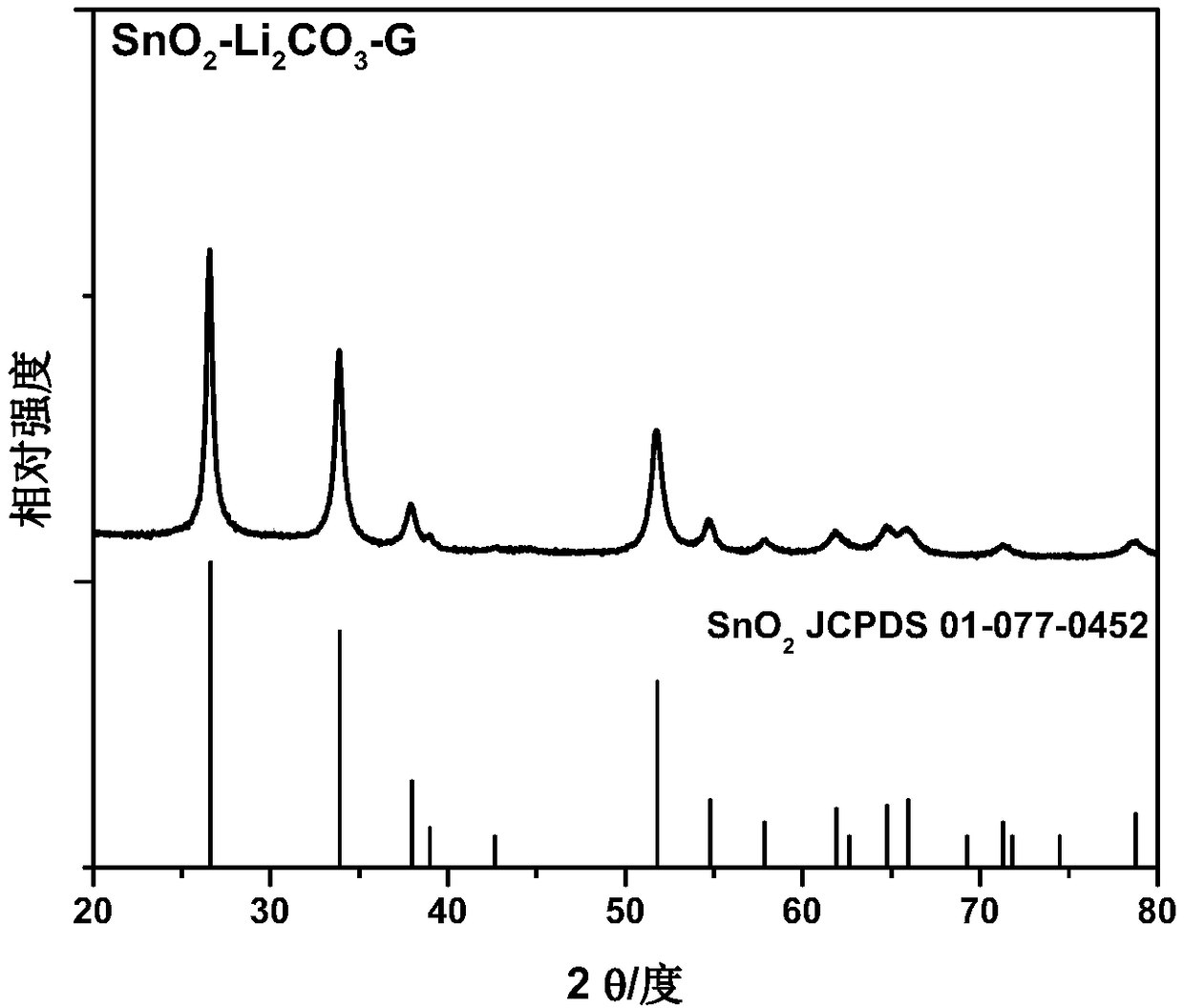

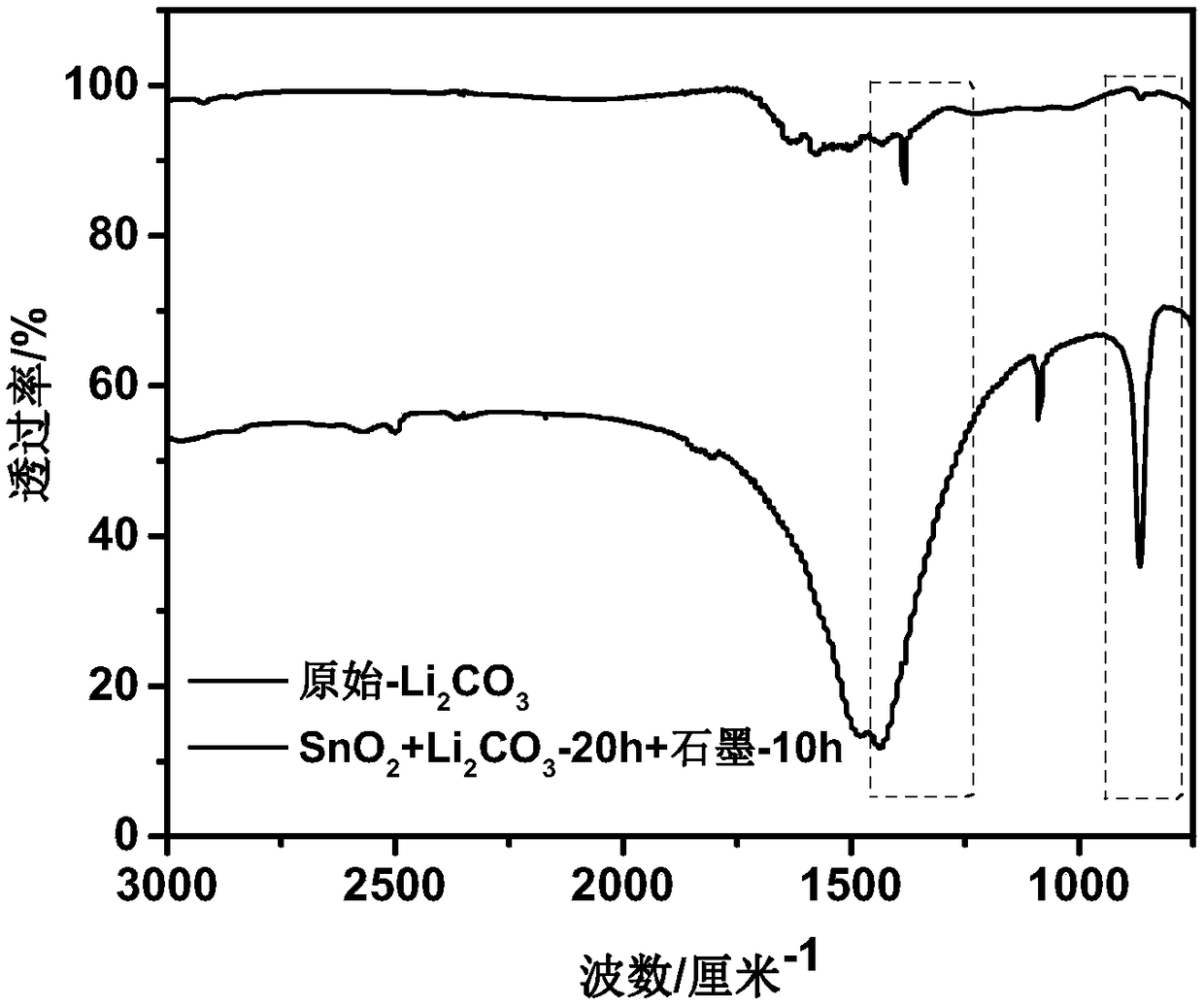

Pre-lithiatedanode material with high reversible capacity and preparation method of pre-lithiatedanode material

InactiveCN109411717AEasy to separateGood effectNegative electrodesSecondary cellsLithium carbonateGraphite

The invention relates to a pre-lithiatedanode material with the high reversible capacity and a preparation method of the pre-lithiatedanode material. The pre-lithiatedanode material comprises a graphite-like carbon material, metallic oxide or silicon uniformly distributed on the pre-lithiatedanode material, and lithium carbonate; the first coulomb efficiency of the anode material is 5%-10% higherthan that of the corresponding pure metallic oxide or silicon anode material, and the capacity retention rate of the anode material is no less than 85% after cycling for 100-350 times. The preparationmethod includes the steps that the metallic oxide or silicon powder, lithium carbonate powder, the graphite-like carbon material and a grinding agent are stirred,mixed and subjected to ball-milling.According to the pre-lithiatedanode material with the high reversible capacity and the preparation method of the pre-lithiatedanode material, by adding the lithium carbonate, the irreversible capacityof the anode material in the initial charging and discharging process is lowered, and thus the first coulomb efficiency is improved; by adding the graphite-like carbon material, structural stabilityof the material in the reaction process and conductivity of an electrode material are improved; and according to the ball-milling method, the size of the anode material particlescan be refined in a short time, and the volume change of the anode material is buffered.

Owner:SOUTH CHINA UNIV OF TECH

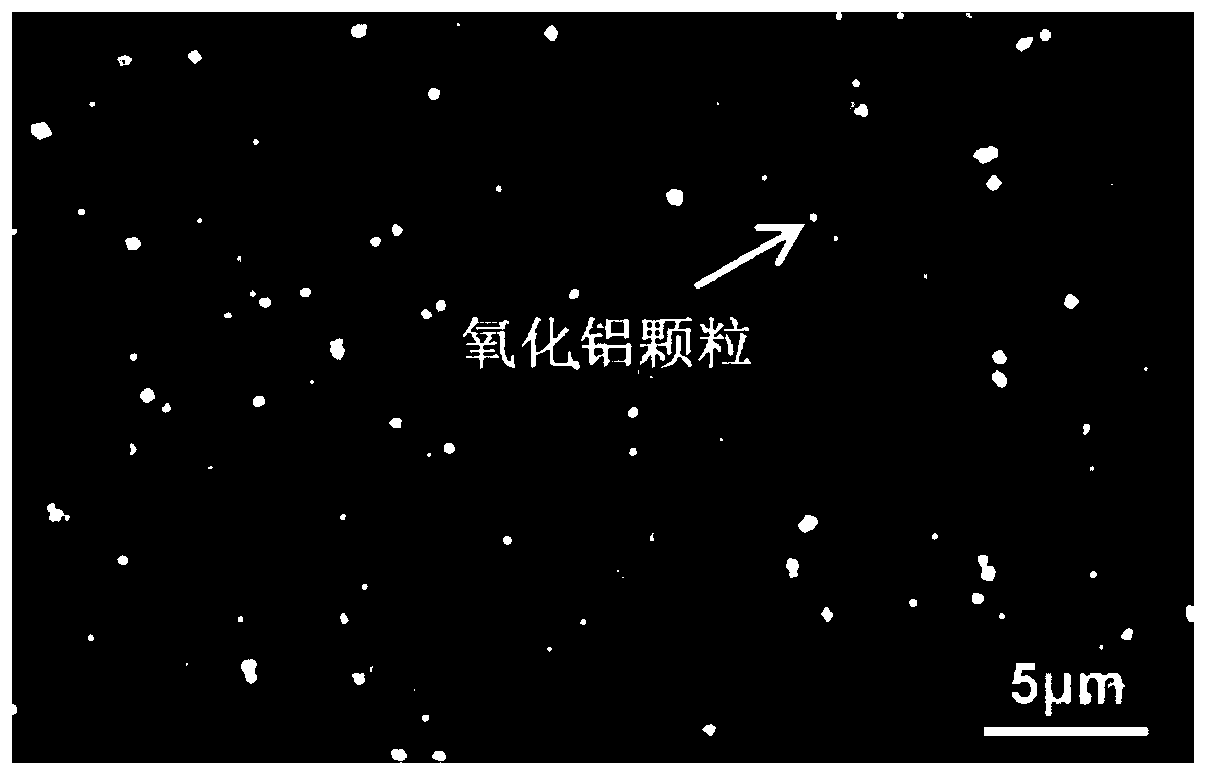

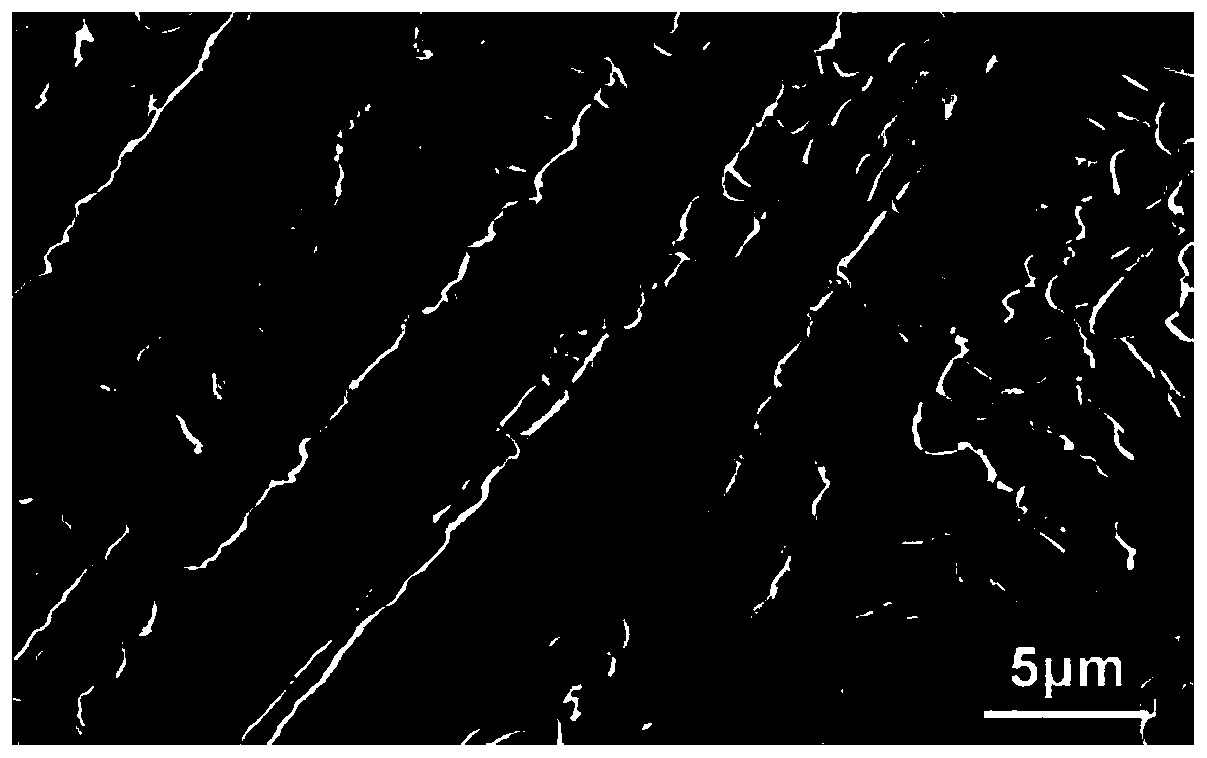

Laser 3D printing method for in-situ synthesized alumina particle reinforced nickel base composite

ActiveCN110976849AEvenly distributedFine particle sizeAdditive manufacturing apparatusTransportation and packagingPhysicsLaser printing

A laser 3D printing method for an in-situ synthesized alumina particle reinforced nickel base composite comprises the steps that firstly, nickel base alloy and pure aluminum powder are subjected to mechanical ball milling, particle size screening is carried out on the powder obtained after ball milling, and a laser 3D printing technological window is initially optimized; a temperature changing curve of a molten pool is recorded regularly with a colorimetric pyrometer, and the average peak temperature T of the temperature curve, the intercept t of the solid phase line and the temperature curveand the average cooling rate Xi of the molten pool are extracted and calculated; and technological parameters are optimized according to the principles that T is higher than or equal to 1.4 Tm and lower than or equal to 1.8 Tm, t is larger or equal to 0.55 s and smaller than or equal to 0.95 s and Xi is larger than or equal to 3.5*103 DEG C / s, and an optimized technological window is obtained, wherein the laser output power is 800-1200 W, the defocusing amount is -2.5 mm, the diameter of a laser spot is 2-3 mm, the scanning speed is 8-14 mm / s, and the powder feeding amount is 12-16 g / min. By means of the laser 3D printing method, in-situ synthesis of alumina particles can be achieved in the forming process, and the mechanical performance of nickel base forming parts can be improved.

Owner:HUNAN UNIV

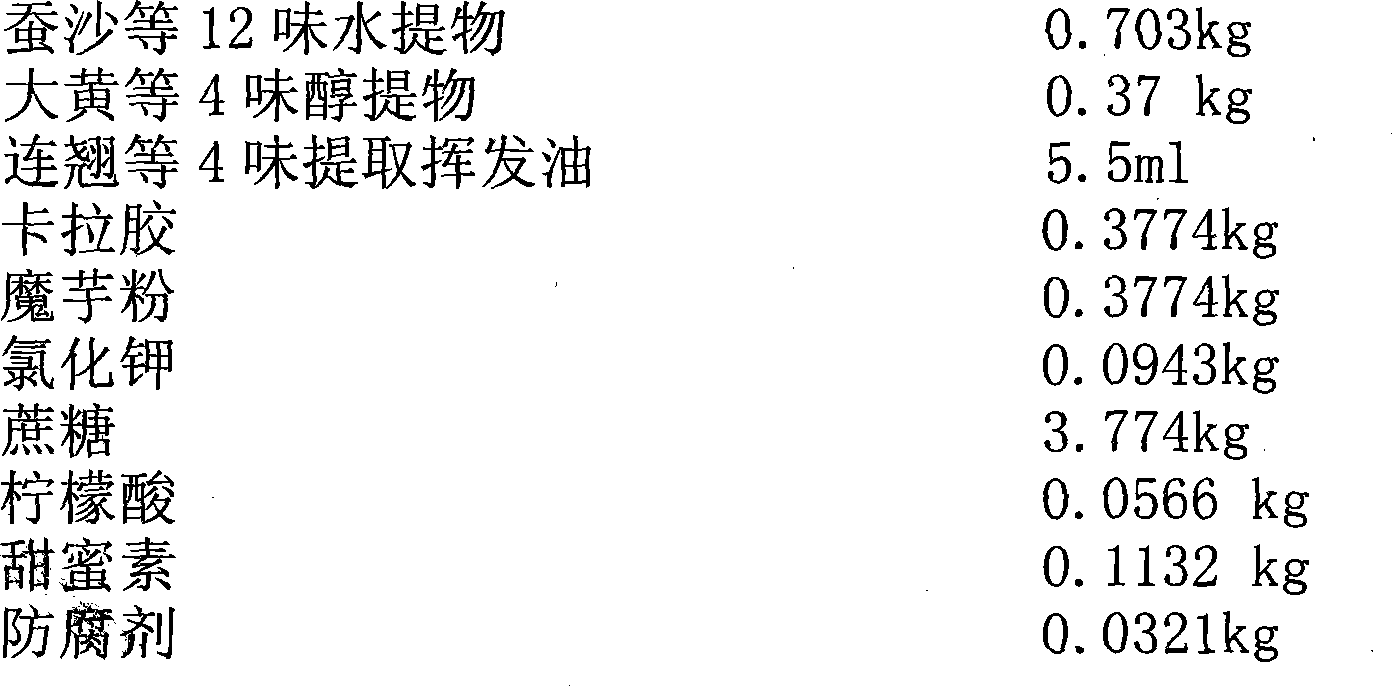

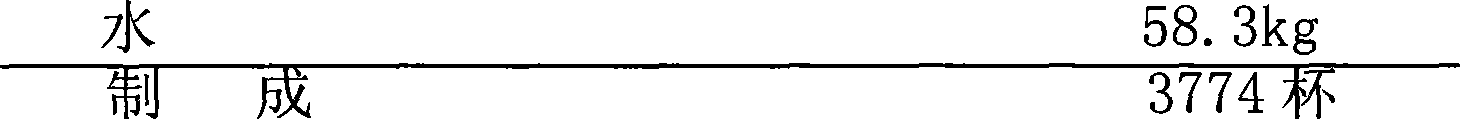

Method for testing Chinese medicinal composition for treating painful swelling of throat and constipation

InactiveCN101461904APromote absorptionParticle refinementComponent separationDigestive systemMedicinal herbsHigh grade fever

The invention belongs to the technical field of traditional Chinese medicine preparation, and relates to a traditional Chinese medicine composition for treating sore throat and constipation and a preparation method thereof, in particular to a medicament prepared from the raw material drugs with effective components such as silkworm excrement, rhubarb, figwort, Chinese honeylocust fruit, red paeony root, dwarf lilyturf turber, forsythia, radix isatidis, rehmannia, honeysuckle, rhizome imperatae, tree peony bark, natural indigo, fritillaria cirrhosa, mint, and licorice and used for clearing away heat and toxic materials and relieving sore throat and pain, and treating diseases such as sore throat caused by pneumogastric intrinsic heat, fever and fidget, constipation, children acute pharyngitis, acute tonsillitis, and the like and a preparation method thereof. The invention also discloses a recipe for gelata prepared by extracting and mixing sixteen medicinal materials such as silkworm excrement, rhubarb and the like, quality standard, and a quality inspection method. The dosage form has the advantages of convenience for taking and carrying, good mouth feel, and easy acceptance by children, overcomes the defect that pills and tablets are difficult for the children to take, and is remarkably superior to cleaning pills.

Owner:津药达仁堂集团股份有限公司达仁堂制药厂

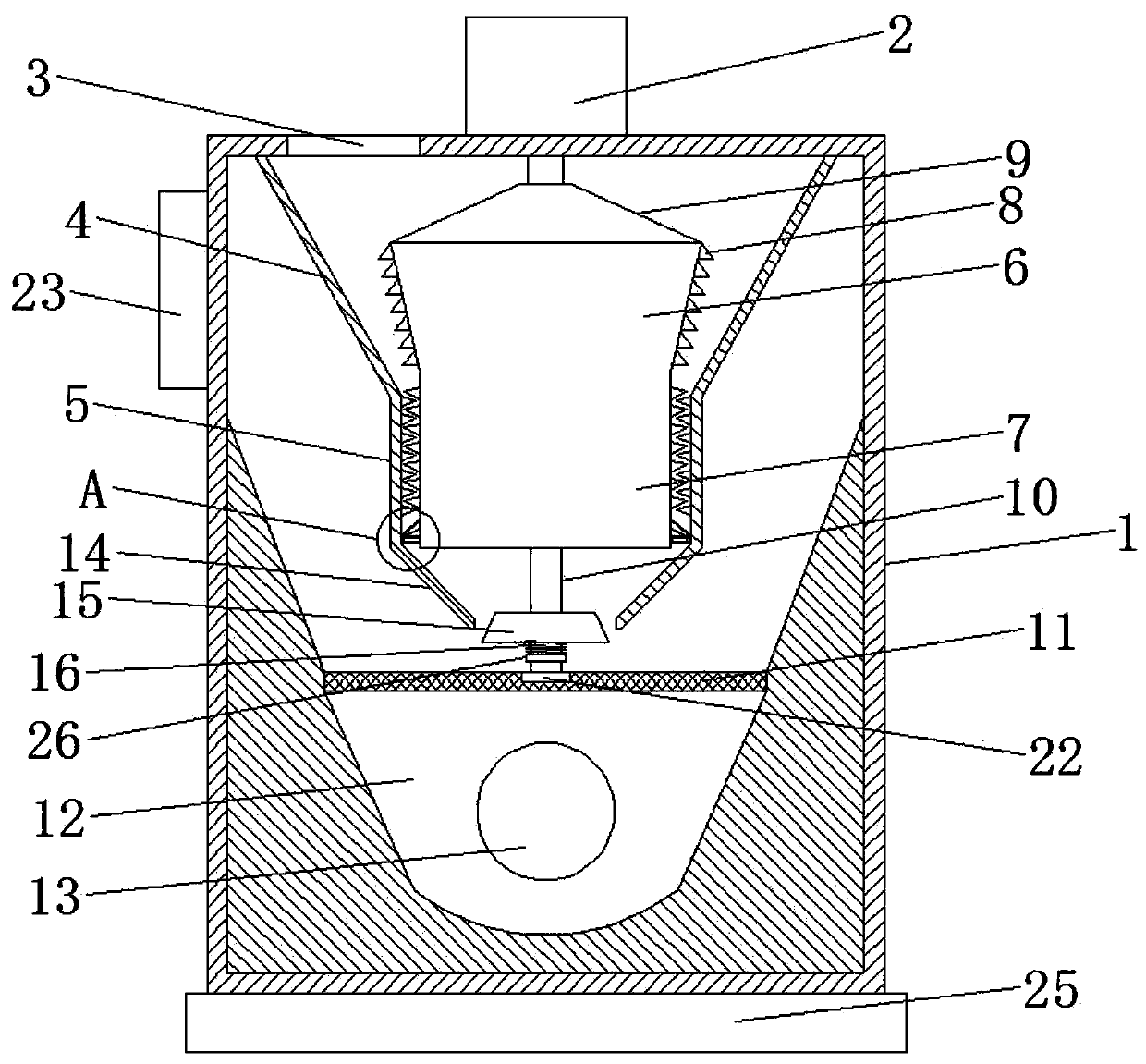

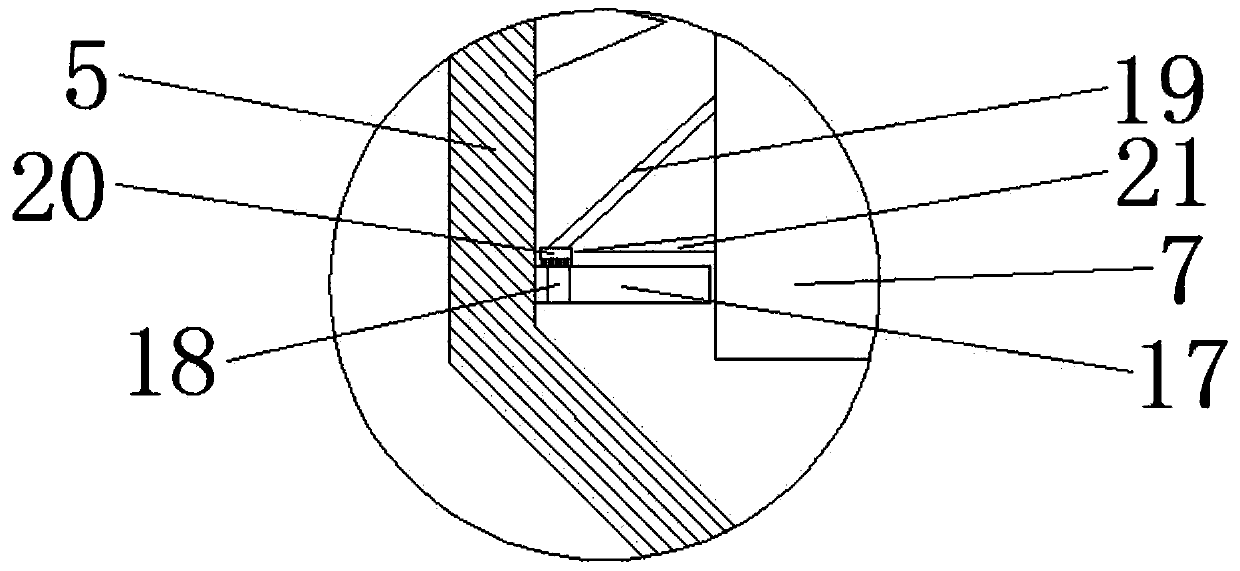

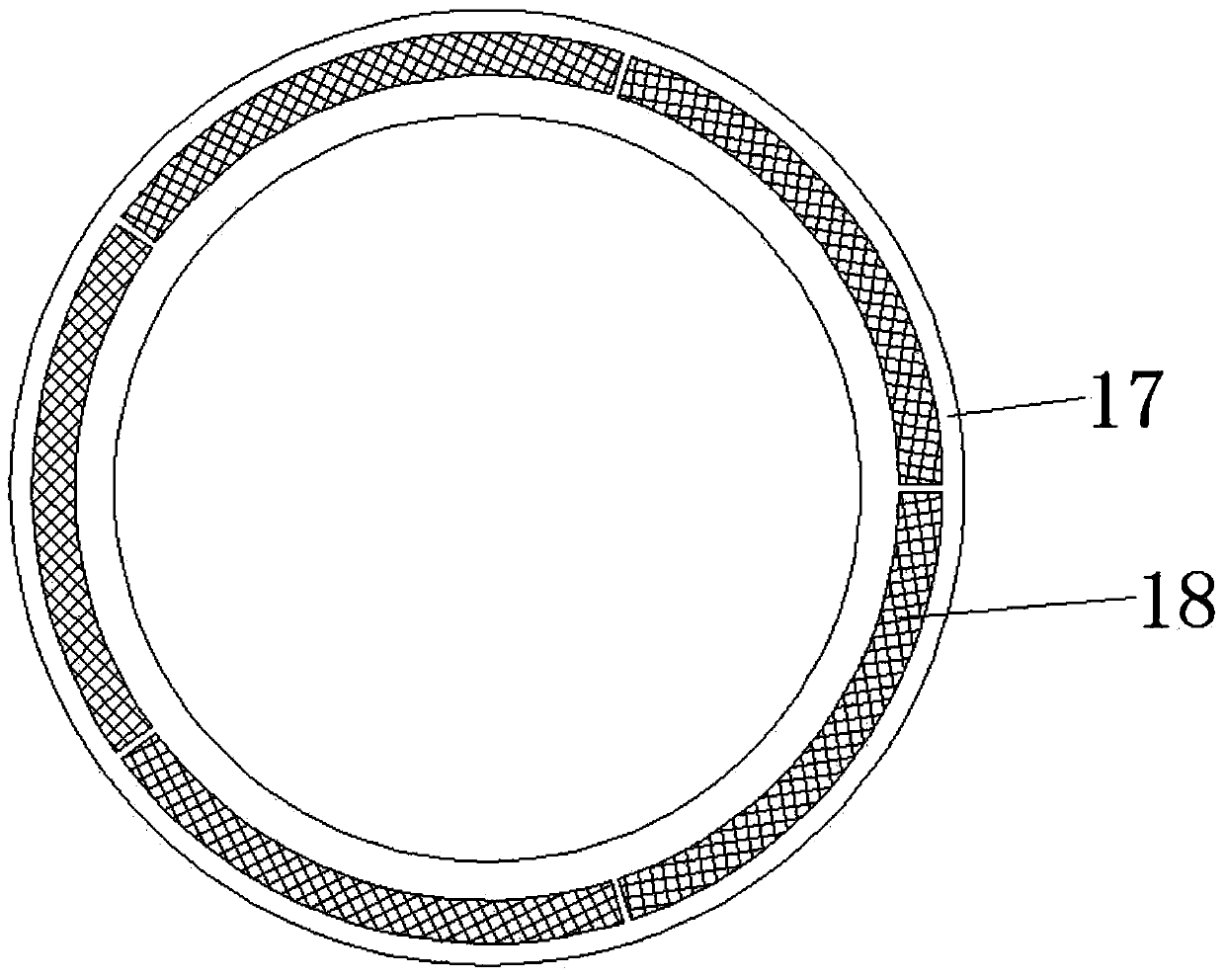

Solid waste treating and crushing device

The invention relates to the field of environmental protection and particularly discloses a solid waste treating and crushing device. The solid waste treating and crushing device comprises a shell, acrushing motor, a feeding opening, a collecting tank, wherein vertical rollers are coaxially and fixedly mounted on a transmission shaft; crushing cylinders are arranged on the outer sides of the crushing rollers and are matched with the crushing rollers; the crushing rollers comprise a first crushing roller and a second crushing roller which are coaxially and integrally arranged; the crushing cylinders comprise a first crushing cylinder and a second crushing cylinder; the first crushing cylinder and the second crushing cylinder are respectively and correspondingly matched with the first crushing roller and the second crushing roller; the distance between the first crushing cylinder and the first crushing roller is gradually reduced from top to bottom; and the collecting tank is arranged under a sieving net. According to the solid waste treating and crushing device, two crushing rollers and the crushing cylinders matched with the crushing rollers are arranged, so that the raw materialcrushing gap is gradually reduced from top to bottom; the raw materials are broken from large to small; the solid wastes are rapidly discharged; the increase of the motor load can also be avoided; andthe solid wastes can be safely and stably crushed.

Owner:ZIBO CREATION OF MECHANICAL & ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com