Semi-solid rheo-extrusion casting technology and equipment of hypereutectic Al-Si alloy casting

A semi-solid rheological and aluminum-silicon alloy technology, which is applied in the field of semi-solid forming of metal materials, can solve the problems of storage, transportation and quantitative pouring of semi-solid slurry, achieve strong practicability of process and equipment, and improve utilization rate. , The effect of small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

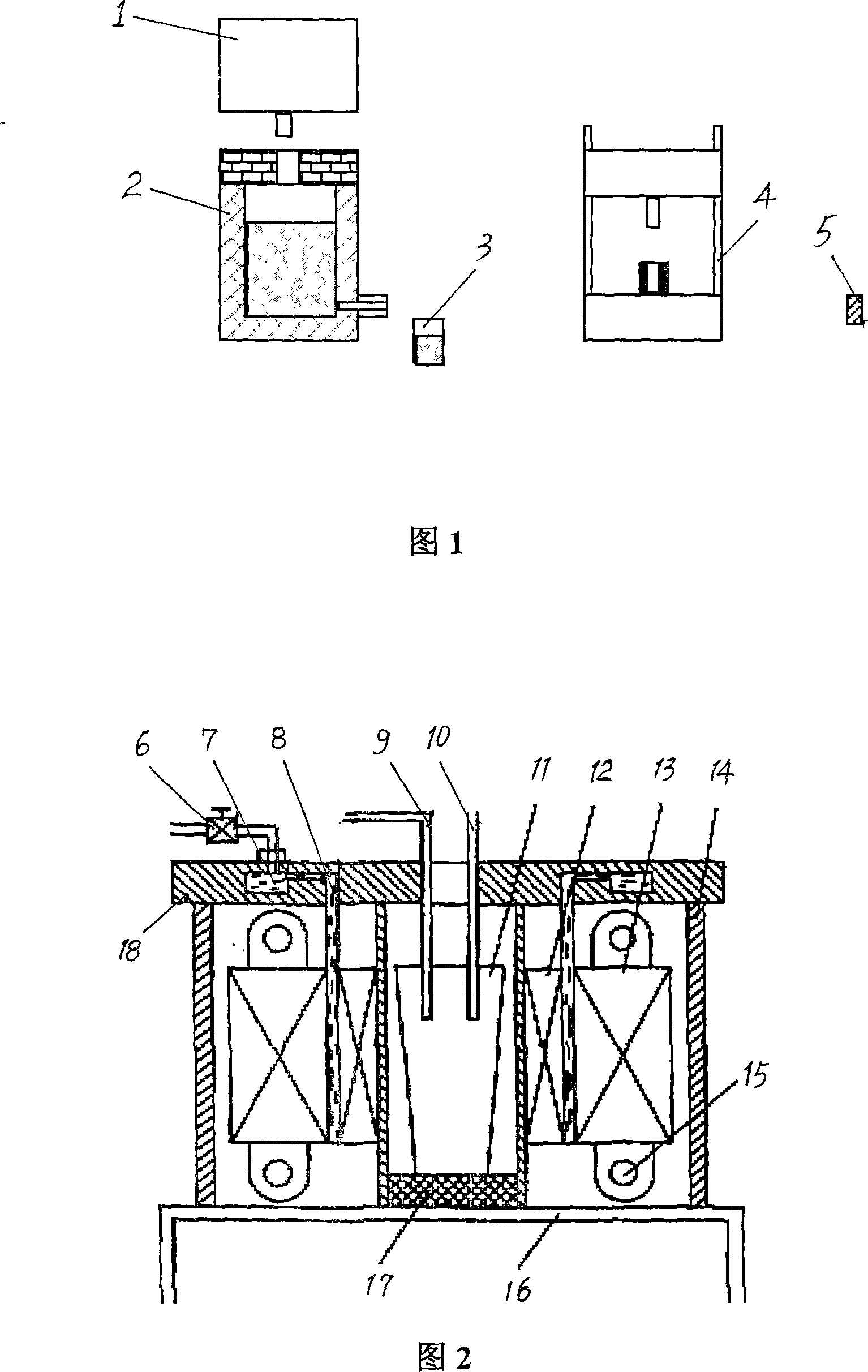

[0030] (1) According to the conventional method, the mass ratio (wt.%) of the components is: 19% Si, 1.0% Cu, 0.4% Mg, 0.3% Mn, 0.5% Re, and the ZL117 alloy whose balance is Al is smelted into molten metal, and then Prepare hypereutectic aluminum-silicon alloy ZL117 semi-solid slurry with the electromagnetic stirrer shown in Figure 2, wherein the electromagnetic stirring current is controlled at 4-10A, and the slurry cooling rate is 4-10°C / s;

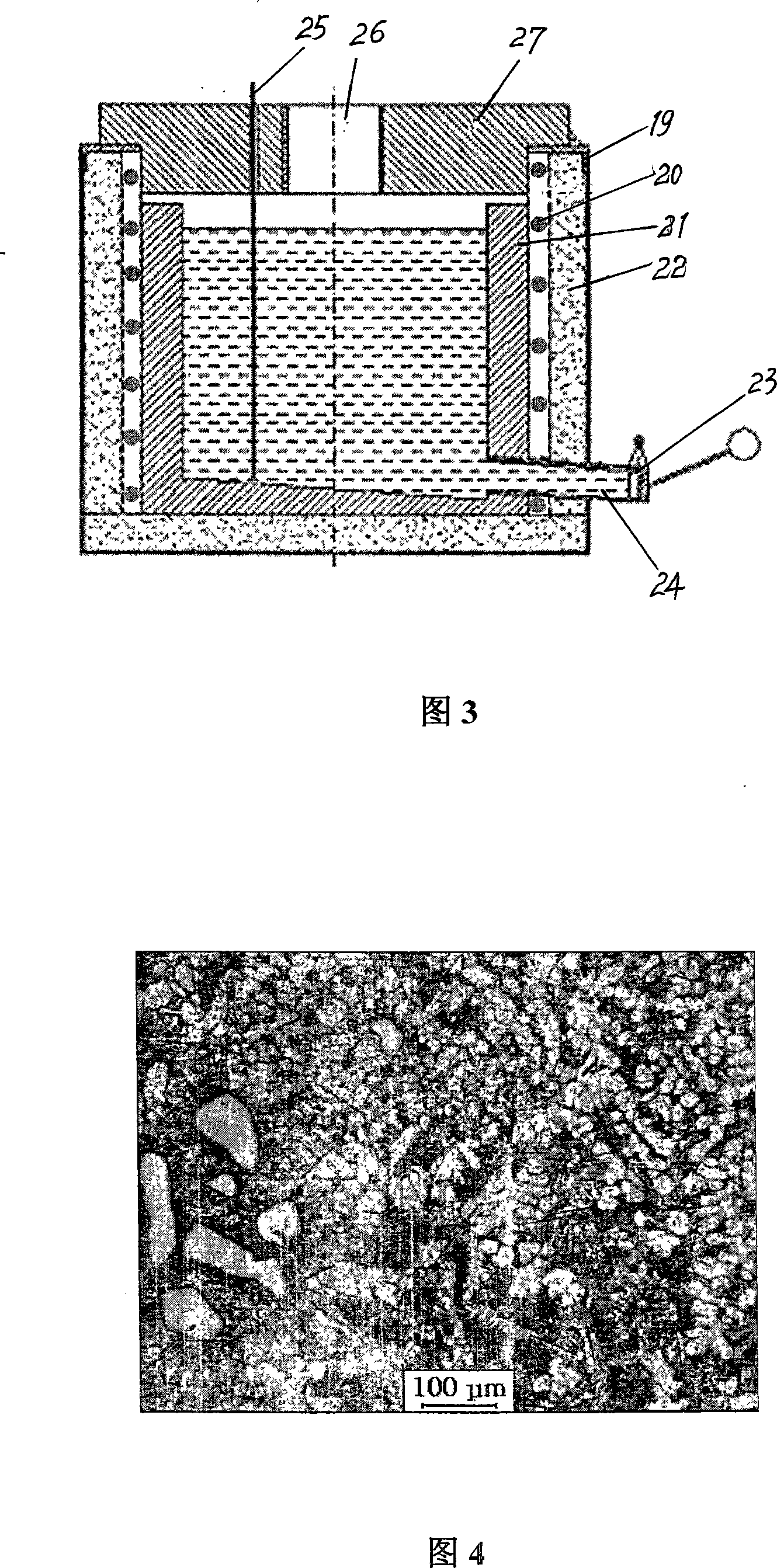

[0031] (2) Pour the semi-solid slurry obtained in the above steps into the holding furnace shown in Figure 3 for storage, control the holding temperature at 610-630°C, and store for 0min-15min;

[0032] (3) Preheat the extrusion casting mold of a cup-shaped casting of the prior art to 200~250 ℃, and spray release agent by conventional amount, release agent adopts FGW01-A commonly used in prior art, and add water 50 times diluted;

[0033] (4) Utilize the thermal insulation quantitative cup 3 in Fig. 1 to take semi-solid slurry from the...

Embodiment 2

[0035] (1) According to the conventional method, the composition mass ratio (wt.%) is: 22% Si, 2.0% Cu, 0.8% Mg, 0.5% Mn, 1.5% Re, and the ZL117 alloy that the balance is Al is smelted into molten metal, and then Prepare hypereutectic aluminum-silicon alloy ZL117 semi-solid slurry with the electromagnetic stirrer shown in Figure 2, wherein the electromagnetic stirring current is controlled at 20-30A, and the cooling rate of the slurry is 20-30°C / s;

[0036] (2) Pour the semi-solid slurry obtained in the above steps into the holding furnace shown in Figure 3 for storage, the holding temperature is 610°C-630°C, and the storage time is 0min-15min;

[0037] (3) Preheat the squeeze casting mold of an engine piston casting to 200-250°C, and spray a release agent in a conventional amount. The release agent is FGW01-A commonly used in the prior art, and diluted with water 150 times;

[0038] (4) Take the semi-solid slurry from the holding furnace by using the heat preservation quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com