Preparation method of alkaline anion-exchange membrane for fuel cell

An alkaline anion and fuel cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of high material cost, reduced fuel cell power generation performance, low ion conductivity, etc., and achieve excellent technical effects and voltage decay rate Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

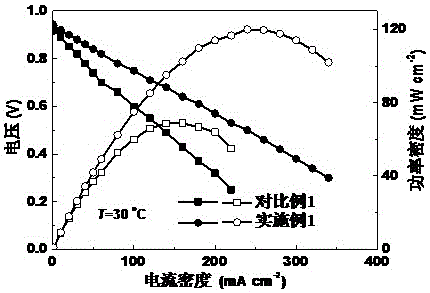

Embodiment 1

[0027] The process of preparing the basic anion exchange membrane of this example is:

[0028] 1) Dissolve 5g of PVA powder in 30 mL of deionized aqueous solution, heat to 80-95 degrees Celsius, and stir for 2.5-3 hours to obtain PVA gel;

[0029]2) Take 2.5g AER basic resin and soak it in 20 mL sodium chloride aqueous solution for 0.5 hours, the concentration of sodium chloride aqueous solution is 1M; then transfer AER basic resin together with sodium chloride aqueous solution to an insulated container, and pour into the container Inject liquid nitrogen to cool the AER basic resin to minus 50 degrees Celsius, grind and crush the AER basic resin particles for 15 minutes; then stop the liquid nitrogen freezing treatment, and after the temperature naturally returns to room temperature, filter the contents of the container with a 120-mesh filter Filter, get the AER basic resin fine powder that can pass through the filter mesh hole for subsequent use;

[0030] 3) Add the fine pow...

Embodiment 2

[0034] The difference between the process of preparing the alkaline anion exchange membrane of this example and Example 1 is that the inorganic salt used in step 2) is CoSO 4 , with a concentration of 0.1 M, the AER basic resin was placed in CoSO 4 Soaking time in aqueous solution is 1 hour, grinding time is 1 hour, other parameters are the same

Embodiment 3

[0038] The difference between the process of preparing the alkaline anion exchange membrane of this example and Example 1 is: step 2) the concentration of the sodium chloride aqueous solution is 5 M, the soaking time of the AER basic resin in the sodium chloride aqueous solution is 0.1 hour, and the grinding time is 0.5 hours, the filter screen is 80 mesh, and other parameters are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com