Pre-lithiatedanode material with high reversible capacity and preparation method of pre-lithiatedanode material

A negative electrode material and a pre-lithiation technology, which are applied in the field of pre-lithiated negative electrode materials and their preparation to achieve the effects of reducing agglomeration effect, improving cycle performance and ensuring cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

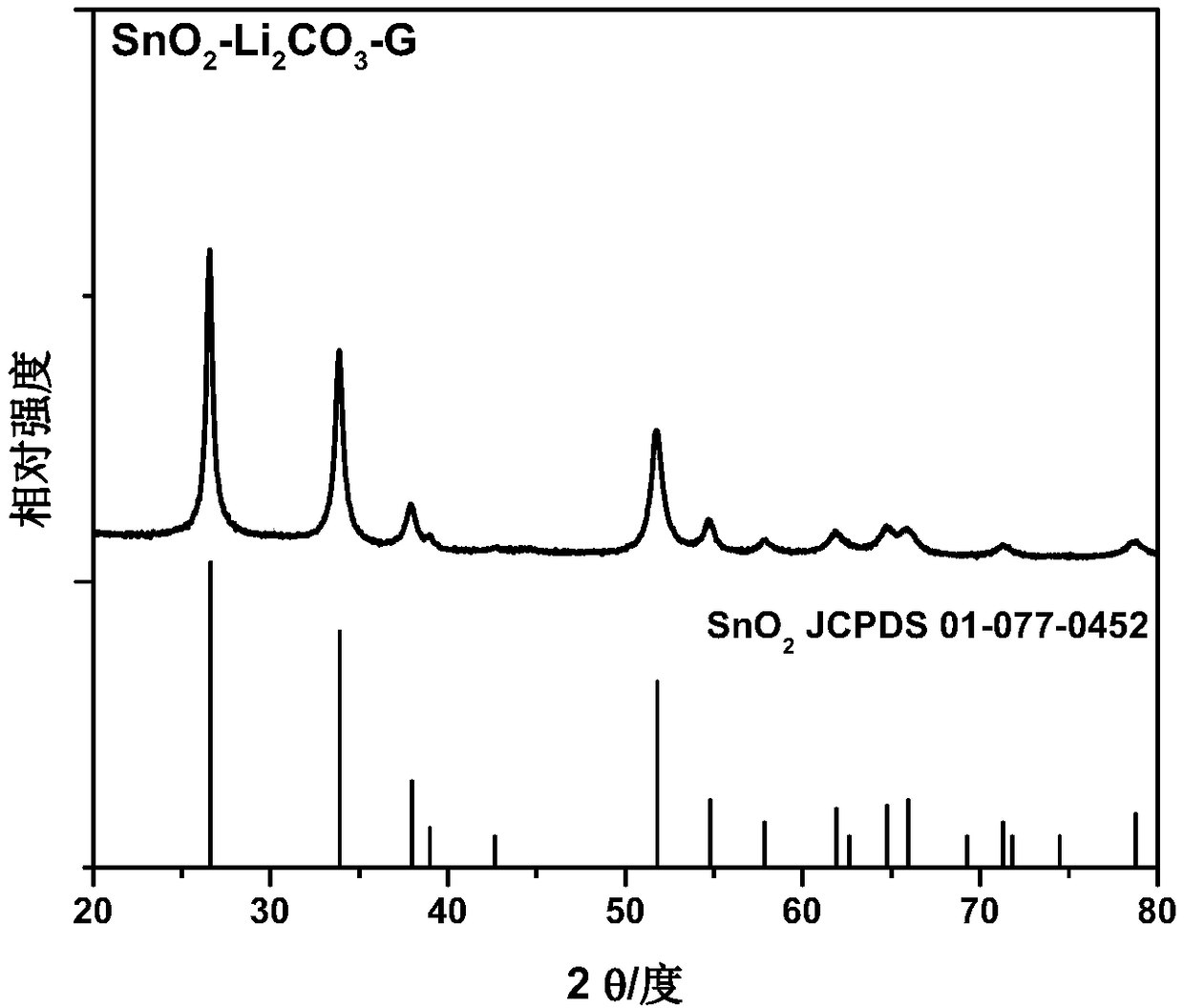

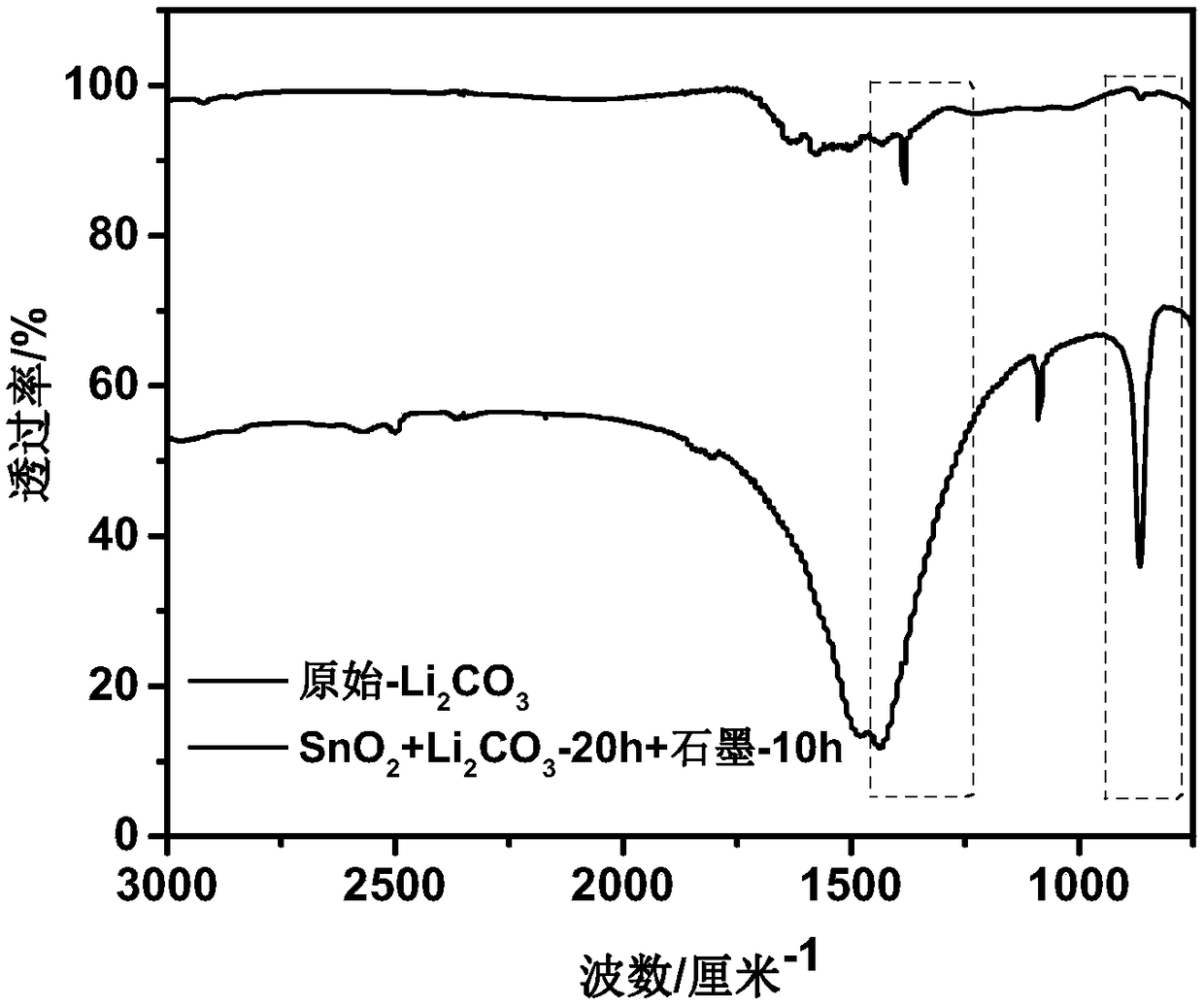

[0041] The SnO with high reversible capacity of this example 2 -Li 2 CO 3 -The preparation method of graphite composite material is as follows:

[0042] Mix pure tin dioxide, lithium carbonate and ordinary graphite powder with a particle size range of 1-3 μm, in which SnO 2 , Li 2 CO 3 The mass ratio of graphite and graphite is 70:5:25, adding quality is 2% dehydrated alcohol of abrasive material gross mass, adopts planetary ball milling method to carry out ball milling, wherein the mass ratio of ball and mixed powder is 40:1, ball milling time Be 30h; The concrete steps of described planetary ball grinding method are as follows:

[0043] (1) Load grinding balls and proportioned original powder in the ball mill jar;

[0044] (2) Vacuumize the ball mill tank through the vacuum valve, and then fill it with hydrogen to make the pressure in the ball mill tank reach 0.12Mpa;

[0045] (3) Turn on the power of the planetary ball mill, set the ball mill mode to "one-way interva...

Embodiment 2

[0052] The SnO with high reversible capacity of this example 2 -Li 2 CO 3 -The preparation method of graphite composite material, wherein SnO 2 , Li 2 CO 3 The mass ratio of graphite to graphite is 70:5:25, and the method of roller milling is adopted, the mass ratio of ball mass to powder mass is 6:1, the rotational speed of ball milling is 13.5Hz, and the time of ball milling is 100h. The concrete steps of described roller ball milling method are as follows:

[0053] (1) Load grinding balls and proportioned original powder in the ball mill jar;

[0054] (2) Vacuumize the ball mill tank through the vacuum valve, and then fill it with hydrogen to make the pressure in the ball mill tank reach 0.12Mpa;

[0055] (3) Turn on the power supply of the roller ball mill, and set the ball mill speed to 13.5Hz. The ball mill jar is fixed on the roller mill frame for roller milling.

[0056] The SnO prepared in this example 2 -Li 2 CO 3 - Graphite composite powder, conductive ag...

Embodiment 3

[0058] The Fe with high reversible capacity of this example 3 o 4 -Li 2 CO 3 -The preparation method of the graphite composite material, except that tin dioxide powder is replaced by ferric oxide powder, other steps and parameters refer to embodiment 1. The Fe prepared in this example 3 o 4 -Li 2 CO 3 - Graphite composite powder, conductive agent and binder are mixed and evenly coated on copper foil according to a certain mass ratio to make electrode sheets, and dried in vacuum. In an argon atmosphere glove box, lithium metal was used as a counter electrode to assemble a coin cell for testing. The test conditions are: the charge and discharge current density is 0.2A / g, and the charge and discharge cut-off voltage is 0.01V~3.0V. For the first charge and discharge curve obtained from the test, see Figure 8 , as shown in the figure, the first charge and discharge specific capacities of the composite materials prepared in this example are 733.9mAh / g and 992.2mAh / g respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com