Preparation method of iron phosphate dihydrate

A technology of iron phosphate dihydrate and phosphoric acid, which is applied in the chemical industry, can solve problems such as complex process and difficult control, and achieve the effects of simple production process, low cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A kind of iron phosphate dihydrate (FePO 4 ﹒ 2H 2 O) The preparation method includes the following steps:

[0063] (1) Add 115 parts of phosphoric acid to 400 parts of deionized water to prepare a phosphoric acid solution, and control the temperature of the solution to 60 o C. Under agitation, slowly add 56 parts of reduced iron powder and react for 2 hours. The product is added to the ball mill and ball milled for 2 hours to obtain ball mill material A;

[0064] (2) Take out the ball mill material A obtained in step (1), add 56 parts of hydrogen peroxide to it, stir evenly and put it into a reaction kettle for treatment at a temperature of 60°C and a time of 12 hours to obtain a reaction product B;

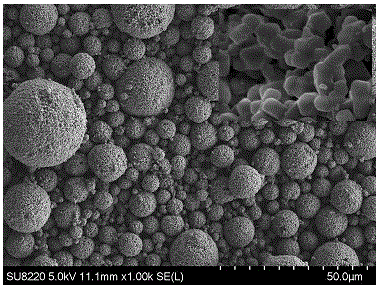

[0065] (3) The reaction product B obtained in step (2) is uniformly stirred and dispersed, and then spray-dried at 170° C. to obtain iron phosphate dihydrate powder.

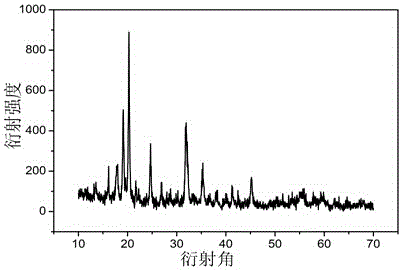

[0066] X-ray diffractometer (XRD, Rigaku, Japan) was used to detect the iron phosphate dihydrate powder obtained...

Embodiment 2

[0069] A kind of iron phosphate dihydrate (FePO 4 ﹒ 2H 2 O) The preparation method includes the following steps:

[0070] (1) Add 121 parts of phosphoric acid to 400 parts of deionized water to prepare a phosphoric acid solution, and control the temperature of the solution to 60 o C. Under agitation, slowly add 56 parts of reduced iron powder and react for 2 hours. The product is added to the ball mill and ball milled for 2 hours to obtain ball mill material A;

[0071] (2) Take out the ball mill material A obtained in step (1), add 62 parts of hydrogen peroxide to it, stir it evenly and put it in a reactor for treatment at a temperature of 100°C and a time of 9 hours to obtain a reaction product B;

[0072] (3) The reaction product B obtained in step (2) is uniformly stirred and dispersed, and then spray-dried at 170° C. to obtain iron phosphate dihydrate powder.

[0073] X-ray diffractometer (XRD, Rigaku, Japan) was used to detect the iron phosphate dihydrate powder obtained in Exa...

Embodiment 3

[0075] A kind of iron phosphate dihydrate (FePO 4 ﹒ 2H 2 O) The preparation method includes the following steps:

[0076] (1) Add 126 parts of phosphoric acid to 400 parts of deionized water to prepare a phosphoric acid solution, and control the temperature of the solution to 60 o C. Under agitation, slowly add 56 parts of reduced iron powder and react for 2 hours. The product is added to the ball mill and ball milled for 2 hours to obtain ball mill material A;

[0077] (2) Take out the ball mill material A obtained in step (1), add 68 parts of hydrogen peroxide to it, stir evenly and put it into a reactor for treatment at a temperature of 140°C and a time of 6 hours to obtain a reaction product B;

[0078] (3) The reaction product B obtained in step (2) is uniformly stirred and dispersed, and then spray-dried at 170° C. to obtain iron phosphate dihydrate powder.

[0079] X-ray diffractometer (XRD, Rigaku, Japan) was used to test the iron phosphate dihydrate powder obtained in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com