Reactor for producing acid phase from urban solid waste through two-phase anaerobic digestion

An anaerobic digestion and solid waste technology, which is applied in the direction of gas production bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of high price and few reactors, Achieve the effects of increasing methane production, increasing reaction rate, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

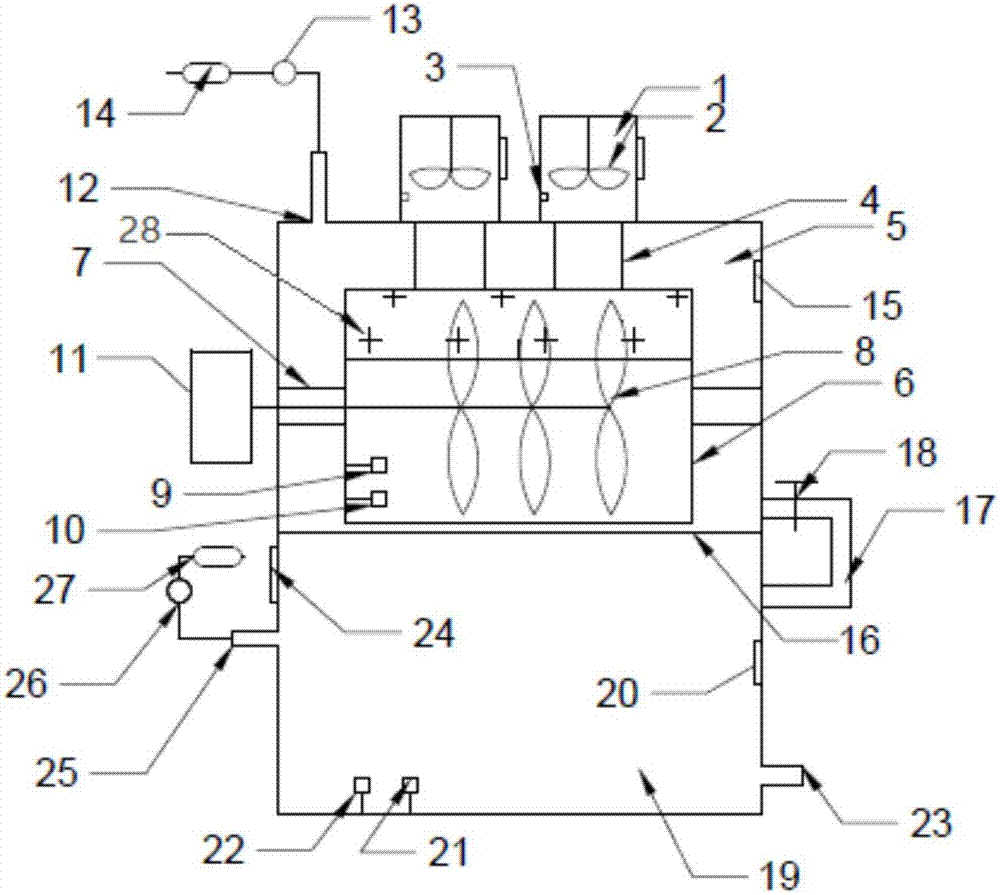

[0029] A kind of urban solid waste two-phase anaerobic digestion acid production phase reactor of this embodiment, its structural schematic diagram is as follows figure 1 shown. The device consists of a pretreatment device 1 distributed from top to bottom, a hydrolysis acidification zone 5 and a methanogenic zone 19; a pulverizer 2 and a heating device 3 are arranged in the pretreatment device 1, and a feed channel 4 and a hydrolysis zone are provided. The acidification areas 5 are connected; in the hydrolysis acidification area 5, a rotatable semi-closed drum reactor 6 and a heating device 15 are arranged, and a multi-layer propulsion type screw agitator 8 is arranged in the drum reactor 6, and the hydrolysis acidification area 5 passes through a partition The plate 16 is separated from the methanogenic area 19, but a draft tube 17 is provided to connect the two; a heating device 20 is arranged in the methanogenic area.

[0030] The main body of the reactor is generally in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com