Patents

Literature

491results about How to "Convenient whereabouts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

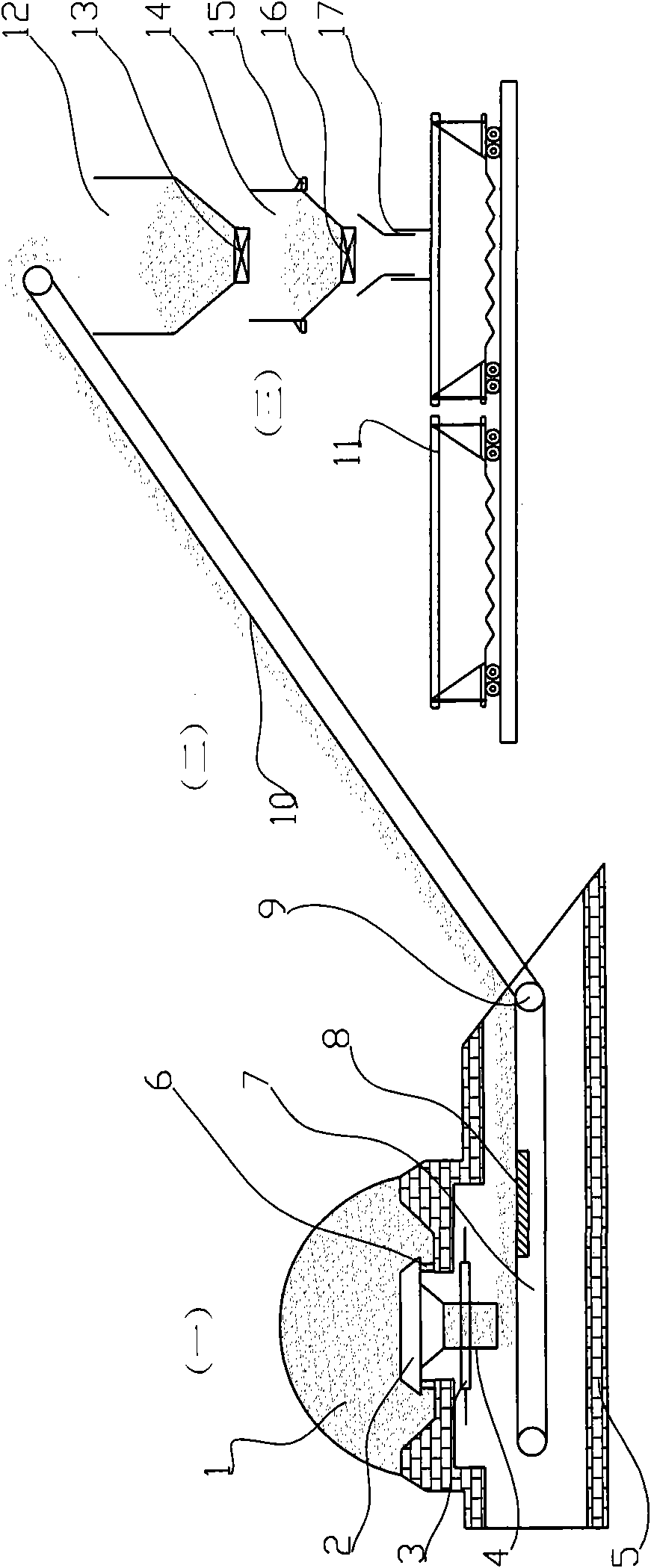

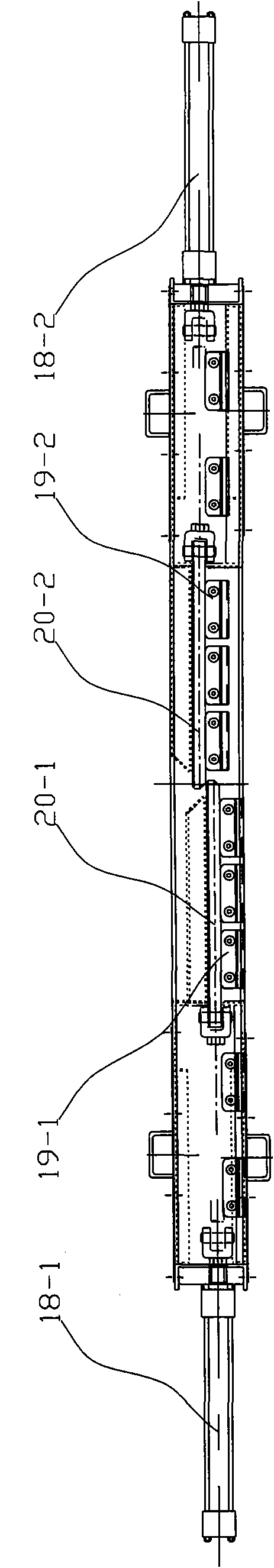

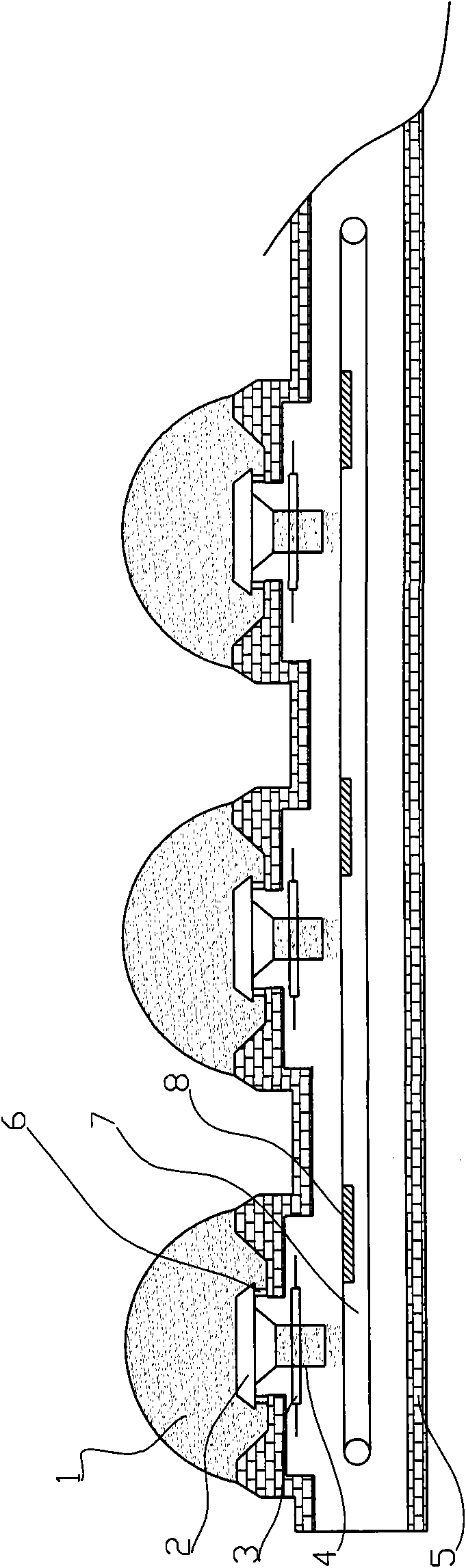

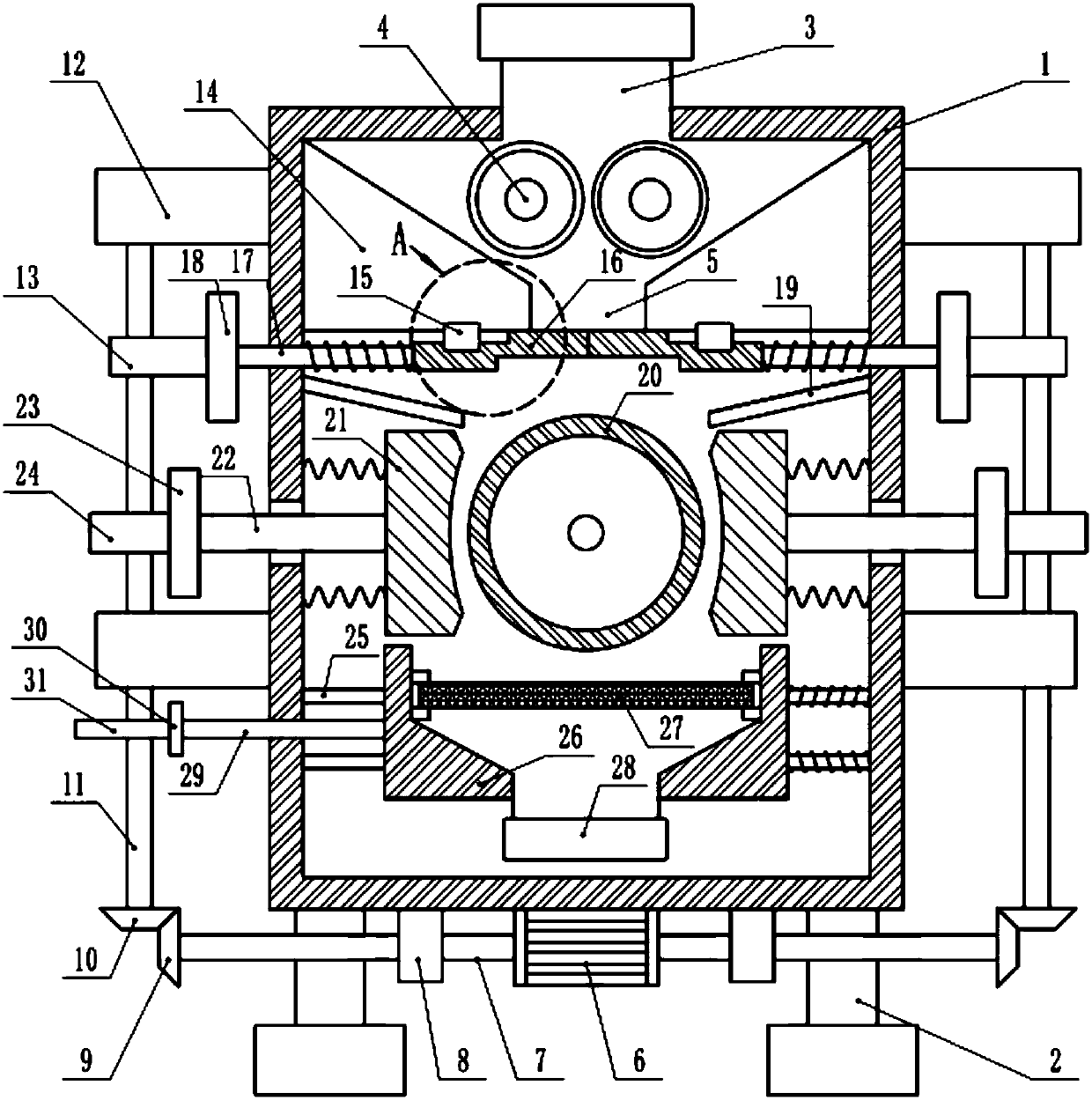

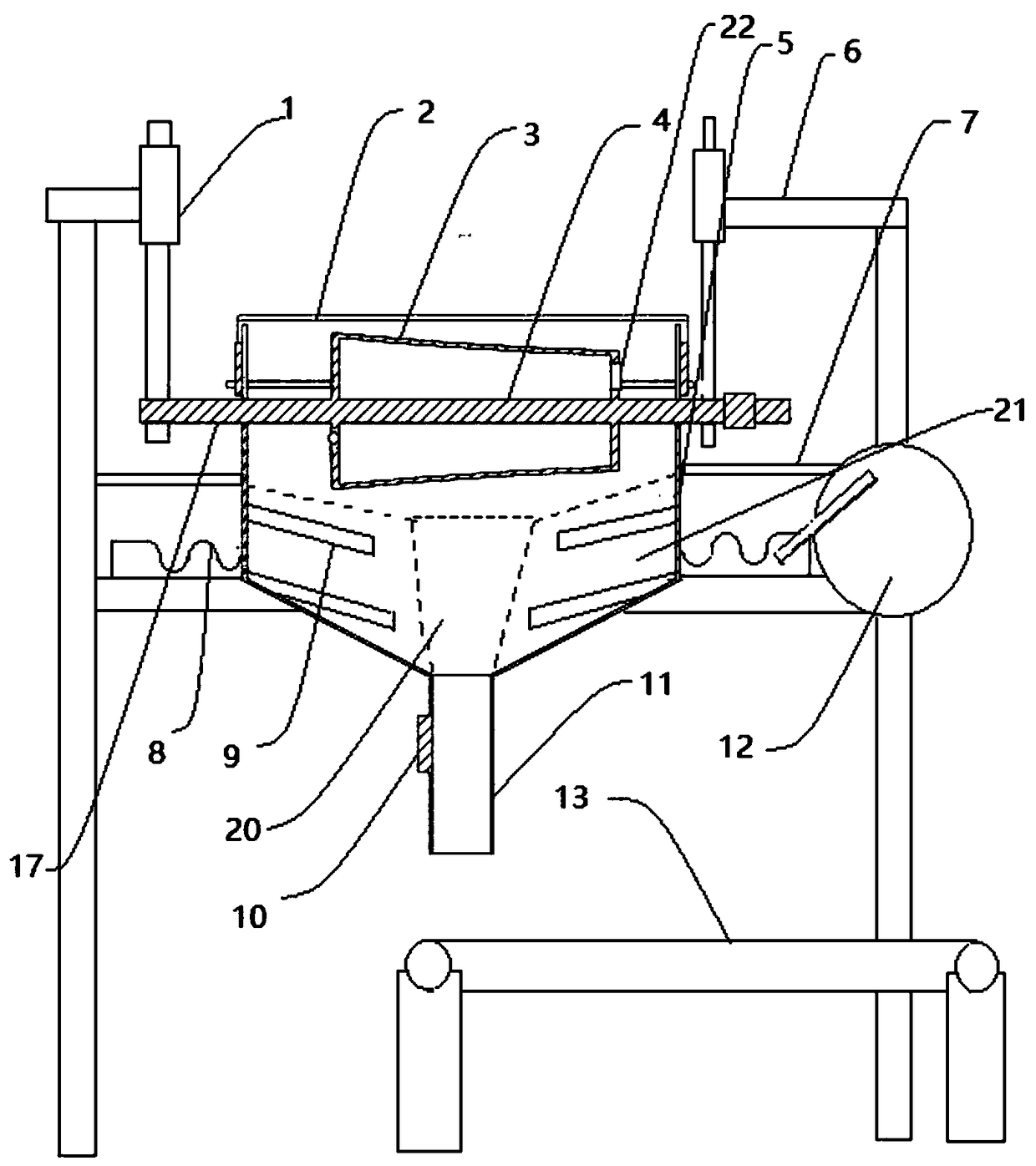

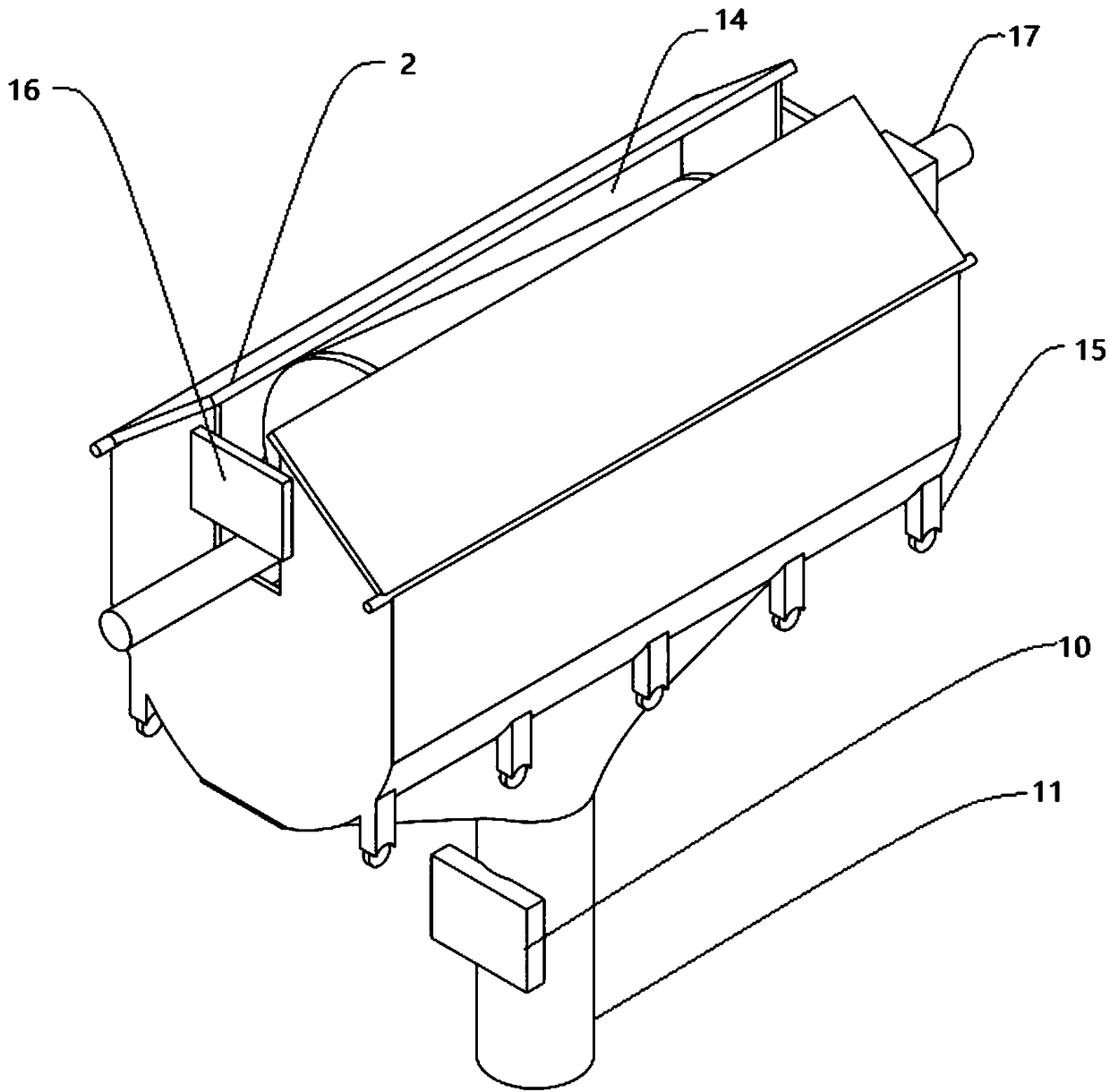

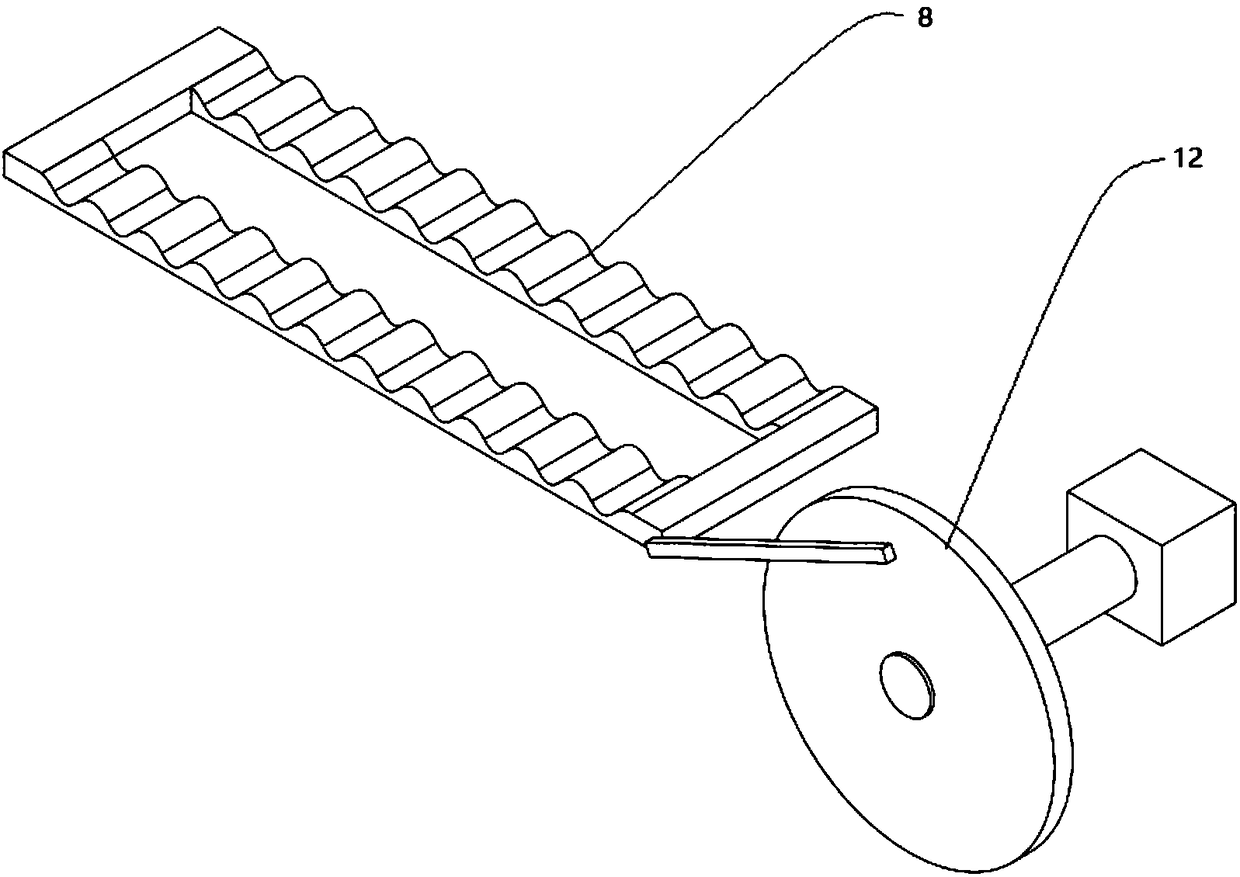

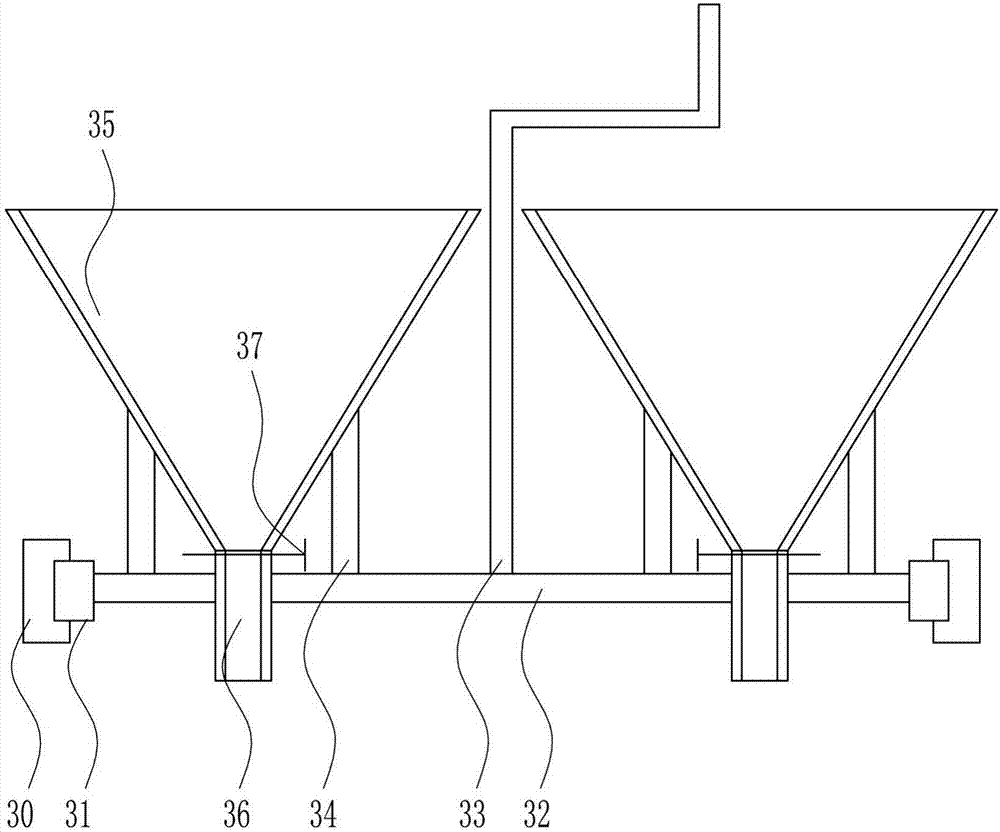

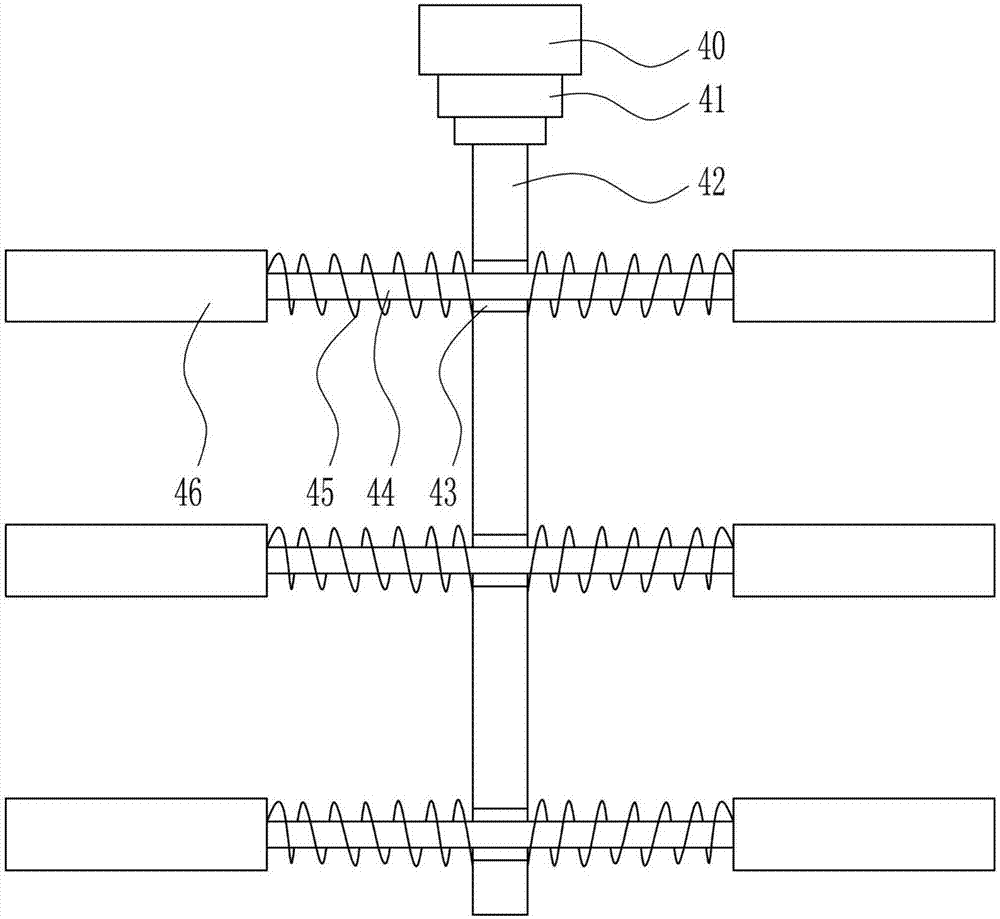

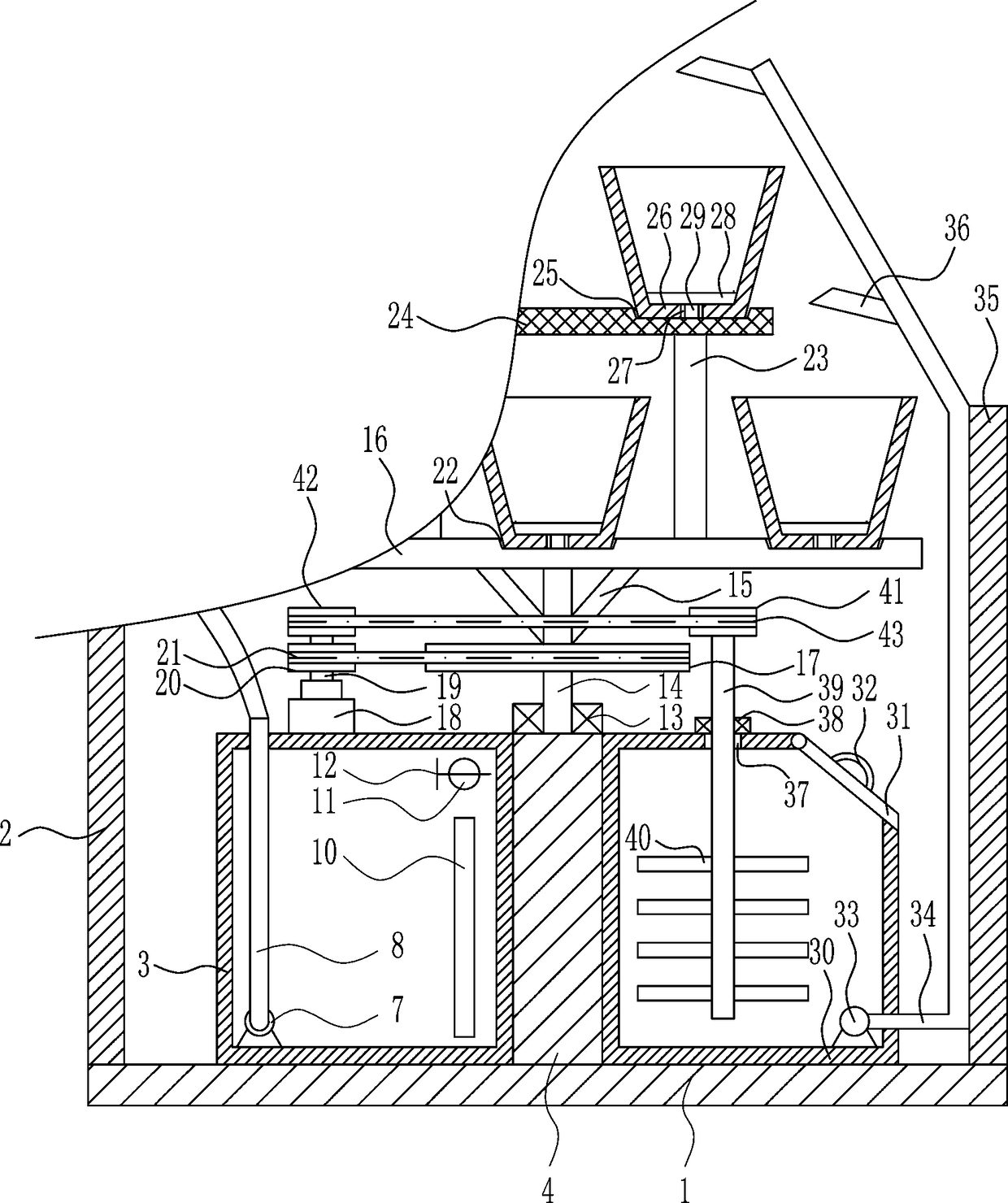

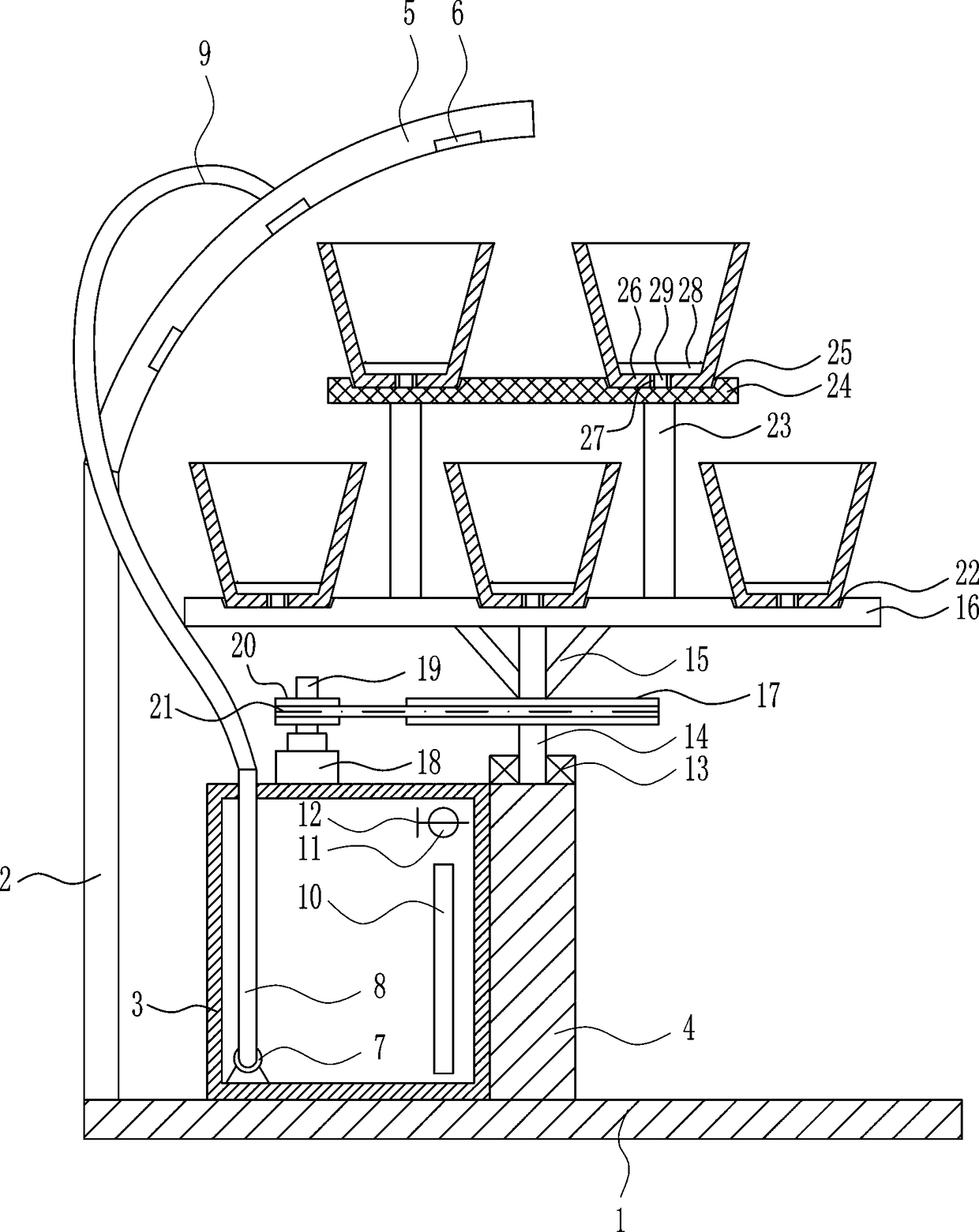

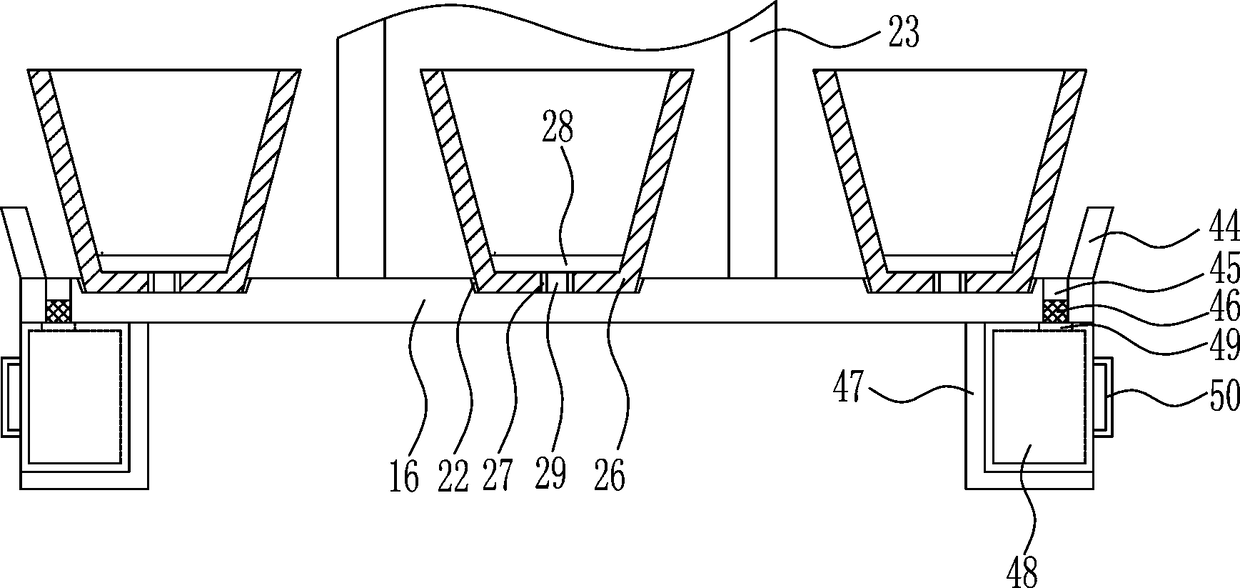

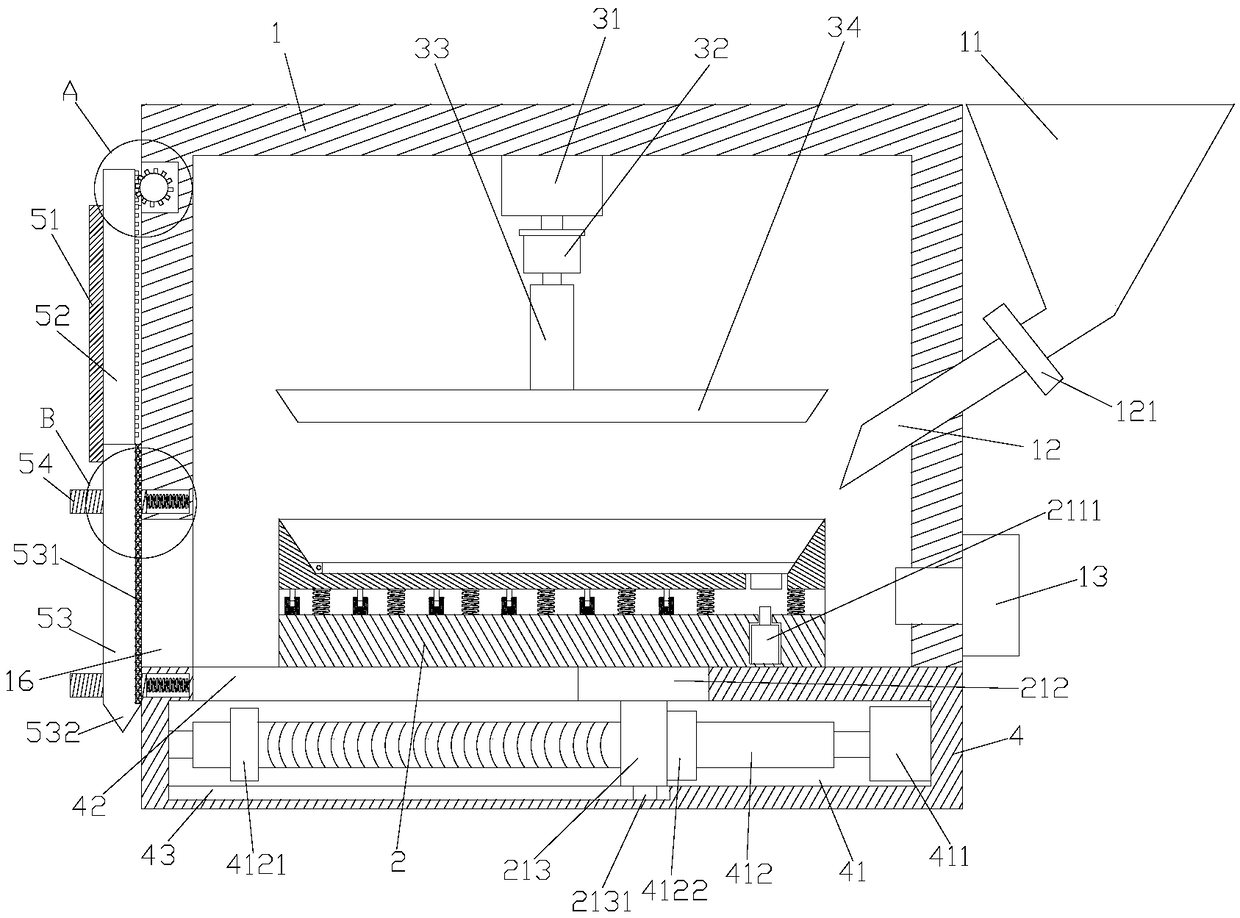

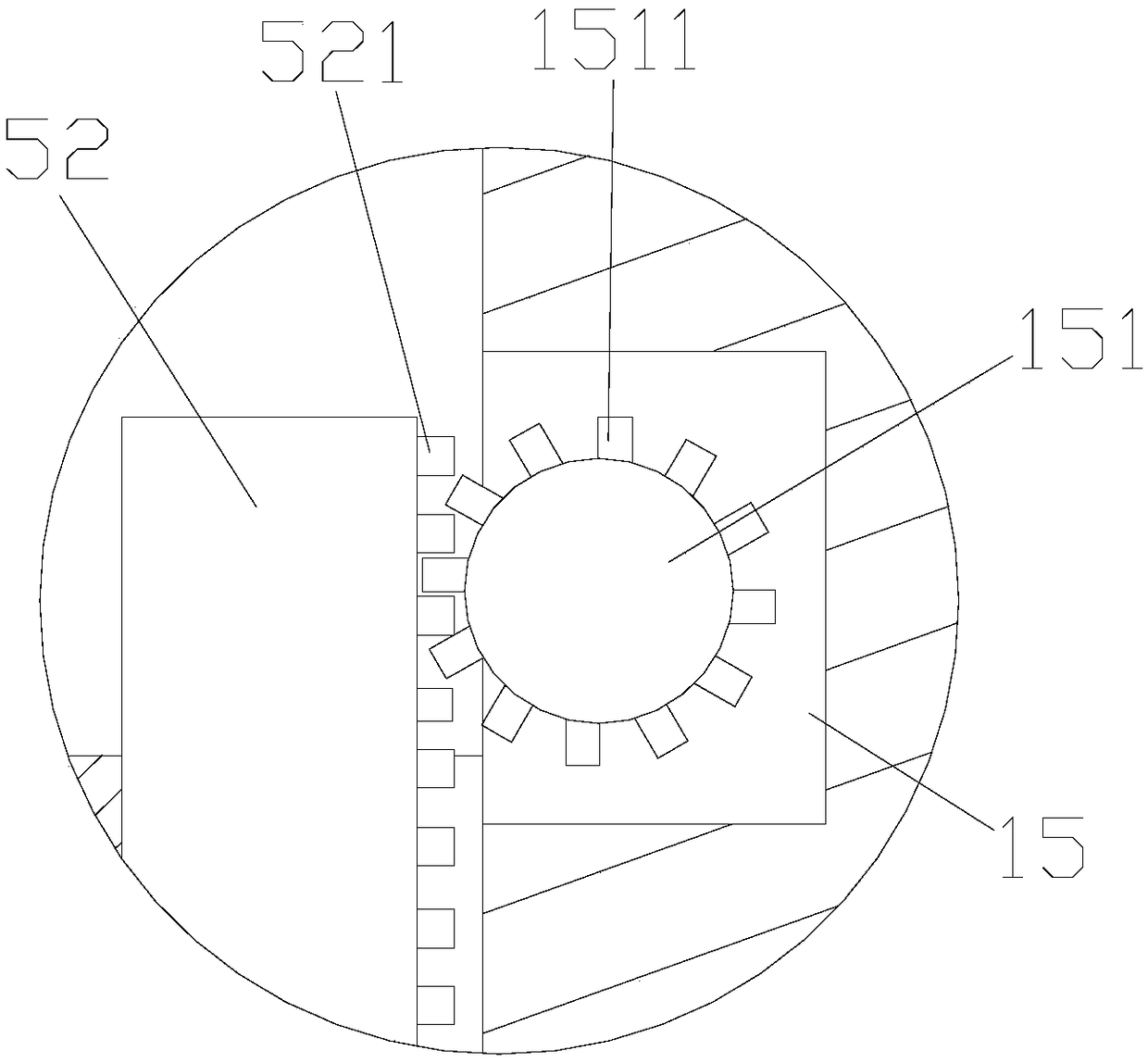

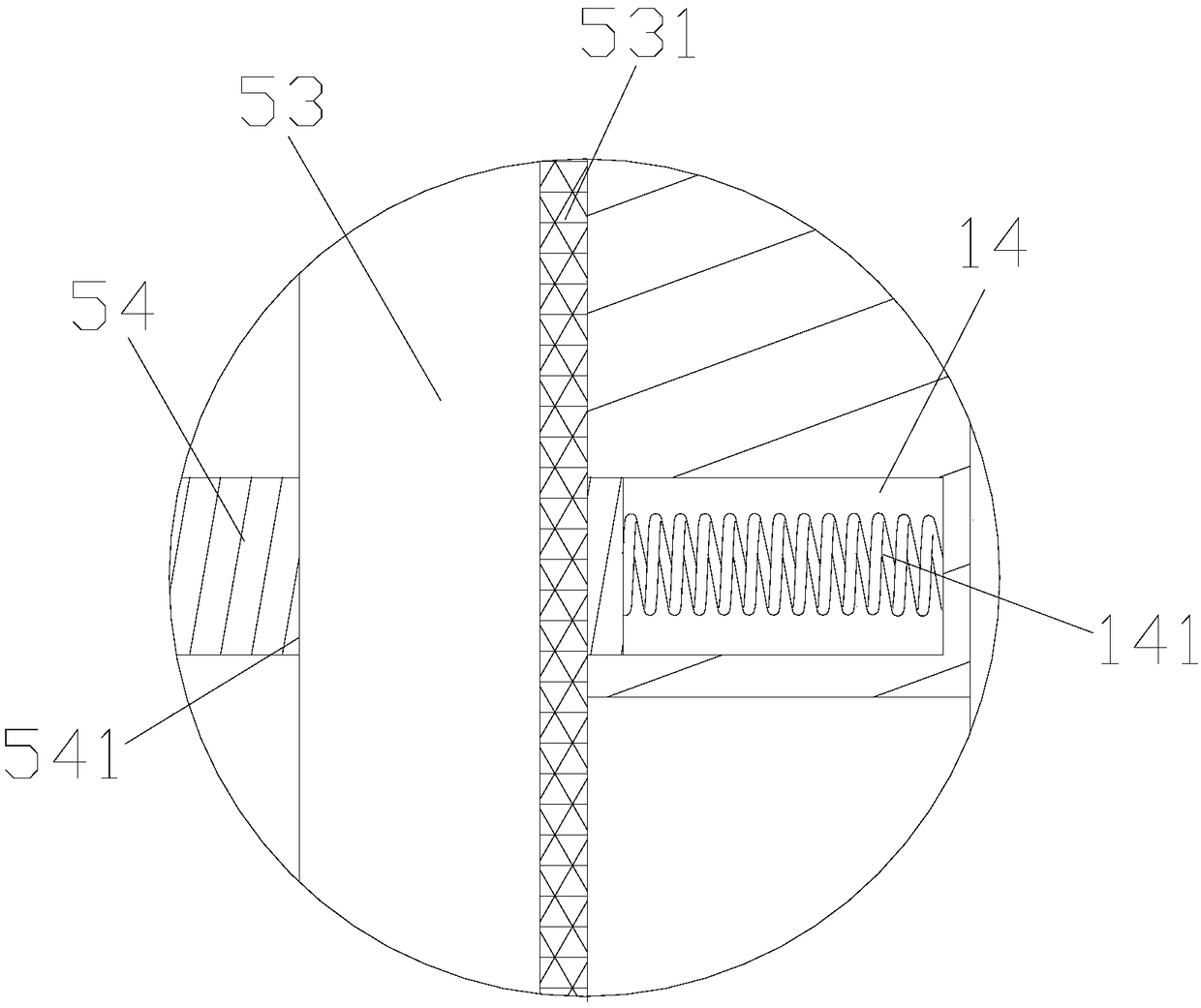

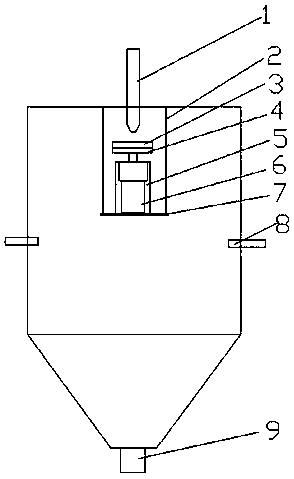

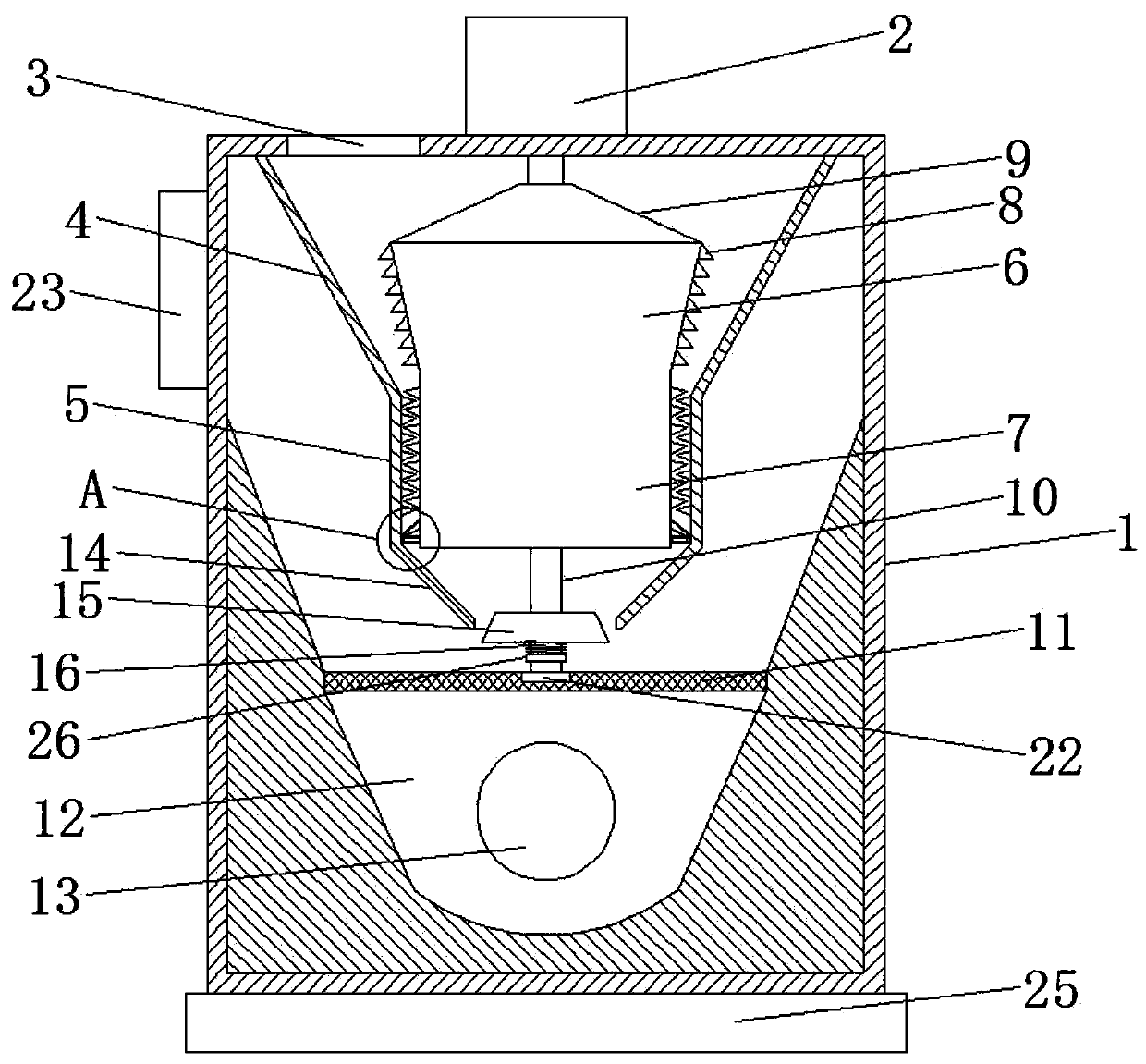

Method and system for transporting and loading bulk materials in storage yard

ActiveCN101786553ANo splashHigh measurement accuracyWeighing apparatus for continuous material flowLoading/unloadingTransport systemUnderground tunnel

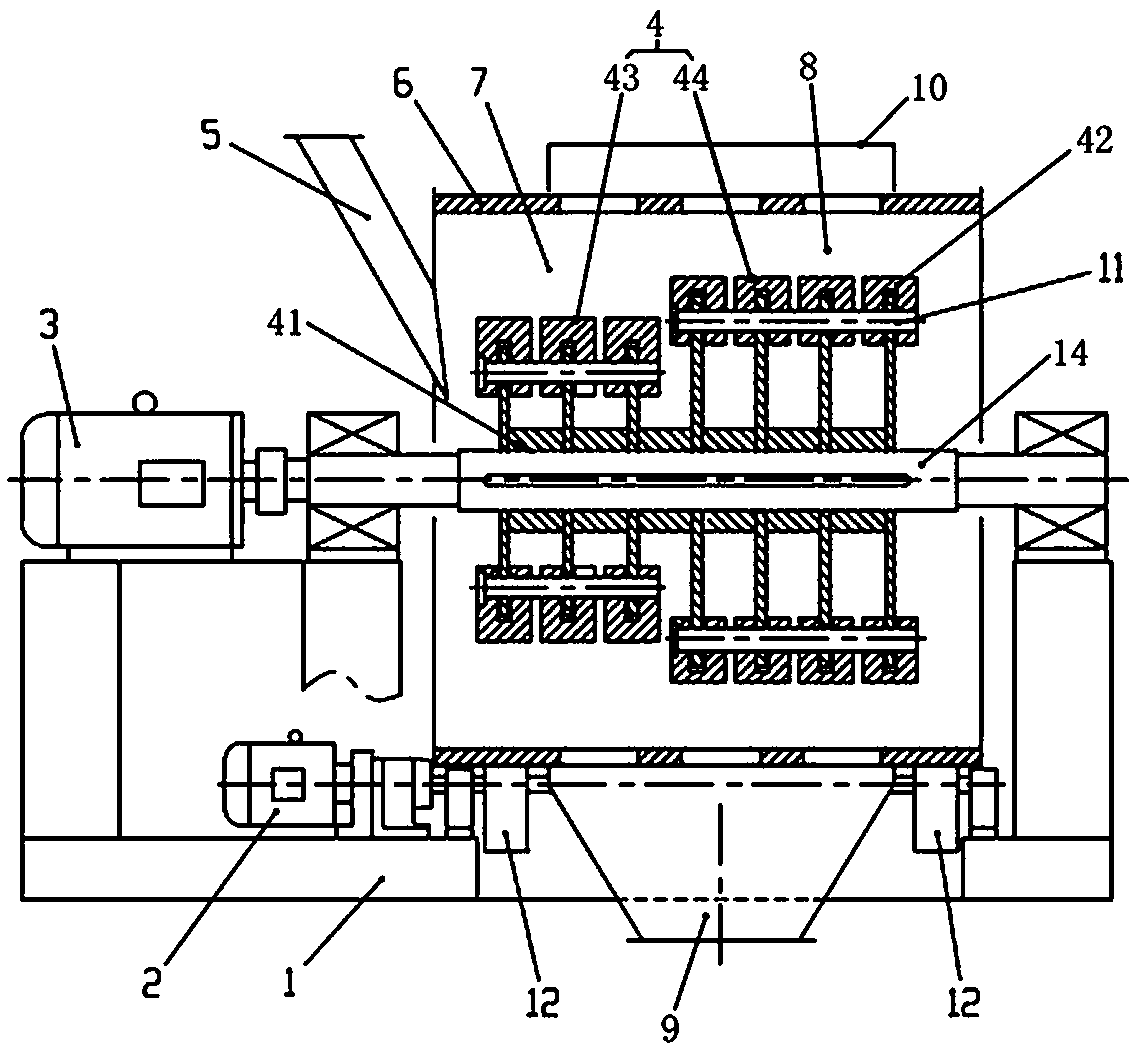

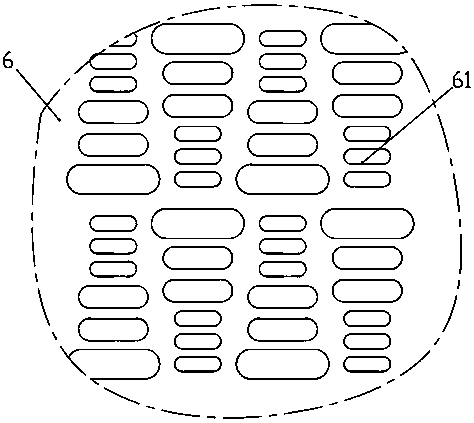

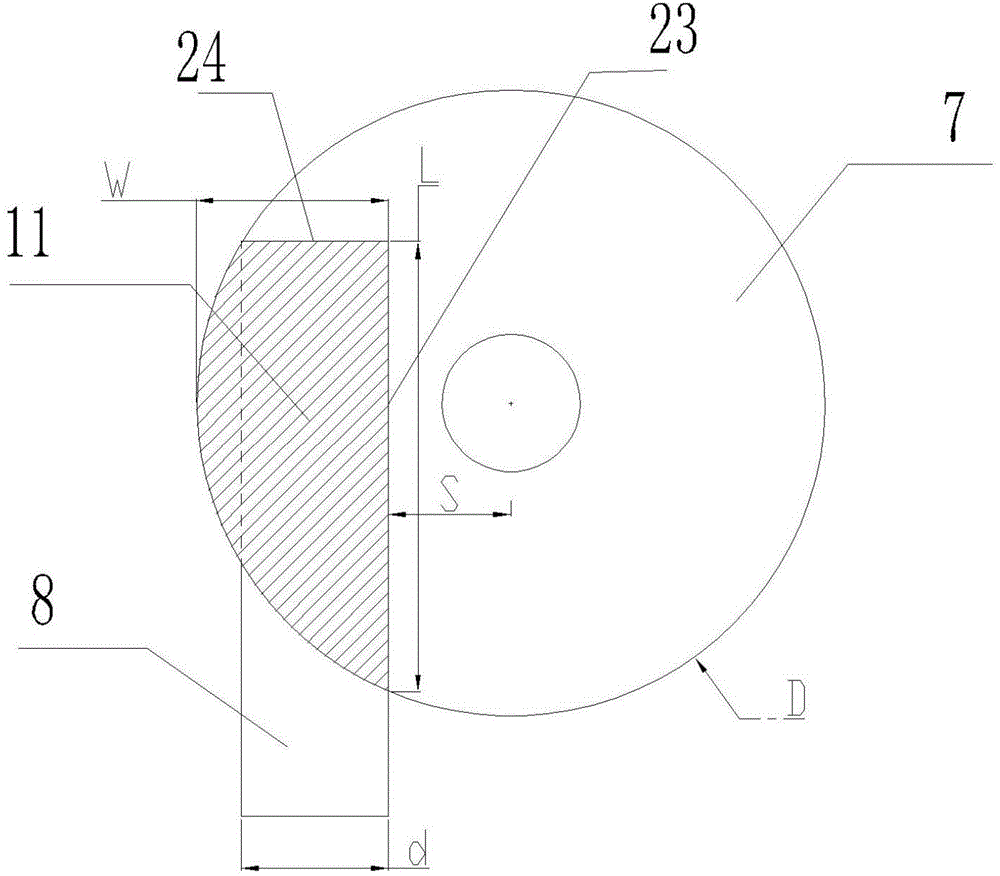

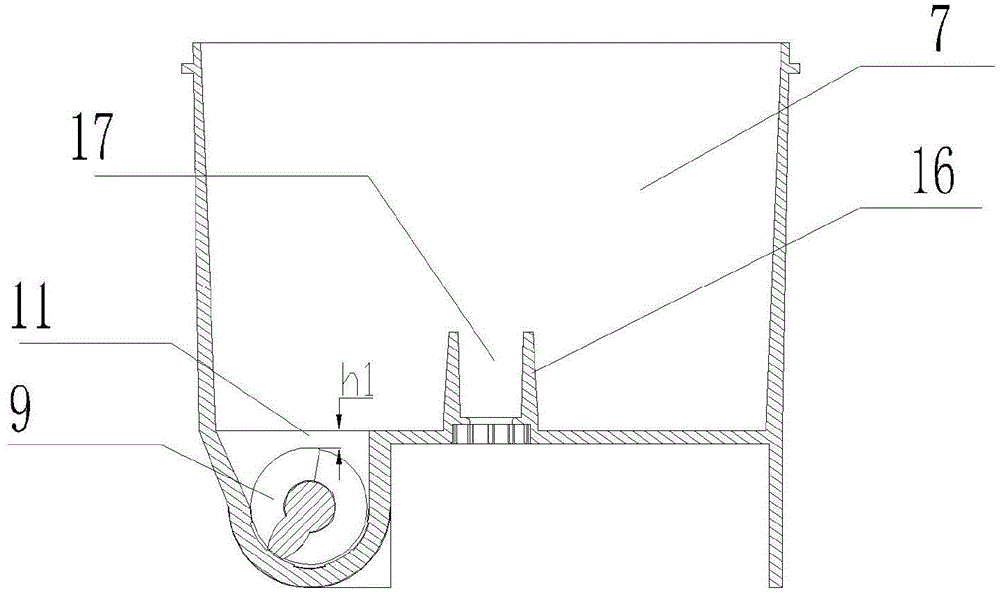

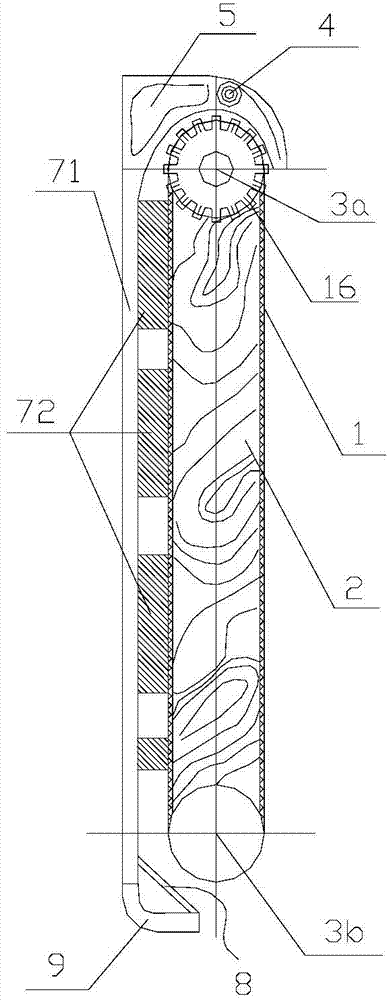

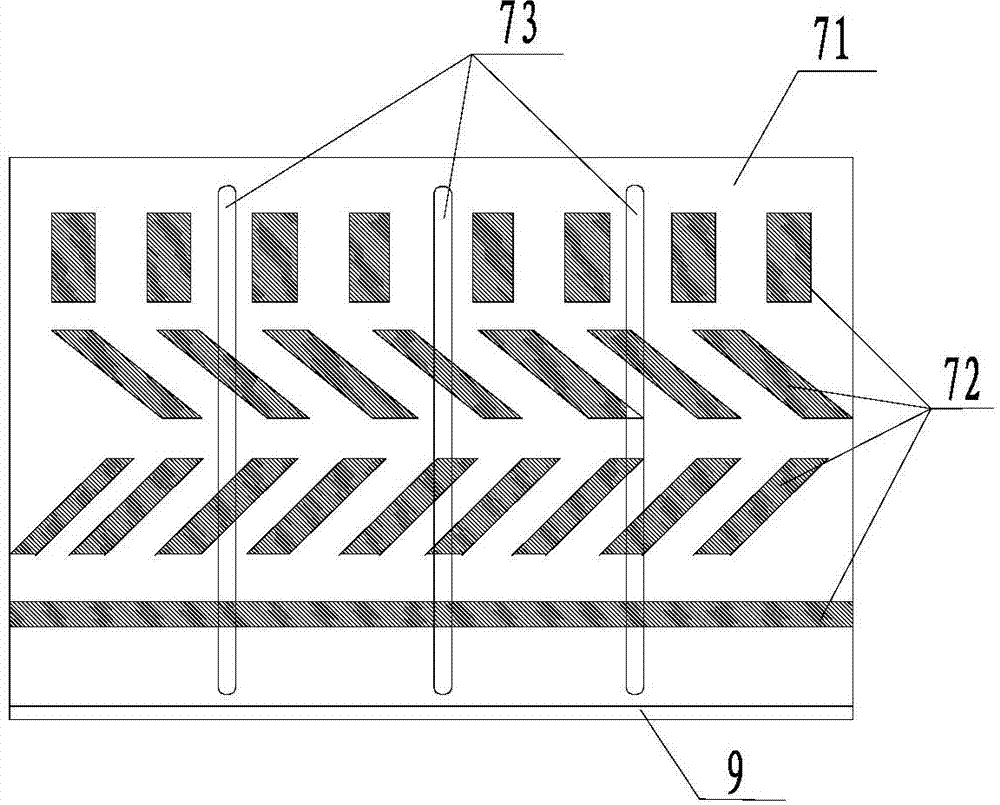

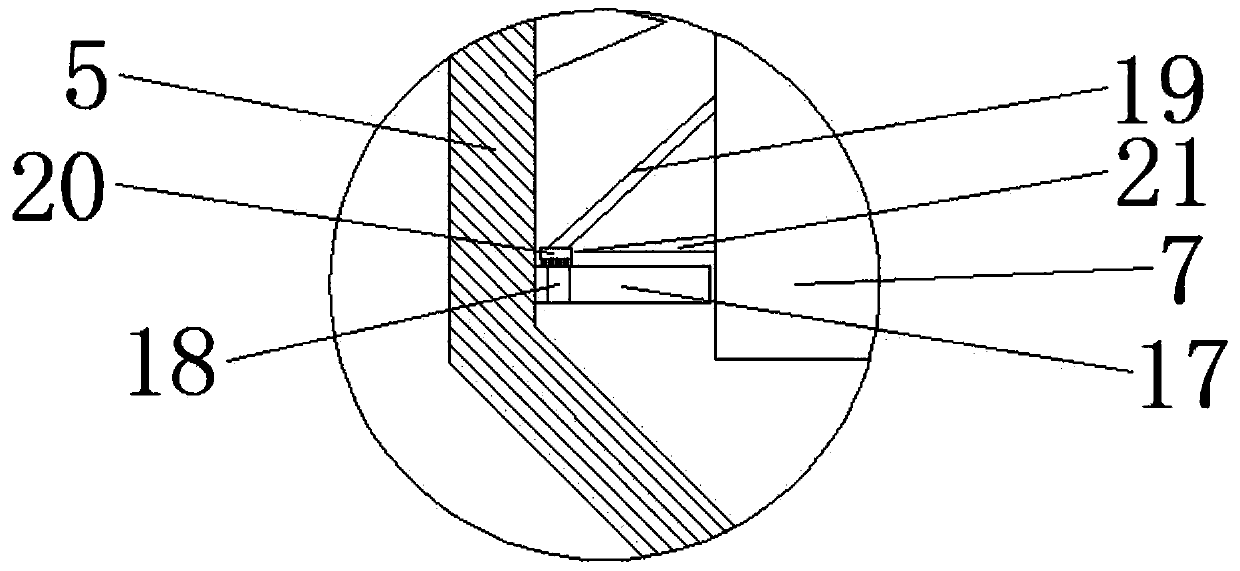

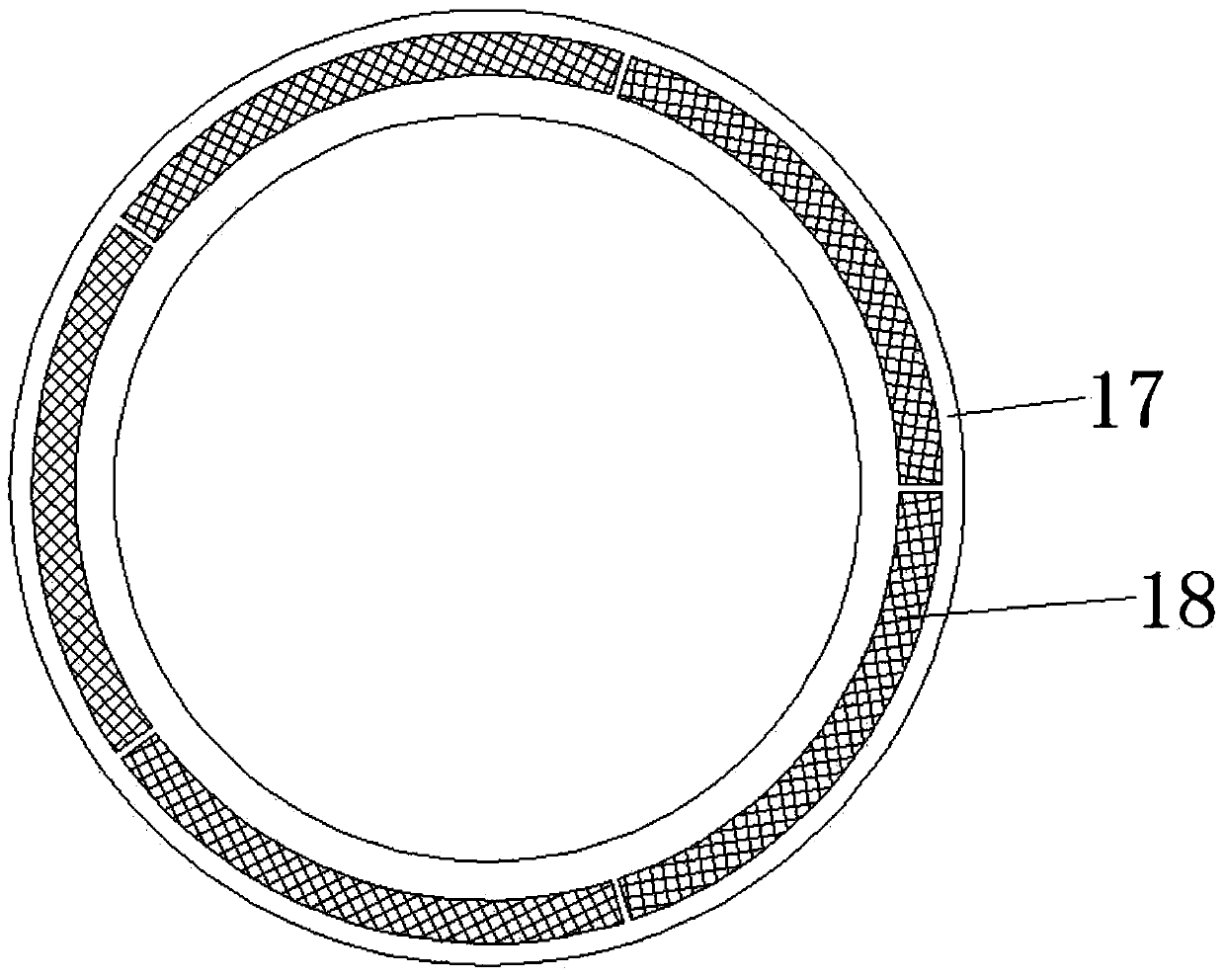

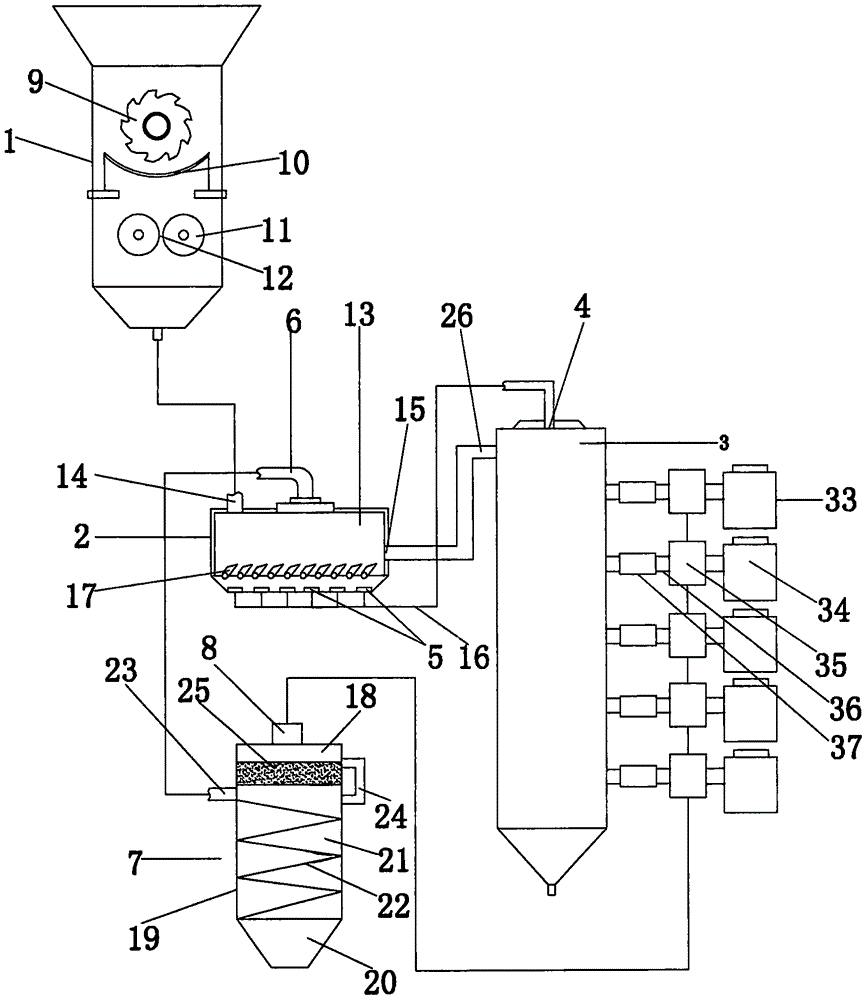

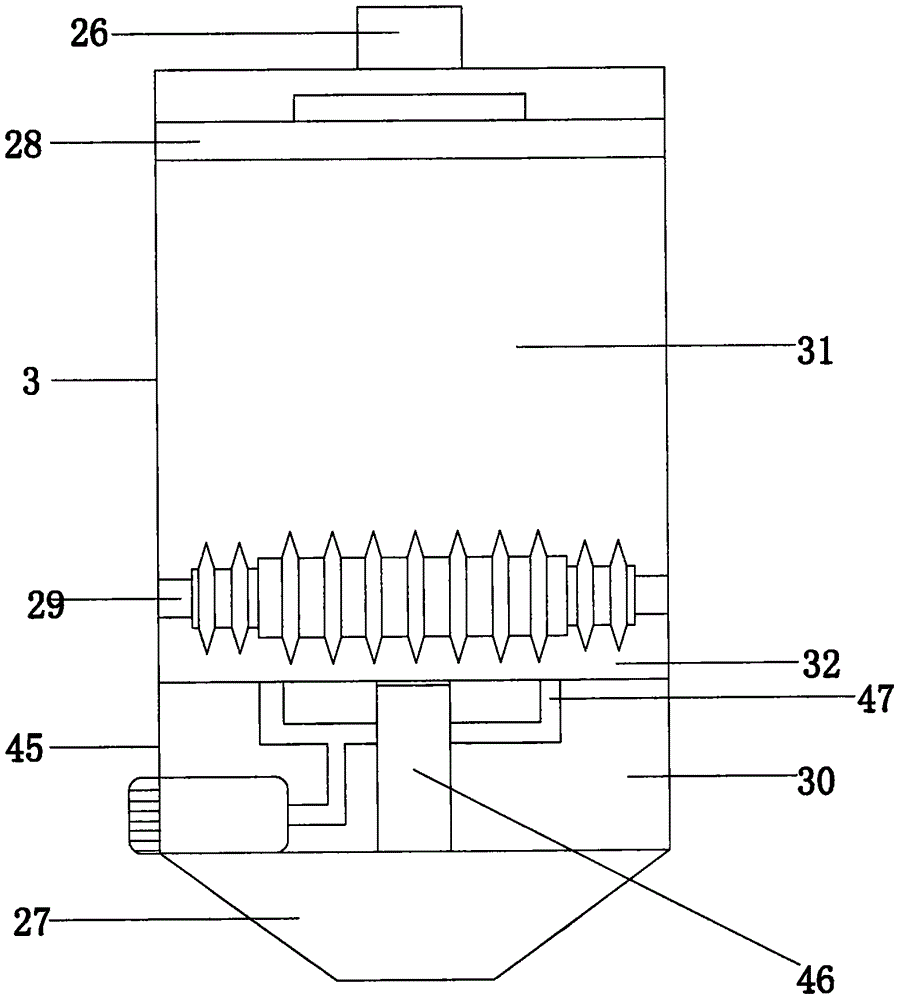

The invention particularly relates to a method and a system for transporting and loading bulk materials in a storage yard, which are suitable for bulk material accurate loading of railways, public roads and ships. The invention comprises a storage yard transporting system, a belt transport system and an accurate and rapid quantitative loading system. The invention provides an economical and effective transporting and loading system for bulk materials in a storage yard, which has the following advantages: 1) the storage yard transport system combing a disc vibrating feeder with a low clearance flow control gate is adopted, thus greatly lowering the upper height of an underground tunnel and improving the capability of transporting the materials in the storage yard; 2) the accurate and rapid quantitative loading system is adopted, thus having the characteristics of rapid loading speed, high loading precision and high automation degree; and 3) a four-roller belt weigher is adopted, thus realizing the linkage of the storage yard transport system, the belt transport system and the accurate and rapid quantitative loading system effectively and greatly improving the operation efficiency of the system.

Owner:BIRTLEY TIANJIN IND EQUIP

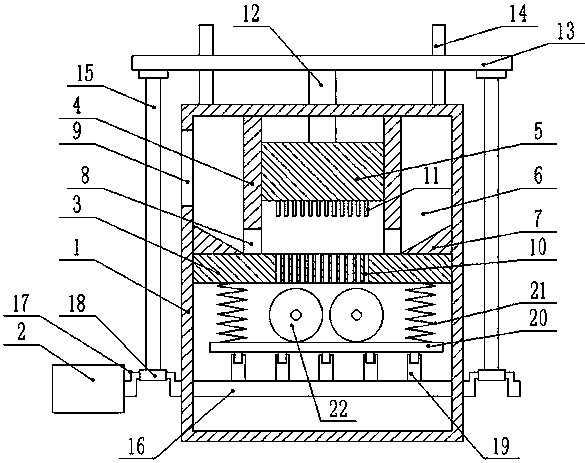

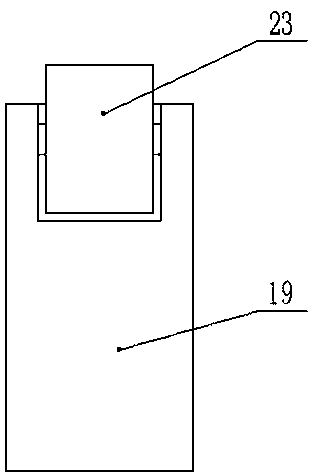

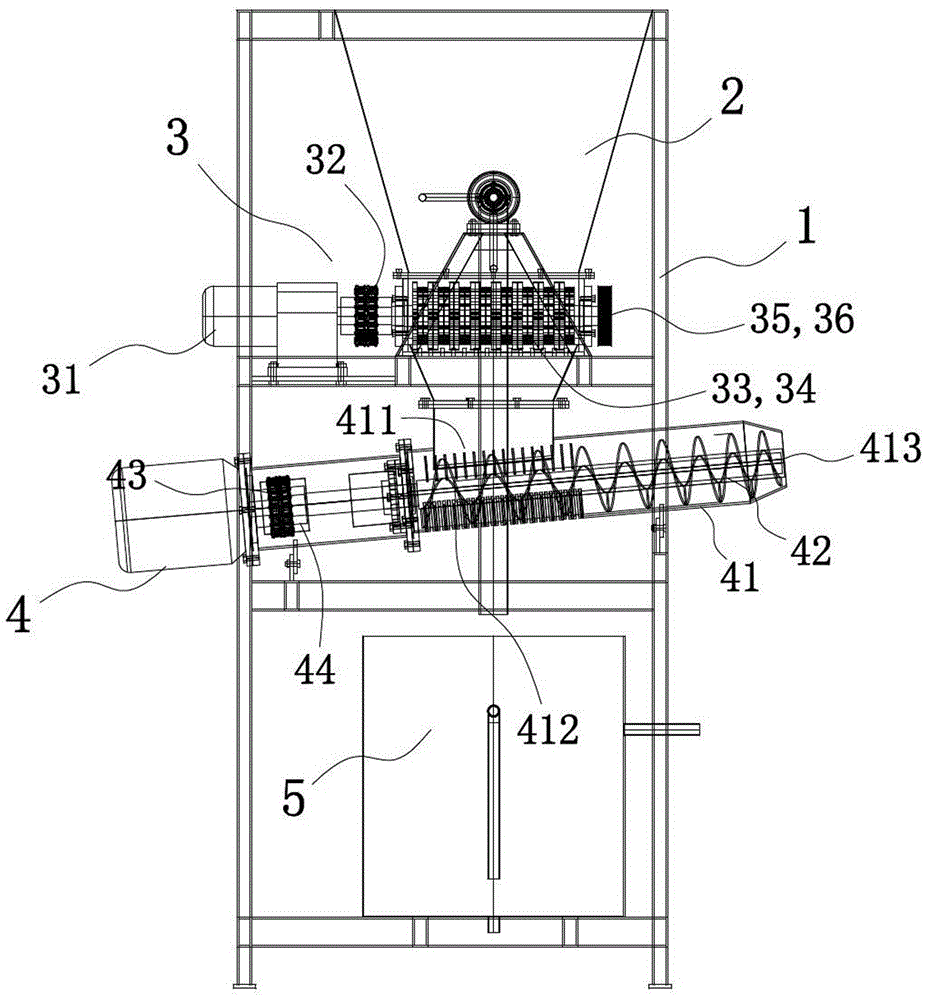

Dry soil fine grinding and screening device for analyzing soil in contaminated area

InactiveCN107684953AImprove screening efficiencyReduce work stressSievingScreeningAgricultural engineeringDry soil

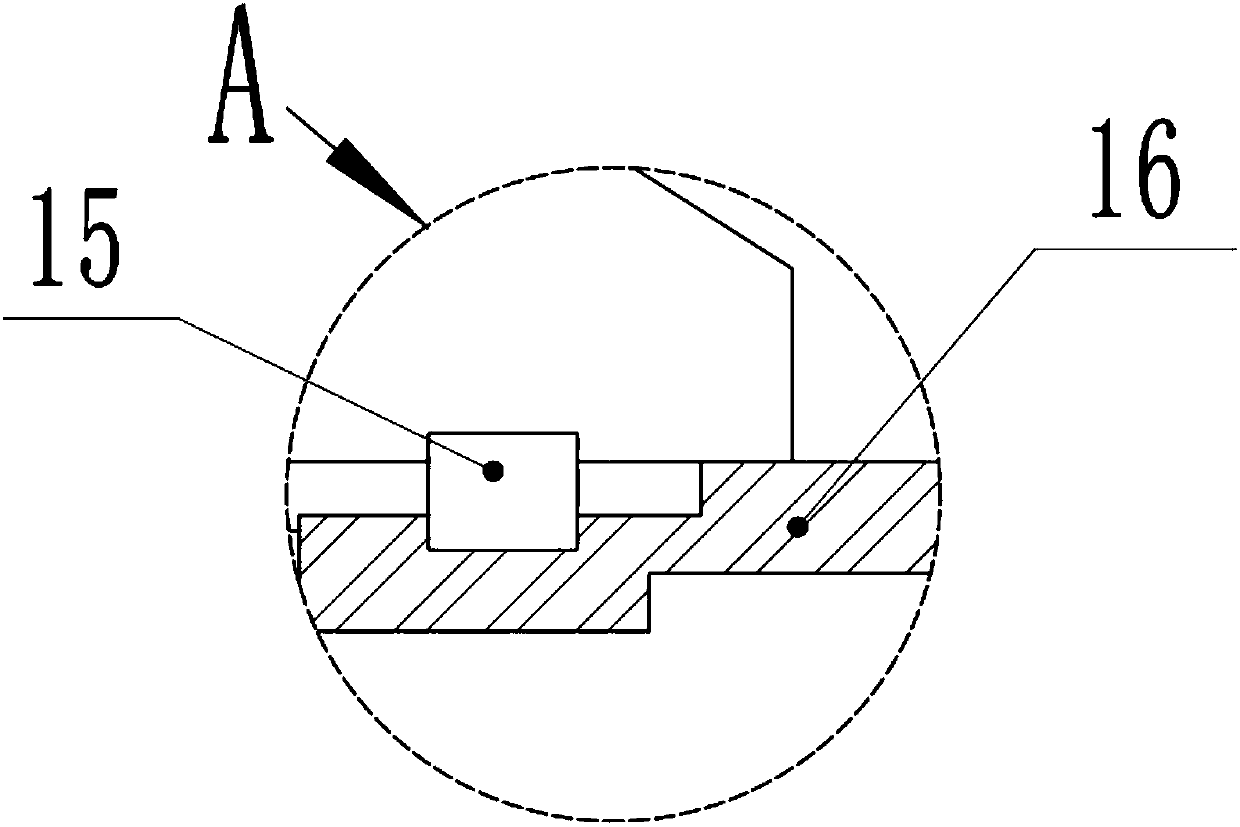

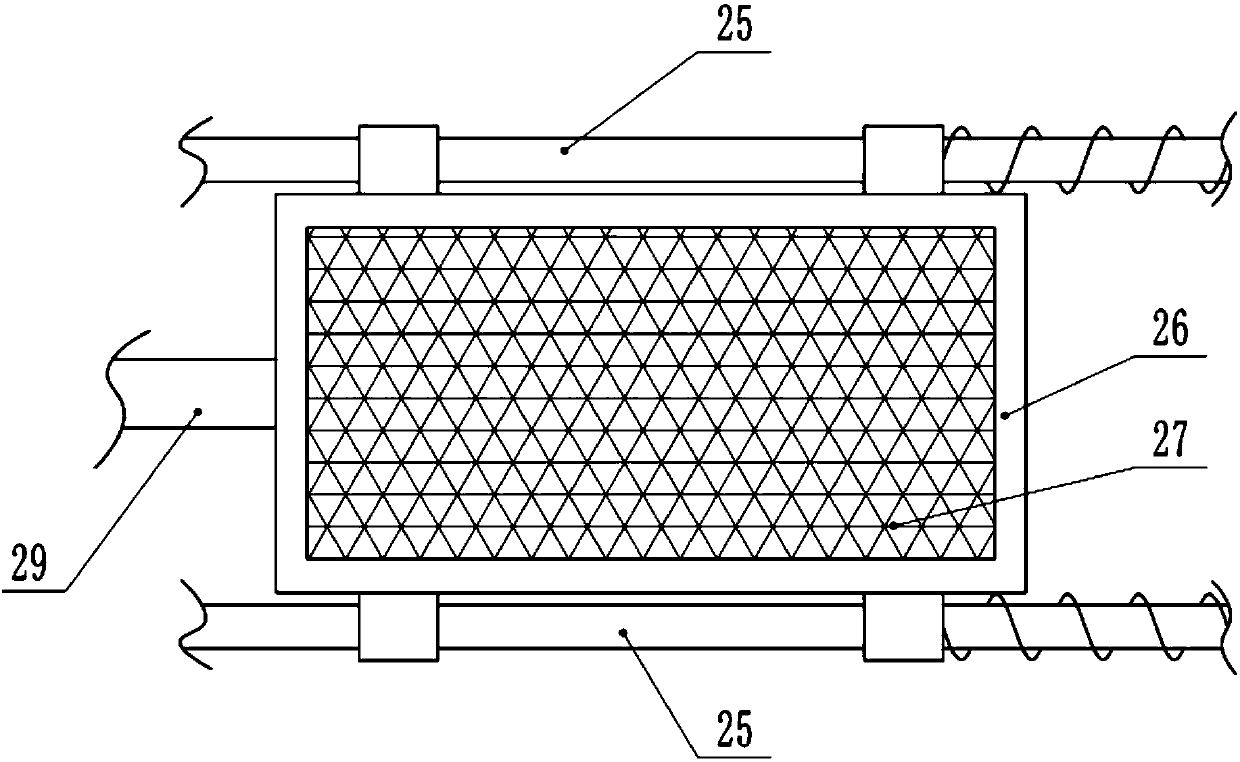

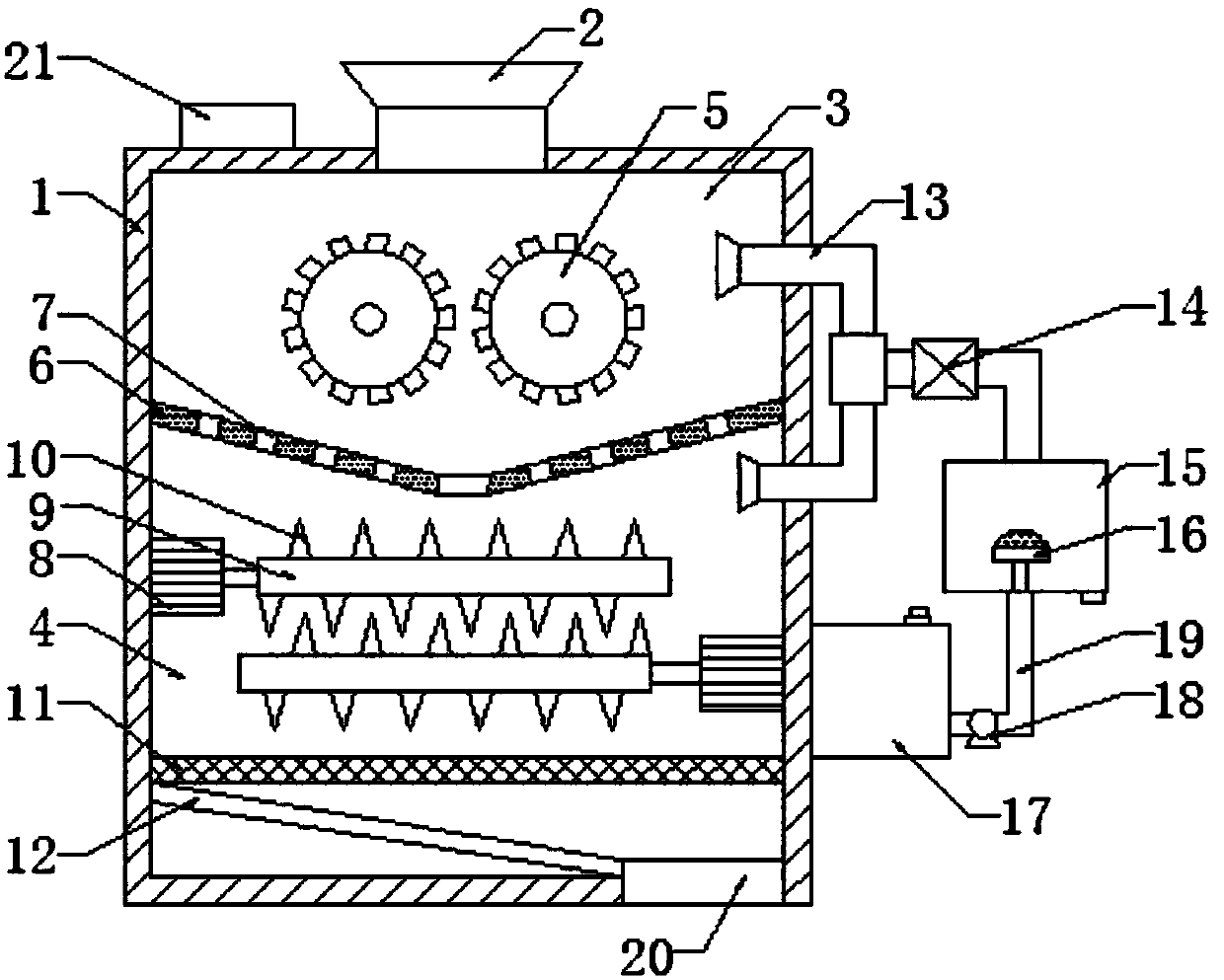

The invention discloses a dry soil fine crushing and screening device for soil analysis in a polluted area, which comprises a device case, a preliminary crushing roller, a double-axis motor, a first cam, a sealing partition, a fine crushing roller and a screening box. A slider is slidably installed on the lower side of the material plate A, and a packing plate is fixedly installed on the lower side of the sliding block. One side of the packing plate is fixedly connected with a first connecting rod, and the first connecting rod passes through the device chassis and is connected with a top block. A. A fine crushing roller is installed in rotation inside the casing of the device, and arc-shaped plates are arranged on the left and right sides of the fine crushing roller; a screening box is slidingly installed on the guide rod. The crushing and screening device can carry out preliminary crushing and fine crushing, so as to improve the effect of crushing. At the same time, it can carry out fine crushing in batches when performing fine crushing after preliminary crushing, thereby reducing the working pressure of the fine crushing roller and improving the effect of crushing. At the same time, after the crushing is completed, the arc-shaped plates on both sides can be moved to both sides, so as to facilitate the falling of the crushed dry soil.

Owner:王连军

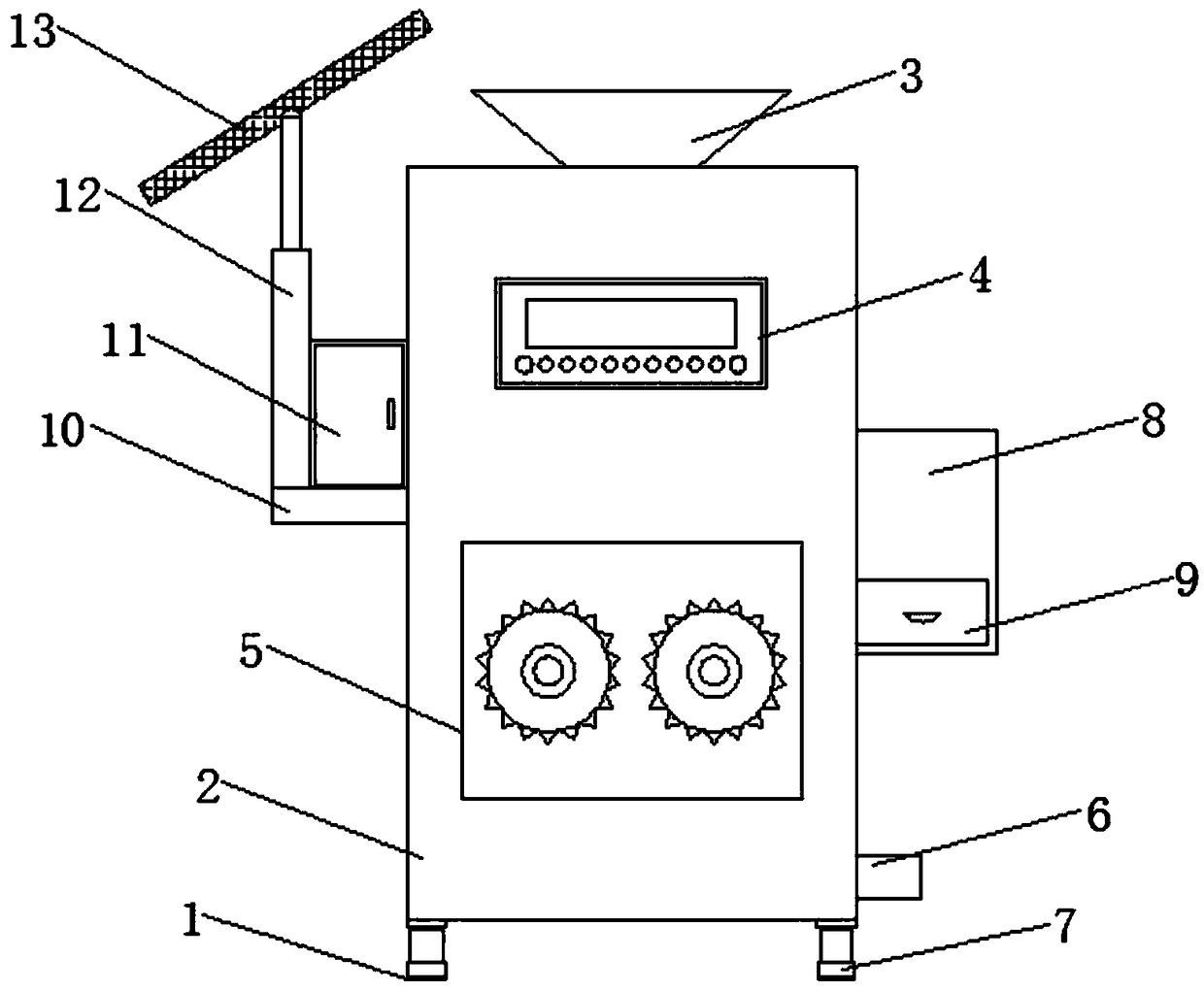

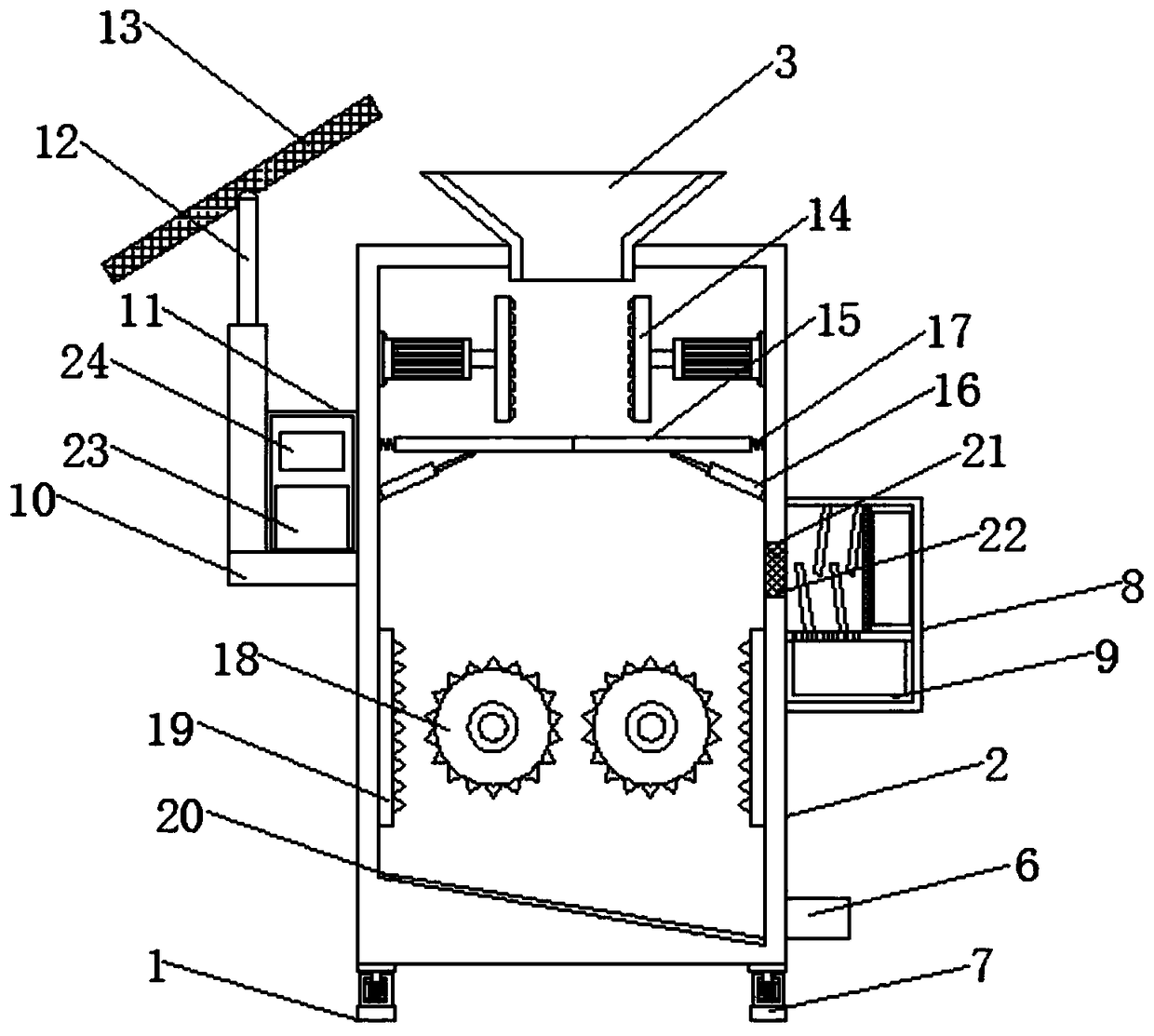

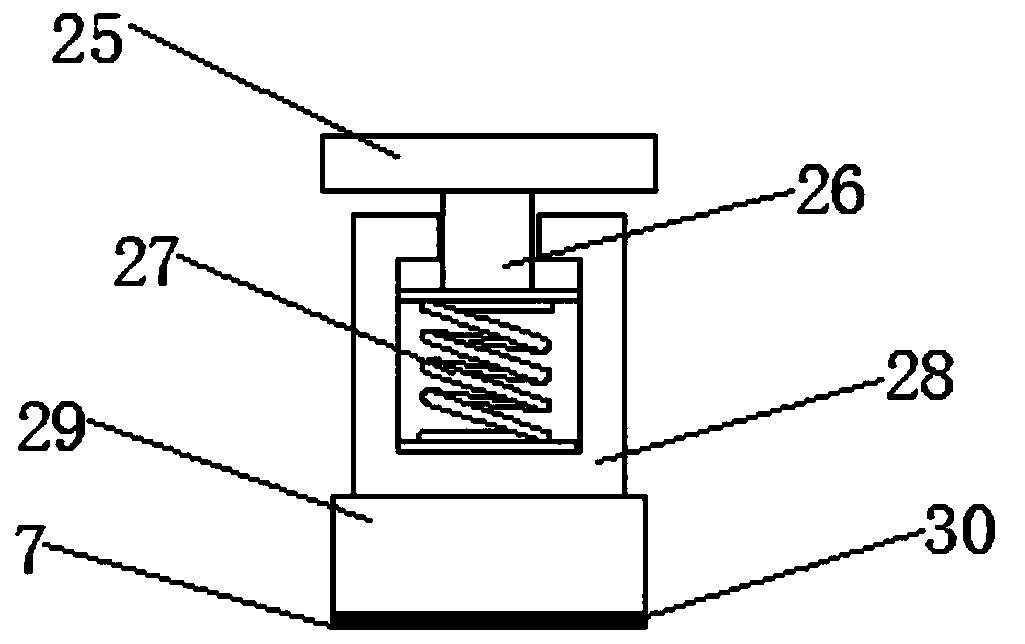

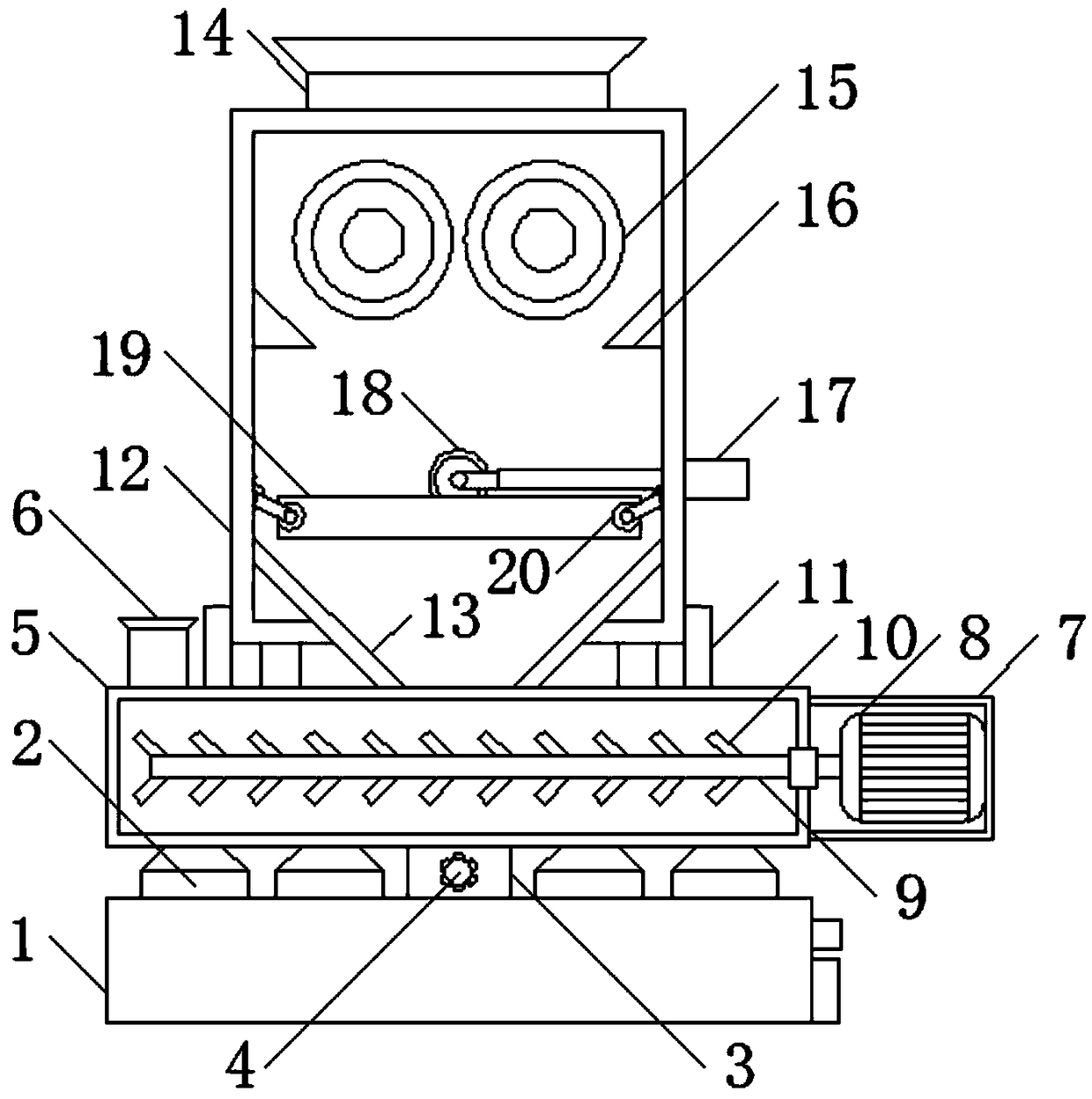

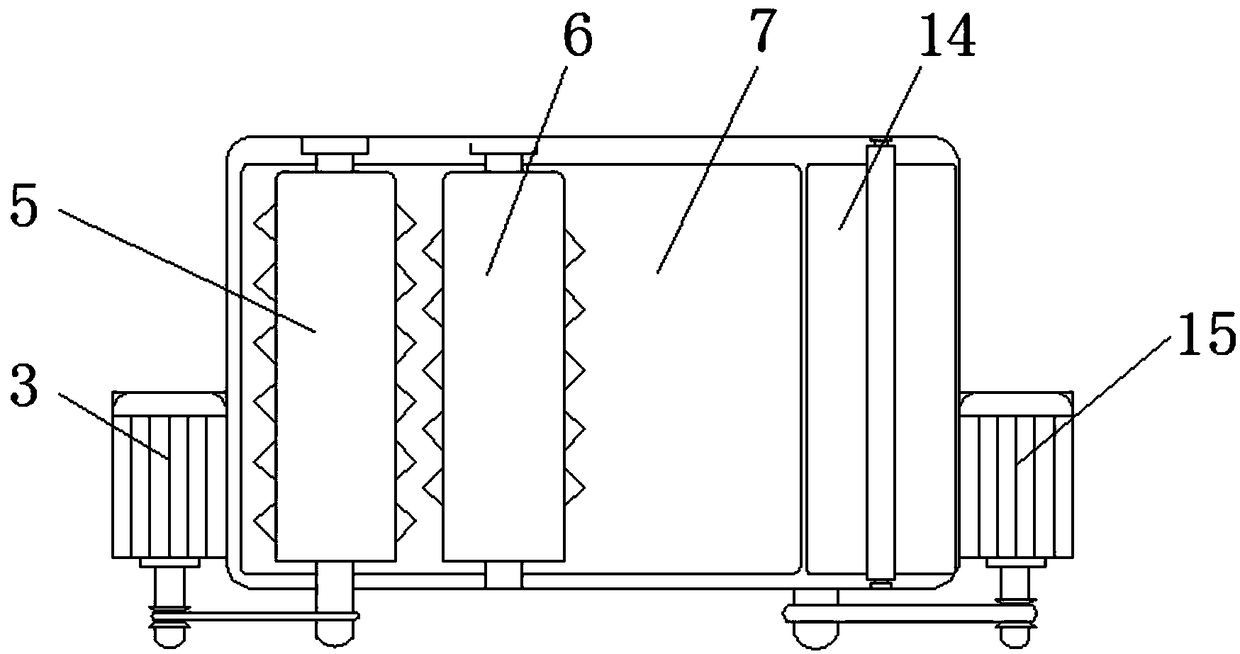

Municipal building waste crushing device with dust removal function

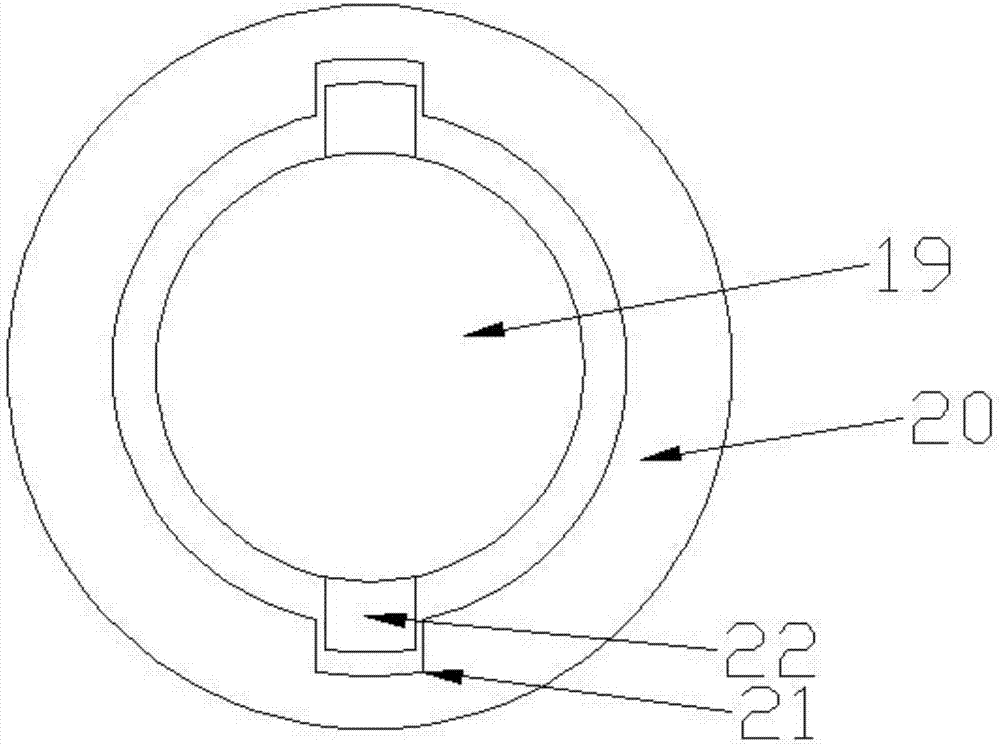

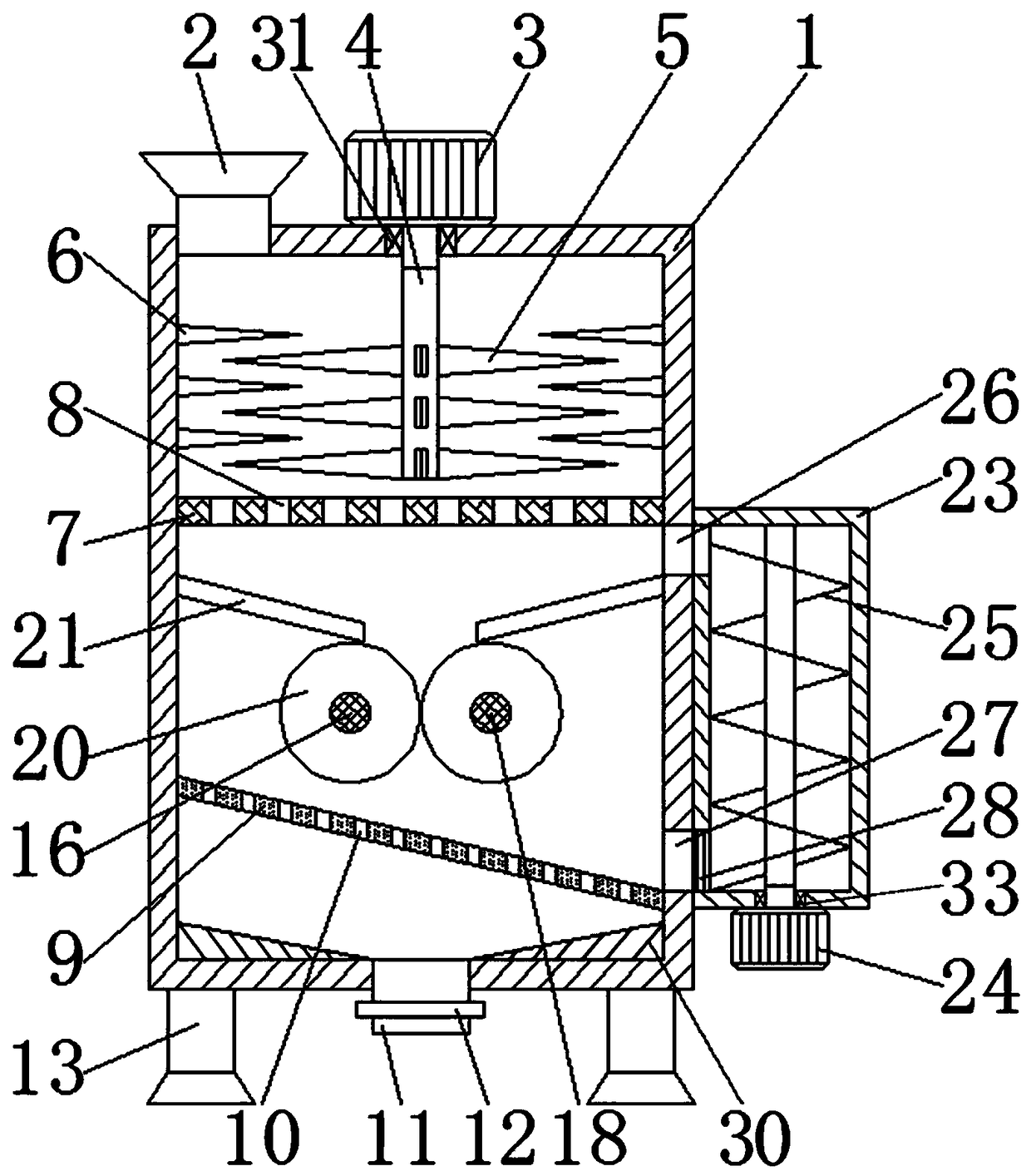

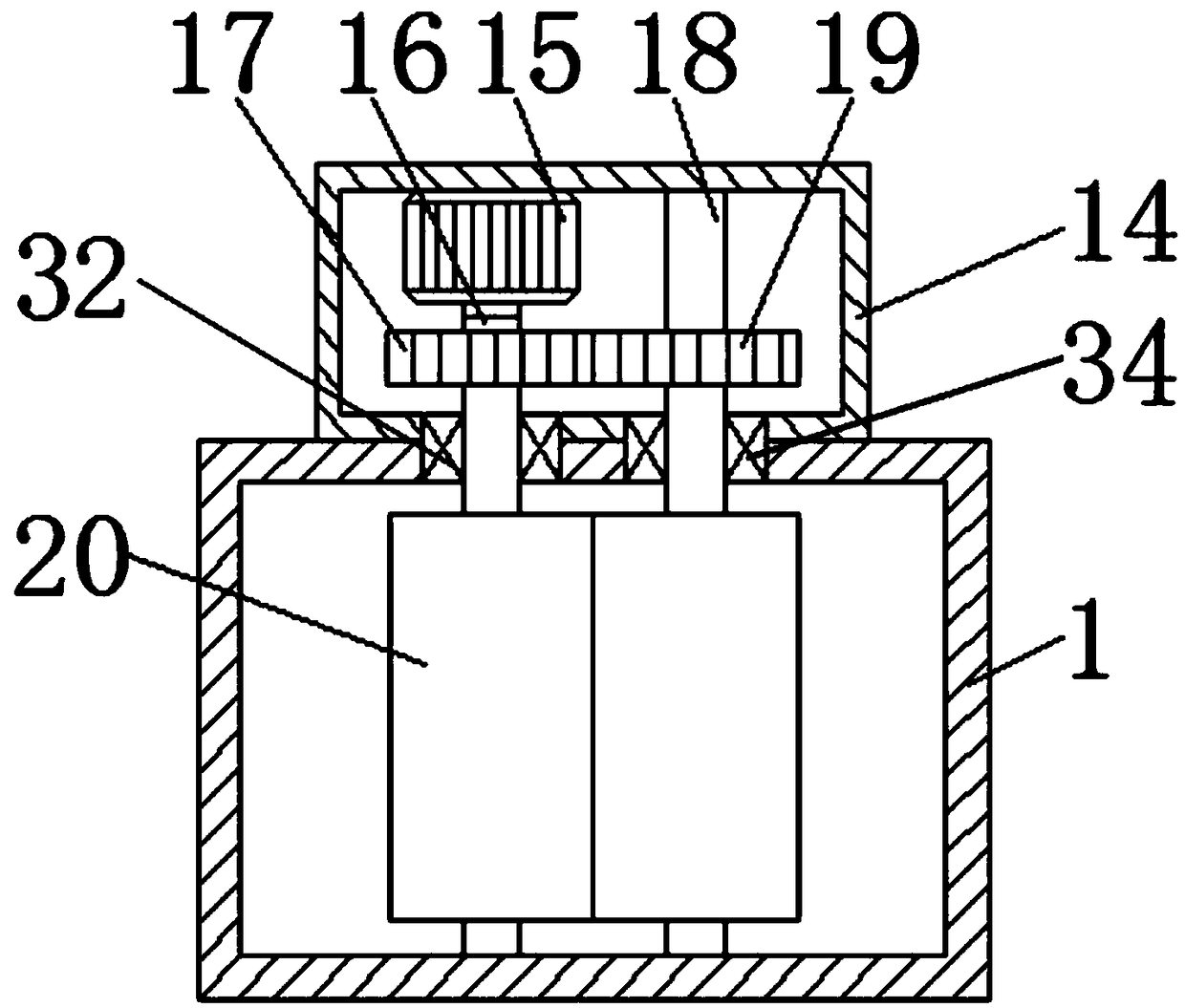

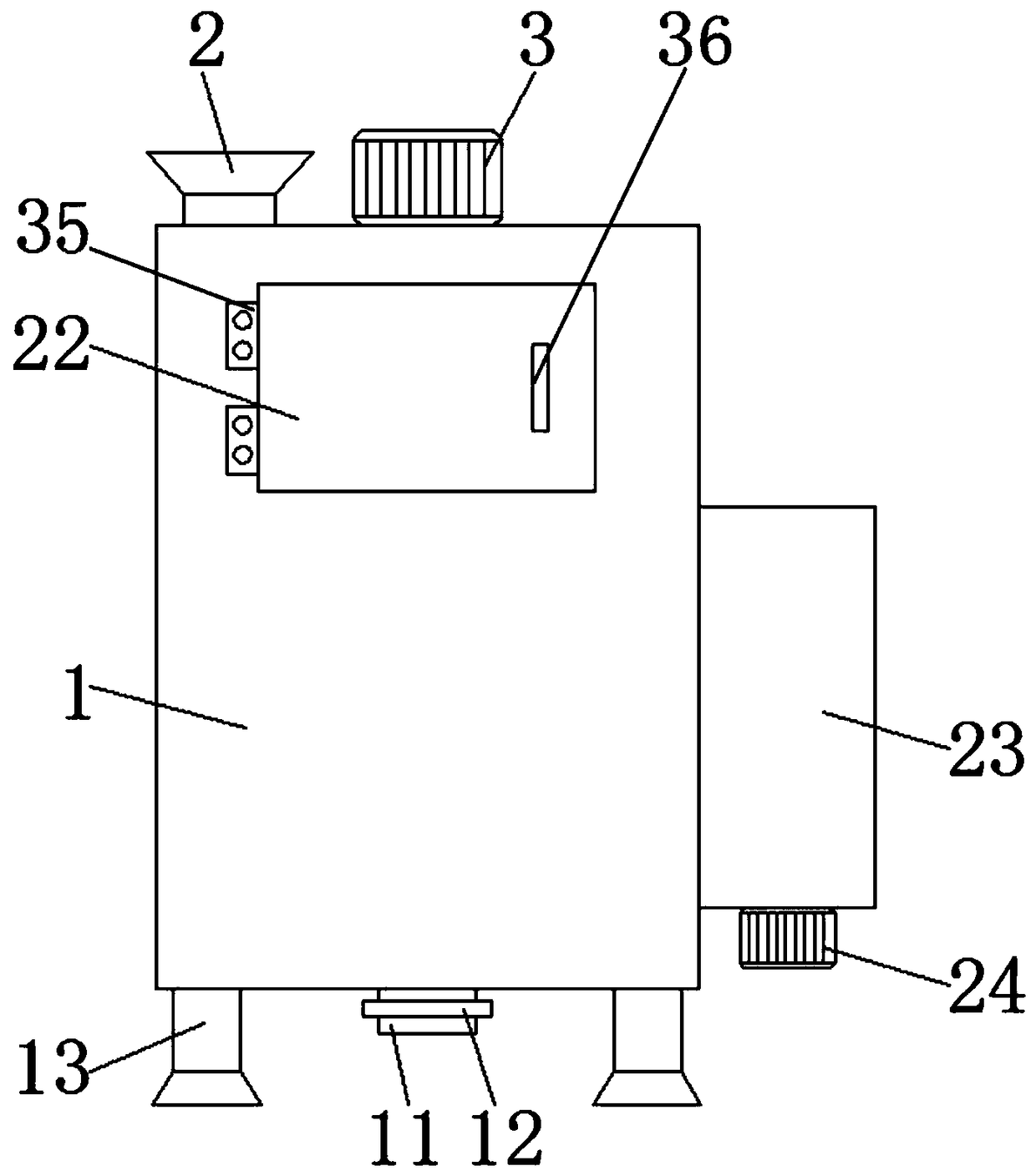

InactiveCN109926145AComplete and compact structural designConvenient whereaboutsUsing liquid separation agentDirt cleaningEngineeringMotor shaft

The invention discloses a municipal building waste crushing device with a dust removal function. The municipal building waste crushing device comprises a crushing box, a coarse smashing chamber, a fine smashing chamber, two servo motors, crushing knives and a dust removal box, the crushing box is internally provided with the coarse smashing chamber and the fine smashing chamber, a feeding inlet isformed in the top of the crushing box, a controller is arranged on one side of the feeding inlet, two crushing rollers are arranged in the coarse smashing chamber in parallel, the coarse smashing chamber and the fine smashing chamber are partitioned by a sieving plate, the sieving plate is evenly provided with a plurality of through holes, the two servo motors are mounted in the fine smashing chamber, motor shafts of the two servo motors are axially connected with two rotating shafts correspondingly, the crushing knives are arranged on the two sides of the two rotating shafts, the directionsof the two rotating shafts are opposite, by arranging the crushing rollers, building waste is preliminarily smashed firstly, coarsely smashed and then smashed by the crushing knives, smashing is morethorough, through mutual action of a water pump, an atomizing nozzle, the dust removal box and a suction ventilator, dust generated in the crushing process is absorbed through water mist, and the effect is good.

Owner:XIAN DONGJIA TRADE CO LTD

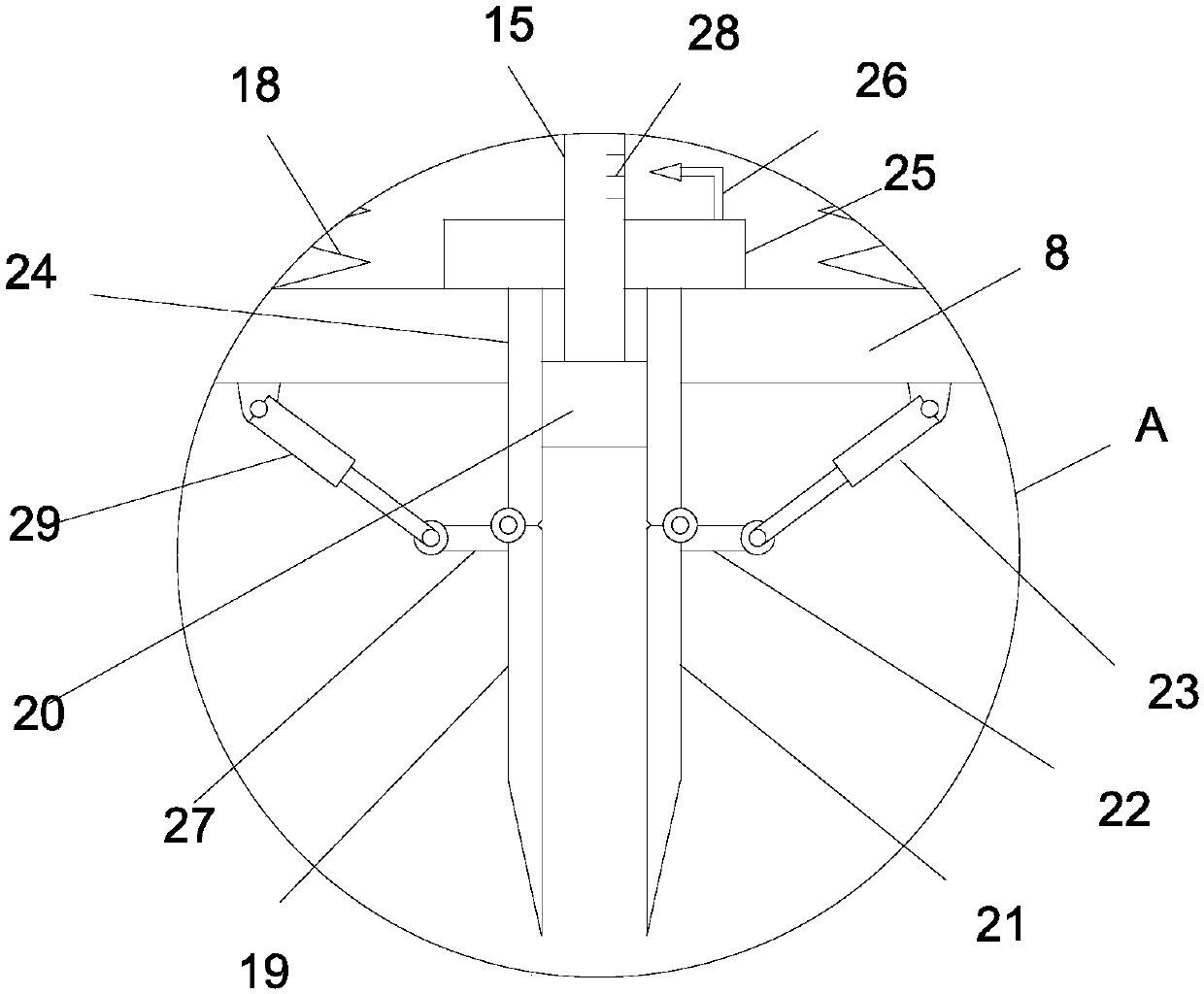

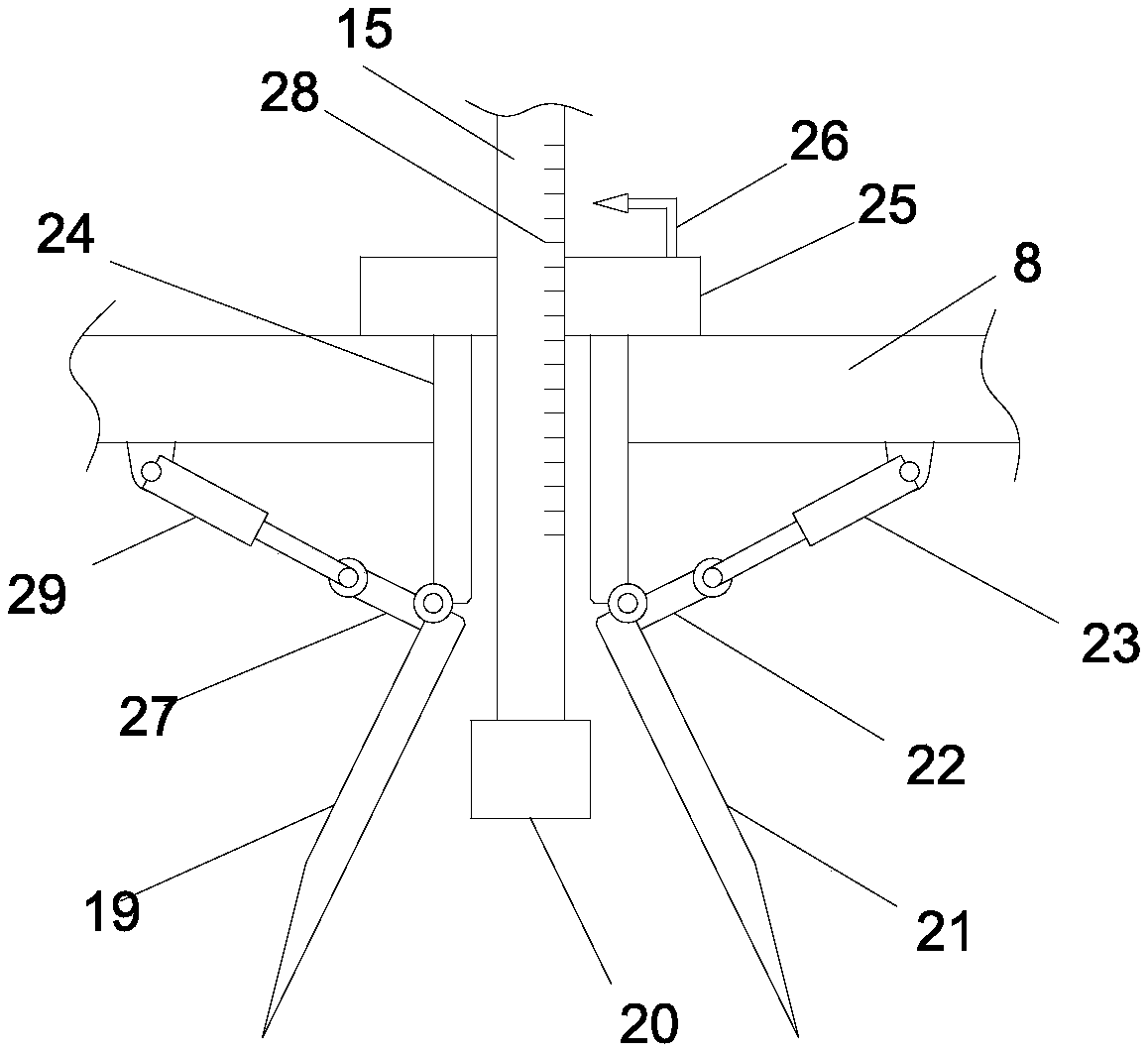

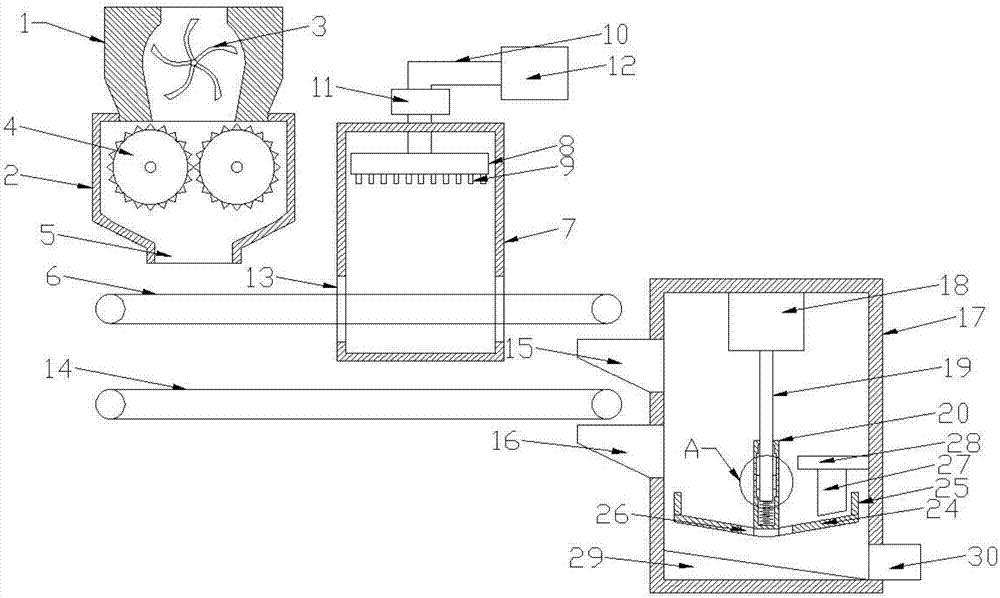

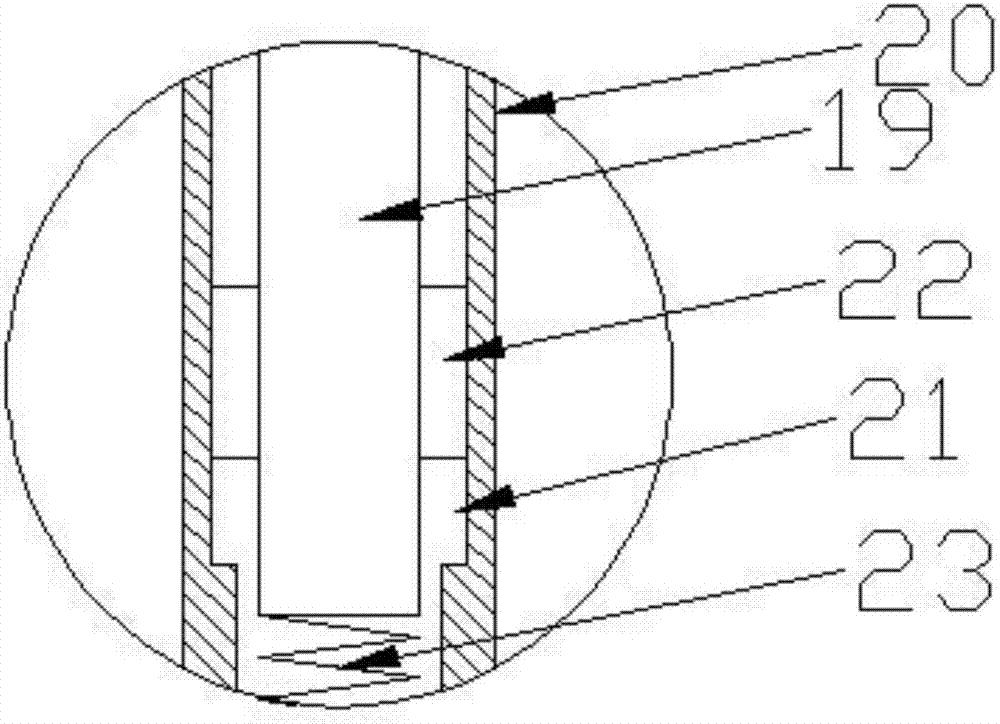

Soil sampling device for geological exploration

InactiveCN107831030AEasy to take outImprove sampling efficiencyWithdrawing sample devicesAgricultural engineeringGeological exploration

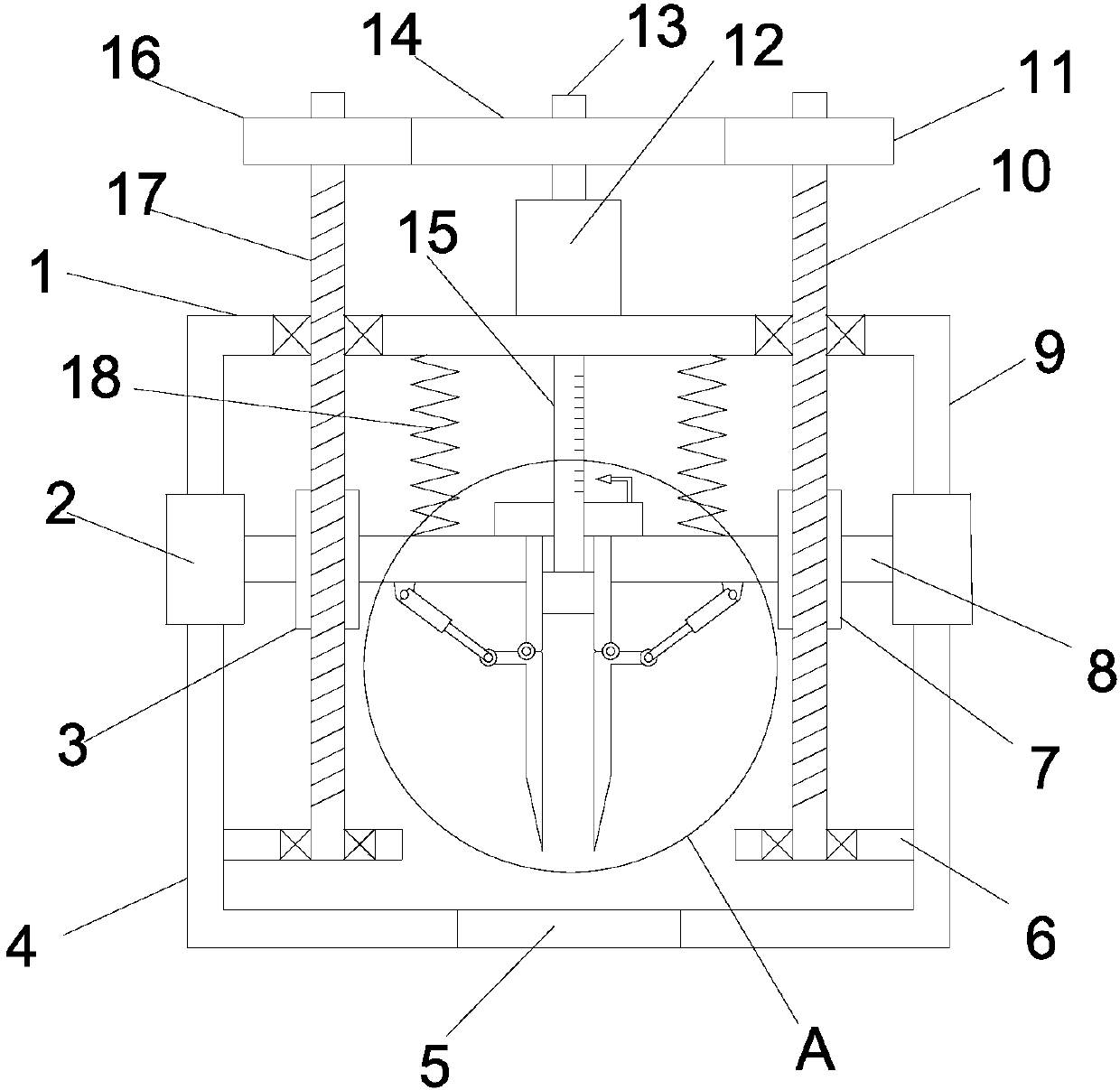

The invention discloses a soil sampling device for geological exploration, comprising a support frame, a left column and a right column are vertically and fixedly installed on the support frame, and both the left column and the right column are slidably provided with limiting sliding sleeves , the horizontal plate is fixed horizontally between the limit sliding sleeves, the sliding sleeve on the extension rod is provided with a block fixed on the upper surface of the horizontal plate, and the side wall of the extension rod is marked with a scale line. The structure of the invention is ingenious and the design is reasonable , through the rotation of the first screw rod and the second screw rod, the horizontal plate drives the first half-arc blade and the second half-arc blade downward to sample the soil, and the sampling process is more stable; the discharge push block is relatively limit-oriented The casing slides down, which is convenient to take out the sample soil between the first half-arc blade and the second half-arc blade, which improves the efficiency of soil sampling and can effectively prevent the viscous soil from adhering to the first half-arc blade It is on the inner wall of the second half-arc blade, and it is easy to clean at the same time, which is convenient for the sampling operation again.

Owner:陈云夫

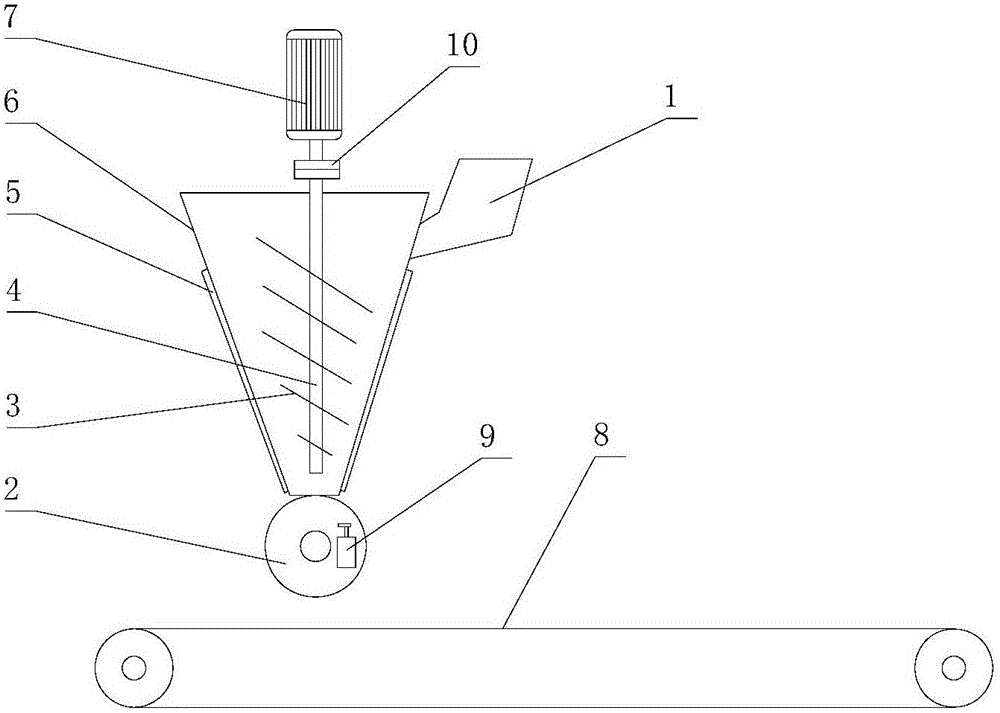

Straw crushing and mixing device for breeding

The invention discloses a straw crushing and mixing device for farming, which comprises a feeding hopper, a crushing box and a mixing box; several cutting blades are installed in the feeding hopper; A horizontal straw conveyor belt is installed below the feeding port, an atomization box is arranged on the right side of the crushing box, and a horizontal feed conveyor belt is arranged below the straw conveyor belt; the lower end of the rotating shaft covers A sleeve is provided, a vertical spring is fixed at the lower end of the rotating shaft, and a vertical chute is provided on the inner wall of the sleeve; a receiving tray is fixed at the lower end of the sleeve; the crushed straw surface There is water vapor attached to it, which can adhere to the feed during mixing, and evenly mix the feed with straw fragments to ensure the mixing ratio of feed and straw; the feeding tray can also move up and down while rotating, so as to realize the vibration of the feeding tray and shake the raw materials. Fall, to facilitate the whereabouts of materials.

Owner:刘志坚

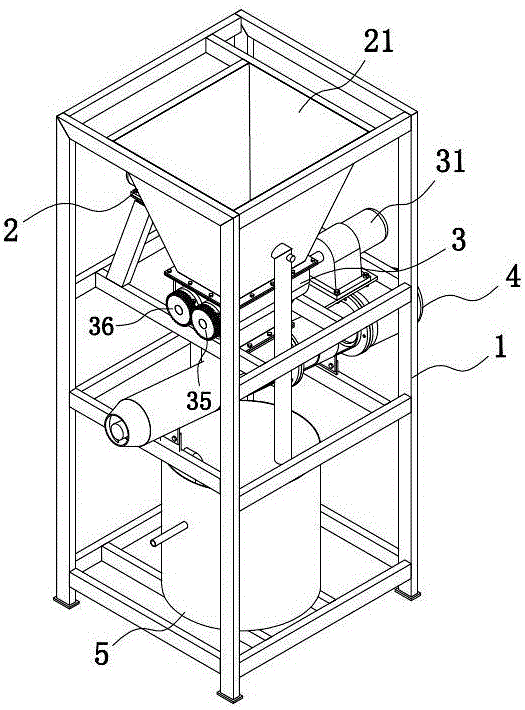

Efficient vertical roll milling machine capable of realizingwith multi-stage crushing

PendingCN109225568AGuaranteed crushing qualityCompact structureGrain treatmentsEngineeringMechanical engineering

The invention discloses an efficient vertical roll milling machine capable of realizingwith multi-stage crushing. The efficient vertical roll milling machine comprises a box body, wherein the left side of the top of the box body is communicated with a feeding pipe; a first motor is fixedly connected onto the top of the box body; the bottom of the output end of the first motor penetrates to the inner cavity of the box body and is fixedly connected with a first rotating rod. The disc matched crushing form of the conventional vertical roll milling machine roller disc matched crushing form is omitted; through the matched use of the first motor, a crushing cutter blade, a fixed cutter blade, a first inclined plate, an electromagnetic valve, support legs, a second motor, a driving gear, a drivengear, a milling roller, a second inclined plate, a conveying case, a third motor, a conveying shaft, a material detection sensor and a processor, the automatic multi-stage crushing on the materials can be realized; the material crushing quality is ensured; the crushing efficiency is improved; in addition, the structure is compact; the technical flow process is simple and safe; the abrasion consumption is low; the production cost is effectively reduced.

Owner:ANHUI UNIV OF SCI & TECH

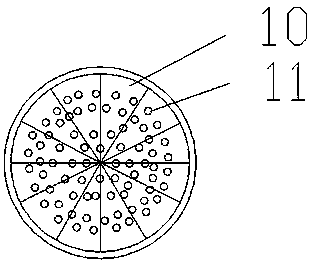

Conical cylinder type soil screening device for soil remediation

The invention discloses a conical cylinder type soil screening device for soil remediation. The conical cylinder type soil screening device comprises a support device, a driving device and a screeningbody, wherein the driving device is erected on the support device; the screening body comprises a screen mesh, a first side plate and a second side plate, the screen mesh is enclosed into a circulartruncated cone structure, the first side plate and the second side plate are respectively fixed to the large end surface and the small end surface of the circular truncated cone structure of the screen mesh, and the size of the first side plate is greater than that of the second side plate; and the driving device is used for driving a rotating shaft so as to drive the screening body to rotate around the axis. According to the conical cylinder type soil screening device for soil remediation, the automatic soil screening is realized, the feed and discharge are convenient, additionally, the accumulation of soil can be effectively avoided, and the soil screening efficiency is greatly improved.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

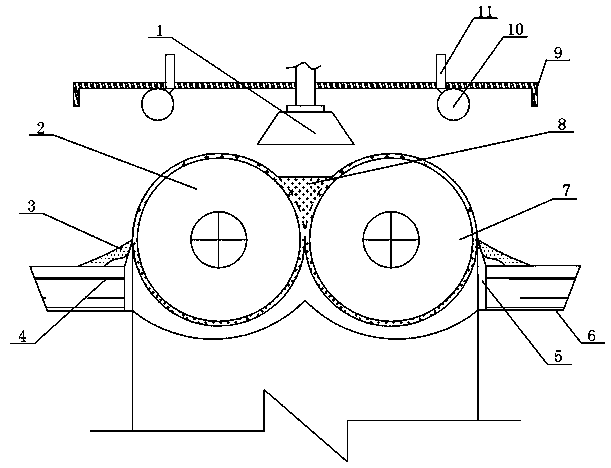

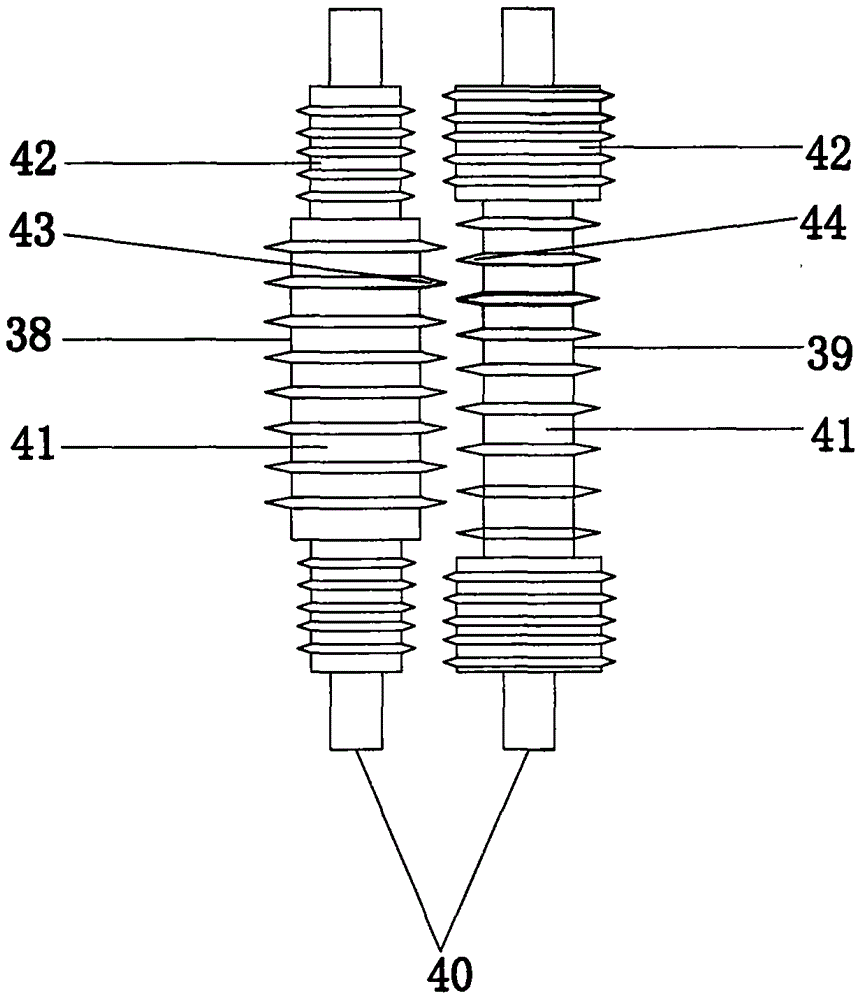

Double-roller dryer

InactiveCN104315829AImprove cooling effectKeep dryDrying solid materialsDrying machinesClassical mechanicsEngineering

The invention relates to the technical field of dryers, in particular to a double-roller dryer. The double-roller dryer comprises a first roller and a second roller, wherein the first roller and the second roller are arranged in parallel and are opposite in rotation direction, a material spraying device is arranged above the first roller and the second roller, a gap smaller than 5 cm is reserved between the first roller and the second roller, and the material spraying device is aligned to the gap. A material bin is arranged on the side opposite to the gap between the first roller and the second roller, a scraping plate is arranged on the material bin, the other end of the scraping plate is in circular contact with the periphery of the first roller and the periphery of the second roller, guide grooves are formed in the positions in contact with the first roller and the second roller, of the scraping plate, and the other end of each guide groove is connected with the inside of the material bin. By means of the technical scheme, the double-roller dryer enables materials to be dried easily and facilitates material discharge.

Owner:CHONGQING TENGHAN IND & TRADE

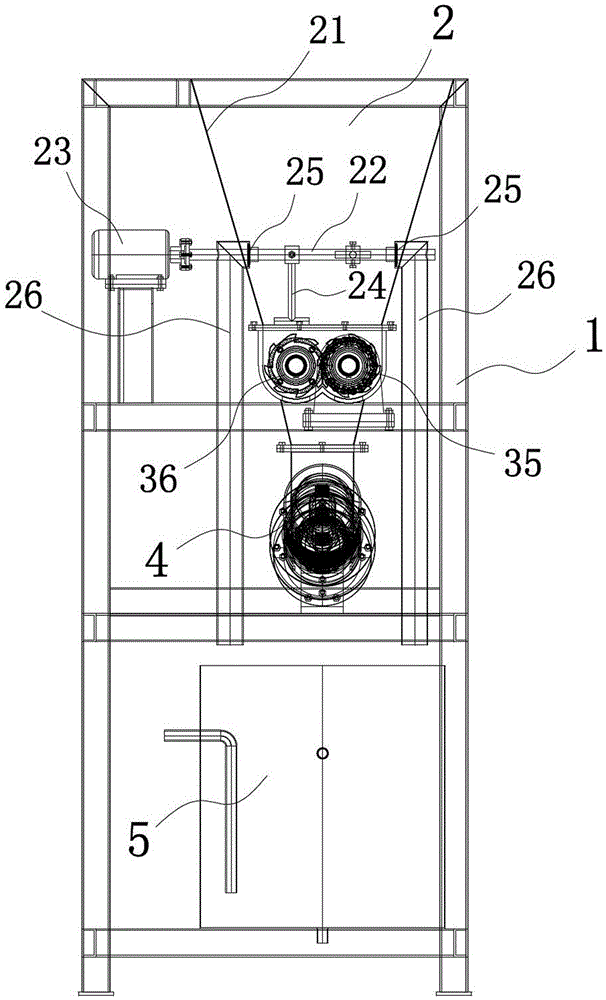

Paper money and coin sorting machine

InactiveCN105513200ASave productivityImprove labor productivityCoin/paper handlersCentrifugationEconomic benefits

The invention relates to the technical field of paper money and coin sorting automation, in particular to a paper money and coin sorting machine. The paper money and coin sorting machine comprises a main rack, a coin feeding part, a paper money sorting part, a coin sorting centrifugation part and a coin sorting guide groove part, wherein the coin feeding part, the paper money sorting part, the coin sorting centrifugation part and the coin sorting guide groove part are installed on the main rack. The paper money sorting part is communicated with the side face of the coin feeding part, the bottom of the coin feeding part is connected with the coin sorting centrifugation part, and the coin sorting centrifugation part is connected with the coin sorting guide groove part. According to the paper money and coin sorting machine, full-automatic design is adopted, paper money and coins can be sorted, the coins of different face values are sorted, previous labor force is changed, productivity is saved, labor productivity is improved, cost is reduced, and great economic benefits are acquired.

Owner:陈金钟

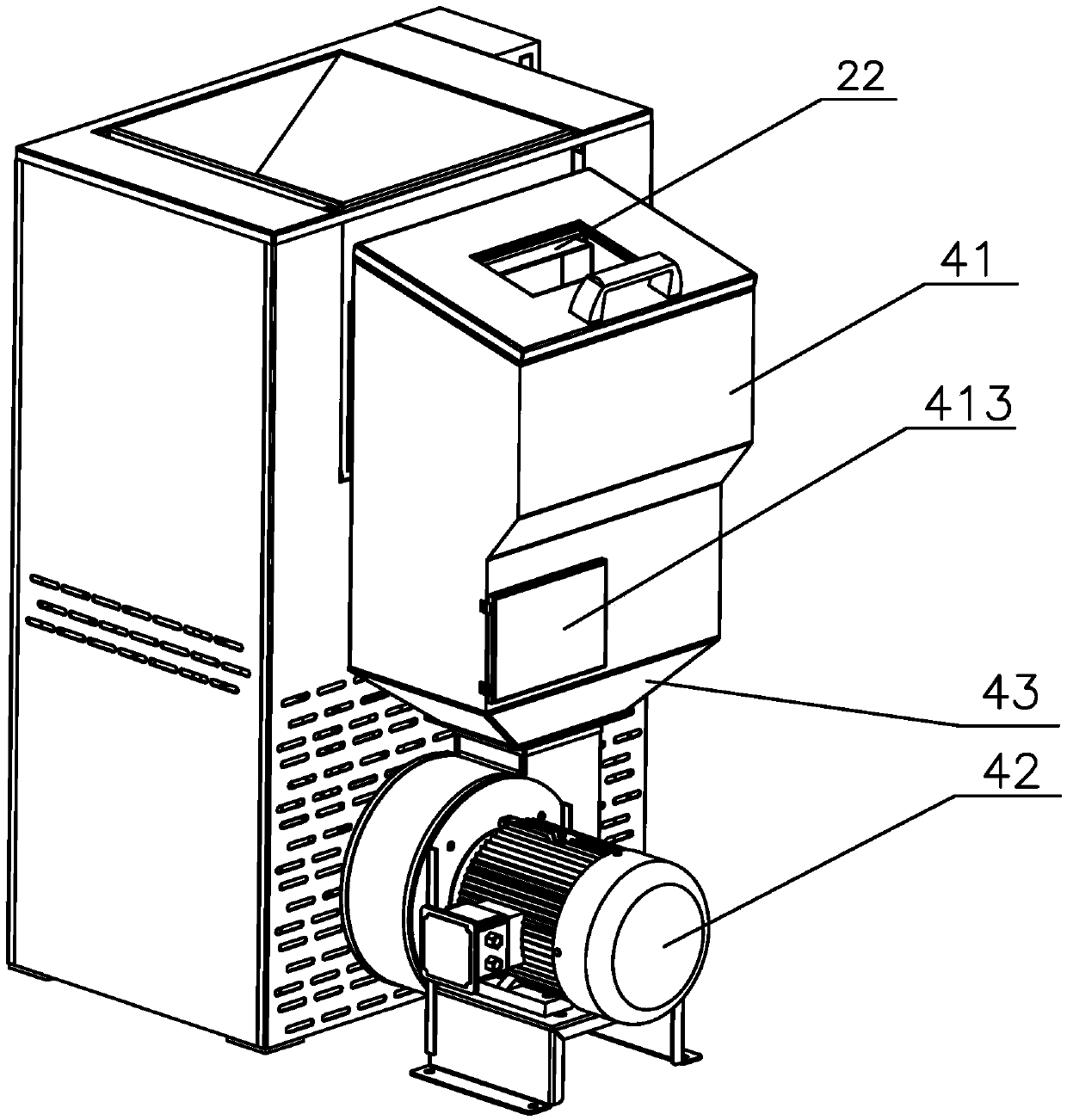

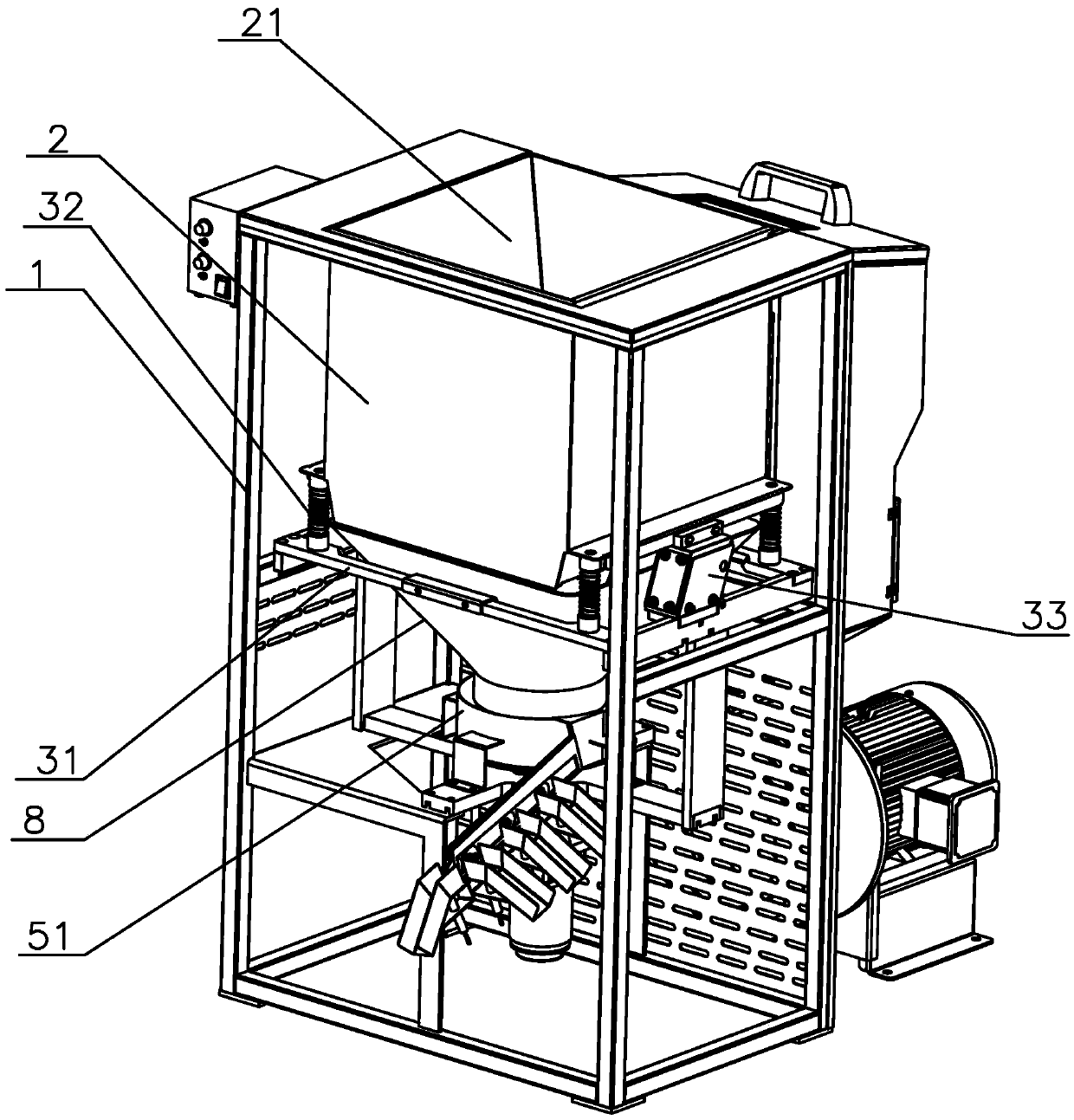

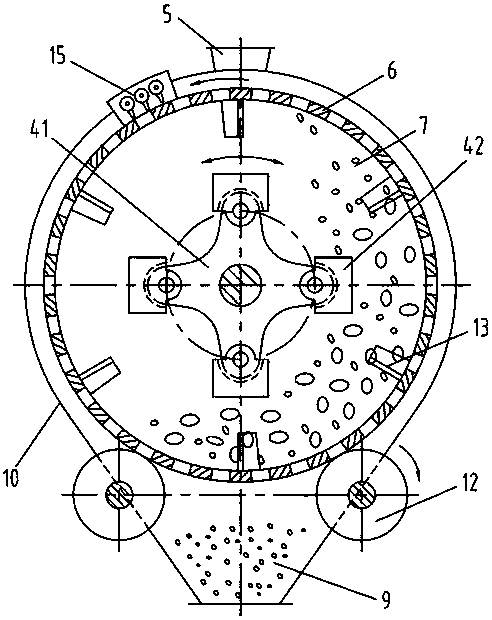

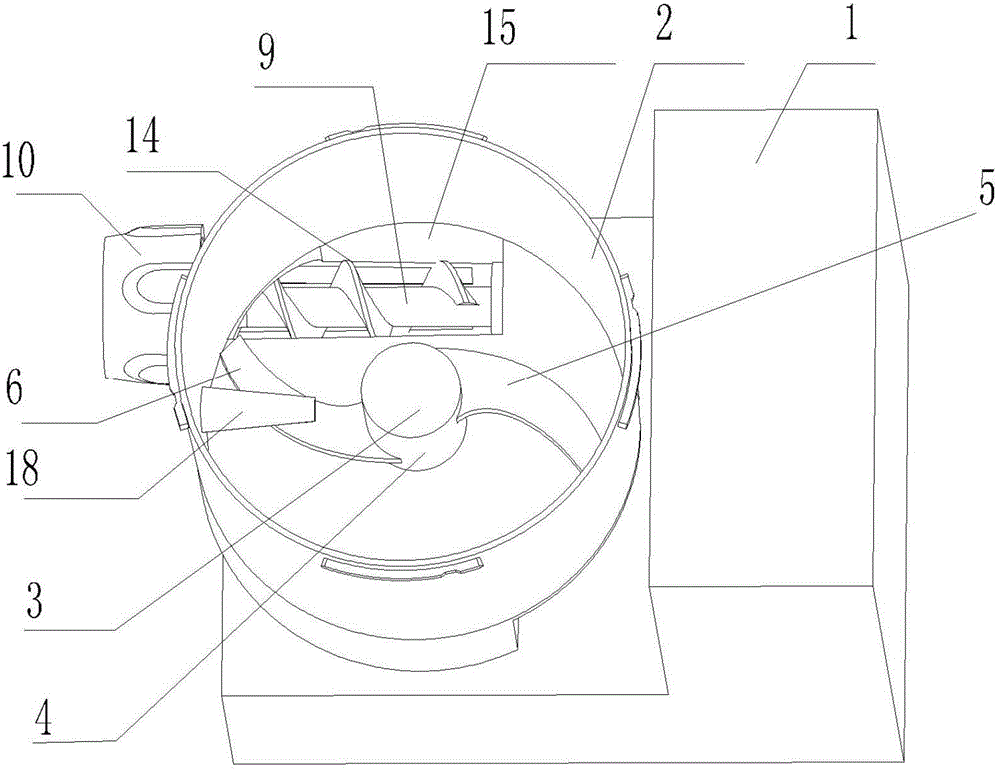

Hammer type dynamically and cyclically screening-crushing machine

The invention discloses a hammer type dynamically and cyclically screening-crushing machine, belonging to the field of material crushing equipment. The hammer type dynamically and cyclically screening-crushing machine comprises a rotatable hammer type rotor group, a feeding port, a discharging port, and a rotatable screening roller, wherein the inner wall of the screening roller is fixedly provided with a lifting plate used for pushing up a material; the hammer type rotor group is arranged in the screening roller along an axial direction; the feeding port communicates with the interior of thescreening roller; and the discharging port communicates with the outer wall of the screening roller. According to the invention, a material is dynamically and cyclically crushed in the screening roller and is discharged only when the granularity of the material is qualified, and cyclic crushing realizes crushing of the material multiple times, so high material crushing efficiency of machine is guaranteed; and a conveying speed can be artificially controlled, and material output and output granule distribution are also completely artificially controlled and are large in adjustment range. Compared with the prior art, the hammer type dynamically and cyclically screening-crushing machine of the invention has the advantages that discharge granularity is no longer determined by a gap between a hammer head and a sieve plate, so the problem that the hammer head and the sieve plate are prone to wearing and are frequently replaced is overcome.

Owner:成都万基电力设备制造有限公司

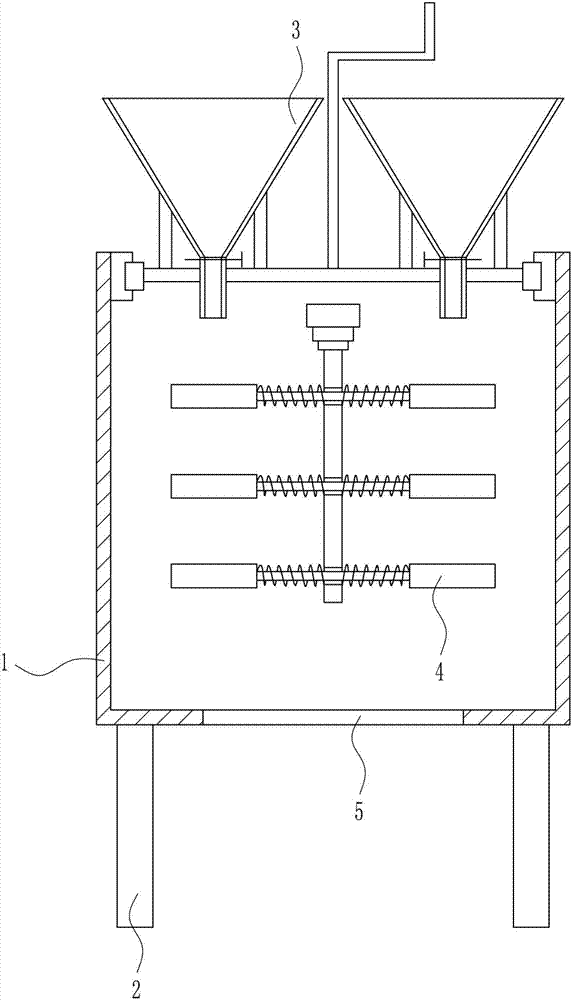

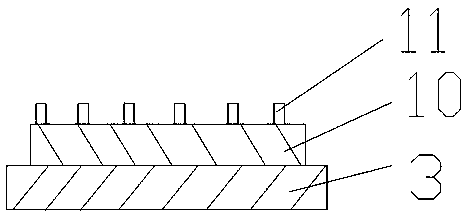

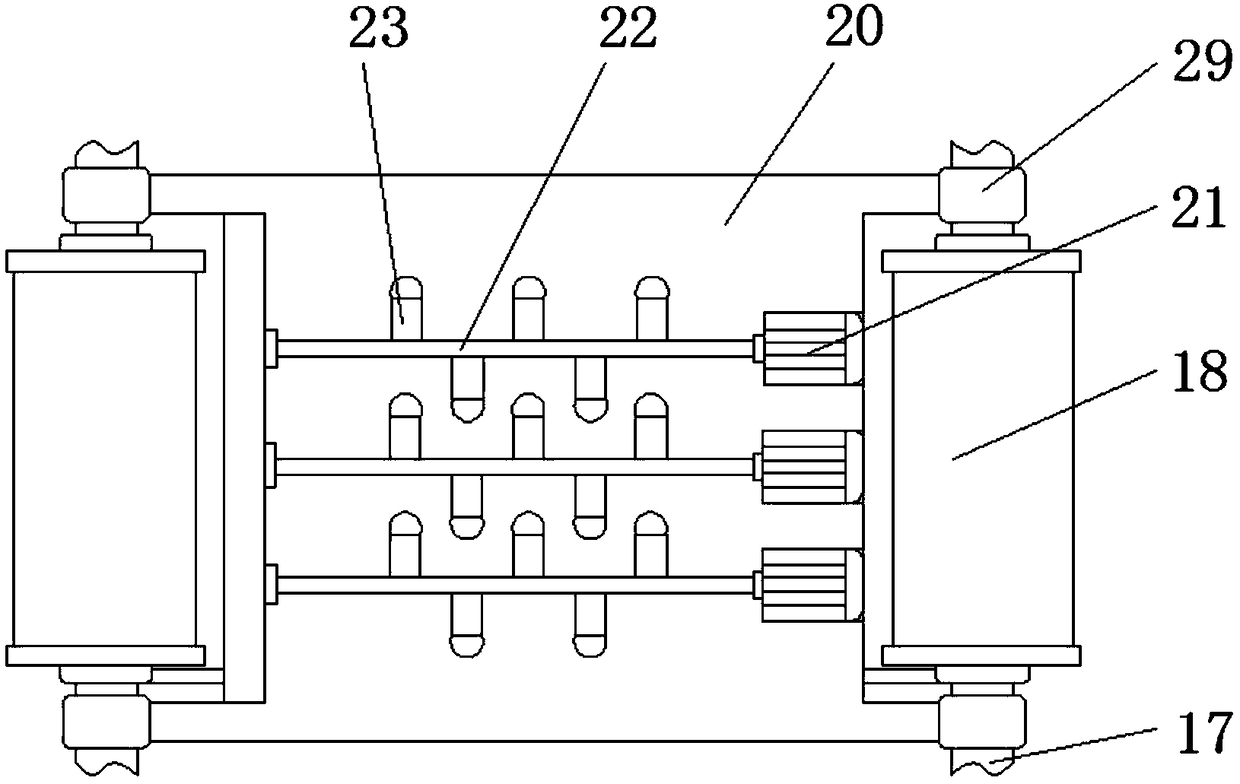

Fertilizer multi-stage crushing device for agriculture

InactiveCN107597262AConvenient whereaboutsFast fallGrain treatmentsAgricultural engineeringContinuous feeding

The invention discloses a fertilizer multi-stage crushing device for agriculture. The fertilizer multi-stage crushing device comprises a housing, a motor, a partition plate and a crushing hammer; thepartition plate is horizontally fixed at the middle part of the housing; an upright guide cylinder is fixedly arranged on the upper surface of the partition plate; a feed chute is formed between the guide cylinder and the housing; a circle of oblique material guide block is arranged at the bottom of the feed chute; a plurality of breaking edges are fixedly arranged at the lower surface of the crushing hammer; corresponding extrusion holes are formed in the part, under the breaking edges, of the partition plate; and two mutually extruded crushing rolls are arranged below the partition plate. Byadopting crank arms to drive a lifting plate and the crushing hammer to move up and down to strike the partition plate, a fertilizer on the partition plate is extruded and crushed, and the breaking edges can extrude the fertilizer out from the extrusion holes, so that continuous feeding and crushing of the fertilizer are realized; and the fertilizer crushed for the first time falls into the spacebetween the two crushing rolls and is crushed again, and the fertilizer is crushed for two times, so that the crushing efficiency is improved and the crushing uniformity is ensured.

Owner:蒋炳坤

Novel energy stone crushing device

The invention discloses a novel energy stone crushing device. A crushing box is arranged at the top of a device body, the two sides of the inner top end of the crushing box are provided with hammeringparts, a baffle is arranged at the bottoms of the hammering parts, springs are arranged at one end of the baffle, second electric push rods are hinged to the bottom of the baffle, a dust removal opening is formed in the right side of the middle of the interior of the crushing box, a dust removal box is arranged on the outer side of the dust removal opening, crushing plates are arranged on the twosides of the bottom of the interior of the crushing box, crushing rollers are arranged on the inner sides of the crushing plates, a supporting plate is arranged in the middle of the left side of thecrushing box, one side of the top of the support plate is provided with a mounting box, one side of the mounting box is provided with a first electric push rod, the top of the first electric push rodis provided with a solar cell panel, the bottom of the crushing box is provided with damping feet. According to the novel energy stone crushing device, the crushing box is elastically connected with the baffle through the springs, and the springs can play a certain damping and buffering role, so that the impact force on the baffle in the falling process of stone is reduced, the service life of thestone is prolonged, and the noise is also prevented from being generated.

Owner:TAIZHOU CHUANGXING ENVIRONMENTAL PROTECTION SCI & TECH

Fodder mixing device for livestock raising

The invention relates to a mixing device, in particular to a fodder mixing device for livestock raising and aims to provide a fodder mixing device for livestock raising. For solving the technical problem, the fodder mixing device for livestock raising comprises a fodder mixing box and the like. A fodder mixing box is arranged at the top of a first support, a first through hole is formed in the bottom of the fodder mixing box, a feeding device is arranged at the top of the fodder mixing box, and a stirring device is arranged in the fodder mixing box. The fodder mixing device achieves the effects of even mixing, higher mixing speed and convenient mixing. When a user needs to take out mixed fodders, and an air cylinder is started firstly, stretches to drive a first sliding block to move up.

Owner:谢陈钗

Vegetation-seedling cultivating device for gardens

ActiveCN108401863AConvenient whereaboutsSelf-acting watering devicesPressurised distribution of liquid fertiliserVegetationNutrient solution

The invention relates to a seedling cultivating device, in particular to a vegetation-seedling cultivating device for gardens. The technical aims that in the vegetation-seedling cultivating device forthe gardens, watering is even during seedling cultivating, water and other nutrient solutions are sprayed separately, and mutual pollution is avoided are achieved. The vegetation-seedling cultivatingdevice for the gardens comprises a bottom plate, a left support, a water tank, a supporting frame, a hollow pipe, first spraying heads, a water pump, a first hardness pipe, a flexible pipe, a transparent plate, a water feeding pipe, a valve, a first bearing base and the like; the left support, the water tank and the supporting frame are sequentially arranged on the bottom plate from left to right, the hollow pipe is arranged at the upper end of the left support, and the first spraying heads are evenly arranged on the inner side of the hollow pipe. According to the vegetation-seedling cultivating device for the gardens, the effects that watering is even during seedling cultivating, water and other nutrient solutions are sprayed separately, and mutual pollution is avoided are achieved, a containing plate rotates to drive cultivating pots on the containing plate to rotate.

Owner:苏州市北雪泾农业开发有限公司

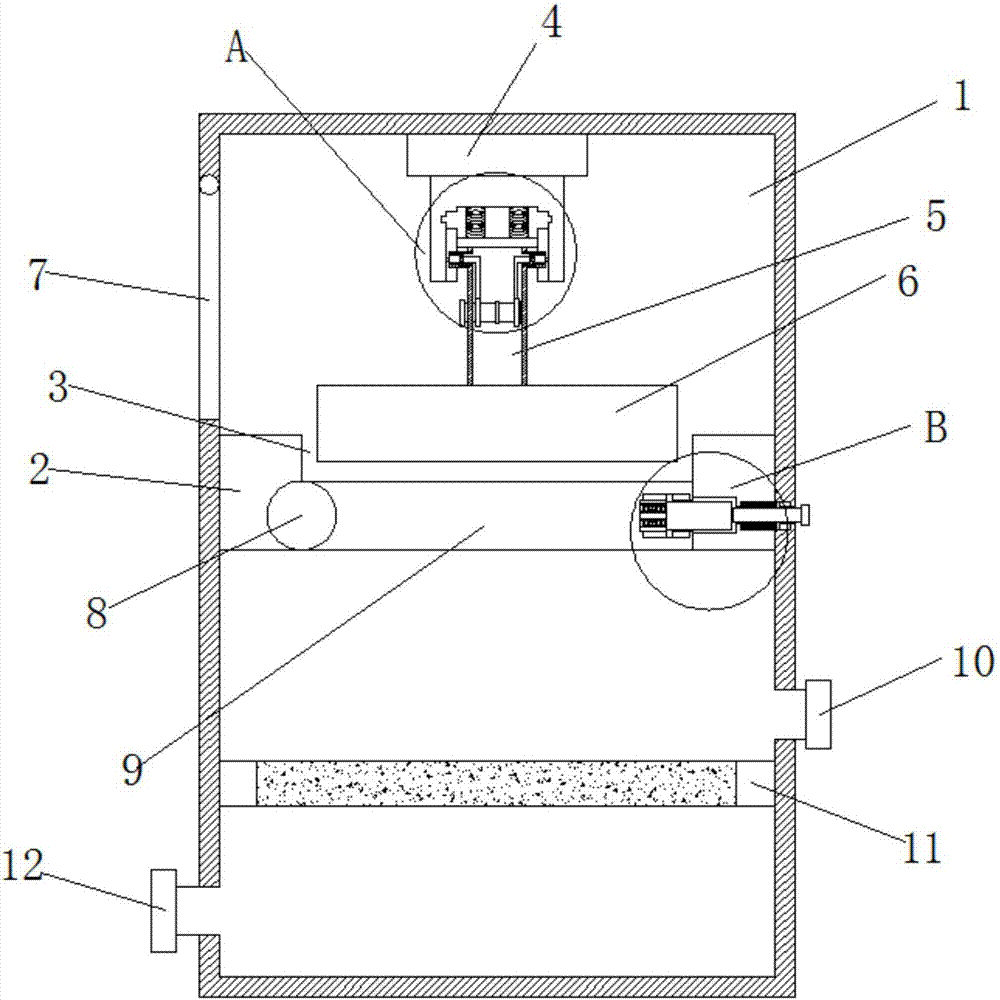

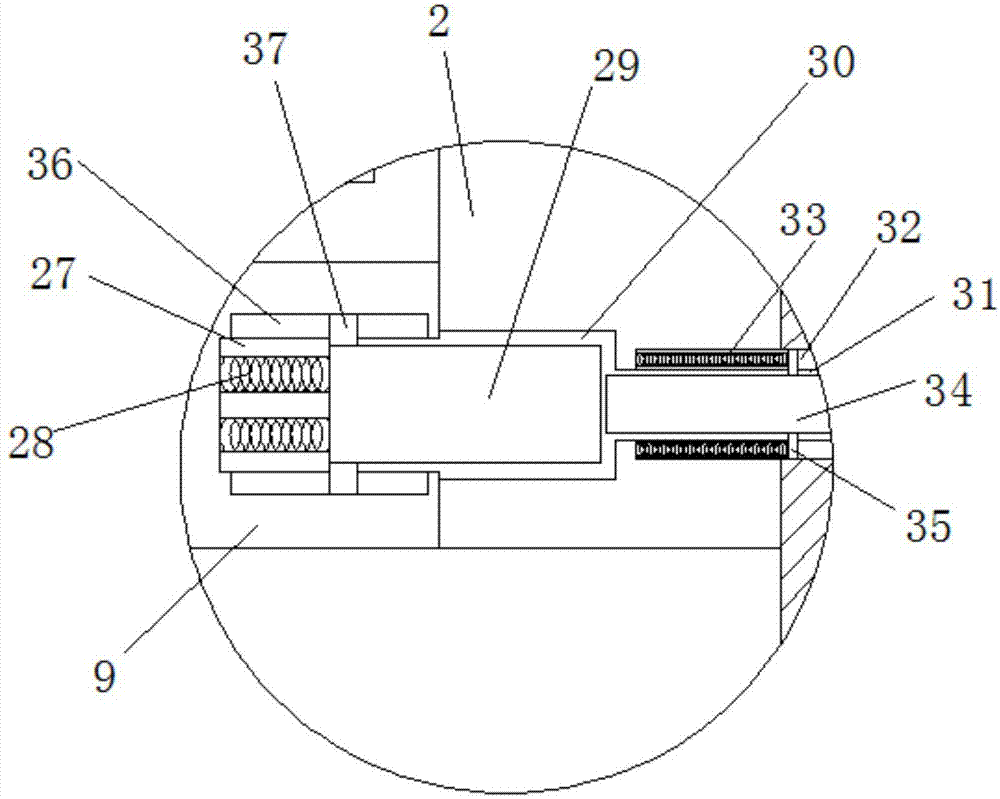

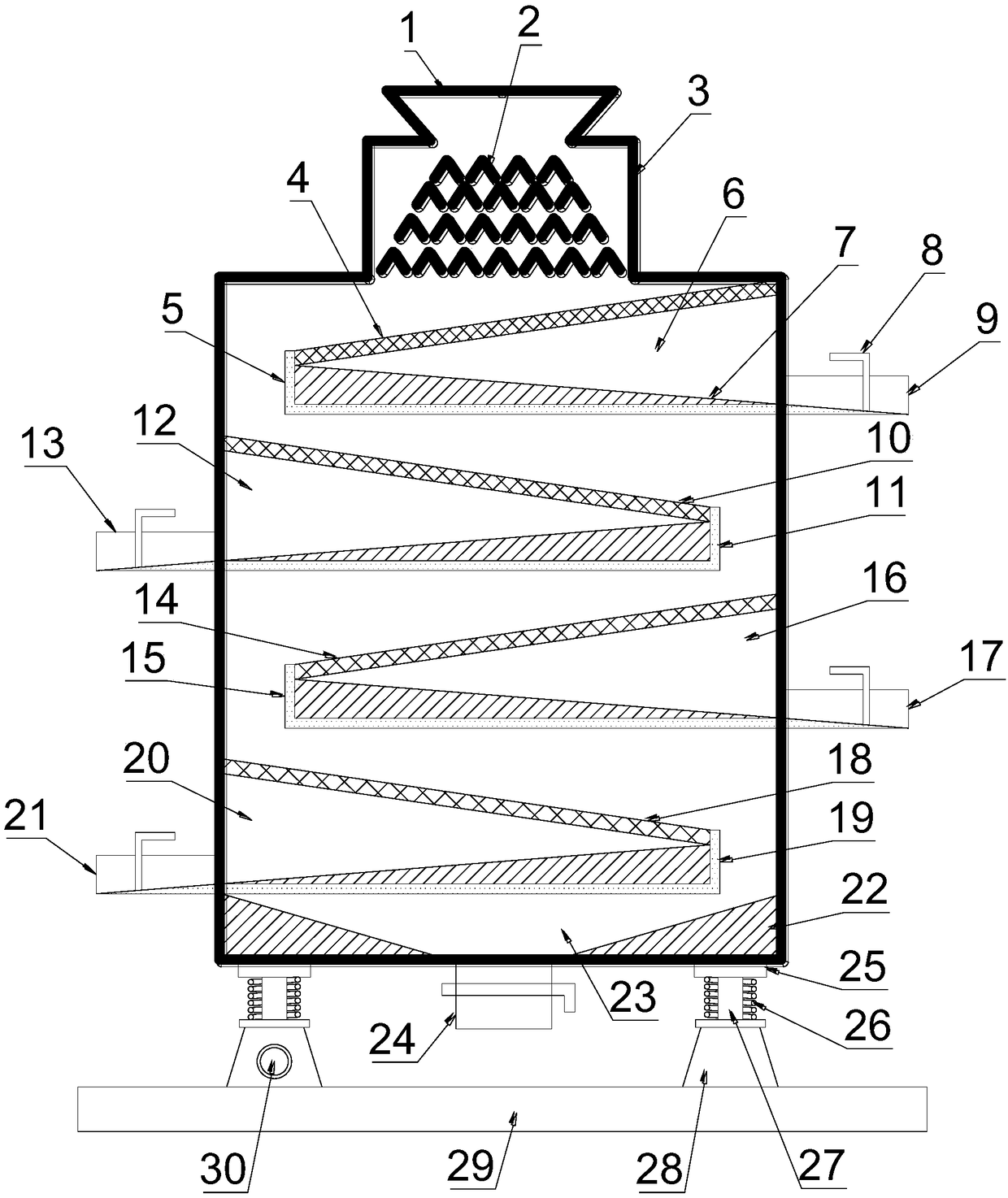

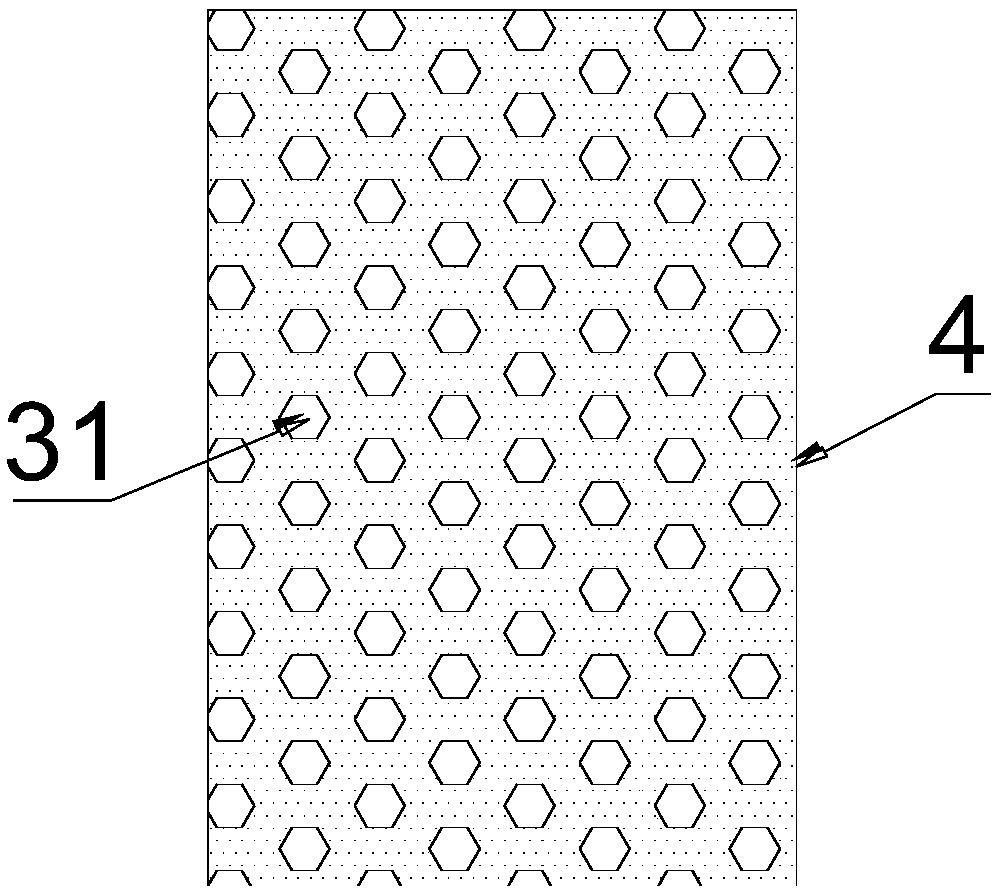

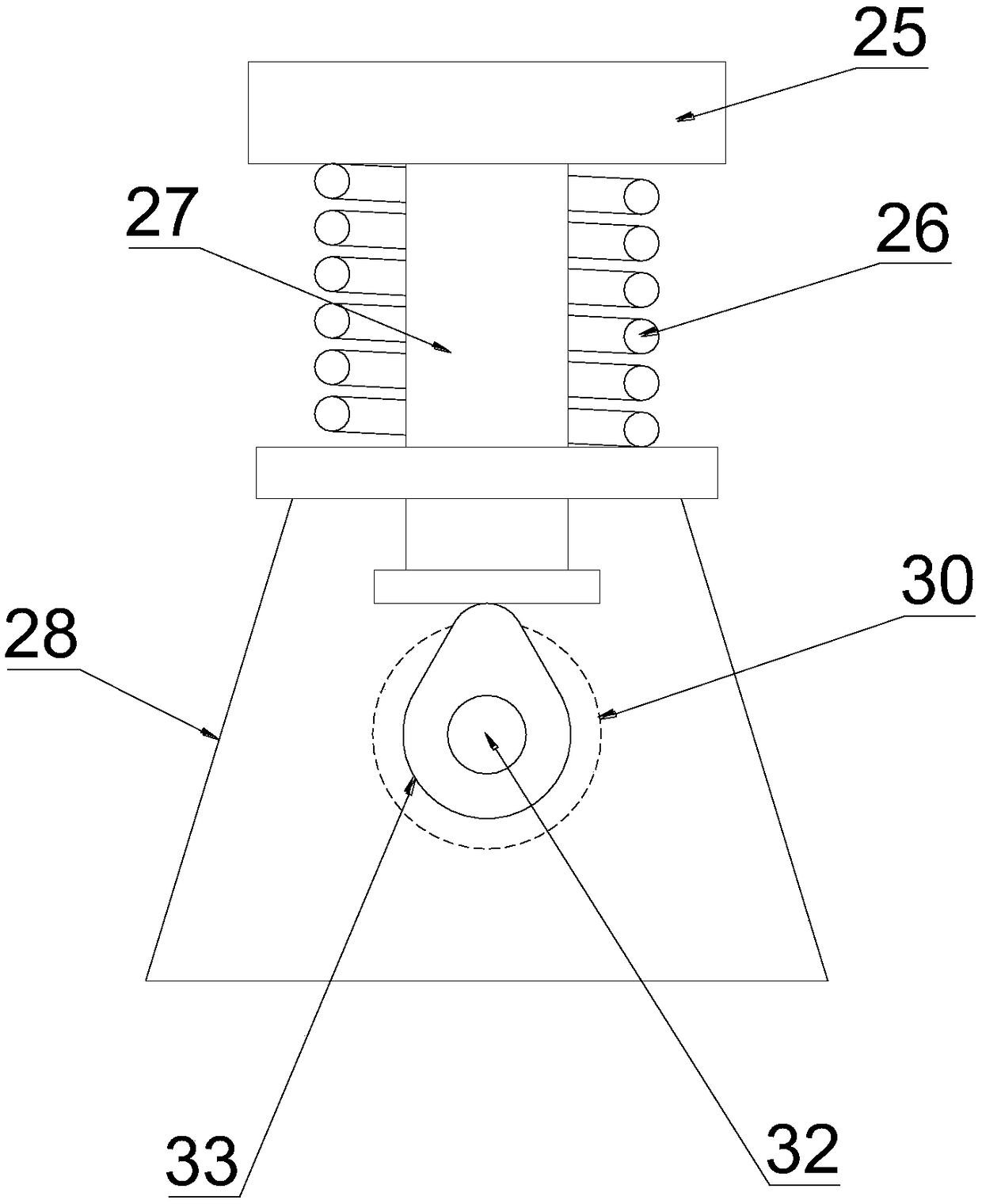

Grinding equipment special for bio-pharmaceuticals

ActiveCN109261282AConvenient whereaboutsAffect the feed workCocoaGrain treatmentsAir heaterEngineering

The invention discloses grinding equipment special for bio-pharmaceuticals. The grinding equipment comprises a box body, a grinding device and a base, wherein the grinding device is arranged in the box body, and the base is arranged at the bottom of the box body; one side of the box body is provided with a feed port; a material guiding pipe communicated with the box body is arranged at the bottomof the feed port; a sealing valve is arranged on the material guiding pipe; an air heater is arranged below the feed port and is fixedly connected to the side wall of the box body; the side wall of the box body is provided with a discharge port; a vibration assembly is arranged in the feed port; and a feeding assembly is arranged in the material guiding pipe. According to the grinding equipment, after materials enter the feed port, under the combined action of the vibration assembly and the feeding assembly, the materials entering the feed port can be better fall from the feed port, so that the phenomenon that the feeding work of the materials is influenced due to the fact that the materials block the feed port can be avoided, and the processing efficiency of the equipment on the materialsis improved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Recovery processing device for producing polyether polyol and using method

InactiveCN109107477AEasy to filterConvenient whereaboutsTransportation and packagingRotary stirring mixersDouble-timePolyol

The invention discloses a recovery processing device for producing polyether polyol, and belongs to the technical field of the polyether polyol production. The recovery processing device comprises a material storage tank. The top of the material storage tank is uniformly provided with a fixing block. The top of the fixing block is provided with a stirring box. Middle positions of the stirring boxand the material storage tank are provided with a through pipe. The outer wall of the front side of the through pipe is provided with a control valve. The left side of the top of the stirring box is provided with a feeding port. The outer wall of the right side of the stirring box is provided with an outer protective housing. A cavity of the outer protective housing is provided with a servo motor.The output end of the servo motor is connected with a stirring shaft. The outer wall of the stirring shaft is uniformly provided with a stirring rod. Double times of grinding is performed on the solid polyether polyol, so the solid polyether polyol can be more uniformly ground, and the ground polyether polyol is sieved, so falling of a material is convenient. A material storage box can be individually taken out from the material storage tank, so the material can be adequately mixed with a catalyst, and a finished product is conveniently taken out.

Owner:JIANGSU GUOJIAO CHEM TECH

Efficient milling device for coix seeds

The invention discloses an efficient milling device for coix seeds. The efficient milling device for the coix seeds comprises a shell. The shell is of a hollow structure. A fixed plate is transversely arranged in the shell. The upper side wall of the fixed plate is provided with a milling groove with an upward opening. A drive motor provided with a downward output shaft is arranged on the inner wall of the upper side of the shell. The output shaft of the drive motor is connected with a millstone through a first connection rod, wherein the millstone is matched with the milling groove. The bottom of the milling groove is further provided with a discharging opening. The discharging opening is rotationally connected with a baffle through a rotating piece. A filtering device is arranged in the shell. The filtering device is located below a fixed plate. The side wall of the shell is further provided with a material inlet, a first material outlet and a second material outlet, wherein the material inlet, the first material outlet and the second material outlet communicate with the inner portion of the shell. By the adoption of the efficient milling device for the coix seeds, the damaged millstone can be conveniently and rapidly replaced, the milling efficiency can be guaranteed, and the milling quality can also be guaranteed; and meanwhile, under the action of the filtering device, coix seed powder not fully milled can be milled again, and therefore the milling quality is guaranteed.

Owner:GUIZHOU HUATENG AGRI TECH CO LTD

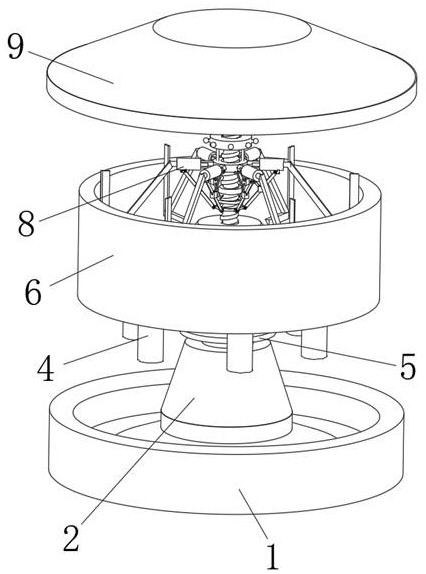

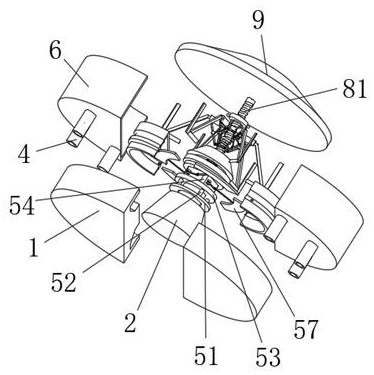

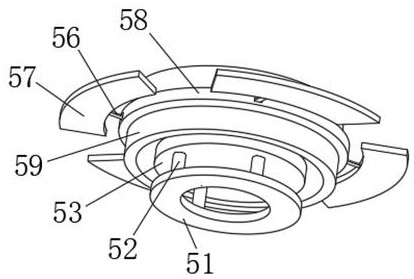

Atomization chamber for preparing firework aluminum powder

The invention provides an atomization chamber for preparing firework aluminum powder. The atomization chamber comprises an atomization chamber body, a flow guide tube and an ultrasonic atomizer, wherein the flow guide tube is arranged at the top of the atomization chamber body, the ultrasonic atomizer is arranged at the lower end of the flow guide tube, and the atomization chamber is characterizedin that a rotary atomizing disc is arranged on the ultrasonic atomizer. According to the scheme, the condensation problem of the molten metal on the atomizing disc is effectively solved, the metal atomization effect and the multiple atomization effect are effectively improved, the effect and the quality of metal powder processing and producing are further improved, and the batch production of thefirework aluminum powder is facilitated.

Owner:衡东县金源铝银粉有限公司

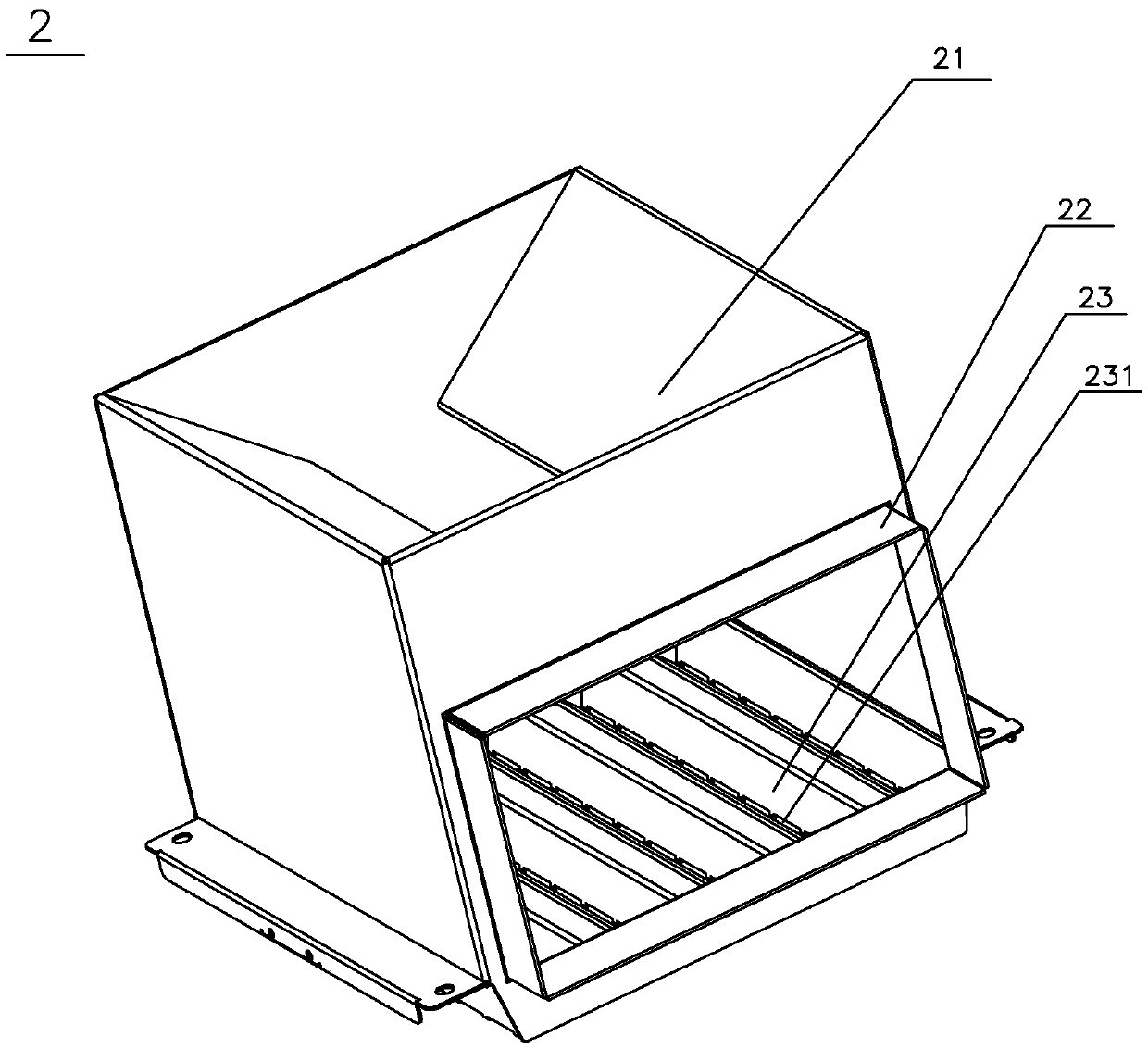

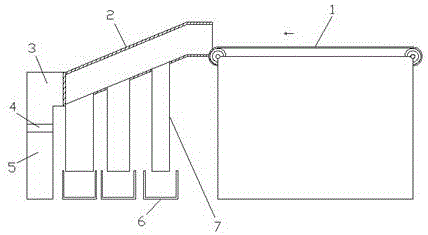

Multi-purpose maze channel seed screening device

The invention discloses a multi-purpose maze channel seed screening device, and belongs to the technical field of agriculture. The multi-purpose maze channel seed screening device solves the problem that seed screening of an existing seed screening device is insufficient. According to the technical scheme, the multi-purpose maze channel seed screening device comprises a vibration mechanism, a seedscreening box, a multistage seed screening mechanism, and maze channels. A maze distributing machine is arranged in the seed screening box below a seed feeding port, and therefore seeds falling fromthe seed feeding port can be dispersed and uniformly distributed and fall, and the seeds are prevented from gathering together and influencing subsequent seed screening operation; in addition, the multistage seed screening mechanism is mounted in the seed screening box, and therefore maze channels distributed in an S shape and communicating in a top and bottom mode are formed in the seed screeningbox, the falling distance of the seeds in the maze channels is increased, and full screening of the seeds is facilitated; the size of screening holes increases step by step, so that withered seeds are screened step by step, and full seeds fall onto the bottom of the seed screening box along the maze channels; and the seed screening box vibrate up and down under driving of the vibration mechanism,and therefore screening, falling and discharging of the seeds in the box can be facilitated.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

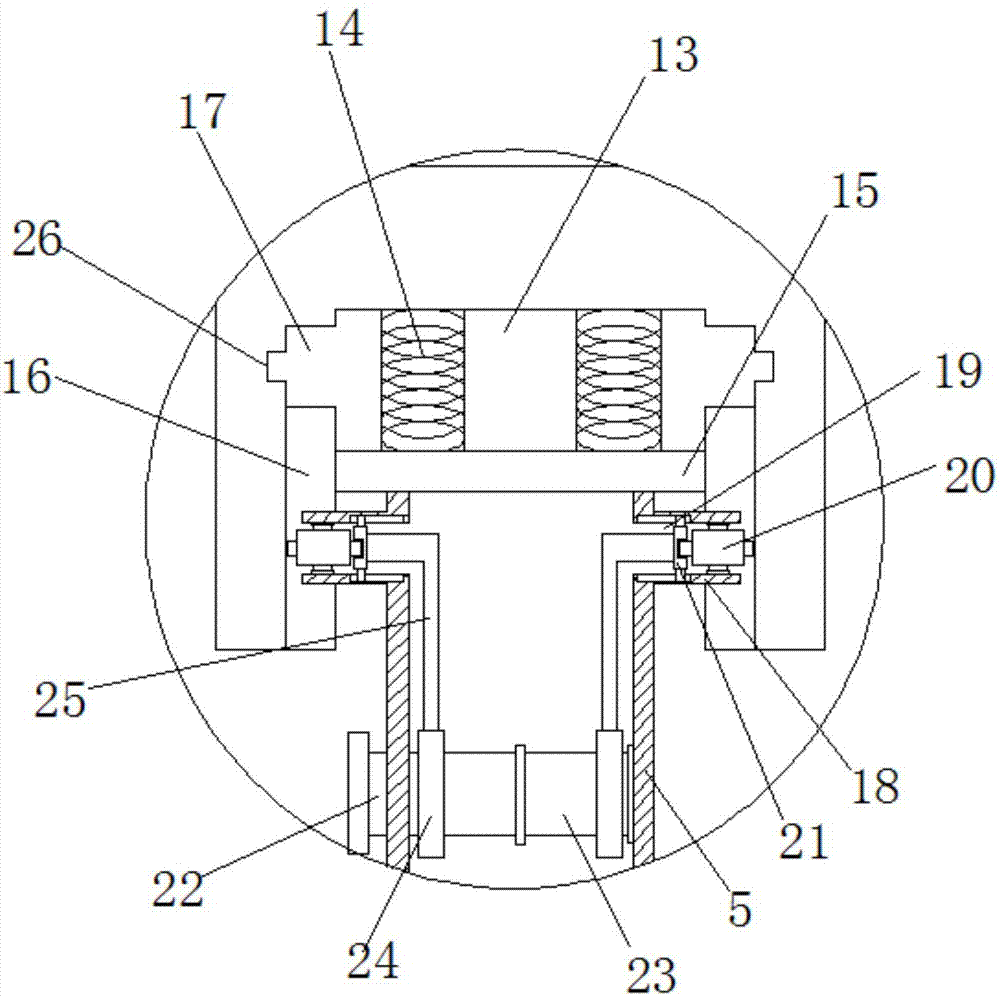

Dynamic anti-blockage pre-treatment dehydration device for kitchen waste

ActiveCN105665424AEasy to separateImprove separation efficiencySolid waste disposalGrain treatmentsDraining tubeOil water

The invention discloses a dynamic anti-blockage pre-treatment dehydration device for kitchen waste. The dynamic anti-blockage pre-treatment dehydration device for the kitchen waste comprises a machine frame. A material storage dehydration mechanism is installed on the machine frame and comprises a material storage hopper, a transmission shaft rod, a water drainage shifting motor, a shifting rod, a water drainage disc and a water drainage pipe. The transmission shaft rod is transversely installed in the material storage hopper and driven by the water drainage shifting motor to rotate so that the shifting rod and the water drainage disc can be driven to rotate. The water drainage disc is arranged on the transmission shaft rod, the water drainage disc is sleeved with a water inlet pipe wall of the water drainage pipe, and a water drainage gap is reserved between the water drainage disc and the water inlet pipe wall and used for draining out liquid oil and water in the kitchen waste. A first scraper piece is further arranged outside the water drainage disc, rotates along with the water drainage disc and is used for scraping off the kitchen waste blocked in the water drainage gap. The dynamic anti-blockage pre-treatment dehydration device for the kitchen waste can continuously and dynamically scrape off the fine kitchen waste prone to be blocked in the water drainage gap, the effect that the water drainage gap is unobstructed continuously and not blocked is guaranteed, the effect of separating solid materials from the liquid oil and water in the kitchen waste is good, and the separating efficiency is quite high.

Owner:DONGGUAN TOK ENVIRONMENTAL PROTECTION TECH CO LTD

No-residual vertical type household noodle maker

ActiveCN104542787AImprove efficiencySmooth entryMixing/kneading with vertically-mounted toolsDough extruding machinesExtrusionPulp and paper industry

The invention discloses a no-residual vertical type household noodle maker which comprises a motor base, a motor arranged in the motor base, a stirring cup arranged above the motor base, a stirring rod and a dough extruding cylinder arranged in the stirring cup, a screw rod arranged in the dough extruding cylinder and a die head arranged on the end part of the dough extruding cylinder, wherein the dough extruding cylinder is horizontally arranged on one side below the stirring cup and consists of a material advancing cavity and an extrusion cavity, the motor drives the screw rod and the stirring rod to move, wherein a dough inlet communicated with the dough extruding cylinder is formed in the position of the bottom of the stirring cup, far away from the center, the material advancing cavity extends upwards and is intersected with the bottom of the stirring cup to form the dough inlet, and the dough inlet horizontally extends to the direction of the dough extruding cylinder along the bottom of the stirring cup, and extends to the side wall of the stirring cup. By adopting the technical scheme, the area of the dough inlet is largest, so that dough feeding is facilitated, residuals of dough in the stirring cavity can be avoided, and the stirring cavity and the stirring rod are conveniently cleaned.

Owner:JOYOUNG CO LTD

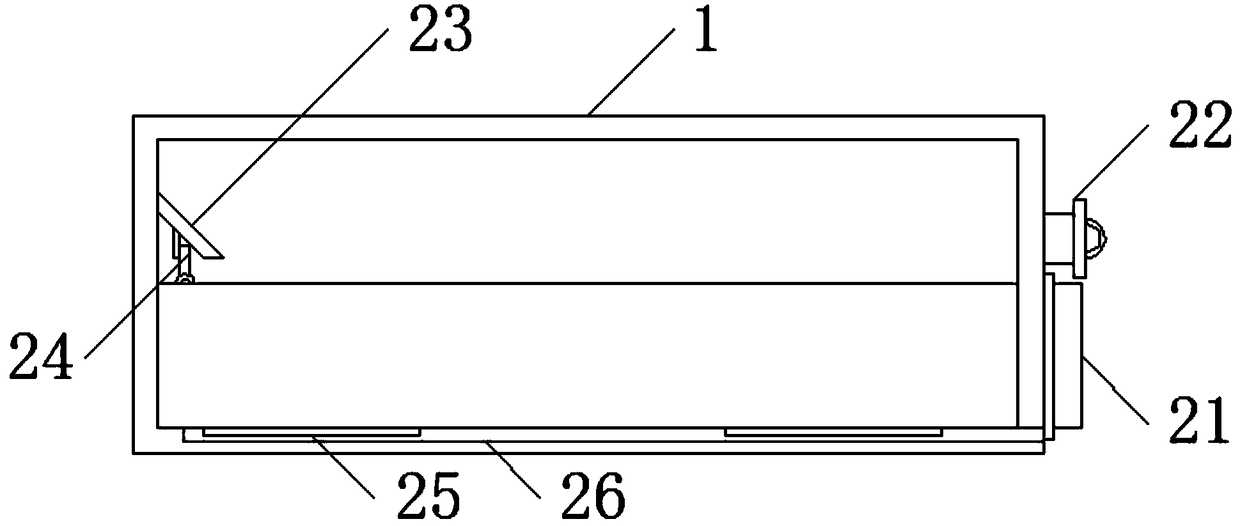

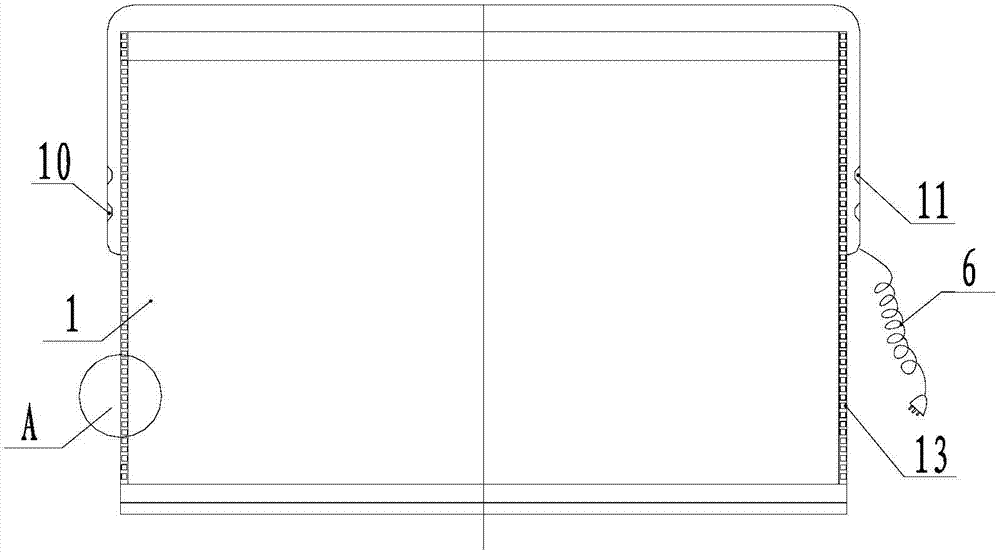

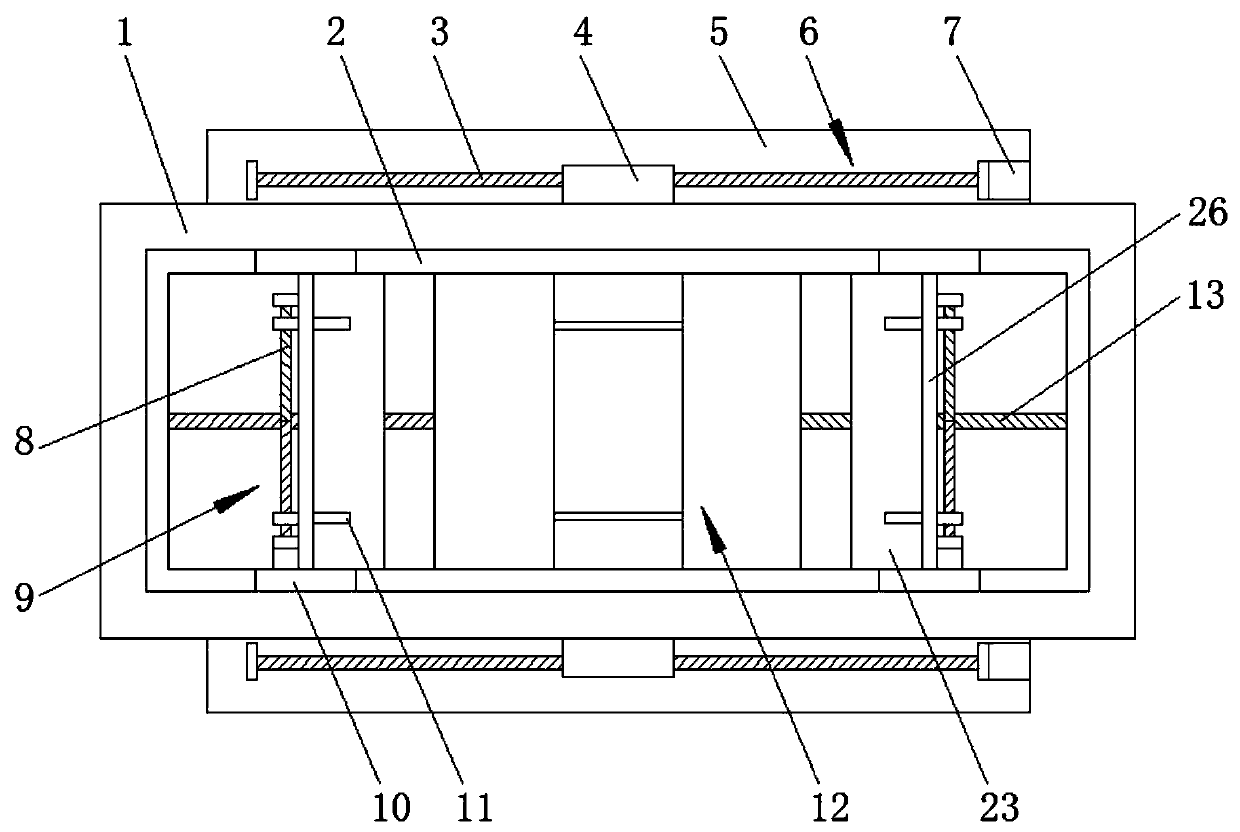

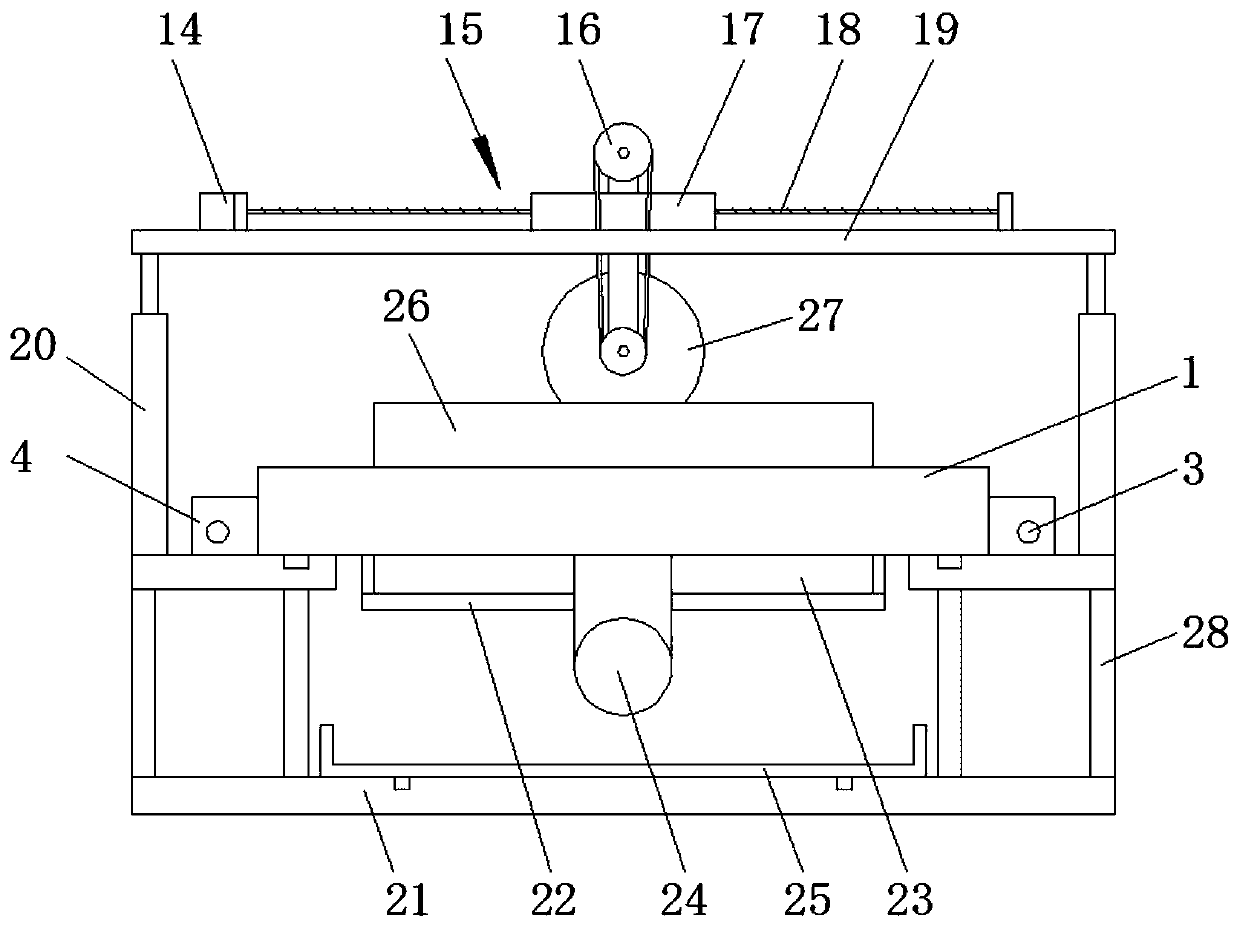

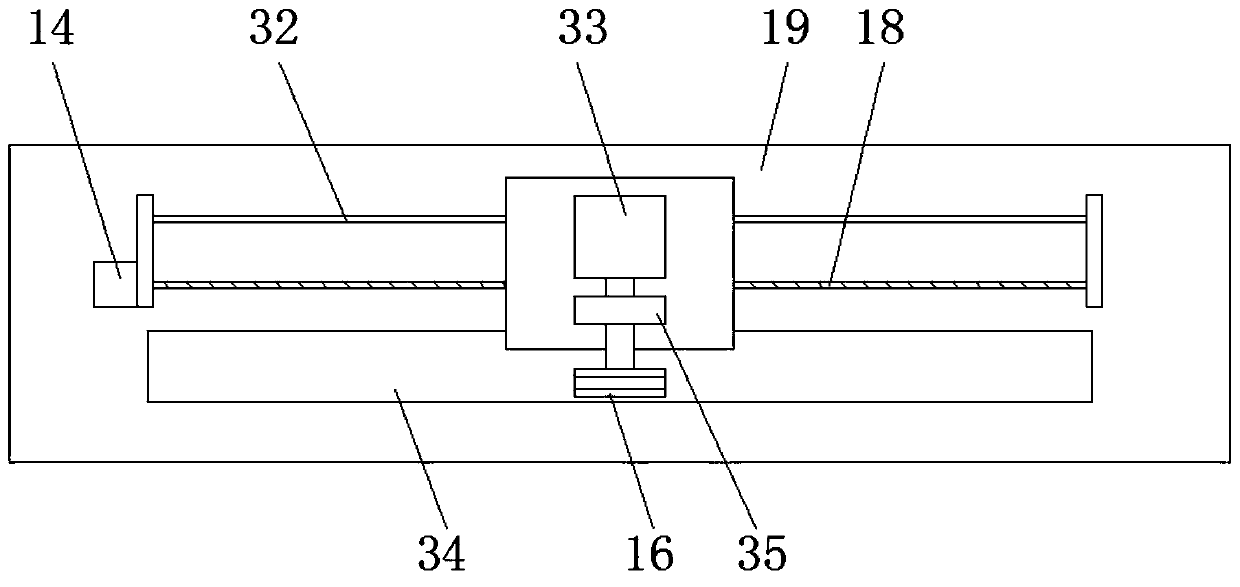

Electric blackboard

InactiveCN103496269ARealize automatic wiping functionGuaranteed wiping effectBoard cleaning devicesWriting boardsElectric machineryEngineering

An electric black board includes a blackboard face, a lining plate, an upper blackboard reel, a lower blackboard reel, a motor, a control switch I, blackboard eraser devices and chalk dust catching grooves, wherein the lining plate is arranged in the middle of the blackboard face, the upper blackboard reel and the lower blackboard reel are used for reeling the blackboard face to rotate, and the motor is used for driving the upper blackboard reel and the lower blackboard reel to rotate; the two ends of one of the upper blackboard reel and the lower blackboard reel are fixedly provided with gears, and the two sides of the blackboard face are provided with bayonets matched with the gears.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cutting device for electrical equipment production and cutting method

InactiveCN110153489AReasonable structural designConvenient whereaboutsShearing machinesShearing machine accessoriesEngineeringElectrical equipment

The invention discloses a cutting device for electrical equipment production. The cutting device comprises a movable framework, a longitudinal clamping assembly, a transverse clamping assembly, a workpiece moving assembly, a pre-bearing table, a movable cutting assembly and a top beam, wherein the longitudinal clamping assembly and the transverse clamping assembly are arranged at the interior of the movable framework, the transverse clamping assembly comprises two transverse clamping plates which are synchronously and reversely moved in sliding grooves, a longitudinal clamping assembly is arranged on each of the two transverse clamping plates, ech longitudinal clamping assembly comprises two longitudinal clamping plates which are synchronously and reversely moved, the pre-bearing table isfixed on the bottom end surface of the movable framework between the two transverse clamping plates through a side plate, the pre-bearing table comprises a pre-bearing plate and a limiting strip, andlifting plates used for lifting a to-be-cut workpiece on the pre-bearing plate are fixed at the bottom ends of the opposite side surfaces of the two transverse clamping plates. The cutting device forthe electrical equipment production has the advantages of being reasonable in structural design, practical, reliable and the like, and can be widely popularized and used.

Owner:QINGDAO HUANGHAI UNIV

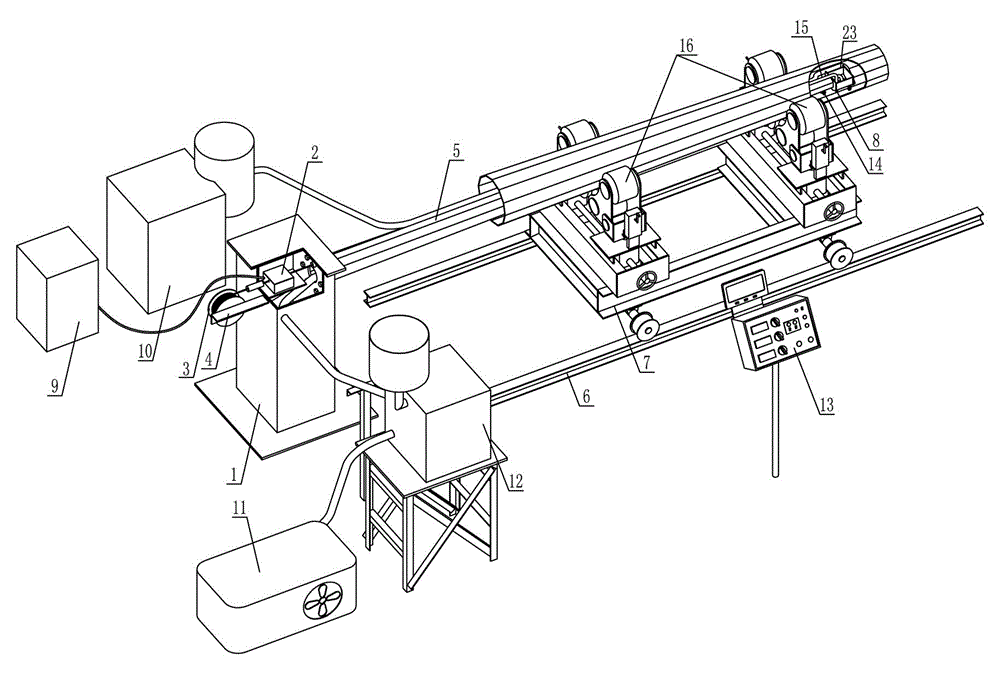

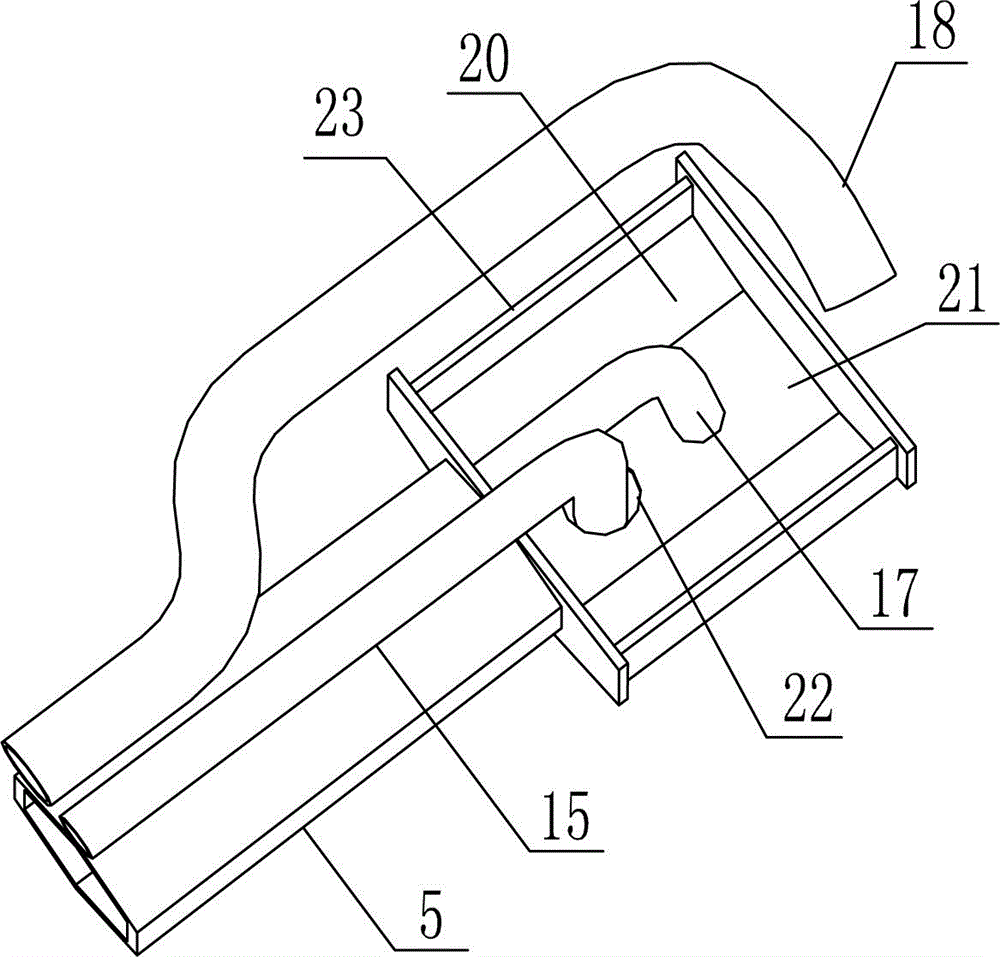

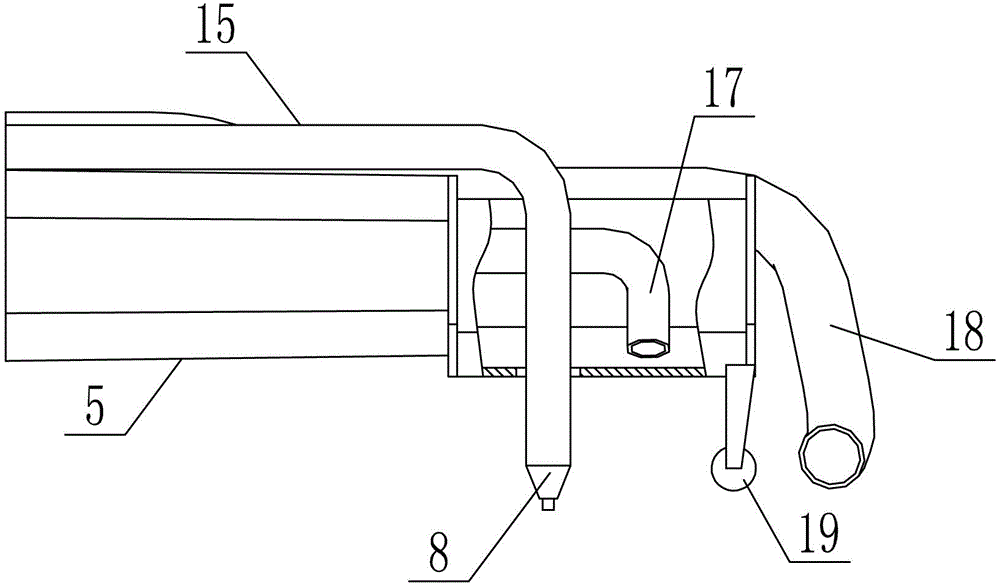

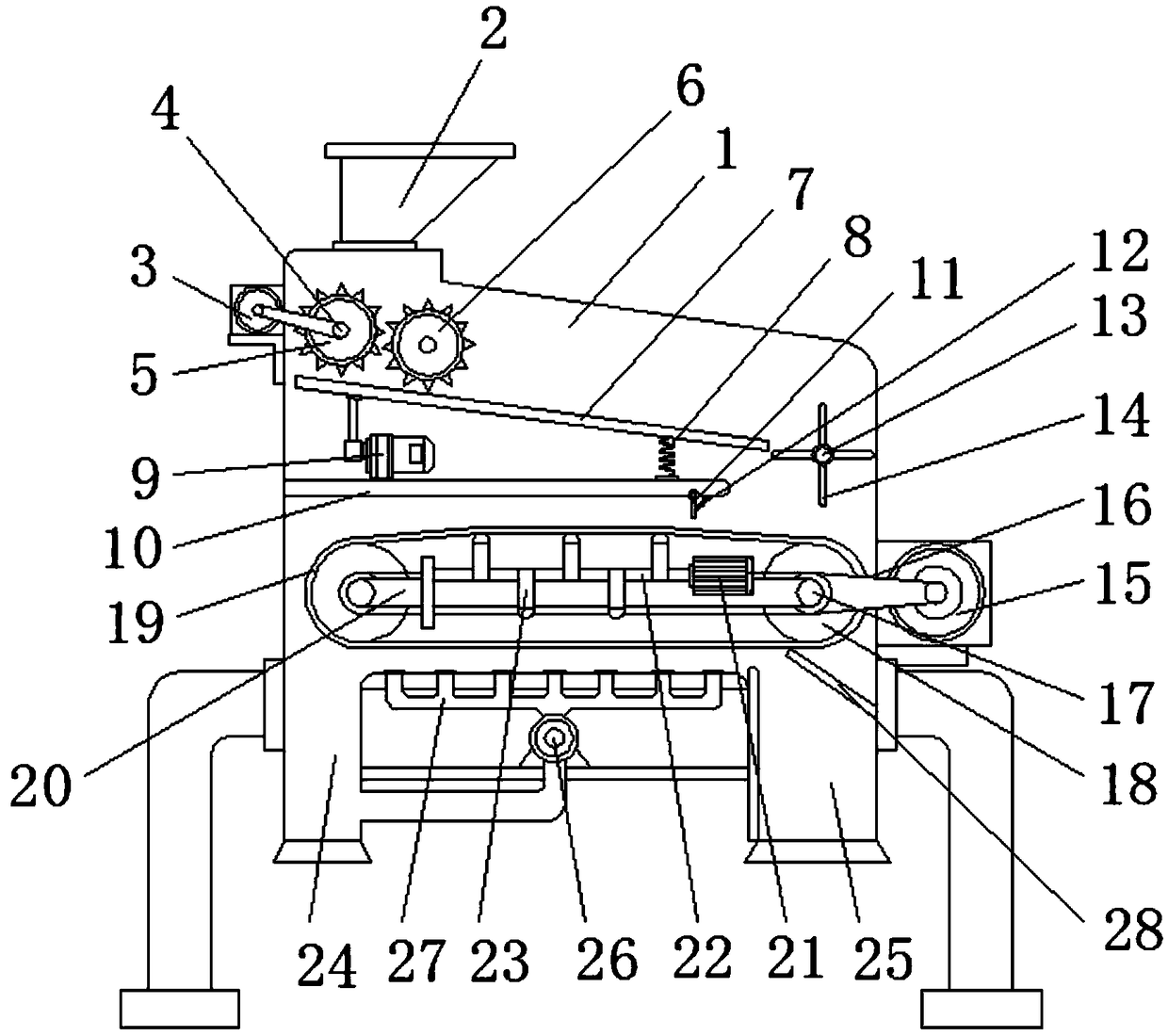

Automatic submerged arc welding device for longitudinal seams in steel tubes

InactiveCN104400198AIncrease stiffnessAvoid accumulationElectrode supporting devicesMetal working apparatusSteel tubeSubmerged arc welding

The invention relates to an automatic submerged arc welding device for longitudinal seams in steel tubes. The device comprises a machine head, an automatic wire feeder, a support arm, a running gear, a welding gun, a wire reel support, an air compressor, a flux conveyer, a welder, a flux recycling machine and a control box, wherein the automatic wire feeder is fixedly arranged in the machine head; the wire reel support is arranged on one side of the outside of the machine head; one end part of the support arm is fixedly arranged on the other side of the machine head; the other end part of the support arm is fixedly provided with a support wheel frame; the welding gun is arranged in the support wheel frame; the welder, the air compressor, the flux conveyer and the flux recycling machine are adjacent to the machine head respectively; the welder is connected with the welding gun through a wire; the flux conveyer is connected with the air compressor through a communicating tube; the control box is arranged on the outer side of the running gear. The automatic submerged arc welding device is simple in structure and convenient to operate, time and labor are saved, the labor intensity is reduced, a welding operator is not required to enter a steel tube to implement other welding methods, harmful gas is prevented from harming the operator, and the welding quality of welding lines is improved.

Owner:河北省景县宏远通讯有限公司

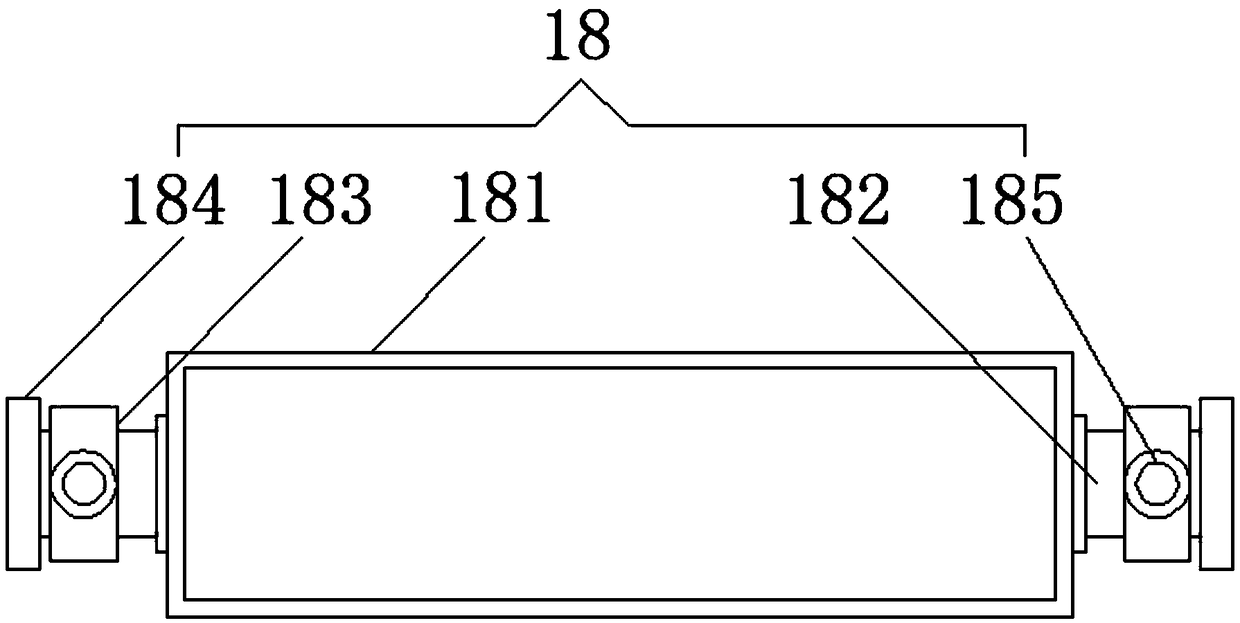

Vibration belt type magnetic extractor

InactiveCN108620232AGood removal effectQuality improvementCleaning using toolsMagnetic separationIron powderEngineering

The invention discloses a vibration belt type magnetic extractor, which comprises a box body, a material charging plate and a second motor, wherein a feeding opening is formed in the left side above the box body; a first motor is arranged at the upper part of the left side of the box body; in addition, a first connecting shaft is arranged at the right side of the first motor; a connecting frame isconnected onto the surface of a third connecting shaft; fixing sleeves are arranged at the left and right ends of the connecting frame; a bearing is arranged inside each fixing sleeve; a third motoris arranged inside the connecting frame; one end of the third motor is connected with a rotating shaft; in addition, a beating rod is arranged on the surface of the rotating shaft; a first material discharging opening is formed in the left side of the box body; a second material discharging opening is formed in the right side of the box body; in addition, a stone scraping plate is fixedly arrangedabove the second material discharging opening; a fan is arranged in the middle part under the box body; the tail end of the stone scraping plate is provided with a stone scraping part. The vibrationbelt type magnetic extractor can be used for sorting the screened ores; further iron powder in ore powder can be conveniently eliminated; the quality of the ore powder is improved.

Owner:会理市财通铁钛有限责任公司

Salt spreading device

InactiveCN105851201AAvoid cakingConvenient whereaboutsClimate change adaptationMeat/fish preservation using solidsEngineeringConveyor belt

The invention relates to a salt spreading device which comprises a salt hopper and a conveyor belt. The conveyor belt is arranged below the salt hopper, and a salt spreading roller is arranged between the salt hopper and the conveyor belt and provided with a vibrating device; the outer wall of the salt hopper is provided with a heating layer; a stirring device is arranged in the salt hopper and comprises a motor, a stirring shaft and stirring paddles, the stirring shaft is connected with the motor, the stirring paddles are fixed to the stirring shaft, and helical stirring paddles are adopted as the stirring paddles. According to the salt spreading device, the heating layer and the stirring device are arranged on the outer side of the salt hopper, salt in the salt hopper is prevented from being agglomerated through heating, stirring of the stirring device is beneficial for the salt to be uniform and keep loose, and then the salt can conveniently fall; meanwhile, the vibrating device is arranged on the salt spreading roller, the salt on the salt spreading roller falls through vibration of the vibrating device, and then the salt is prevented from being stuck to the salt spreading roller.

Owner:任大勇

Vibrating rapid screening device

The invention discloses a vibrating rapid screening device. The vibrating rapid screening device comprises a square drum, a vibration generator, a base and a buffer device, wherein the buffer device is arranged on the base; the vibration generator is arranged on the buffer device; the bottom end of the square drum is connected with the vibration generator, and the top end of the square drum extends upwards obliquely; the bottom of the square drum is sequentially provided with a plurality of guide pipes which point downwards from top down; the inner diameters of the guide pipes from top down are sequentially increased; screening holes corresponding to the inner diameters of the guide pipes are formed in the bottom of the square drum; and the bottom of each guide pipe is provided with a guide slide chute. Through the above mode, the vibrating rapid screening device has the advantages that products are sequentially conveyed into the square drum through a conveyer belt, slide down along the slope of the square drum and sequentially pass through the screening holes; the diameters of the screening holes are sequentially increased, so that falling of the products of corresponding sizes is facilitated; and besides, the products and the square drum vibrate together due to the vibration generator, so that the condition that the products stop at the screening holes and block the screening holes is avoided.

Owner:苏州立源信智能科技有限公司

Animal husbandry feed mixing and releasing device with inner wall cleaning structure

InactiveCN111887169AConvenient whereaboutsAvoid affecting the feed rateTransportation and packagingRotary stirring mixersAnimal scienceAgricultural science

The invention relates to the technical field of feed releasing devices, in particular to an animal husbandry feed mixing and feeding device with an inner wall cleaning structure. The animal husbandryfeed mixing and feeding device comprises a trough, wherein the center of the top end of the trough is fixedly connected with a connecting sat, a support column is inserted in the top end of the connecting seat, a quantity limiting mechanism is fixedly mounted at the top end of the support column, and the quantity limiting mechanism comprises two groups of fixing rings. The animal husbandry feed mixing and feeding device is provided with an adjusting mechanism, after raw materials of feed are mixed and released into a feed storage bin, a second connecting rod is rotated, a threaded knob moves during rotation, meanwhile, the threaded knob pushes an inner shaft to move through the second connecting rod, the inner shaft drives an outer shaft to move during movement to enable a connecting shaftto push a connecting plate to move, so that a push plate makes contact with the inner wall of the bottom end of the feed storage bin, then, a motor is started to drive the threaded shaft to rotate tomix multiple feeds, meanwhile, the push plate pushes the feed, so that the feeds can drop from a discharging pipe.

Owner:林凌

Solid waste treating and crushing device

The invention relates to the field of environmental protection and particularly discloses a solid waste treating and crushing device. The solid waste treating and crushing device comprises a shell, acrushing motor, a feeding opening, a collecting tank, wherein vertical rollers are coaxially and fixedly mounted on a transmission shaft; crushing cylinders are arranged on the outer sides of the crushing rollers and are matched with the crushing rollers; the crushing rollers comprise a first crushing roller and a second crushing roller which are coaxially and integrally arranged; the crushing cylinders comprise a first crushing cylinder and a second crushing cylinder; the first crushing cylinder and the second crushing cylinder are respectively and correspondingly matched with the first crushing roller and the second crushing roller; the distance between the first crushing cylinder and the first crushing roller is gradually reduced from top to bottom; and the collecting tank is arranged under a sieving net. According to the solid waste treating and crushing device, two crushing rollers and the crushing cylinders matched with the crushing rollers are arranged, so that the raw materialcrushing gap is gradually reduced from top to bottom; the raw materials are broken from large to small; the solid wastes are rapidly discharged; the increase of the motor load can also be avoided; andthe solid wastes can be safely and stably crushed.

Owner:ZIBO CREATION OF MECHANICAL & ELECTRICAL TECH CO LTD

Garbage cracking furnace system

InactiveCN105757676AOutstanding and Beneficial Technical EffectsAvoid pollutionIncinerator apparatusCold airCold blast

The invention provides a garbage cracking furnace system and belongs to the technical field of a garbage cracking furnace.The system solves the problems that an existing garbage cracking furnace causes environment pollution, and the cracking effect is not good.The garbage cracking furnace system comprises a garbage smashing and dehydrating mechanism, a garbage pre-airing mechanism and a garbage cracking furnace which are sequentially connected.A high-temperature waste gas outlet of the garbage cracking furnace is connected with a hot air inlet of the garbage pre-airing mechanism through a pipeline, and accordingly pre-airing treatment is conducted on garbage by means of high-temperature waste gas.A cold air outlet of the garbage pre-airing mechanism is connected to a purification condenser, and a purified air outlet of the purification condenser is connected to the garbage cracking furnace so that the purified air can return into the garbage cracking furnace for use.The system has the advantages of being capable of avoiding environment pollution, according with the concept of environment friendliness, improving work efficiency of the garbage cracking furnace, being high in carbon recycling efficiency and the like.

Owner:赵君华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com